Hobart Endeavor Owner's Manual

ts

OM-272 158A

2015−09

Endeavor Seriest

Auto-Darkening Welding Helme

www.HobartWelders.com

TABLE OF CONTENTS

SECTION 1 − WELDING HELMET SAFETY PRECAUTIONS −READ BEFORE USING 1

1-1. Symbol Usage 1...............................................................

1-2. Arc Welding Hazards 1.........................................................

1-3. Proposition 65 Warnings 3.......................................................

1-4. Lens Shade Selection Table 3....................................................

1-5. Principal Safety Standards 3.....................................................

SECTION 2 − SPECIFICATIONS 4.....................................................

SECTION 3 − OPERATING INSTRUCTIONS 5..........................................

3-1. Helmet Controls 5..............................................................

3-2. Reset Button And Low Battery Indicator 5..........................................

3-3. Lens Delay Control 6...........................................................

3-4. Variable Shade Control (No. 8 − 13) 6.............................................

3-5. Sensitivity/Grind Mode Control 7..................................................

SECTION 4 − ADJUSTING HEADGEAR 8..............................................

SECTION 5 − REPLACING THE LENS COVERS 9......................................

5-1. Replacing Outside Lens Cover 9.................................................

5-2. Replacing Inside Lens Cover 10..................................................

SECTION 6 − REPLACING THE BATTERIES 11........................................

SECTION 7 − INSTALLING OPTIONAL MAGNIFYING LENS 11..........................

SECTION 8 − MAINTENANCE 12.....................................................

SECTION 9 − TROUBLESHOOTING 12................................................

SECTION 10 − PARTS LIST 13.......................................................

SECTION 11 − LIMITED WARRANTY 13...............................................

SECTION 1 − WELDING HELMET SAFETY PRECAUTIONS −

READ BEFORE USING

helmet 2013-09

Protect yourself and others from injury — read, follow, and save these important safety

precautions and operating instructions.

1-1. Symbol Usage

DANGER! − Indicates a hazardous

situation which, if not avoided, will

result in death or serious injury. The

possible hazards are shown in the

adjoining symbols or explained in

the text.

Indicates a hazardous situation

which, if not avoided, could result in

death o r serious injury. The possible

hazards are shown in the adjoining

symbols or explained in the text.

NOTICE − Indicates statements not related to

personal injury.

Indicates special instructions.

This group of symbols means Warning! W atch

Out! ELECTRIC SHOCK, MOVING PARTS,

and HOT PARTS hazards. Consult symbols

and related instructions below for necessary

actions to avoid the hazards.

1-2. Arc Welding Hazards

Only qualified persons should install, operate, maintain, and repair this unit.

ARC RAYS can burn eyes and skin.

Arc rays from the welding process produce intense visible and invisible (ultraviolet and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

Wear a welding helmet fitted with a proper shade of filter to protect your face and eyes when

welding or watching (see ANSI Z49.1 and Z87.1 listed in Safety Standards). Refer to Lens

Shade Selection table in Section 1-4.

Wear approved safety glasses with side shields under your helmet.

Use protective screens or barriers to protect others from flash, glare, and sparks; warn

others not to watch the arc.

Wear body protection made from durable, flame−resistant material (leather, heavy cotton,

wool). Body protection includes oil-free clothing such as leather gloves, heavy shirt, cuffless

trousers, high shoes, and a cap.

• Before welding, adjust the auto-darkening lens sensitivity setting to meet the application.

• Stop welding immediately if the auto-darkening lens does not darken when the arc is struck.

See the Owner’s Manual for more information.

OM-272 158 Page 1

WELDING HELMETS do not provide unlimited eye, ear, an

d

t

face protection.

Arc rays from the welding process produce intense visible and invisible (ultraviole

and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

Use impact resistant safety spectacles or goggles and ear protection at all times when using

this welding helmet.

Do not use this helmet while working with or around explosives or corrosive liquids.

Do not weld in the overhead position while using this helmet.

Inspect the auto-lens frequently. Immediately replace any scratched, cracked, or pitted cover

lenses or auto-lenses.

NOISE can damage hearing.

Noise from some processes or equipment can damage hearing.

Wear approved ear protection if noise level is high.

READ INSTRUCTIONS.

Read and follow all labels and the Owner’s Manual carefully before in-

stalling, operating, or servicing unit. Read the safety information at the beginning of the manual and in each section.

Use only genuine replacement parts from the manufacturer.

Perform maintenance and service according to the Owner’s Manuals, industry standards,

and national, state, and local codes.

FUMES AND GASES can be hazardous.

Welding produces fumes and gases. Breathing these fumes and gases can be

hazardous t o your health.

Keep your head out of the fumes. Do not breathe the fumes.

If inside, ventilate the area and/or use local forced ventilation at the arc to remove welding

fumes and gases. The recommended way to determine adequate ventilation is to sample f or

the composition and quantity of fumes and gases to which personnel are exposed.

If ventilation is poor, wear an approved air-supplied respirator.

Read and understand the Safety Data Sheets (SDSs) and the manufacturer’s instructions for

adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals.

Work in a confined space only if it is well ventilated, or while wearing an air-supplied respirator.

Always have a trained watchperson nearby. Welding fumes and gases can displace air and

lower the oxygen level causing injury or death. Be sure the breathing air is safe.

Do not weld in locations near degreasing, cleaning, or spraying operations. The heat and rays

of the arc can react with vapors to form highly toxic and irritating gases.

Do not weld on coated metals, such as galvanized, lead, or cadmium plated steel, unless the

coating i s removed from the weld area, the area is well ventilated, and while wearing an airsupplied respirator. The coatings and any metals containing these elements can give off toxic

fumes if welded.

OM-272 158 Page 2

1-3. Proposition 65 Warnings

Welding or cutting equipment produces fumes or gases which contain chemicals known

to the State of California to cause birth defects and, in some cases, cancer. (California

Health & Safety Code Section 25249.5 et seq.)

This product contains chemicals, including lead, known to the state of California to cause

cancer, birth defects, or other reproductive harm. Wash hands after use.

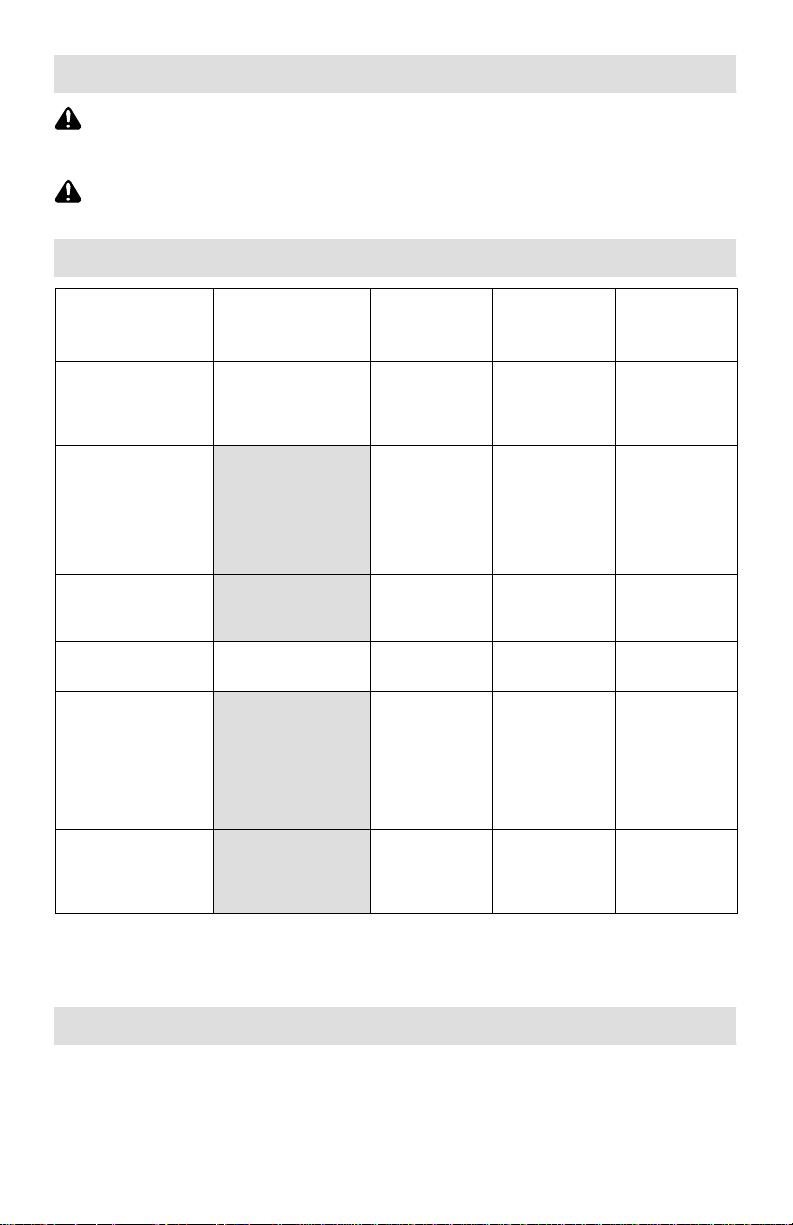

1-4. Lens Shade Selection Table

Process

Shielded Metal Arc

Welding (SMAW)

Gas Metal

Arc Welding

(GMAW)

Flux Cored

Arc Welding

(FCAW)

Gas Tungsten Arc

Welding (TIG)

Air Carbon

Arc Cutting (CAC-A)

Plasma Arc

Cutting (PAC)

Plasma Arc Welding

(PAW)

Electrode Size

in. (mm)

Less than 3/32 (2.4)

3/32−5/32 (2.4−4.0)

5/32−1/4 (4.0−6.4)

More than 1/4 (6.4)

Light

Heavy

Arc Current

in

Amperes

Less than 60

60−160

160−250

250−550

Less than 60

60−160

160−250

250−500

Less than 50

50−150

150−500

Less than 500

500−1000

Less than 20

20−40

40−60

60−80

80−300

300−400

400−800

Less than 20

20−100

100−400

400−800

Minimum

Protective

Shade No.

7

8

10

11

7

10

10

10

8

8

10

10

11

4

5

6

8

8

9

10

6

8

10

11

Suggested

Shade No.

(Comfort)*

−−

10

12

14

−−

11

12

14

10

12

14

12

14

4

5

6

8

9

12

14

6−8

10

12

14

Reference: ANSI Z49.1:2005

* Start with a shade that is too dark to see the weld zone. Then, go to a lighter shade which gives a

sufficient view of the weld zone without going below the minimum.

1-5. Principal Safety Standards

Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, is available as a free download f r o m the American W elding Society at http://www.aws.org or purchased from Global Engineering

Documents (phone: 1-877-413-5184, website: www.global.ihs.com).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1,

from American National Standards Institute, 25 West 43rd Street, New York, NY 10036 (phone:

212-642-4900, website: www.ansi.org).

OM-272 158 Page 3

Loading...

Loading...