Page 1

Installation!&!Operating!Manual

P61A-2!Pellet!Stove!Owners!Manual

Safety!Testing!by

ASTM!E1509

Mobile!Home!Approved

ìCe!manuel!est!disponible!en!FranÁais!sur!demandeî

SAFETY!NOTICE

PLEASE!READ!THIS!ENTIRE!MANUAL!BEFORE!YOU!INSTALL !AND!USE!YOUR!NEW!ROOM!HEA TER.!!FAILURE

TO!FOLLOW!INSTRUCTIONS!MAY!RESUL T!IN!PROPERTY!DAMAGE,!BODILY!INJURY,!OR!EVEN!DEATH.

FOR!USE!IN!THE!U.S.!AND!CANADA.!!SUITABLE!FOR!INSTALLATION!IN!MOBILE!HOMES

IF! THIS! HARMAN! STOVE! IS! NOT! PROPERLY!

FOLLOW! INSTALLATION! DIRECTIONS.

CONT ACT!LOCAL!BUILDING!OR!FIRE!OFFICIALS!ABOUT!RESTRICTIONSAND!INSTALLATION!INSPECTION

REQUIREMENTS!IN!YOUR!AREA.

INST ALLED,!A! HOUSEFIRE! MA Y!RESULT.!!FOR!YOUR!SAFETY,

R5

CONTACT!YOUR!LOCAL!AUTHORITY!(SUCH!AS!MUNICIPAL!BUILDING!DEPARTMENT,!FIRE!DEPARTMENT,

FIRE!PREVENTION!BUREAU,!ETC.)!TO!DETERMINE!THE!NEED!FOR!A!PERMIT .

CETTE!GUIDE!D'UTILISATION!EST!DISPONIBLE!EN!FRANCAIS.!CHEZ!VOTRE!CONCESSIONNAIRE!DE!HARMAN

STOVE!COMP ANY.

R1

SA VE!THESE!INSTRUCTIONS.

Page 2

2 P61A!!Pellet!Stove

Fig.!1

Page 3

Table!of!Contents

Testing! Lable 2

Assembly! &! Installation 4

Installation 5

Venting !!!!!!!!!!6

Automatic! Operation 12

ESP! Control 16

Maintenance 17

Trouble! Shooting 22

Feeder! Parts 23

Specifications 23

Options 2 4

Wiring! Diagram 26

Parts!List 27

Warranty 28

Please!read!this!entire!manual!before!you!install!and!use!your!new

room!heater.!!Failure!to!follow!instructions!may!result!in

property!damage,!bodily!injury,!or!even!death.

SUITABLE!FOR!MOBILE!HOME!INSTALLATIONS.

Harman!Stove!Company

352!Mountain!House!Road

Halifax,!PA!17032

P61A!Pellet!Stove

3

Page 4

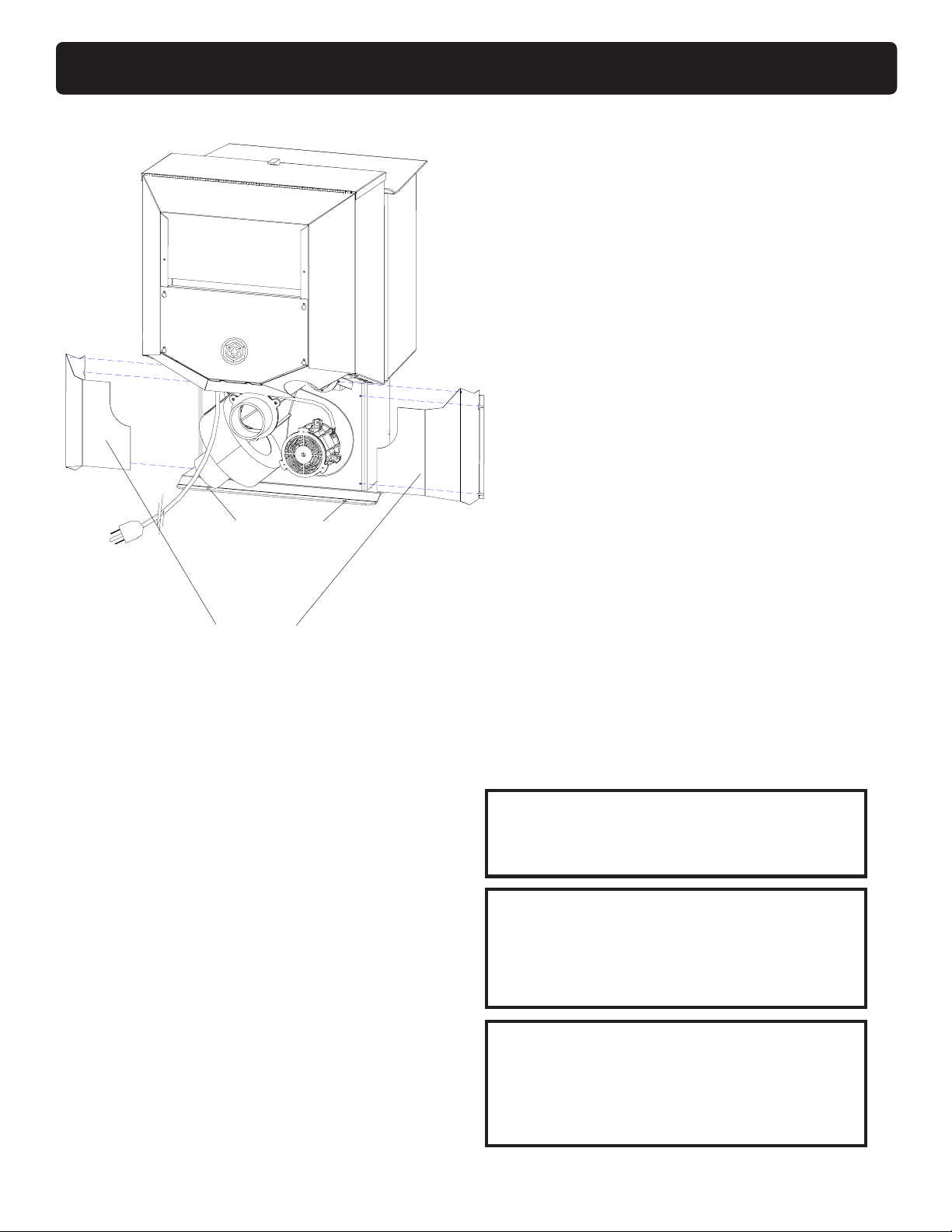

!!!!!!!Assembly!and!Installation

Unpacking

The!P61!is!bolted!to!the!skid!to!prevent!movement

during!shipping.

To!free!the!stove!from!the!skid!you!must!remove

the!hold-down!bolts!in!the!rear!of!the!pedestal!base.

!

Removing!or! Installing! rear!cover!panels

To! remove!the! rear! cover!panels,! loosen! the

screws! slightly! and! slide ! the! covers! outward! as

shown! in! the! illustration.!!To !reinstall,!simply! slide

back!into!place!and!retighten!the!screws.

Firebrick

Install!the!firebrick!vertically!on!the!angle!above

the!burnpot.

Flame!Guide

Install!the!cast!iron!flame!guide!on!top!of!the

burnpot!and!make!sure!it!is!fully!seated!against!the

Shipping!Bolts

Note:! These! same! holes

are!used!for!mobile!home

installation

auger!opening.!The!bottom!of!the!flame!guide!is!marked

38+.

Rear!Cover

Panels

Fig.!2

DO!NOT!INSTALL!A!FLUE!DAMPER!IN!THE

EXHAUST!VENTING!SYSTEM!OF!THIS

UNIT .

DO!NOT!CONNECT!THIS!UNIT!TO!A

CHIMNEY!FLUE!SERVING!ANOTHER

APPLIANCE.

INSTALL!VENT!AT!CLEARANCES

SPECIFIED!BY!THE!MANUFACTURER

Mobile!home!installation!should!be!done!in

accordance!with!the!Manufactured!Home!and

Safety!Standard!(HUD),!CFR!3280,!Part!24.

WARNING

DO!NOT!INSTALL!IN!SLEEPING!ROOM

CAUTION

THE!STRUCTURAL!INTEGRITY!OF!THE

MOBILE!HOME!FLOOR,!WALL,!AND

CEILING/ROOF!MUST!BE!MAINTAINED.

CAUTION

KEEP!COMBUSTIBLE!MA TERIALS

(SUCH!AS!GRASS,!LEAVES,!ETC.)!AT!LEAST!3

FEET!AWAY !FROM!THE!FLUE!OUTLET!ON

THE!OUTSIDE!OF!THE!BUILDING.

4 P61A!!Pellet!Stove

Page 5

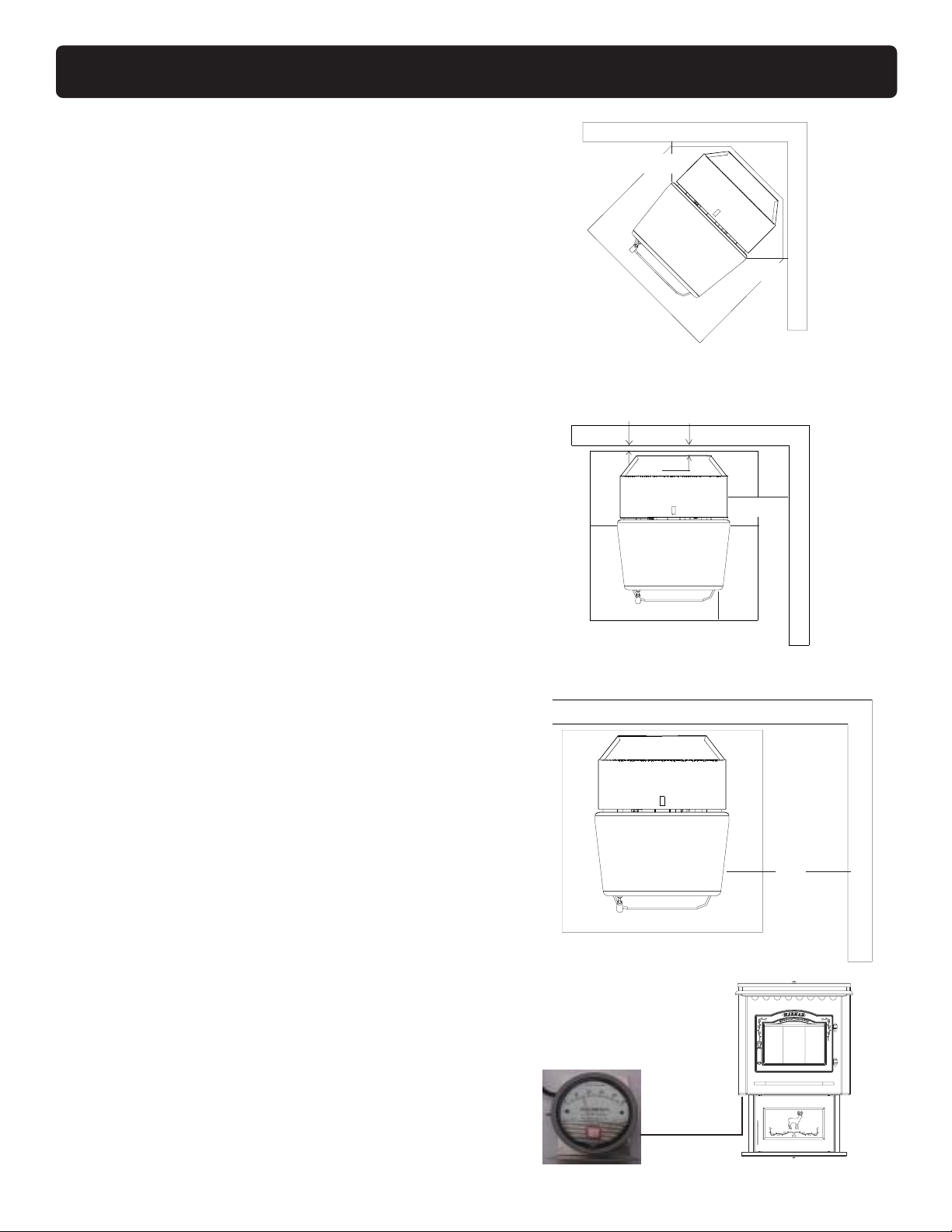

Installation

Installing

Place!the!stove!on!a!noncombustible!floor!protector

that!extends!6!inches! to! the! front,! 6! inches! to! the! sides

and!1! inch! to!the!rear! of! the!stove.!The! minimum! floor

protector!material!is!24!gauge!sheet!metal.

Place!the!stove!away!from!combustible!walls!at!least

as! far! as! shown! in! figures! 3,4! and! 5.! Please! note! the

difference!in!side! wall! clearance! with! and! without! side

shields.

Note! that! the! clearances! shown! are! minimum! for

safety!but!do!not!leave!much!room!for!access!when!cleaning!or!servicing.!Please!take!this!into!account!when!placing!the!stove.

Connect! the! power! cord! to! a! 120! V.A.C.! 60Hz

grounded!receptacle.!(A!surge!protector!is!recommened

to!protect!the!circuit!board).

Prior!to!installing!the!flue!pipe,!connect!a!draft!meter

to!the!stove! as! shown! in! fig.! 6.!!(The! draft! meter! must

have!a!minimum!range!of!0-.5).!However,!prior!to!taking

the! draft! reading! be! sure! all!doors!and! windows! in! the

home!are! closed.!!Record!the!draft! reading_______.!!If

this!reading!is!more!than!.05"!lower!than!the!unconnected

reading,! check! for! possible!restrictions! or! the! need! for

outside!air!(see! page!7).

9"-13"

FLOOR! PROTECTOR

9"!With!Side!Shields

13"!Without!Side!Shields

1"

6"

9"-13"

Fig.!3

2"

12"

6"

Mobile!Home!Installation

When!installing!this!unit!in!a!mobile!home!several!requirements!must!be!followed:

1.!The!unit! must! be! bolted! to!the!floor.!This! can! be

done!with! 1/4"! lag! screws!through!the!2! holes! in!the!base

plate.

2.!The!unit!must!also!be!connected!for!the!outside!air.

See! page! 8.

3.!Floor! protection! and! clearances! must! be! followed

as! shown.

4.! Unit! must! be! grounded! to!the!metal! frame! of! the

mobile!home.

CAUTION:!This! appliance! must!be!vented! to! the!outside.

Due!to!high!temperatures,!the!stove!should!be!placed

out!of!traffic!and!away!from!furniture!and!draperies.

Children!and!adults!should!be!alerted!to!the!hazards!of

high!surface!temperatures! and! should! stay! away!!to! avoid

burn!to!skin!and/or!clothing.

Young!children! should!be! carefully!supervised! when

they!are!in!!the!same!room!as!the!stove.

Clothing!and!other!flammable!materials!should!not!be

placed!on!or!near!this!unit.

Installation!and!repair!of!this!Harman!Stove!should!be

done!by!a!qualified!service!person.!The!appliance!should!be

inspected! before! use! and! at! least! annually! by! a! qualified

service!person.!More!frequent!cleaning! will!be! required.!It

is!imperative!that!control!compartments,!burners,!and!circulating!air! passageways!of! the!stove!be! kept!clean.

FLOOR! PROTECTOR

Fig.!4

FLOOR! PROTECTOR

Fig.!5

6"

With!Side!Shields

18"

Without!Side!Shields

Fig.!6

P61A!Pellet!Stove

5

Page 6

Venting

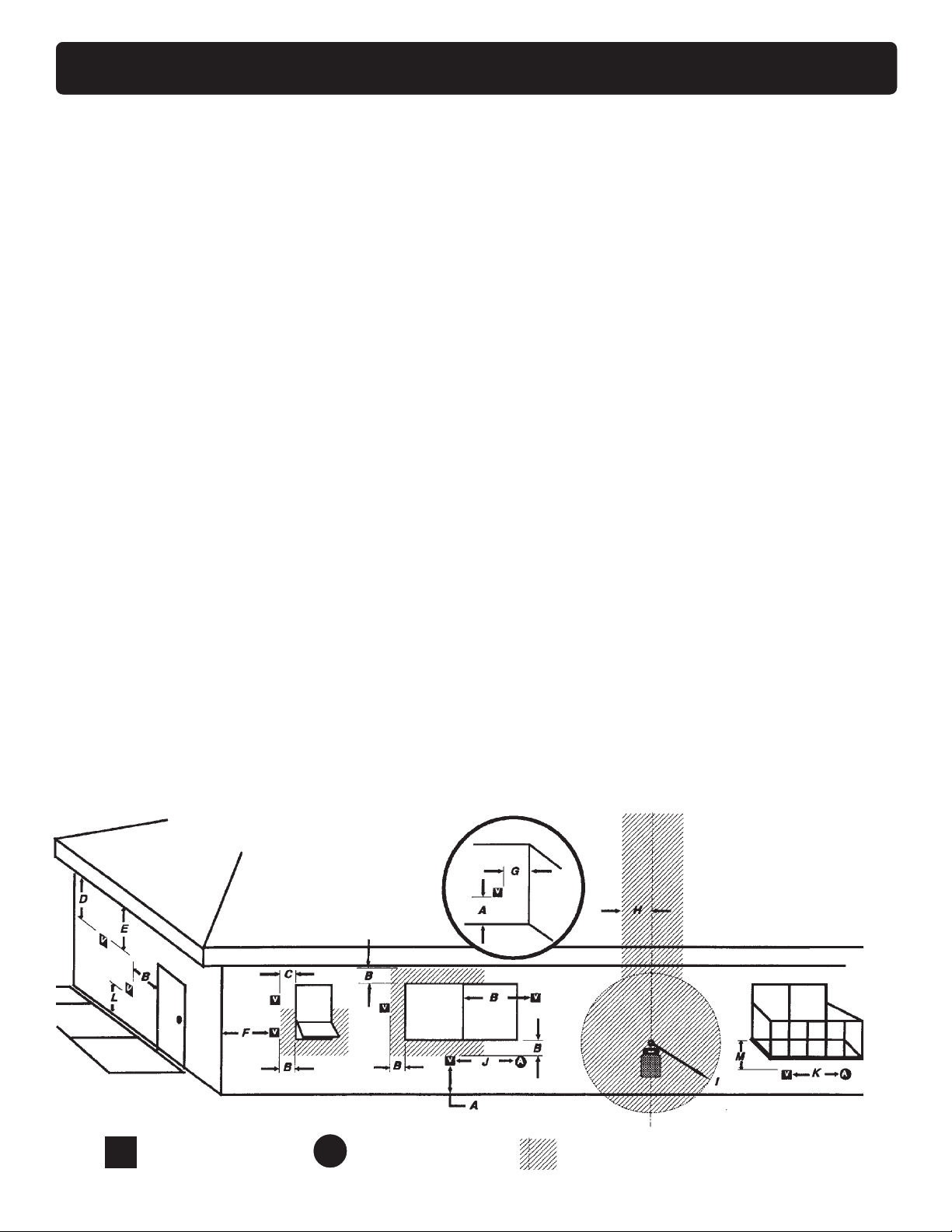

Requirements!for! Terminating! the! Venting

WARNING:!Venting! terminals!must!not!be!re-

cessed!into!a!wall!or!siding.

NOTE:!Only! PL! vent! pipe! wall!pass-throughs

and!fire!stops!should!be!used!when!venting!through

combustible! materials.

NOTE:!Always!take!into! consideration! the! effect!!the!prevailing!wind!direction!or!other!wind!currents!will!cause!with!flyash!and!/or!smoke!when!placing!the!termination.

In!addition,!the!following!must!be!observed:

A.!The!clearance!above!grade!!must!be!a!minimum!of!18".

B.!The!clearance!to!a!window!or!door!that!may

be!opened!must! be! a! minimum! of! 48"! to!the!side,

48"!below!the!window/door,!and!12"!above!the!window/door.

(!with!outside!air!installed,!18î!)

C.!A! 12"!!clearance! to!a! permanently! closed

window!!is!!recommended!to!prevent!condensation

on!the!window.

D.!The!vertical!clearance!to!a!ventilated!soffit

located!above!the!terminal!within!a!horizontal!distance!of!2!feet!(60!cm)!from!the!center-line!of! the

terminal!!must!be!a!minimum!of!18".

E.!The!clearance!to!an!unventilated!soffit!!must

be!a!minimum!of!12".

F.! The! clearance! to! an! outside! corner! is! 11"

from!center!of!pipe.

G.!The!clearance!to!an!inside!corner!is!12".

H.!! A!vent!must!not!be!installed!within!3!feet!(90

cm)! above! a! gas! meter/regulator! assembly! when

measured!from!the!horizontal!center-line!of!the!regu-

1

lator.

1

1

I.!The!clearance!to!service!regulator!vent!outlet

must!be!a!minimum!of!6!feet.

1

J.!The!clearance!to!a!non-mechanical!air!supply!inlet!to!the!building!or!the!combustion!air!inlet!to

any!other!appliance!must!be!a!minimum!of!48î.

1

K.! The! clearance! to! a! mechanical! air! supply

inlet!must!be!a!minimum!of!10!feet.

1

(with!outside!air!installed,!6!feet!)

L.!The!clearance!above!a!paved!sidewalk!or!a

paved!driveway!located!on!public!property!must!be

a!minimum!of!!7!feet.

!

M.!The!clearance!under!a!veranda,!porch,!deck

or!balcony!must!be!a!minimum!of!12!inches.

1,2

1,3

NOTE:!!The!clearance!to!vegetation!and!other

exterior!combustibles!such!as!mulch!is!36î!as!measured!from!the!center!of!the!outlet!or!cap.!This!36î

radius! continues! to!grade! or! a! minimum! of! 7! feet

below!the!outlet.

1

Certain!Canadian!and!or!!Local!codes!or!regu-

lations!may!require!different!clearances.

2

A!vent!shall!not!terminate!directly!above!a!sidewalk! or! paved! driveway! which!is! located!between

two!single!†family!dwellings!and!serves!both!dwellings.

3

Only!permitted!if!veranda,!porch,!deck,!or!balcony!is!fully!open!on!a!minimum!of!!2!sides!beneath

the!floor.

NOTE:! Where! passage! through! a! wall,! or

partition!of!combustible!construction!is!desired,

the!installation!shall!conform!to!CAN/CSA-B365.

(if!in!!Canada)

=!Vent!terminal

6 P61A!!Pellet!Stove

V

Fixed

Closed

Openable

A

Openable

=!Air!supply!inlet

Inside! Corner

Detail

Fixed

Closed

=!Area! where!terminal! is!not! permitted

Page 7

Venting

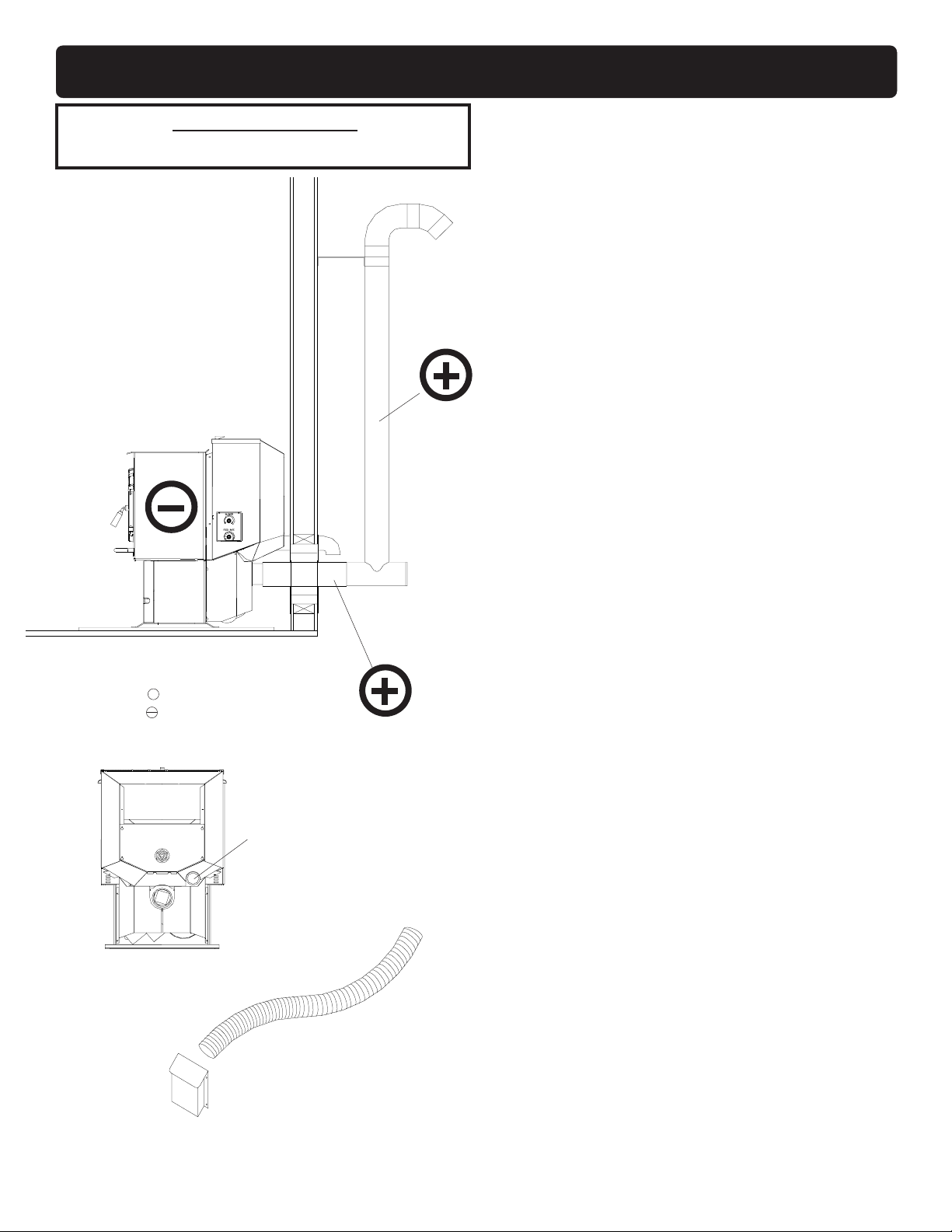

IMPORTANT!NOTICE

Pellet!Vent!Pipe!or!PL!Vent!Pipe!Must!be!used.

!!!!!!!!!!!!!!!!!!!!!!!!!!Fig.!7

!!+!=!Positive!static!pressure

!!!!!=!!Negative!static!pressure

Venting

A!combustion!blower!is!used!to!extract!the!combustion!gases!from!the!firebox.!This!causes!a!negative

pressure!in!the!firebox!and!a!positive!pressure!in!the

venting!system!as!shown!in!fig.!7.!The!longer!the!vent

pipe!and!more!elbows!used!in!the!system,!the!greater

the!flow!resistance.!Because!of!these!facts!we!recommend!using!as!few!elbows!as!possible!and!15!feet!or

less!of!vent!pipe.!The!maximum!horizontal!run!should

not!exceed!48".!If!more!than!15!feet!of!pipe!is!needed,

the!diameter!should!be!increased!from!3"!to!4"!because

a!larger!pipe!causes!less!flow!resistance.!Be!sure!to

use!approved!pellet!vent!pipe!wall!and!ceiling!pass

through!fittings!to!go!through!combustible!walls!and

ceilings.!Be!sure!to!use!a!starting!collar!to!attach!the

venting!systen!to!the!stove.!The!starting!collar!must

be! sealed! to! the! stove! with! high! temp! silicone

caulking.

Vent!Pipe

Pellet!venting!pipe!(!also!known!as!PL!vent!)!is

constructed!of!two!layers!with!air!space!between!the

layers.!This!air!space!acts!as!an!insulator!and!reduces

the!outside!surface!temperature!to!allow!a!clearance!to

combustibles!of!only!3!inches.!The!sections!of!pipe!lock

together!to!form!an!air!tight!seal!in!most!cases;!however ,

in!some!cases!a!perfect!seal!is!not!achieved.!For!this

reason!and!the!fact!that!the!P61!operates!with!a!positive

vent!pressure!we!specify!that!the!joints!also!be!sealed

with!!clear!silicone.

Inlet!Cover! part#

1-10-08543

Outside!air!flex!pipe

goes!here

Flex!pipe! part#

2-00-08543

Outside!Air

Outside!air!is!optional!except!in!mobile!homes!and

where!building!codes!require.!!The!benefit!of!outside!air

is!mainly!noticed!in!small!very!tight!houses.

To!install!outside!air!use!2!3/8"!I.D.!flex!pipe!part

number!2-00-08543.!There!is!a!break-away!hole!on

the!rear!panel!which!must!be!removed!before!connecting!the!flex!pipe.!The!pipe!should!be!run!outside!and

terminate!to!the!side!or!below!the!vent!pipe!outlet!so!the

flue!outlet!is!more!than!12"!from!the!inlet!cover.The!maximum!length!run!of!this!pipe!is!15!feet.!If!a!longer!run!is

needed!the!size!must!be!increased!to!3".!Inlet!cover!part

number!1-10-08542!should!be!used!to!keep!birds,!rodents!etc.!out!of!!the!pipe.

.

HRV

When!installing!in!a!house!with!a!Heat!Reclaiming

Ventilation!System!(HR V)!be!sure!the!system!is!balanced

and!is!not!creating!a!negative!pressure!in!the!house.

P61A!Pellet!Stove

7

Page 8

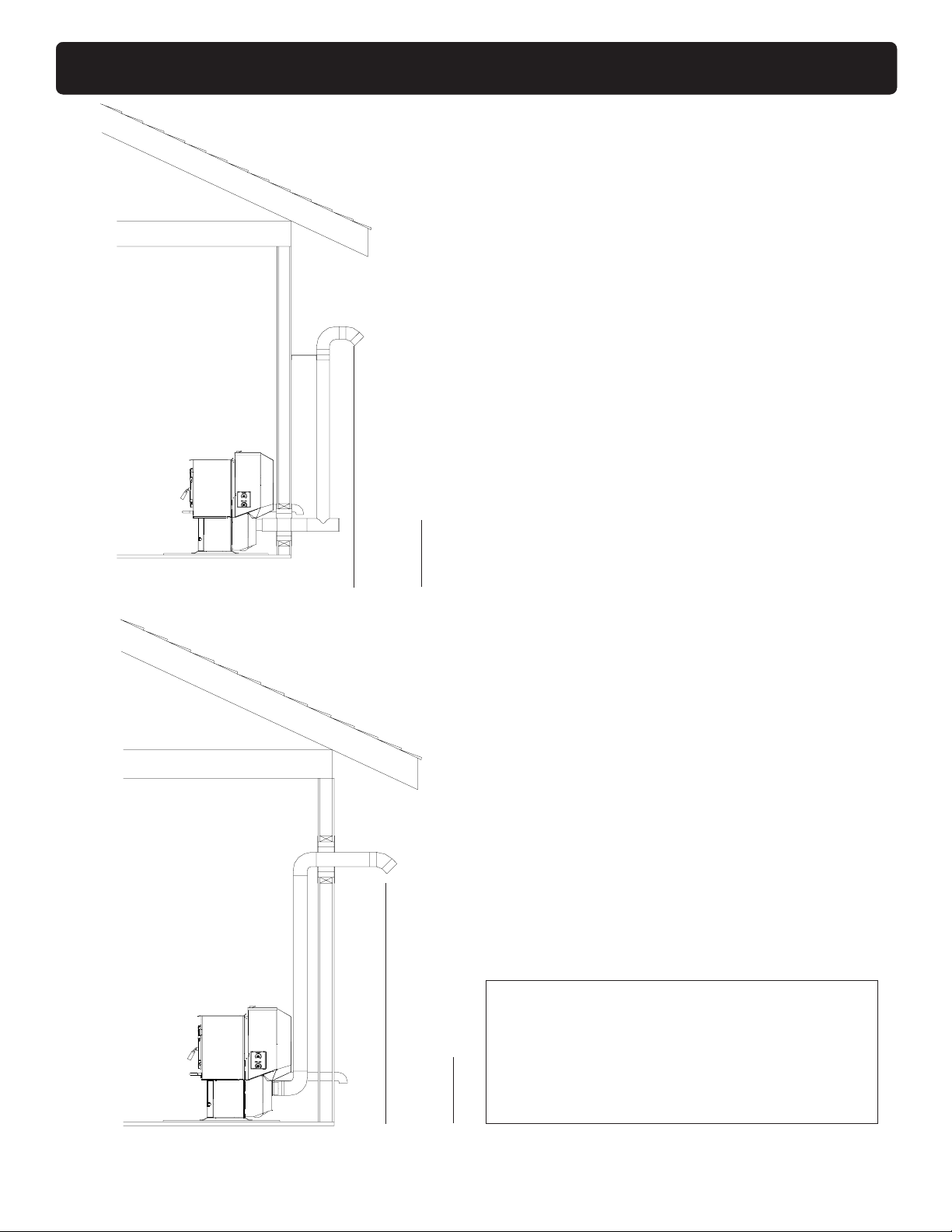

Venting

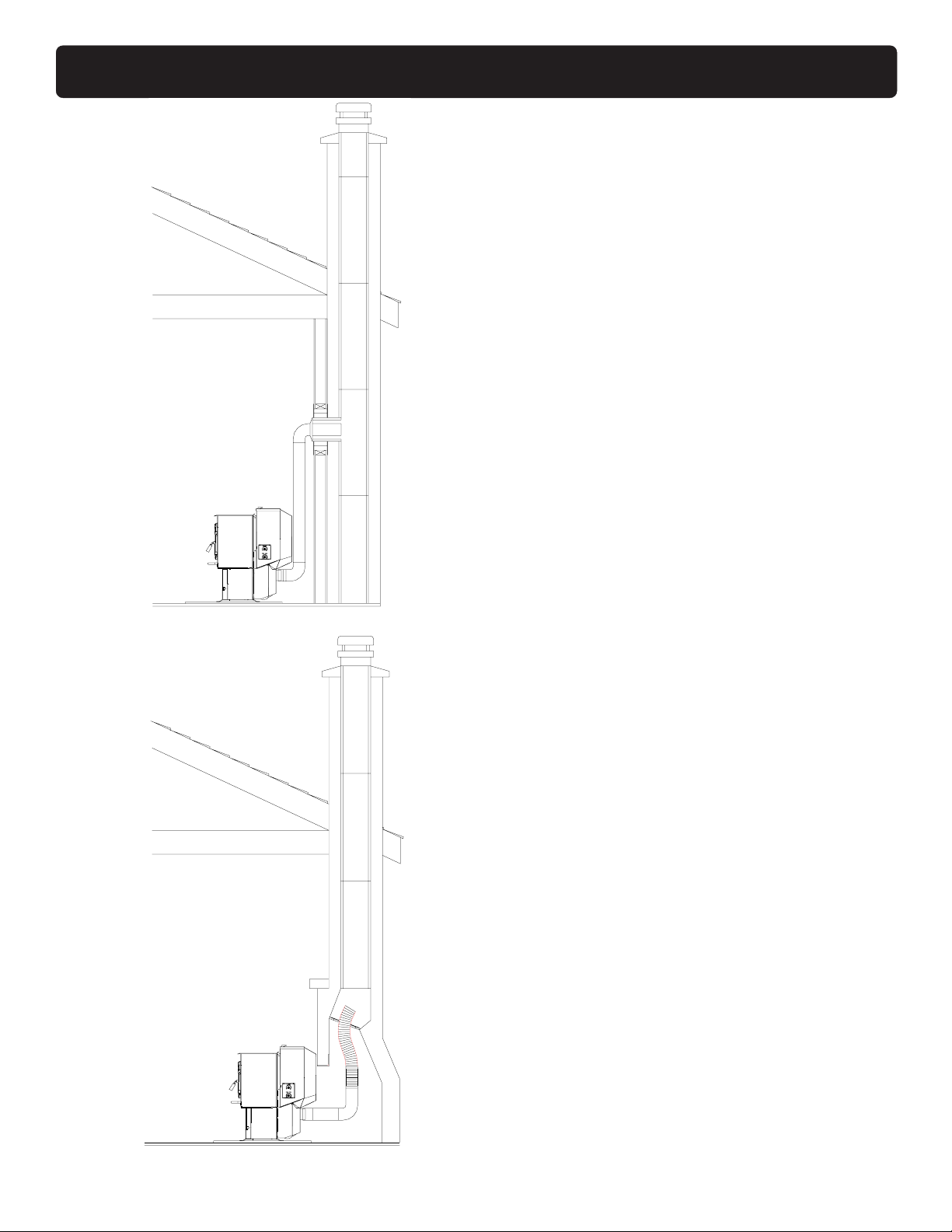

#1!Preferred!method

operation!and!allows!the!stove!to!be!installed!closest!to

the!wall.!Two!inches!from!the!wall!is!safe;!however,!four

inches!allows!better!access!to!remove!the!rear!panel.

The!vertical!portion!of!the!vent!should!be!three!to!five

feet!high.!This!vertical!section!will!provide!natural!draft

in!the!event!of!a!power!failure.

This!method!provides!excellent!venting!for!normal

Fig.!8

3!ft.

to!combustibles

#2!Preferred!method

This!method!also!provides!excellent!venting!for

normal!operation!but!requires!the!stove!to!be!installed

farther!from!the!wall.!The!vertical!portion!of!the!vent

should!be!three!to!five!feet!high!and!at!least!three!inches

from!a!combustible!wall.!This!vertical!section!will!provide!natural!draft!in!the!event!of!a!power!failure.

If!the!stove!is!installed!below!grade!be!sure!the

vent!termination!should!be!at!least!1!foot!above!grade.

CAUTION

8 P61A!!Pellet!Stove

Fig.!9

3!ft.

to!combustibles

Keep!combustible! materials! (such

as! grass,! leaves,! etc.)! at! least! 3! feet

away!from! the!flue!outlet!on!the! outside

of!the!building.

Page 9

Venting

#4!Installing!into!an!existing

chimney!(!US!only!)

operation.!!This!method!also!provides!natural!draft!in

the!event!of!a!power!failure.!If!the!chimney!condition!is

questionable!you!may!want!to!install!a!liner!as!in!method

#7.

This!method!provides!excellent!venting!for!normal

Fig.!10

#5!Installing!into!an!existing

fireplace!chimney!(!US!only!)

This!method!provides!excellent!venting!for!normal

operation.!!This!method!also!provides!natural!draft!in

the!event!of!a!power!failure.

The!damper!area!must!be!sealed!with!a!steel!plate

or!fiberglass.!A!cap!should!be!installed!on!the!chimney

to!keep!out!rain.!If!the!chimney!condition!is!questionable!you!may!want!to!install!a!liner!!all!the!way!to!the!top

as!in!method!#6.

Fig.!11

P61A!Pellet!Stove

9

Page 10

Venting

#6!Installing!into!an!existing

fireplace!chimney!(!US!and

Canada!)

operation.!!This!method!also!provides!natural!draft!in

the!event!of!a!power!failure.

that!the!vent!pipe!extend!all!the!way!to!the!top!of!the

chimney .

chimney!to!keep!out!rain.!Be!sure!to!use!approved!!pellet!vent!pipe!fittings.!Seal!pipe!joints!with!silicone!in!addition!to!the!sealing!system!used!by!the!manufacturer.

Pipe!size!should!be!increased!to!4"!using!this!method.

This!method!provides!excellent!venting!for!normal

In!Canada!and!some!places!in!the!US!it!is!required

In!this!method!a!cap!should!also!be!installed!on!the

Fig.!12

#7!Installing!into!an!existing

chimney!(!US!and!Canada!)

This!method!provides!excellent!venting!for!normal

operation.!!This!method!also!provides!natural!draft!in

the!event!of!a!power!failure.

In!Canada!and!some!places!in!the!US!it!is!required

that!the!vent!pipe!extend!all!the!way!to!the!top!of!the

chimney .!The!pipe!or!liner!inside!the!chimney!should!be

4"diameter.

In!this!method!a!cap!should!also!be!installed!on!the

chimney!to!keep!out!rain.!One!disadvantage!of!this

method!is!that!it!is!harder!to!clean!!the!vent!pipe,!therefore,!there!is!a!tendancy!not!to!do!it!as!often!as!needed.

10 P61A!!Pellet!Stove

Fig.!13

Page 11

Venting

12"!min.

3"!min.

3"!min.

PL! vent! manufacturer's

firestop!spacer!and!support

Storm!collar

Flashing

3"!min.

No! insulation! or

other! combustible

materials! are

allowed! within! 3"

of!the!PL!vent!pipe.

Minimum! flue! vent

configuration

It!is!recommended!that

outside!air!be!installed!with!this

venting!configuration.

(See! Page! 9! for

corner

installation

clearances)

Fig.!14

#8!Installing! through! the!ceiling!vent

Through! the! ceiling! vent,! follow! PLvent

manufacturers!recommendations!when!using!wall!and

ceiling!pass!through.

18"

Fig.!15

Min.!above! ground! level

Fig.!16

P61A!Pellet!Stove

11

Page 12

P61A-2 AUTOMATIC IGNITION/OPERATION

The!P61A!pellet!stove!is!more!than!just!automatic!ignition,!it!is!also!automatic!temperature!control.

The!automatic!system!will!allow!the!fire!size!to!be!adjusted!to!match!the!heating!needs!and!even!put

the!fire!out!if!necessary.!If!heat!is!needed!after!the!fire!is!out,!the!P61A !will!automatically!re-ignite

o

Room!Temperature!Mode:! This! setting! will!produce!a! room

temperature! of! 70! degrees! with! the! distribution! blower! at

medium!speed.

o

Stove! Temperature! Mode

This!setting!will!produce!medium!heat!with!the

distribution! blower! on! "low".

and!adjust!the!fire!size!to!match!the!heating!need.!The!totally!automatic!room!sensor!mode!is

recommended!because!of!its!efficiency.

The!unit!can!be!switched!between!"AUTO"!and!"MANUAL"!at!any!time!during!operation.

Ignitor!switch! to!"AUTO"

Room! Temperature! Mode

In!"Room!Temp!Mode"!heat!output!is!controlled!automatically!by!the!Room!Sensing!Probe.!When!the!Room!Sensing!Probe!calls!for!heat,!the!stove!will!increase!output.!When

the!Room!Sensing!Probe!is!getting!close!to!the!set!temperature,!the!stove!will!begin!to!level!off!output!and!keep!the!fire

burning!at!just!the!right!temperature!to!maintain!that!setting.

High!output!is!determined!by!the!feed!rate!setting.

This!setting,!generally!on!#4,!can!be!increased!if!higher!burn

rates!are!necessary.!The!unit's!maximum!burn!rate!should!not

create!less!then!1"!of!ash!on!the!burn!pot!front!edge.!See

Fig.2.!Overfeeding!is!not!a!safety!concern,!but!fuel!may!be

wasted!if!unburned!pellets!fall!into!the!ash!pan.

In!"Room!T emp!Mode"!a!constant!fuel!consumption!rate

is!sacrificed!for!exact!room!temperature.!Therefore,!as!it!gets

colder!!more!pellets!will!be!burned!automatically .

The!distribution!blower!speed!will!vary!according!to!the

position!of!the!mode!selector!pointer,!and!fire!size.

Ignitor!switch! to!"AUTO"

Stove!Temperature! Mode

This!allows!for!automatic!ignition!upon!start-up!only.!The

unit!can!then!be!set!at!any!desired!setting.!The!heat!output

and!fuel!consumption!will!remain !constant!regardless!of!room

temperature.!The!unit's!maximum!feed!rate!should!not!create

less!than!1"!of!ash!on!the!burn!pot!front!adge.!See!Fig!2.

The!unit's!low!burn!or!maintenance!setting!is!as!low!as!it

will!go.!It!will!not!go!out!unless!it!runs!out!of!fuel!or!is!turned

off.

This!setting! will! produce! continuous!maximum!heat! output

with!the! distribution!blower!at! full!speed.

12 P61A!!Pellet!Stove

Shut-Down! Procedure

To!kill!the!fire!or!stop!burning!the!stove,!turn!the!Mode

Selector!to!"OFF".!This!will!cause!the!fire!to!diminish!and

burn!out.!When!the!fire!burns!out!and!the!stove!cools!down

everything!will!stop.

If!you!pull!the!plug!to!shut!down!the!stove,!all!motors

will!stop.!This!may!cause!incomplete!combustion!and!smoke

in!the!firebox.!If!the!load!door!is!opened!the!smoke!may!escape.

The!best!way!to!shut!down!the!stove!is!simply!let!it!run

out!of!pellets,!then!the!stove!will!shut!down!automatically.

Page 13

Fig.!17

P61A-2!!AUTOMATIC!!START!!UP

Starting!First!Fire

Ignitor!Switch!to"AUTO"(up!position)

Make!sure!the!unit!is!plugged!into!a!120

VAC,!60!HZ!electrical!source.!The!power!light

should!be!the!only!light!lit.

See!Note!7.

1"

When!power!is!given!to!the!stove,!the!control!board

will!blink!a!few!times!to!indicate!current!version!of

1.! Turn! Mode! Selector!to! "OFF".

2.!Fill!hopper!with!pellets.

3.!Clean!burn!pot!with!scraper,!if!necessary.

4.! If! starting! after! an! empty! hopper,! turn

NOTICE:

control!board.

1

5

Fig.!18

1.!Fines!are!small!pieces!of!broken!pellets!(sawdust).!Fines!do!not

flow!easily!and!often!build!up!on!the!hopper!funnel!bottom!angles.

These!fines!can!be!pushed!into!the!feeder!opening!and!then!fill!the

hopper!with!pellets.!As!the!system!works,! they!will!be!burned.

2.!The!"TEST"!cycle!will!operate!the!feeder!motor!for!exactly!one

minute.!Turning!to!"TEST"!again!and!again!may!purge!too!much

fuel!into!the! burn!pot! causing!excessive!smoke!on!start-up.

3.!The!firebox!low!pressure!switch!will!not!allow!the!auger!motor

or!the! igniter!element!to! operate!if! the! view!door! or!the!ash! pan

door!are!open.

4.!Adjust!Feed!Rate.!If!this!is!your!first!fire!or!you!are!trying!different

pellets,!set!the!feed!adjuster!to!#4,!Fig.!17.!This!is!a!conservative

number!and!will!probably!need!to!be!increased.!After!you!know!a

feed! rate! setting! that!works! well,! use! that!setting.! Remember,! if

your!feed!rate!is!too!high!you!may!waste!fuel.

5.! This! is! usually! a! weekly! maintence! procedure.! Cleaning! the

burn!pot! with! the!scraper! with!a!small!amount!of! new!fuel! in!the

bottom!is!not!a!problem.!First,!scrape!the!ashes!on!the!front!of!the

burn!pot !into!the!ash!pan.!Then!scrape!the!holed!surface!downward

into!the!burn!pot.!When!the!stove!is!ignited!these!scrapings!will!be

pushed!out!by! the!feeder.

6.! The! ash! pan! can! hold!the! ashes! from! approximately!1! ton! of

premium!fuel.!This!means!the!ashes!will!only!need!to!be!emptied!a

few!times!a!year.

7.! Setting! the! feed! adjuster! #! for! maximum! burn:! With! the! unit

burning!in!"AUTO",!turn!to!"Stove!Mode"!and!put!the!fan!on!"H".

Set!the! Temperature! Dial!to! #7.!Allow!the! unit!to!burn! for!about

30!minutes!and!check!ash!on!front!of!burn!pot.!Fig.!18.!If!the!ash

line!is!larger!than!1",! turn!the!feed!adjuster!from!#3! to!#4.!Allow

another!30!minutes!of!burn!time!and!check!again.!If!,!at!#6!setting,

a!1"!or!less!ash!bed!is!not!obtainable,!it!is!not!a!problem.!The!1"

ash!bed!is!only!a!maximum!burn!rate!and!at!most!normal!settings

the!ash!bed!will! be!larger.

Feed!Adjuster!to!"TEST"!(for!one!60!second

cycle).

2!!

This!will!purge!pellets!into!the!auger

tube! and! also! allow! you! to! check!the! motors

for!operation.!NOTE:! The! auger!motor!will

not!operate! with!the! view! door!or! ash! pan

door! open.

5.!Turn!Feed!Adjuster! to! #4.

3

4

6.!Flip!the!Ignitor!Switch!up!into!the!"AUTO"

position.

7.!Turn!the!T emperature!Dial!to!desired!room

temperature.

8.!Turn!Mode!Selector!to!Room!Temperature

or!Stove!Temperature.

9.!Fill!hopper!with!pellets! and!remove!ashes

as!required.

6

Warning

"NEVER!USE!GASOLINE,!GASOLINE-TYPE!LANTERN

FUEL,!KEROSENE,! CHARCOAL!LIGHTER!FLUID,! OR

SIMILAR!LIQUIDS!TO!START!OR!"FRESHEN!UP !"!A!FIRE

IN!THIS!HEATER.!KEEP!ALL!SUCH!LIQUIDS!WELL!AWAY

FROM!THE!HEATER!WHILE!IN!USE".

P61A!Pellet!Stove

13

Page 14

P61A-2!!MANUAL!!IGNITION/OPERATION

The!P61A!Pellet!Stove!is!capable!of!manual!operation.!This!also!allows!the!operator!to

manually!control!operation!during!an!emergency!(i.e.!ignitor!failure,!when!using!a!502H!battery

backup,!or!when!using!certain!generators.)

o

Room!Temperature!Mode:! This! setting! will!produce!a! room

temperature! of! 70! degrees! with! the! distribution! blower! at

medium!speed.

o

Manual!Stove!Temperature!Mode

The!unit!can!be!switched!between!"AUTO"!and!"MANUAL"!at!any!time!during!operation.

NOTE:!When!starting!the!unit!in!the!"AUTO"

mode!and!switching!to!"MANUAL",!the!fire!must!be

large!enough!to!start!!the!distribution!blower .!The!starting!of!the!blower!is!a!signal!that!the!start!cycle!is!completed!and!the!fire!will!not!go!out.

Ignitor!Switch!to!"MANUAL"

Room! Temperature! Mode

The!fire!will!have!to!be!lit!with!starting!gel!and!a!match,

or!started!automatically,!see!"Automatic!Operation".!Turn

to!"Manual"!position!when!the!fire!is!established.

The!difference!between!"AUTO"!Room!Temperature

Mode!and!"Manual"!Room!Temperature!Mode!is!that!the

fire!will!not!go!out!as!the!room!temperature!goes!above!the

control!board!setting. !The!unit!can!only!go!to!low!burn!and

will!remain!there!until !it!runs!out!of!fuel!or!until!more!heat!is

needed!and!the!feed!rate!increases.!Feed!rate!adjustments

and!dial!settings !are!the!same!as!"AUTO"!settings.

O

O

O

O

This!setting!will!produce!a!large!viewing!fire!without

a!distribution!blower!operating.

14 P61A!!Pellet!Stove

Ignitor!Switch!to!"MANUAL"

Stove! Temperature! Mode

The!advantage!of!this!mode!is!to!allow!the!operator!to

have!a!large!viewing!fire!without!blowing!extra!heat!into!the

room.

During!operation,!with!the!temperature!dial!set!at!#5

or!less,!the!distribution!fan!will!not!operate.!A!#5!on!the

temperature!dial!and!a!#5!on!the!feed!adjuster!is!approximately!80%!output.!It!is!not!necessary!to!operate!the!distribution!blower!below!this!point.!Therefore,!there!can!be!a

higher!feed!rate!(!a!larger!viewing!fire)!without!an!excess!of

hot!air!blowing!into!the!room.

An!example!of!when!to!use!the!Manual!Stove!Temperature!Mode!is!if!you!want!to!watch!a!large!fire!and!the

room!is!aleady!!up!to!temperature.!The!S tove!Temperature

Mode!allows!you!to!have!a!larger!fire!and!a!lower!sound

level,!without!the!distribution!blower.

NOTE:!During!the!use!of!this!mode,!if!you!keep

increasing!the!temperature!dial!setting!to!increase!the

fire!size,!the!distribution!blower!will!automatically!come

on!when!the!ESP!Temperature!reaches!350o!F, !or!81%

output.

Page 15

P61A-2!!MANUAL!!START!!UP

Fig.!20

Fig.!19

See!Note!7.

1"

Fig.!21

1.!Fines!are!small!pieces!of!broken!pellets!(sawdust).!Fines!do!not

flow!easily!and!often!build!up!on!the!hopper!funnel!bottom!angles.

These!fines!can!be!pushed!into!the!feeder!opening!and!then!fill!the

hopper!with!pellets.!As!the!system!works,! they!will!be!burned.

2.!The!"TEST"!cycle!will!operate!the!feeder!motor!for!exactly!one

minute.!Turning!to!"TEST"!again!and!again!may!purge!too!much

fuel!into!the! burn!pot! causing!excessive!smoke!on!start-up.

3.!The!firebox!low!pressure!switch!will!not!allow!the!auger!motor

or!the! igniter!element!to! operate!if! the! view!door! or!the!ash! pan

door!are!open.

4.!Adjust!Feed!Rate.!If!this!is!your!first!fire!or!you!are!trying!different

pellets,!set!the!feed!adjuster!to!#4,!Fig.!19.!This!is!a!conservative

number!and!will!probably!need!to!be!increased.!After!you!know!a

feed! rate! setting! that!works! well,! use! that!setting.! Remember,! if

your!feed!rate!is!too!high!you!may!waste!fuel.

5.! This! is! usually! a! weekly! maintence! procedure.! Cleaning! the

burn!pot! with! the!scraper! with!a!small!amount!of! new!fuel! in!the

bottom!is!not!a!problem.!First,!scrape!the!ashes!on!the!front!of!the

burn!pot !into!the!ash!pan.!Then!scrape!the!holed!surface!downward

into!the!burn!pot.!When!the!stove!is!ignited!these!scrapings!will!be

pushed!out!by! the!feeder.

6.! The! ash! pan! can! hold!the! ashes! from! approximately!1! ton! of

premium!fuel.!This!means!the!ashes!will!only!need!to!be!emptied!a

few!times!a!year.

7.! Setting! the! feed! adjuster! #! for! maximum! burn:! With! the! unit

burning!in!"AUTO",!turn!to!"Stove!Mode"!and!put!the!fan!on!"H".

Set!the! Temperature! Dial!to! #7.!Allow!the! unit!to!burn! for!about

30!minutes!and!check!ash!on!front!of!burn!pot.!Fig.!21.!If!the!ash

line!is!larger!than!1",! turn!the!feed!adjuster!from!#3! to!#4.!Allow

another!30!minutes!of!burn!time!and!check!again.!If!,!at!#6!setting,

a!1"!or!less!ash!bed!is!not!obtainable,!it!is!not!a!problem.!The!1"

ash!bed!is!only!a!maximum!burn!rate!and!at!most!normal!settings

the!ash!bed!will! be!larger.

Starting!First!Fire

Ignitor!Switch!to"MANUAL"

(down!position)

Make!sure! the! unit!is!plugged! into! a

120! VAC,! 60! HZ! electrical! source.! The

power!light!should!be!the!only!light!lit.

1.!Turn! FEED!ADJUSTER! to! desired! feed

rate.!No.!4!is! good! for!most!pellets.

4

2.!Turn!the! MODE! SELECTOR! to! ìOFFî

and! then! to! the! desired! mode.!!This! will

reset! control! and! start! the! combustion! motor.

3.!Turn! the! TEMPERATURE!DIAL! to!the

desired! setting.

4.!Clean!burn!pot!with!scraper!if!necessary.

5.!Fill!burn!pot!with!pellets,!only!level!with

front!edge.!(Do!Not!Over!Fill).

6.!Add!starting!gel!on!top!of!the!pellets.!Stir

gel!into!pellets!for!fast!lighting.

7.!Light!starting!gel!with!a!match,!and!close

the!door.!!Operation!will!begin!when!the!fire

reaches!the!proper!temperature.

3

8.!Fill!hopper!with!pellets!and!remove!ashes

as! required.

1,! 6

Warning

"NEVER!USE!GASOLINE,!GASOLINE-TYPE!LANTERN

FUEL,!KEROSENE,! CHARCOAL!LIGHTER!FLUID,! OR

SIMILAR!LIQUIDS!TO!START!OR!"FRESHEN!UP!"!A!FIRE

IN!THIS!HEATER.!KEEP !ALL!SUCH!LIQUIDS!WELL!AWAY

FROM!THE!HEATER!WHILE!IN!USE".

5

P61A!Pellet!Stove

15

Page 16

P61A-2!!AUTOMATIC!IGNITION!!ESP!!CONTROL

Power!Light

Indicates!power! to! the

control.

Status!Light

Will!be!lit!in!either!stove!or

room!temp!mode!when

pointer!is!not! within!off

position!band!except! after

normal!shut! down.! Blinks

to!indicate! errors! listed

below.

Indicates!power! to

distribution! blower.

!Indicates!power! to

combustion! blower

Indicates!power! to! the

feed!motor.

Indicates!ignitor! is!on.

Temp! dial

Allows!you!to!adjust!the!room!temperature!in!Room!Temp

Mode!using!the!outer! scale!marked! in!degrees! Fahrenheit.

It!also!allows!you!to!adjust! the!stove!temperature! while!in

Stove!Temp!Mode!using!the!inner!scale!marked!from!1!to!7.

Status!light!error!messages:

Feed!adjuster

Sets!the!maximum!feed

rate

Test

Runs!all!motors!at!full

speed! for! one! minute

to! check! operation.

After!two!minutes!the

stove! will! go! to

minimum!burn!and!the

blowers!will!alternate

from!high!to!low!every

minute!to!remind! you

O

O

Dealer!Diagnostic!Port

For! dealer! maintenance

only.!Requires!special!DDM

monitor!supplied! to! Harman

Dealers!exclusively.

that! you! are! still! in

"Test! Mode".

Ignitor!switch

Set! to! appropriate

Start-Up!mode.

Distribution!Blower!speed

adjustment!range.

L!=!low

H!=!high

Variable! speed! anywhere

between! L! and! H;

although! as! the! stove

temp.!goes!up!,!so!does!the

L!and!H!scale.

Mode!Selector

Allows!you!to!choose!between

Room!Temp!Mode,!Stove!Temp

Mode,!or!OFF.!Also!allows!you

to!vary!the!distribution!blower

speed! by! turning! the! knob! to

the! high! or! low! side! of! each

mode.

1!Blink:!Indicates!control!board!self!diagnostic!failure.

This!requires!a!manual!reset*.

2!Blinks:!!Indicates!that!the!jumper!(J2)!on!the!rear!of

the!control!board!is!not!connected.!Without!this!jumper

the!unit!will!only!burn !at!minimum!rate.

3!Blinks:!Indicates!ESP!(Exhaust!Sensing!Probe)!fail-

ure.!This!requires!a!manual!reset*.

4!Blinks:!Can!occur!only!in!Room!Temp!Mode!and

indicates!Room!Sensing!Probe!failed!or!not!installed.!If

a!Room!Sensing!Probe!is!then!installed,!the!status!light

will!automatically!reset.

5!Blinks!(In!Igniter!Auto.!Mode!Only):!!Indicates

that!the!unit!has!failed!to!light!within!the!36!minute!start

cycle.!To!reset!-!Turn!Mode!Selector!to!"OFF",!then

16 P61A!!Pellet!Stove

turn!to!either!mode!again.)

6!Blinks!:!Indicates!that!the!control!has!calculated!poor

or!incomplete!combustion!occurring!for!more!than!50

minutes.

A!six!blink!status!may!be!set!if!the!stove!is!allowed!to

run!out!of!pellets.!To!reset,!turn!mode!selector!to!"OFF"

then!back!on!to!the!desired!mode.!If!the!unit!was!not

out!of!pellets,!see!T roubleshooting!section!for!more!de-

tails.

*!Manual!reset-!disconnect!power!cord!for!a!few!sec-

onds!and!reconnect.!If!error!still!occurs!call!your!Dealer.

NOTICE:!When!power!is!given!to!the!stove,!the!control!board!will!blink!a!few!times!to!indicate!current!version!of!control!board.!This!should!not!be!confused!with

error! messages.

Page 17

P61A-2!!Low!!Draft!!Voltage!!Adjustment

Combustion

Motor! Speed

Control

Low! draft! only

set! point.

The!small!straight

screwdriver!slot!is

plastic;!therefore,

the! unit! can! be

adjusted!while! in

operation.

Draft!Meter!bolt

hole!location

On! a! P61A

the!draft! hole!is!under

the! left! rear! corner! of

the! firebox.

Fig.22

Fig.1

Low!!Draft!!Voltage!! Adjustment

These!units!are!pre-tested!at!the!factory!with!exactly

120!Volts!A.C.,!60!Hz.!They!are!checked!and!adjusted!!for

firebox!tightness,!gasket!leakage,!motor!operation!and!ignitor

operation.!!The!P61A!is!then!factory!set!at! a!mid-point

adjustment!and!in!most!cases!will!not!need!any!adjustments.

NOTE:!The!factory!low!draft!setting!may!not!be!correct

for!the!units!permanent!installation!conditions.

The!control!board!on!the!P61A!is!equipped!with!a

low!draft!adjustment!port.!!Located!on!the!control!face!just

to!the!right!of!the!igniter!light.!This!voltage!adjustment!is

provided!to!allow!the!unit!to!be!adjusted!for!the!household

voltage!where!the!unit!is!going!to!be!in!permaneant!operation.

NOTE:!The!line!voltage!varies!from!area!to!area!and!often

home!to!home.

The!low!draft!voltage!should!be!adjusted!to!achieve

the!most!efficient!burn!on!low!burn!or!"maintenance".!This

voltage!adjustment!allows!the!installer!to!change!the!low

voltage!set!point!approximately!10!volts.!!This!adjustment

should!be!done!by!the!installer!during!set!up!because!a!draft

meter!reading!is!required!to!insure!proper!set!up.

If!the!unit!is!not!!adjusted!properly,!it!does!not!cause

a!safety!concern.!If!the!unit!is!adjusted!too!high,!only!effiency

is!lost.!If!the!unit!is!adjusted!too!low,!the!low!draft!pressure

switch!will!not!allow!the!feeder!motor!or!the!igniter!to!operate.

Fig.!23

A! simple! draft! test! should! be! performed! after

completing!the!flue!pipe!installation.!To!record!the!results!for

future!reference:

1.!!Plug!unit!into!a!120VAC,!60!HZ!outlet.

2.!!Close!the!hopper!lid,!front!view!door,!and!the!ash!pan.

Neither!pellets!or!a!fire!are!required!for!this!test.

3.!!With!the!mode!selector!in!the!"OFF"!position,!turn!the

feed!adjuster!to!"TEST".

4.!!Record!the!high!draft_____in!W.C.!(Normal!is!-.50!to!.60)!The!control!will!be!on!the!High!Draft!for!a!total!of!2

minutes.

5.!!After!2!minutes!is!up,!the!combustion!motor!will!go!down

to!low!draft!and!the!distribution!blower!will!go!on!high.!Allow

approximately!15!seconds!to!pass!for!the!combustion!motor

to!slow!before!checking!the!low!draft.

6.!!If!the!low!draft!is!between!-.35!and!-.45,!record!the

reading!_____!in!W.C.!!If!the!reading!is!higher ,!slowly!turn

the!set!screw!counter-clockwise!until!the!draft!lowers.!If!the

reading!is!lower,!very!slowly!turn!the!set!screw!clockwise

until!the!draft!increases.

NOTE:!The!test!mode!alternates!from!high!to!low!draft

every! 60! seconds.! If! more! time! is! needed! for!draft

adjustment,!wait!until!the!next!low!draft!cycle.

NOTE:!In!some!cases,!the!draft!may!not!go!as!low!as

-.35!to!-.45!even!with!the!set!screw!completely!counterclockwise.

P61A!Pellet!Stove

17

Page 18

Room!Sensor!and!Rear!Shield!Installation

Room! Sensor! Installation

Fig.!24

The!room!sensor!is!a!small!temperature!sensor! on! the! end! of! a! 60"! gray! wire.! This! sensor! is

installed!much!like!a!standard!wall!thermostat.!Because!it!is!so!small,!it!can!be!hidden!along!the!trim

of!a! doorway! or! even!up!the!leg! of! a! coffee!table.

There!is! a!remote! room!sensor!port! on!the!rear! of

the!unit!for!easy!external!connection.!Use!standard

18-2!thermostat! wire!to!extend! the!distance!to! the

desired!location! (100'!!maximum).! The! room! sensor!should!be!installed!in!the!location!where!you!want

to!control!the!temperature.

NOTE:! Distances! of! more! than! 25! feet! from

the!unit!or!in!another!room!are!not!recommended.

The!room!sensor!is!essential!for!the!P61A's!excellent!efficiency.

NOTE:! It! is! recommended! that! the! room

sensor!be! installed,! even! if! only! installed!on! the

rear!of!the!unit!as!a!return!air!sensor.

Rear! Shields

5/16"!Hex

Head

Screws!(2

on! each

side)

Fig.!25

The!rear!isolated!shields!are!split!in!the!middle!for

easy!removal.!Each!shield!has!two!5/16"!hex!head

screws! that! only! need! to! be! loosened! (NOT

REMOVED)!to! allow! the!shield!to! slide! away!from

the!unit.!NOTE:! It! is! not! recommended! that! the

unit!be!operated!with!the!shields!removed,!due

to!the!hot!and!moving!parts!which!they!protect.

5/16"!Hex! Head

Screws!(2!on

each! side)

18 P61A!!Pellet!Stove

Page 19

Combustion

Blower!Cover

Fig!26

Maintenance

Blower!Cover

Latch

Removing!Ashes:

When!approximatly!1!ton!of!pellets!has!been

burned!it!will!be!necessary!to!empty!the!ash!pan.

Ashes!should!be!placed!in!a!metal!container

with!a!tight!fitting!lid.!The!closed!container!of

ashes! should! be! placed! on! a! noncombustible

floor!or!on!the!ground,!!well!away!from!all!combustible!materials,!pending!final!disposal.!If!ashes

are!disposed!of!by!burial!in!soil!or!otherwise!locally!dispersed,!they!should!be!retained!in!the

closed!container!until!all!cinders!have!thoroughly

cooled.

It!is!recommended!that!the!stove!is!cold!and

shut!down!when!removing!ash!pan.

1.!Pull!on!latch!handle!and!remove!ash!pan!as

shown!at!left.!Use!ash!pan!handle!to!carry!and

dispose!of!ashes.

2.!Slide!the!ash!pan!back!into!the!stove!and!latch

by!pushing!in!on!latch!handle.

Blower! Wheel

Heat!Exchanger!Fins

Scraper

Flue!Outlet

Blower!Cover

Latch

Cleaning:

The!stove!will!need!to!be!cleaned!for!approximately!every!2!to!5!tons!of!pellets!burned.!The!amount

of!pellets!burned!before!cleaning!will!vary!depending

on!the!brand!of!pellets.

1.!Shut!down!stove!and!disconnect!power!cord!to

insure!that!all!motors!are!stopped.

2.!Remove!ash!pan!as!described!earlier.

3.!Remove!combustion!blower!cover!by!turning!the

blower!cover!latch!vertical!as!shown!in!Fig.26

and!sliding!the!cover!out!of!the!slot!on!the

left.This!will!expose!the!combustion!blower

wheel!and!flue!outlet,!Fig.27.

4.!Clean!the!blower!wheel!with!a!brush!and!a

vacuum!cleaner.

5.!Use!a!brush!to!clean!the!flue,!being!careful!not!to

damage!the!ESP!probe.!The!flue!goes!straight

through!into!the!vent!pipe!(Fig.27)!therefore, !the

vent!pipe!can!also!be!cleaned!to!some!extent

through!the!flue!outlet.

Fig!27

6.!Reinstall!blower!cover!and!relatch.

P61A!Pellet!Stove

19

Page 20

Maintenance

Fig.!28 Fig.!29

Latch!"closed!"with

blower!cover!in!place.

Burn!pot!clean-out!is

closed.

ESP!probe

Clean-out! plate

Latch!"open!"with!blower

cover!partly!removed.

Burn!pot!clean-out!is

open.

7.!Open!burn!pot!clean-out!!as!shown!to!the!left,

clean!fly!ash!from!burn!pot!and!replace!cover.

8.!Clean!heat!exchanger!with!scraper!as!shown!in!fig

25.

9.!Brush!or!scrape!the!inside!of!the!stove!to!remove

fly!ash.

10.!Scrape!burnpot!with!flat!end!of!scraper!provided

with!the!stove.!Fig.!33.

11.Slide!ash!pan!into!stove!and!latch!into!place.

Brush!not

supplied.!Can!be

found!in!hardware

stores.

Fig.!32

Fig.!30

Exposed!!blower!wheel

and!flue!opening,

NOTE:!ESP!probe!is

visible.

Fig.!31

Blower!cover

removed.

ESP!Probe

Be!careful!not!to

damage!ESP!probe

when!cleaning! with

brush.

Soot!and!Fly!Ash

The!products!of!combustion!will!contain!small

particles!of!fly!ash.!!The!fly!ash!will!collect!in

the!exhaust!venting!system!and!restrict!the!flow

of!the!flue!gases.!!Incomplete!combustion,

such!as!occurs!during!startup,!shutdown,!or

incorrect!operation!of!the!room!heater,!will

lead!to!some!soot!formation!which!will

collect!in!the!exhaust!venting!system.!!The

exhaust!venting!system!should!be!inspected!at!least!once!every!year!to!determine!if!cleaning!is!necessary.

Fig.!33

20 P61A!!Pellet!Stove

Page 21

P61A-2!!Maintenance!-!Burn!Pot

Burn! Pot! Cleaning!and! Maintenance

1.!!Scrape!the!top!holed!surface!and!sides!of!the!burn

pot.(Fig!!34)!It!is!not!necessary!to!completely!remove

all!material!from!the!burn!pot.!The!excess!will!be

pushed!out!during!the!next!use.

2.!!Loosen!the!(2)!wing!thumb!screws!on!the!lower

front!angle!of!the!burn!pot.!(Fig.!34)

3.!!Lift!off!the!clean-out!cover!(Fig.35)!to!open!the

bottom!clean-out!chamber.!(Fig.36)

DANGER

Disconnect!the!power!to!the!unit!before

removing!cover.

Fig.!34

Fig.!35

Burn!pot!ignitor

4.!!Clean!ash!buildup!from!inside!the!chamber!while

cover!is!off.!Use!the!scraper!to!tap!on!the!top!front

edge!of!the!burn!pot.!This!will!help!knock!pieces!of

ash,!loosened!by!the!scraping!process,!down!through

the!holes.!It!also!helps!knock!scale!off!of!the!ignitor

element.

Figure! 36

The!ignitor!is!made!to!be!removable!for!service

by!insulated!male/female!wire!connectors.!These

connections!between!the!hot!leads!(the!wires!inside

the!burn!pot)!and!the!cold!leads!(the!wires!from!the

control!board)!are!always!pulled!to!the!inside!rear!of

the!feeder!body.!(Not!coiled!inside!the!burn!pot.)

It!is!very!important!that!these!connections!are

to!the!inside!rear!of!the!feeder!body.!Also,!the!extra

wire!of!the!ignitor!wire!service!loop!must!be!pulled!out

through!the!rear!of!the!feeder!and!tied!up!so!that!it!will

not!be!damaged!by!any!moving!parts.

DANGER

Disconnect!the!power!to!the!unit!before

removing!cover.

Fig.!36

Viewed!from!below!throught!the!ash!pan!opening.

Warning

Use!caution! when!cleaning!burn! pot!clean-out

chamber.!Do!not!damage!the!high!temperature

igniter! wires.

Ignitor!hot!lead!wires

(high!temperature)

Note:!The!hot!lead/cold!lead

connection!must!always!be!pulled

to!the!rear!of!the!feeder!body

before!operation.

P61A!Pellet!Stove

21

Page 22

P61A-2! Trouble-Shooting

!!FEEDER!DOES!NOT!FEED

1.!No!pellets!in!hopper.

2.!Firebox!draft!may!be!too!low!for!low!draft!pressure

switch!in!feeder!circuit!to!operate.!Check!for!closed

doors,!loose!or!missing!gasket!on!doors!or!hopper!lid,

faulty!pressure!switch.

3.!Feed!motor!will!not!run!until!ESP

senses!165!deg.!F.!Maybe!you!did!not!put

enough!pellets!in!the!burn!pot!before!lighting!the!fire.

4.!Something!is!restricting!flow!in!the!hopper!or!causing!the!slide!plate!to!stick.

5.!Feed!motor!has!failed.

PARTIALLY!BURNED!PELLETS

1.!Feed!rate!too!high.

2.!Draft!too!low.!(Check!burn!pot!clean!!out!slide!and

door!gasket).

3.!Burn!pot!or!heat!exchanger!tubes!may!need!!to!be

cleaned.

4.!Combination!of!all!the!above.

5.!#6!status!blink:!A!6!blink!control!board!status!indication!is!caused!by!poor!or!incomplete!combustion.

The!Automatic!Ignition!circuit!board!has!the!ability!to

track!the!combustion!through!feed!settings!and!ESP

temperatures.!When!the!control!board!has!calculated

poor!or!incomplete!combustion!it!will!shut!down!the

unit!as!a!safety!feature.!(Poor!or!incomplete!combustion!is!a!contributer!of!creasote!which!may!cause!a

chimney!fire)

A!6!blink!status!may!be!caused!by!several!things:

1.!Blocked!or!partially!blocked!flue.

2.!Blocked!or!partially!blocked!inlet!air.

a.!backdraft!damper!on!the!inlet!pipe!may!be!stuck

closed.

b.!if!outside!air!is!installed!the!inlet!cover!may!be

blocked.

3.!The!air!chamber!under!the!burnpot!may!be!filled

with!fines!and!small!bits!of!ash.

4.!The!holes!in!the!burnpot!may!be!getting!filled!with

ash!or!carbon!buildup.

5.!Combustion!blower!fan!blades!may!need!cleaned.

6.!No!fuel!in!hopper.

SMOKE!SMELL

Seal!the!vent!pipe!joints!and!connection!to!stove!with

silicone.

FIRE!HAS!GONE!OUT

1.!No!pellets!in!hopper.

2.!Draft!setting!is!too!low.

3.!Something!is!restricting!fuel!flow.

4.!Feed!motor!or!draft!motor!has!failed.

5.!Power!failure!or!blown!fuse.

SMOKE!IS!VISIBLE!COMING!OUT!OF!VENT

1.!Air-fuel!ratio!is!too!rich.

A.!Feed!rate!too!high.

B.!Draft!too!low!caused!by!a!gasket!leak.

LOW!HEA T !OUTPUT

1.!Feed!rate!too!low

2.!Draft!too!low!because!of!gasket!leak.

3.!Poor!quality!or!damp!pellets

4.!Combination!of!1.!and!2.

Helpful!Hints

Cleaning!Burn!Pot

Whenever!your!stove!is!not!burning,!take!the!opportunity!to! scrape!the!burn! pot!to!remove!carbon

buildup.!A!vacuum!cleaner!is!handy!to!remove!the!residue.!Be!sure!the!stove!is!cold!if!you!use!a!vacuum.

Carbon!buildup!can!be!scraped!loose!with!the!fire

burning!using!the!special!tool!provided!with!your!stove.

Scrape!the!floor!and!sides!of!the!burn!pot.!The!carbon

will!be!pushed!out!by!the!incoming!fuel.!Always!wear

gloves!to!do!this.

Removing!Ashes

Turn!the!Temp!Dial!to!number!1!approximately

30!minutes!before!removing!ashes.!This!will!result!in!a

cooler!stove!and!ash!pan.

Maximum!Feed!Adjuster!settings!are!not!needed

in!most!cases.!Operating!in!the!normal!range!(#4)!is

recommended!when!maximum!heat!output!is!not!required.!The!ESP!probe!prevents!the!stove!from!being

over-fired.

Keep!the!stove!free!of!dust!and!dirt.

Fuel

Pellet!fuels!are!put!into!3!categories!in!terms!of!ash

content.!Premium!at!1%!or!less,!Standard!at!3%!or!less

and!all!others!at!3%!or!more.

The!P61A!is!capable!of!burning!all!3!categories!of

pellets!due!to!a!patented!feeder!and!burn!pot!system.

It!should!be!noted,!however,!that!higher!ash!content!will!require!more!frequent!!ash!removal!and!may

provide!less!BTU's!per!pound.!Normally,!standard!and

high!ash!pellets!cost!less!than!premium!pellets!and!can

be!cost!effective!when!burned!in!the!P61A.

The!moisture!content!must!not!exceed!8%.!Higher

moisture!will!rob!BTU's!and!may!not!burn!properly.

22 P61A!!Pellet!Stove

Page 23

P61A-2!Feeder!and!Specifications

P61A!Feeder

Specifications

34.5"

9"

12.375"

5.250"

W eight 249!lbs.

Blower 135!cfm

Feed!Rate .75!to!7.5!lbs.!per!hr.

Hopper!Capacity 72!lbs.

Fuel Wood!Pellets

Flue!Size 3!inch

Outside!Air!Size 2!3/8!I.D.!inch

Fuse!Rating 5!amp

32.375"

29.5"

23.5"

P61A!Pellet!Stove

23

Page 24

Door!Options

Optional! Trim

To! install,! lay! the! frame! face! down! on! a! soft

surface.!!Fasten! door! frame! by! inserting! the! 4

threaded!posts!on!the!frame!through!the!door.!!The

posts!should!line!up!with!the!4!holes!located!at!the

corners!of!the!door.!!Once!the!posts!are!through!the

door,!fasten!frame!with!4!nuts!and! tighten!until!the

frame!is!snug.

To!install!ash!lip!trim,!simply!slide!the!trim!over

the!ash!lip!and!into!the!groove!on!the!trim.

24 P61A!!Pellet!Stove

Decorative! Tile

Decorative!tile!is!available!in!several!configurations.!!The!tile!installs!behind!the!trim!on!the!ash

door.

Cleaning! Plated! Trim

Gold!or! nickel! plated! hardware! should! never

be!buffed!or!polished.!Abrasive!cleansers!and!metal

polishes!will!remove!the!plating!and!therefore!should

never!be!used.!If!the!plating!needs!to!be!cleaned,

wait!until!the!stove! is! completely! cool,! then! use! a

sponge,!soap!and!water!to!gently!remove!dirt! and

stains.!!Before!relighting!the!stove,!remove!all!soap

residue!and!wipe!dry.

Page 25

OPTIONS

Side! Heat! Shields

Side!heat!shields!are!available!to!reduce

the!clearance!to!combustible!materials.

Hopper! Extension

The! hopper! extension! allows! you! to

put!more!pellet !fuel!in!the!hopper!and!extends

burn!time!on!one!load!of!pellets.!The!hopper

extension!adds!60!pounds!to!the!existing!72

pound!hopper!capacity,!allowing!you!to!load

132!pounds!of!pellets!at!one!time.

P61A!Pellet!Stove

25

Page 26

P61A-2!Wiring!Diagram

26 P61A!!Pellet!Stove

Page 27

Options:

P61A-2!!Parts!List

Description Part!Number

Hopper!Gasket(6!ft.) 0-88-00248

Ash!Pan!Assembly 1-10-05800

Burn!Pot!Weldment 1-10-05802

Right!Rear!Shield 2-00-06468-1

Left!Rear!Shield 2-00-06468-2

Arrow!Scraper 2-00-773850

Flame!Guide 3-00-08534

Wiring!Harness!Assembly 3-20-08727

Thermister!Probe 3-20-00744

Room!Sensor 3-20-00906

Circuit!Board 3-20-05374

Differential!Switch 3-20-9301

5"!Double!Fan!Blade 3-20-502221

Combustion!Blower 3-21-08639

Distribution!Blower 3-21-22647

Hopper!Lid!Latch 3-31-199110

3/16"!Rubber!Washer!(for!Hopper!Lid) 3-31-90131101

Power!Cord 3-20-29685

Auto!Ignite!Label!(Control!Panel!Door)3-90-08627

Fire!Brick!(3) 3-40-900450125

White/Black!Control!Knob(3) 3-31-00605

Control!Knob!Shaft(3) 3-31-00015

Front!Glass 3-40-950133125

Burn!Pot!Gasket(2) 3-44-00409

Tailpipe!Gasket 3-44-06179

Wiring!Diagram 3-89-06504

Control!Panel!Sticker 3-90-06655

Owner's!Manual 3-90-05822

Hopper!Lid!Label 3-90-08416

Igniter!Assembly 1-10-06620

Cleanout!Cover(1) 2-00-06623

1/4-20!x!1/2"!Wing!Screw!w/Collar(2) 3-31-782108

Hopper!Extension!Assembly 1-00-08636

Outside!Air!Assembly 1-10-08542

Inlet!Cover 1-10-08543

3'!Flex!Pipe 2-00-08543

Log!Set 3-40-5647

Trim!Kit 1-00-06802

Tile!Pack(1!piece) 3-43-12601(10!choices)

P61A!Pellet!Stove

27

Page 28

HARMAN!GOLD!WARRANTY

Harman!Gold!Warranty

6!YEAR!TRANSFERABLE!LIMITED

WARRANTY!(Residential)

1!YEAR!LIMITED!WARRANTY!(Commercial)

Harman!Stove!Company!warrants!its!product s!to!be!free!from!defects!in!material!or!workmanship,!in!normal!use

and!service,!for!a!period!of!6!years!from!the!date!of!sales!invoice!and!for!mechanical!and!electrical!failures,!in!normal

use!and!service,!for!a!period!of!3!years!from!the!date!of!sales!invoice.

If!defective!in!material!or!workmanship,!during!the!warranty!period,!Harman!Stove!Company!will,!at!its!option,

repair!or!replace!the!product!as!described!below.

The!warranty!above!constitutes!the!entire!warranty!with!respect!to!Harman!Stove!Company!products.!!HARMAN

STOVE!COMPANY!!MAKES!!NO!!OTHER!!WARRANTY,!!EXPRESSED!!OR!!IMPLIED,!!INCLUDING!!ìANYî!!WARRANTY!!OF!MERCHANTABILITY,!!OR!!WARRANTY!!OF!!FITNESS!!FOR!!A!!P AR TICULAR!!PURPOSE. !!No!employee,

agent,!dealer,!or!other!person!is!authorized!to!give!any!warranty!on!behalf!of!Harman!Stove!Company.!!This!warranty

does!not!apply!if!the!product!has!been!altered!in!any!way!after!leaving!the!factory.!!Harman!Stove!Company!and!its

agents!assume!no!liability!for!ìresultant!damages!of!any!kindî!arising!from!the!use!of!its!products.!!In!addition,!the

manufacturer!and!its!warranty!administrator!shall!be!held !free!and!harmless!from!liability!from!damage!to!property

related!to!the!operation,!proper!or!improper,!of!the!equipment.

THERE!! ARE!!NO!!WARRANTIES!!WHICH!!EXTEND!!BEYOND!!THE!!DESCRIPTION!!ON!!THE!!FACE!!HEREOF.

THESE!!WARRANTIES!!APPLY!only! if! the! device! is! installed! and! operated! as! recommended! in! the! userís

manual.

THESE!!WARRANTIES!WILL!!NOT!! APPLY!if!abuse,!accident,!improper!installation,!negligence,!or!use!beyond

rated!capacity!causes!damage.

HOW!!TO!MAKE!A!CLAIM!-!Any!claim!under!this!warranty!should!be!made!to!the!dealer!from!whom!this!appliance

was!purchased.!!Then!contact!is!made!with!manufacturer,!giving!the!model!and!serial!numbers,!the!date!of!purchase,

your!dealerís!name!and!address,!plus!a!simple!explanation!of!the!nature!of!the!defect.!!Extra!costs!such!as!mileage

and!overtime!are!not!covered.!!Nuisance!calls!are!not!covered!by!these!warranties.

THIS!!!WARRANTY!!!IS!!!LIMITED!!!TO!!!DEFECTIVE!!!PAR TS!-!REPAIR!!!AND/OR!!!REPLACEMENT!!!AT

HARMAN!!!STOVE!!COMPANYíS!!!OPTION!!!AND!!!EXCLUDES!!!ANY!!INCIDENTAL!!!AND!!!CONSEQUENTIAL

DAMAGES!!!CONNECTED!!THEREWITH.

WARRANTY!EXCLUSIONS:!Failure!due,! but!not!limited!to,!fire,!lightning,!acts!of!God,!power!failures ! and/or

surges,!rust,!corrosion!and!venting!problems!are!not!covered.!!Damage!and/or!repairs!including!but!not!limited!to;

remote!controls,!filters,!fuses,!knobs,!glass,!ceramic!brick!panels,!ceramic!fiber!afterburners,!door!packing,!tile,!ceramic!log! sets,!paint,! batteries!or! battery!back-up!and! related!duct!work! are!not! covered.!Also!excluded!from! this

warranty!are!consumable!or!normal!wear!items!including!but!not!limited!to;!flame!guides,!grates,!coal!bars,!afterburner

hoods,!fire!brick,!gaskets.!Additional!exclusions!for!corn!stoves!are!burnpot!housing!weldment,!burnpot!grate!weldment

(pellet!or!corn),!burnpot!front!plate!(pellet!or!corn),!burnpot!front!plate!lock,!corn!auger!extension,!ceramic!insert,!and

ceramic!insert!plate.!Additional!or!unusual!utility!bills!incurred!due!to!any!malfunction!or!defect!in!equipment!and!the

labor!cost!of!gaining!access!to!or!removal!of!a!unit!that!requires!special!tools!or!equipment!are!not!covered.!!Maintenance!needed! to!keep! the!stove!in!ìgood!operating! conditionî!is! not!covered.!!This!includes,!but!is! not!limited! to,

cleaning,!adjustment!of!customer!controls!and!customer!education.!!Labor,!materials,!expenses!and/or!equipment

needed!to!comply!with!law!and/or!regulations!set!forth!by!any!governmental!agencies!are!not!covered.

This!Warranty!provides!specific!legal!rights!and!the!consumer!may!have!other!rights!that!vary!from!state!to!state.

In!the!event!of!change!in!ownership,!the!remaining!portion!of!this!warranty!may!be!transferred!to!the!new!owner!by

sending!the!new!owner!information!and!a!transfer!fee!of!$25.00!US!to!the!Harman!Stove!Company.

PLEASE!!READ!!THE!!LITERATURE!!BY!!THE!!MANUFACTURER!!FOR!!THE!!VARIOUS!!ACCESSORY

DEVICES.!!!THE!MANUFACTURER!!WARRANTS!!THESE!!ACCESSORY!!DEVICES,!!NOT!!HARMAN!!STOVE

COMPANY!!OR!!THEIR!WARRANTY!!ADMINISTRATOR.!!!FURTHERMORE,!!THESE!!ACCESSORY!!DEVICES

MUST!!BE!!INSTALLED!!AND!!USED!ACCORDING!!TO!!THE!!RECOMMENDATIONS!!OF!!THE!!MANUFACTURER.

REMEDIES!-!The!remedies!set!forth!herein!are!exclusive!and!the!liability!of!seller!with!respect!to!any!contract!or

sale!or!anything!done!in!connection!therewith,!whether!in!Contract,!in!tort,!under!any!warranty,!or!otherwise,!shall!not,

except!as!herein!expressly!provided,!exceed!the!price!of!the!equipment!or!part!of!which!such!liability!is!based.

CLARIFY!-!The!above!represents!the!complete!warranty,!which!is!given!in!connection!with!stoves,!manufactured

by!Harman!Stove!Company.!!No!other!commitments,!verbal!or!otherwise,!shall!apply!except!by!a!written!addendum!to

this!warranty.

28 P61A!!Pellet!Stove

Loading...

Loading...