Ge HOME GENERATOR SYSTEM 45000 Manual

GE Home Generator Systems

45000 Watt Home

Generator System

Installation and

Start-Up Manual

Thank you for purchasing this quality-built GE home generator. We’re pleased that you’ve placed your confidence in the GE brand. When operated and maintained according to the instructions in the operator’s manual, your home generator will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with residential generator systems and how to avoid them. This generator system is designed and intended only for use as an optional home standby system that provides an alternate source of electric power and to serve loads such as heating, refrigeration systems, and communication systems that, when stopped during any power outage, could cause discomfort or inconvenience. Save these instructions for future reference.

This home standby generator requires professional installation before use. The installer should follow the instructions completely.

Where to Find Us

You never have to look far to find support and service for your generator. For quick service when you need it most fill out the information below and keep your original receipt with this manual. You may contact Customer Service at (888) 575-8226, or use the Service Center Locator at www.BRIGGSandSTRATTON.com, which provides a list of authorized dealers.

For Future Reference

Please fill out the information below and keep with your receipt to assist in unit identification for future purchase issues.

Date of Purchase

Generator

Model Number

Model Revision

Serial Number

Engine

Serial Number

2

Table of Contents

Important Safety Instructions . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . 7

Home Owner Responsibilities . . . . . . . . . . . . . . . . . . . . . 7 Installing Dealer/Contractor Responsibilities . . . . . . . . . . . . . . 7 Unpacking Precautions . . . . . . . . . . . . . . . . . . . . . . . . 7 Shipment Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Home Generator Location . . . . . . . . . . . . . . . . . . . . . . 8 Electrical and Fuel Inlet Locations . . . . . . . . . . . . . . . . . . 10 The Gaseous Fuel System . . . . . . . . . . . . . . . . . . . . . . 13 Fuel Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . 15 System Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 16 Grounding the Generator . . . . . . . . . . . . . . . . . . . . . . 18 Final Installation Considerations . . . . . . . . . . . . . . . . . . . 20 Initial Start-up (No Load) . . . . . . . . . . . . . . . . . . . . . . . 21 Test Shutdown(s) Procedure . . . . . . . . . . . . . . . . . . . . . 22 Fuel Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 24 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation . . . . . . . . . . . . . . . . . . . . . . . . 26

Automatic Operation Sequence . . . . . . . . . . . . . . . . . . . 26 Setting Exercise Timer . . . . . . . . . . . . . . . . . . . . . . . . 26 Installation Inspection . . . . . . . . . . . . . . . . . . . . . . . . 27

3

Safety Rules

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains important instructions that should be followed during installation and maintenance of the generator and batteries.

Safety Symbols and Meanings

Explosion |

Fire |

Electrical Shock |

Toxic Fumes |

Rotating Parts |

Hot Surface |

Auto Start |

Explosive Pressure |

Chemical Burn |

The manufacturer cannot possibly anticipate every possible circumstance that might involve a hazard. The warnings

in this manual, and the tags and decals affixed to the unit are, therefore, not all-inclusive. If you use a procedure, work method or operating technique that the manufacturer does not specifically recommend, you must satisfy yourself that it is safe for you and others. You must also make sure that the procedure, work method or operating technique that you choose does not render the generator system unsafe.

WARNING Running engine gives off carbon monoxide, an odorless, colorless, poison gas.

WARNING Running engine gives off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache, fatigue,

Breathing carbon monoxide can cause headache, fatigue,  dizziness, vomiting, confusion, seizures, nausea, fainting or death.

dizziness, vomiting, confusion, seizures, nausea, fainting or death.

•Operate generator ONLY outdoors.

•Install a battery operated carbon monoxide alarm near the bedrooms.

•Keep exhaust gas from entering a confined area through windows, doors, ventilation intakes, or other openings.

Rotating Belt/Pulley |

Rotating Fan Blade |

Exploding Battery |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lift Hazard |

Read Manual |

The safety alert symbol indicates a potential personal injury hazard. A signal word (DANGER, WARNING, or CAUTION) is used with the alert symbol to designate a degree or level of hazard seriousness. A safety symbol may be used to represent the type of hazard. The signal word NOTICE is used to address practices not related to personal injury.

The safety alert symbol indicates a potential personal injury hazard. A signal word (DANGER, WARNING, or CAUTION) is used with the alert symbol to designate a degree or level of hazard seriousness. A safety symbol may be used to represent the type of hazard. The signal word NOTICE is used to address practices not related to personal injury.

DANGER indicates a hazard which, if not avoided, will result in death or serious injury.

DANGER indicates a hazard which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or moderate injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

WARNING The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

WARNING The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

WARNING Certain components in this product and related accessories contain chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. Wash hands after handling.

WARNING Certain components in this product and related accessories contain chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. Wash hands after handling.

4

WARNING Storage batteries give off explosive hydrogen gas during recharging.

WARNING Storage batteries give off explosive hydrogen gas during recharging.

Slightest spark will ignite hydrogen and

cause explosion.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents will cause severe chemical burns. A battery presents a risk of electrical shock and high short circuit current.

•DO NOT dispose of battery in a fire. Recycle battery.

•DO NOT allow any open flame, spark, heat, or lit cigarette during and for several minutes after charging a battery.

•DO NOT open or mutilate the battery.

•Wear protective goggles, rubber apron, rubber boots and rubber gloves.

•Remove watches, rings, or other metal objects.

•Use tools having insulated handles.

WARNING Propane and Natural Gas are extremely flammable

WARNING Propane and Natural Gas are extremely flammable

and explosive.

Fire or explosion can cause severe burns or death.

•Install the fuel supply system according to NFPA 37 and other applicable fuel-gas codes.

•Before placing the generator into service, the fuel system lines must be properly purged and leak tested.

•After the generator is installed, you should inspect the fuel system periodically.

•NO leakage is permitted.

•DO NOT operate engine if smell of fuel is present or other explosive conditions exist.

•DO NOT smoke around the generator. Wipe up any oil spills immediately. Ensure that no combustible materials are left in the generator compartment. Keep the area near the generator clean and free of debris.

WARNING Hazardous Voltage - Contact with power lines can cause electric shock or burn.

WARNING Hazardous Voltage - Contact with power lines can cause electric shock or burn.

Lifting Hazard / Heavy Object - Can cause muscle strain or back injury.

•If lifting or hoisting equipment is used, DO NOT contact any power lines.

•DO NOT lift or move generator without assistance.

•Use lifting pipes as described in Lifting the Generator. The unit may shift on the lifting pipes during movement, which can cause injury.

•DO NOT lift unit by roof as damage to generator will occur.

WARNING Generator produces hazardous voltage. Failure to properly ground generator can result in electrocution.

WARNING Generator produces hazardous voltage. Failure to properly ground generator can result in electrocution.

Failure to isolate generator from power utility can result in death or injury to electric utility workers due to backfeed of electrical energy.

•When using generator for backup power, notify utility company.

•DO NOT touch bare wires or bare receptacles.

•DO NOT use generator with electrical cords which are worn, frayed, bare or otherwise damaged.

•DO NOT handle generator or electrical cords while standing in water, while barefoot, or while hands or feet are wet.

•If you must work around a unit while it is operating, stand on an insulated dry surface to reduce the risk of a shock hazard.

•DO NOT allow unqualified persons or children to operate or service generator.

•In case of an accident caused by electrical shock, immediately shut down the source of electrical power and contact the local authorities. Avoid direct contact with the victim.

•Despite the safe design of the residential generator, operating this equipment imprudently, neglecting its maintenance or being careless can cause possible injury or death.

•Remain alert at all times while working on this equipment. Never work on the equipment when you are physically or mentally fatigued.

•Before performing any maintenance on the generator, disconnect the battery cable indicated by a NEGATIVE, NEG or (-) first. When finished, reconnect that cable last.

•After your system is installed, the generator may crank and start without warning any time there is a power failure. To prevent possible injury, always set the generator’s system switch to OFF, remove the service disconnect from the disconnect box AND remove the 15 Amp fuse BEFORE working on the equipment.

5

WARNING Contact with muffler area can result in serious burns.

WARNING Contact with muffler area can result in serious burns.

Exhaust heat/gases can ignite combustibles or structures causing a fire.

•DO NOT touch hot parts and AVOID hot exhaust gases.

•Allow equipment to cool before touching.

•DO NOT install the generator closer than 5 feet (1.5m) from any combustibles or structures with combustible walls having a fire resistance rating of less than 1 hour.

•Keep at least minimum distances shown in General Location Guidelines to insure for proper generator cooling and maintenance clearances.

•It is a violation of California Public Resource Code, Section 4442, to use or operate the engine on any forest-covered, brushcovered, or grass-covered land unless the exhaust system is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order. Other states or federal jurisdictions may have similar laws.

Contact the original equipment manufacturer, retailer, or dealer to obtain a spark arrester designed for the exhaust system installed on this engine.

•Replacement parts must be the same and installed in the same position as the original parts.

WARNING Moving parts can crush and cut. Starter and other rotating parts

WARNING Moving parts can crush and cut. Starter and other rotating parts

can entangle hands, hair, clothing,

can entangle hands, hair, clothing,  or accessories.

or accessories.

•NEVER operate generator without protective housings, covers, or guards in place.

•DO NOT wear loose clothing, jewelry or anything that may be caught in the starter or other rotating parts.

•Tie up long hair and remove jewelry.

•Before servicing, remove 15 Amp fuse from control panel and disconnect Negative (NEG or -) battery cable.

WARNING Hot pressurized coolant can cause severe injury

WARNING Hot pressurized coolant can cause severe injury

and/or property damage.

and/or property damage.

•DO NOT open radiator cap when hot.

•Before servicing, allow coolant to cool.

CAUTION Installing the 15A fuse could cause the engine

CAUTION Installing the 15A fuse could cause the engine  to start.

to start.

•Observe that the 15 Amp fuse has been removed from the control panel for shipping.

•DO NOT install this fuse until all plumbing and wiring has been completed and inspected.

CAUTION Excessively high operating speeds increase risk of injury and damage to generator.

CAUTION Excessively high operating speeds increase risk of injury and damage to generator.

Excessively low speeds impose a heavy load on generator.

•DO NOT tamper with governed speed. Generator supplies correct rated frequency and voltage when running at governed speed.

•DO NOT modify generator in any way.

NOTICE Exceeding generators wattage/amperage capacity can damage generator and/or electrical devices connected to it.

•See Essential Circuits in operator’s manual.

•Start generator and let engine stabilize before connecting electrical loads.

NOTICE Improper treatment of generator can damage it and shorten its life.

•Use generator only for intended uses.

•If you have questions about intended use, contact your authorized ealer.

•Operate generator only on level surfaces.

•Adequate, unobstructed flow of cooling and ventilating air is critical to correct generator operation.

•The Oil Fill, Oil Drain and the Control Panel doors must be installed whenever the unit is running.

•DO NOT expose generator to excessive moisture, dust, dirt, or corrosive vapors.

•Despite the safe design of the residential generator, operating this equipment imprudently, neglecting its maintenance or being careless can cause possible injury or death.

•Remain alert at all times while working on this equipment. Never work on the equipment when you are physically or mentally fatigued.

•DO NOT start engine with air cleaner or air cleaner cover removed.

•DO NOT insert any objects through cooling slots.

•DO NOT use the generator or any of its parts as a step. Stepping on the unit can cause stress and break parts. This may result in dangerous operating conditions from leaking exhaust gases, fuel leakage, oil leakage, etc.

•If connected devices overheat, turn them off and disconnect them from generator.

•Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames; -unit vibrates excessively.

6

Installation

This product is intended for use as an optional home generator system which provides an alternate source of electric power and to serve loads such as heating, refrigeration systems, and communication systems that, when stopped during any power outage, could cause

discomfort or inconvenience. This product does not qualify for emergency standby as defined by NFPA 70 (NEC).

Every effort has been made to ensure that information in this manual is accurate and current. However, we reserve the right to change, alter, or otherwise improve the product and this document at any time without prior notice.

Home Owner Responsibilities

•Read and follow the instructions given in the

Operator’s Manual, especially the section regarding selecting essential circuits.

•Follow a regular schedule in maintaining, caring for and using your home generator, as specified in the Operator’s Manual.

Installing Dealer/Contractor Responsibilities

•Read and observe the safety rules.

•Install only an UL approved transfer switch that is compatible with the generator.

•Read and follow the instructions given in this

Installation and Start-up Manual.

IMPORTANT: The system is equipped with a water heater that is activated when ambient temperature is less than 80°F AND utility power is present at the transfer switch.

If you need more information on this matter, please call (888) 575-8226, between 8:00 AM and 5:00 PM CT.

Unpacking Precautions

The unit is shipped ready for installation on a prepared reinforced cement slab or engineered base. Avoid damage from dropping, bumping, collision, etc. Store and unpack carton with the proper side up, as noted on the shipping carton.

7

Delivery Inspection

After removing the carton, carefully inspect the generator for any damage that may have occurred during shipment.

IMPORTANT: If loss or damage is noted at time of delivery, have the person(s) making delivery note all damage on the freight bill and affix his signature under the consignor’s memo of loss or damage. If loss or damage is noted after delivery, separate the damaged materials and contact the carrier for claim procedures. Missing or damaged parts are not warranted.

Shipment Contents

The home generator system is supplied with: |

Not Supplied: |

•Fully-serviced coolant system

•Fully-serviced oil/lubricating system

•Flexible fuel hook-up hose

•Installation and start-up manual

•Operator’s manual

•Engine operator’s manual

•Installation checklist

•Access door keys

•Spare 15 Amp ATO-type fuse

•Ten-pole control panel connector

•Touch up paint

•Remote LED indicator kit (LED/plate/screws)

•Starting battery (see p. 20)

•Reinforced concrete pad

•Connecting wire and conduit

•Fuel supply valves/plumbing

•Two 60” lengths of 2” Schedule 40 pipe (NOT conduit)

•Crane, lifting straps, chains or cables

•Hole punches for 7 ga steel

•Torque screwdriver, 5 to 50 inch-pound range

•Voltage/frequency meter

•Ignition timing light (if converting fuel type)

•Air Fuel Ratio Meter (O2 Sensor and Analyzer, if converting fuel type)

•Dummy load (if converting fuel type)

•Various special tools and equipment

Generator Location

Before installing the generator, consult with the homeowner and convey the following guidelines, which may affect the desired location.

WARNING Exhaust heat/gases can ignite combustibles or

WARNING Exhaust heat/gases can ignite combustibles or  structures causing a fire.

structures causing a fire.

•DO NOT install the generator closer than 5 feet (1.5m) from any combustibles or structures with combustible walls having a fire resistance rating of less than 1 hour.

WARNING Running engine gives off carbon monoxide, an odorless, colorless, poison gas.

WARNING Running engine gives off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache, fatigue,

Breathing carbon monoxide can cause headache, fatigue,  dizziness, vomiting, confusion, seizures, nausea, fainting or death.

dizziness, vomiting, confusion, seizures, nausea, fainting or death.

•Operate generator ONLY outdoors.

•Install a battery operated carbon monoxide alarm near the bedrooms.

•Keep exhaust gas from entering a confined area through windows, doors, ventilation intakes, or other openings.

8

Install generator outdoors in an area which will not accumulate deadly exhaust gas. DO NOT install generator where exhaust gas could accumulate and enter inside or be drawn into a potentially occupied building. Ensure exhaust gas is kept away from windows, doors, ventilation intakes or other openings that can allow exhaust gas to collect in a confined area. Prevailing winds and air currents should be taken into consideration when positioning generator.

General Location Guidelines

•Install the unit outdoors ONLY.

•Place the unit on a prepared concrete slab that is flat, level, and has provisions for water drainage.

•Install the unit in a location where sump pump discharge, rain gutter down spouts, roof run-off, landscape irrigation, or water sprinklers will not flood the unit or spray the enclosure and enter any air inlet or outlet openings.

•Install the unit where it will not affect or obstruct any services (including covered, concealed and underground), such as telephone, electric, fuel, irrigation, air conditioning, and so forth.

•Install the unit where air inlet and outlet openings will not become obstructed by leaves, grass, snow, etc. If prevailing winds will cause blowing or drifting, you may need to construct a windbreak to protect the unit.

•Install the generator as close as possible to the transfer switch and fuel supply to reduce the length of wiring, conduit, and piping.

IMPORTANT: Laws or local codes may regulate the distance to the fuel supply.

The minimum (MIN) clearances from aerial view of generator

(B) to combustible (D), and non-combustible (A) materials is shown below.

•These distances are provided to give generator location guidance relative ONLY to combustibles, generator cooling, and maintenance.

•The minimum distances in the figure are as shown.

All four sides of the generator cannot be enclosed or restricted, even if the minimum distances are maintained. DO NOT connect (A) and/or (D) to (E).

•A roof cannot be used.

•Exhaust (C) must not be allowed to accumulate.

B

C

D A  D

D

E  E

E

ANon-Combustible material with Fire Resistant Rating of 1 hour or greater

BHome Standby Generator

CEngine Exhaust

DCombustible Material or Structure with a Fire Resistance Rating of less than 1 hour

EAny structure or material. DO NOT connect (A) and/or

(D) to (E)

9

Concrete Slab

At the appropriate location, construct a concrete slab:

•28 day compression strength of 3000 psi (200 MPa)

•Minimum 5 inches thick

•Minimum 6 inches wider than enclosure on all sides

(shown as D in figure)

•Strengthen slab with No. 6 reinforcing bars (on 12” centers) or 8 ga. steel wire fabric (6” centers).

NOTE: Avoid placing reinforcement in entrance stub-up area (shown as (B)).

Attach unit to slab at four corner locations (A) with minimum

5/16” diameter (8mm) masonry anchor bolts long enough to secure the unit.

The fuel inlet location (C) and the exhaust opening (E) are shown for reference.

|

|

49” |

10.13” |

7” |

7.38” |

|

|

34.25” |

19” |

|

8” |

|

|

|

|

|

A |

9.5” |

|

|

92”

59” |

B |

|

C |

108” |

|

D

E

Electrical and Fuel Inlet Locations

A through-slab power cable stub-up is preferred (see |

|

|

|

figure above). If stub-up’s are not used, (F) indicates the |

|

|

|

recommended location for punching holes for attaching |

|

|

|

power conduit. The 1 inch N.P.T. fuel inlet connector (C) is |

F |

C |

|

shown for reference. |

|||

|

|

10

Lifting the Generator

The generator weighs more than 2,070 pounds (941 kg). Proper tools, equipment and qualified personnel should be used in all phases of handling and moving the generator.

WARNING Hazardous Voltage - Contact with power lines can cause electric shock or burn.

WARNING Hazardous Voltage - Contact with power lines can cause electric shock or burn.

Lifting Hazard / Heavy Object - Can cause muscle strain or back injury.

•If lifting or hoisting equipment is used, DO NOT contact any power lines.

•DO NOT lift or move generator without assistance.

•Use lifting pipes as described in Lifting the Generator. The unit may shift on the lifting pipes during movement, which can cause injury.

•DO NOT lift unit by roof as damage to generator will occur.

Two 60” lengths of 2” Schedule 40 pipe (G), supplied by the installer, are required to lift the generator onto cement pad. Insert pipes through the lifting holes (H) located near the unit’s base.

A B

Use a spreader bar to ensure that the chains, straps or cables DO NOT touch the generator’s roof. Retouch any chipped paint with supplied touch-up paint.

11

Access Ports

The generator is equipped with an enclosure that has several access doors, as shown. The doors are named for a significant component located behind them, as follows:

A - Fuel Inlet port (shown for reference)

B - Control Panel door (may be two doors( C - Exhaust opening (shown for reference) D - Coolant/Oil Fill door

E - Battery door

WARNING Contact with muffler and engine parts can result in

WARNING Contact with muffler and engine parts can result in  serious burns.

serious burns.

•DO NOT touch hot parts and AVOID hot exhaust gases.

•Allow equipment to cool before touching.

The Coolant Fill, Battery and Control Panel doors must be installed whenever the unit is running to assure proper cooling, reduce noise and for added safety. The enclosure also includes muffler and radiator access panels, used for cleaning those components. Those panels should remain closed at all other times.

Each generator is shipped with a set of identical keys. These keys fit the locks that secure the access ports.

To open access door:

1.Insert key into lock of access door handle and turn key one quarter turn counterclockwise.

2.Grasp door’s handle and turn one quarter turn counterclockwise to open. Remove key.

3.Coolant Fill door is unlocked in the same manner. It can be used for adding coolant or oil.

To close access door:

1.Close door and turn door’s handle one quarter turn clockwise.

2.Insert key into lock of door handle and turn key one quarter turn clockwise. Remove key.

C D

A B E

12

The Gaseous Fuel System

The information below is provided to assist gaseous fuel system technicians in planning installations. In no way should this information be interpreted to conflict with applicable fuel gas codes. Consult with your local fuel supplier or Fire Marshall if questions or problems arise.

WARNING Propane and Natural Gas are extremely flammable

WARNING Propane and Natural Gas are extremely flammable

and explosive.

Fire or explosion can cause severe burns or death.

•LP gas is heavier than air and will settle in low areas.

•Natural gas is lighter than air and will collect in high areas.

•The slightest spark can ignite these fuels and cause an explosion.

•DO NOT light a cigarette or smoke.

TO THE INSTALLER: Consult with the home generator owner(s) and convey any technical considerations that might affect their installation plans before applying these general guidelines.

The following general rules apply to gaseous fuel system piping:

•The piping should be of a material that conforms to federal and local codes, rigidly mounted and protected against vibration.

•Piping should be protected from physical damage where it passes through flower beds, shrub beds, and other cultivated areas where damage could occur.

CAUTION The supplied flexible gaseous pipe is not to be installed underground or in contact with the ground.

CAUTION The supplied flexible gaseous pipe is not to be installed underground or in contact with the ground.

•The entire flexible gaseous pipe must be visible for periodic inspection and must not be concealed within nor contact nor run through any wall, floor, or partition.

•Install the flexible, gaseous hose (supplied) between the home generator Fuel Inlet port and rigid piping to prevent thermal expansion or contraction from causing excessive stress on the piping material.

NOTE: Where local conditions include earthquake, tornado, unstable ground, or flood hazards, special consideration shall be given to increase strength and flexibility of piping supports and connections.

•Piping must be of the correct size to maintain the required supply pressures and volume flow under varying generator load conditions with all gas appliances connected to the fuel system turned on and operating.

WARNING Propane and Natural Gas are extremely flammable

WARNING Propane and Natural Gas are extremely flammable

and explosive.

Fire or explosion can cause severe burns or death.

•Before placing the generator into service, the fuel system lines must be properly purged and leak tested.

•No leakage is permitted.

•Use a pipe sealant or joint compound approved for use with NG/LPG on all threaded fittings to reduce the possibility of leakage.

•Installed piping must be properly purged and

leak tested, in accordance with applicable codes and standards.

Consider the following factors when planning the fuel supply system installaton:

•Air density is less at high altitudes, resulting in less available engine power. See Power Decrease at High Altitude or High Temperature in the operator’s manual.

•A minimum of one accessible, approved manual shutoff valve shall be installed in the fuel supply line within 6 ft (1.8 m) of the home generator. A union or flanged connection shall be provided downstream from this valve to permit removal of controls.

•Both LP vapor and natural gas fuel supply pressure at the generator’s fuel inlet port should be between 7 to 11 inches of water (in. W.C.) at full load with all gas appliances turned on and operating.

The generator has been factory load tested to run on either natural gas or LP vapor fuel. The unit can be converted from natural gas to LP vapor or vice versa using two people and special tools. See Fuel Conversion, later in this manual.

13

It is recommended that the fuel connection incorporate the following components:

•A minimum 10 ft. (3 m) section of gas pipe between the primary fuel regulator and the generator fuel inlet connection (acts as accumulator for high block loads).

•A manual fuel shut-off valve located in the interior of the building.

•A manual fuel shut-off valve located outside the building, just before the generator unit.

•Where the formation of hydrates or ice is known to occur, piping should be protected against freezing. The termination of hard piping should include

a sediment trap where condensate is not likely to freeze.

•A manometer port should be provided.

The manometer port permits temporary installation of a manometer to ensure that the engine receives the correct fuel pressure to operate efficiently throughout its operating range.

When the initial test runs are completed, the manometer is removed and the port is plugged. A typical final fuel connection assembly is shown here, where (A) is the fuel supply and (B) goes to the home generator.

A B

Fuel Pipe Sizing

There are numerous on-line or otherwise-published references for fuel pipe sizing. For example, NFPA 54 - National Fuel Gas Code, 2006 (Item #: 320-6031-06) is a common resource. The installer should consider the specific gravity of gas and compensate for a nominal amount of restriction from bends, fittings, etc. If an unusual number of fittings, bends, or other restrictions are used, refer to federal and local codes for guidance.

14

Fuel Consumption

Estimated fuel supply requirements at half and full load for natural gas and LP vapor fuels are shown here.

Natural Gas |

LP Vapor |

||

1/2 Load |

Full Load |

1/2 Load |

Full Load |

|

|

|

|

483 C |

777 C |

178 C |

297 C |

|

|

|

|

483,000 B |

777,000 B |

445,000 B |

742,000 B |

|

|

|

|

C = Cubic feet per hour

B = BTU’s per hour

Physical |

LP Vapor |

Natural |

Properties |

|

Gas |

Normal Atmospheric |

Gas |

Gas |

State |

|

|

|

|

|

Boiling Point (in °F): |

|

|

Initial |

-44 |

-259 |

End |

-44 |

-259 |

|

|

|

Heating Value: |

|

|

BTU per gallon (Net |

|

|

LHV*) |

83,340 |

63,310 |

BTU per gallon (gross**) |

91,547 |

|

Cubic feet (gas) |

2,500 |

1,000 |

Density*** |

36.39 |

57.75 |

|

|

|

Weight† |

4.24 |

2.65 |

|

|

|

Octane Number: |

|

|

Research |

110+ |

110+ |

Motor |

97 |

|

|

|

|

* LHV (Low Heat Value) is the more realistic rating.

** Gross heat value does not consider heat lost in the form of water during combustion.

*** Density is given in “Cubic Feet of Gas per Gallon of Liquid”.

† Weight is given in “Pounds per Gallon of Liquid”.

15

System Connectors

Low voltage connections to signal fault contacts, transfer switch communication, remote LED and auxiliary 12VDC power are made via a removable ten-pole connector plug. Compare this illustration with your generator to familiarize yourself with the location of these connections. Count down to the proper pin location on the control board since visual alignment with the decal can be misleading:

A

B

C

D

E

A - Ten Pole Connector Plug — Used to connect signal wires to the control panel. Connect only one wire per terminal.

B - Fault Contacts —Use NO, COM and NC to hook up a siren, light, etc. to alert you in case of a fault. Contacts reverse state (NO goes to NC and vice versa) upon a fault condition.

C - Transfer Switch Communication — Connect to transfer switch control board for communication interface using 18AWG copper twisted pair wire.

IMPORTANT:

D - Remote LED Output — Use this to hook up the remote LED supplied with the generator. The remote LED will turn on and off in a series of blinks if certain faults are detected in the generator.

E - +12 Volt DC, .5 Amp Output — Internal auxiliary power supply.

•For power output connection, use #3/0 AWG minimum 300 volt 75°C-90°C copper wire, (ref. NEC Table 310.16, 100 ft.

Use National Electric Code for correction factors and wire size calculations.)

•For Utility Circuit connection use #14 AWG minimum 300 volt 75°C-90°C copper wire.

•For transfer switch communication use #18 AWG twisted pair conductors, no greater than 200 ft in length, 300 volt

75°C-90°C copper wire.

•When connecting to the ten-pole connector plug, fasten only one wire to each connector screw.

•Torque connector plug screws to 7 in-lb (7.9 Newton meter).

16

Generator AC Connection System

A single-phase, three-wire AC connection system is used in the home generator. The stator assembly consists of a pair of stationary windings with two leads brought out of each winding. The junction of leads T2 and T3 forms the neutral lead, as shown schematically and as wiring diagram. A complete schematic and wiring diagram can be found later in this manual.

NOTE: Neutral is not bonded to ground at generator.

When making connections, obey wire type and torque specifications shown on the circuit breaker and neutral/ ground connector.

|

T2 |

|

Neutral |

|

T3 |

|

|

Winding |

|

|

120 V |

Power |

|

|

|

|

|

Circuit |

120 V |

|

|

|

|

|

|

Breaker |

|

|

T4 |

|

240 V |

|

T1 |

|

|

|

|

|

|

Neutral |

T4 |

T1 |

Ground |

N |

|

|

G |

Neutral |

Line 1 |

Line 2 |

Ground |

To Transfer Switch

Control |

Water |

Board |

Heater |

10 A |

10 A |

240 VAC

To Transfer Switch

Utility Fuse Connection

17

Grounding the Generator

Ground the generator per applicable codes, standards and regulations. There are two generator GND lug locations. The one inside the alternator junction box next to the circuit breaker is the primary lug and should suffice for most

applications. The second generator GND lug is located on the frame below the generator circuit breaker cover and should ONLY be used for a ground rod located at the generator, if required by local codes. See Controls for location.

Utility Circuit Connection

“240V Utility” leads must be routed in conduit. The

“240V Utility” leads deliver power to the generator’s circuit board and water heater. This power also charges the battery. When power on these leads is lost, the generator will start.

Using installer-supplied minimum 300V, 14 AWG copper wire, connect each ten amp fuse terminal in the alternator junction box to the ten amp fuse terminals in the automatic transfer switch.

When making connections, obey wire type and torque specifications printed on the circuit breaker and neutral/ ground connector.

Fault Detection System

The generator may have to run for long periods of time with no operator present. For that reason, the system is equipped with sensors that automatically shut down the generator

in the event of potentially damaging conditions, such as low oil pressure, high temperature, over speed, and other conditions. Refer to Fault Detection System in the operator’s manual for more detailed information.

The owner will use the remote LED indicator to observe the status of the home generator system. The remote LED will turn on and off in a series of blinks if certain faults are detected in the generator system. Consult with the owner for a convenient location. Locate the electrical box in an

area visible by the home owner such as near a garage door opener or security control panel.

To install the remote LED indicator:

1.Push the LED through the mounting plate from the front until it snaps in place.

IMPORTANT: The LED is polarity sensitive.

2.Using provided 10 pole connector and installersupplied minimum 18AWG wire, connect the remote LED to the generator control board +LED and GND connection. Use wire nuts to attach wire to LED leads.

3.Attach mounting plate to installer-supplied electrical box.

18

System Control Panel

The home generator control panel, located inside the generator housing, is shown below.

E F

D

C

B

A

Brief descriptions of the controls used during installation are:

A - Circuit Breaker — Must be ON to supply power to the transfer switch. Breaker enclosure includes removable bottom panel to assist with conduit connections.

B - SET EXERCISE — Used to set exercise cycle start time.

C - MANUAL OVER-RIDE — Used to manually start and stop the generator.

D - 15 Amp fuse — Protects DC control circuits.

E - System Switch — Switches modes to OFF or AUTO.

F - Digital Display — Displays running time in hours or fault codes.

See Controls in the Operator’s Manual for more information..

System Switch

This two-position switch is the most important control on the home generator and is used as follows:

•“AUTO” position is the normal operating position. If a utility power outage is sensed, the system will start the generator. When utility power is restored, lets the engine stabilize internal temperatures, shuts off the generator, and waits for the next utility power outage.

•“OFF” position turns off running generator, prevents unit from starting and resets any detected faults.

15 Amp Fuse

Protects the home generator DC control circuits. If the fuse has ‘blown’ (melted open) or was removed, the engine cannot crank or start. Replace the fuse using only an identical ATO 15 Amp fuse. One spare fuse is supplied with the unit.

If fuse was blown or removed, you will need to reset the exercise timer (see Setting Exercise Timer).

19

Final Installation Considerations

Engine Oil

NOTICE Any attempt to crank or start the engine before it has been properly serviced with the recommended oil will result in equipment failure.

•Refer to Maintenance in the Operator’s Manual and engine manual for oil fill information.

•Damage to equipment resulting from failure to follow this instruction will void engine and generator warranty.

The engine is shipped from the factory pre-run and filled with non-synthetic oil (API SL 10W-30). This allows for system operation in a wide range of temperature and climate conditions. Before starting the engine, check oil level and ensure that engine is serviced as described in the engine operator’s manual.

Coolant System

The engine is shipped from the factory filled with a

50 50 mix of automotive (Dex-Cool™ orange) anti-freeze and water. This will provide optimum year round protection against freezing, boiling and corrosion. The coolant system incorporates a water heater that operates when ambient temperature is below 80ºF AND utility power is present at the transfer switch. Periodically check coolant level as described in the engine manual.

Battery

The installer must supply and install a valve-regulated rechargeable starting battery. The starting battery MUST conform to the specifications shown in this chart.

Battery Specifications

Volts |

12 Volt DC |

|

|

Amps (MIN) |

650 CCA (cold cranking amps) |

Type |

Valve Regulated Lead Acid (VRLA) |

|

|

Terminal Hardware |

Post |

|

|

Dimensions (MAX): |

|

Width |

7.5 inches (191mm) |

|

|

Length |

11.25 inches (286mm) |

|

|

Height |

10.0 inches (254mm) |

Install the battery as described in Servicing the Battery in the Maintenance section of the operator’s manual. Always make sure the NEGATIVE cable is connected last.

WARNING Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

WARNING Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Fuel Supply System

Ensure that all fuel pipe connections are tight, secure and without leaks.

Ensure that all gas line shutoff valves are OPEN and that adequate fuel pressure is available whenever automatic operation is desired.

20

Initial Start-up (No Load)

Before operating the generator or placing it into service, inspect the entire installation carefully. Then begin testing the system without any electrical loads connected, as follows:

NOTE: Unit has been set-up for NG or LP vapor operation at the factory. Fuel conversion, if needed, must be completed prior to performing these steps. See Fuel Conversion, later in this manual.

1.Connect an accurate AC voltmeter and a frequency meter to check generator output at load side of circuit breaker.

2.Set generator’s circuit breaker to its ON (closed) position.

3.Confirm 15 Amp fuse is installed in system control panel.

4.Set generator’s system switch to AUTO.

5.Push and hold MANUAL OVER-RIDE button on control panel for about six seconds. Engine will start.

NOTE: When the generator is started for the very first time, it will require that air in the gaseous fuel lines be purged. This may take a few minutes.

6.Listen for unusual noises, vibration or other indications of abnormal operation. Check for oil or coolant leaks while engine runs.

7.Let engine warm up for about five minutes to allow internal temperatures to stabilize.

8.No-load voltage should be 239 - 244 Volts, frequency should be 59.8 - 60.2 Hz.

NOTE: If AC voltage is outside these ranges, perform the generator adjustment, Steps 11 and 12 below.

9.Check generator output between one of the generator connection lugs and the neutral lug, then between the other generator connection lug and the neutral lug. In both cases, voltage reading should be 117 - 123 Volts.

IMPORTANT: DO NOT proceed until you are certain that generator AC voltage is correct and within the stated limits. Generator frequency is fixed and not adjustable.

10.If voltage and frequency values are correct, proceed to step 13.

11.Connect voltmeter as described in step 1 above.

12.While observing voltmeter, adjust alternator voltage control (A) for 240 volts. DO NOT adjust either of the other alternator controls.

VOLTAGE ADJUST |

STABILITY ADJUST |

FREQ-UNDER ADJUST |

A

13.Push and hold MANUAL OVER-RIDE button on control panel until engine stops.

14.Install alternator circuit breaker enclosure cover.

21

Test Shutdown(s) Procedure

The installer will test the system to verify that diagnostic messages are correctly shown on the system control panel digital display, as follows:

FC_1 - Low Battery

No test procedure required for this fault.

FC_2 - Low Oil Pressure

Locate wire #85 (A) connected to the Oil Pressure Switch.

A

Connect an installer-supplied jumper wire to wire #85. With the system switch in AUTO position, push MANUAL OVER RIDE to start the generator. With the

generator running, connect other end of jumper to a good ground location such as the engine block. The generator will shut down and FC_2 will be displayed on the system control panel. Remove the jumper wire. Turn the system switch to OFF for 30 seconds to clear the fault.

FC_3 - Low Voltage

With the system switch in AUTO position, push MANUAL OVER RIDE to start the generator. With the generator running at no load, turn the generator circuit breaker to OFF. The generator should shut down and

FC_3 will be displayed on the system control panel. Turn the system switch to OFF for 30 seconds to clear the fault. Turn the circuit breaker to ON position.

FC_4 - Engine Fails to Start

With the generator not running, turn the installer supplied manual fuel valve to the OFF position. With the system switch in AUTO, turn off utility power. The engine will crank, attempting to start. After approximately a two-minute start attempt (10 seconds of crank, 10 seconds of rest) the generator should terminate the start attempt and FC_4 will be displayed on the system control panel. Turn the system switch to OFF for 30 seconds to clear the fault. Turn the installer supplied fuel valve to the ON position.

FC_5 - Low Frequency

No test procedure required for this fault.

FC_6 - Engine Overspeed

No test procedure required for this fault.

FC_7 - High Temperature

Locate wire #95 (B) connected to the temperature switch.

B

Connect an installer-supplied jumper wire to wire #95. With the system switch in AUTO position, push MANUAL OVER RIDE to start the generator. With the

generator running, connect other end of jumper to a good ground location such as the engine block. The generator should shut down and display FC_7 on the system control panel. Remove the jumper wire. Turn the system switch to OFF for 30 seconds to clear the fault.

FC_8 - Transfer Switch Fault

(Units with ACCM II or later transfer switch only)

Verify that utility power is present at the automatic transfer switch. With the system switch in AUTO position, carefully remove one of the 2 Amp fuses from the transfer switch. FC_8 will display on the system control panel. Carefully reinstall the fuse in the transfer switch, then turn the system switch to OFF for 30 seconds to clear the fault.

Analyze Test Results

If any test procedure above does not cause the generator to shut down and display the indicated fault, repair the fault condition before putting the unit into service.

22

Fuel Conversion

The unit is shipped from the factory calibrated for NG or LP vapor operation. To convert the engine from NG to LP vapor or from LP vapor to NG operation, follow these steps:

1.Set generator circuit breaker to OFF

2.Set control panel system switch to OFF

3.Remove 15 Amp fuse from system control panel.

4.Remove Zero Pressure Regulator (ZPR) tower cap (A). The Main Adjust control is shown as (B).

B A

5.Calibrate O2 sensor per Analyzer manufacturer specification. Install O2 sensor into exhaust pipe. (Note: technician supplies O2 sensor and analyzer)

6.Attach timing light to #1 spark plug on engine (see engine manual for diagram).

7In control panel enclosure, “OPEN” fuel selector jumper for NG operation and “CLOSE” connector for LP operation. See schematic or wire diagram for further information.

8.Re-install 15 Amp fuse in system control panel.

9.Set generator circuit breaker to ON

10.Set control panel system switch to AUTO

11.After purging fuel supply line, push

MANUAL OVER-RIDE button on control panel for six seconds. When engine starts, allow unit to warm up for ten minutes under no load.

NOTE: If utility power is not connected, the generator will start automatically.

12.Using technician-supplied timing light, locate timing marks on crankshaft vibration dampener.

13.If timing is not within specification, loosen distributor hold-down clamp. While observing timing indicator, adjust distributor as listed below

LP = 24 degrees before top dead center NG = 32 degrees before top dead center

NOTE: Timing values are approved by PSI Engineering.

14.Tighten distributor hold-down clamp.

15.While observing O2 Analyzer readout, adjust zero pressure (A) and main adjustment (B) screws to obtain stoichiometric value shown in table. Select table value

that corresponds to your O2 Analyzer display. The shaded line in table indicates optimum target value.

Voltage |

Phi |

Lamda |

2.40 |

1.000 |

1.000 |

|

|

|

2.45 |

1.012 |

0.988 |

|

|

|

2.50 |

1.024 |

0.977 |

2.55 |

1.036 |

0.966 |

|

|

|

2.60 |

1.048 |

0.955 |

|

|

|

2.65 |

1.060 |

0.944 |

16.Using technician-supplied load, add half load to generator. Check and adjust (A) and (B) to achieve target value.

17.Using technician-supplied load, add full load to generator. Check and adjust (A) and (B) to achieve target value.

18.Remove load and check if sensor value remained in target area. If needed, adjust (A) and (B) to achieve target value.

19.Add half, then full load to generator. Recheck and verify sensor value remains in target area.

IMPORTANT: It may take several attempts to achieve the target setting. Continue to test and adjust with engine stabilized at no, half and full loads until target value is achieved at all generator loads.

20.Remove load from generator. Allow generator to run for ten minutes to stabilize internal temperatures. Turn control panel system switch to OFF.

21.Remove 15 Amp fuse from system control panel.

WARNING Contact with muffler and engine parts can result in

WARNING Contact with muffler and engine parts can result in  serious burns.

serious burns.

•DO NOT touch hot parts and AVOID hot exhaust gases.

•Allow equipment to cool before touching.

22.Install the ZPR tower cap, remove O2 sensor, and timing light.

23.Re-install fuse in system control panel.

24.Set exercise timer.

25.Complete emissions statement and send with installation checklist.

23

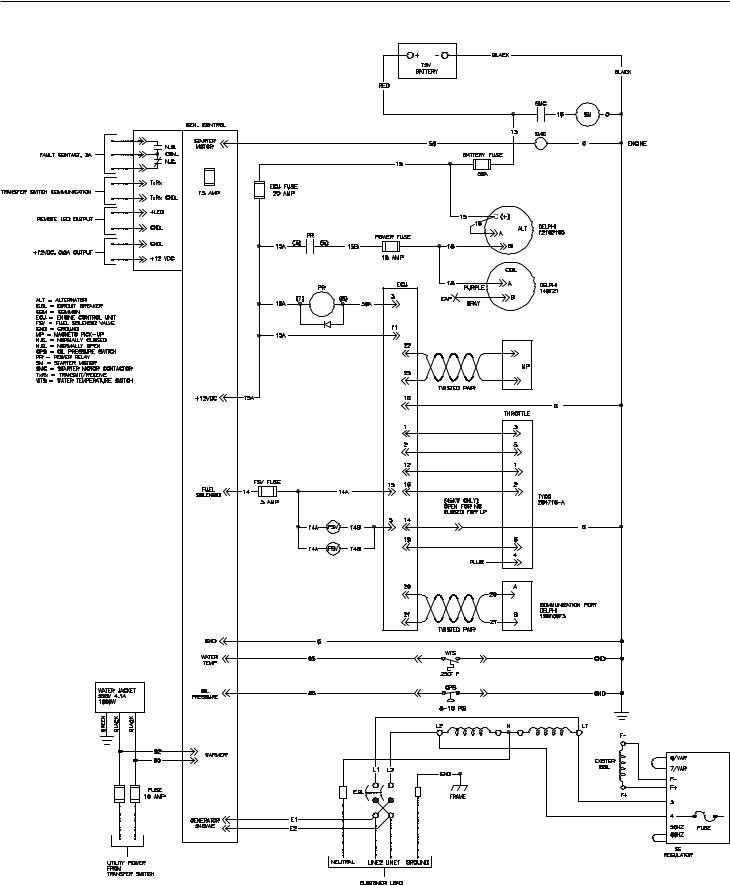

Schematic Diagram

24

Loading...

Loading...