GE ROTA Brochure

GE

Measurement & Control

Nutronik Testing Machines

Full Body and Volumetric

Inspection of Tubes and Bars

ROTA Ultrasonic Testing Machine Series

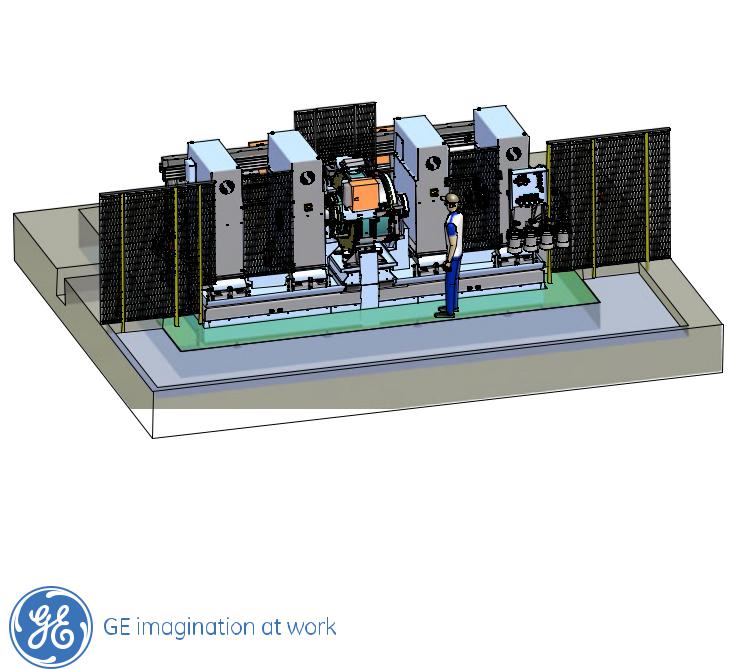

The ROTA Ultrasonic Testing Machine Series |

ROTA Systems Product Line |

GE Sensing & Inspection Technologies supplies the ROTA

– systems which, depending on the client’s requirements, can be configured for individual manual, central or motor adjustment, and are notable for highly repeatable results.

A probe revolution rate of 6000-8000 rpm provides highest productivity rates.

In addition to defect detection, ROTA systems can also be used for geometry checking. ROTA series systems are well known for high test accuracy, repeatability of results, and test speed. Flaw-type defects throughout the material crosssection, and divergences in the dimensions for internal and external diameter, wall thickness, ovality and eccentricity can all be detected in a single inspection cycle. A manual probe fine-adjustment system is installed as standard. It enables fast and repetitive adjustment. The equipment is fitted with single or multiple probes, depending on the particular test application. Single or multi-channel, manual or computercontrolled, parallel scanned inspection electronics systems are used, depending on the equipment configuration. Many test standards require a second, independent physical test procedure. GE Sensing & Inspection Technologies fulfils this specification via the integration of eddy-current test systems.

Nonferrous tube testing

GE Sensing & Inspection Technologies’ ROTA test systems have their origins in high-precision testing of tubes and heat-exchanger tubes for nuclear applications. The ROTA 25 and ROTA 45 Z inspection systems are designed for this dimension range. The ROTA Z is a derivate from the standard ROTA line with central probe adjustment capabilities for

fast changeover times. The ROTA and ROTA Z systems are conform to the extremely strict inspection requirements for nuclear specifications and permit not only defect detection but also complete geometrical checking of the tube crosssection, including internal and external diameter quality and eccentricity. These systems are in use with virtually all manufacturers of nuclear piping around the world.

Testing of hot-processed tubes and bars

Hot-processed tubes and bars necessitate special design features for test and inspection systems, in terms of surface quality, fouling, coarse manufacturing tolerances, test throughputs and test speeds. GE Sensing & Inspection Technologies meets these requirements with its ROTA S systems. In the ROTA S series, a special water routing and cleaning system reliably removes particles from the probes. The ROTA S series was specially developed for hot processed tube with rough surfaces, bend tolerance greater than standard API specification and including tubes with upset ends. Unlike the conventional ROTA systems, the ROTA

S features a central probe distance adjustment system providing extremely fast change of material dimensions.

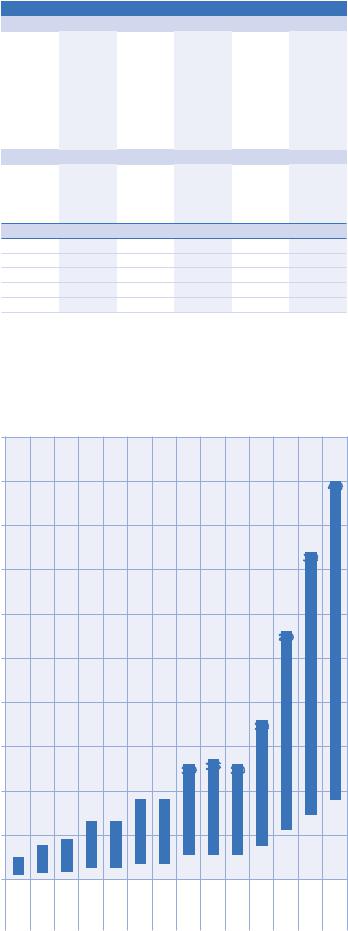

Name |

Version |

OD max |

TRD flaw |

TRD dim |

RPM |

Conventional ROTA |

|

|

|

|

|

25 |

8k8 |

25 |

4 |

4 |

8000 |

40 |

6k8 |

38,1 |

4 |

4 |

6000 |

65 |

6k8 |

65 |

4 |

4 |

4000 |

|

8k10 |

65 |

6 |

4 |

4000 |

90 |

8k10 |

90 |

8 |

2 |

3000 |

|

12k22 |

90 |

18 |

4 |

3000 |

130 |

8k10 |

130 |

6 |

4 |

2000 |

|

12k22 |

130 |

18 |

4 |

2000 |

ROTA Z |

|

|

|

|

|

45 Z |

8k10 |

45 |

4 |

2 |

4500 |

65 Z |

8k22 |

65 |

6 |

2 |

3500 |

90 Z |

8k22 |

90 |

6 |

2 |

2850 |

130 Z |

8k22 |

135 |

6 |

2 |

2000 |

ROTA S

|

130 S |

|

16k18 |

130 |

|

|

16 |

|

2 |

|

|

1600 |

|

|

|

180 S |

|

16k20 |

180 |

|

|

18 |

|

4 |

|

|

1200 |

|

|

|

280 S |

|

16k24 |

280 |

|

|

20 |

|

4 |

|

|

900 |

|

|

|

370 S |

|

16k24 |

370 |

|

|

20 |

|

4 |

|

|

650 |

|

|

|

450 S |

|

16k24 |

450 |

|

|

20 |

|

4 |

|

|

500 |

|

|

500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

450 |

|

|

|

|

|

|

|

|

|

|

|

|

|

450 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

350 |

|

|

|

|

|

|

|

|

|

|

|

|

370 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

280 |

|

|

250 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

180 |

|

|

|

150 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

130 |

135 |

130 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

|

|

|

|

|

|

90 |

90 |

|

|

|

|

|

74 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

65 |

65 |

|

|

|

|

|

|

56 |

|

|

|

|

|

|

|

|

|

|

|

|

38 |

|

|

|

|

|

|

38 |

45 |

|

|

|

|

28 |

28 |

28 |

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|||||

|

|

13 |

13 |

18 |

18 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

0 |

6 |

8 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

ROTA 25 |

ROTA 40 |

ROTA 45Z |

ROTA 65 |

ROTA 65Z |

ROTA 90 |

ROTA 90Z |

ROTA 130 |

ROTA130Z |

ROTA 130S |

ROTA 180S |

ROTA 280S |

ROTA 370S |

ROTA 450S |

Loading...

Loading...