1

1

2

PRECAUTION: The installer should be an experienced service technician. Disconnect electrical power before

beginning installation. Do not install where temperatures fall below 32 degrees F or where plenum temperatures

exceed 200 degrees F. For maximum evaporative capacity, install this humidifier on the warm air supply plenum.

When wiring into a multi-speed blower circuit see Step 6C & 6D.

FOR INSTALLATION ON A VERTICAL

SURFACE OF THE WARM AIR PLENUM

OF ANY FORCED AIR FURNACE

INSTALLER: PLEASE FILL OUT AND MAIL GUARANTEE CARD AFTER INSTALLATION

IS COMPLETE. LEAVE INSTALLATION INSTRUCTIONS WITH HOME OWNER

ADDITIONAL MATERIALS THAT MAY BE NECESSARY:

1. 1/4" diameter plastic supply tubing or 1/4" copper supply tubing for hot water applications

2. air pressure switch (G.F. Model #12500 suggested)

3. junction box, 115 V. grounding outlet, cover and wire

4. 1/2” I.D. drain hose

5. #8 x 3/4” mounting screws

2

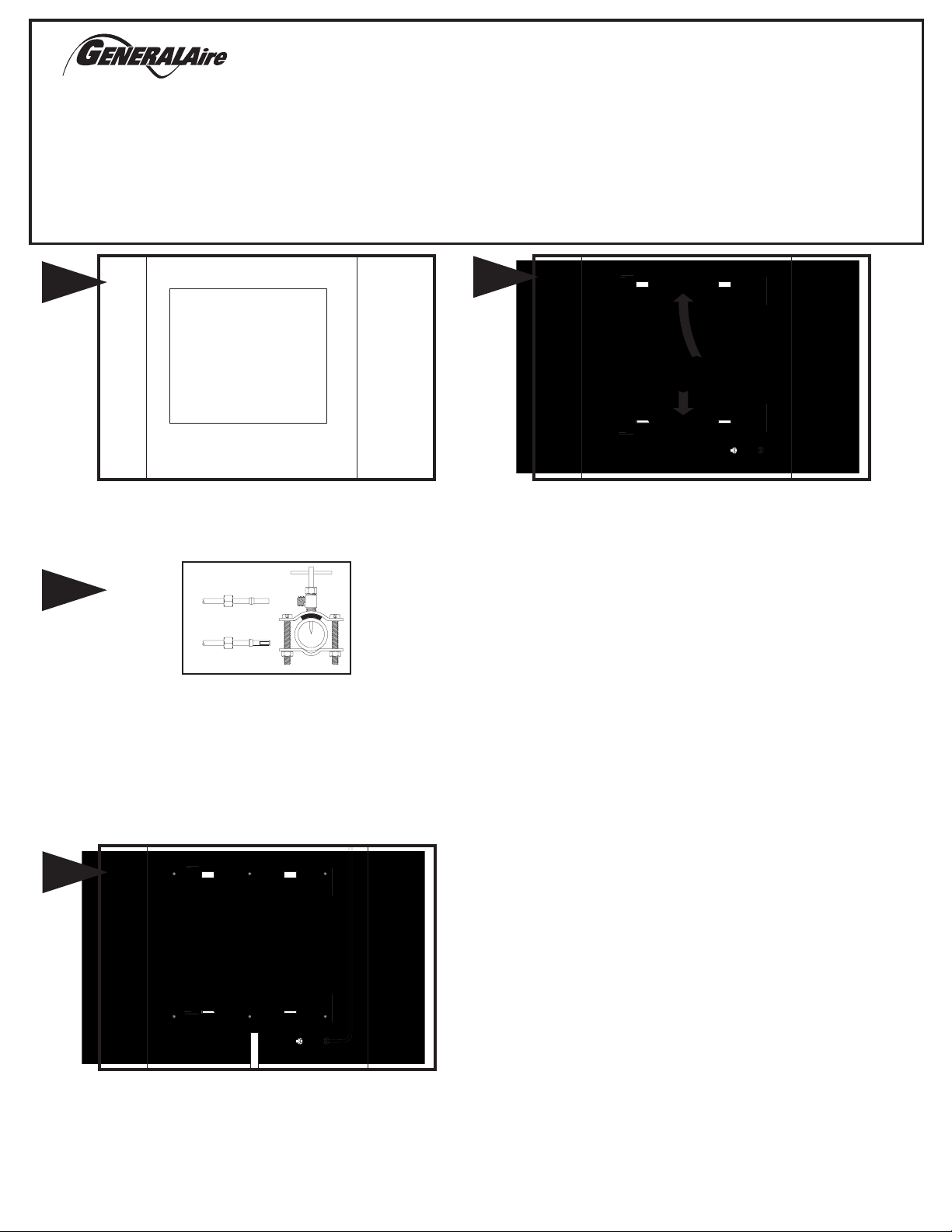

SADDLE VALVE INSTALLATION INSTRUCTIONS

Copper Pipe

1. Retract piercing pin into valve body by turning handle

counterclockwise.

2. Screw valve body into upper bracket and tighten.

3. Place rubber gasket over piercing pin.

4. Assemble saddle valve over copper pipe using enclosed screen, �

nuts and lower bracket.

5. Tighten screws evenly and firmly. Brackets should be parallel.

6. Complete compression connection to saddle valve outlet.

7. Turn handle clockwise to pierce tubing and close saddle valve.

8. Turn handle counterclockwise to open saddle valve, leave open for �

several seconds to flush dirt from pipe and tubing.

Steel, Brass or Hard Plastic Pipe

1. Shut off water supply and drain pipe.

2. Turn handle clockwise to expose piercing pin and close saddle

valve.

3. Place rubber gasket over piercing pin.

4. Drill 1/8" hole in pipe using a hand crank drill to avoid shock hazard.

5. Assemble saddle valve over steel, brass or hard plastic pipe using �

enclosed screws, nuts and lower bracket.

6. Tighten screws evenly and firmly. Brackets should be parallel.

7. Complete compression connection to saddle valve outlet.

8. Turn handle counterclockwise to open saddle valve, leave open for �

several seconds to flush dirt from pipe and tubing.

Threaded Pipe Fittings

1. Turn handle clockwise to expose piercing pin and close saddle

valve.

2. Seal valve body threads using pipe tape or sealant.

3. Install valve into 1/8" NPT fitting.

4. Complete compression connection to saddle valve outlet.

5. Turn handle counterclockwise to open saddle valve, leave open for

several seconds to flush dirt from pipe and tubing.

1000 SERIES

FLOW THROUGH

POWER HUMIDIFIER

3

COPPER

TUBING

PLASTIC

TUBING

Mount the self tapping saddle valve on either a cold or a hot water pipe.

A side or top mount is best to avoid clogging from pipe sediment.

Connect 1/4” O.D. tubing to the saddle valve. Copper tubing requires a

brass compression nut and brass sleeve. Plastic tubing requires a brass

insert inside the tubing, a plastic sleeve on the outside with a brass

compression nut.

NOTE: DO NOT USE PLASTIC TUBING ON HOT WATER OR IN

CONTACT WITH ANY HOT PLENUM SURFACE OR DUCT.

INSTALLATION OF THIS SADDLE VALVE MUST MEET OR EXCEED

LOCAL CODES AND ORDINANCES.

Select location on vertical surface of warm air plenum for mounting

humidifier. Tape mounting template in place making sure the template is

level. Do not install humidifier where the blanked off ends of a cooling coil

will restrict air flow to the humidifier. Cut out center section of template.

Open cover and remove evaporator pad assembly. Humidifier

chassis is self retaining, slide top side in first then slide chassis

down. Level chassis and install eight screws.

Fresh Indoor Air Quality

Connect 1/4" water supply tube to inlet of solenoid.

DO NOT USE

PLASTIC TUBING IN CONTACT WITH ANY HOT PLENUM

SURFACE OR DUCT. IF USING PLASTIC TUBING, USE TUBE

SUPPORT P189 AND PLASTIC COMPRESSION SLEEVE P190.

Connect drain hose to 1/2" spout on humidifier cabinet using hose clamp if

necessary. Run 1/2" hose to suitable drain such as floor drain, sewer or

laundry sink. Be sure hose has continuous slope and is not kinked at any point.

4

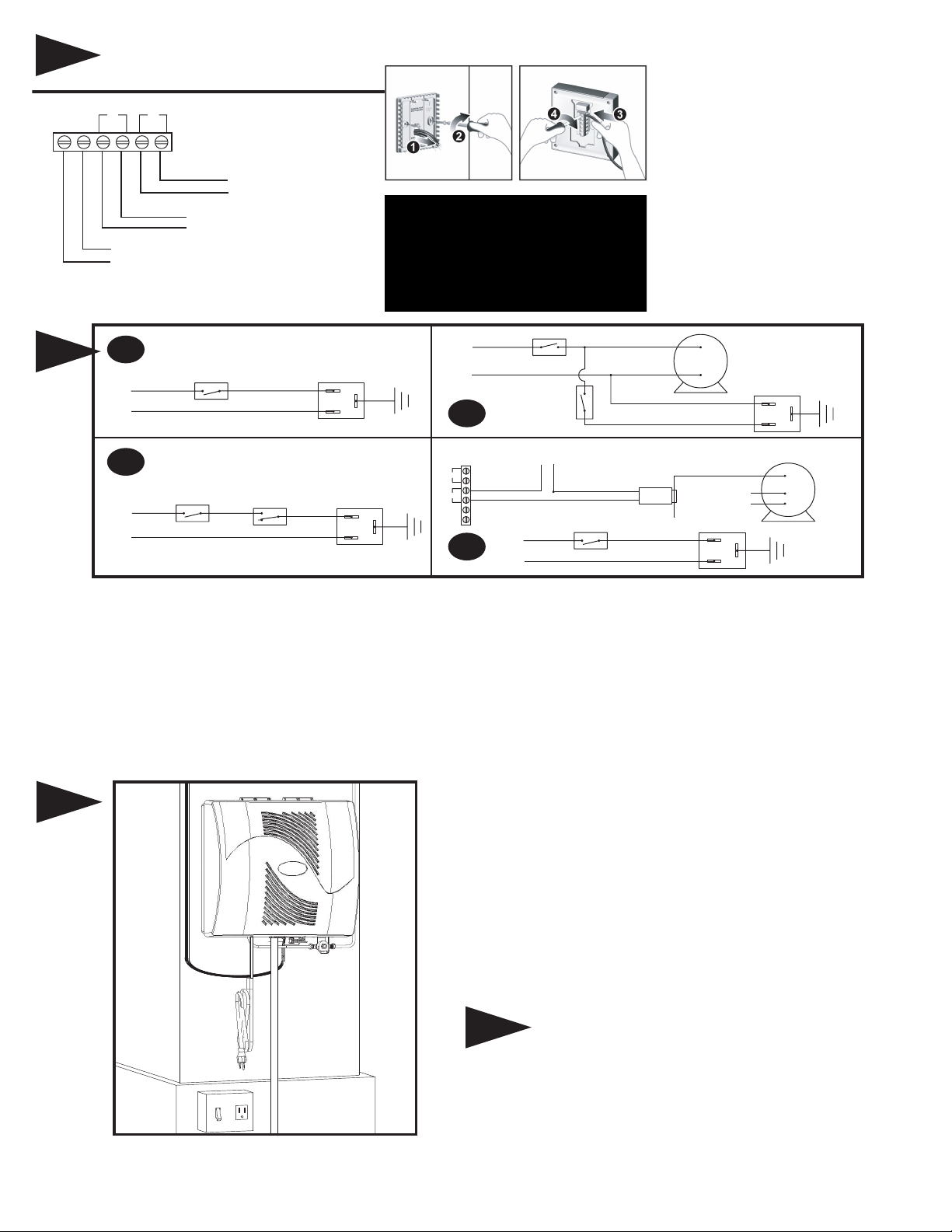

24V OUTPUT FROM HUMIDIFIER (RED WIRES) OR

727-58 24 V. TRANSFORMER SWITCHED WITH FURNACE

OR 24 VAC POWER SUPPLY SWITCHED WITH FURNACE.

HUMIDIFIER CONTROL LEADS

(YELLOW WIRES)

OUTDOOR TEMP. SENSOR

(NOT USED IN MANUAL MODE)

AC L

AC N

HUM

SNSR

AC L

AC N

HUM

SNSR

Turn on water supply and plug in power cord to check operation of

humidifier. Set humidistat to a demand setting. With the furnace off, the

solenoid valve should be closed and the humidifier fan not running. Start

the furnace, the solenoid valve should open and the humidifier fan run

when the blower or burner circuit is energized. Check flow of water

through distributor trough and evaporator pad. The standard GA4231

yellow orifice will supply approximately 3.5 GPH of water at a line water

pressure of 60 psi. For low water pressures (20-40 psi) a larger orifice

GA4299 is available to provide the same flow. Leave humidistat set at the

recommended setting.

Replace evaporator pad assembly and humidifier cover. Insert low

voltage six connector wiring harness from cover into chassis solenoid

harness.

7

8

CIRCUIT DESCRIPTION

The humidifier is connected to the 120 volt AC circuit through a control

relay. The secondary coil of an isolation transformer, a diode and resistor

supply 24 volts DC for the control circuit which also includes the humidistat

and relay coil. When the control circuit is completed by the humidistat, the

relay closes, supplying 120 volts to the fan motor and 24 volts to the

solenoid valve.

L1

(HOT)

L2

115v.

60CY.

HUMIDIFIER CONTROL LEADS

(YELLOW WIRES)

FAN CONTROL

ON-OFF

SWITCH

SINGLE SPEED

BLOWER MOTOR

ACC

EAC

(HOT)

C

115v.

60CY.

ON-OFF

SWITCH

6A

6C

6B

INSTRUCTIONS FOR WIRING HUMIDIFIER

FIG. 6A WITH FURNACE CIRCUIT BOARD

On furnaces with output terminals ACC, or EAC check output

voltage to determine that terminals are 115V. Connect on-off

switch in series with the hot wire.

NOTE: ALL WIRING SHOULD COMPLY WITH LOCAL

ELECTRICAL CODES.

FIG. 6B WITH SINGLE SPEED BLOWER MOTOR

On furnaces with single speed blowers, mount a junction box and 115v.

grounded outlet connected in parallel with the blower circuit. Connect the

on-off switch in series with the hot or black wire.

FIG. 6C WITH TWO SPEED BLOWER MOTOR

On furnaces with a two speed blower, the humidifier and a Model 12500

Air Pressure Switch may be wired from a continuous 115 volt power

source. Install the on/off switch and Air Pressure Switch in series with the

hot or black wire. The Air Pressure Switch will detect furnace operation

and supply power to the humidifier accordingly.

FIG. 6D WITH TWO SPEED BLOWER MOTOR

On furnaces with a two speed blower, the humidifier may be wired from a

continuous 115 volt power source. Install the on/off switch in series with

the hot or black wire. Install the GA50 Current Sensing Relay in series

with the humidistat circuit. The Current Sensing Relay will detect furnace

operation and supply power to the humidifier accordingly.

GRD

HUMIDIFIER

120v. OUTLET

HUMIDIFIER

COMMON LEAD

120v. OUTLET

C

HI

LO

GA50 CURRENT

SENSING RELAY

MULTI

SPEED

BLOWER

MOTOR

6D

12500 AIR

PRESSURE

SWITCH

NO

C

L1

(HOT)

L2

115v.

60CY.

ON-OFF

SWITCH

GRD

HUMIDIFIER

120v. OUTLET

L1

(HOT)

L2

115v.

60CY.

ON-OFF

SWITCH

GRD

HUMIDIFIER

120v. OUTLET

GRD

6

5

1. Follow the installation instructions

supplied with the humidistat.

2. To remove the humidistat from the

base, squeeze the louvered base at

the top and bottom.

3. Before wall mounting, please

remove the gasket.

�

4. Before return air duct mounting,

please remove the breakout piece.

E2 HUMIDISTAT

8

PARTS LIST FOR HUMIDIFIER

900-9 NOZZLE

900-10 SPOUT

900-40 PAD RAIL

GA19 EVAPORATOR PAD

900-15 DISTRIBUTOR TROUGH

GA4247 FAN BLADE

900-14 DRAIN PAN

GA4237 MOTOR

900-16 NAMEPLATE

1000-11 HARNESS - BOARD

GA4238 RELAY ASS'Y

1137-31 POWER SUPPLY CORD

GA4231 ORIFICE - YELLOW

P-190 COMPRESSION SLEEVE (PLASTIC)

P-101 COMPRESSION NUT

GA4235 DISTRIBUTOR TUBE

P-189 TUBE SUPPORT

P-101 COMPRESSION NUT

P-102 COMPRESSION SLEEVE (BRASS) OR

P-190 COMPRESSION SLEEVE (PLASTIC)

GA4004 STRAINER SCREEN

GA4045 SOLENOID & HARNESS

ASSEMBLY

Fresh Indoor Air Quality

FILL OUT AND MAIL THIS

WARRANTY CARD AND

LITERATURE REQUEST FORM

A

IR CLEANERS AND AIR PURIFIERS

H

UMIDIFIERS

D

IGITAL HUMIDITY GAGE

A

IR FILTER GAGE

FORM NO. 1000-16 (FILE 15066) REV. A

F

UEL OIL FILTERS AND

A

CCESSORIES

Litho in U.S.A.

The operating principle of the humidifier is based on the most efficient

and economical means of evaporating water to the air. The heat

necessary for evaporating water is produced by the furnace.

The water supply to the humidifier is controlled by the electric solenoid

valve. The solenoid valve and humidifier fan are controlled by a

humidistat connected through an isolation relay. The humidistat is

designed for wall mounting in the living area or surface mounting on the

return air duct. ELECTRICAL RATING: 24 VAC/ 60 Hz.

DO NOT SET RELATIVE HUMIDITY TOO HIGH DURING COLD

WEATHER. EXCESSIVE HUMIDITY MAY CAUSE CONDENSATION

ON WINDOWS OR IN WALLS. REFER TO RECOMMENDED

SETTINGS AS DESCRIBED IN THE HUMIDISTAT OWNERS

MANUAL.

Water flows through a strainer, is metered through an orifice to provide

the proper amount of water, and is supplied to the evaporator pad by

the distributor trough. Air from the warm air plenum is pulled through

the wetted evaporator pad by the humidifier fan and returned to the

warm air plenum to be circulated through the living area. Moisture is

evaporated to the air passing through the evaporator pad.

Minerals are not blown into the air stream as occurs in atomizing

humidifiers; they are left on the evaporator pad where a high

percentage is carried off with the waste water.

When the humidifier is installed and operating, no adjustments are

necessary other than setting the control knob on the humidistat to the

desired level of humidification.

To turn the humidifier off, close water supply valve, switch electrical

power off and turn humidistat off.

This humidifier, if properly registered by the return of the warranty registration card to the manufacturer, is warranted to the consumer against defects in

materials and workmanship for a period of ten years from the date of installation. Evaporator pads, water strainers or metering orifices are not covered by

this limited warranty or any other warranties. Any other defective parts will be repaired without charge except for removal, reinstallation and

transportation costs. To obtain repair service under this limited warranty, the consumer must send the defective part or the complete humidifier to the

manufacturer.

THERE ARE NO EXPRESS WARRANTIES COVERING THIS AIR CLEANER OTHER THAN AS SET FORTH ABOVE, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. THE MANUFACTURER ASSUMES NO

LIABILITY IN CONNECTION WITH THE INSTALLATION OR USE OF THIS PRODUCT, EXCEPT AS STATED IN THIS LIMITED WARRANTY. THE

MANUFACTURER WILL IN NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do not allow either

limitations on implied warranties, or exclusions from incidental or consequential damages, so the above exclusion and limitation may not apply to you.

Any questions pertaining to this limited warranty should be addressed to the manufacturer. (U.S.A.: The manufacturer has elected not to make available

the informal dispute settlement mechanism which is specified in the Magnuson-Moss Warranty Act.)

GENERAL FILTERS, INC. CANADIAN GENERAL FILTERS, LTD.

NOVI, MICHIGAN 48375-1115 SCARBOROUGH, ONTARIO M1R3B7

WWW.GENERALAIRE.COM WWW.CGFPRODUCTS.COM

Your Humidifier is engineered to give helpful and trouble-free humidification. For maximum efficiency the following cleaning procedures should be carried

out at the end of each heating season:

1. Turn off water supply and electrical power to humidifier.

2. Remove cover, water distributor trough, evaporator pad, pad rails and drain pan. Clean excessive mineral

deposits from the distributor trough, drain pan, pad rails and humidifier cabinet. A solution of 1/2 vinegar & 1/2

water will help loosen mineral deposits.

Inspect drain hose, clean or replace as necessary.

3. If the evaporator pad has excessive mineral deposits, replace with a new “GA19” evaporator pad. Install

trough, pad rails and drain pan. Replace cover, reconnect electrical plug..

4. In heavy mineral areas or if the solenoid valve fails to function disconnect the 1/4” water supply line from the

solenoid valve. Carefully pull the strainer screen (P.N. 900-8) from the valve body (P.N. 900-6). Clean the

mineral deposits from all parts. If the orifice is clogged, it may be opened by inserting a small pin. Reinsert the

filter into the valve body.

5. Reconnect the 1/4” water line to the solenoid valve if necessary. Turn on the water supply and check all points

for leakage. The operation of the unit may be checked by starting the furnace. The humidifier operates only

when the furnace blower is running or the burner circuit is energized. The humidifier is now ready for operation.

6. During the summer, turn off water supply and electrical power to humidifier.

CARE AND MAINTENANCE

LIMITED WARRANTY

HOW THE HUMIDIFIER WORKS

AU PROPRIÉTAIRE� : INSCRIVEZ-VOUS EN LIGNE AU

WWW.GENERALAIRE.COM OU REMPLISSEZ LA CARTE

D’ENREGISTREMENT PUIS POSTEZ-LA À L’ADRESSE SUIVANTE� :

OWNER REGISTER ONLINE AT

WWW.GENERALAIRE.COM OR

FILL IN REGISTRATION AND MAIL TO:

O

WNER'S NAME

Nom du propriétaire:

MODEL 1000

MODÈLE 1000

WARRANTY REGISTRATION

Enregistrement de la garantie

S

TREET

A

DDRESS

Adresse:

D

EALER'S

N

AME

Nom du marchand:

D

ATE OF

I

NSTALLATION

D

ATE DE

I

NSTALLATION

C

ITY

Ville:

P

OSTAL

C

ODE

Code postal:

S

TATE

Province:

S

TREET

A

DDRESS

Adresse:

C

ITY

Ville:

P

OSTAL

C

ODE

Code postal:

S

TATE

Province:

S

ERIAL

N

UMBER

N

UMÉRO DE

S

ÉRIE

GENERAL FILTERS, INC.

43800 GRAND RIVER AVE

NOVI, MI 48375-1115

AT

OUTSIDE

TEMPERATURE

RECOMMENDED

SETTING

-20ϒF -29ϒC 15%

-10ϒF -23ϒC 20%

0ϒF -18ϒC 25%

+10ϒF -29ϒC

+20ϒF - 7ϒC

30%

35%

+30ϒF - 1ϒC 40%

Loading...

Loading...