Page 1

GE

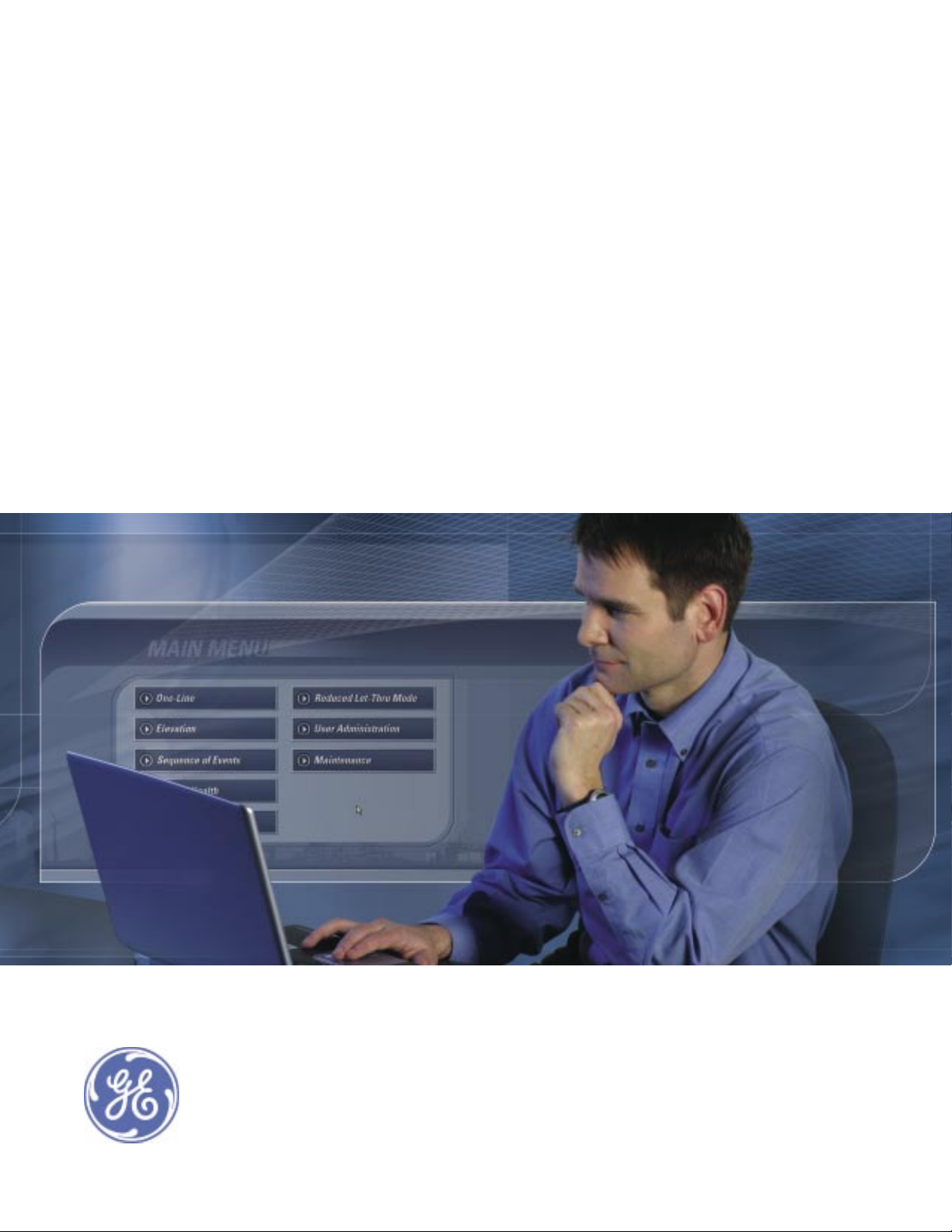

Entellisys™ Low Voltage Switchgear

System Test Kit

User Manual

Page 2

DEH-233

Warnings, Cautions, and Notes as used in this publication

Warnings

WARNING! Warning notices are used in this publication to emphasize that hazardous voltages, currents,

or other conditions that could cause personal injury exist in this equipment or may be associated with its

use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge could

cause either personal injury or damage to equipment.

Cautions

CAUTION: Caution notices are used for situations in which equipment might be damaged if care is not

taken.

Notes

NOTE: Notes call attention to information that is especially significant to understanding and operating

the equipment.

This document is based on information available at the time of its publication. While efforts have been

made to ensure accuracy, the information contained herein does not cover all details or variations in

hardware and software, nor does it provide for every possible contingency in connection with installation,

operation, and maintenance. Features may be described in here that are not present in all hardware and

software systems. GE Consumer & Industrial assumes no obligation of notice to holders of this document

with respect to changes subsequently made.

GE Consumer & Industrial makes no representation or warranty, expressed, implied, or statutory, with

respect to, and assumes no responsibility for the accura cy, completeness, sufficiency, or usefulness of the

information contained herein. No warrantees of merchantability or fitness for purpose shall apply.

Entellisys™, EntelliGuard™, and FlexLogic™ are trademarks of the General Electric Company.

Modbus RTU is a registered trademark of AEG Schneider Automation.

©Copyright 2005 General Electric

All Rights Reserved

Page 3

How to contact us

Please have your Entellisys System Summary # and Sub # ready when calling. This information can be

found on the Entellisys HMI on the System Health screen by clicking the Job Info button.

Post Sales Service

GE Switchgear

510 Agency Road

West Burlington, IA 52655

Phone (toll free): 1-888-437-3765

Additional information:

www.entellisys.com/support

Page 4

Contents

1 System Test Kit

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Test overview/architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Test kit hardware/specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Test Unit PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Test kit power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.3 Test connector (System Test Kit to EntelliGuard Messenger cable). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.4 USB-to-USB cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.1 Start up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.2 Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.3 Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.4 General navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5 Download switchgear configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.1 Direct Connect Download from HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5.1.1 System Configuration Download Link communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.5.2 Last Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.6 Test Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.6.1 Overcurrent Protection Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.6.1.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.6.1.2 Test methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.6.1.3 Pre-Defined Overcurrent Protection Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.6.1.4 User-Defined Overcurrent Protection test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.6.1.5 Automatic Trip Time Curve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.6.2 Relay Protection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.6.2.1 Pre Defined Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1.6.2.2 User Defined Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.6.2.3 Relay Protection Test Results screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.7 Ground Fault Defeat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1.7.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1.8 Summary of Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.9 Manual Breaker Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1.9.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.9.2 Manual circuit breaker injection input range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1.10 Post Analysis Selection screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.11 Test Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.12 Test kit administration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1.12.1 HMI setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.12.2 Disk cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.12.3 System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.12.4 Test Kit Validation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.12.4.1 Customer Validation Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.12.4.2 Factory Test only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.13 Long-term maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.13.1 Motherboard battery maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Contents 5

Page 5

1.13.2 Test kit care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.13.2.1 Handling the test kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.13.2.2 Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.13.2.3 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.13.2.4 Cleaning the LCD screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1.13.2.5 Cleaning the keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1.13.2.6 Cleaning the fan filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1.14 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A Definition of terms

6Contents

Page 6

1 System Test Kit

1.1 Introduction

The Entellisys™ System Test Kit is a portable test instrument designed for field testing of the

Entellisys Low Voltage Switchgear System.

The test kit includes the following features:

• Simulates power line characteristics for a single circuit breaker in the Entellisys Low Voltage

System

• Verifies the function/operation of the protection system

• Overcurrent Protection Tests – Long Time, Short Time, Instantaneous and Ground Fault

Protection Tests

• Single Point Relay Protection Tests (Overvoltage, Undervoltage, Over Frequency, Under

Frequency, Power Reversal and Phase Loss, High Current Test)

• Verifies the calibration of the trip time current curve

• Verifies the operation of the circuit breaker actuation in “Trip mode”

• Performs tests without trips in “No Trip mode”

• Ground Fault Defeat function provides temporarily suspension of all Ground Fault protection

in the system

• Automatically retrieves system configuration for increased productivity

• Displays a summary of all protection configuration

• Saves test results to be reviewed later

• Windows Interface for ease of use

• Operation from 120 Vac

The test kit Interface with the system is through the EntelliGuard™ Messenger protection unit.

The interface consists of 7 analog and several digital channels representing actual power li ne

characteristics. The signals are injected directly into the Messenger A/D converters. This tests

the entire Entellisys System, excluding the CTs, the CT interface (burden resistors) inside the

Messenger, and the PTs.

Introduction 7

Page 7

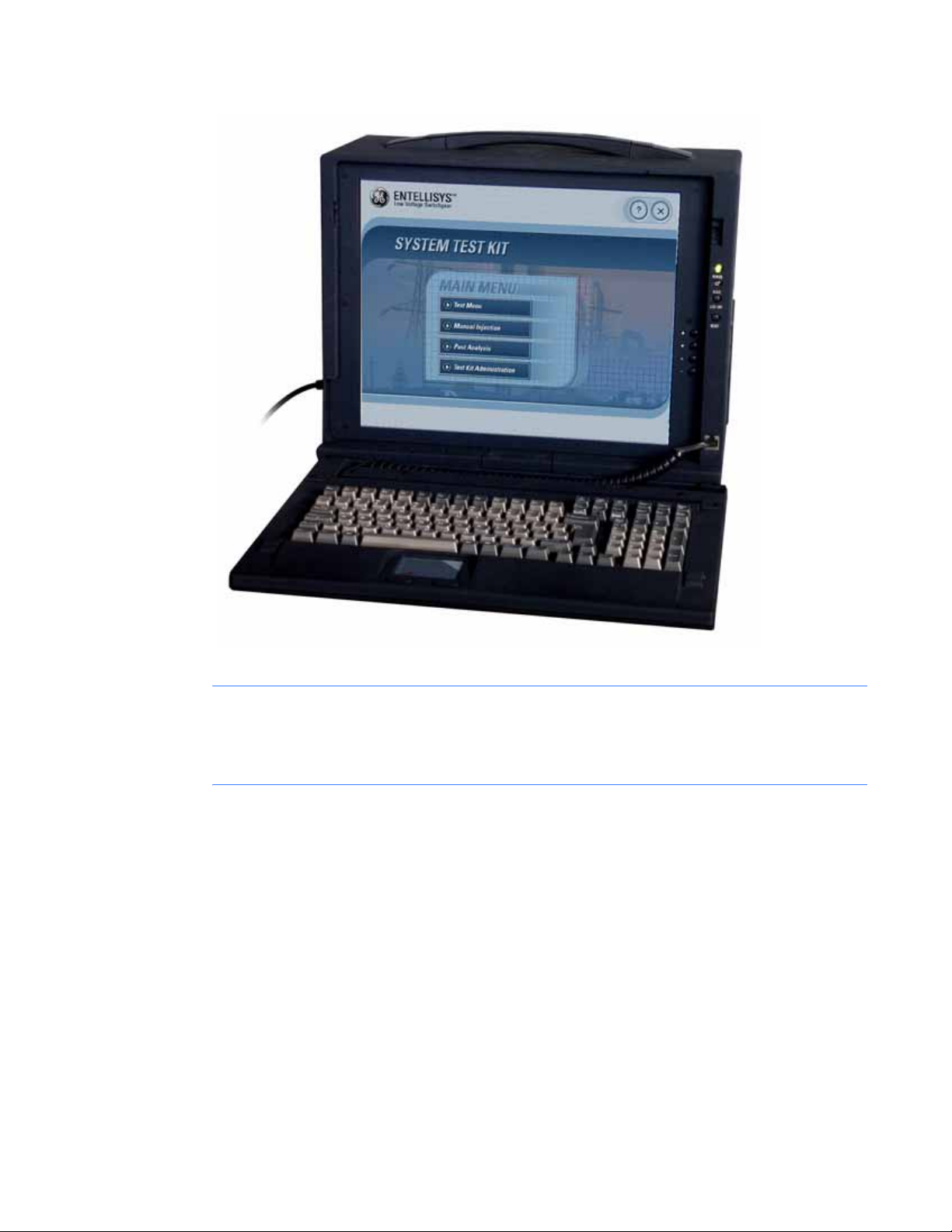

Figure 1-1 System Test Kit photograph

CAUTION: Tests conducted with the System Test Kit must be performed with the circuit

breaker de-energized and racked-out to the test position. The test inputs will supersede the

normal current and voltage inputs which disables normal protection, preventing response to

fault conditions.

System Test Kit8

Page 8

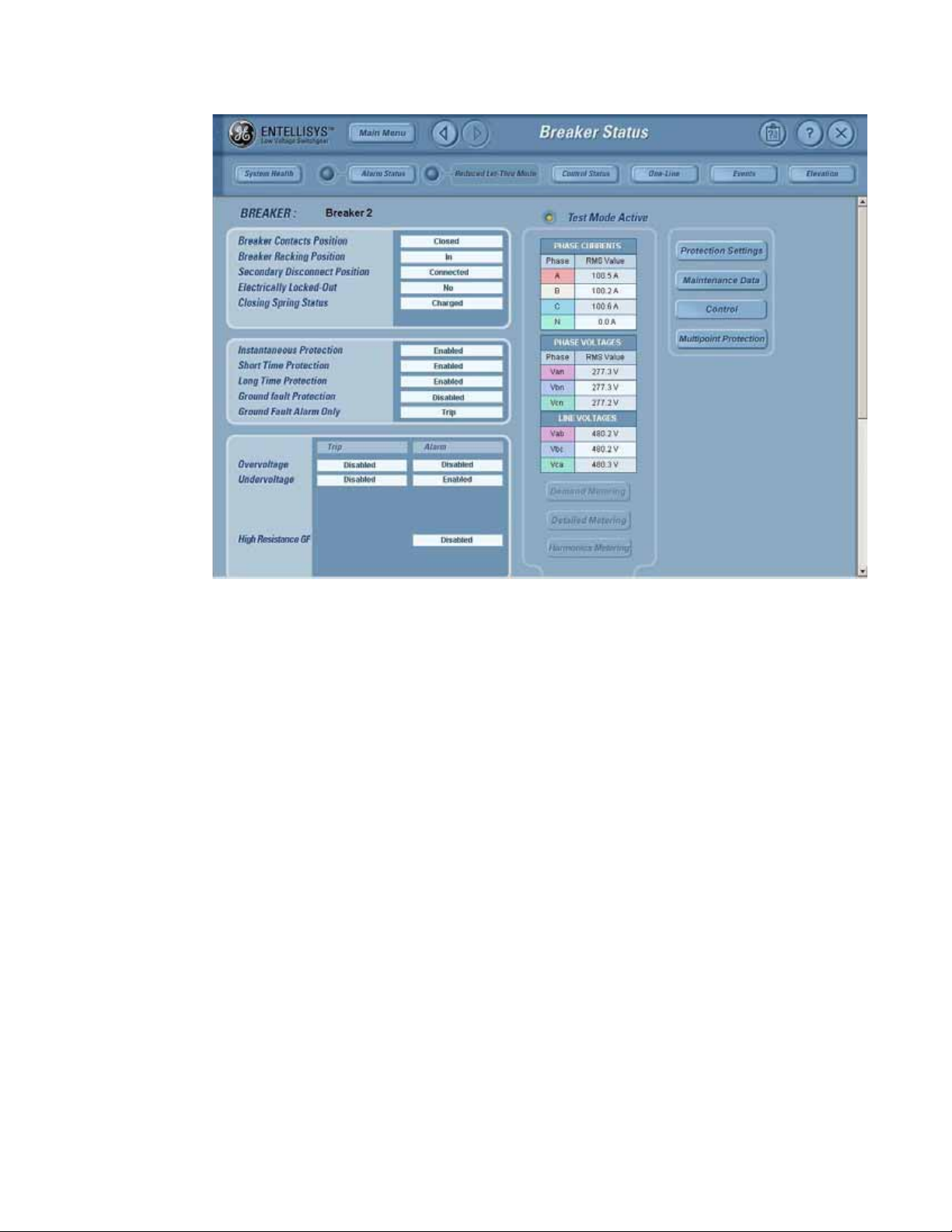

Figure 1-2 HMI screen showi ng circuit breaker in Test Mode

The HMI will indicate that the unit is in Test Mode. It will also display the output analog

waveforms in response trip test.

Introduction 9

Page 9

1.2 Test overview/architecture

The System Test Kit uses the method of low voltage injection to perform its tests. The test kit

drives these low level voltages (10V p-p) into individual test input s of the Messenger's A/D

converter. Basic protection scheme, Functional protection, and Single Point Relay protection of

the entire system can be tested using low voltage injection from the System Test Kit.

Figure 1-3 Entellisys system architecture with System Test Kit

System C onfiguration

System C onfiguration

Dow nload Link

Dow nload Link

USB

USB

CPU A CPU B

CPU A CPU B

HMI

HMI

System Interface

System Interface

E t h e r n e t S w itc h

E t h e r n e t S w itc h

System

System

Test Kit

Test Kit

USB

USB

DB-25

DB-25

DB-25

DB-25

Test C onnector

Test C onnector

Messenger

Messenger

CT CT

CTCT CTCT

CT

CTCT

Breaker

Breaker

Messenger

Messenger

CT CT

CTCT CTCT

CT

CTCT

Breaker

Breaker

M essenger Sw itchM essenger Sw itch

M essenger Sw itchM essenger Sw itchM essenger Sw itchM essenger Sw itch

M essenger

M essenger

CTCT

CTCTCT

CTCT

CTCT

Breaker

Breaker

Messenger

Messenger

CT CT

CTCT CTCT

CT

CTCT

Breaker

Breaker

PT’s

PT’s

System Test Kit10

Page 10

1.3 Test kit hardware/specs

All the digital signals given from the test kit and accepted from the test kit are active low TTL

signals.

Table 1-1 Actual System Test Kit output accuracy

Sl.No Parameter Accuracy

1. Voltage ±0.1%

2. Frequency ±0.05 Hz

3. Phase angle ±0.1

4. Time Stamping ±0.5 ms

Required accuracy for protection testing is based on the accuracy of Entellisys S ystem

Accuracy.

Table 1-2 System accuracy with the test kit

Sl.No Protection Accuracy

1. Current Protection 1X ±6.5%

2. Relay Protection ±6.5%

3. Ground Fault 0.2X ±2%

1.3.1 Test Unit PC

System Test Kit PC is a rugged Portable PC unit with multiple PCI slots. It uses two data

acquisition cards to generate required test signals for injecting for testing protection elements

in the Entellisys Low Voltage Switchgear system.

The test kit is entirely kiosked and runs on the Windows 2000 operating system.

1.3.2 Test kit power cord

The test kit power cord is designed with integr ated surge protection equipment to protect the

system from normal power anomalies.

Once the surge protector is triggered, it will be grounded (which can be detected by the surge

protector; the LED will be ON). Once this occurs, the power cord will need to be replaced.

NOTE: The power cord must be replaced with the same cord to ensure proper operation.

Replacement Power Cord: GE CAT# ETSTESTKITCBLSRG

Test kit hardware/specs 11

Page 11

1.3.3 Test connector (System Test Kit to EntelliGuard Messenger cable)

The test connector is a 25-pin DB Type connector used for injecting signals to/from the Test Kit

to the Messenger.

• Seven channels are analog outputs that represent three-phase voltages and currents plus a

neutral. These –10V to +10V sinusoidal analog outputs are injected directly into a

Messenger's A/D converter via the Messenger front panel. The test kit changes the waveform

characteristics of these sinusoids to test the different protection schemes.

NOTE: If the cable is lost or broken, it must be replaced with the same cable to ensure proper

operation.

Replacement “Test Connector” Cable: GE CAT# E TSTESTKITCBLMSR

1.3.4 USB-to-USB cable

The test kit communicates with the Entellisys Low Voltage HMI to download system

configuration, preventing the operator from entering it manually.

A USB-to-USB cable, running a peer-to-peer network communication bridge, is used between

the test kit and the HMI for communication. The USB-to-USB bridge arrives pre-configured in

both the HMI and the test kit. See HMI setup

on page 52 for configuration details.

To enable this communication, from the Test Kit Administration menu, enter the HMI IP

address in the HMI Setup window.

NOTE: Special USB drivers for the cable supplied are preinstalled on the HMI. If the cable is lost

or broken, it must be replaced with the same model.

Replacement USB to USB Cable: GE CAT# ETSTESTKITCBLUSB

System Test Kit12

Page 12

1.4 Getting started

1.4.1 Start up

Start the test kit by pushing the Power On button on the right-side panel.

After the test kit boots, the following startup screen will be displayed:

Figure 1-4 Start Up screen

The System Test Kit is kiosked to prevent users from exiting the program and editing the system

files and operating system. This provides added security to protect the system setup.

Press any key to continue.

Getting started 13

Page 13

1.4.2 Self Test

Each time the test kit is powered on, a Self Test is performed to verify the major components are

functioning properly. The following tests are performed:

• Memory test – checks the physical memory in the system. At least 20 MB of free memory

• Hardware configuration – checks the data acquisition card status. Two cards must be

• Test kit setup – checks the setup files and verifies the software and hardware version of the

• Ethernet connectivity – checks the Ethernet connectivity of the system to ensure the System

Figure 1-5 Self-Test screen

must be available after loading the application to ensure the system runs properly.

installed properly and have the proper device number.

test kit.

Configuration Download Link (USB-to-USB Network Bridge) is working properly.

The test kit will display the test being performed on the screen. If any errors are encountered,

the test kit will generate pop-up messages for the user regarding the type of error. Any issues

must be corrected and the unit restarted before continuing. See Troubleshooting

help diagnosing issues.

When the Self Test completes successfully, the Main Menu will be displayed.

System Test Kit14

on page 59 for

Page 14

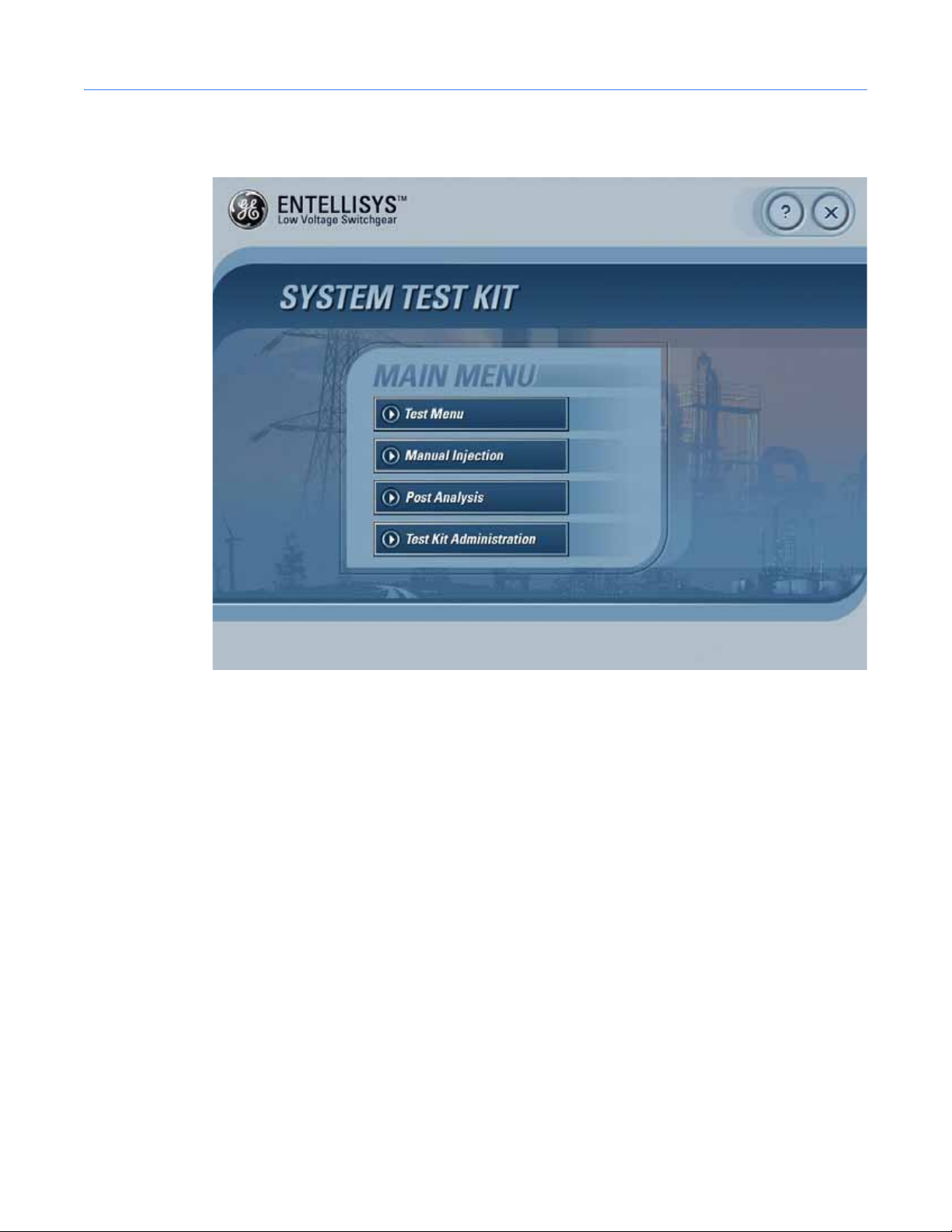

1.4.3 Main Menu

Figure 1-6 Main Menu screen

On the Main Menu, the following choices are provided:

Test Menu

This option lets the user download the settings either from the HMI or from the previously

downloaded settings.

Manual Injection

The Manual Injection screen can be used to inject the signals by manually setting the test kit.

The Manual Injection screen will pop out to accept the settings for the test kit.

Post Analysis

Provides access to the test kit log files for off-line analysis of the test results.

Test Kit Administration

This option allows the user to perform various tasks regarding the test kit setup.

Getting started 15

Page 15

1.4.4 General navigation

X Quit

Quit allows the user to quit from the application and shut down the system.

? Help

Clicking Help provides the user with help on the selected screen.

Tips

Moving the mouse cursor over the control provides tips for that control.

Short Cut Keys

Short cut keys are provided for the following controls:

F1 Pressing F1 will display help

F4 Main Menu

Ctrl F4 Back

F10 Quit the application

1.5 Download switchgear configuration

The test kit requires information about the switchgear lineup under test. For exa mple:

• Circuit breakers by name, for ease of identification

• For each circuit breaker:

• Circuit breaker frame size, CT rating, and PT rating

• Rating switch setting

• Protection options enabled

• Protection elements Pickup and Delay Band Settings

This data provides the operator valid selections when selecting tests, and provides the proper

output levels for the “Pre-Defined” Tests.

Once downloaded, this step can be avoided by using the “Last Download” information—so long

as no configuration or settings have changed.

NOTE: To ensure the test kit has the correct configuration, download the configuration rather

than using the “Last Download”.

System Test Kit16

Page 16

1.5.1 Direct Connect Download from HMI

Select this option to download the System Configuration from the HMI.

Before proceeding, connect the USB-to-USB cable between the HMI and the test kit. Figure 1-7

shows the USB port on the test kit. Note the white cable. Figure 1-8 shows the USB port on the

HMI. Once the cable is connected, click OK to continue.

Figure 1-7 USB port on test kit

Download switchgear configuration 17

Page 17

Figure 1-8 USB port on HMI

System Test Kit18

Page 18

Figure 1-9 shows the screens that will be encountered during the Direct Connect Download

from HMI.

Figure 1-9 Switchgear configuration download process

Download errors will be displayed for the following reasons:

• Settings are not available

• Communications are not established

• Communication is lost

Download switchgear configuration 19

Page 19

1.5.1.1 System Configuration Download Link communication

The test kit communicates with the HMI over the System Configuration Download Link. This link

is a USB-to-USB Network Bridge-Ethernet connection. The IP addresses are programmed by

default into the test kit and the HMI and should not be changed

these IP addresses are mismatched.

• Default HMI USB-to-USB Network Bridge IP address is 192.168.2.50.

• Default test kit USB-to-USB Network Bridge IP address is 192.168.2.25.

The HMI’s IP address must be set in the test kit. To verify this is set properly, from the HMI Setup

screen, go to the Test Kit Administration.

1.5.2 Last Download

Select this option to download the previously downloaded switchgear lineup configuration.

Figure 1-10 Process to download previous settings

. Download failure will result if

Care should be taken before deciding to use previously downloaded settings.

• Is this the same lineup that was downloaded previously?

• Has anything changed since the configuration was downloaded previously?

NOTE: Mismatch in configuration and/or settings will result in incorrect test results.

System Test Kit20

Page 20

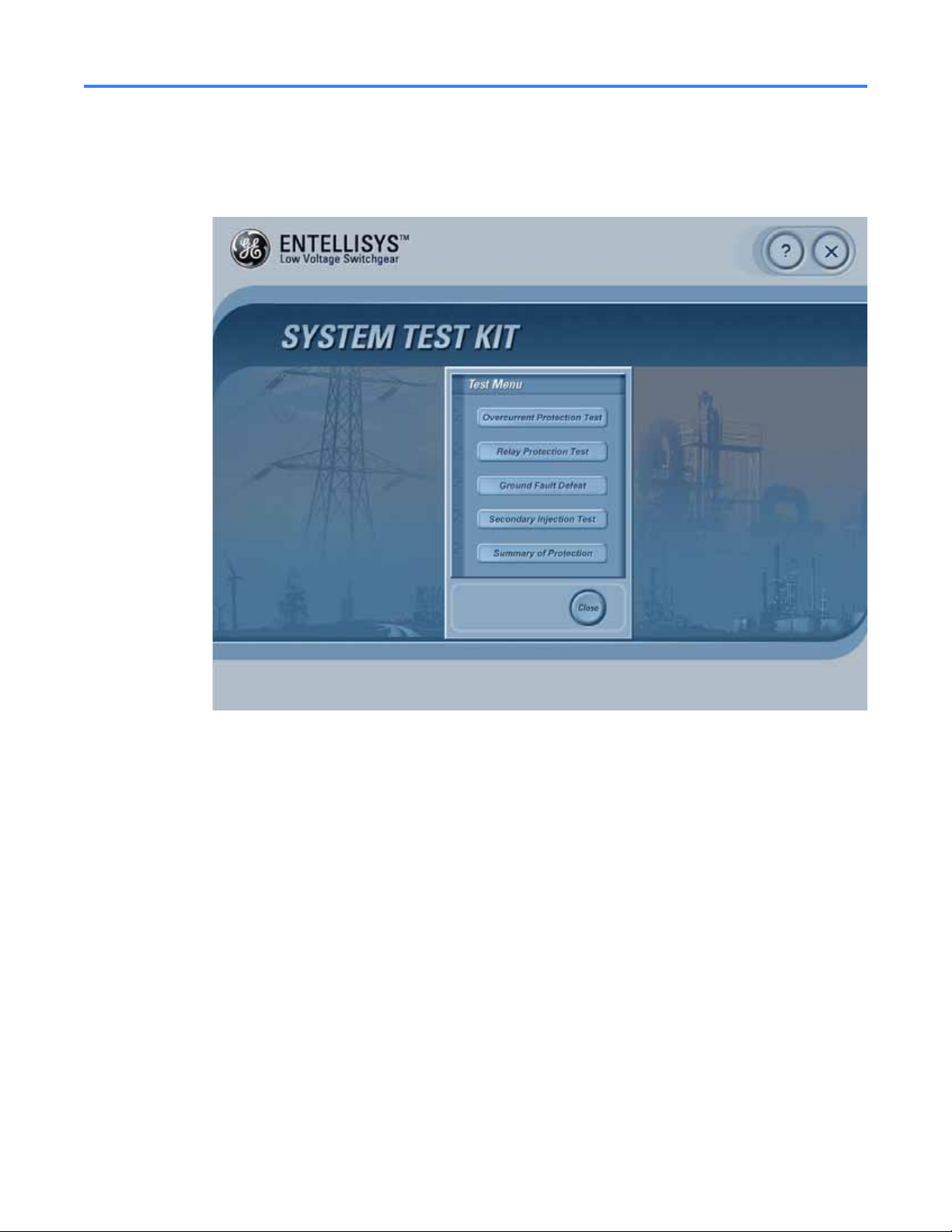

1.6 Test Menu

Once the switchgear configuration has been loaded, the Test Menu will display.

Figure 1-11 Test Menu

Below is a brief description of each of the tests:

Overcurrent Protection Test

Allows operator to perform Overcurrent Protection tests.

Relay Protection Test

Allows operators to perform Relay Protection tests.

Ground Fault Defeat

Allows operator to temporarily Defeat/Disable or Resume Ground Fault protection. This may be

required for Primary or Secondary injection testing outside the test kit.

Secondary Injection Test

Allows operator to temporarily suspend CT Compensation for Secondary Injection testing

outside the test kit.

Summary Of Protection

Provides the protection enabled at each circuit breaker.

Test Menu 21

Page 21

1.6.1 Overcurrent Protection Test

1.6.1.1 Functions

Tests various Overcurrent Protection functions. The functions must be optioned and enabled in

the system to perform the respective tests.

Long Time (LT) Overcurrent Protection

Verifies the long time overcurrent protection function for a circuit breaker in the system. It can

be performed as either a trip or no trip test. To test LT, the test kit injects a sum-of-squares

current value for any phase above the LT pickup setting. The result of the test is a trip time with

an accuracy of 10% of the expected trip time.

Short Time (ST) Overcurrent Protection

Verifies the short time overcurrent protection function for a circuit breaker in the system. The

test can be performed as either a trip or no trip test. To test ST, the test kit injects a

sum-of-squares current value for any phase above the ST pickup setting. The result of the test is

a trip time with an accuracy of 10% of the expected trip time.

Instantaneous (IOC) Overcurrent Protection

Verifies the instantaneous overcurrent protection function for a circuit breaker in the system.

The test can be performed as either a trip or no trip test. To test IOC, the test kit provides an

input current that exceeds the programmed IOC threshold. The result of the test is a trip time

with an accuracy of 10% of the expected trip time.

Ground Fault (GF) Protection

Verifies Ground Fault protection function for a circuit breaker in the system. The test can be

performed as either a trip or no trip test.

In a three-wire system, the test kit will provide three phase currents with vector sum greater

than the pickup threshold.

In a four-wire, WYE-system, the test kit will provide three phase currents and a neutral with

vector sum greater than the pickup threshold.

In either case, the result is a trip time with an accuracy of 10% of the expected trip time.

System Test Kit22

Page 22

1.6.1.2 Test methods

There are three test methods:

• Pre-Defined Test – Uses pre-defined fault levels for the test selected.

• User-Defined – Allows the operator to set fault levels for the test selected.

• Autom atic Trip time Curve Test – Automatic Trip Time Curve will automatically compute the

expected trip time curve for the circuit breaker under test depending on Protection elements

enabled, Rating Switch, and CT rating of the circuit breaker connected. This will then

automatically inject low voltage levels at different test points and graph the curve with

expected and observed tested points.

The test kit requires the actual circuit breaker settings to compute the required fault levels and

expected trip time for the selected protection test. The circuit breaker settings are read by the

test kit during the Switchgear Configuration Download process described in Download

switchgear configuration on page 16.

1.6.1.3 Pre-Defined Overcurrent Protection Test

Tests the various Overcurrent Protection functions using pre-defined fault levels for ease of use.

Figure 1-12 Pre-Defined Over Current Protection Test

Test Menu 23

Page 23

Quick Test Guide

1. Enter Operator Name and Test Description.

2. Select a Circuit Breaker.

3. Select Breaker Trip or No Trip Test.

4. Select Ground Fault Defeat (or not) depending on Fault Phase(s) desired.

5. Select the Test Selection to perform.

6. Select the Fault Phase.

7. Click “Perform Test”.

Test setup field description

Table 1-3 Test setup field description

Test Name Unique test identifier, assigned by the test kit, generated by the type of test

selected and the date the test is performed.

Operator Operator name entered by the Test Operator. (20-character limitation)

Test Description Test description entered by the operator, t o be st ored in the log file.

(150-character limitation)

Breaker Selection Circuit breaker to be tested, selected by the operator.

Compartment # Displays the Compartment number of the circuit breaker selected.

Breaker Trip Specifies whether the test will physically trip the circuit breaker.

; – Circuit breaker will Trip

– Circuit breaker will not Trip

Ground Fault Allows users to temporarily Defeat Ground Fault during the test, or to

Resume/Run Ground Fault as normal during the test. Ground Fault must be

defeated for single phase tests—otherwise a trip on Ground Fault will occur.

; – GF will Resume/Run as Normal.

– GF will be temporarily defeated during the test period.

Note: After the test has concluded, Ground Fault will resume automatically.

This feature is enabled only when Ground Fault is enabled in the selected

circuit breaker.

Breaker Setting Table/Tabs Displays the actual settings for the circuit breaker selected. This is for

information only.

Test Selection Specifies the type of test to perform. Operator selectable.

Only enabled protection functions for the selected circuit breaker are

provided in drop-down.

Pre-Defined Settings Displays the pre-defined fault levels to be injected for the test and circuit

breaker selected. Levels for Prefault, Fault, and Post faults are described in

Table 1-4.

These values are determined with respect to the circuit breaker selected and

its protection settings.

System Test Kit24

Page 24

Table 1-3 Test setup field description

Fault Phase The phase(s) for fault injection. Operator selectable.

Options for LT, ST, IOC Test Selection is: Phase A, Phase B, Phase C, Phase A &

B, Phase B & C, Phase C & A, Phase A, B & C

Option for GF Test Selection: Phase A, Phase B, Phase C, and Neutral

Pre-defined values for Overcurrent Protection tests

Table 1-4 Pre-defined values for Overcurrent Protection tests

Type of Test Prefault

(for all Phases)

Long Time 80.00% of LT Pickup 135.00% of LT Pickup 0% of LTPickup

Short Time 80.00% of ST Pickup 110.00% of ST Pickup 0% of LTPicku p

Instantaneous 80.00% of IOC Pickup 110.00% of IOC pickup 0% of LTPickup

Ground Fault 10% of CT 110.00% of GF Pickup 0% of GF Pickup

Fault

(for selected Phases)

Post Fault

(for all Phases)

Test results

Table 1-5 Test results

Time Stamp Table Provides a time stamp history of the Breaker Status (Open or Closed) and the

Breaker Actuation device involved in the trip (Flux Shifter or Shunt Trip).

Expected Trip Time Expected trip time automatically calculated from the pickup & delay band

settings and circuit breaker clearing time.

Observed Trip Time Observed trip time displayed after the test is performed.

Test Summary LED Specifies the test results by comparing the observed trip time with the expected

trip time.

Green Successful (within +/– 20% of expected time)

Red Unsuccessful

Gray Test Aborted

Test settings and results are saved to the hard drive with the report name as Test Name_Time.

Test Menu 25

Page 25

1.6.1.4 User-Defined Overcurrent Protection test

Provides operators with a more advanced method for Overcurrent Protection testing. Operators

set the Pre-Fault, Fault, and Post-Fault levels for the circuit breaker under test.

Figure 1-13 User-Defined Overcurrent Protection test

Quick Test Guide

1. Enter Operator Name and Test Description.

2. Select a Breaker.

3. Select Breaker Trip or No Trip Test.

4. Select Ground Fault Defeat or Resume depending on Fault Phase(s) desired.

5. Set the required fault levels.

a. Select Level (Pre-Fault, Fault, or Post-Fault).

b. Set the % of CT & Phase Angle for Phase IA, IB, IC, and Neutral.

c. Repeat for each Level.

6. Set the Pre-Fault, Fault, and Post-Fault times.

7. Click Apply to save the test param eters.

8. Click Perform Test.

System Test Kit26

Page 26

Test setup field description

Table 1-6 Test setup field description

Test Name Unique test identifier, assigned by the test kit, generated by the type of test

selected and the date the test is performed.

Operator Operator name entered by the Test Operator. (20-character limitation)

Test Description Test description entered by the operator, t o be stored in the log file.

(150-character limitation)

Breaker Selection Circuit Breaker to be tested, selected by the operator.

Compartment # Compartment number of the circuit breaker selected.

Breaker Trip Specifi es whether or not the test will physically trip the circuit breaker.

; – Circuit Breaker will Trip

– Circuit Breaker will not Trip

Ground Fault Allows users to temporarily Defeat Ground Fault during the test, or to

Resume/Run Ground Fault as normal during the test. Ground Fault must be

defeated for single phase tests—otherwise a trip on Ground Fault will occur.

; – GF will Resume/Run as Normal.

– GF will be temporarily defeated during the test period.

Note: After the test has concluded, Ground Fault will resume automatically.

This feature is enabled only when Ground Fault is enabled in the selected

circuit breaker.

Breaker Setting Table/Tabs Displays the actual settings for the circuit breaker selected. This is for

information only.

Level Allows the user to set the required levels for the corresponding test

(Pre-Fault, Fault, and Post-Fault).

% of CT Percentage of the CT Rating to be injected for a given input (IA, IB, IC, and

optionally Neutral)

Max values:

Pre-Fault: 10% of CT

Fault: 28x CT

Post-Fault: 10% of CT

Phase Angle Phase angle to be injected. (Range between –360° to +360°)

Expected Trip Module Type of trip that should be observed, calculated from the operat or-entered

fault levels.

Expected Trip Time Trip time that should be observed, calculated from the operator-entered

fault levels.

Pre-Fault Time The time duration Pre-Fault levels will be injected from test kit. Operator

selectable.

Test Menu 27

Page 27

Table 1-6 Test setup field description

Fault Time The time Fault levels will be injected. Operator selectable.

Post-Fault Time The time duration Post-Fault levels will be injected. Operator selectable.

User-Defined Test Settings Displays the curr en ts and v o ltage s t hat will b e inj ected, ca lcul ated f r om t he

operator's selections (for the Fault Level currently displayed).

Test results

Prior to a test the “Test Results” button will be grayed out.

After a test is performed, the “Te st Results” button will display. Once pressed, the following is

displayed:

Figure 1-14 Overcurrent Protection Test Results

System Test Kit28

Page 28

Table 1-7 Test results

Level User-Defined Test Settings are displayed separately for each Level

(Pre-Fault, Fault, and Post-Fault). Use the pull-down menu to select the Level

for the corresponding User-Defined Test Settings.

User-Defined Test Settings Summarizes the test settings injected for the level shown.

Test Results Once the test is performed, it displays the time sequence of circuit breaker

status and the device that actuated the circuit breaker (Shunt Trip or Flux

Shifter).

Expected Trip Time Expected trip time automatically calculated from the pickup, delay band

settings, and circuit breaker clearing time.

Observed Trip Time Observed trip time displayed after the test is performed.

Test Summary LED Specifies the test results by comparing the observed trip time with the

expected trip time.

Green Successful (within +/– 20% of expected time)

Red Unsuccessful

Gray Test Aborted

Test settings and results are saved to the hard drive with the report name as Test Name_Time.

1.6.1.5 Automatic Trip Time Curve Test

The automated trip curve test is a test that can automatically verify long time, short time,

instantaneous, and ground fault functions based on the settings (ST, LT, IOC, frame size, etc.).

The test kit will inject signals and measure the amount of time delay before the circuit breaker

trips. It would then compare the timing to the circuit breaker trip-time curve to pass or fail each

protection function. Trip time of the circuit breaker will determine the Pass or Fail for the

protection test. It is a No Trip test that will not trip the circuit breaker.

Test Menu 29

Page 29

Figure 1-15 Automatic trip time curve test

Quick Test Guide

1. Enter Operator Name and Test Description.

2. Select a Breaker.

3. Select Breaker Trip or No Trip Test.

4. Select Ground Fault Defeat or Resume depending on Fault Phase(s) desired.

5. Select the Curve Type.

6. Select the Fault Phase.

7. Click Perform Test.

Test setup field description

Table 1-8 Test setup field description

Test Name Unique test identifier , a ss ig ne d by the test kit, generated by the type of

test selected and the date the test is performed.

Operator Operator name entered by the Test Operator. (20-character limitation)

Test Description Test description entered by the operator, to be stored in the log file.

(150-character limitation )

Breaker Selection Circuit Breaker to be tested, selected by the operator.

Compartment # Compartment number of the circuit breaker selected.

System Test Kit30

Page 30

Table 1-8 Test setup field description

Breaker Trip Specifies whether the test will physically trip the circuit breaker.

; – Circuit Breaker will Trip

– Circuit Breaker will not Trip

Ground Fault Allows users to temporarily Defeat Ground Fault during the test, or to

Resume/Run Ground Fault as normal during the test. Ground Fault must

be defeated for single phase tests—otherwise a trip on Ground Fault will

occur.

; – GF will Resume/Run as Normal.

– GF will be temporarily defeated during the test period.

Note: After the test has concluded, Ground Fault will resume

automatically.

This feature is enabled only when Ground Fault is enabled in the selected

circuit breaker.

Breaker Setting Table/Tabs Displays the actual settings for the circuit breaker selected. This is for

information only.

Select Curve Type Select one of two types of curves to generate—either “Overcurrent Trip

Time Curve” or “Ground Fault Trip Time Curve”. Operator selectable.

Fault Phase The phase(s) for fault injection. Operator selectable.

Options for LT, ST, IOC Test Selection: Phase A, Phase B, Phase C, Phase A &

B, Phase B & C, Phase C & A, Phase A, B & C

Option for GF Test Selection: Phase A, Phase B, Phase C, and Neutral

Automatic Trip Time Settings This table displays the amount of test kit voltages that will be inje cted with

respect to the calculated trip time curve.

How trip time curve generated

For Overcurrent Protection test, three LT Points, three ST points, and two IOC Points are tested

for generating the Automatic Trip time curve. Overcurrent test points are considered as

multiples of LT pickup.

For Ground Fault Protection test, four points are tested when GFI2T curve is enabled and two

points when disabled. Ground Fault test points are considered in multiples of GF pickup.

The setup required for Overcurrent Protection tests is based on Protection bits enabled.

Test Menu 31

Page 31

Test Results

The Test Results tab will be enabled when all the test points are tested. The test kit will display

the Expected, Observed, and the % error in the table.

Figure 1-16 Automatic Trip Time Test results

1.6.2 Relay Protection Test

The Relay Protection Test screen allows the user to perform various tests for Relay protection

functionality based on the options enabled in the syst em. Possible tests are as follows:

• Over Frequency Test

• Under Frequency Test

• Overvoltage Test

• Undervoltage Test

• Phase Lo ss

• Power Reversal

• High Current Alarm

Over Frequency

Sets the frequency above the set point for the specified time delay.

Under Frequency

Sets the frequency below the set point for the specified time delay.

System Test Kit32

Page 32

Overvoltage

Injects a phase voltage greater than the set point for the specified time delay. There are three

options:

• One phase is above the pickup threshold

• Two phases are above the pickup threshold

• Three phases are above the pickup threshold

Undervoltage

Injects a phase voltage less than the set point for the specified time delay. There are three

options:

• One phase is below the pickup threshold

• Two phases are below the pickup threshold

• Three phases are below the pickup threshold

Phase Loss

Injects a negative-phase-sequence voltage greater or less than the nominal 1X value of the

system voltage.

Power Reversal

Injects waveforms that have the direction of the power reversed and the magnitude of the

power greater than the set point for the specified time delay.

High Current Alarm

Injects waveforms that have currents greater than the programmed threshold for a time

greater than the programmed delay to generate high current alarm.

NOTE: For the High Current Alarm test only, the test kit will not be able to provide any Test

Results because the test kit does not receive any feedback from the Messenger. To verify the

results, the operator must check for a High Current Alarm event in the Entellisys HMI, Sequence

of Events screen.

Two test methods are provided for Relay Protection:

• Pre-Defined Test – uses pre-defined fault levels for the test selected.

• User-Defined – allows the operator to set fault levels for the test selected.

Test Menu 33

Page 33

1.6.2.1 Pre Defined Test

Tests the various Relay Protection functions using pre-defined fault levels for ease of use.

Figure 1-17 Pre-Defined Relay Protection Test

Quick Test Guide

1. Enter Operator Name and Test Description.

2. Select a Breaker.

3. Select Breaker Trip or No Trip Test.

4. Select Ground Fault Defeat or Resume depending on Fault Phase(s) desired.

5. Select the Test Selection to perform.

6. Select the Fault Phase.

7. Click Perform Test.

System Test Kit34

Page 34

This screen has the following selections and controls available. A user can perform either trip or

no trip single point protection relay function tests at the Messenger.

Table 1-9 Selecti ons and controls

Test Name Unique test identifier, assigned by the test kit, generated by the type of test

selected and the date the test is performed.

Operator Operator name can be entered here for the Reports. (20-character limitation)

Test Description Operator enters test description to be stored in the log file. (150-character

limitation)

Breaker Trip Specifies whether the test will physically trip the circuit breaker.

; – Circuit Breaker will Trip

– Circuit Breaker will not Trip

Ground Fault Allows users to temporarily Defeat Ground Fault during the test, or to

Resume/Run Ground Fault as normal during the test. G round Fault must be

defeated for single phase tests—otherwise a trip on Ground Fault will occur.

; – GF will Resume/Run as Normal.

– GF will be temporarily defeated during the test period.

Note: After the test has concluded, Ground Fault will resume automatically.

This feature is enabled only when Ground Fault is enabled in the selected

circuit breaker.

Compartment # Switchgear compartment number of the circuit breaker selected for testing.

Breaker Selection The circuit breaker to perform the test.

Test Selection Test Selection will let the type of protection fault be generated.

Breaker Settings Circuit Breaker settings will display the cu rrent sett ings of that se lected circuit

breaker.

Pre-defined Settings This table displays the amount of test kit voltages that will be injected with

respect to the present settings of the selected c ircuit breaker.

Fault Phase Requirement Displays the present Fault Phase Requirement for the selected Relay

protection:

One phase is above the pickup threshold.

Two phases are above the pickup threshold.

Three phases are above the pickup threshold.

Breaker Settings This will display the current circuit breaker settings on which the test will be

performed.

Overvoltage Settings This will display the current overvoltage settings of the system.

Undervoltage Settings This will display the current undervoltage settings of the system.

Over Frequency Settings Over Frequency settings will be displayed depending on the setting from

CCPU.

Test Menu 35

Page 35

Table 1-9 Selecti ons and controls

Under Frequency Settings Under Frequency settings will be displayed depending on the settings from

CCPU.

Phase Loss settings Phase Loss settings will be displayed depending on the settings from CCPU.

Power Reversal Power Reversal settings will be displayed depending on the settings from

CCPU.

High Current High Current Settings will be displayed depending on the settings from CCPU.

Pre-Defined Settings Depending on the current Messenger settings, Selected Level, Phase selected,

Frequency or Multiplier value IA, IB, IC, IN, VA, VB, VC will be calculated and

displayed on the screen.

Test results

Table 1-10 Test results

Time Stamp Table Once the test is performed, it displays the time stamping of circuit breaker

status and the device that actuated the circuit breaker (Flux Shifter or Breaker

Open).

Expected Trip Time Expected trip time automatically calculated from the pickup, delay band

settings, and circuit breaker clearing time.

Observed Trip Time Observed trip time displayed after the test is performed.

Test Summary LED Specifies the test results by comparing the observed trip time with the

expected trip time.

Green Successful (within +/– 20% of expected time)

Red Unsuccessful

Gray Test Aborted

Table 1-11 Default values for pre-defined relay protection tests

Type of Test Prefault Fault Post Fault

Over Frequency System Frequency Pickup *1.01 System Frequency

Under Frequency System Frequency Pickup * 0.99 System Frequency

Overvoltage 100% of PT P ickup * 1.05 96% of PT

Undervoltage 100% of PT Pickup * 0.95 100% of PT

Phase Loss 0% Pickup + 1% 0%

Power Reversal 10 KW Positive Power Pickup * 1.1 Reverse Power 10 KW Positive Power

High Current Pickup * 0.5 Pickup * 1.1 Pickup * 0.5

System Test Kit36

Page 36

Table 1-12 Phase Selectors for pre-defined relay protection test

Type of Test Phases Selected

Over Frequency All Phases

Under Frequency All Phases

Overvoltage Depends on the Phase Requirement in HMI

Undervoltage Depends on the Phase Requirement in HMI

Phase Loss Phase VC

Power Reversal Phase IA, IB, IC

High Current All Phases

1.6.2.2 User Defined Test

This test method allows the operator to change the protection parameters and perform the test

according to the user-intended settings.

Figure 1-18 User-defined Relay Protection Test

Test Menu 37

Page 37

Quick Test Guide

1. Enter Operator Name, and Test Description.

2. Select a Breaker.

3. Select Breaker Trip or No Trip Test.

4. Select Ground Fault Defeat or Resume depending on the test desired.

5. Set the required fault levels:

a. Select Level (Pre-Fault, Fault, or Post-Fault).

b. Set the % Multiplier or KW or Frequency to change the Voltage or Phase or Frequency of

Current signals (IA, IB, IC, & IN) or Voltage signals (VA, VB, VC) based on the selected

protection test.

c. Repeat for each level.

6. Set the Pre-Fault, Fault, and Post-Fault times.

7. Click Apply to save the test param eters.

8. Click Perform Test.

Setup

Table 1-13 Setup

Test Name Unique test identifier, assigned by the test kit, generated by the type of

test selected and the date the test is performed.

Operator Operator name can be entered here for the reports. (20-character

limitation)

Test Description Operator enters test description to be stored in the log file. (150-character

limitation)

Breaker Selection Circuit Breaker selection on which the signals will be injected.

Compartment # Compartment number of the system will be displayed depending on the

circuit breaker selected for testing.

Breaker Trip Specifies whether the test will physically trip the circuit breaker.

; – Circuit Breaker will Trip

– Circuit Breaker will not Trip

Ground Fault Allows users to temporarily Defeat Ground Fault during the test, or to

Resume/Run Ground Fault as normal during the test. Ground Fault must

be defeated for single phase tests—otherwise a trip on Ground Fault will

occur.

; – GF will Resume/Run as Normal.

– GF will be temporarily defeated during the test period.

Note: After the test has concluded, Ground Fault will resume

automatically.

This feature is enabled only when Ground Fault is enabled in the selected

circuit breaker.

System Test Kit38

Page 38

Table 1-13 Setup

Breaker Settings This will display the current circuit breaker settings on which the test will

be performed.

Overvoltage Settings This will display the current overvoltage settings of the system.

Undervoltage Settings This will display the current undervoltage settings of the system.

Over Frequency Settings Over Frequency settings will be displayed depending on the setting from

CCPU.

Under Frequency Settings Under frequency settings will be displayed depending on the settings from

CCPU.

Phase Loss settings Phase Loss settings will be displayed depending on the settings from

CCPU.

Power Reversal Power Reversal settings will be displayed depending on the settings from

CCPU.

High Current High Current Settings will be displayed depending on the settings from

CCPU.

User-defined Settings This table displays the amount of test kit volta ges that will be injected with

respect to the settings made by the operator.

Pre-Fault Time This will be the time set for injecting the set pre-fault values.

Expected Trip Time Trip time is calculated automatically from the pickup and the delay band

settings. Entering Offset timing will prolong the output of the test kit for

that duration.

Post-Fault Time This will be the time set for injecting the set Post-Fault values.

Level Level selection allows the user to set the required levels for the

corresponding test. Based on the selected protection test. Currents IA, IB,

IC, IN or Voltage signals V A, VB, VC along with phase a ngle can be modified

using this selection.

Expected Trip module Expected Trip module will display the type of trip that will happen when

the fault levels for protection test are set.

Test Results Test Results will display the current results after performing the test. This

button will be grayed out if the test is aborted.

Apply Apply will save the current settings to the selected Messenger.

Default Default will set all the curren t s e tt in gs for fault generation to default level s.

Test Menu 39

Page 39

Table 1-14 Default values for user-defined relay protection tests

User-Defined Frequency / Multiplier / KW Range

Prefault Fault Post Fault

Over Frequency 50 Hz – 60 Hz

0.1 Hz increment

Under Frequency 50 Hz – 60 Hz

0.1 Hz increment

Overvoltage 96% to 104%

0.5% increment

Undervoltage 96% to 104%

0.5% increment

Phase Loss 0% to 7%

1% increment

Power Reversal 0 to 100 KW

10 KW increment

High Current 0% to 100%

5% increment

50 Hz – 70 Hz

0.1 Hz increment

44 Hz – 60 Hz

0.1 Hz increment

104% to 132%

0.5% increment

47.5% to 95%

0.5% increment

7% to 51%

1% increment

0 to 1000 KW

10 KW increment

45% to 205%

5% increment

50 Hz – 60 Hz

0.1 Hz increment

50 Hz – 60 Hz

0.1 Hz increment

96% to 104%

0.5% increment

96% to 104%

0.5% increment

0% to 7%

1% increment

0 to 100 KW

10 KW increment

0% to 100%

5% increment

System Test Kit40

Page 40

1.6.2.3 Relay Protection Test Results screen

The Relay Protection Test Results screen will display the results for the tests performed using

the user-defined tests.

Figure 1-19 Relay protection test results screen

Table 1-15 Selections and controls

Level Select the fault level to display the test settings.

User-Defined Test Settings Summarizes the test performed at the level shown.

Test Results Once the test is performed, it displays the time sequence of circuit breaker

status and the device that actuated the circuit breaker (Shunt Trip or Flux

Shifter).

Expected Trip Time Expected trip time automatically calculated from the pickup, delay b and

settings, and beaker clearing time.

Observed Trip Time Observed trip time displayed after the test is performed.

Test Summary LED Specifies the test results by comparing the observed trip time with the

expected trip time.

Green Successful (within +/– 20% of expected time)

Red Unsuccessful

Gray Test Aborted

Test settings and results are saved to the hard-drive with the report name as TestNumber_Time.

Test Menu 41

Page 41

1.7 Ground Fault Defeat

Performing single phase tests may unintentionally trigger a Ground Fault trip in circuit breakers

with Ground Fault protection enabled. This may not be desired when testing other protection

functions (e.g., short time, single phase test).

The Ground fault defeat screen allows the operator to “Defeat” or suspend Ground Fault

protection temporarily for external Secondary or Primary Injection—single phase testing

without Ground Fault trips.

Only circuit breakers with Ground Fault enabled are eligible for this. If GF is disabled, the Breaker

and selection box will be grayed out.

NOTE: The test kit connector must be attached to the desired Messenger/circuit breaker to

defeat Ground Fault.

Once the test connector is removed from the Messenger, the Ground Fault protection function

resumes as normal.

Figure 1-20 Ground fault defeat screen

System Test Kit42

Page 42

1.7.1 Setup

Circuit Breaker Name ; Resume GF will Resume/Run as normal.

Circuit Breaker Name Defeat GF will be temporarily defeated for the circuit breaker

specif ied while the test kit's test connector is physically

connected to the Messenger.

Ground Fault Defeat 43

Page 43

1.8 Summary of Protection

The Summary of Protection screen displays the list of circuit breakers in the system. Also

displayed are the protection elements enabled for each circuit breaker to be used as a

reference for the operator. The test kit will not allow tests for a protection function that is not

enabled.

Figure 1-21 Summary of Protection

System Test Kit44

Page 44

1.9 Manual Breaker Injection

The Manual Breaker Injection feature allows the operator to inject currents and v oltages without

knowledge of the Switchgear conf iguration.

Operators must enter the configuration of the circuit breaker under test and must calculate the

levels required to generate the expected trip conditions.

NOTE: This feature is for the advanced operator who knows the configuration of the circuit

breaker under test, and knows what levels to inject to test the desired protection functions.

Figure 1-22 Manual Breaker Injection

Quick Test Guide

1. Select the Frame Rating of the circuit breaker.

2. Select the CT rating.

3. Select the Rating Switch.

4. Select the PT rating of the system.

5. Enter the Test Description.

6. Enter the Operator name.

7. Select the Breaker Selection for Trip or Not Trip operation.

Manual Breaker Injection 45

Page 45

1.9.1 Setup

8. Select the Ground Fault Defeat or Resume depending on the Fault Level test required.

9. Enter the Frequency of the test kit output.

10. Enter the Breaker connection Forward or Reverse direction.

11. Enter the desired Voltage and Phase angle for Voltage phases.

12. Enter the desired Current and Phase angle for Current phases.

13. Enter the Test time for the test signals to be injected.

14. Press Perform test to perform the test.

Table 1-16 Setup

Frame Rating Select Frame Rating.

CT Rating Select CT Rating.

Rating Switch Select Rating Switch.

PT Rating Select PT Rating.

Test Name Unique test identifier, assigned by the test kit, generated by the type of

test selected and the date the test is performed.

Test Description Lets the user enter the Test Description (150-character limitation)

Operator Let the user enter the operator name (20-character limitation)

Breaker Trip Specifies whether the test will physically trip the circuit breaker.

; – Circuit Breaker will Trip

– Circuit Breaker will not Trip

Ground Fault Allows users to temporarily Defeat Ground Fault during the test , or t o

Resume/Run Ground Fault as normal during the test. Ground Fault

must be defeated for single phase tests—otherwise a trip on Ground

Fault will occur.

; – GF will Resume/Run as Normal.

– GF will be temporarily defeated during the test period.

Note: After the test has concluded, Ground Fault will resume

automatically.

This feature is enabled only when Ground Fault is enabled in the

selected circuit breaker.

Maximum Test Voltage Displays Maximum Test Voltage that can be set for testing from

Manual Injection.

Maximum Test Current Displays Maximum Test Current that can be set for testing from

Manual Injection.

System Test Kit46

Page 46

Table 1-16 Setup

Frequency Frequency of the Signal to be injected.

Breaker Connection Flow current Forward / Reverse connected circuit breakers.

Voltage Inputs Inputs for Voltage Phases.

Current Inputs Inputs for Current phases.

Test Settings for Fault Generation Display of Current and Voltage settings.

Test Results Once the test is performed, it displays the time stamping of circuit

breaker status and the device that actuated the circuit breaker (Flux

Shifter or Breaker Open).

Test Time Time entry for test kit execution.

1.9.2 Manual circuit breaker injection input range

Table 1-17 Manual circuit breaker injection input range

Parameter Range

Voltage 0 to 2x PT Rating Volts

Current 0 to 28x CT Rating Amps

Phase Angle –360° to +360°

Test Time 0.5 to 17000 secs

Manual Breaker Injection 47

Page 47

1.10 Post Analysis Selection screen

The Post Analysis feature allows users to analyze test results.

Users can generate reports and save to a USB Memory Stick. The reports are in HTML format.

NOTE: Upon exiting the Post Analysis screen, the USB drive will automatically eject. Users must

re-insert the USB Memory stick before generating the next report.

1.11 Test Reports

System Test Kit Reports can be generated from the Post Analysis screen. Depending on the type

of test for which the reports are generated, the output settings will change in the report.

All the reports are HTML reports and it will be generated on the USB Memory stick.

Following are the fields available in the Test Reports:

Table 1-18 Fields available in the test reports

General Test Information

Test Name Uniquely identified test kit-assigned name.

Operator Name Operator name that was entered while performing test.

Test Description Description of the test entered during testing.

Breaker Settings Displays the circuit breaker settings depending on the type of test for which

the report was generated. See Table 1-19 for the protection settings that will

display with respect to the test.

Breaker Name Name of the circuit breaker under test.

Compartment # Compartme nt number of the circuit breaker.

Frame Rating Prints the Frame rating of the circuit breaker.

CT Rating Prints the CT rating of the circuit breaker.

Rating Switch Prints the Rating switch value.

PT Rating Outputs the PT rating value.

Test Settings

Pre-Fault Settings All the Pre-Fault settings will be reported.

Fault Settings All the Fault settings that were injected during Fault time will be displayed.

Post-Fault Settings All the Post-Fault settings that were injected during post-fault time will

display.

System Test Kit48

Page 48

Table 1-18 Fields available in the test reports

Test Results

Trip Time Information Displays all the Trip time Information.

Pre-Fault Time Time for which the Pre-Fault signals are injected.

Expected Trip time Expected trip time for the test.

Post-Fault Time Time for which the Post-Fault signals are injected.

Observed Trip time Observed Trip time for the test.

Digital Input Time Stamping Time Stamping for Digital inputs.

Comments Comments that are entered by the user while generating reports.

Prepared by This is an empty field given for the operator to manually sign after report

generation.

Date Date is the report generated date.

Circuit Breaker Settings in report for Protection Test

Table 1-19 Circuit Breaker settings in report for Protection Test

LT Protection Test

Pickup setting Long time pickup setting.

Delay setting Delay band setting.

Short Time Protection Test

Status ST Protection enabled or disabled condition.

Pickup Setting Pickup setting of Short time protection.

I2T Status Inverse trip time enabled status.

Delay setting Delay setting of Short time protection.

Ground fault

Status GF Protection Enabled or Disabled condition.

Pickup Setting Pickup setting of Short time protection.

I2T Status Inverse trip time enabled status.

Delay setting Delay setting of Short time protection.

IOC Protection Test

Status Enabled or Disa bled status of the IOC Protection.

Pickup Setting Pickup setting of IOC.

Test Reports 49

Page 49

Table 1-19 Circuit Breaker settings in report for Protection Test

Over Frequency

Status Protection enabled condition.

Pickup Setting Pic kup Setting of the OF protection.

Delay Setting Prints Delay Setting of OF protection.

Under Frequency

Status Protection enabled condition.

Pickup Setting Pic kup Setting of the UF protection.

Delay Setting Prints Delay Setting of UF protection.

Overvoltage

Status Protection enabled condition.

Pickup Setting Pickup Setting of the OV protection.

Delay Setting Prints Delay Setting of OV protection.

Undervoltage

Status Protection enabled condition.

Pickup Setting Pickup Setting of the PL protection.

Delay Setting Prints Delay Setting of PL protection.

I2T Inverse Trip time enabled or disabled for Undervoltage protection.

Phase Loss

Status Protection enabled condition.

Pickup Setting Pickup Setting of the PL protection.

Delay Setting Prints Delay Setting of PL Protection.

Power Reversal

Status Protection enabled condition.

Pickup Setting Pic kup Setting of the PR protection.

Delay Setting Prints Delay Setting of PR protection.

System Test Kit50

Page 50

1.12 Test kit administration

Figure 1-23 Administration menu

Test kit administration 51

Page 51

1.12.1 HMI setup

The test kit communicates with the Entellisys Low Voltage HMI to download system

configuration, preventing the operator from entering it manually.

A USB-to-USB cable, running a peer-to-peer network communication bridge, is used between

the test kit and the HMI for communication. Both the HMI and test kit have dedicated LAN

connections enabled for this. The test kit must know the HMI IP address. These IP addresses

have been pre-set and should not be changed.

In the event the addresses must be changed, this screen provides the ability to enter the HMI

USB-to-USB Network Communication Bridge IP address.

NOTE: For most systems the HMI IP address for the USB-to-USB bridge should remain at the

default setting of 192.168.2.50. Modify this setting only if it was changed in the HMI.

Figure 1-24 HMI Setup screen

Enter the IP address in the X.X .X.X format, where X = 0 to 255. The maximum value that can be

entered is 255.255.255.255.

System Test Kit52

Page 52

1.12.2 Disk cleanup

This option enables operators to delete unwanted test reports from the System Test Kit. This

should be done periodically to prevent the hard drive from filling up.

NOTE: It is recommended to have at least 50,000 KB of free space at all times.

Figure 1-25 Disk cleanup screen

List of Files – displays the test reports available in the test kit.

To select files:

• Click an individual file.

• Press Shift to select multiple files.

• Or click Select All to select all files.

Delete File – prompts the operator with a confirmation to delete the selected files. The Delete

File button will be grayed out if no files are selected.

Test kit administration 53

Page 53

1.12.3 System Information

This function displays the hardware version and data acquisition card information for the

hardware present in the test kit. It is provided for technical support information only.

Figure 1-26 System Information screen

System Test Kit54

Page 54

1.12.4 Test Kit Validation Test

This feature provides internal tests to validate the test kit hardware.

Figure 1-27 Test Kit Validation screen

1.12.4.1 Customer Validation Tests

These tests are provided for the customer to validate the test kit hardware. The pre-set tests

check both the analog output and the digital output signals.

To perform tests

1. Remove the “Test Kit Output Connector” from the Messenger.

2. Press Perform Test.

NOTE: Remove the test kit connector from the Messenger during Test Kit Validation tests to

prevent false results and to prevent test signals from being injected into the Messenger.

Test Results

The results are summed up in the two LED indicators on the left-hand side of the screen.

• Green = Pass (indicating the hardware is working properly).

• Red = Failure (indicating there is a hardware problem). More detailed data is available on the

left-hand side. For any failures, contact GE Post Sales Service for technical help (see How to

contact us on page 2).

Test kit administration 55

Page 55

1.12.4.2 Factory Test only

The Factory Tests are provided for factory personnel only and should not be performed by

customers. This test requires special production test hardware and will fail without the proper

equipment.

NOTE: Remove the test kit connector from the Messenger during factory test kit validation

tests to prevent false results and to prevent test signals from being injected into the Messenger.

1.13 Long-term maintenance

The following preventative maintenance is recommended for the long-term care of your test kit.

• Keep the system in a cool, dry, and dust-free environment.

• Power ON the system at least once every 3 months to recharge the CMOS battery.

• Make sure the system is OFF whenever it is shifted from one place to another.

1.13.1 Motherboard battery maintenance

The CMOS or Complementary Metal Oxide Semiconductor battery is an on-board

semiconductor chip. This chip is used to store system information and configuration settings

while the computer is off and on.

Lifetime: The standard lifetime of a CMOS battery is around 10 Years, however this amount of

time can change depending on the use and environment that the computer resides.

Detection: A Low battery can be detected by checking the time stamping of test results. See

Troubleshooting

Corrective action

• Replace the CMOS battery. Follow the manufacturer’s instructions for proper battery

disposal.

• Make sure that the polarity of the batt ery is right before inserting inside the slot.

• Reload the saved CMOS Setup Details. (There are no special settings for the System Test Kit,

so this step can be skipped.)

on page 59 for help diagnosing the issues.

System Test Kit56

Page 56

Figure 1-28 CMOS battery on motherboard

1.13.2 Test kit care

The following outlines tips for taking good care of your test instrument.

1.13.2.1 Handling the test kit

Make sure that the keyboard assembly is properly closed onto the SAX before transporting it.

This will ensure you do not lose the keyboard as well as protecting the LCD screen. The handle is

located securely to the strongest part of the machine and distributes the load of the SAX evenly

to allow easy carriage and proper balance.

1.13.2.2 Cables

All cables should be treated with care. Do not over extend any cable as this could result in

internal breakage in the cable. It is essential that the cable and its plug be handled in the proper

manner without force.

1.13.2.3 Power

Always make sure the power cord is in top condition before using them with the SAX. Make sure

the power source is reliable and of proper standard. The power supply is capable of handling

100-240 V and 50-60 Hz. Do not use on an already overloaded circuit.

Long-term maintenance 57

Page 57

1.13.2.4 Cleaning the LCD screen

• Do not use cleaner that contains alcohol.

• Do not use cloth that could be abrasive to the surface of the LCD.

• Always gently wipe the LCD surface when cleaning.

Do not use any abrasive material to scratch the LCD screen, as they can leave marks on the

surface. Do not apply any pressure to the surface of the LCD screen either with objects or

hands; this will ensure that the screen do not suffer from internal damage or cracks.

1.13.2.5 Cleaning the keyboard

• Do not spill any liquid on to the keyboard.

• Do not drop particles into the spacing between keys.

• Use a compressed air cleaner to remove the dust within the keyboard.

The keyboard is essential in that it helps protect the LCD during tra nsportation. Avoid liquid spills

or small objects entering the keyboard. The touch pad surface should be kept dry and clean.

1.13.2.6 Cleaning the fan filter

• Remove the filter from its housing.

• Use a compressed air cleaner to blow off the dust from the filter.

If necessary, wash the filter material and dry completely before reinserting it.

System Test Kit58

Page 58

1.14 Troubleshooting

Table 1-20 Troubleshooting

Error Potential Cause Suggest ed Fix

Main Menu—Test Menu and

Manual Injection Button grayed

out

Self Test Error—Memory Failure Correct the Physical Memory

Self Test Error—Hardware

Configuration Error

Self Test Error—Test Kit Setup Invalid File Setting requires

Self Test Error—Ethernet

Connectivity

When there is a problem in the

Power DAQ driver or with the

Hardware cards, these buttons will

not be available to inject signals

from the test kit.

problem and restart the machine.

Problem in Hardware

Wrong Power DAQ drivers

reinstallation of test kit software.

Mismatch in the installed software

and hardware versions.

Cable not connected. Verify USB cable is connected to

Check System information i n the

Test Kit administration.

Contact GE Post Sales Service for

technical support (see How to

contact us onpage2).

Have User Administrator check

physical memory space. Or, send

unit for repair.

Contact GE Post Sales Service for

technical support (see How to

contact us onpage2).

Check System information i n the

Test Kit administration.

Contact GE Post Sales Service for

technical support (see How to

contact us onpage2).

Check System information i n the

Test Kit administration.

Contact GE Post Sales Service for

technical support (see How to

contact us onpage2).

both the System Test Kit and the

HMI.

Download Switchgear

Configuration from HMI

Error Msg—“Download Failed.

Check the USB cable and verify

the IP address configuration of

HMI and System Test Kit”

HMI USB-to-USB Network Bridget

IPAddress is not set properly in the

test ki t.

Verify USB port enabled. Requires User Admin to log onto

Cable not connected. Verify USB cable is connected to

Verify the address in Test Kit

Administration, HMI Setup. Default

address is 192.168.2.50, which

matches the HMI setup. Only in rar e

cases should this be changed. See

DEH-230 Entellisys Low Voltage

Switchgear System Administrator

Manual for details.

unit.

both the System Test Kit and the

HMI.

Troubleshooting 59

Page 59

Table 1-20 Troubleshooting

Error Potential Cause Suggest ed Fix

HMI IP Address incorrect. Check the HMI IP address in HMI

Setup, under the Test Kit

Administration. This should be the

same IP address as set in the HMI

(by default, HMI IP address is set at

192.168.2.50).

Download from HMI failed due to

improper access/non availability

of settings f ile

Error Msg—No Files are available

for retrieving. Check/Connect

USB cable and verify the

IP address of HMI and System

Test Kit for a new download.

Error Msg—Default CPU is not

Commissioned. Please check and

try again.

Error Msg—No breakers Available

for testing

Communication failed between HMI

and test kit. Note: This download

should only be done between

In-Gear or Near-Gear touchscreen

HMIs (and not remote HMIs).

The test kit uses a f ixed User,

ELVSTESTKIT to login to the HMI.

Make sure the user is still set up in

the test kit and the HMI, with the

same passwords and administrator

rights.

Problem in Settings files of HMI. Improper User access from test kit

to HMI.

Missing or No Settings files in HMI

for download.

There are no valid previous settings

available.

The settings must be downloaded

from the HMI.

Contact GE Post Sales Support for

help (see How to contact us

on page 2).

Configuration downloaded

successfully, but there are no

Call GE Post Sales Support for hel p

(see How to contact us on page2).

commissioned Messengers/circuit

breakers available for testing.

Test Menu