Harman Stove Company Magnum Stoker Installation And Operating Manual

Installation & Operating Manual

The Harman Magnum Stoker

Tested by:

OMNI-TEST Laboratory

DO NOT BURN WET COAL.

R15

SAFETY NOTICE

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW ROOM HEATER. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

FOR USE IN THE U.S. AND CANADA.

IF THIS HARMAN STOVE IS NOT PROPERLY INSTALLED, A HOUSEFIRE MAY RESULT. FOR YOUR SAFETY, FOLLOW

INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONSAND INSTALLATION INSPECTION

REQUIREMENTS IN YOUR AREA.

CONTACT YOUR LOCAL AUTHORITY (SUCH AS MUNICIPAL BUILDING DEPARTMENT, FIRE DEPARTMENT, FIRE

PREVENTION BUREAU, ETC.) TO DETERMINE THE NEED FOR A PERMIT.

CETTE GUIDE D'UTILISATION EST DISPONIBLE EN FRANCAIS. CHEZ VOTRE CONCESSIONNAIRE DE HARMAN STOVE

COMPANY.

MGMR13

SAVE THESE INSTRUCTIONS.

INDEX

Introduction 3

Warnings 3

Packing List 5

Assembly 6

Installation 9

2

Verti-Flow Stoker Control 10

Operation 14

Maintenance 15

Trouble-Shooting 17

Wiring Diagram 19

Feeder Parts 20

Domestic Hot Water Coil 21

Hot Air Option 22

Warranty 23

DO NOT BURN WET COAL

INTRODUCTION

3

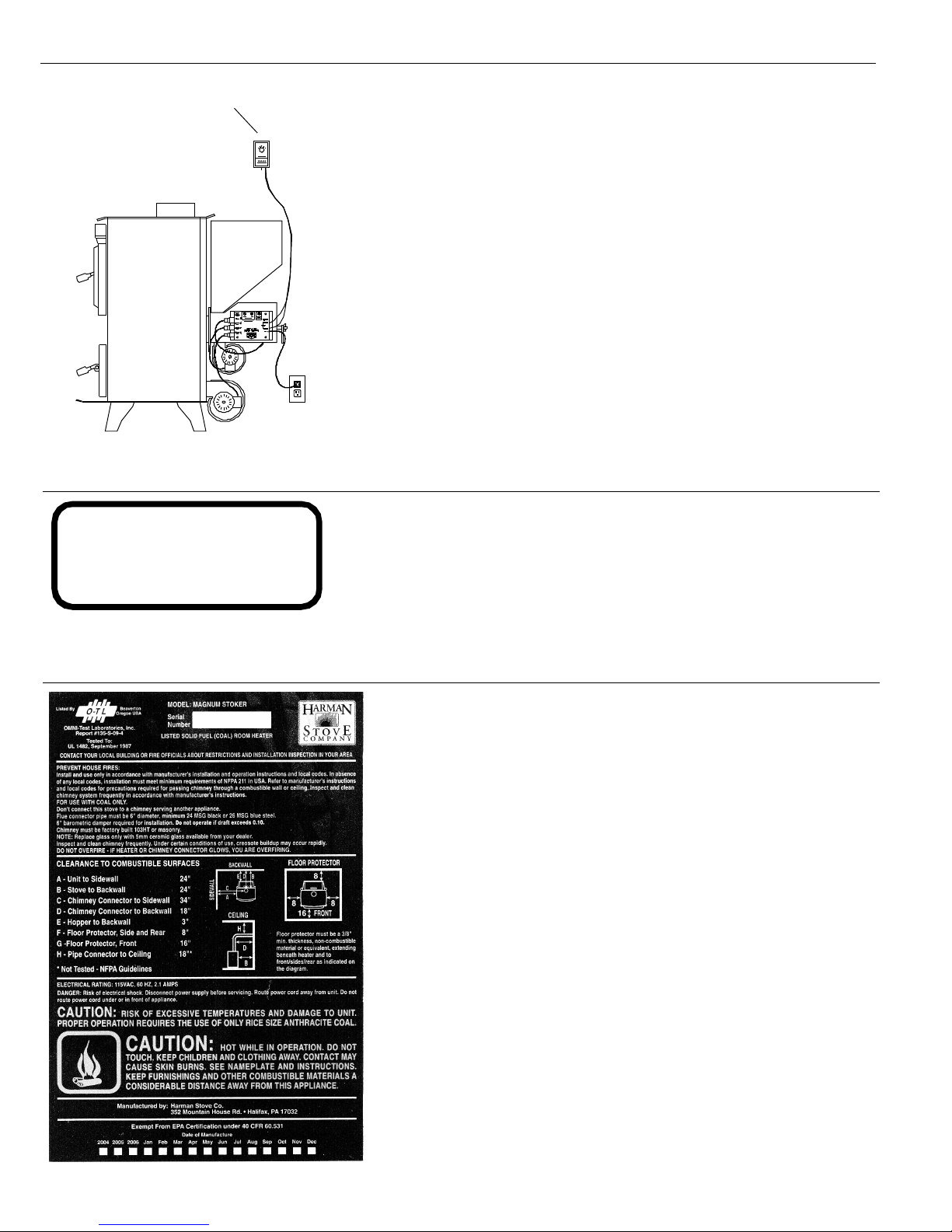

THERMOSTAT

100 LBS.

COAL

WARNINGS

Never sleep in the same

room with any coal

burning stove.

This all new design by Harman features the Verti-Flow Stoker System.

This unique system provides a very wide range of heat output. The

Verti-Flow Stoker can operate from 5000 to over 85,000 btu's automatically.

This unit has a 100 pound coal capacity and can provide 85,000 btu's

for 17 hours or stretch out to over 100 hours when less heat is required.

A thermostat is used to regulate the heat output of the stove. When no

heat is needed, the stoker stops and only runs to maintain the fire. If heat is

needed, the thermostat can turn on the stoker at any time. After the thermostat

is satisfied, the stoker will turn off for twelve minutes and then run for four

minutes.

The four minutes "on" and twelve minutes "off" is a setting that will

perform well under most conditions. This "on" and "off" time can be changed

to provide more or less heat during the maintenance cycle.

This unit must be connected to a chimney capable of providing a .04

minimum draft reading. WARNING!! If the chimney has no draft, coal gases

may escape from the unit and stovepipe. These gases are toxic and can be

fatal. It is recommended that a gas detector be installed to warn of this

condition. Check with your local stove dealer for purchasing a gas detector.

TESTING INFORMATION

This unit has been tested and approved by OMNI-TEST Labo-

ratories in accordance to the listed codes.

DO NOT BURN WET COAL

READ THIS

Always empty hopper when not burning for more than a

week. When left standing for long periods with wet coal,

the pusher block will rust and corrode, causing it to

seize. If the stoker is then turned "on", damage to the

pusher assembly and feed motor will result. This will be

considered neglect and will void the warranty on those

parts. Always check to see if moving parts are free

4

before using if the unit has not been burned for a period

of time. This can best be determined by shaking the

adjuster rod.

Wet Coal

Freshly delivered coal is watered down

to eliminate dust when loading and unloading.

Wet rice coal does not flow as well as damp or

dry coal. We do not recommend burning wet

coal, however, we realize if it's the only coal you

have it is better to burn it than freeze. If you

must burn wet coal, the feed rate must be increased in order to get the same size fire. As the

wet coal in the hopper dries out, the feed rate

must be decreased. If you don’t, the feeder will

over-fire the stove and waste coal. Doing this

once or twice a year will not damage your stove

as long as it is hot and burning. The damage is

caused when the hopper has wet coal in it when

the sto ve is co ld .

sion and it is totally the operator’s fault.

This will cause rust and corro-

Usually after the coal dries for three

or four days, depending on conditions, it will

flow very well and feed properly. Feed rate

will be the same as dry coal.

Damp coal also should not be left in

the hopper of a cold stove.

Damp Coal

DO NOT BURN WET COAL

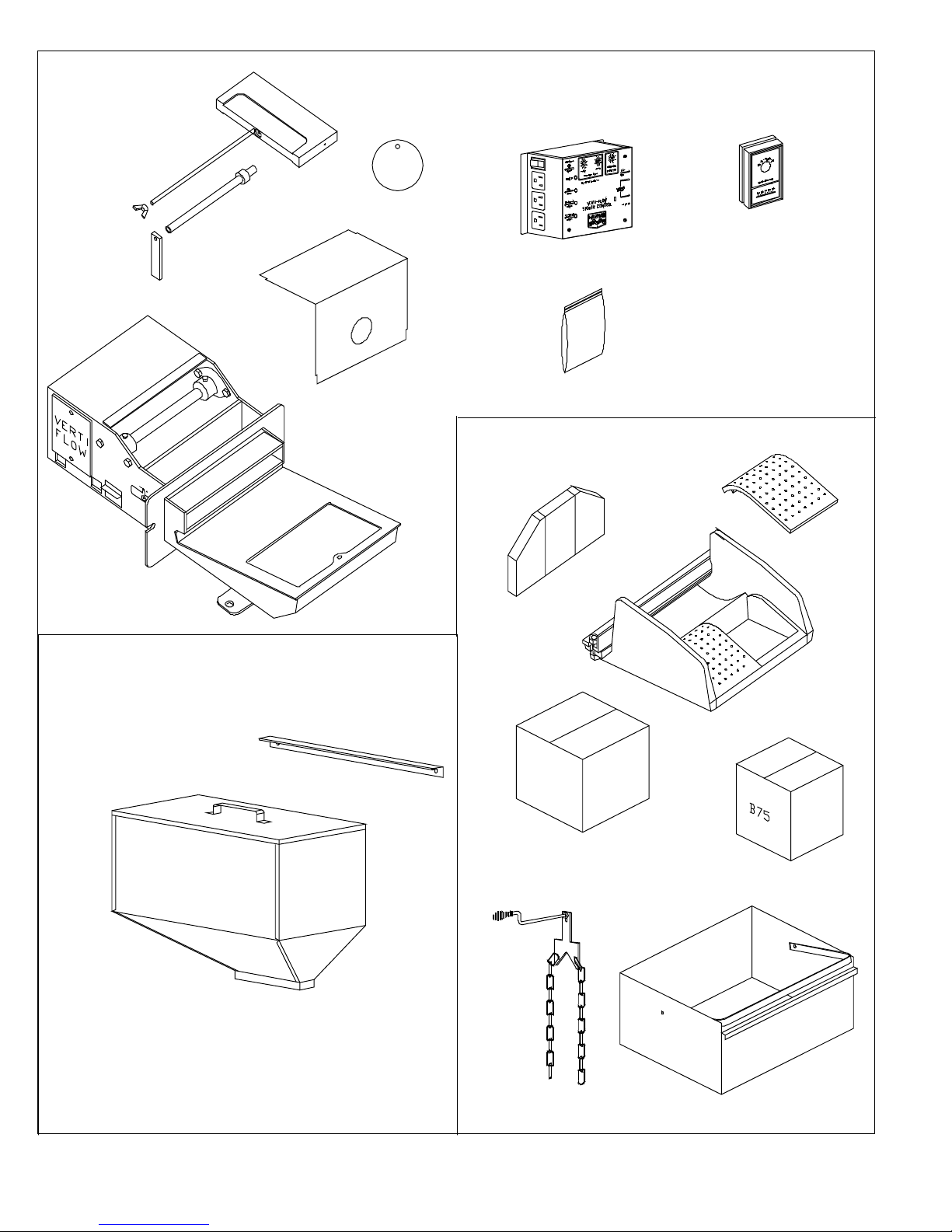

PACKING LIST

5

adjuster rod

wing nut

adjuster

Pusher block

adjuster tube

Parts inside feeder box

Restricter Plate

thermostat

control box

Inside bag

(2) terminals for thermostat wire

(4) 8-32 x 1/2 screws and nuts

motor cover

Parts inside stove

main feeder body

Parts inside hopper box

hopper lid

(2) grate inserts

firebricks

grate holder

hopper support

distribution blower

combustion blower

hopper

scraper

assembly

ash pan

DO NOT BURN WET COAL

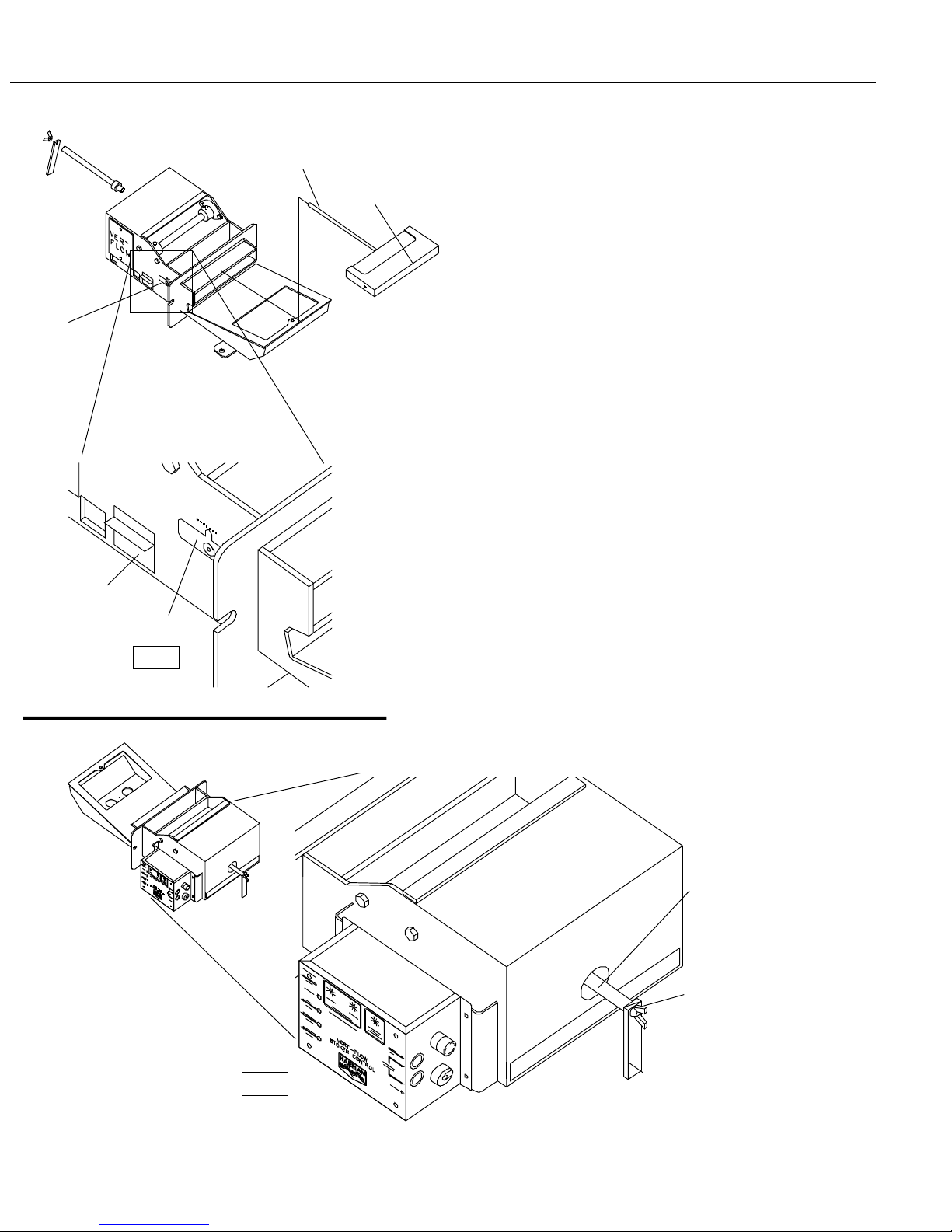

ASSEMBLY

slot

6

adjuster rod

Pusher

block

First, a note to you, the customer.

This section on Assembly is in the manual for your information

should you ever need to move your unit and to help you understand how each part is installed.

dust tray

feed indicator

fig 1

It is not intended by Harman Stove Company that you

assemble this unit. This job is to be performed by your Harman

Dealer who has been taught how to assemble and explain the

operation of your new stoker to you.

Your dealer will also take a draft reading with the stoker

burning. This reading must be recorded on the warranty coupon in

order to activate your warranty.

The assembly and set-up are free. However, we do not

wish to imply that delivery and installation are free.

adjuster tube

fig 2

wing nut

adjuster

DO NOT BURN WET COAL

Feeder

adjuster rod from the front through the slot shown in fig.1.

Blowers

Be sure the pusher block is turned with the bolt hole to

feed indicator side.

7

Begin assembly by sliding the pusher block with the

fig 3

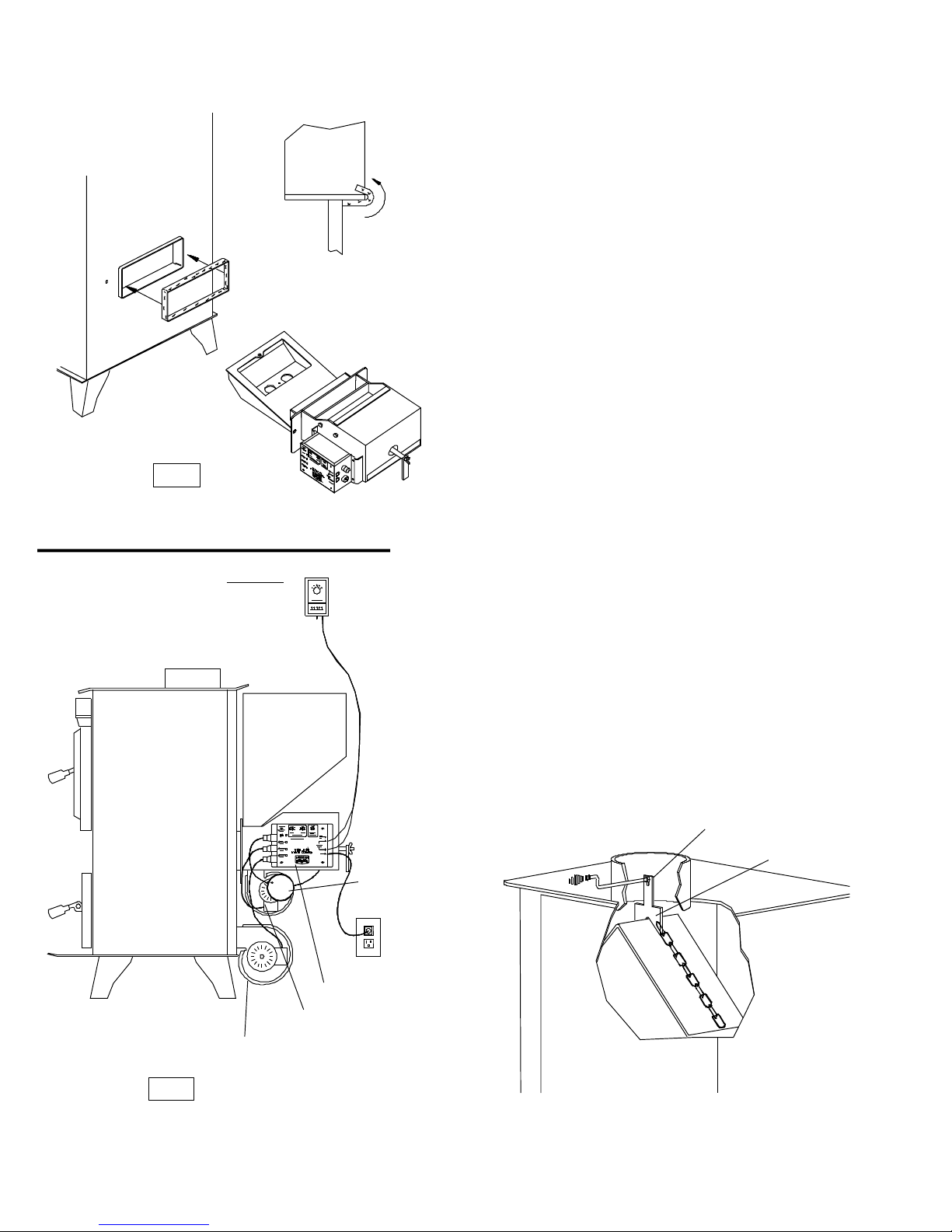

thermostat

gasket

Next, hold pusher block in the most rearward position and slide the adjuster tube over the adjuster rod until it

bottoms out on the pusher block. Thread the adjuster

over the adjuster rod. Thread wing nut on the end of the

adjuster rod.

Make sure the gasket is in place on the feeder

Control Box

opening on the rear of the unit, as shown in fig 3. Insert the

stoker into the opening in the rear of the unit. Bolt fast and

tighten with (2) 5/16 X 1 1/4 bolts.

Install the smaller of the two blowers on the bottom

of the feeder by sliding it into the bracket as far as it will

go. Install restricter plate on blower as shown below in

Fig. 4.

Slide the larger blower into place on the bottom rear

Cleanout Scraper

Large blower

fig 4

Install scraper as shown below with locking nut

on each side of the scraper. Tighten nuts when in the

rear most position to assure alignment. Cycle rod in

and out to clean unit.

lock nut

scraper

Restricter Plate

Control Box

Small blower

DO NOT BURN WET COAL

Loading...

Loading...