Garmin 1.2-Liter Pump Kit, 2-Liter Pump Kit Installation manual

1.2 AND 2.0 L HYDRAULIC

PUMP

Installation Instructions

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

product box for product warnings and other important

information.

You are responsible for the safe and prudent operation of your

vessel. The autopilot is a tool that enhances your capability to

operate your boat. It does not relieve you of the responsibility of

safely operating your boat. Avoid navigational hazards and

never leave the helm unattended.

Always be prepared to promptly regain manual control of your

boat.

CAUTION

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

To avoid damage to your boat, the autopilot system should be

installed by a qualified marine installer. Specific knowledge of

hydraulic steering componentry and marine electrical systems is

required for proper installation.

When drilling or cutting, always check what is on the opposite

side of the surface.

This pump is only for use with Garmin autopilot systems.

Attempting to use this pump with any other system may damage

the system, the pump, or the vessel.

The hydraulic pump steers your boat by interacting with the

hydraulic steering system, based on commands from the

autopilot system. The pump is not included in the autopilot

corepack box because the type of pump you use with your

autopilot is determined by the size and type of steering system

on your boat.

Registering Your Device

Help us better support you by completing our online registration

today. Keep the original sales receipt, or a photocopy, in a safe

place.

Go to my.garmin.com.

1

Sign in to your Garmin® account.

2

Tools Needed

• Safety glasses

• Drill and drill bits

• Wrenches

• Torque wrench (if installing unbalanced kit)

• Wire cutter/stripper

• Screwdrivers: Phillips and flat

• Cable ties

• Marine corrosion inhibitor spray

• Hydraulic hose with machine-crimped or field-replaceable

fittings that have a minimum rating of 1000 psi

• Hydraulic T-connectors

• Thread sealant

• Hydraulic bleeding equipment

• Hydraulic fluid

• Unbalanced kit (if installing in a boat with an unbalanced

steering cylinder, part number 010-11201-00)

• Mounting screws: the pump kit includes mounting screws, but

if the included screws are not appropriate for the mounting

surface, you must provide the correct types of screws

Mounting Considerations

• Before you start the pump installation, you must identify the

type of hydraulic steering system in your boat and consult the

hydraulic diagrams. Each boat is different, and you must

consider the existing hydraulic layout before deciding where

to mount the pump (Hydraulic Considerations, page 1).

• The pump must be located within 19 in. (0.5 m) of the ECU.

• The cables that connect the pump to the ECU cannot be

extended.

• You should mount the pump horizontally, if possible.

• If you cannot mount the pump horizontally, you must mount it

vertically with the pump head connectors facing up.

• You must mount the pump in a location to which you can

extend the hydraulic steering lines of the boat.

Mounting the Pump

Before you mount the pump, if your boat has an unbalanced

cylinder steering system, you must re-configure the pump to

work properly with the unbalanced cylinder (Calibrating the

Unbalanced Valve, page 3).

Before you can mount the pump, you must select a location

(Mounting Considerations, page 1) and determine the correct

mounting hardware (Tools Needed, page 1).

Hold the pump in the intended mounting location and mark

1

the locations of the mounting holes on the mounting surface,

using the pump as a template.

Using a drill bit appropriate for the mounting surface and

2

selected mounting hardware, drill the four holes through the

mounting surface.

Secure the pump to the mounting surface using the selected

3

mounting hardware.

Hydraulic Considerations

NOTICE

Do not attempt to use the autopilot to steer the boat until you

bleed all air from each part of the hydraulic system.

When adding hydraulic line to the system, use only hose with

machine-crimped or field-replaceable fittings that have a

minimum rating of 1000 lbf/in² (6,895 kPa).

Do not use plumber’s tape on any hydraulic fitting. Use an

appropriate thread sealant rated for marine use on all pipe

threads in the hydraulic system.

Before you connect the pump to the hydraulic lines, you should

consult the diagram for the hydraulic system of your boat to find

the correct place to add the fittings and hose for the pump.

The pump has two sets of hose-connector fittings to allow for

different hose configurations. You can use either set of fittings or

a combination of the two. Where necessary, add hydraulic hose.

If your boat has an unbalanced cylinder steering system, you

must install the optional unbalanced valve kit (Installing the

Unbalanced Valve Kit, page 1).

Installing the Unbalanced Valve Kit

If your boat has an unbalanced cylinder steering system, you

must install the optional unbalanced valve kit. The unbalanced

valve kit is available from your Garmin dealer.

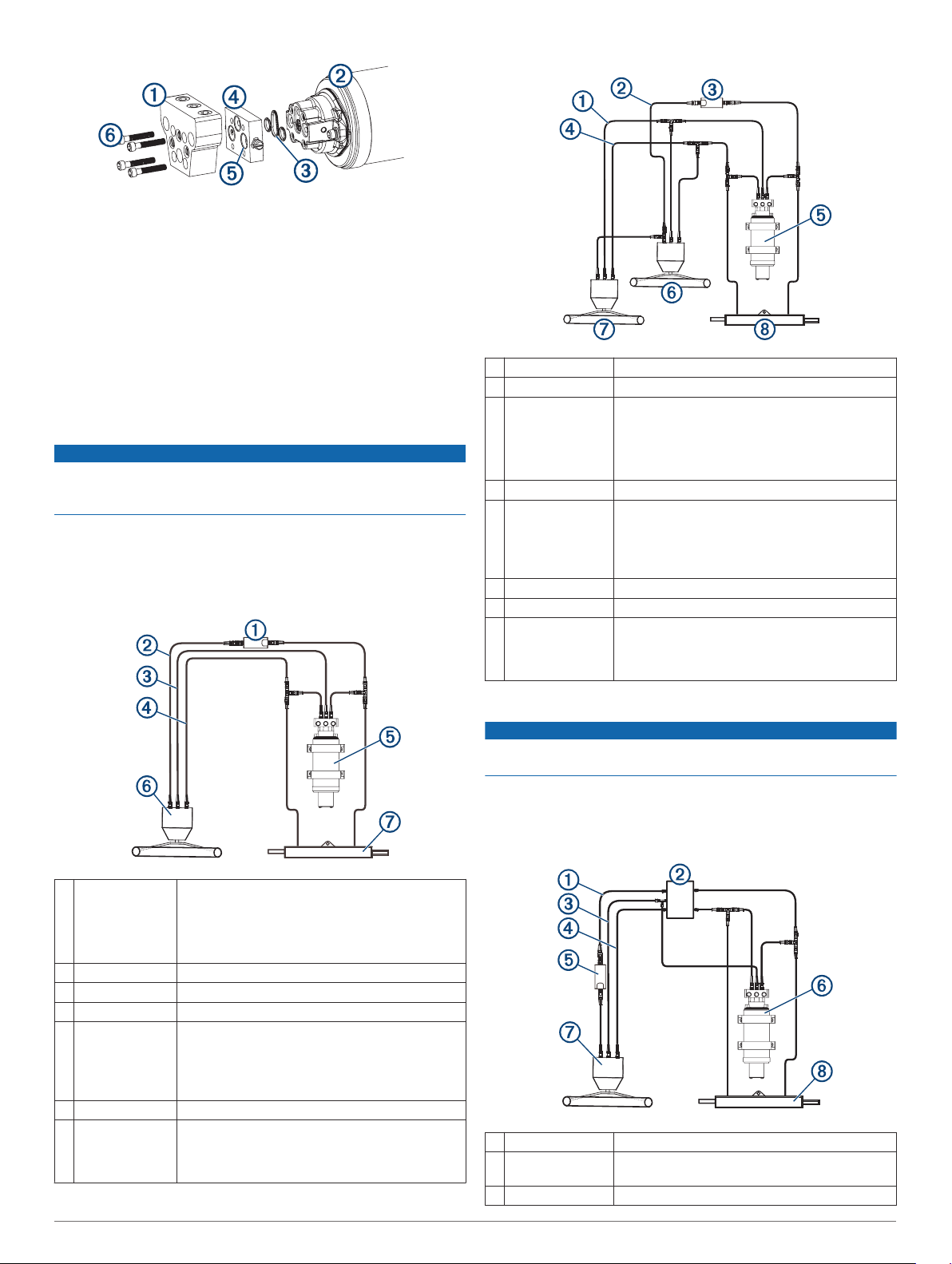

Remove the four screws that hold the manifold À to the

1

pump body Á, and remove the manifold from the pump body.

December 2017

190-02320-02_02

Replace the O-rings on the pump body with the O-rings

2

included in the unbalanced kit Â.

Place the unbalanced valve à between the pump body and

3

the manifold, with the O-rings on the unbalanced valve

Ä

facing the manifold.

Apply a thread-locking compound to the longer screws

4

included in the unbalanced kit Å, and use the screws to

connect the manifold and unbalanced valve to the pump

body.

Tighten the screws to 35 lbf-in. (3.95 N-m).

5

After the hydraulic lines are connected, you must calibrate the

unbalanced valve (Calibrating the Unbalanced Valve, page 3).

Hydraulic Layouts

NOTICE

If the steering system in your boat does not match any of the

hydraulic layouts in this manual and you are unsure how to

install the pump, contact Garmin Product Support.

Before you start the pump installation, identify the type of

hydraulic steering system in your boat. Each boat is different,

and you must consider certain aspects of the existing hydraulic

layout before deciding where to mount the pump.

Single Helm without Power Assist Layout

Dual-Helm without Power Assist Layout

Return line

À

Starboard line

Á

Shadow Drive

Â

valve

Port line

Ã

Pump You should mount the pump horizontally, if

Ä

Lower helm

Å

Upper helm

Æ

Steering cylinder If your boat has an unbalanced cylinder steering

Ç

See the installation instructions provided in the

autopilot corepack when installing the Shadow

Drive valve.

NOTE: You can install the Shadow Drive valve

in either the starboard or port line.

possible.

If you cannot mount the pump horizontally, you

must mount it vertically with the pump head

connectors facing up.

system, you must install the optional unbalanced

valve kit (Installing the Unbalanced Valve Kit,

page 1).

Shadow Drive

À

valve

Starboard line

Á

Return line

Â

Port line

Ã

Pump You should mount the pump horizontally, if

Ä

Helm

Å

Steering cylinder If your boat has an unbalanced cylinder steering

Æ

™

See the installation instructions provided in the

autopilot corepack when installing the Shadow

Drive valve.

NOTE: You can install the Shadow Drive valve in

either the starboard or port line.

possible.

If you cannot mount the pump horizontally, you

must mount it vertically with the pump head

connectors facing up.

system, you must install the optional unbalanced

valve kit (Installing the Unbalanced Valve Kit,

page 1).

Single Helm with Power Assist Layout

NOTICE

You must install the pump between the cylinder and the powerassist module to function correctly.

You must install the Shadow Drive valve between the helm and

the power-assist module to function correctly.

NOTE: You may need to remove the power assist-module to

gain access to the fittings, hoses, and bleed-tee fitting.

Starboard line

À

Power-assist

Á

module

Return line

Â

2

Loading...

Loading...