Page 1

PS 250 /

PS 200 S

Operating instructions en

Mode d’emploi fr

Manual de instrucciones es

Manual de instruções pt

Printed: 10.12.2013 | Doc-Nr: PUB / 5135501 / 000 / 01

Page 2

1

PS 200 Ferroscan

2.

PSA 93

Green

Red

Printed: 10.12.2013 | Doc-Nr: PUB / 5135501 / 000 / 01

Page 3

2

0,

PS 200 Ferroscan

3

PS 200 Ferroscan

4

0,

Printed: 10.12.2013 | Doc-Nr: PUB / 5135501 / 000 / 01

Page 4

ORIGINAL OPERATING INSTRUCTIONS

PS 250 ferroscan system

PS 200 S ferroscan

en

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions together with the tool.

Ensure that the operating instructions are

with the tool when it is given to other persons.

Contents Page

1 General information 1

2Description 2

3 Items supplied, accessories, spare parts 3

4 Technical data 7

5 Safety instructions 10

6Beforeuse 11

7 Operation 11

8 Care and maintenance 28

9 Troubleshooting 29

10 Disposal 31

11 Manufacturer’s warranty 32

12 FCC statement / IC statement 32

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover

pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the designation “the tool”

always refers to PS 200 S Ferroscan. The designation

“PS 250 Ferroscan system” applies to the whole system

consisting of the PS 200 S scanner, PSA 100 monitor and

PROFIS Ferroscan PC software for data evaluation. The

designation “PS 200 S Ferroscan”, on the other hand,

appliesonlytothescanner.

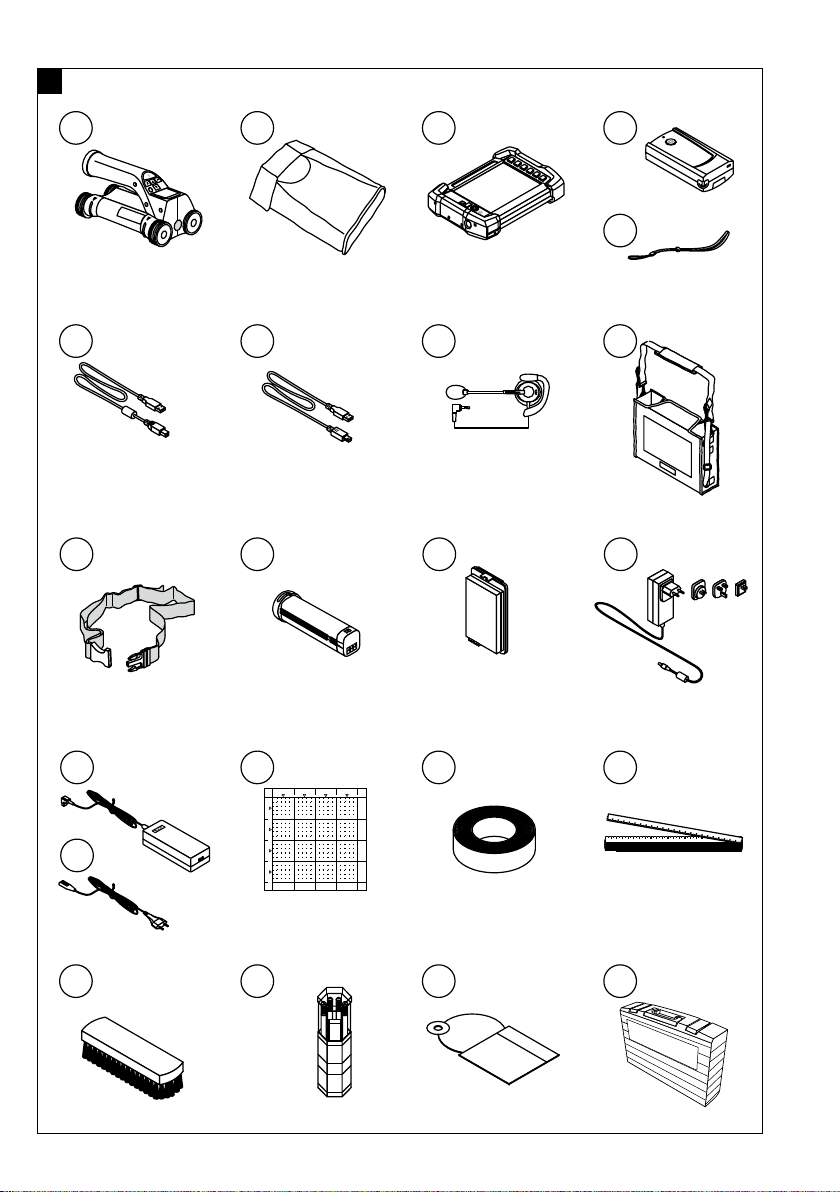

Components 1

PS 200 S scanner

@

PSA 60 soft pouch

;

PSA 100 monitor

=

PSA 55 infrared adapter

%

PSA 63 hand strap

&

PSA 92 USB data cable

(

PUA 95 Micro USB data cable

)

PSA 93 headset with microphone

+

PSA 64 soft pouch

§

PSA 62 carrying strap

/

PSA 80 battery pack

:

PSA 82 battery pack

·

PUA 81 AC adapter

$

PUA 80 charger

£

Supply cord

|

PSA 10/11 reference grid set

¡

PUA 90 adhesive tape

Q

Folding rule

W

PSA 70 brush

E

PUA70markingpenset

R

PROFIS Ferroscan software

T

PS 250 toolbox

Z

1 General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that will lead to

seriousbodilyinjuryorfatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

1.2 Explanation of the pictograms and other

information

Warning signs

General

warning

Warning:

electricity

Warning:

caustic

substances

1

Page 5

Symbols

Location of identification data on the tool

The type designation and serial number can be found on

thetypeidentificationplateonthetool.Makeanoteof

this data in your operating instructions and always refer

to it when making an enquiry to your Hilti representative

or service department.

Type:

en

Read the

operating

instructions

before use.

Return waste

material for

recycling.

Generation: 02

Serial no.:

2 Description

2.1 Use of the product as directed

The tool is intended to be used for locating reinforcing bars in concrete, measuring depth of concrete cover and

estimating the diameter of the bars in the uppermost layer in accordance with the specifications detailed in the

technical data provided in these operating instructions.

The tool is designed for professional use and may be operated, serviced and maintained only by trained, authorized

personnel. This personnel must be informed of any special hazards that may be encountered. The tool and its ancillary

equipment may present hazards when used incorrectly by untrained personnel or when used not as directed.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

Take the influences of the surrounding area into account. Do not use the tool or appliance where there is a risk of fire

or explosion.

Modification of the tool or tampering with its parts is not permissible.

2.2 PSA 55 infrared adapter

The PSA 55 infrared adapter is used to store scans before they are subsequently transferred to a computer. The

adapter has a storage capacity of approx. 100 scans.

2.3 Applications

The tool can be used for various non-destructive detection applications on steel-reinforced concrete structures (e.g.

locating reinforcing bars in the uppermost layers, measuring depth of concrete cover and estimating the diameter

of the bars detected). The scanning mode used depends on the application. These fall broadly into the following

categories:

Application

Scanning mode

Avoiding damage to reinforcing bars when drilling or core drilling Quickscan detection, Imagescan or

Blockscan

Determining the position / number and diameter of bars for load-

Imagescan

bearing capacity checks or depth of cover measurements

Determining depth of concrete cover over large areas Quickscan recording

2.4 Using the system

The system functions by running the scanner directly over the surface of the structure. The data collected is stored in

the scanner until it can be transferred to the monitor. The monitor is used for storing large amounts of data and for

viewing the scans. It can also be used for on-the-spot evaluation of scans. The data can also be downloaded to a

PC. The PC software offers advanced evaluation options, data archiving functions and the ability to quickly print out

complete reports.

2.5 Quickscan detection

The scanner is moved across the surface at right angles to the reinforcing bars. The position and approximate depth

of the reinforcing bars can be determined and marked right away on the surface of the concrete.

2

Page 6

2.6 Quickscan detection with accurate depth measurement

Before scanning, the operator is required to enter values for the diameter of the reinforcing bars and the spacing

between the bars. The scan is then carried out as described for Quickscan detection.

2.7 Quickscan recording

Data is recorded automatically as the scanner is moved over the surface of the concrete. This data is subsequently

transferred to the monitor where it can be evaluated and the average depth of cover determined. If the data is

downloaded to a PC, the information can be evaluated, archived and a report printed. Further evaluation options

allow Quickscan recordings to be imported and evaluated automatically, statistical evaluations prepared and scans

displayed in the form of large-area evaluations.

2.8 Imagescan

A reference grid is attached at the area of interest using the adhesive tape supplied. After selecting the Imagescan

mode with the scanner, the rows and columns of the grid are scanned following the instructions on the screen. The

data is transferred to the monitor where the image can be viewed and evaluated. The position of the reinforcing bars

relative to the concrete surface is indicated. Bar diameter can be estimated and bar depth determined. If the data is

downloaded to the PC application, this information can be evaluated as on the monitor, with the additional advantage

of allowing a series of points to be recorded along with associated depth and diameter, and the data saved for

future use. Reports can also be printed. Further evaluation options allow Imagescans to be imported and evaluated

automatically, statistical evaluations prepared and scans displayed in the form of large-area evaluations.

2.9 Blockscan

A reference grid is attached at the area of interest using the adhesive tape supplied. After selecting Blockscan mode,

the user is prompted to select the first area to scan. An Imagescan is then made. After completing the Imagescan, the

user is prompted to select the next area to scan. This should be adjacent to the previous area. Attach the grid and then

scan as before. This procedure can be repeated for up to 3 x 3 Imagescans. The data is transferred to the monitor. The

Imagescans are automatically stitched together to form a larger image. The reinforcement layout can then be viewed

over the whole area. Individual Imagescans can be selected for evaluation by “zooming in”. If the data is downloaded

to the PC application, this information can be evaluated as on the monitor, with the additional advantage of allowing a

series of points to be recorded along with associated depth and diameter, andthedatasavedforfutureuse.Reports

can also be printed.

en

3 Items supplied, accessories, spare parts

3.1 Items supplied

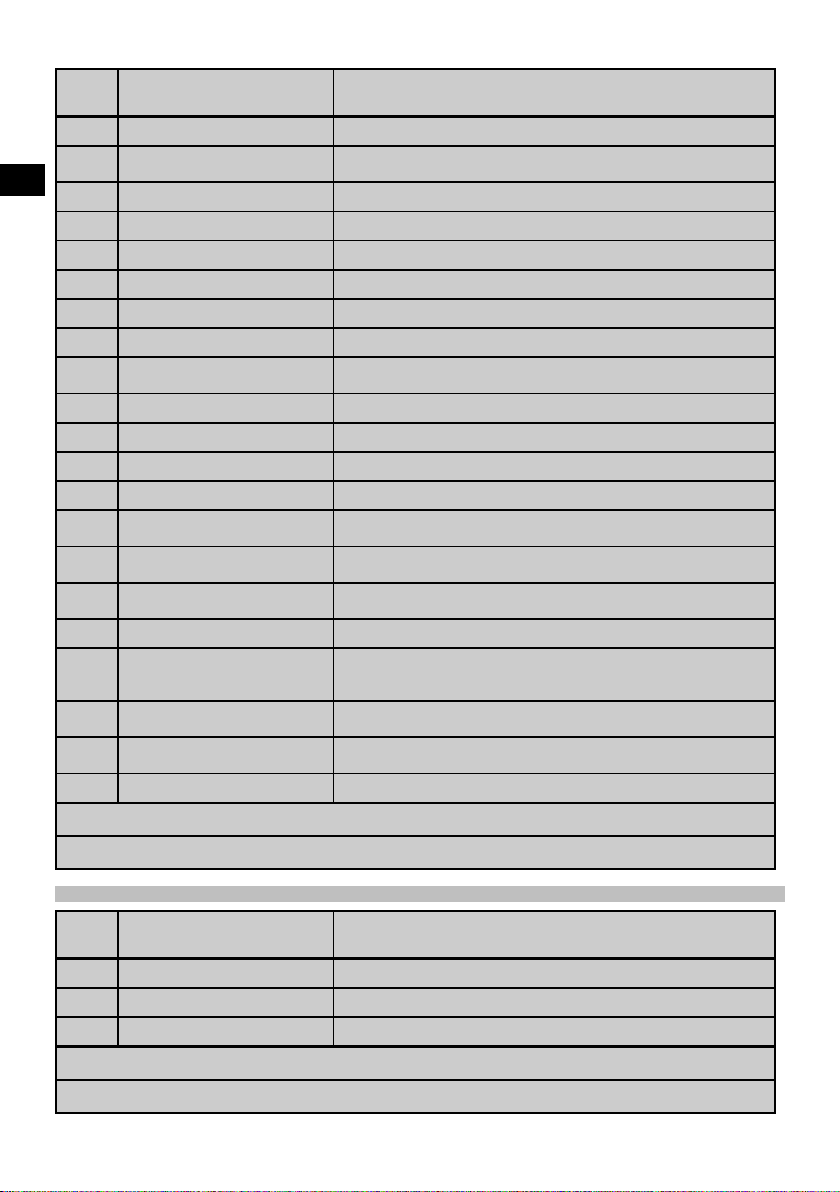

3.1.1 PS 250 Ferroscan system

Number

1

1 PSA 60 soft pouch Soft pouch for the PS 200 S scanner

1

1 PSA 64 soft pouch Soft pouch for the PSA 100 monitor

1 PSA 63 hand strap For the PS 200 S scanner

1 PSA 55 infrared adapter For temporary storage of data from the PS 200 S scanner

1 PUA 95 Micro USB data cable Data cable for connecting the PSA 55 infrared adapter to a PC

1 PSA 97 data module Contains the operating instructions in electronic form and is used to

1

2

Designation

PS 200 S scanner

PSA 100 monitor

1

1

Comments

update the PSA 100 monitor

Version depends on the country-specific version of the system ordered.

May or may not be included in the items supplied, depending on the country-specific version of the system ordered.

3

Page 7

Num-

Designation

Comments

ber

1 PSA 92 USB data cable PSA 100 monitor to PC

1 PSA 93 headset with micro-

en

2 AA-size alkaline batteries For the PSA 55 infrared adapter

phone

For the PSA 100 monitor

1 PSA 80 battery pack NiMH battery pack for the PS 200 S scanner

1 PUA 80 charger Charger for the PSA 80 battery pack

1

Supply cord

1

Supply cord for the PUA 80 charger

1 PSA 82 battery pack Li-ion battery pack for the PSA 100 monitor

1 PUA 81 AC adapter AC adapter for charging the PSA 100 monitor

1 PSA 75 brush For removing dust and particles of concrete before applying

PUA 90 adhesive tape

1 Cleaning cloth

1

5

Folding rule

PSA 10/11 reference grid

2

1

For making an Imagescan

1 PUA 90 adhesive tape For attaching the reference grid to a dry, dust-free concrete surface

1 PUA 70 marking pen set Set of 6 red and 6 black marking pens for marking the grid position

and object position

1 PROFIS Ferroscan software PC software on CD-ROM for the PS 250 Ferroscan system /

PS 200 S Ferroscan set

1 PSA/PUA operating instruc-

tions

1 PSA 100 operating instructions

1 PS 200 S Ferroscan / PS 250

Ferroscan system operating

instructions

1 PS 200 S manufacturer’s cer-

tificate

1 PSA 100 manufacturer’s certifi-

cate

1 PS 250 toolbox Plastic toolbox with insert for the PS 250 Ferroscan system

1

Version depends on the country-specific version of the system ordered.

2

May or may not be included in the items supplied, depending on the country-specific version of the system ordered.

3.1.2 PS 200 S Ferroscan set

Num-

Designation

Comments

ber

1

PS 200 S scanner

1

1 PSA 55 infrared adapter For temporary storage of data from the PS 200 S scanner

1 PSA 60 soft pouch Soft pouch for the PS 200 S scanner

1

Version depends on the country-specific version of the system ordered.

2

May or may not be included in the items supplied, depending on the country-specific version of the system ordered.

4

Page 8

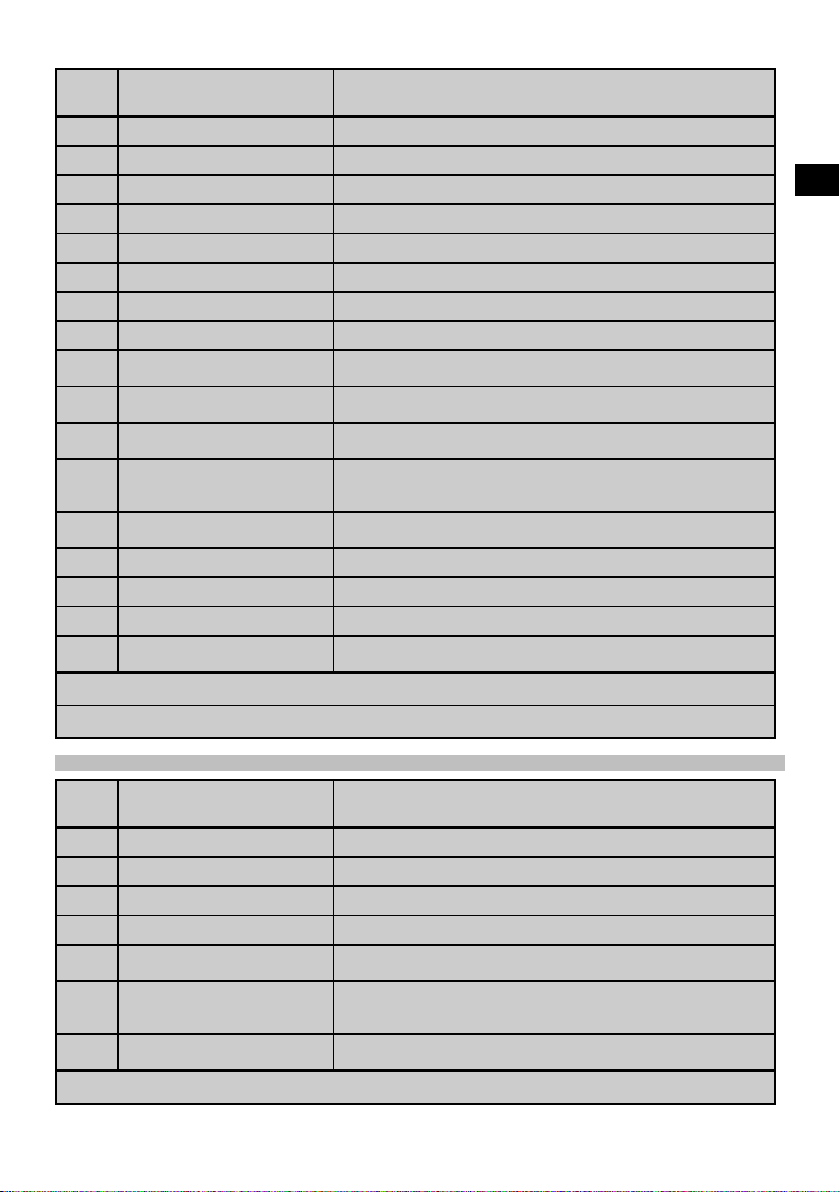

Num-

Designation

Comments

ber

1 PSA 62 carrying strap

1 PSA 63 hand strap Soft pouch for the PS 200 S scanner

2 AA-size alkaline batteries

1 PSA 80 battery pack NiMH battery pack for the PS 200 S scanner

1 PUA 80 charger Charger for the PSA 80 battery pack

1 PUA 95 Micro USB data cable Data cable for connecting the PSA 55 infrared adapter to a PC

5

PSA 10/11 reference grid

1

For making an Imagescan

1 PUA 90 adhesive tape For attaching the reference grid to a dry, dust-free concrete surface

1 PUA 70 marking pen set Set of 6 red and 6 black marking pens for marking the grid position

and object position

1 PROFIS Ferroscan software PC software on CD-ROM for the PS 250 Ferroscan system /

PS 200 S Ferroscan set

1 PSA/PUA operating instruc-

tions

1 PS 200 S Ferroscan / PS 250

Ferroscan system operating

instructions

1 PSA 75 brush For removing dust and particles of concrete before applying

PUA 90 adhesive tape

1

Folding rule

2

1 Cleaning cloth

1 PS 200 S toolbox Plastic toolbox with insert

1 PS 200 S manufacturer’s cer-

tificate

1

Version depends on the country-specific version of the system ordered.

2

May or may not be included in the items supplied, depending on the country-specific version of the system ordered.

en

3.1.3 PS 200 S scanner

Num-

Designation

Comments

ber

1

PS 200 S scanner

1

1 PSA 60 soft pouch Soft pouch for the PS 200 S scanner

1 PSA 80 battery pack NiMH battery pack for the PS 200 S scanner

1 PSA 63 hand strap For the PS 200 S scanner

1 PSA/PUA operating instruc-

tions

1 PS 200 S Ferroscan / PS 250

Ferroscan system operating

instructions

1 PS 200 S manufacturer’s cer-

tificate

1

Version depends on the country-specific version of the system ordered.

5

Page 9

3.2 Accessories and spare parts

Item no. Designation

2006082 PSA 100 monitor PSA 100 monitor, PSA 82 battery pack, PUA 92 USB data

en

377654 PSA 10 reference grid Reference grid in mm (in packs of 5)

377655 PSA 11 reference grid Reference grid in inches (in packs of 5)

319362 PUA 90 adhesive tape For attaching the reference grid to a dry, dust-free concrete

340806 PUA 70 marking pen set For marking the grid position and object position (12 pens)

305144 PSA 63 hand strap For the PS 200 S scanner

377657 PSA 60 soft pouch For the PS 200 S scanner

2006088 PSA 64 soft pouch For the PSA 100 monitor

319412 PSA 62 shoulder strap For carrying the PS 200 S scanner

2004459 PUA 81 AC adapter For charging the PSA 100 monitor

1

2006180 PUA 82 motor vehicle power

377472 PSA 80 battery pack For the PS 200 S scanner

416930 PSA 82 battery pack For the PSA 100 monitor

2006183 PSA 85 charger Charger for the PSA 82 battery pack

2013775 PSA 92 USB data cable For transferring data from the PSA 100 monitor to a PC

2031976 For data transfer from the

305143 PSA 93 headset For the PSA 100 monitor

2006187 PSA 55 infrared adapter For temporary storage of data from the PS 200Sscanner

2006191 PSA 97 data module Contains the operating instructions in electronic form and is

2006200 PSA 65 carrying device For the PSA 100 monitor

319416 Hilti PROFIS Ferroscan PC soft-

2031824 Hilti toolbox for PS 250

2044483 Hilti toolbox for PS 200 S

2013776 PSA 75 brush For removing dust and particles of concrete before applying

276946 Folding rule

2005011 Cleaning cloth

2004955 PSA/PUA P1 operating instruc-

2012529 PSA/PUA P2 operating instruc-

2004954 PSA 100 P1 operating instruc-

PUA 80 charger For charging the PSA 80 battery pack, incl. supply cord

adapter

PUA 95 Micro USB data cable

ware

tions

tions

tions

Comments

cable, PSA 97 data module, manufacturer’s certificate, operating instructions, packed in a cardboard box

surface

AC adapter for charging the PSA 100 monitor

PSA 55 infrared adapter for PC

used to update the PSA 100 monitor

PC software on CD-ROM for the PS 250 Ferroscan system /

PS 200 S scanner set

PUA 90 adhesive tape

For Europe / Asia

ForUSA/Canada

For Europe / Asia

6

Page 10

Item no. Designation

2004815 PSA 100 P2 operating instruc-

tions

2037330 PS 200 S Ferroscan / PS 250

Ferroscan system P1 operating

instructions

2037331 PS 200 S Ferroscan / PS 250

Ferroscan system P2 operating

instructions

Comments

ForUSA/Canada

For Europe / Asia

ForUSA/Canada

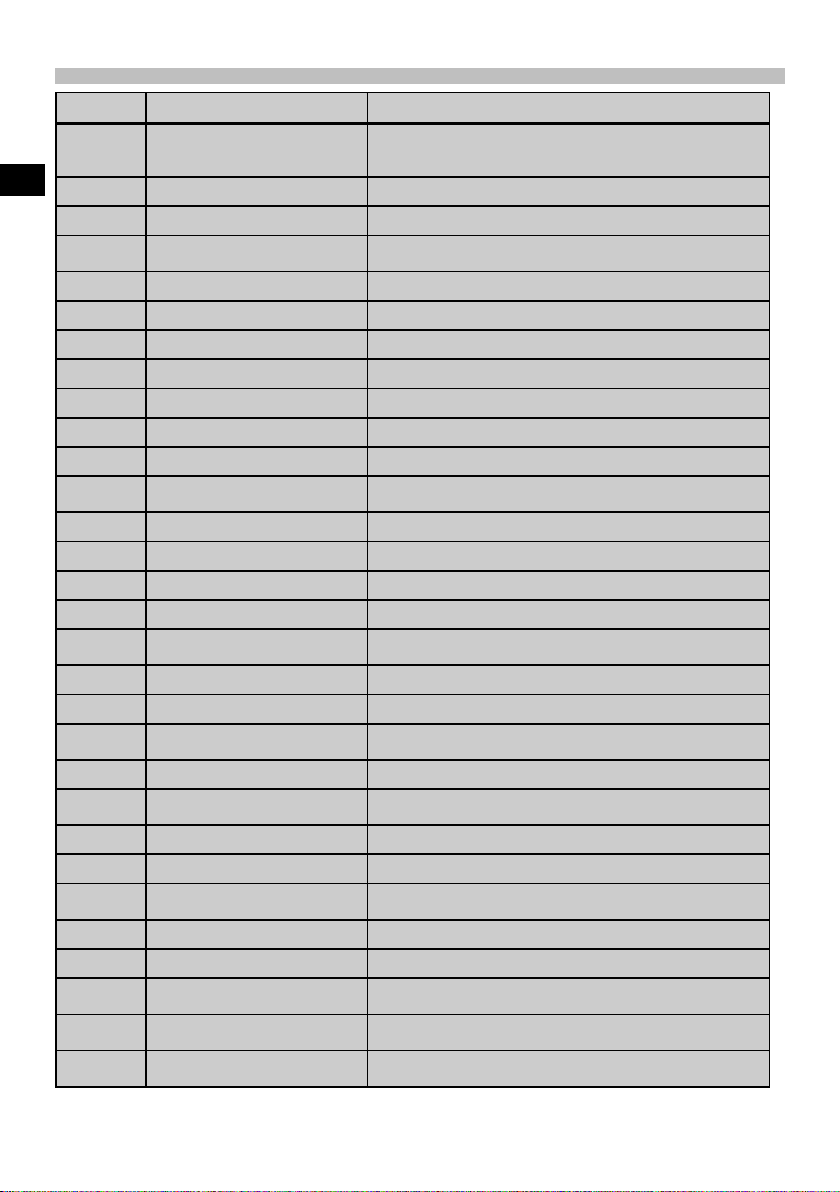

4 Technical data

4.1 Ambient conditions

Operating temperature range -10…+50°C (+14…+122 °F)

Storage temperature -20…+60°C (−4…+140 °F)

Relative humidity (operation)

Dust and water protection (operation) IP54

Impact resistance (tool in toolbox) EN 60068-2-29

Dropping EN 60068-2-32

Vibration(notinoperation) MIL-STD810D

4.2 System scanning performance

For reliable scanning results, the following conditions must be fulfilled:

Concrete surface smooth and flat.

Reinforcement not corroded.

Reinforcement lying parallel to concrete surface.

Concrete does not contain additives or components with magnetic properties.

Reinforcing bars lying within ± 5° of right angle to the scanning direction.

Reinforcing bars are not welded.

Neighboring bars are of similar diameter.

Neighboring bars are at a similar depth.

Accuracy specifications are valid only for the first layer of reinforcement.

No interfering influences from external magnetic fields or objects nearby with magnetic properties.

Bars have relative magnetic permeability of 85–105.

The scanner wheels are clean and free from sand and grit etc.

All 4 scanner wheels are in contact and rotate when the scanner is moved across the object to be scanned.

The bars comply with one of the following standards (depending on system item no.):

Max. 90%, no condensation

en

Standards for steel reinforcing bars

Item no.

2044434, 2044439, 2044473,

2044435, 2044472, 377646,

377652

2044436, 2044474, 377649 ASTM A 615 / A 615M‑01b United States of America, Taiwan,

2044437, 2044475, 377650 CAN/CSA-G30, 18-M92 Canada

Standard Origin / applicability of the stan-

dard

DIN 488 European Union and all other coun-

tries not listed below

Latin America and Central America

7

Page 11

Item no.

Standard Origin / applicability of the stan-

dard

2044438, 2044470, 2044476,

JIS G 3112 Japan, Korea

2044478, 377651

2044471, 2044479, 408056 GB 50010-2002 China

en

2078650, 2078660, 2078670 GOST 5781-82 Russia

2078651, 2078661, 2078671 BIS 1786:1985 India

4.3 Detection range, measurement range and accuracy

NOTE

If one or more of the specified conditions are not fulfilled, accuracy and precision may be compromised. The ratio of

bar spacing to depth of cover (s:c) is often a limiting factor in resolving individual bars.

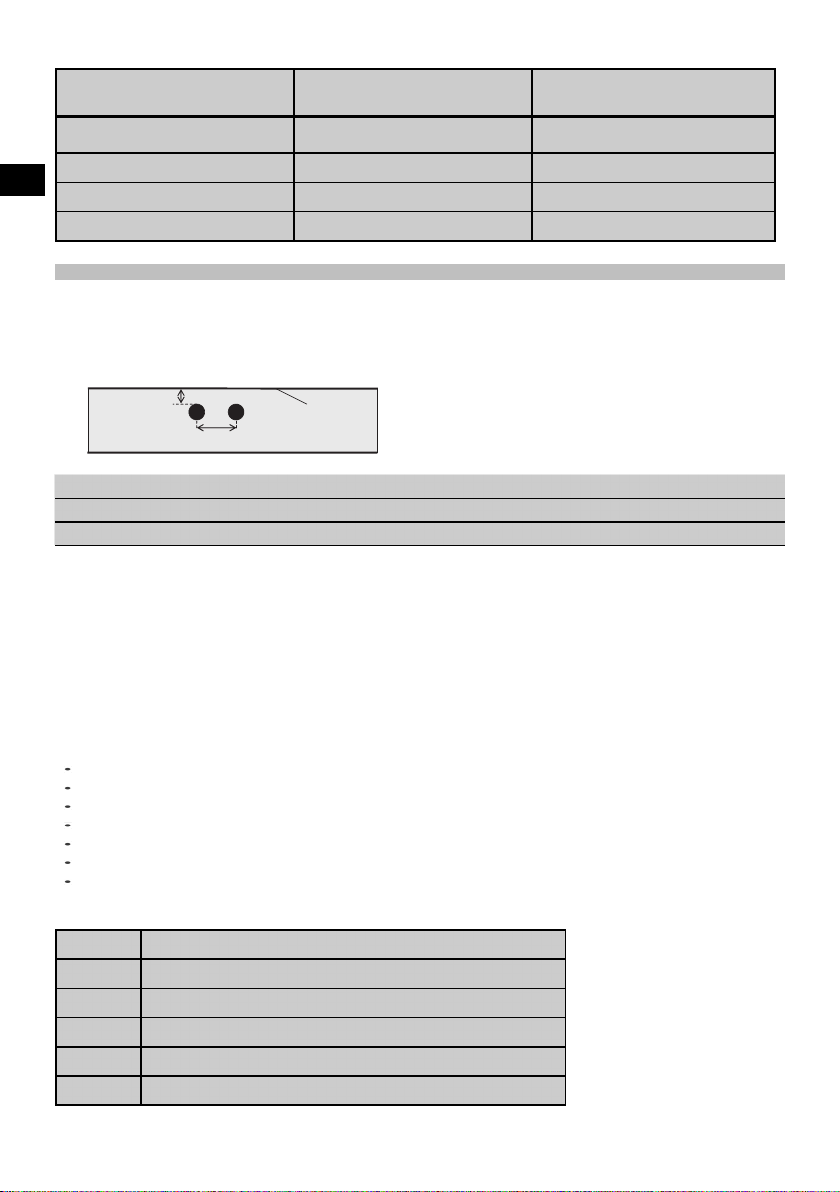

This is defined as:

c

Depth of cover

s

Spacing

F

V

;

XSurface

In order to be able to resolve and locate individual bars, the ratio of bar spacing (s) to depth of cover (c) must be at

least 2:1. Minimum bar spacing is 36 mm (1.4"). The higher of the two values applies when resolving individual bars. A

depth of at least c≧10 mm (0.4") is required in order to carry out a depth measurement.

NOTE

Place a sheet of non-metallic material (e.g cardboard, wood, polystyrene foam,...) between the scanner and the surface

to be scanned if the minimum depth cannot be adhered to.

The starting point and finishing point of the scan (e.g. from the edge of the reference grid) must be at least 30 mm

(1.2") away from the nearest reinforcing bar.

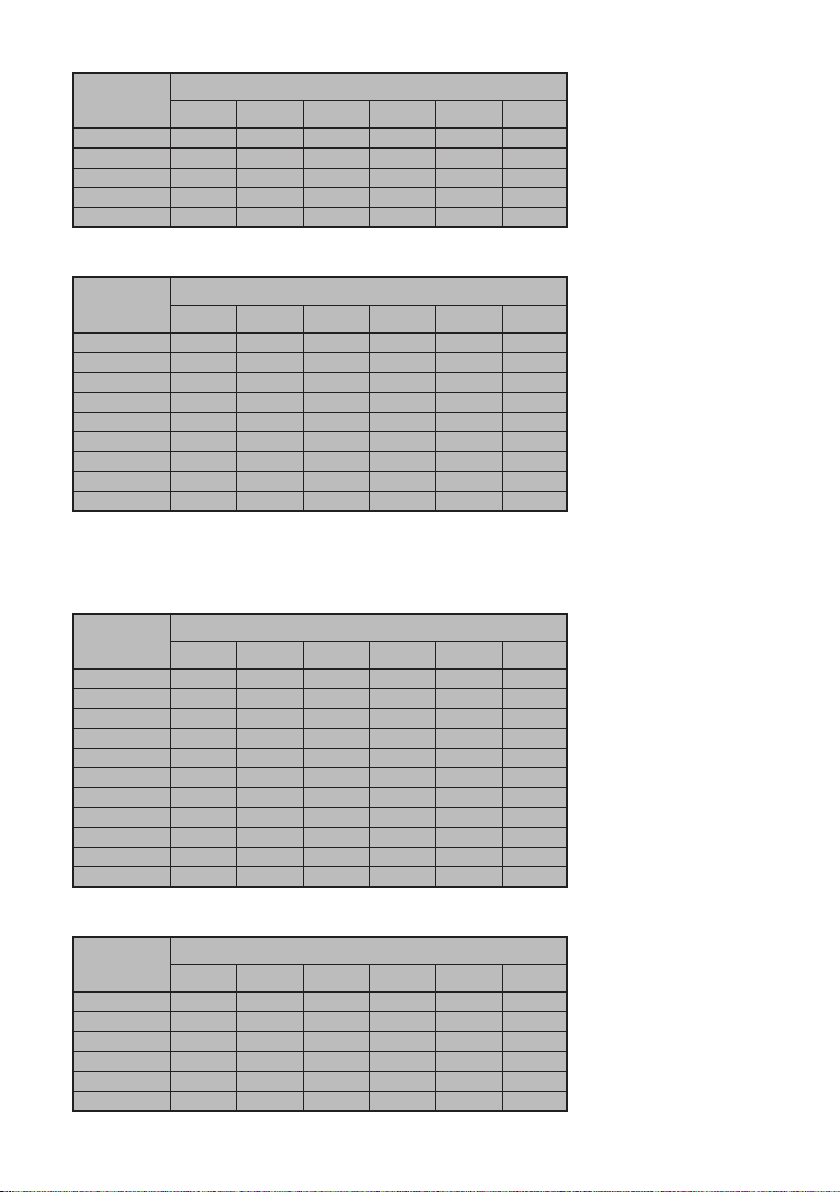

In the annex of these operating instructions you will find bar diameter tables in accordance with:

DIN 488

ASTM

CAN

JIS

GB 500110-2002

GOST 5781-82

BIS 1786:1985

Explanation of the bar diameter tables in the annex

∅ [mm] Bar diameter in mm

∅

↧[in]

↧ [mm]

Bar diameter

Depthininches

Depthinmm

0 Bar is visible at this depth but no depth is calculated.

X Bar cannot be detected at this depth.

8

Page 12

The value indicates the typical accuracy of the depth measurement (deviation

from actual) in mm or, respectively, in inches.

4.3.1 Imagescan and Blockscan: Rebar diameter is known

Pleaserefertothebardiametertablesintheannex(1.).

4.3.2 Imagescan and Blockscan: Rebar diameter is not known

Pleaserefertothebardiametertablesintheannex(2.).

4.3.3 Quickscan recording: Rebar diameter is known

Pleaserefertothebardiametertablesintheannex(3.).

4.3.4 Quickscan detection with depth measurement: Rebar diameter is known

Pleaserefertothebardiametertablesintheannex(4.).

4.3.5 Quickscan detection

Depth measurement is accurate to within ±10% of the effective depth.

4.3.6 Accuracy of bar diameter measurement

± 1 standard diameter when rebar spacing : depth of cover ≥ 2 : 1. Bar diameter measurement is possible only at

depths of up to 60 mm (2.4").

4.3.7 Reinforcing bar location accuracy

Bar center locating accuracy (all modes): Typically ± 3 mm (0.12") relative to the measured position, when the ratio of

bar spacing : depth of cover is ≥ 1.5:1.

4.4 Technical data for PS 200 S scanner

Maximum scanning speed 0.5 m/sec (1.64 ft/s)

Memory type Built-in flash memory for data

Memorycapacity 9Imagescansplusupto30m(98ft)ofrecorded

Quickscan (max. 10 scans)

Screentype/size LCD/50×37mm(2"x1.5")

Screen resolution 128 × 64 pixels

Dimensions 260×132×132mm(10.2x5.2x5.2")

Weight (with PSA 80 battery pack) 1.4 kg (3.09 lb)

Minimum battery life (with PSA 80 battery pack) 8 hours under typical conditions

Automatic power-off 5 min. after last press of a button

Backup battery type / life Lithium / 10 years (typically)

Scanner-monitor data interface Infrared

Scanner-monitor data transfer time ≦16 s for 9 images, ≦2 s for 1 image

Infrared range Typically 0.3 m (1 ft)

Infrared output power Max. 500 mW

en

4.5 Technical data for PSA 55 infrared adapter

Battery 1 x 1.5 V AAA

Dimensions 90 x 50 x 28 mm (3.5 x 2 x 1.1")

Weight 65 g (0.14 lb)

9

Page 13

Scanner - adapter data interface IrDa

Adapter - computer data interface USB

en

5 Safety instructions

In addition to the information relevant to safety given

in each of thesections ofthese operatinginstructions,

the following points must be strictly observed at all

times.

5.1 Intended use

a) The tool and its ancillary equipment may present

hazards when used incorrectly by untrained personnel or when used not as directed.

b) To avoid the risk of injury, use only genuine Hilti

accessories and additional equipment.

c) Modification of the tool or tampering with its parts

is not permissible.

d) Observe the information printed in the operat-

ing instructions concerning operation, care and

maintenance.

e) Do not render safety devices ineffective and do

not remove information and warning notices.

f) Check the condition of the tool before use. If the

tool is found to be damaged, have it repaired at a

Hilti Service Center.

g) In particularly critical situations where measurements

have safety and structural stability implications, always check results by removing material from the

surface of the structure and physically checking the

position, depth and diameter of reinforcement at key

positions.

h) When drilling at or near to a bar indicated by the sys-

tem, never drill deeper than the bar depth indicated.

5.2 Proper organization of the workplace

a) Keep the workplace tidy. Objects which could

cause injury should be removed from the working area. Untidiness at the workplace can lead to

accidents.

b) Keep other persons, especially children, away

from the area in which the work is being carried

out.

c) Wear non-skid shoes.

d) Avoid unfavorable body positions when working

from ladders. Make sure you work from a safe

stance and stay in balance at all times.

e) Only use the tool within the defined limits.

f) Check with a qualified person that it is safe to drill at

a specified point before beginning drilling.

g) Donotusethetoolwherethereisariskoffireor

explosion.

h) Make sure that the toolbox is properlysecured during

transport and does not present a risk of injury.

5.3 Electromagnetic compatibility

Although the tool complies with the strict requirements of

the applicable directives, Hilti cannot entirely rule out the

possibility of interference to the tool caused by powerful

electromagnetic radiation, leading to incorrect operation.

Accuracy must be checked by taking measurements by

other means when working under such conditions or

if you are unsure. Likewise, Hilti cannot rule out the

possibility of interference with other devices (e.g. aircraft

navigation equipment).

5.4 General safety precautions

5.4.1 Mechanical safety precautions

a) Check the tool for damage before use. If the tool

is found to be damaged, have it repaired at a Hilti

Service Center.

b) You must check the accuracy of the tool after it

has been dropped or subjected to other mechanical stresses.

c) When the tool is brought into a warm environment

from very cold conditions, or vice-versa, allow it

to become acclimatized before use.

d) Although the tool is protected against the entry of

moisture,itshouldbewipeddrybeforebeingput

away in its transport container.

5.4.2 Electrical safety precautions

a) Avoid short circuiting the battery terminals. Check

that the terminals on the battery pack and in the tool

are free from foreign objects before inserting the

battery pack. Short circuiting the battery terminals

presents a risk of fire, explosion and chemical burns.

b) Make sure that the outer surfaces of the battery

pack are clean and dry before inserting it in the

charger. Observe the operating instructions for

the charger.

c) Use only the battery pack specified in these operating

instructions.

d) Batteries that have reached the end of their life must

be disposed of safely and correctly to avoid environmental pollution.

e) Remove the battery pack before transporting the tool

or storing it for a long period of time. Inspect the

battery pack for any signs of leakage or damage

before reusing it.

f) To avoid pollution of the environment, the tool

must be disposed of in accordance with the cur-

10

Page 14

rently applicable national regulations. Consult the

manufacturer if you are unsure of how to proceed.

5.4.3 Liquids

c) Do not use the tool if it is defective.

d) If you are unsure of the scan results, consult a Hilti

specialist before proceeding.

e) Observe all warning and information messages dis-

played by the scanner and monitor.

Caustic liquids may leak from defective batteries. Avoid

contact with these liquids. In case of skin contact, wash

the area affected with soap and plenty of water. In case

of eye contact, rinse the eyes immediately with water and

subsequently consult a doctor.

5.5 Requirements to be met by users

a) The tool may be operated, serviced and repaired

only by authorized, trained personnel. This personnel

must be informed of any special hazards that may be

encountered.

b) Concentrate on your work. Stay alert. Pay atten-

tion to what you are doing. Approach the work

with common sense. Do not use the tool if you

are not concentrating.

6Beforeuse

6.1 Charging the battery pack

Use the PUA 80 charger to charge the PSA 80 battery

pack. Full instructions are contained in the charger operating instructions. The battery pack must be charged for

14 hours before first use.

6.1.1 Inserting and removing the battery pack

CAUTION

The battery pack must slide easily into the scanner. Do

not use force when inserting the battery pack into the

scanner as this may damage the battery pack and/or the

scanner.

5.6 Scanning requirements and limitations

a) Always check the accuracy of the tool before com-

mencing work on structures where measurements

have safety and structural stability implications. Scan

a reinforcing bar of known location, depth and diameter and check the results against the accuracy

specifications.

b) Do not use the PS 200 S scanner if the wheels do

not turn freely or appear to be worn. Contact Hilti for

repair information. The wheels may also be cleaned

or replaced by the user.

c) Always check how the tool is configured before

using it.

d) Applyonly light pressure to the scanner when moving

it across the surface.

e) Reinforcement that lies beneath the uppermost layer

of reinforcement may not be detected.

f) Remove all metal items of jewelry such as rings, pen-

dants, bracelets, etc. before commencing scanning.

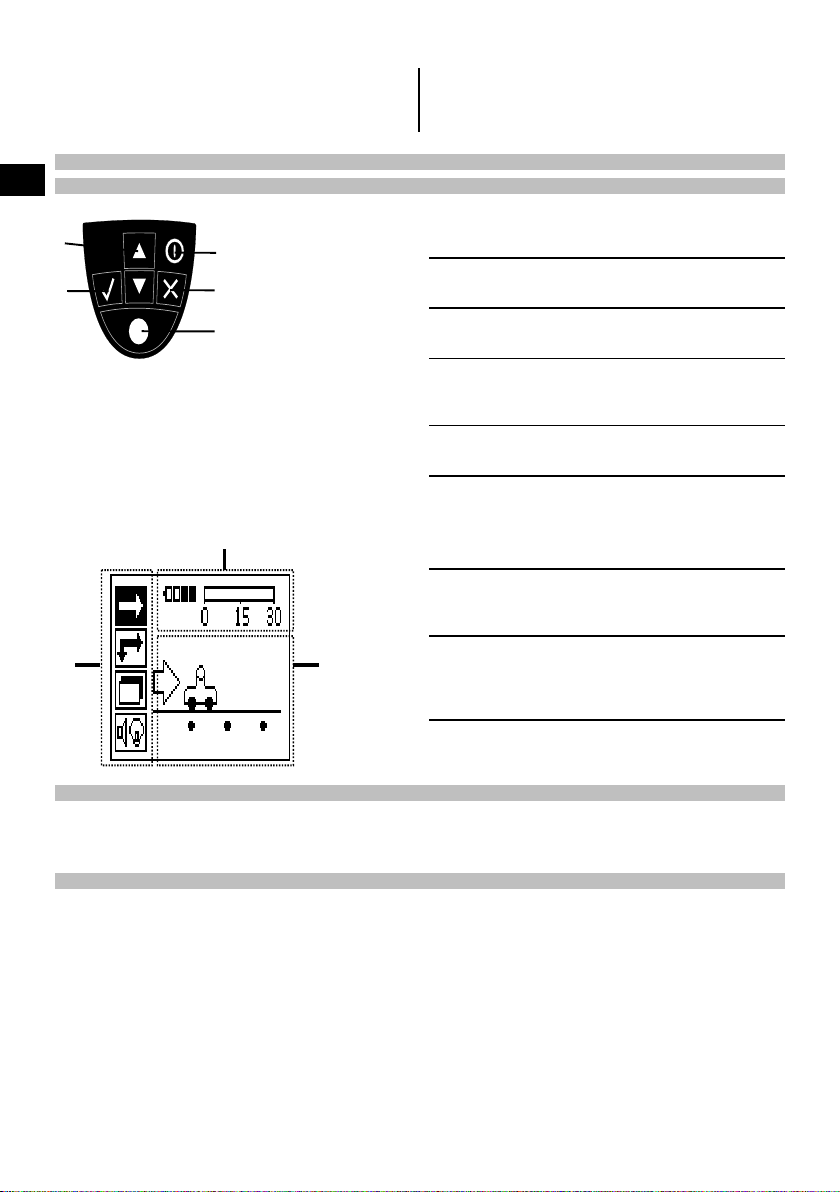

Check that the battery pack is correctly aligned with the

scanner. When the battery pack end cap is facing you,

the large groove in the battery pack must be on the left.

n

a

c

s

o

rr

e

F

0

0

2

S

P

Push the battery pack into the opening as far as it will go.

Turn the end cap clockwise until it clicks into place.

To remove the battery pack, turn the end cap anticlockwise as far as it will go. Pull the battery pack out of

the scanner.

en

7Operation

7.1 Carrying and using the system

CAUTION

The temperature inside a motor vehicle exposed to the

heat of the sun can easily exceed the maximum permissiblestoragetemperatureforthePS250Ferroscansystem. Some of the components of the PS 250 Ferroscan

system may suffer damage if exposed to temperatures

exceeding 60°C (140°F).

The scanner can be used without the monitor for scanning, or the monitor can be carried in the PSA 64 soft

pouch. The first option is advantageous when working

in areas that are difficult to access and maximum mobility is required, such as on a scaffold or ladder. When

scanner memory is full (9 Imagescans made, 1 complete

Blockscan or 30 mm (98 ft) of Quickscan have been

recorded) the data can be transferred to the PSA 55

infrared adapter or the PSA 100 monitor. The monitor

11

Page 15

can be kept nearby (e.g. at the foot of the scaffold, in a

vehicle, in the site office etc.). When the user intends to

make more scans than the scanner is capable of storing

7.2 Operating the scanner

en

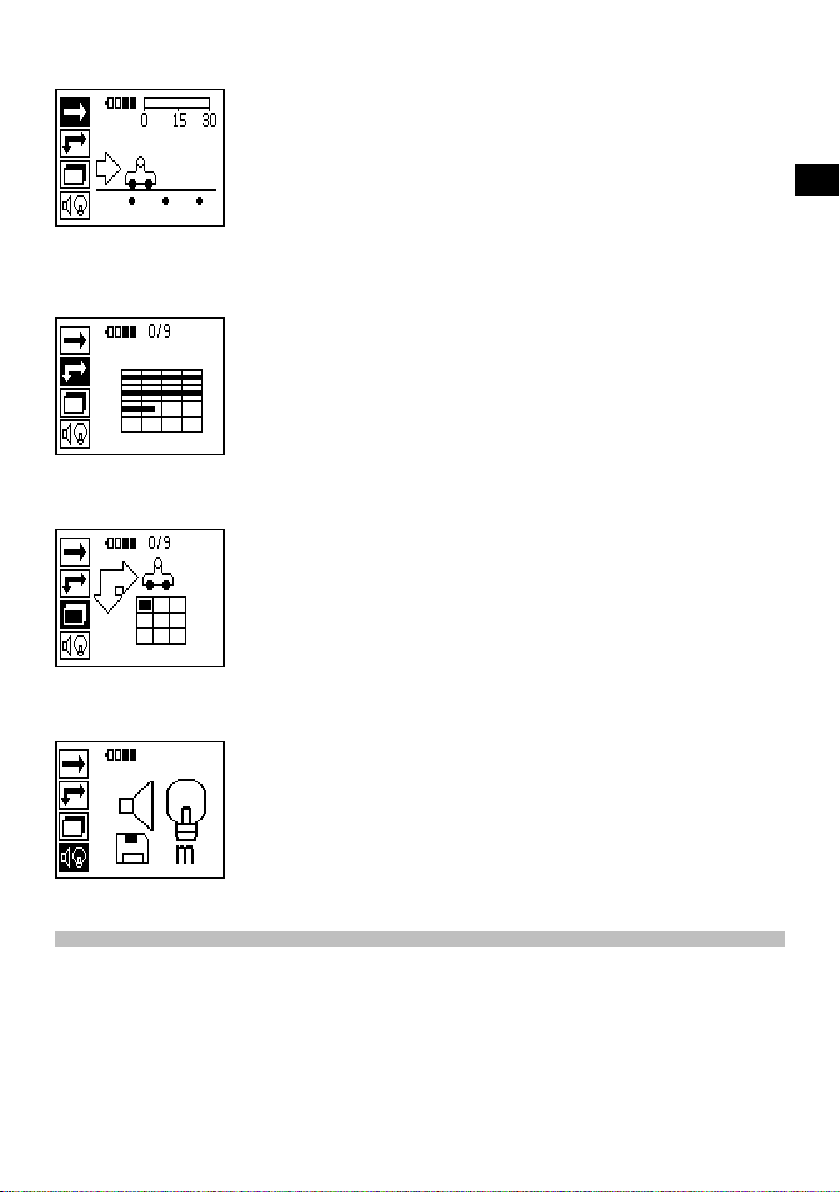

7.2.1 Control panel and display

Control panel

1

2

3

4

5

Display

2

13

in its memory and wishes to avoid repeated journeys to

the monitor, the PSA 55 infrared adapter can be used

or the monitor attached to a belt or carried using the

shoulder strap supplied.

Arrow but-

@

tons

Confirm

;

button

On/off but-

=

ton

Cancel but-

%

ton

Record

&

button

Menu area. Functions that can be selected

@

Status in-

;

formation

Variable

=

area.

Toggle up or down in options or

values.

Confirms a value or a selection.

Switches the tool on or off.

Cancelsaninput,cancelsthe

path being scanned or goes

back one step within a menu.

Starts or stops a recording.

using the Arrow and Confirm

buttons

Informationsuchasbattery

charge status and memory

status.

This is where feedback / information for the user is displayed,

e.g. scanning mode, bar depth,

scanning progress, etc.

7.2.2 Switching on and off

Press the on / off button to switch the scanner on or off.

The scanner can be switched off only when the main menu is displayed. To reach this screen, press the Cancel button

repeatedly until the main menu is displayed.

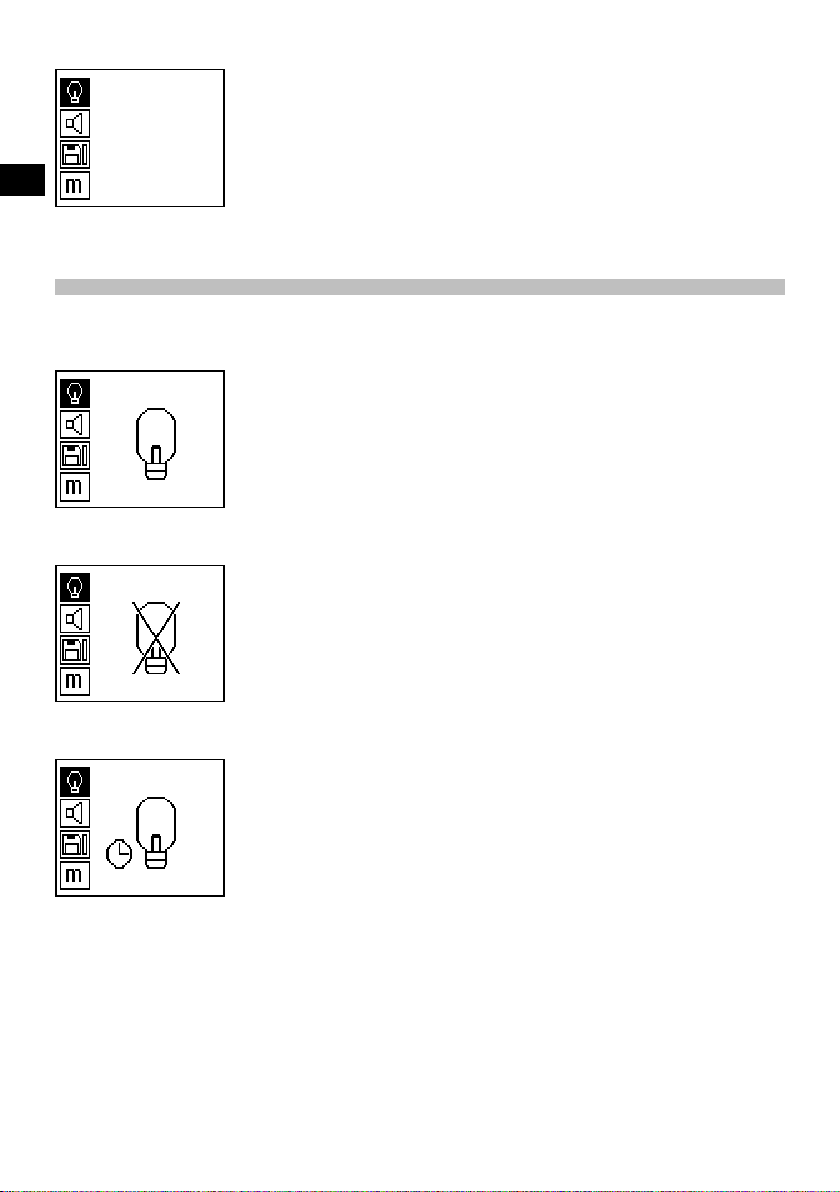

7.2.3 Main menu

The system always starts in the main menu. All scanning functions and set-up options are selected here. The battery

charge status is displayed at the top of the screen together with the memory status. The various scan modes and

settings menus are displayed as symbols on the left side of the screen. Use the Arrow buttons to toggle between

these options. Press the Confirm button to confirm the selected option.

12

Page 16

Quickscan

The remaining memory for Quickscan recording is shown at the top of the screen in meters or feet (depending on the

scanner type and units set).

Imagescan

The number of Imagescans in the scanner, up to a maximum of 9, is shown at the top of the screen.

Blockscan

en

The number of Imagescans in the scanner, up to a maximum of 9, is shown at the top of the screen.

Settings

Sets various parameters and deletes all scans held in memory.

7.2.4 Settings

This menu is used to set general parameters and to delete data from scanner memory.

After opening the settings menu, this screen appears.

13

Page 17

en

The Arrow buttons are used to select the options. The selected option can be confirmed / activated by pressing the

Confirm button and the Cancel button then pressed to return to the main menu.

7.2.4.1 Set display backlight

Select the backlight adjustment function by pressing the Confirm button. Use the Arrow buttons to toggle between

the individual options. Press the Confirm button to select the desired option and press the Cancel button to return to

the settings menu.

Switch backlight on

Switch backlight off

Backlight is controlled automatically. With this option, the backlight is switched off automatically after 5 minutes if no

button is pressed during this time and is switched back on again the next time a button is pressed.

14

Page 18

7.2.4.2 Adjusting the volume

Sets the volume level of the audible signal during scanning. Use the Arrow buttons to toggle between the various

options. Press the Confirm button to select the desired option and press the Cancel button to return to the settings

menu.

7.2.4.3 Setting the units

On systems with the item nos. 2044436, 2044474 and 377649 can the unit of measure used for scanning can be

configured by the user. Use the Arrow buttons to toggle between the various options. Press the Confirm button to

select the desired option and press the Cancel button to return to the settings menu.

Metric (mm or m, as appropriate)

en

Imperial (feet, as appropriate)

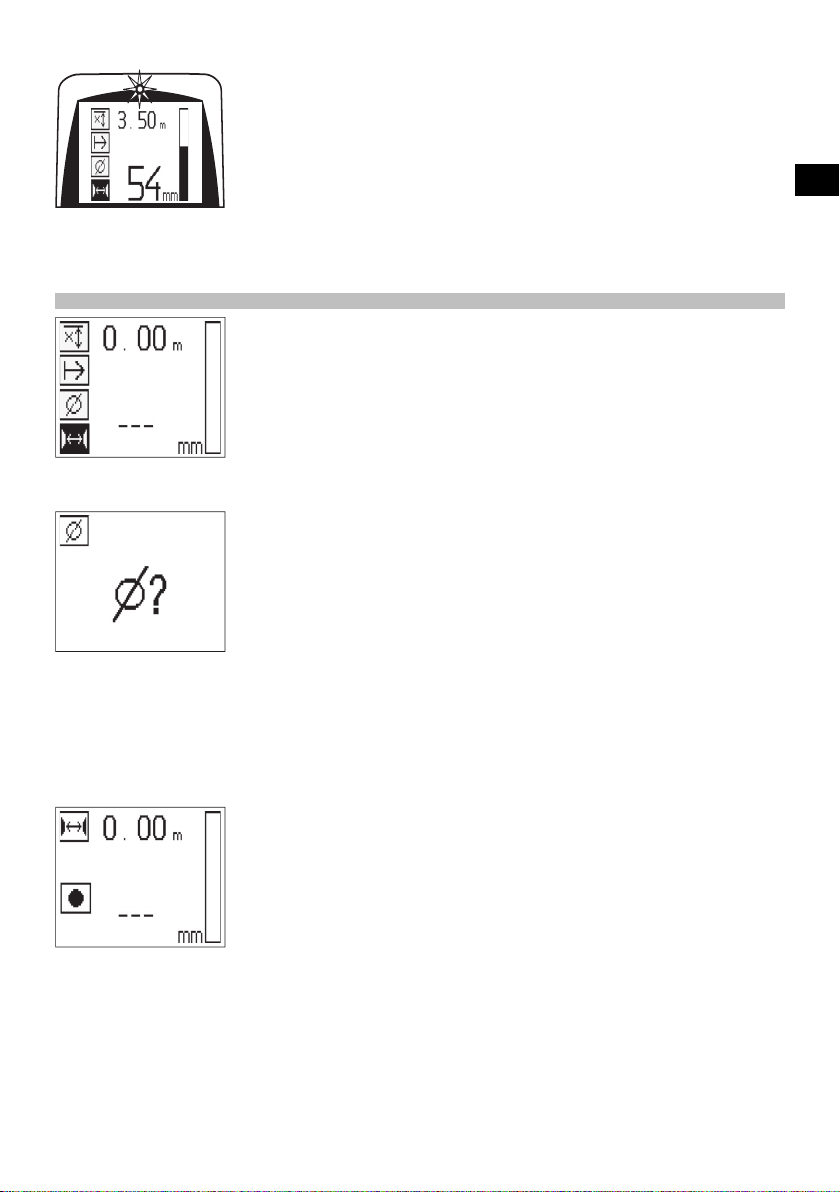

7.2.4.4 Deleting data

Deletes all scan data stored in the scanner. This function is available only if data is contained in memory. If data is

contained in memory, the bar shown next to the diskette symbol is filled. The bar is shown empty when no data is

contained in memory.

NOTE

Deleting memory contents presents a risk of losing data. Data that has not been transferred to the monitor before

deletion will be permanently lost.

15

Page 19

Press the Down arrow button followed by the Confirm button to delete data. Alternatively, press the Cancel button to

return to the settings menu.

7.2.5 Quickscan

CAUTION

The scanner detects only reinforcing bars that lie at right angles to the direction of travel. Bars that lie parallel to the

direction of travel will not be detected.

en

Make sure that the object is scanned in both the horizontal and vertical directions.

An incorrect depth may be calculated for bars that lie diagonal to the direction of travel.

Quickscan can be used to quickly detect the positions and approximate depths of reinforcing bars, which can then be

marked on the surface. This is procedure is named Quickscan detection.

Another function in Quickscan mode is accurate depth measurement, which requires that values for bar diameter and

bar spacing are previously entered.

Alternatively, the data can be recorded and evaluated on the monitor or using the PC application. The average depth

of cover over the reinforcement over large stretches of the surface can thus be easily determined. This procedure is

known as Quickscan recording.

Switch on the scanner. The Quickscan symbol is selected first automatically.

Use the Confirm button to select the Quickscan function from the main menu.

Bar depth

@

Distance traveled

;

Signal strength

=

Settings: Minimum depth, scanning direction,

%

bar diameter, bar spacing

7.2.5.1 Quickscan detection

Move the scanner over the surface. Reinforcing bars that lie at right angles to the direction of travel will be detected.

The distance covered by the scanner is recorded.

Signal strength indicated by the column in the display increases as the scanner approaches a bar and the depth value

is also shown. When the scanner is positioned over the center of a reinforcing bar:

The red LED lights.

A signal tone is emitted.

Maximum signal strength is indicated.

The approximate depth of the bar is indicated (lowest depth value indicated = center of the bar).

16

Page 20

The bar is positioned along the center line of the scanner and may be marked on the surface using a PUA 70 marking

pen. Depth measurement accuracy can be increased by entering the correct rebar diameter or by switching to accurate

depth measurement measuring mode (see 7.2.5.2).

7.2.5.2 Quickscan with accurate depth measurement

The measuring mode “Quickscan with accurate depth measurement” is selected by pressing the Confirm button.

The correct diameter must be known and previously entered.

The bar spacing distance must also be entered if within the 36 mm≦s≦120 mm (1.4"≦s≦4.7") range (see 4.3). This

value can be taken from building plans, confirmed by chipping away a channel in the concrete to view the bars, or

measured using Quickscan detection.

NOTE

A rebar spacing distance s≦36 mm (1.4") (see 4.3) cannot be measured.

en

The bar spacing distance can be calculated automatically using the Quickscan detection function by searching for

the center of the bar and pressing the red Record button when the scanner is over the mid point of the bar. Find the

mid point of the next bar and then press the Record button again. Bar spacing is then calculated automatically and

recorded.

17

Page 21

en

If the spacing distance is known, the value can also be entered manually using the Arrow buttons.

After setting the bar diameter and the spacing distance, the procedure is exactly the same as for Quickscan detection

( see 7.2.5.1).

7.2.5.3 Quickscan recording

WARNING

Always make an Imagescan or use Quickscan detection in both directions prior to making a Quickscan recording in

order to:

– establish the direction of the uppermost layer of reinforcement,

– minimize the risk of scanning a spliced bar,

– and immediately see if there are any ferrous materials in the concrete that may affect the accuracy of the scan.

CAUTION

Do not press the Record button before placing the scanner at the point where the scan should begin.

The scan should not, under any circumstances, be started or stopped while the scanner is directly over a bar. Keep

an eye on the display (observe a distance of at least 30 mm (1.2") to the nearest reinforcing bar).

Incorrect or misleading measurements may otherwise result.

WARNING

Do not lift the scanner from the surface before stopping the recording or setting a marker.

To record the position and depth of all reinforcing bars detected, place the scanner on the surface and use Quickscan

detection to find a position where there are no bars present. Mark the startingpointwithaPUA70markingpenand

press the Record button. The diskette symbol appears on the screen, indicating that the scanner is recording data.

Move the scanner over the surface.

Attheendofthescan,takecaretoensurethattheendpointisnotdirectlyover a rebar. To stop recording, press

Record again. Use a PUA 70 marking pen to mark the end of the stretch that has been scanned.

NOTE

Reinforcing bars that lie at right angles to the direction of travel will be detected and automatically recorded. Check to

ensure that the settings are correct before beginning recording.

18

Page 22

A stretch of up to 30 m (98 ft) in length can be recorded before it is necessary to transfer the data to the PSA 100

monitor or the PSA 55 infrared adapter. It is also possible to record several separate stretches (max. 10) that add up

to a maximum of 30 m (98 ft).

The data recorded can be transferred to the monitor for analysis ( see section 7.4.1).

7.2.5.4 Quickscan settings

The Quickscan settings are shown on the left hand side of the display. The settingscanbemadebeforemakinga

QuickscanoraQuickscanwithaccuratedepthmeasurement.UsetheArrowbuttons and Confirm button to access

the settings.

Limited depth scan

NOTE

This measurement mode allows rebars to be located within a specified depth range.

NOTE

When using the tool in this mode, the preset depth must take a clearance distance from the rebar into account.

Minimum depth

Use this setting when scanning a surface and looking specifically for bars that are located within a certain depth. For

example, if checking for 40 mm (1.6") minimum depth of cover, set the value to 40 mm (1.6"). (For quality assurance

measurements add an extra 2 mm (0.08") to account for any accuracy limitations). A signal tone is emitted and the

LED lights only if a reinforcing bar located within 40 mm (1.6") of the surface is detected.

CAUTION

Before making a scan, check to ensure that the depth range restriction is set correctly or deactivated if this feature is

not required.

en

Use the Arrow buttons to select the minimum depth function and then press Confirm.

Minimum depth function disabled.

When the value is set to "0", the function is deactivated and appears as above. Use the Arrow buttons to enter the

desired depth value and then confirm the setting by pressing the Confirm button. The system returns to the main

menu.

NOTE

If reinforcing bars are located at depths greater than the minimum depth set, no signal tone is emitted and no LED

lights.

Scanning direction

This setting is used to set the direction in which Quickscan recording is performed. Although they have no direct

effect on any measurement values later obtained from the monitor or PC application, the settings help to ensure that

19

Page 23

individual Quickscan recordings are subsequently correctly displayed in Hilti PROFIS Ferroscan MAP (data evaluation

and presentation application) and that the depth values correspond with the actual surface of the structure. This

makes it easier to subsequently locate the positions of areas with inadequate cover. The scanning direction is saved

together with each scan.

en

Select the desired scanning direction and press the Confirm button.

Bar diameter

This setting must be made in order to obtain an accurate depth of cover measurement (= rebar depth). Depth can be

measured accurately only when correct rebar diameter has been entered.

Use the Arrow buttons to select the bar diameter function and then press the Confirm button.

If no bar diameter is selected, the scanner will take the average diameter value for the relevant standard setting range

and calculate the depth accordingly.

CAUTION

Use the “Unknown diameter” function only under exceptional circumstancesastheresultsofthescanmaybe

distorted considerably if rebars of a different diameter have, in fact, been incorporated in the structure.

Average bar diameter according to standards

Standard

DIN 488 16 mm (0.63")

ASTM A 615 / A 615M‑01b

CAN / CSA-G30, 18-M92 C 20

JIS G 3112 D 22

GB 50012-2002 18 mm (0.71")

GOST 5781-82 18 mm (0.71")

BIS 1786:1985 16 mm (0.63")

∅

#7

NOTE

The bar diameter previously set will be saved in the scanner when switching it off. Check each time before using the

scanner that the rebar diameter has been preset correctly.

20

Page 24

7.2.5.5 Setting a marker

The surfaces of many structures contain obstacles that make it impossible to record the scan without lifting the

scanner from the surface. Examples of such obstacles are piers or columns on a wall, door openings, expansion joints,

pipes, scaffold bars, corners etc.

If an obstacle is encountered, a marker can be set. This interrupts the scan and allows the user to lift the scanner away

from the surface, place it beyond the obstruction and then continue scanning. It also indicates where certain objects

are located within a scan, providing additional information that creates a reference between the scan data and the

actual surface.

To set a marker, press and hold the Confirm button while in recording mode. The diskette symbol will be crossed out,

indicating that recording has been suspended and a marker has been set.

CAUTION

Due to interruption of the recorded signal, scanning results are less accurate immediately before and after the point

where a marker is set.

Do not interrupt the scan at the position of a reinforcing bar.

Then lift the scanner from the surface while keeping the Confirm button pressed. If necessary, mark the position on

the surface using a PUA 70 marking pen. Place the scanner back on the surface beyond the obstacle, release the

Confirm button and continue scanning. The marker will be shown as a vertical line in the scan data when viewed on

the monitor or in the PC application.

7.2.6 Imagescan

Imagescan is used to create an image of the reinforcement layout. The depth and diameter of the bars can be

determined or, respectively, estimated.

A reference grid must first be fixed to the wall. Use the adhesive tape supplied for this purpose. This tape adheres well

to concrete and can be torn off the roll by hand in the lengths required. For most surfaces, a 10 cm (4") length of tape

at each corner is adequate to secure the grid. If the concrete surface is very damp or dusty, use the brush supplied to

clean off any dirt and dust. The reference grid may then have to be attached by applying a strip of tape along the full

length of each edge.

Alternatively, a grid can be marked directly on the surface. Using a straight edge (such as a piece of wood) as a

guide, mark out a 4 x 4 grid with the parallel lines spaced at intervals of 150 mm (6"). The holes punched in the paper

reference grid can also be used to mark the positions of the grid lines on the concrete surface.

Switch the scanner on and select the Imagescan symbol. The battery level is displayed together with the number of

Imagescans currently held in memory (a maximum of 9).

en

Select Imagescan from the main menu.

The Imagescan screen is displayed.

21

Page 25

en

A representation of the grid appears on the screen with a suggested starting point (triangle). This is always at upper

left and will be suitable for most scans. Image data will be generated only for areas of the grid that have been scanned

both vertically and horizontally. In some cases, obstacles in the scan area may prevent this (e.g. a pipe penetrating a

beam). The starting point may be changed in such cases in order to allow the areatobescannedoptimally.Usethe

Arrow buttons to change the starting point if necessary.

5

150

PS 200 S Ferroscan

Æ

1

Æ

150

PS 200 S Ferroscan

2

Place the scanner on the grid at the starting point shown by the blinking arrow. Ensure the alignment marks on the

scanner are aligned correctly with the reference grid as shown above.

NOTE

Incorrect alignment of the scanner on the reference grid may lead to the bar positions being incorrect in the image

generated.

Press Record and move the scanner along the first row. Scanning progress is indicated by a thick black line that

advances across the display as the scanner is moved over the surface.

22

Page 26

PS 200 S Ferroscan

Æ

Æ

PS 200 S Ferroscan

The scanner emits a double beep at the end of the row and automatically stops recording. This procedure should be

repeated for each row and column while observing the instructions shown in the display.

When all rows have been completed, the columns should also be scanned in the same way.

The scanning operation for any row or column may be interrupted before reaching the end by pressing Record again.

This may be necessary if an obstacle prevents the full path being scanned. Similarly, an entire row or column may be

skipped by starting and stopping the recording without running the scanneroverthegrid.

Please note that no image will be created for areas of the reference grid that are not scanned in both directions.

It is possible to repeat the previous row or column by pressing Cancel. This may be necessary if the user is not

sure whether the path to be scanned has been followed accurately or if the scanner slipped out of position. Pressing

Cancel a second time aborts the scan and the system then returns to the main menu. Press Confirm to save the scan.

Pressing Cancel after scanning the last column or row will cause the scan to be deleted.

When the scan is complete, press the Confirm button to return to the main menu. The data can be transferred to the

monitor for viewing and evaluation ( see 7.4.1).

7.2.7 Blockscan

Blockscan automatically stitches Imagescans together to provide an impression of the reinforcement layout over a

large area. The exact bar position, depth and diameter can also be determined on the monitor by selecting each

Imagescan individually.

en

23

Page 27

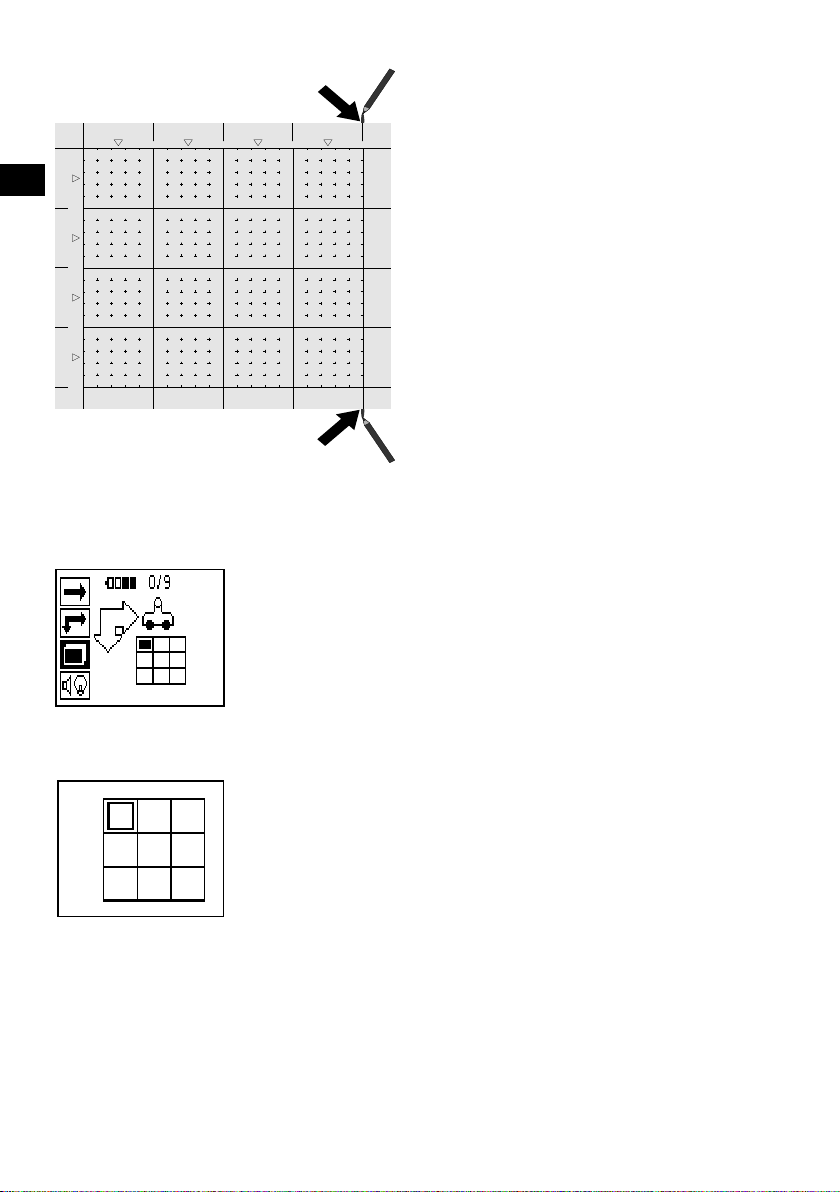

5 6 7 8

en

150

1

150

300 450 600

2

300

3

450

4

600

Attach the reference grid in the same way as for an Imagescan. Use a PUA 70 marking pen to mark the edges or the

punched holes at the end of each reference grid for the transition to the next grid, as shown below. Any additional

reference grids required should be attached to the wall so that their edges correspond and are in alignment with each

other.

Switch the scanner on and use the Arrow buttons to select the Blockscan symbol from the main menu. The battery

level is displayed together with the number of Imagescans currently held in memory (a maximum of 9).

A representation of a Blockscan is shown on the screen. Each square represents an Imagescan. Up to 3 x 3 Imagescans

can be made. Use the Arrow buttons to select the position of the first Imagescan to be made. Press Confirm to begin

the first Imagescan. Note that the coordinates of any points on the Blockscan will be referenced from the upper left

corner.

For details of how to carry out the Imagescan, see 7.2.6. When the Imagescan is complete, the system returns to the

Blockscan screen.

24

Page 28

The completed Imagescan is shown shaded.

en

5 6 7 8

150

1

150

2

300

3

450

4

600

300 450 600

5 6 7 8

150

1

150

2

300

3

450

4

600

300 450 600

Select the next Imagescan position and repeat the scanning procedure. Imagescans already made may be repeated

simply by reselecting the area to scan and carrying out the Imagescan again. The data will be overwritten. Once all the

Imagescans have been recorded, or the maximum number of scans that can be held in memory is reached (9), press

the Cancel button to return to the main menu. Transfer the data to the monitor for viewing and analysis ( see 7.4.1).

NOTE

Pressing the Cancel button twice causes the recorded Imagescan to be deleted. The screen then returns to the main

menu.

7.3 PSA 55 infrared adapter

7.3.1 Before first use

NOTE

Install the Hilti PROFIS Ferroscan 5.7 software (or a higher

version) on your PC/laptop. The date and time must be

set before using the PSA 55 IR adapter for the first time

in order to ensure that the scan data subsequently shows

the correct date and time.

To do this, use the PUA 95 Micro USB cable to

connect the PSA 55 IR adapter to the computer.

Start the Hilti PROFIS Ferroscan application.

Go to “Tools”, “Workflow” and then select “Set PSA

55 date and time”.

The date and time are then set in the PSA 55 IR

adapter.

NOTE

The device driver is installed together with the Hilti

PROFIS Ferroscan (V 5.7) software. If this is not the

case, the device driver must be installed manually by

running the “setup.exe” file located in the “Drivers” folder

on the PSA 55 IR adapter.

7.3.2 Operating the PSA 55 infrared adapter

The scans can be transferred to the adapter via the

infrared interface and from there to the PC/laptop.

Switch the adapter on or off by pressing the on / off

button for about 3 seconds.

The LED display on the adapter can indicate the following

statuses:

25

Page 29

The green LED lights constantly: The adapter is

switched on and is ready for operation.

The red LED blinks rapidly: Battery charge state is

low.

The green LED blinks: The adapter has just been

switched on.

en

ThegreenLEDblinks:Datatransferinprogress.

The red LED blinks and the adapter switches itself

off: Memory is 95% full.

7.4 Data transfer

7.4.1 Transferring data from the scanner to the

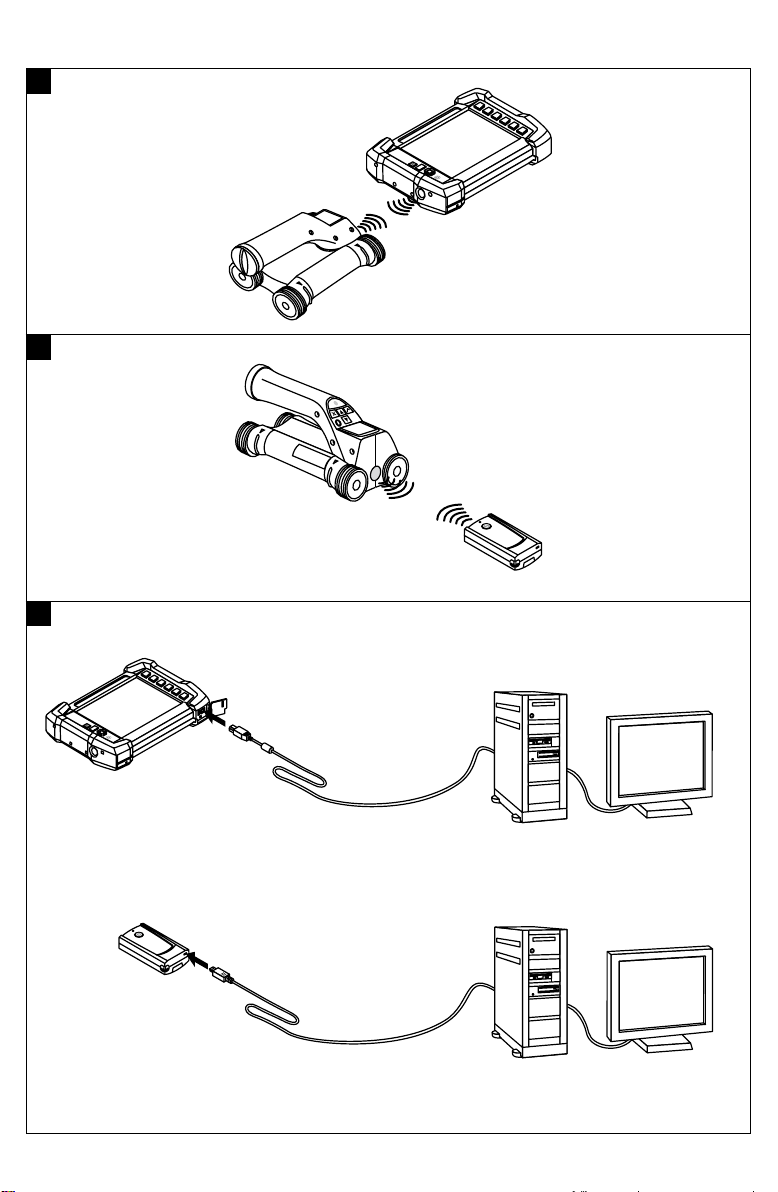

monitor 2

NOTE

Ensure that the correct project is selected on the monitor

before transferring data.

NOTE

Check that the windows over the infrared ports are

free from dirt, dust and grease and are not excessively

scratched before commencing data transfer. Failure to

do so may result in reduced data transfer range or may

prevent data transfer.

Data is transferred from the scanner to the monitor using the infrared connection. The infrared windows are

situated at the ends of scanner and the monitor.

Data can be transferred at any time when the scanner

and monitor are switched on, the PS 200 S scanner is

displaying the main menu and data transfer by infrared is

activated on the monitor.

The project into which the data is to be copied is selected

on the monitor under Projects.

Then select Import and confirm “From PS 200 S” by

pressing the OK button. The infrared symbol then appears

in the status area of the PSA 100 monitor.

Bring the scanner and monitor close together so that

the infrared windows are facing each other. The two

devices recognize each other automatically and establish

communication.

This screen appears on the scanner and a beep sounds:

Press the Confirm button on the scanner to begin importing all scan data into the selected project.

This screen appears on the scanner while data transfer

is in progress and the red LED on the scanner blinks

continuously.

Data transfer takes between 1 and 15 seconds, depending on the number and length of scans contained in the

scanner.

This screen is displayed by the scanner when data transfer is complete:

Press the Confirm button on the scanner again to end the

data transfer procedure.

The scan data in the scanner is then deleted automatically.

7.4.2 Transferring data from the scanner to the

adapter 3

DANGER

Use the adapter only indoors. Avoid moisture ingress.

CAUTION

Check that the windows over the infrared ports are

free from dirt, dust and grease and are not excessively

scratched before commencing data transfer.

Failure to do so may result in reduced data transfer range

or may prevent data transfer.

Data is transferred from the scanner to the adapter using the infrared connection. The infrared windows are

situated at the ends of scanner and the adapter.

NOTE

The maximum range of the infrared connection is approximately 30 cm (11.8"). The maximum permissible angle

between the scanner and monitor for successful data

transmission at close ranges (up to 10 cm (4")) is ± 50°

relative to the axis of the infrared port on the adapter.

At a distance of 15 cm (6") this angle is reduced to ±

30°. At a distance of 30 cm (11.8") the scanner must be

accurately aligned with the monitor to ensure successful

data transmission.

Bring the scanner and adapter close together so that

the infrared windows are facing each other. The two

devices recognize each other automatically and establish

communication. The following screen appears on the

scanner and a beep sounds:

26

Page 30

Press the Confirm button on the scanner to begin data

transfer. The following may be observed while data transfer is in progress:

The PSA 92 USB data cable is used to transfer data from

the monitor to the computer.

7.5 Tips for scanning and evaluation

The object is too narrow to scan or reinforcement is

too close to an outside edge to be scanned properly.

en

The green LED on the adapter blinks rapidly to indicate

that data transfer is in progress. The red LED on the

scanner blinks continuously.

Data transfer takes between 1 and 15 seconds, depending on the number and length of scans contained in the

scanner. The LED on the adapter lights green again when

data transfer is finished.

This screen is displayed by the scanner when data transfer is complete.

All scan data has then been successfully transferred.

Press the Confirm button on the scanner to delete the

data in the scanner and return to the main menu.

7.4.3 Transferring data from the adapter to the

computer 4

NOTE

To ensure data security, data integrity and to avoid malfunctions, use only the PUA 95 Micro USB cable supplied

by Hilti.

The PUA 95 Micro USB data cable is used to transfer

data from the adapter to the computer.

The adapter can be removed once data transfer is complete.

NOTE

In order to remove the PSA 55 adapter safely, we recommend use of the “Remove hardware safely” function

of the operating system. This helps prevent loss of data

integrity.

7.4.4 Transferring data from the monitor to the

computer 4

NOTE

To ensure data security, data integrity and to avoid malfunctions, use only the PSA 92 Micro USB cable supplied

by Hilti.

Use a thin sheet of non-metallic material (e.g cardboard,

wood, polystyrene foam,...) as an overlay that extends

beyond the edge. The scanner can then be moved over

the sheet to beyond the edge of the structure. Note that

the thickness of the board must be deducted from any

depth measurements. The thickness of the board can

be entered in the PC application. This value will then be

automatically deducted from any depth measurements.

The surface is rough.

Rough surfaces (e.g. concrete surfaces with exposed

aggregates) cause additional noise in the signal and may

mean that the depth or diameter of a bar cannot be

determined. In such cases it is also advantageous to

scan through a thin overlay board. Also in this case, the

thickness of the board must be deducted from any depth

measurements.

Interference in images

Interference in images may occur due to:

Scraps of reinforcement in the concrete

Tie wires where rebars cross

Aggregates with ferromagnetic properties

Ends of bars lying parallel to the scanning plane

27

Page 31

Ends of bars lying at right angles to the scanning

plane (standing bars)

NOTE

Diameters and depths calculated in the area where interference occurs must be treated with caution as they may

be inaccurate.

en

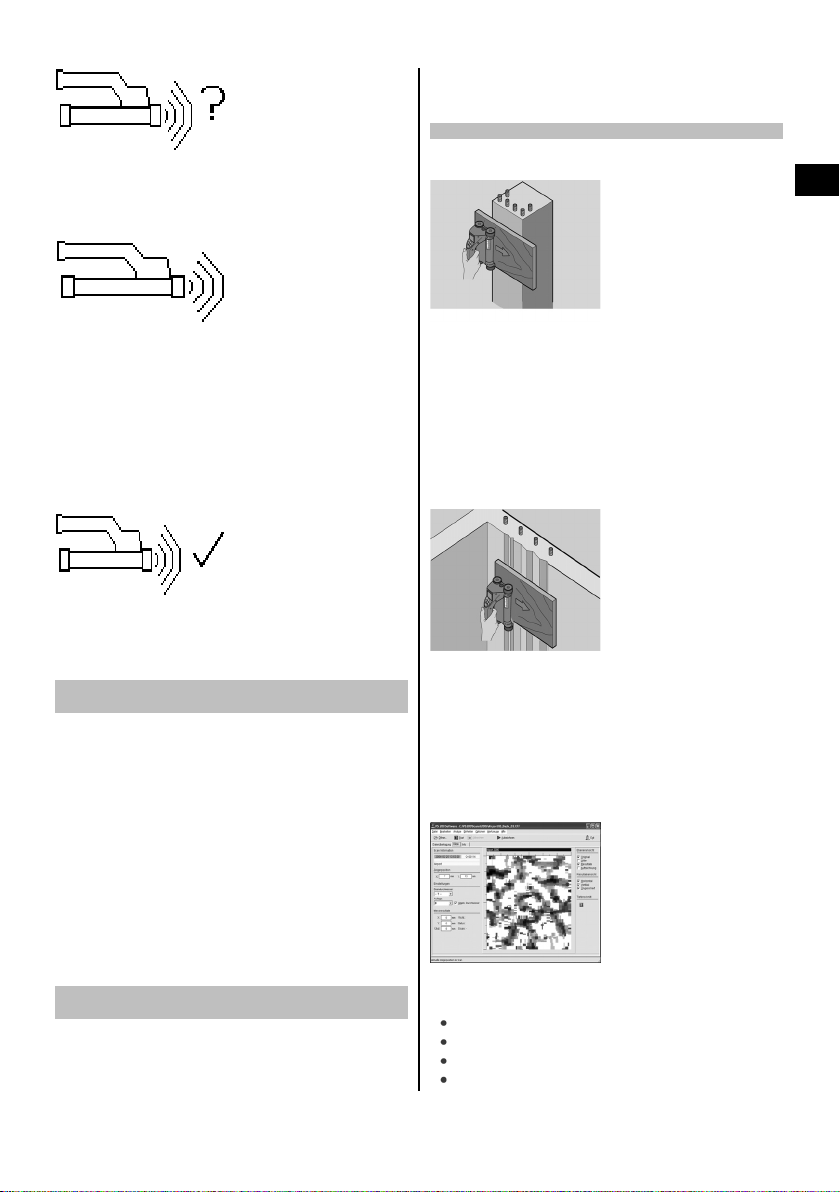

Scanning columns and beams for making penetrations

In cases where the reinforcement must not be damaged,

ensure that Imagescans are made on at least three sides

8 Care and maintenance

8.1 Cleaning and drying

CAUTION

Do not use liquids other than alcohol or water. Other

liquids may damage plastic parts.

Clean the parts of the tool only with a clean, soft cloth.

Moisten the cloth with pure alcohol or a little water if

necessary.

8.2 Storage

Do not store the tool when it is wet.

Dry and clean the tool, its case and accessories before

storing.

Remove the batteries before storing.

After storing for a long period of time, carry out a measurement check before use.

Observe the temperature limits when storing your equipment. This is particularly important in winter / summer if

the equipment is kept inside a motor vehicle (-25°C to

+60°C / -13°F to +140°F).

8.3 Transport

DANGER

Remove the battery before storing or transporting the

tool.

Always use the original Hilti toolbox when transporting

the tool.

of the component in order to ensure that shear bars

(placed at an angle in the concrete) can also be detected.

Simple diameter check

A simple, rough check of the diameter of the bars in the

first layer can be made by deducting the depth of the

second perpendicular layer from that of the first. This

assumes however that the two layers touch each other

or are at least very close.

7.6 PC software

The Hilti PROFIS Ferroscan PC applicationprovides functions for enhanced analysis, easy creation of reports, data

archival, image and data export to other PC applications

as well as automated batch processing of large volumes

of data.

The Hilti PROFIS Ferroscan MAP application makes it

possible to merge large volumes of data, allowing the

creation and evaluation of large-area images covering

areasofupto45x45m(148x148ft).

Installation instructions can be found on the Hilti PROFIS

Ferroscan software CD-ROM. Detailed information about

using the PC application can be found in the Help menu.

8.4 Removing / replacing the scanner wheels

CAUTION

Do not overtighten the screw when refitting the wheel as

this may result in damage to the wheel and axle. Replace

only one wheel at a time.

The scanner wheels can be removed either for cleaning

or replacement.

Use a 2.5 mm (¹⁄₈") Allen wrench to loosen and remove

the screw at the wheel axle.

Carefully pull the wheel off the axle while holding the opposite end of the axle or other wheel. If necessary, clean

the casing and/or wheel carefully see 8.1 before refitting

the wheel to the axle and reinserting and tightening the

screw.

8.5 Hilti Calibration Service

We recommend that the tool is checked by the Hilti

Calibration Service at regular intervals in order to verify its reliability in accordance with standards and legal

requirements.

Use can be made of the Hilti Calibration Service at any

time, but checking at least once a year is recommended.

The Calibration Service provides confirmation that the

tool is in conformance, on the day it is tested, with the

specifications given in the operating instructions.

After checking, acalibration sticker applied to the tool and

a calibration certificateprovide writtenverification that the

28

Page 32

tool is operating in accordance with the manufacturer’s

specification.

Calibration certificates are always required by companies

certified according to ISO 900x.

Your local Hilti Center or representative will be pleased

to provide further information.

9 Troubleshooting

Message displayed Fault Possible cause Remedy

The scanner is not recording.

Symbol appears while using Quickscan detection

mode.

The scanner is not recording.

Symbol appears while

making a Quickscan

recording.

The scanner is not recording.

Symbol appears while

making an Imagescan.

The scanner is not recording.

Symbol appears.

The maximum scanning

speed of 0.5 m/s (1.64

ft/s) has been exceeded.

The maximum scanning

speed of 0.5 m/s (1.64

ft/s) has been exceeded.

The maximum scanning

speed of 0.5 m/s (1.64

ft/s) has been exceeded.

This symbol may appear

if the scanner is moved in

the wrong direction when

in Quickscan recording mode, i.e. you begin

scanning, for example,

from right to left but at

some point during the

Quickscan recording you

move the scanner to the

right.

Press the Confirm button

and repeat the scan.

Move the scanner over

the surface more slowly.

Press the Confirm button.

Repeat the scanning operation from the starting point or from the last

pointatwhichamarker

was set.

Move the scanner over

the surface more slowly.

Press the Confirm button.

Scan the row or column

again.

Move the scanner over

the surface more slowly.

Press the Confirm button

and repeat the scan.

Move the scanner in the

correct direction.

NOTE

The warning does not appear immediately, only

whenamovementof15

cm (6") or more in the

wrong direction occurs.

en

29

Page 33

Message displayed Fault Possible cause Remedy

This symbol may appear

on the scanner during

data transfer between the

en

scanner and monitor.

This symbol may appear

on the scanner during

data transfer between the

scanner and monitor.

This symbol may appear

during the transfer of data

between the PS 200 S

scanner and the PSA 55

adapter.

A stop symbol generally

indicates a fatal error in

the scanner.

Data is not being transferred.

Data is not being transferred.

Data is not being transferred.

One of these symbols

may be displayed immediately after the scanner is

switched on.

Data transfer was interrupted or a connection

could not be established.

Indicates that the scanner

or monitor may be defective.

Indicates that the scanner

or adapter may be defective.

They indicate a possible

electronic fault.

Check that the scanner

and monitor are positioned within the maximum range of 30 cm (12")

and that they are correctly

aligned with each other.

Make sure that the atmosphere is as dustfree as possible and that

the infrared windows on

both scanner and monitor are clean and not

badly scratched. Badly

scratched windows must

be replaced by Hilti Service.

Try to hold the monitor and scanner steady

and in correct alignment

with each other until data

transfer is completed.

Remedy the problem by

switching the units off and

on or adjusting their alignment with each other.

NOTE

Data is not lost in the

event of an interruption

in data transfer. Data is

deleted from the scanner

only once all scan data

has been correctly transferred and the Confirm

button on the scanner is

pressed.

If the error message is still

displayed the tool must

be returned to a Hilt Service Center.

Remedy the problem by

switching the unit off and

on or adjusting its alignment.

Switch the scanner off

andthenonagain.

If the error message reappears the tool must be

returned to Hilti for repair.

A stop symbol generally

indicates a fatal error in

the scanner.

30

Page 34

Message displayed Fault Possible cause Remedy

This symbol may appear

when trying to enter the

An exclamation mark indicates either an error

caused by the operator

or an error that can be

solved by the operator.

Fault Possible cause Remedy

The scanner doesn't start. The battery pack is not charged. Change the battery.

The scanner doesn't run freely. The wheels are dirty or dusty. Remove the wheels and casing and

The scanner operates only for

ashorttimebeforethebattery

pack is exhausted.

The scan date and time are not

correct.

Thedateandtimecannotbe

set.

Imagescan or Blockscan

scanning mode, when tryingtobeginanewImagescan within Blockscan

scanning mode or when

trying to start Quickscan

recording.

The contacts on the battery pack or in

the scanner are dirty.

The battery pack is old or defective,

or the maximum number of charging

cycles has been exceeded.

The drive belt or gear teeth are worn. Contact Hilti Service.

The battery pack is old or defective,

or the maximum number of charging

cycles has been exceeded.

The Hilti PROFIS Ferroscan application was not used to set the date.

The date and time cannot be set as

no device driver was found.

This indicates that the

memory allocated to the

operation is full and that

no more data can be

stored.

Clean the contacts.

Contact Hilti Service.

clean the parts.

Contact Hilti Service.

Install Hilti PROFIS Ferroscan V 5.7

(or a higher version) and start the application.

Use the PSA 95 data cable to

connect the adapter and then go to

“Tools”, “Workflow”, “Set PSA 55

date and time” and set the current

date and time.

Install the driver manually: Use the

PSA 95 data cable to connect the

PSA 55 adapter to the computer.

Install the device driver

(Setup_PSA55.exe)

In this situation, the data

must either be transferred

to the monitor or deleted

from scanner memory.

NOTE

Deleting the contents of

scanner memory may result in data loss. Data that

has not been transferred

to the monitor will be permanently deleted.

en

10 Disposal

WARNING

Improper disposal of the equipment may have serious consequences:

The burning of plastic components generates toxic fumes which may present a health hazard.

Batteries may explode if damaged or exposed to very high temperatures, causing poisoning, burns, acid burns or

environmental pollution.

Careless disposal may permit unauthorized and improper use of the equipment. This may result in serious personal

injury, injury to third parties and pollution of the environment.

31

Page 35

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must be

correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking

en

back old tools or appliances for recycling. Ask Hilti Customer Service or your Hilti representative for further information.

For EC countries only

Do not dispose of electronic measuring tools or appliances together with household waste.

In observance of the European Directive on waste electrical and electronic equipment and its implemen-

tation in accordance with national law, electric tools and batteries that have reached the end of their life

must be collected separately and returned to an environmentally compatible recycling facility.

11 Manufacturer’s warranty

Hilti warrants that the tool supplied is free of defects in

materialandworkmanship.Thiswarrantyisvalidsolong

as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

Operating Instructions, and the technical system is maintained. This means that only original Hilti consumables,

components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only over the entire lifespan

of the tool. Parts requiring repair or replacement as a

result of normal wear and tear are not covered by this

warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular, Hilti

is not obligated for direct, indirect, incidental or consequential damages, losses or expenses in connection with, or by reason of, the use of, or inability to

use the tool for any purpose. Implied warranties of

merchantability or fitness for a particular purpose are

specifically excluded.

For repair or replacement, send the tool or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

12 FCC statement / IC statement

Increase the separation between the equipment and re-

12.1 FCC statement (applicable in US) / IC

statement (applicable in Canada)

CAUTION

This equipment has been tested and found to comply

with the limits for a class B digital device, pursuant to

part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates,

uses and may radiate radio frequency energy. Accordingly, if not installed and used in accordance with the

instructions, it may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the

interference by taking the following measures:

Re-orient or relocate the receiving antenna.

ceiver.

ConsultyourdealeroranexperiencedTV/radiotechnician for assistance.

NOTE

Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s

authority to operate the equipment.

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired operation.

This device complies with the requirements defined in

RSS-220 in conjunction with RSS-Gen of IC.

32

Page 36

1. This device may not cause harmful interference. 2. This device must accept any interference received,

including interference that may cause undesired operation.

en

33

Page 37

ANNEX

1.

DIN 488

Ø [mm]

6 ±2 ±3 ±3 ±4 ±5 0 X X X

8 ±2 ±2 ±3 ±4 ±5 0 0 X X

10 ±2 ±2 ±3 ±4 ±5 0 0 X X

12 ±2 ±2 ±3 ±4 ±5 ±10 0 X X

14 ±2 ±2 ±3 ±4 ±5 ±10 0 0 X

16 ±2 ±2 ±3 ±4 ±5 ±10 ±12 0 X