Page 1

GE

Entellisys™ Low Voltage Switchgear

System User Manual

Page 2

DEH-231

Warnings, Cautions, and Notes as used in this publication

Warnings

WARNING! Warning notices are used in this publication to emphasize that hazardous voltages,

currents, or other conditions that could cause personal injury exist in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Cautions

CAUTION: Caution notices are used for situations in which equipment might be damaged if care is

not taken.

Notes

NOTE: Notes call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts have been

made to ensure accuracy, the information contained herein does not cover all details or variations in

hardware and software, nor does it provide for every possible contingency in connection with

installation, operation, and maintenance. Features may be described in here that are not present in all

hardware and software systems. GE Consumer & Industrial assumes no obligation of notice to holders

of this document with respect to changes subsequently made.

GE Consumer & Industrial makes no representation or warranty, expressed, implied, or statutory, with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warrantees of merchantability or fitness for purpose shall apply.

Entellisys™, EntelliGuard™, and FlexLogic™ are trademarks of the General Electric Company.

Modbus RTU is a registered trademark of AEG Schneider Automation.

©Copyright 2005 General Electric

All Rights Reserved

Page 3

How to contact us

Please have your Entellisys System Summary # and Sub # ready when calling. This information can be

found on the Entellisys HMI on the System Health screen by clicking the Job Info button.

Post Sales Service

GE Switchgear

510 Agency Road

West Burlington, IA 52655

Phone (toll free): 1-888-437-3765

Additional information:

www.entellisys.com/support

Page 4

Page 5

Contents

1 System architecture

1.1 Description of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Switchgear installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 System components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3.1 EntelliGuard circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3.2 Current transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.3 Potential transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3.4 EntelliGuard Messenger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.3.4.1 Messenger User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.3.5 Compartment ID button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.3.6 Messenger communications network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3.7 Messenger switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3.8 CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.9 Synch clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.10 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.1 CPU digital I/O cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.2 Digital I/O cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.3 Terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.4 “OR” boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.5 Relay blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.6 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.10.7 Digital I/O customer interface wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3.11 System interface Ethernet communication network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3.12 System interface Ethernet switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3.13 Touchscreen HMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3.13.1 In-gear HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3.13.2 Near-gear HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3.14 Remote HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.3.15 VPN firewall device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.3.16 Control power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.3.17 UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.3.18 UPS to HMI connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3.19 RS-232 to RS-485 converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3.20 Entellisys System Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3.21 Clamp circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 Specifications

2.1 Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2 Type tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

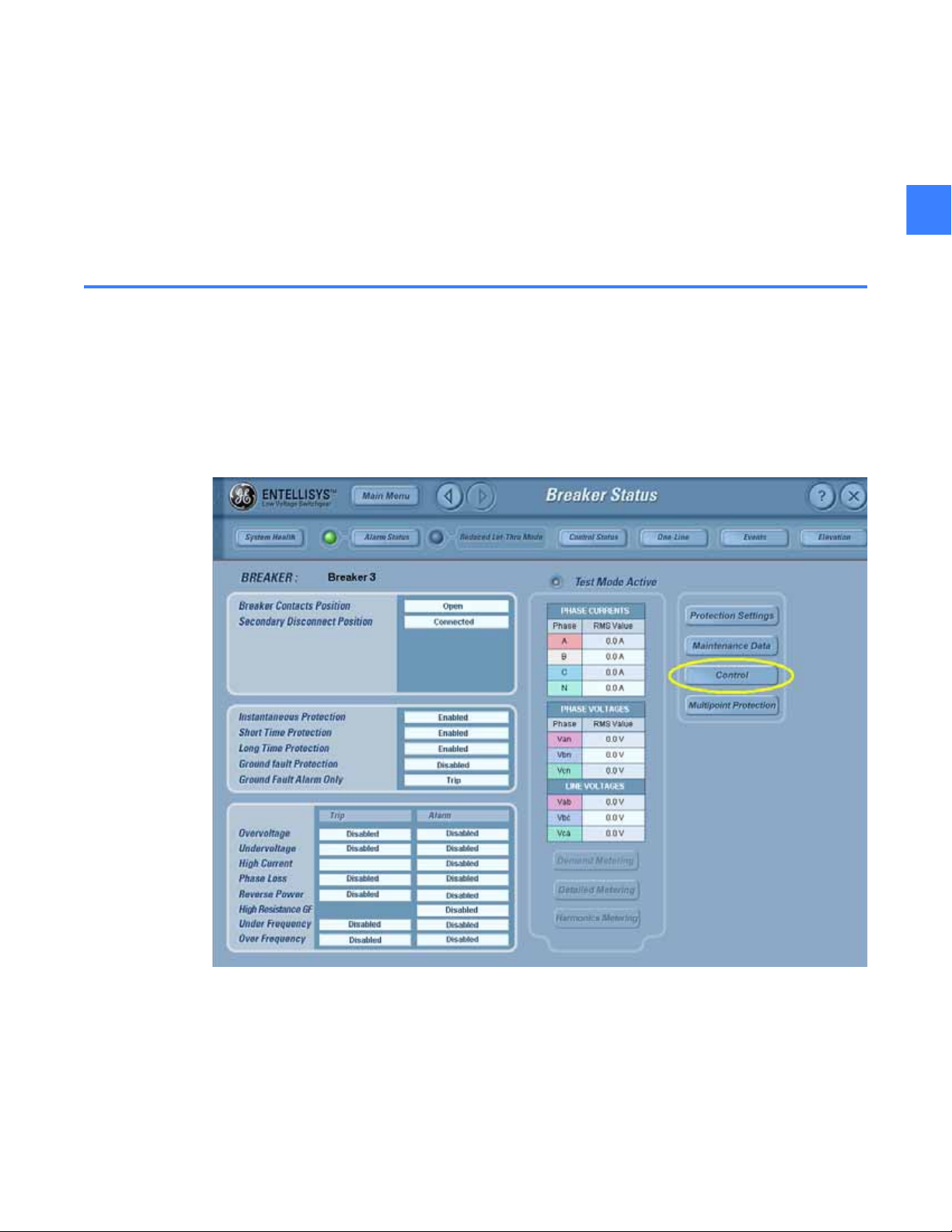

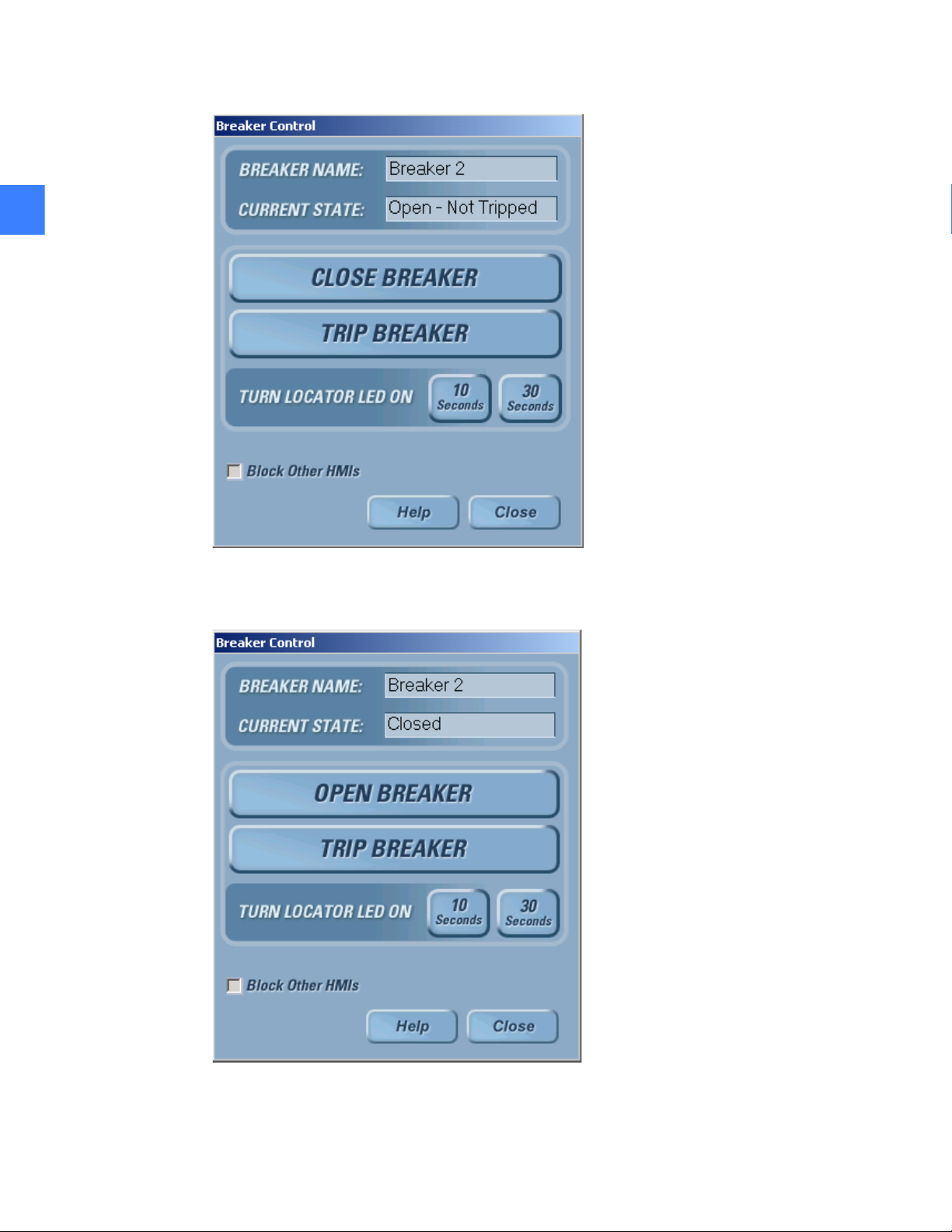

3 Basic control

3.1 Controlling circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Block other HMIs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3 Open circuit breaker (electrically operated circuit breakers only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4 Close circuit breaker (electrically operated circuit breakers only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Contents 5

Page 6

3.5 Trip circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.6 Locator LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 Metering

4.1 Basic metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Expanded metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Demand metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Advanced metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5 Metering accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.1 Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6.3 Programmable parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6.4 Meter distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7 Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.7.1 Viewing basic metering data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.7.2 Viewing demand metering data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7.3 Viewing detailed metering data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.4 Viewing harmonics metering data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5 Single point functions

5.1 Overcurrent protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1.1 Long Time Overcurrent protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1.1.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1.1.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1.1.3 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1.2 IOC/Short Time Overcurrent protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.1.2.1 Short Time Overcurrent protection curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.1.2.2 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.2.3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.2.4 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1.3 Ground Fault protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1.3.1 Ground Fault protection curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1.3.2 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.1.3.3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.1.3.4 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2 Single Point Relay protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2.0.1 Enabling Single Point Relay packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2.1 Undervoltage Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2.1.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2.1.2 Trip settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2.1.3 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.2.1.4 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.2.2 Overvoltage Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.2.2.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.2.2.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.2.2.3 Trip settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.2.2.4 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2.2.5 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6 Contents

Page 7

5.2.3 Over Frequency Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.2.3.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.2.3.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.2.3.3 Trip settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.2.3.4 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.2.3.5 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.2.4 Under Frequency Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2.4.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2.4.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.2.4.3 Trip settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.2.4.4 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.2.4.5 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.2.5 Phase Loss Relay protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.2.5.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.2.5.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2.5.3 Trip settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2.5.4 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2.5.5 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.2.6 Reverse Power Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2.6.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2.6.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2.6.3 Trip settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2.6.4 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2.6.5 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2.7 High Current Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2.7.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2.7.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2.7.3 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.2.7.4 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.2.7.5 Event logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.2.8 High Resistance Ground Fault Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2.8.1 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2.8.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2.8.3 Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2.8.4 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.2.8.5 Event logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.3 Synch Check relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.3.1 Synch check status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.3.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.3.2.1 Source voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.3.2.2 Maximum differentials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.3.2.3 Source 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.3.2.4 Source 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.3.2.5 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.3.3 Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.3.3.1 Event logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6 Zones, buses, and topologies

6.0.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.0.1.1 Zones and buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.0.1.2 Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Contents 7

Page 8

6.0.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.0.2.1 Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.0.2.2 Buses, topologies and the Association Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.0.3 Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7 Multipoint functions

7.1 Bus Differential Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1.1.1 Configuring Bus Differential zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1.1.2 User settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1.1.3 Setting Bus Differential pickups/delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.1.1.4 Setting up Bus Differential alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.1.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.1.3 Events generated by the Bus Differential Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.1.4 Alarms generated by the Bus Differential Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2 Multi-Source Ground-Fault Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.2.0.1 Interoperation with Zone Selective Interlock function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.2.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.2.1.1 User settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.2.1.2 Setting Multi-Source Ground-Fault pickup/delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.2.1.3 Setup of Multi-Source Ground-Fault alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7.2.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.2.3 Events generated by Multi-Source Ground-Fault Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.2.4 Alarms generated by Multi-Source Ground-Fault Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.3 PT Throw-Over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.3.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7.3.2 Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.4 Zone Selective Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4.1 Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4.2 ZSI zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4.3 Protection types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4.4 Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.4.5 Tiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.4.6 Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.4.7 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.4.7.1 Configuring ZSI parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.4.7.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.4.7.3 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.4.7.4 Configuration events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.4.7.5 Confirmation events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.4.7.6 Operation events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.4.8 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8 Reduced Let-Thru Mode

8.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.1.1 User settings for Bus Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.1.2 User settings for Multi-Source Ground-Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.1.3 User settings for Zone Selective Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8 Contents

Page 9

9 Sequence of events, fault reports, and waveform capture records

9.1 Event configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

9.2 Viewing the SOE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

9.3 Waveform capture configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

9.4 Waveform capture operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

9.5 Viewing waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.6 Waveform viewer functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

9.7 Grouping waveform signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

10 Digital I/O

10.1 Discrete inputs/outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

10.1.1 Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

10.1.1.1 Non-redundant discrete I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

10.1.1.2 Redundant discrete I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

10.1.1.3 Discrete I/O boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

10.1.1.4 “OR” board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

10.1.1.5 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

10.1.1.6 Relay blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

10.1.1.7 Terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.1.1.8 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.1.1.9 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.1.2 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.1.2.1 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.1.2.2 Test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.1.3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.1.3.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.1.3.2 I/O points direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.1.3.3 Input configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

10.1.3.4 Output configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

10.1.3.5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.1.3.6 Contact input states. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.1.3.7 Contact output states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.1.3.8 Test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.1.3.9 Input test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

10.1.3.10 Output test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

10.1.3.11 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

10.1.3.12 Configuration events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.1.3.13 Confirmation events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.1.3.14 Operation events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.1.4 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11 FlexLogic™

11.1 Introduction to FlexLogic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

11.2 FlexLogic rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

11.3 FlexLogic evaluation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.4 FlexLogic Equation Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.5 FlexLogic equation viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.6 FlexLogic timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

11.7 FlexLogic virtual inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

11.8 FlexLogic virtual outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

11.9 FlexLogic circuit breaker commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Contents 9

Page 10

11.10 FlexLogic control alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

11.11 Load FlexLogic equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

11.12 Save FlexLogic equation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

11.13 FlexLogic example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

11.14 FlexLogic redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

11.14.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

11.14.2 Throw-over and throwback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

11.14.3 Failure mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

11.14.4 Discrete I/O card redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

12 Preventive maintenance

12.1 Viewing and understanding PM data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

12.1.1 Total operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.1.2 Total no-load operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.1.3 Total load operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.1.4 Total fault operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.1.5 Percent load life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.1.6 Percent mechanical life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

12.1.7 Last circuit breaker operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

12.2 Adjusting preventive maintenance values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

12.2.1 Notification thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

12.2.2 Hours of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

13 Alarms

13.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

13.2 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

14 System health

14.1 Monitoring system health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

14.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

15 Control power and UPS configuration

15.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

15.2 Bus & CPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

15.3 UPS compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

15.4 Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

15.5 Instrument and circuit breaker compartments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

A Alarms and events

A.1 Sequence of events cause code cross reference index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

A.2 Alarms and events description and system troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

10 Contents

Page 11

1 System architecture

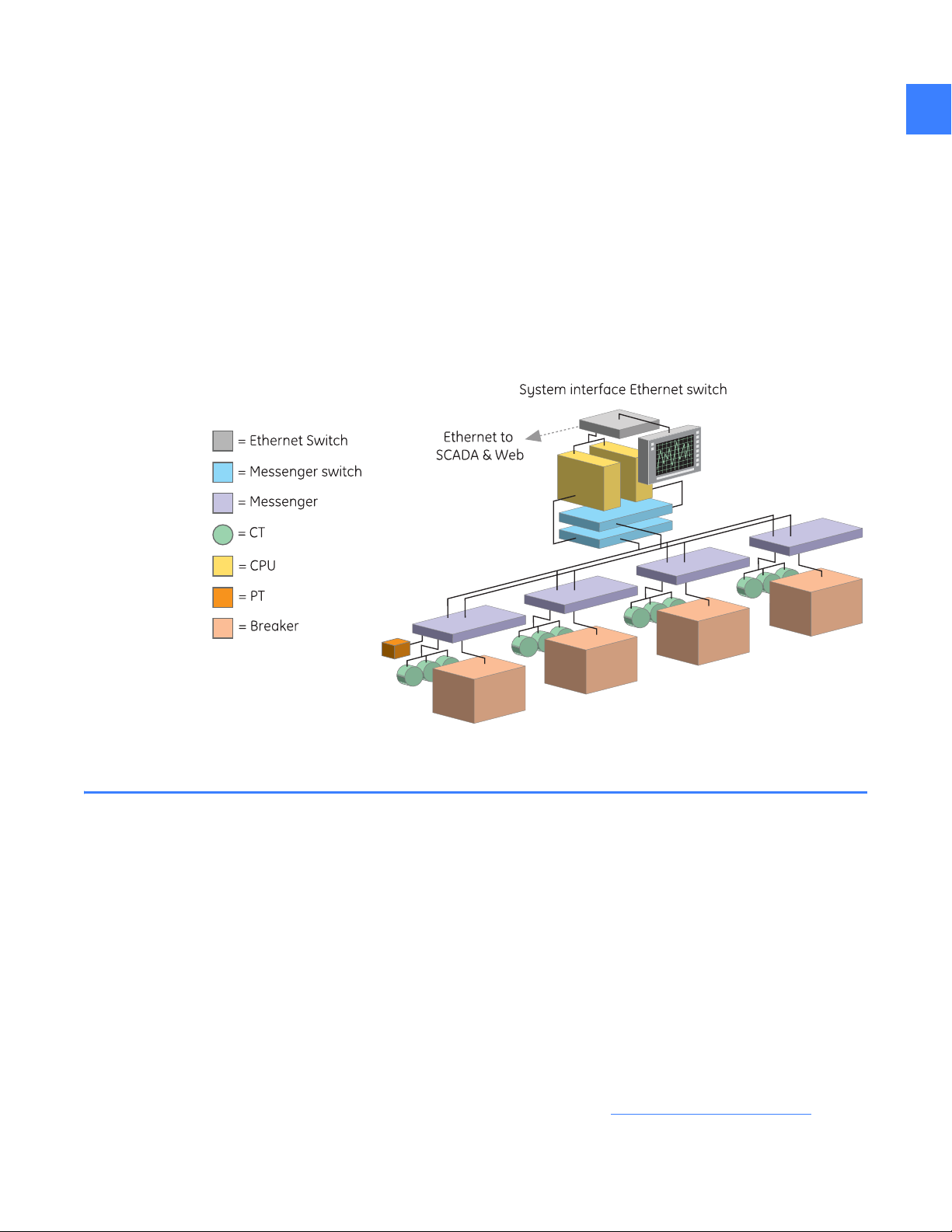

The Entellisys™ Low-Voltage Switchgear architecture is unique. The central processor unit (CPU)

is the basis of this new protection-and-control architecture. The CPU provides protection and

control functions over the entire low-voltage switchgear system.

The key advantage of this architecture is that the CPU has all the information from all circuit

breakers simultaneously. The architecture also has built in redundancy to increase system

availability.

Figure 1-1 Entellisys LV Switchgear simplified architecture

1

1.1 Description of operation

Current transformers (CTs) and potential transformers (PTs) measure current and voltage and

transmit the analog information to the EntelliGuard™. The Messenger digitizes and sends the

information over the Messenger communication network to two redundant CPUs.

The CPUs make protection decisions, capture events, process waveform data, and provide

status information. For example, if the CPUs identify a trip condition at a circuit breaker, the CPU

alerts the EntelliGuard Messenger at that circuit breaker, which then actuates the circuit breaker

and returns the circuit breaker status to the CPU.

Modbus

external components such as the Entellisys HMI, SCADA, or other Building Automation Systems.

The Human Machine Interface (HMI) is the central user interface for the system. HMIs are

touchscreen computers located in-gear or near-gear (see Touchscreen HMI on page 22

Remote HMIs are available for desktop users who want to view the switchgear from their office.

®

communication, an open industry standard protocol, is provided as an interface to

) and

Description of operation 11

Page 12

Digital I/O is provided for customer-specific inputs and outputs. This equipment is resident in the

1

switchgear and is connected through the CPUs. Digital I/O and custom control schemes will run

in the CPUs if enabled.

In summary, Entellisys changes the protection paradigm from individual circuit protection to

system protection.

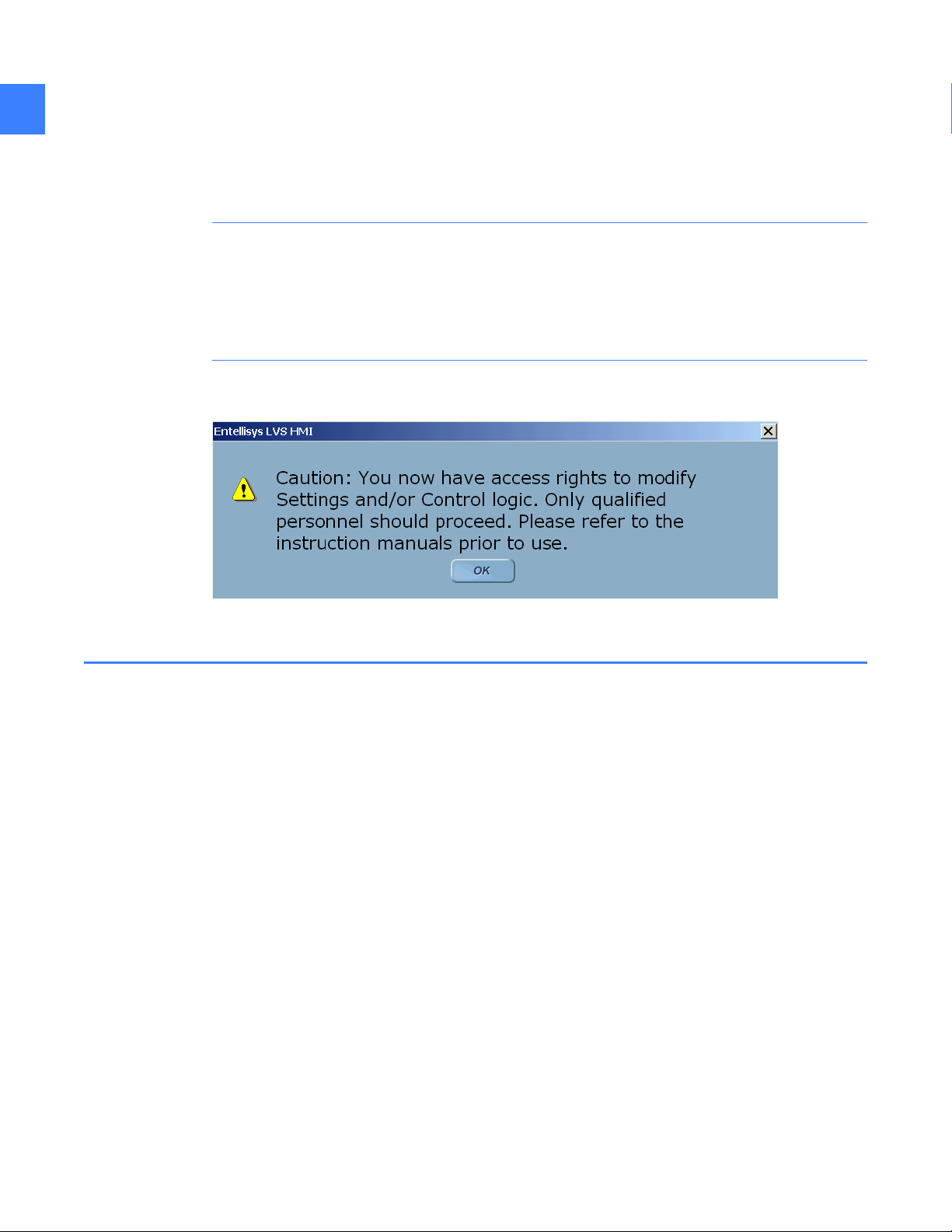

CAUTION: Users that have been assigned Group Permissions by the System Administrator for

features that allow the changing of settings and/or access to control functions must be

established as qualified personnel only. See Chapter 4 in DEH-230, Entellisys Low Voltage

Switchgear System Administrator Manual, for more information about programming user

permissions. As a reminder, users with such privileges will be presented with the following

screen upon initial login:

Figure 1-2 Initial login Caution screen

1.2 Switchgear installations

There are two primary installation methods in the switchgear:

• Standard

• Split-redundant

With standard installation, redundant components such as the CPUs, Messenger switches, and

UPSs are installed together in the equipment. This method optimizes footprint and convenience

of maintenance.

With split-redundant installation, redundant components such as the CPUs, Messenger

switches, and UPSs are split-up with at least one switchgear stack separating them. This

method optimizes system availability.

For more information, see DEH-237 Entellisys Low Voltage Switchgear Installation and

Maintenance Instruction Guide.

System architecture12

Page 13

1.3 System components

Following are brief descriptions of each component in the Entellisys system.

1.3.1 EntelliGuard circuit breaker

EntelliGuard low-voltage power circuit breakers control and protect power circuits up to

600 volts. They will safely switch loads and automatically clear circuits when abnormal

conditions occur. These include short circuits, sustained overloads, ground faults, and other

programmable conditions.

The EntelliGuard circuit breakers are available in 800 ampere, 1,600 ampere, 2,000 ampere,

3,200 ampere, 4,000 ampere, and 5,000 ampere frame sizes. These values represent the

maximum continuous-current rating of each frame.

Circuit breakers may be equipped with a combination of accessories and interlocking devices.

Figure 1-3 EntelliGuard small frame circuit breaker

1

•The network interlock accessory selectively prevents the closing of specific circuit

breakers in the electrical distribution network. The CPU sets and resets network interlock

devices remotely while continuously monitoring their status. For example, in a

double-ended substation, these devices could be used to interlock the main and tie

circuit breakers to prevent connecting two unsynchronized power sources.

•The bell alarm lockout accessory prevents a circuit breaker from closing after receiving

a trip command from the EntelliGuard Messenger. Closing of the circuit breaker is

permitted only after the lockout is reset manually at the front of the circuit breaker.

For more information, see the following EntelliGuard Circuit Breaker Instruction Books:

• DEH-201 EntelliGuard Power Circuit Breakers 800-2,000A Frames, 240-600Vac Users Guide

• DEH-202 EntelliGuard Power Circuit Breakers 3,200-5,000A Frames, 240-600Vac Users Guide

System components 13

Page 14

1

1.3.2 Current transformers

Current transformers (CTs) are sensors that measures current. Each circuit breaker requires

input from three CTs (one per phase) and an optional neutral CT. Unlike traditional switchgear,

this single set of CTs provides the necessary current sensing for all needs including protection,

metering, and control.

The CTs are attached to the power bus behind the circuit breaker in the circuit breaker

compartment. Only Entellisys CTs may be used with the Entellisys system.

CTs either come in a 3-pack (shown in Figure 1-4) or as single CTs.

Figure 1-4 CT 3-pack

System architecture14

Page 15

1.3.3 Potential transformers

Potential or voltage transformers (PTs) are sensors that measure voltage. Unlike traditional

switchgear, only the main (or source) circuit breakers in the system require PTs. This hardware

and wiring reduction is possible because of the central processor architecture and the sampling

synchronization maintained by the system.

Three PTs, one for each phase, are required on the main circuit breakers in the system. The

remaining circuit breakers reference one circuit breaker with physical PTs and use that source's

voltage readings for metering calculations. This source reference may change as the system

topology changes.

The PTs are located outside the circuit breaker compartments in auxiliary compartments.

Figure 1-5 Entellisys PT

1

System components 15

Page 16

1

1.3.4 EntelliGuard Messenger

The EntelliGuard Messenger electronic device provides the interface between the circuit

breakers and the CPUs in the Entellisys system.

Following is a summary of the Messenger’s functionality:

• Digitizes all switchgear signals

• Communicates the raw samples to CPUs via the Messenger network

• Controls the circuit breaker

• Performs independent backup trip capability at all times

• Powered by dual 120v control power sources or self-powered from the current sensors

• Provides LED illumination of circuit breaker status, power status, communication status, and

GE “Locator” information

• Provides seal-able switches to set CT rating, and (long time) multiplier setting

• Provides a test connector for trip curve testing using the Entellisys System Test Kit

1.3.4.1 Messenger User Interface

The Messenger User Interface, as show in Figure 1-6, is described below.

Figure 1-6 Messenger front

LED Indicator Lights

• Locate: LED blinks for 10 or 30 seconds on command from the HMI to help operator

physically locate a circuit breaker in the switchgear lineup.

• Com1, Com2: Illuminates when Ethernet communication is plugged in and ready to

communicate.

• Power: Illuminates when either Control Power A or Control Power B sources are powering the

node.

• Circuit Breaker Status Open: Illuminates when the circuit breaker is Open. This sensor is

independent of the circuit breaker Close sensor.

• Circuit Breaker Status Closed: Illuminates when the circuit breaker is Closed. This sensor is

independent of the circuit breaker Open sensor.

Switches

• Rating: Ampere rating of the circuit in use. Maximum value is the CT Rating.

• Setting: Multiplier setting for Long Time Overcurrent Protection, specified as X times the

Rating switch value.

Rating Label

• Frame: Circuit breaker frame size, in Amperes, represents the maximum continuous-current

rating.

• CT: Maximum Ampere rating of the CTs.

System architecture16

Page 17

Test Connector

Connection point between the Entellisys System Test Kit and the Messenger.

Figure 1-7 EntelliGuard Messenger

The Messenger is located directly above the circuit breaker compartment.

1.3.5 Compartment ID button

The Compartment ID button stores compartment configuration information in non-volatile

memory. It informs the system about the circuit breaker residing in the cubicle.

The Compartment ID button is shipped inserted into the EntelliGuard Messenger, tethered to the

equipment, and does not require any user interface during normal operation. It remains within

the switchgear cubicle at all times.

1

WARNING! Compartment ID buttons are set at the factory and are not interchangeable

between compartments. Failure to utilize the correct compartment ID button can result in

personal injury and damage to equipment.

The ID button provides the system with necessary information such as circuit breaker frame

size, CT size, and overcurrent protection capabilities as follows:

• Ground fault protection always on

• Ground fault protection always off

• Ground fault protection switchable (enabled/disabled) in the HMI

If the ground fault protection options need to change, a replacement ID button must be ordered

(GE CAT# ETSCOMPID).

System components 17

Page 18

Figure 1-8 Compartment ID Button un-tethered from switchgear

1

1.3.6 Messenger communications network

The Messenger communications networks are closed, dedicated LANs for transmitting

information between the Messengers and the CPUs in the system. The LANs are for the

Entellisys system only and should never be connected to other networks.

CAUTION: Failure to maintain a dedicated LAN will result in the EntelliGuard Messenger

reverting to back-up Overcurrent protection.

A Messenger switch is required to route information appropriately. The communication wiring

required is 100BaseT, CAT5 cables.

Each CPU resides on a separate network, providing redundant communications.

1.3.7 Messenger switch

The Messenger switch enables the communication network between the Messengers and

corresponding CPU. A Messenger switch is required for each of the two redundant networks. The

number of ports provided is determined by the number of circuit breakers in the system. Each

circuit breaker requires its own port in the switch.

The largest switch provides only 24 ports. If the number of circuit breakers in the system

exceeds 22, a pyramid switch scheme, utilizing multiple switches, is required.

System architecture18

Page 19

1.3.8 CPU

1

The CPU is a rack-mount industrial computer running a real-time operating system. The CPU

provides the processing capability to support all switchgear functions. Two redundant CPUs

(CPU A and CPU B) are used per lineup, supporting up to 30 circuit breakers.

The CPUs run simultaneously. If one CPU has an issue, the other continues to run providing

redundancy. One CPU should be running at all times to maintain the highest level of protection.

In the event that the Messenger-to-CPU communication network is down or power to the CPU is

not available, the EntelliGuard Messenger will provide back-up overcurrent protection

functionality.

The redundant CPUs are synchronized by a common connection to a synch clock. Each CPU has

a slot for synch clock, although only one synch clock is used per system. The synch clock is

programmed for either 60 Hertz or 50 Hertz frequency operation.

Each CPU has two slots for optional digital I/O cards.

Figure 1-9 Redundant CPUs with synch clock connection

1.3.9 Synch clock

To maintain system synchronization, a mechanism exists to provide a single sampling time

source. This time source is provided on a separate hardware card, called the Synch Clock. The

Synch Clock sits in CPU A and has a connection to CPU B.

In the event of an issue with the Synch Clock or its connections, the CPUs fall-back to software

synch functionality. When this occurs CPU A maintains full functionality. As time drifts, CPU B

may suspend advanced multi-source protection and may not be able to provide metering

information for the circuit breakers without PTs. If CPU A is powered down to provide

maintenance, CPU B will run full functionality.

System components 19

Page 20

1

1.3.10 Digital I/O

The Digital I/O equipment provides programmable input and output logic for customer-specific

requirements.

Examples include the following:

• Sound a horn when a circuit breaker is open

• Trigger an output when voltage exceeds a value

The redundant digital I/O option provides signal processing to/from either CPU. One CPU (the

Master) processes the information and responds. The other provides a backup of the Master

fails. Redundant digital I/O is recommended if any of the signals are critical to the operation of

the system. Critical I/O examples include the following:

• Inputs to automatic throw-over schemes

• Inputs that must trip circuit breaker (such as high transformer pressure)

For more information on Digital I/O, see Digital I/O on page 127

1.3.10.1 CPU digital I/O cards

The input and output signals from the CPU are transferred through the CPU digital I/O Cards.

Each card supports 64 bi-directional points that range from 0 to 5 volts. A maximum of two

cards may be inserted for a total of 128 I/O points. The cards come installed in the CPU upon

purchase.

1.3.10.2 Digital I/O cable

This cable connects the CPU digital I/O card to the terminal block. Each cable transmits 64 I/O

points.

1.3.10.3 Terminal block

The terminal block accepts 64 I/O signals from the CPU digital I/O card through a single cable

and breaks out the individual signals into 64 terminals for wiring.

1.3.10.4 “OR” boards

These boards are only required for redundant digital I/O. The output signals from both CPUs

must be “Horde” together, between the terminal blocks and the relay blocks, to prevent

increased voltages from damaging the relays. Each “OR” board supports 16 output signals.

.

1.3.10.5 Relay blocks

The relay blocks hold solid state input and output relays (16 per block).

Relay blocks are configured as all inputs or all outputs. Unused digital I/O points may have

relays left off.

1.3.10.6 Relays

The input relays transform the customer input (120 Vac or 24-125 Vdc) to 5V inputs for the

Entellisys system.

The output relays are either opened or closed based on programmable logic in the Entellisys

system.

System architecture20

Page 21

1.3.10.7 Digital I/O customer interface wiring

The customer interface to the digital I/O is provided at the I/O module relay blocks. These relay

blocks and the customer wire termination points are mounted in the digital I/O cubicle and are

accessed from the front of the switchgear. Control conduits are terminated in the rear cable

compartment and the digital I/O wiring is routed to the front of the switchgear through an

opening in the digital I/O cubicle rear barrier.

1.3.11 System interface Ethernet communication network

The system interface Ethernet communication network is a 10/100 Mbps Ethernet LAN that

provides an interface into the Entellisys system for systems such as the Entellisys HMI, SCADA

systems, building automation, HVAC systems or other. The system interface Ethernet

communication network provides information and control of all circuit breakers in the system.

The external communications network will use 100BaseT (copper twisted pair) CAT5 or better

cabling. A fiber optic connection is available as an option.

1.3.12 System interface Ethernet switch

The interface between the Entellisys system and the external world is through the system

interface Ethernet switch, an industrial hardened 10/100 Mbps Ethernet switch. An 8-port

copper model is standard. Optionally customers may choose a 9-port model with an additional

fiber port for external gear communication. The fiber port supports 100FL connections only.

1

Figure 1-10 Ethernet switch, 8-port

System components 21

Page 22

1

1.3.13 Touchscreen HMI

The system interface for the Entellisys switchgear will be through one or more touchscreen

computer displays. The display is driven by a separate computer and communicates to the

CPUs through an Ethernet connection. The System Interface Ethernet Switch provides the

physical interface.

The HMI communicates primarily with one of the CPUs but can switch to the other in event of a

failure. Functionality provided by the HMI includes:

• Programmable user login to grant/deny access to specific features

• Animated one-line that shows the current status of the entire system

• Circuit breaker status, circuit breaker control

• Metering, demand logging, harmonics

• User settings for overcurrent protection, relay protection, advanced multi-source protection.

This may be writable or read-only depending on permissions granted.

• Customer-specific discrete I/O programming and status

• Customer-specific control scheme programming and status

• Sequence of events

• System health – showing the health of the Entellisys equipment

• Alarm panel – setup, panel status, e-mail configuration for alarms

NOTE: The HMI is not critical to the protection functionality of the system. The HMI can be

brought down for service with no loss of protection in the system.

1.3.13.1 In-gear HMI

Typically a touchscreen HMI is installed in the switchgear. This is deemed an “in-gear” HMI.

A redundant in-gear HMI is available as an option. The redundant HMI is also a touchscreen HMI

located in the gear.

1.3.13.2 Near-gear HMI

Optionally, a touchscreen HMI may be installed near the switchgear equipment, but away from

the hazardous arc flash zone. This can be in a separate stack or in a wall-mount box up to

250 feet from the switchgear. This is deemed a “near-gear” HMI.

System architecture22

Page 23

1.3.14 Remote HMI

The Entellisys system offers desktop access to the switchgear with the same HMI software

installed in the gear. The remote HMI software can be installed on any Windows 2000 desktop

computer and requires an intranet connection to the switchgear. The intranet connection is

connected to the system interface Ethernet switch.

Two versions of remote HMI are offered:

• User Interactive

Permissions are programmable and can be set for full Administrator access down to Guest

access.

• Viewer

Allows read-only access to the system.

1.3.15 VPN firewall device

Virtual Private Network (VPN) firewall device provides business-class network security providing

Denial of Service (DoS) protection and intrusion detection using Stateful Packet Inspection (SPI),

URL access and content filtering, logging, reporting, and real-time alerts. Up to eight users can

access the system simultaneously.

1

It is strongly recommended that anytime an Entellisys system is connected to the intranet, a

VPN firewall be installed to protect the Entellisys system from network threats.

For more information, see DEH-230 Entellisys Low Voltage Switchgear System Administrator

Manual.

1.3.16 Control power

Control Power is 120 Vac, 50 and 60 Hz only. Uninterruptible power is provided standard with

each system. The control power scheme is specific to each installation and constructed from

standard elements using defined practices for Entellisys control power distribution.

1.3.17 UPS

Two Universal Power Supplies are installed in the switchgear to provide backup power to the

control power network. The UPSs are powered from the primary power buses (utility or

generator) and are redundant.

The UPS serves all 120 Vac control power network devices. It does not power the charging

motors of electrically operated circuit breakers.

For more information on the Control Power Network, see Control power and UPS configuration

on page 183.

For more information on the UPS, see the “GE Digital Energy GT Series™ - UL, Product

Description” at www.gedigitalenergy.com

.

System components 23

Page 24

1

1.3.18 UPS to HMI connection

The Entellisys system provides event/alarm/e-mail information when the UPS A has gone on

battery backup and when the batteries are low. When the batteries are low, the HMI safely shuts

down to avoid abrupt power interruption. To enable this communication, a link between UPS A

and the primary touchscreen HMI is established. This link is a serial connection between the

DB-9 serial port connection on the UPS and the DB-9 serial port connection on the HMI. Since

distances between the HMI and UPS may exceed serial cable distances, a pair of RS-232 to

RS-485 converters are installed at each end to accommodate the cabling distance through the

switchgear.

1.3.19 RS-232 to RS-485 converter

This device converts RS-232 signals to RS-485 signals. This is required to support the cable

lengths in the switchgear. RS-232 imposes a distance limitation of only 15 meters. RS-485 can

transmit data over distances up to 1.2 km.

1.3.20 Entellisys System Test Kit

The Entellisys System Test Kit is a portable test instrument designed for field testing of the

Entellisys Low-Voltage Switchgear system.

The test kit includes the following features:

• Simulate power-line characteristics for a single circuit breaker in the Entellisys Low-Voltage

System

• Verify the function/operation of the protection system

• Overcurrent protection tests – long time, short time, instantaneous and ground fault

protection tests

• Single point relay protection tests (overvoltage, undervoltage, over frequency, under

frequency, power reversal and phase loss, high current test)

• Verify the calibration of the trip time current curve

• Verify the operation of the circuit breaker actuation in “Trip mode”

• Perform tests without trips in “No Trip mode”

• Ground Fault Defeat function provides temporarily suspension of all ground fault protection

in the system

• Automatically retrieves system configuration for increased productivity

• Displays a summary of all protection configuration

• Saves test results to be reviewed later

• Windows Interface for ease of use

• Operation from 120 Vac

For more information, see DEH-233 Entellisys Low Voltage Switchgear System Test Kit User

Manual.

1.3.21 Clamp circuit

The clamp circuit is an intermediary device between the CTs with 150ampere and 400ampere

ratings only. The clamp circuit protects the Messenger from large current outputs from the CTs.

The clamp circuit is installed in the circuit breaker compartment on the left-hand side sheet.

System architecture24

Page 25

2 Specifications

2.1 Environmental

Storage/shipping temperatures

–40 to 85° C

Operating temperatures

0 to 40° C ambient, indoor use

Humidity

5% to 95%, non-condensing, indoor use

2.2 Type tests

Tests are split into two categories:

• EntelliGuard Messenger Tests – the primary protection control element

2

• Entellisys System Tests – the complete system

Table 2-1 Type tests

Type Name EntelliGuard Messenger

Tests

EMC/Transient Harmonic Currents IEC60947-2 sec.F.4.1.2

EMC/Transient Current Dips and

Interruptions

EMC/Transient Fast Transient Burst IEC61000-4-4

EMC/Transient Voltage/Current Surge

Immunity

EMC/Transient Electrostatic Discharge

Immunity

EMC/Transient 1MHz Oscillatory SWC IEC 60255-22-1

EM emission Conducted FCC part 15, subpart B, Class A

IEC60947-2 sec. F.4.2

ANSI C37.90.1

IEC61000-4-5

IE255-22-5

IEC60947-2 sec. F.4.3

IEC60255-6

ANSI C37.90.1

Entellisys System Tests

ANSI C37.90.1

ANSI C62.41

IEC61000-4-4

ANSI C62.41

IEC61000-4-4

EN61000-4-2

ANSI C37.90.1

EM emission Radiated FCC part 15, subpart B, Class A

RFI Electromagnetic Field

Immunity

IEC60947-2 sec. F.4.4

Environmental 25

Page 26

Table 2-1 Type tests

Type Name EntelliGuard Messenger

Tests

Entellisys System Tests

22

RFI RFI with portable

transmitters

RFI ANSI Radiated

Susceptibility

RFI Conductive RF Immunity IEC60255-22-6

Environment Dry Heat IEC60947-2 sec. F.7

Environment Thermal Shock IEC60947-2 sec. F.9

Environment Damp Heat IEC60947-2 sec. F.8

Environment Humidity IEC60947-1

Mechanical Sinusoidal Vibration IEC255-21-1

Safety Dielectric Strength IEC60255-6 ANSI C37.20.2 Paragraph 5.3

IEC60255-6

ANSI C37.90.2 ANSI C37.90.2

IEC60068-2-1

IEC60068-2-2

IEC60947-2 sec. F.8

Safety Insulation Resistance IEC60255-6

Safety Impulse Voltage Withstand IEC60255-6

Magnetic Power Frequency

Magnetic Power Magnetic Field

Voltage Overvoltage ANSI C84.1

Voltage Undervoltage ANSI C84.1

Voltage Ramp voltage ANSI C84.1

Voltage Line Interruption ANSI C84.1

2.3 Approvals

IEC61000-4-8

Magnetic Field

IEC61000-4-9

Immunity

IEC 61000-4-11

IEC 61000-4-11

UL Listed – Low Voltage AC Power Circuit Breaker Trip Unit - E-48428

FCC Class A listed

Specifications26

Page 27

3 Basic control

Entellisys allows users to control EntelliGuard circuit breakers from the HMI. A circuit breaker

may be commanded to open, close or trip. To locate or confirm the circuit breaker shown on the

HMI screen matches the physical circuit breaker, the locator LED on each EntelliGuard

Messenger can be set to flash for 10 or 30 seconds.

3.1 Controlling circuit breakers