MODEL 2212 SLICER

MODEL

2212 Slcier

2212 ML-136132

701 S. R IDGE AV ENUE

TRO Y, O HIO 4 5374- 0001

937 332-3000

www.h obartcor p.com

FORM 35215 (Apr. 2006)

Installation, Operation, and Care of

MODEL 2212 Slicer

SAVE THESE INSTRUCTIONS

GENERAL

The model 2212 slicer is equipped with a 1⁄2 HP motor and is available for single-phase electrical

service. The slicer is furnished with a cord and plug as standard equipment.

The low carriage fence is an accessory on 2212. A tubular food chute, 4" leg set and slaw tray are

other available accessories.

The standard meat grip is front-mounted. Heavy front-mounted meat grip is an available accessory.

MODEL 2212 SLICER

© HOBART CORPORATION, 1998

– 2 –

INSTALLATION

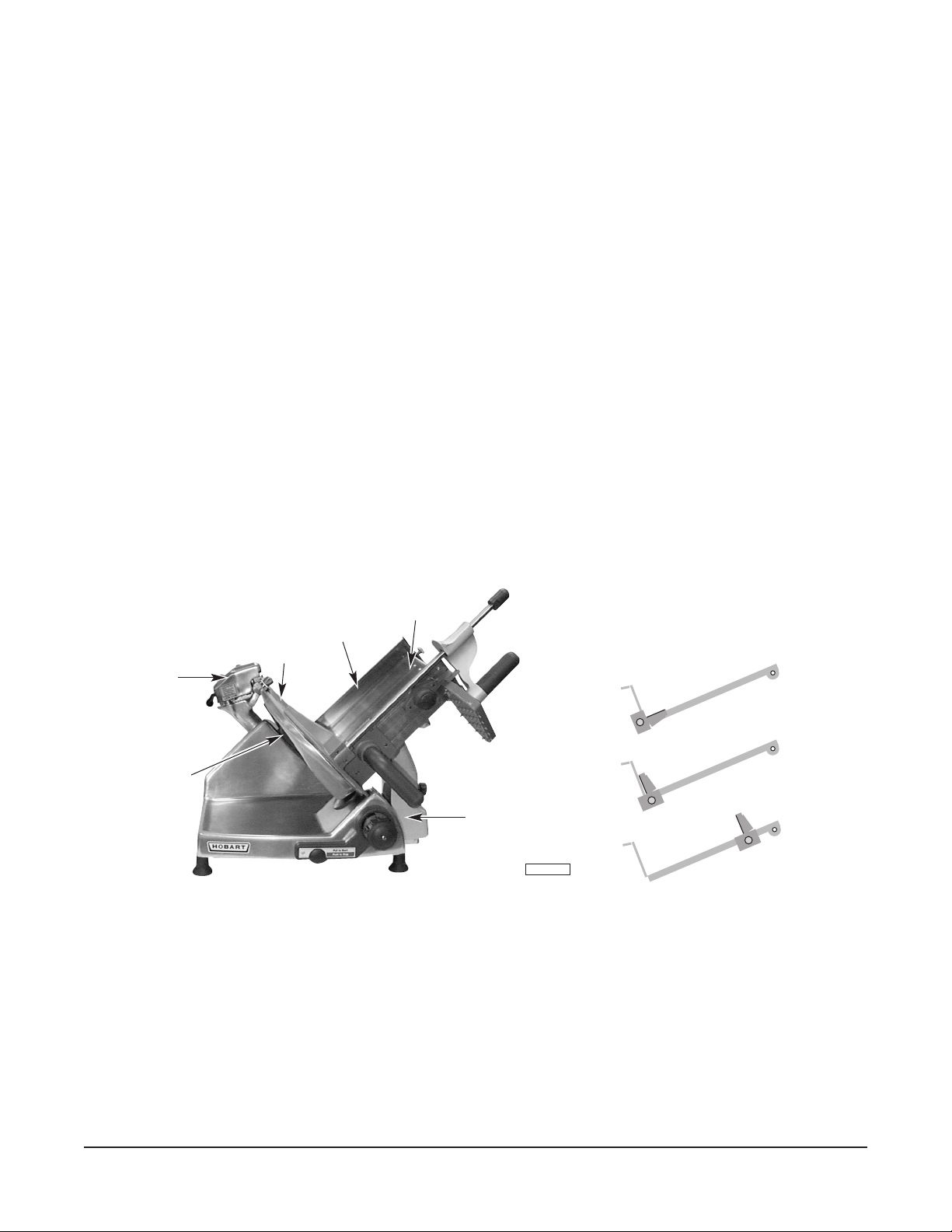

PL-41405-1

SHARPENER

DEFLECTOR

TOP KNIFE COVER

CARRIAGE TRAY

CARRIAGE TRAY /

SUPPOR

T ARM

FENCE

UNPACKING

Immediately after unpacking the slicer, check for possible shipping damage. If the slicer is found

to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installing the slicer, test the electrical service to assure it agrees with the specifications on

the machine data plate. The data plate is located on the right side of the slicer base.

CARRIAGE TRAY

The Carriage Tray is secured to the slicer when the knob on the Carriage Tray / Support Arm is

turned clockwise until snug (Fig. 1). Refer to page 6 for assembly information.

SHARPENER

The Sharpener should already be mounted on top of the slicer and locked to its bracket (Fig. 1).

TOP KNIFE COVER

The Top Knife Cover should already be in place and secured with its Latch Knob (Fig. 1).

FENCE (Low and High Fences are accessories used with front-mounted meat grip only.)

Either Fence (Fig. 1) can be clamped on the Carriage Tray to limit product movement during

slicing.

Model 2212

1. Ba ck out Th umb Sc rew.

Lay Fence on Carriage Tray.

2. Rotate to Vertical.

3. Slide Fence Up. Tighten Screw.

Fig. 1

ELECTRICAL

WARNING

THE OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF

: THIS MACHINE IS PROVIDED WITH A THREE-PRONG GROUNDING PLUG.

THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

CLEAN BEFORE USING

The 2212 slicer must be thoroughly cleaned and sanitized after installation and before being used.

Refer to Cleaning, page 5.

– 3 –

OPERATION

SWITCH KNOB

GAUGE PLATE

LATCH KNOB

TOP KNIFE COVER

CARRIAGE TRAY

MEAT GRIP

CARRIAGE TRAY HANDLE

INDEX KNOB

FENCE

SAFETY

SAFETY DEVICES INCORPORATED IN THIS SLICER MUST BE IN THEIR CORRECT OPERATING

POSITIONS ANYTIME THE SLICER IS IN USE.

OP KNIFE COVER must be in position and secured with the LATCH KNOB (Fig. 2). The RING GUARD

The T

is not removable.

The M

EAT GRIP (Fig. 2) must be used when slicing short ends to keep your hand(s) away from the

knife.

When the slicer is not running, the I

The G

AUGE PLATE will then cover the knife edge.

NDEX KNOB (Fig. 2) must be turned back below zero (fully clockwise).

Always UNPLUG the POWER CORD before cleaning or moving the Slicer.

Model 2212

Fig. 2

WARNING: ROTATING KNIFE. USE FEED GRIP. UNPLUG MACHINE POWER CORD BEFORE

CLEANING, SERVICING, OR REMOVING PARTS. REPLACE PARTS BEFORE USE.

SLICING — MODEL 2212

With the Gauge Plate fully closed, pull the Carriage all the way toward you until it reaches its stop.

With the Meat Grip out of the way, place the product to be sliced on the Carriage Tray. Set the Meat

Grip against the product. Turn the slicer on by pulling the Switch Knob (Fig. 2) forward until it starts

and then releasing it.

Adjust the gauge plate to obtain the desired slice thickness by turning the Index Knob (Fig. 2). The

numbers on the Index Knob do not indicate actual measurements but may be used for reference to

duplicate slice thickness.

Use the Carriage Tray Handle (Fig. 2) to push the Carriage back and forth to slice.

– 4 –

CLEANING

PL-41402-1

GAUGE PLATE

KNIFE

SHARPENER

LOCK LEVER

PL-41403-1

GAUGE PLATE

KNIFE

RING GUARD

PAPER TOWEL

PL-41252-1

LA

TCH KNOB

TOP KNIFE COVER

CARRIAGE TRAY /

SUPPORT ARM

CARRIAGE TRAY

KNOB

This machine must be thoroughly cleaned and

sanitized after each day’s operation or after being idle

for an extended period of time.

WA R NIN G

: TH E SL I CER KNI FE I S VE R Y

SHARP. EXERCISE EXTREME CAUTION WHEN

WORKING NEAR THE KNIFE.

WARNING

: UNPLUG MACHINE POWER CORD

AND TURN THE INDEX KNOB FULLY CLOCKWISE

BEFORE CLEANING THE SLICER.

Fig. 3

Use a clean cloth soaked in mild detergent and warm water to wipe all surfaces of the machine.

Rinse using a fresh cloth and clean water. Use only products formulated to be safe on stainless

steel or aluminum.

To clean the Carriage Tray, close the gauge plate and pull the Carriage all the way to the front.

Unscrew the Knob on the Carriage Tray / Support Arm (Fig. 3). Tilt the Carriage Tray / Support

Arm to the right until almost horizontal (Fig. 3). The Carriage Tray / Support Arm can be cleaned

while in this horizontal position, or it can be removed by grasping with both hands and lifting

straight up. Once removed, the Carriage Tray / Support Arm can be cleaned in a sink. NOTE: The

last three digits of the slicer serial number are etched on the Key (Fig. 7) so you can make sure

the Carriage Tray stays with its own slicer.

Remove the Top Knife Cover by rotating the Latch Knob (Fig. 3) counterclockwise and lifting it

free of the guide pins. Remove the Deflector (Fig. 1) from its mount below the slicer knife by rotating

downward. Clean both Top Knife Cover and Deflector with warm soapy water in a sink. Rinse

with clean water.

Fig. 4 Fig. 5

Remove the sharpener by pushing the Lock Lever to the left (Fig. 4). Tilt the right side up, clearing

the right guide pin, then lift the sharpener up, clearing the left guide pin. Wipe out any residue

remaining inside the sharpener housing and clean the sharpener in a sink. Rinse with fresh water.

Clean completely around the Ring Guard by working a moistened, folded paper towel between

the Ring Guard and Knife. Insert the towel at the base of the Ring Guard. Manually rotate the knife

and the towel will wipe the Ring Guard and the edge of the Gauge Plate as it follows the knife

(Fig. 5).

– 5 –

Wash and rinse both sides of the knife by wiping outward from the center. Use a mild detergent or

PL-41253-1

CARRIAGE PIVOT

CARRIAGE TRAY /

SUPPORT ARM

KEY

PL-41402-1

GAUGE PLATE

KNIFE

SHARPENER

LOCK LEVER

sanitizer solution only. Never clean any part of the slicer with steel pads. Do not exceed chemical

manufacturer’s recommended concentrations for detergent or sanitizer. Do not exceed 200 parts

per million concentration of available chlorine. For example, mixing 1 tablespoon of 5.25% sodium

hypochlorite bleach with 1 gallon of water yields a solution containing 200 ppm of available chlorine.

Solution with concentrations greater than 200 ppm will accelerate corrosion of metals. Maximum

exposure to sanitizing solution varies with temperature and concentration. Rinse with clean water.

Reassemble the sharpener to the mounting

bracket by sliding the left slot on the sharpener

over the left guide pin on the bracket while tilting

slightly (Fig. 6). Then, press down on the right

side of the sharpener so the locking hole fits

over the right guide pin on the bracket. Slide the

Lock Lever to the right to lock the sharpener in

position. Make sure the sharpener is securely

engaged to the pins on the bracket.

Carefully reassemble the Top Knife Cover by

putting it in position (three guide pins). Lock by

turning the Latch Knob to the left while lowering

the Top Knife Cover; then, release the Latch

Fig. 6

Knob and turn it to the right until snug.

Make sure the digits etched on the Key (Fig.

7) match the last three digits of the slicer

serial number. To rei n s tall the Carriage

Tray / Support Arm: Hold it with both hands

and lower it so the Key at the bottom of the

Support Arm fits into the slot of the Carriage

Pivot (Fig. 7). The Carriage Tray should rest

almost horizontal (Fig.3). Return the Carriage

Tray to the Gauge Plate by tilting to the left.

Turn the Knob on the Carriage Tray / Support

Arm clockwise until snug.

DO NOT wash any slicer componets in a

dishwasher. DO NOT immerse slicer b ase or

motor in water. DO NOT hose down slicer or

Fig. 7

splash excessively with water.

If using a chlorinated sanitizing solution, dilute per manufacturer’s guidelines. Rinse with fresh

water.

NOTE: Failure to follow use, care, and maintenance instructions may void your Hobart warranty.

– 6 –

MAINTENANCE

TOP KNIFE COVER

IS REMOVED

PL-41404-1

TO SHARPEN:

PULL SHARPENER HANDLE

FULLY FORWARD

FOR 5 SECONDS

PL-41146-1

WICK HOLE

CARRIAGE SLIDE ROD

CARRIAGE TRANSPORT

KNIFE SHARPENING

The knife will provide long service in normal food retail or commercial kitchen use. However, in high

volume applications where it is a practice to sharpen the knife frequently or even daily, the knife will

be expended in a shorter time.

Sharpen only when necessary; prolonged or too frequent sharpening results in unnecessary

knife wear

WARNING: UNPLUG MACHINE POWER CORD.

Turn the index knob fully clockwise to close the

gauge plate. Remove the Top Knife Cover by

rotating the Latch Knob counterclockwise and lifting

it off the slicer. Thoroughly wash the area around

the knife, the exposed knife surfaces, and the

knife edge. Fat from meat or cheese should not

be allowed to transfer from the knife to the

sharpener.

Plug in machine power cord. Start the slicer by

pulling the start switch forward until it starts and

then releasing it. If the sharpener handle is the

type that does not hang downwards, pull it fully

forward for 5 seconds (Fig. 8). If the sharpener

handle does hang downwards, lift it with your

left hand until horizontal and pull forward for

5 seconds (Fig.8). Slowly release the sharpener

handle. If necessary, repeat sharpening for another

5 seconds.

.

Fig. 8

Turn the slicer off. Unplug machine power cord. Wipe

the slicer with a clean damp cloth to remove any

grinding particles. Replace the Top Knife Cover.

LUBRICATION — Carriage Slide Rod

Lubricate the Carriage Slide Rod with Lubriplate

FMO-200-AW oil. Either squirt 8 – 10 drops every

2 – 3 months (depending on usage) in the Wick

Hole on the Carriage Transport (Fig. 9). Or, once

monthly, apply 4 – 5 drops directly on the Carriage

Slide Rod on each side of the Carriage Transport

(Fig. 9).

To apply oil, pull out the telescoping tube on the oil bottle, aim the tube, and squeeze gently on the

sides of the bottle. After applying oil, move the Carriage Tray back and forth a few times so the oil

spreads over the entire length of the slide rod.

SERVICE

Contact your local Hobart-authorized service office for any repairs or adjustments needed on this

equipment.

Fig. 9

– 7 –

FORM 35215 (Apr. 2006) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...