Page 1

GETTING TO KNOW THE 9Z:

by:

Futaba Service Center

Service and Support Team

SOME OF THE MOST COMMON QUESTIONS AND ANSWERS

ON USING THIS POWERFUL RADIO SYSTEM.

9Z WC2

9-Channel System

Page 2

This booklet is intended to be a user’s guide to help you get to know some of the many powerful

features of the 9Z. It is a supplement to the very detailed instruction manual, and is not meant to

replace it in any manner. Rather it is intended to provide some in-depth explanations and detailed

examples to answer questions you may have about using your new radio.

Note that each example and glossary item includes keystroke-by-keystroke instructions of how to

set up each feature. Every example assumes you have started from a totally blank model memory, and

every command group includes closing the feature back to the home menu and starting from the home

menu to start the next feature. This is done so that you can quickly and easily access one feature

discussed in an example without using all features discussed in that example. You do not need to

close and reopen every menu every time you use a feature. This is simply done for consistency. Every

step assumes you are starting from the home menu unless it is a continuation of programming a

feature from the step before it.

Similarly, each example will have 3 columns: the first explains what the programming is going to

do; the second explains the process, and the third is the actual keystrokes of how. By reading through

all 3 columns with each example you will become more familiar with the radio’s layout and

programming. It may take some time, so be patient, but the end result is well worth it!

Updates and Additions? Please visit www.futaba-rc.com. As corrections and additions are made,

new pages will be available here.

Additional questions? We hope you find this guide helpful in getting to know your 9Z. Have

suggestions for future additions, or other questions? Please visit our Frequently Asked Questions area

at www.futaba-rc.com/faq to see if your question may have already been answered. If not, then

follow the “contact us” information area to contact our support team directly as listed below.

Need to send your 9Z for service? Please ship your radio (including the module, receiver, servos,

battery, switches, and any other installed electronic equipment, especially following a crash or if asking

us to diagnose an unknown problem) to:

Please be sure to provide us a detailed explanation of your concerns and service required, as

well as at least 2 means of daytime contact: phone, fax, or email are great, as well as your return

mailing address. If this is non-warranty service, please also provide a means of payment (Visa,

Mastercard). Please note that upon request we will contact you with an estimate prior to performing

ANY repairs to a non-warranty item, so be sure to provide an easy way to reach you to avoid delays.

ADDRESS: Questions for Service? Questions for Support?

Futaba Service Center phone: 217-398-0007 217-398-3630 x4

1610 Interstate Drive fax 217-398-7721 217-398-7721

Champaign, IL 61822 email: service@futaba-rc.com email: support@futaba-rc.com

Page 3

TABLE OF CONTENTS

I. Equipment Selection. Answering Common Questions

A. Channels/Frequencies and Frequency Bands

B. Modules/Receivers/Accessories and Synthesized Equipment

C. Modulation, FailSafe and Resolution (512 vs 1024)

D. Batteries: Charging and Cycling

E. Training Equipment and Functions

II. Programming Specifics

A. Selecting the Correct Model Type 2-1

B. Understanding Servo Travel vs. Function Travel (Multiple Rates) 2-2

C. Multiple Servos for One Control Type and Other Set-up Options 2-4

D. P-Mix Features 2-8

E. Understanding the Basics of Conditions 2-10

F. Specific Programming Examples 2-12

III. Glossary of Terms, Keystroke Commands, and Primary Manual Page References

1-1

1-3

1-6

1-9

1-10

Page 4

CHAPTER I. EQUIPMENT SELECTION

A. Channels/Frequencies and Frequency Bands

How do I change the frequency of my transmitter?

Using a single-fr

equency module: To change the frequency when using a TK-FM non-synthesized

module, with the transmitter off, remove the module and replace it with a module on the desired

channel. (Note that you can even change transmitter “bands”, for example from 72mHz to 50mHz.)

All radio frequency circuitry is in the module so there is no need to “retune” after a module change.

Using a synthesized module:

To change the frequency when using a TK-FSS synthesized module, first

follow your flying site’s procedures to have exclusive use of your desired channel, then turn the

transmitter on while holding down the A or R key (so the radio does not transmit on its current

channel.) Notice the “ON AIR” message normally under Futaba is replaced with “Radio Control

Systems”. The 9Z is not transmitting and will not transmit again until you turn the power off and

back on.

How do I change the frequency of my receiver?

Using a single-fr

equency receiver: When using a non-synthesized receiver on 72mHz, the channel can

USUALLY be changed within certain groupings without requiring retuning of the receiver. Any

Futaba receiver purchased on 11-35 (“low band”), can be used on any other channel within that band

by changing crystals and properly range checking the radio system. Any Futaba receiver purchased

on 36-60 (“high band”) can similarly have a crystal change. Always fully range check your radio

equipment after a crystal change, and if identical or improved range is not verified, DO NOT FLY.

Send the transmitter and receiver to the Futaba service center for testing and tuning.

Using a synthesized r

eceiver: To set the frequency on the R309DPS synthesized receiver, unplug the

receiver battery. Open the receiver’s dust cover. Adjust the left switch for the first digit of the desired

channel and the right switch for the last digit of the desired channel. Close the dust cover. Plug in the

receiver battery. For more information see p.36 of the manual.

Can I use my 9Z on a different frequency BAND than it currently uses? Can I go to 75mHz for

ground use for Battlebots

®

, boats or cars? If I have a HAM license, can I use the radio on 50mHz?

The real plus of using a modular radio is that you can purchase a module and receiver on any

frequency for the band legal for your intended use and use it safely and without any loss of

performance. For example, you can purchase the TK modules on 50mHz, and we can convert TK

modules and most receivers to 75mHz. Please contact the Futaba Service Center for further

information.

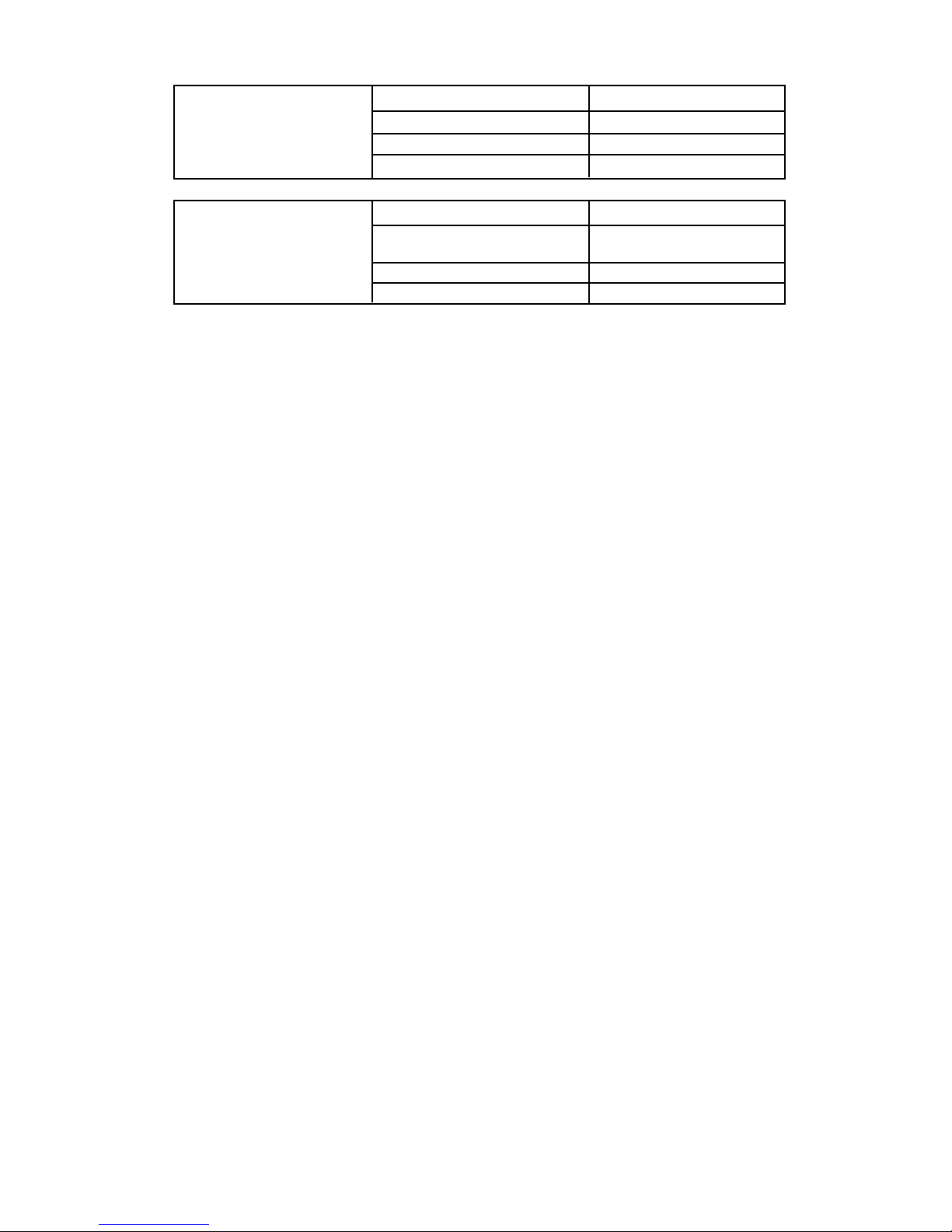

Desired Result Process Keystrokes

Turn On Without Transmitting Hold A or R during power on

Open Frequency (FRQ) Q C I

Select the Desired Frequency (use R & Q to page through)

Use Set to Confirm and Close O N R

Cycle the Transmitter N R (power off, power on)

Power up without transmitting,

then select the desired

frequency and cycle the

transmitter to transmit on the

new frequency.

1-1

Page 5

I fly on channel xx. A quarter wave antenna for that frequency would be xx", not the 9Z antenna’s

full length. Would I be better off using that transmitter antenna length instead of it fully extended?

Each Futaba transmitter has been tuned so that it will get the maximum output with the antenna

provided. The FCC certification was made with that antenna. The tuning circuitry in the transmitter

makes allowances for any differences in the actual length of the transmitter antenna, and the

theoretical ideal length. You should fly your models with the transmitter antenna fully extended. If

you shorten it, you will suffer a considerable decrease in range.

1-2

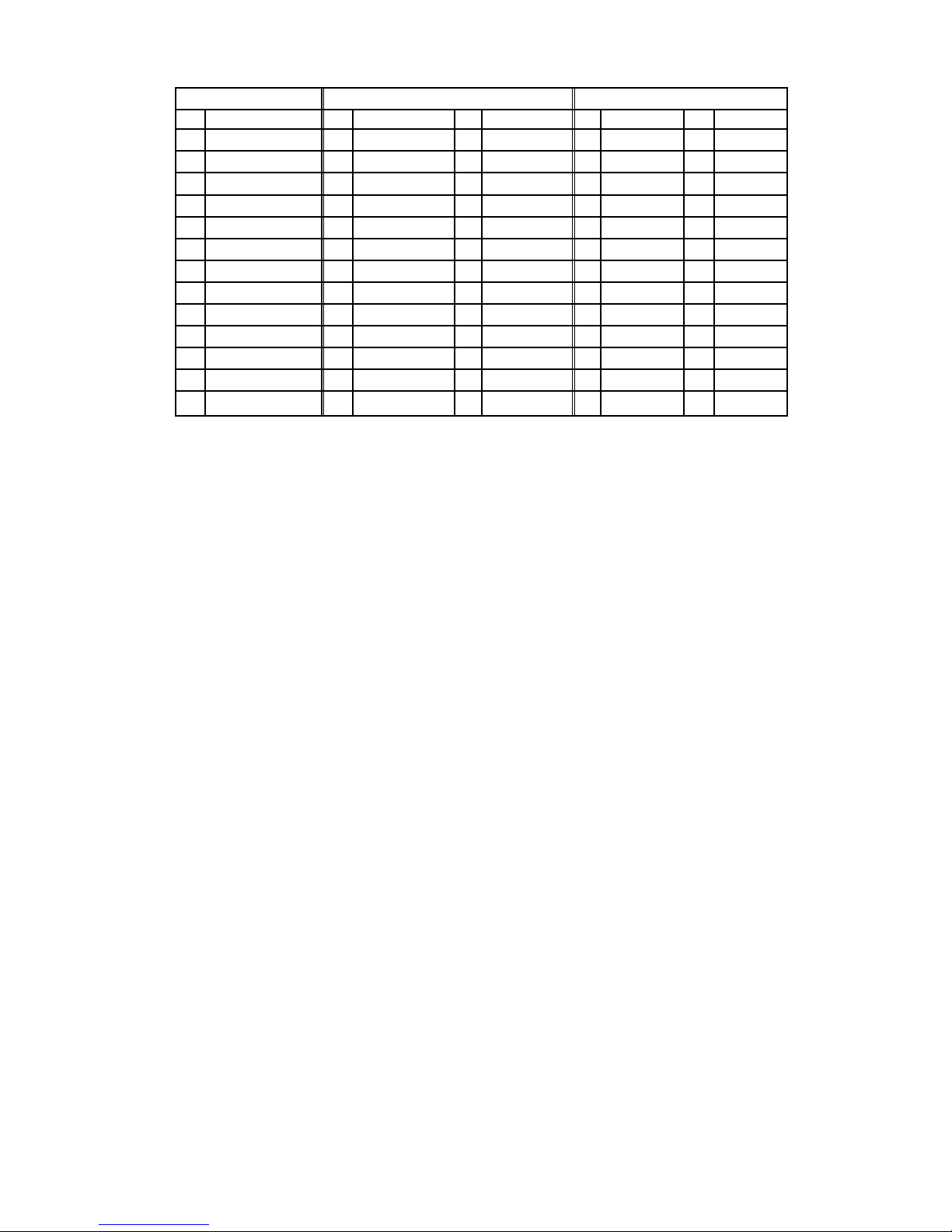

50 MHz 72 MHz Low Band 72 MHz High Band

Ch. Freq. Ch. Freq. Ch. Freq. Ch. Freq. Ch. Freq.

00 50.800

01 50.820

02 50.840

03 50.860

04 50.880

05 50.900

06 50.920

07 50.940

08 50.960

09 50.980

11 72.010

12 72.030

13 72.050

14 72.070

15 72.090

16 72.110

17 72.130

18 72.150

19 72.170

20 72.190

21 72.210

22 72.230

23 72.250

24 72.270

25 72.290

26 72.310

27 72.330

28 72.350

29 72.370

30 72.390

31 72.410

32 72.430

33 72.450

34 72.470

35 72.490

36 72.510

37 72.530

38 72.550

39 72.570

40 72.590

41 72.610

42 72.630

43 72.650

44 72.670

45 72.690

46 72.710

47 72.730

48 72.750

49 72.770

50 72.790

51 72.810

52 72.830

53 72.850

54 72.870

55 72.890

56 72.910

57 72.930

58 72.950

59 72.970

60 72.990

Radio Frequency Chart

Page 6

Can I use my 9Z module in my 5/7/8U and vice versa?

The TK module, which is designed specifically for the 9V and 9Z models, is an acceptable replacement

for the TP module. The TP module, which is used in the 5U, 7U and 8U radios, should NOT

be used

in the 9 channel radios in place of the TK module. The TK module is specifically designed for the

unique environment of the 9Z. The TK-FSS module can not be used in any other radio because of the

specialized pins and input information required from the 9Z transmitter to set the channel.

Can I use an aftermarket transmitter module? Does this affect my warranty?

There are many aftermarket items that fit specific needs and are terrific products to use. However, the

use of a non-stock transmitter module in Futaba modular radios is not one of these circumstances. Based

upon FCC regulation 95.645(b), a modeler is in violation of the FCC regulations when using a non-Futaba

module in a Futaba transmitter. Therefore we cannot service a radio which is using any after-market

transmitter module, and its use voids the radio's warranty. Please also note that making modifications to

your radio system or using non-certified equipment may void any AMA insurance coverage.

Can I use a receiver with a different number of channels?

Yes. As long as the receiver is compatible with your 9Z (all Futaba FM (PPM) and PCM1024 receivers are),

you can use a receiver with fewer than, the same number of, or more channels than the transmitter. Of

course, you won't be able to use features which use, for example, servo 5, if you use a 4 channel receiver.

Can the 9Z's synthesized module/receiver be used with non-synthesized modules/receivers?

Absolutely! You can use the synthesized module with any receiver compatible with the radio, and you

can use the synthesized receiver with any transmitter module (set to the proper channel of course), or

even with other compatible Futaba radio systems.

How do I keep track of the channel my model is on?

The base condition name can be set as the frequency used with your FSS module to easily keep track

of channel and still have 8 characters to name your model.

Can I copy a model from my 9Z*P radio to my 9Z*W radio using the Campac, or vice versa?

Yes, you can! Simply use the copy model (CPM) function. And the model from the 9Z will work

perfectly in the 9Z World. HOWEVER, please remember that if you copy from a 9Z World back to a

9Z, the model will not retain any of the features of the 9Z World radio such as the gyro set-ups, etc.

Can I use the Campac to copy a model from my 9Z to my 8U or vice versa?

No, the model memories for a 9Z model and an 8U model are not compatible. You CAN use the 64K 9Z

Campac in an 8U, but must re-initialize it to be able to be read in the 8U, and all stored data will be lost.

How do I start a brand new model in my Campac?

ALL memory in the 9Z’s Campac is set up as conditions, not individual model memories, until you

tell it otherwise. Therefore, if you want to start a model in the Campac, do so by copying a model over

from your transmitter's main memory. Now you can edit that model and attach other conditions to

that model using Condition Select (CSL). This approach allows the maximum possible flexibility of the

Campac's memory. (A detailed explanation of conditions and condition use is covered in Chapter 2.)

1-3

B. Modules/Receivers/Accessories and Synthesized Equipment

Page 7

How do I delete a condition or a whole model out of the Campac?

My Campac shows an unused model. Why won’t it let me copy into that unused model?

The incredible flexibility of the Campac can lead to programming mistakes. In this example, the

modeler used the first conditions, which are intended to be individual models, as conditions in other

models. This flexibility exists in the Campac so that you can use up these extra conditions if needed;

however, the model select (MSL) reading does not realize that these conditions have already been

used. Assuming you have not also used up all other conditions in the Campac, you can simply copy

from condition 3, for example, into a higher numbered blank condition, reassign the condition select

(CSL) in the model that condition 3 is used in to the new condition number, and now condition 3 is

available as model 3.

I have an open model in my Campac, but I can’t copy my helicopter into the Campac. Why not?

First, make sure you haven’t made the error described in the previous paragraph. Assuming you have

not, while you may have a base model open in the Campac, you may not have enough conditions

open in the Campac to hold all the conditions needed for the model you are copying. For example,

you might have model 3 and condition 21 as the only open slots in the Campac; your helicopter has 4

conditions and so you do not have sufficient memory to store the helicopter. To solve the problem you

will need to free up additional storage space in the Campac by deleting complete models or unused

conditions.

Can I copy a baseline set-up into all Campac model memories and then just modify it?

You CAN, but we do not recommend it. You can use up all the conditions in the Campac as models;

then you have no extra conditions left for the models. In general, copying a previous or a “basic setup” and working from it is not recommended. There may be set-ups you’re copying you’ve forgotten

that could get you into trouble, such as maximum sub-trims (STM), an obscure mix (PMX), etc.

I damaged my 9Z antenna. Can I replace it myself?

Replacing the antenna on this particular model radio requires major disassembly, due primarily to the

radio's complexity and number of boards installed within a standard size case. Therefore, we strongly

recommend sending it to the service center rather than attempting to replace the antenna yourself.

1-4

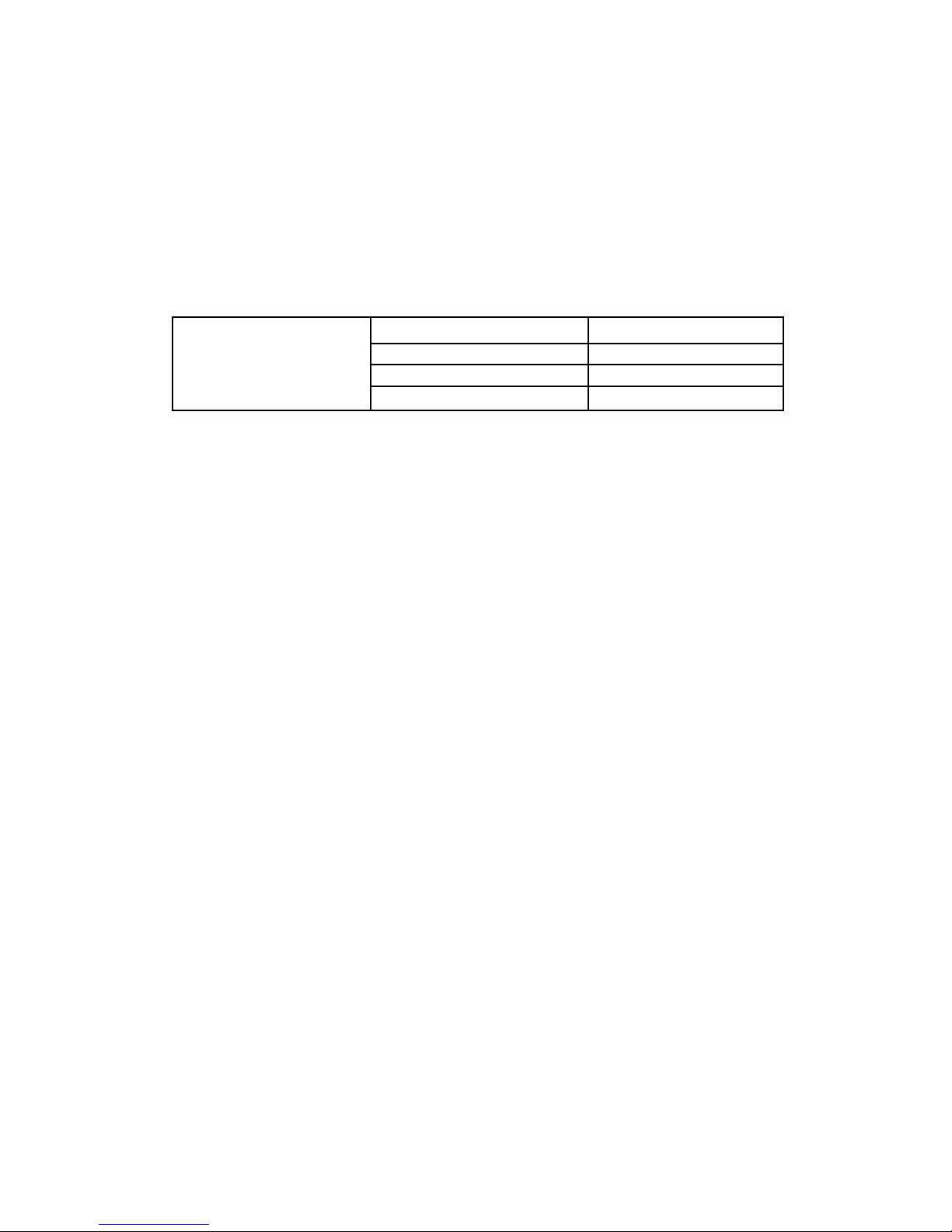

Open Condition select (CSL) P B F

Select the Desired Condition (choose it – B through H)

Set the Condition to Null H O

Close the Function N R

Delete a Condition from the

Campac, with the Campac in the

transmitter and while you are in the

model to which the condition is tied.

Open Model select (MSL) Q B F

Select the Desired Model P (then choose the model:

A–J or P)

Press Delete and Confirm R L

Close the Function N R

Delete a Model from the Campac,

with the Campac in the transmitter

and the model selected is NOT the

model to be deleted.

Page 8

I am building a large scale gasoline-powered model and it will require 18"+ extensions. Do I need

voltage suppressors, noise suppressors, chokes or to take any other precautions?

In general, there is no need for noise suppressors in current Futaba equipment.Some other brands’

current equipment do require this; however, Futaba does not.

Twisting servo extensions lightly and gently is a good idea, as it helps minimize the combination of

the 3 leads’ electrical fields. Heavier gauge extensions are highly recommended, both due to the length

of the leads and the high current drain of high torque, high speed, ball bearing or digital servos.

If you see radio interference in your gasoline aircraft, look first to the engine's installation. All ignition

equipment, including electronic kill switch, must be mounted 12+" (preferably 14+") away from all

radio equipment, including throttle servos. The ignition kill switch should always be on the opposite

fuselage side from the receiver’s switch. All pushrods to anything engine-related must be nonconductive (nonmetal clevises are required, but alone are not sufficient).

My expensive, ball bearing servos “buzz,” “hum,” or “chatter,” especially when I first turn on the

receiver. My standard servos never did this. What's wrong? What do I need to do?

Modelers often report "servo chatter" in ball bearing servos. This may or may not indicate a problem.

First make sure the transmitter is a sufficient distance from the aircraft so that “swamping” is not

occurring. Then check your linkages and set-ups for binding, servos fighting each other on the same

working surface, and bad extensions. Be sure that there are no problems in your physical system.

Assuming there is no binding or other issues, buzzing is a common and harmless occurrence, and

indicates that your servo is "checking" itself for true center. There will many times be an audible

"buzz" from the servos, even when there is no noticeable movement. This is also harmless, as when

the plane is airborne, the wind will load the control surfaces, which will correct this small amount of

vibration and noise.

Many times if a modeler is using a 6-Volt receiver battery, or a fully charged battery, they will notice

buzzing, but, when the voltage drops slightly with some amount of load, the movement and noise

subside. This is commonly known as “a hot charge”, and is perfectly normal.

Digital servos: Note that digital servos emit a high-frequency “hum” at all times. This is very normal.

1-5

Page 9

My transmitter has a PPM and PCM function. Which function should I use and how?

If you have an FM (PPM) receiver, your transmitter must be set on PPM. If you have a PCM receiver,

your transmitter must be set on PCM. To check which type of modulation (also known as pulse mode)

your model memory is currently set for, turn on the transmitter. In the upper right corner, just to the

left of the elapsed timer, you will see either PPM or PCM. If necessary, change, as described below.

Turn the power off and back on to actively transmit in the other Pulse Mode type. Note: Pulse Mode

(PMD) type is selected separately for each model, so, for example, changing from model 1 which is

PCM to model 2 which is FM (PPM) would require you to cycle the transmitter off and back on after

making the model selection so the radio now transmits in the matching pulse mode.

What advantages do I gain by using PCM rather than FM (PPM)? I heard PCM has better range?

And better noise interference rejection? Also, what is FailSafe and how is it related to PCM?

Range and Noise: There is no range increase associated with PCM; however, there is marked

improvement in noise reduction, and in safe performance during noise. Basically, PCM takes your

radio's FM (PPM) signal and codes it. Then the PCM receiver decodes it and utilizes it. Random noise

from other sources are less likely to be mistakenly read as actual servo instructions, which regularly

happens with FM (PPM).

FailSafe: If your PCM receiver detects interference or a loss of signal, it maintains the last task it was

doing until a preset time interval programmed in the radio. If it continuously receives interference

past the preset, the receiver then obeys the commands you set in the transmitter which were

previously transmitted and have been stored, waiting for just such a situation. (For example on giant

scale gas planes we set FailSafe to shut down the kill switch and throttle and leave all other surfaces in

the last commanded position). Battery FailSafe (BFS) is explained in the next question. Please see P. 1-7

for information on combining FailSafe and the PA2 Pilot Assist Tool for even more in-flight protection.

My throttle servo suddenly went to my FailSafe position but all other controls operated normally. I

pulled my throttle stick all the way back and then moved it again, and the throttle worked for a

while, then did it again. Why?

Battery FailSafe (BFS) is an automatic safety function of the 9Z computer radio. When the receiver's

battery voltage drops below a predetermined cut off (approximately 3.8V) and remains there for more

than a set amount of time (several seconds – this allows for occasional hard drains caused by violent

maneuvers such as snaps which immediately returns the voltage back to above 3.8V), the receiver

recognizes that you are in a dangerous condition, and brings your throttle servo to a preset position.

This is a warning that you must safely retrieve the model (meaning land for aircraft/helicopters), as

you are nearing a point where there will not be sufficient voltage to operate the receiver.

An additional aspect of this feature is that you can pull your throttle stick to idle and readvance it,

allowing you to use power to retrieve the model. You will typically have throttle control for

approximately 30 seconds before the feature reactivates, returning the throttle to the preset when this

feature reactivates. IT IS IMPERATIVE THAT YOU LAND OR OTHERWISE RETRIEVE YOUR

MODEL IMMEDIATELY BEFORE LOSING CONTROL OF THE MODEL ALTOGETHER.

1-6

C. Modulation, FailSafe and Resolution (512 vs. 1024)

Open Pulse Mode (PMD) P B I

Select PCM F

Close Function N R

Cycle Transmitter Power power off power on

Change Pulse Mode (PMD)

Type from PPM to PCM, and cycle

power to transmit in the new Pulse

Mode type.

Page 10

Special note for 6-Volt battery users: By the time a 6V battery pack has dropped to 3.8V, the battery is

discharging VERY rapidly. As a result, by the time the Battery FailSafe (BFS) throttle warning occurs,

it is very likely that you do not have sufficient voltage to support the receiver long enough to

land/return your model to you safely. If you are using a 6V receiver pack you MUST keep an extracareful eye on your receiver voltage and watch carefully for high drain problems to avoid the loss of

your model, as the Battery FailSafe (BFS) safety feature will not operate properly in these conditions.

Transmitter low voltage: Note: if transmitter

battery voltage drops too low, transmitter beeps and

flashes a warning. Modeler should land immediately upon encountering this behavior.

What does it mean when you list a radio or receiver as PCM 1024?

PCM512 indicates a PCM transmitter/receiver which offers 512 separate possible positions or points of

resolution to a servo’s full travel; PCM1024 indicates a PCM transmitter/receiver which offers 1024

points. These are not interchangable. The 9Z family of radios are PCM1024 and can not be used with

PCM512 receivers.

My airplane is on PCM. Can I use a trainer cord with it?

Yes. The master radio, the one that the instructor is using, can operate in either FM (PPM) or PCM, so

your transmitter would remain set to PCM in the Pulse Mode (PMD) Screen. The student radio,

however, MUST be set to FM (PPM). For more information on training, please see Training

Equipment and Functions. For how to change a student 9Z from PCM to PPM please see P. 1-6.

Can I use the PA2 Pilot Assist Tool in conjunction with FailSafe on my PCM transmitter to help

protect my airplane in the event of interference?

Absolutely! This is an excellent safety idea. The FailSafe (F/S) feature, if set to continue the last

command, will often keep your model in the loop or straight flight it was last doing, but unfortunately,

sometimes it will keep your model in a precarious situation you didn't want, such as a snap or spin.

The PA2 is a unique flight training tool which uses light sensors to correct the aircraft’s orientation. By

using the PA2 in combination with preset positions on the FailSafe (F/S) settings, you can help ensure

your model will go to level flight at slow but safe airspeeds and hopefully safely ride out the

interference.

To set up the FailSafe (F/S) for this combination, we recommend the following:

First, please remember that you must be using a PCM receiver and have the transmitter set to PCM.

Second, fly the aircraft and turn the gain up on the PA2 until you find its maximum setting before the

plane starts to “hunt” or “waggle” because the gain is set too high. Have your spotter notice where the

dial is set at that time.

Now, land the aircraft and set up the FailSafe (F/S) programming so that the PA2 is brought up to that

maximum gain setting, throttle is set at a safe high idle for flight, and all other surfaces go to neutral.

1-7

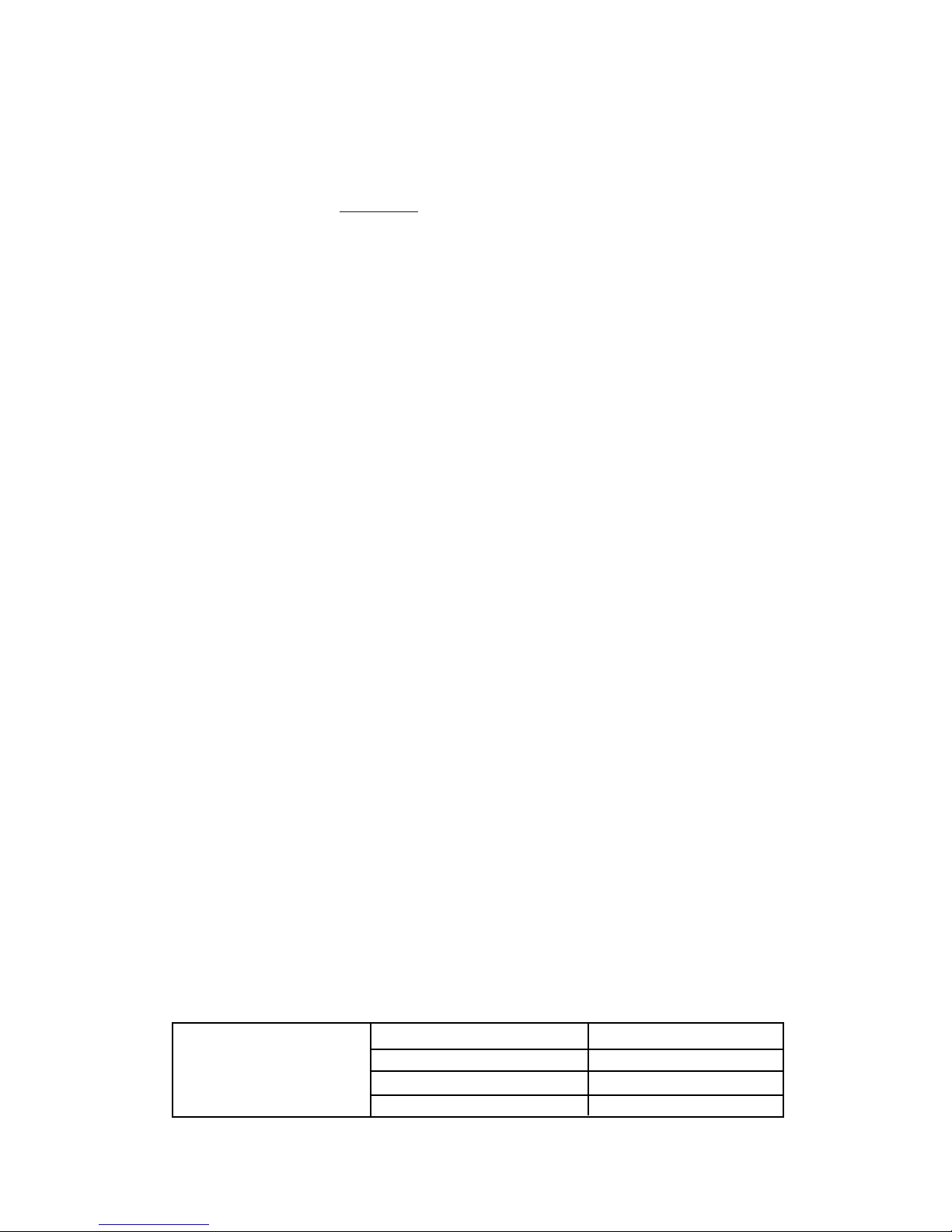

Open FailSafe (F/S) P B H

Select Throttle and Set it H O

Select Gain (Aux 2) and Set it M O

Close the Function N R

Position the throttle stick and Aux2

(gain) knob at the desired FailSafe

positions and set the FailSafe.

Page 11

Before you fly, test this combination on the ground. Have a helper hold the (engine off) aircraft

above the ground in a banked attitude. Put in some aileron inputs as if you were going to roll it even

further, not correct it. Now turn the transmitter off. Your receiver will maintain the last inputs given

for a set amount of time, then will go to FailSafe (F/S) settings. The ailerons, elevator and rudder

should go to neutral very briefly, then the PA2 should correct elevator and aileron. Try having the

helper move the plane around, and be sure the PA2 is correcting it properly.

Also, with the helper securely holding the aircraft in case the engine races, start the engine and check

that the throttle is about where you would like it to be in FailSafe .

Note: If your model has retractable gear or other functions needed to land safely, have these deploy in

case of FailSafe so that the model can set down properly if the FailSafe (F/S)and PA-2 should ease it to

the ground.

1-8

Page 12

How long should I use the charger? Does it turn off when the batteries are charged?

The wall charger included with your radio is a “C/10” charger. It will continue to charge close to its

given rate until unplugged. You should charge the first time approximately 16 hours to ensure a full

charge, then an overnight charge is sufficient, as the charger charges at approximately 1/10th the

capacity of the standard pack for 10 hours. Do not just leave your equipment on the charger

indefinitely as this is bad for the batteries and poses a fire risk. Note that charging higher capacity

batteries on the wall charger will require longer times to reach peak.

The manufacturer of my charger says my transmitter has a “diode” in it and that's why I can't

discharge my battery. What does this mean and how can I get around it?

A diode is a safety device which only allows voltage to go one way. All Futaba transmitters have

diodes built into their circuits to protect the radio against power surges, reversed polarity, defective

chargers, etc. If you accidentally plug an unprotected transmitter into the wrong brand of charger, you

may destroy the transmitter. But if you accidentally plug a Futaba transmitter into a JR charger, for

example, all that will happen is your transmitter does not get charged -- no risk, no damage.

If you wish to cycle your 9Z’s transmitter batteries, you will need to purchase a discharge jumper from

the Futaba Service Center. Then, remove the transmitter pack from the transmitter, temporarily insert

the jumper, discharge/cycle the pack, remove the jumper, and reinstall the battery.

Can I use 6V (5 cell) receiver packs? Will I get increased performance from my equipment? Are

there any drawbacks to using 6 volts?

All Futaba systems are designed to operate on either 4.8 volts (NiCD 4 cells) or 6 volts (Alkaline 4 cells

OR NiCD 5 cells), except certain gyros which are specifically labeled for use at one voltage or the other only. A

6-volt pack does provide more torque and speed, which may be desirable in certain competition

situations, or when the servos available for the model are of marginal speed or torque.

However, while 6 volts provides more torque and speed, it also provides a significantly shorter run

time for the same milliamp hours of capacity and may shorten servo life proportionally. This sounds

confusing -- let’s compare the current in the battery to water in a bucket. If you have four small holes

in the bucket, the water will come out at a certain rate. Add a fifth hole the same size, and you're

supplying more water (increasing the current and therefore making the servos stronger AND faster);

however, the bucket empties 25% sooner than when it only had four holes.

If I remove my transmitter battery, will all my stored data be lost?

No. The 9Z’s memory is protected by a lithium back-up battery. So long as either the lithium battery

or the transmitter battery are providing proper voltage to the memory, your settings will not be lost.

Does my radio have a lithium battery to store all my programming, or how is this data stored?

Do I need to service this memory in any way?

The 9Z uses a lithium battery to provide back up power to protect your programming in case of

primary battery failure or removal from the radio. This battery should be replaced every 5 years to

protect your data. Please send your radio to the service center every 5 years for replacement of this

lithium battery. Please be sure to back-up all data from your radio onto a Campac (or write it all

down) to avoid loss of your programming. Please note that there is no warning that the lithium

battery has failed, so regular maintenance of this battery is important to protect your model data.

1-9

D. Batteries: Charging and Cycling

Page 13

What is the function in the 9Z trainer programming called “mixer”? What does this mean?

How does it differ from other radios?

The 9Z offers a uniquely powerful option where the instructor can chose to make corrections for the

student without taking the aircraft completely back from the student. This is called "Mix" mode.

The 9Z also offers the option for the master radio to maintain control of any channel(s), giving the

student only the channels the instructor feels s/he can comfortably control.

If I am using the trainer function of my 9Z, does my radio's auto-shut-off feature know it?

Or do I need to turn off auto-shut-off while I'm instructing?

The 9Z's Auto-Shut-Off feature only looks for commands given by your 9Z. Therefore, if you have this

feature turned on while teaching and your student flies longer than the auto-shut-off time, the 9Z will

shut down, with potentially disastrous results. The solution to prevent this ever occurring is simple –

set your auto-shut-down feature to your model’s maximum flight time + pre-flight time + 5 minutes.

We recommend setting the timer to 20 minutes. This should avoid this potential issue at any time.

Additionally, please note that simply moving any stick, even only for a split second, is enough to restart

the counter; so as a safety precaution we recommend moving the sticks slightly periodically while your

student is flying (no need to resume control.)

If my receiver is PCM can I use the trainer function?

Yes. The master radio, the one that the instructor is using, can operate on either FM (PPM) or PCM, so

in your situation your transmitter will remain set to PCM. The student radio, however, MUST be set

to FM (PPM). For more information on PCM, please see the Pulse Mode (PMD) section on P. 1-6.

1-10

E. Training Equipment and Functions

Page 14

CHAPTER II. PROGRAMMING SPECIFICS

Editor’s Note: While we have made every effort to ensure that every instruction in this manual is

100% accurate, mistakes will inevitably happen. Additionally, the keystroke commands assume you

began from a blank model and are not writing over any existing programming. Therefore, always

double-check to be sure the end result is exactly what you intended.

A. Selecting the Correct Model Type

The glider model type names are a bit confusing. Basically, the model type names represent the

smallest number of servos which would effectively be used to operate this type of wing configuration.

So, for example, while it is called a 5-servo glider wing, the wing may have as many as 8 servos on

board.

2-servo glider: this wing has ailerons and airbrakes (spoilers). Typically this wing would actually have

3 servos installed, to allow for use of the aileron differential (ADF) and flaperon (FPN) functions and

other mixes you may create to couple airbrake and flaperon (FPN) movement.

4-servo glider: this wing has ailerons, airbrakes (spoilers), and speed flaps. Typically this wing would

actually have 5 servos installed, allowing full span aileron, full span flaps, etc.

5-servo glider: this wing has ailerons, speed flaps, brake flaps (small, very inboard flaps), and

airbrakes (spoilers). Typically this wing would have 6 servos installed, allowing aileron-to-speed flap

(ASF), brake flap mixing, brake flap to aileron mixing, etc.

2-1

Page 15

B. Understanding Servo Travel vs. Function Travel (Multiple Rates)

What is the relationship between dual rates, exponential, AFR and ATV?

ATV: ATV, or adjustable travel volume, is each individual servo's end point adjustment. ATV is

specific to each individual servo, so adjusting the ATV to the aileron channel will not, for example,

adjust the servo throw of the second aileron servo if you have flaperon (FPN) set up. ATV is the

“master” control. That is to say, it takes priority over all other items. Since adjusting ATV will affect

everything else – including rates, exponentials, and mixes – it should only be adjusted during initial set-up

to avoid binding, etc.

ATV/EPA/AST: ATV is an older terminology for adjustable end points. It has been used to mean a

variety of combinations of adjustability. Futaba now uses the clearer EPA and AST terms. EPA is end

point adjustments, which provides a separate adjustment for each end of the servo. All 9Z ATVs are

EPA type. AST is adjustable servo travel, which is a single adjustment which affects the travel at both

ends of the servo.

AFR: AFR, or adjustable function rate, is each individual function’s end point adjustment, or,

essentially, "primary rate" (or high rate) to go with the “dual rate (D/R)” (or low rate) function of the

radio. This is what the 8U and 6X consider the first switch position in dual rate, which most modelers

use as their high rate. BUT, AFR is available on all 8 proportional channels on the 9Z. AFR is active

until the dual rate (D/R) is activated, and it belongs to each CONTROL or AXIS of the airplane.

Therefore, adjusting AFR for ailerons in a model with flaperons (FPN) will affect the throw of both

servos.

D/R: D/R, or dual rate, is essentially “secondary rate” (or low rate) to go with the AFR function. This

is what the 8U and 6X consider the second switch position in dual rate, which most modelers use as

their low rate. But, the 9Z offers three dual rate (D/R) circuits which can be used for any of the 8

channels. Find more information on dual rates, triple rates, and condition functionality later in this

chapter.

Why set AFR instead of adjusting ATV? Easy. ATV is your end point for EVERYTHING that SERVO

does....mixes, expos, everything. So if you have low rate, mixes, etc., that you like, but you need a little

more (or less) on high rate, adjusting ATV will mess up all that other work. AFR is your “high rate”,

so adjust it to your liking. For an example of when to adjust AFR and not ATV, please see P. 2-11 in the

conditions section on trim effects in various conditions.

How do I set Exponential?

Exponential is set independently for your *high rate* (called AFR) and *low rate* [called dual rate

(D/R)]. So you have to go into AFR, set your high rate how you want it, then go to the NEXT screen

to set exponential. This is your expo setting for when your dual (low) rate is not activated for that

channel. Now if you also want expo on your low rate, then go to dual rate (D/R), set up your low rate

and its switch, and then set an expo here as well.

What does "Limit Mode" mean in the ATV function of my radio?

Normal ATV sets the amount of travel (how far a servo moves) in response to the primary control (ie

throttle stick, switch, knob). Limit Mode ATV (functional only in the World Champion editions) limits

how far that servo will move no matter what is making the servo move.

For example: In normal mode ATV you set your elevator servo’s travel, for example 1" when the

elevator stick is moved full throw. However, a mix/dual rate (D/R)/AFR that is set to, say 110%, will

take the elevator servo to 1.1". Depending on your installation, you may never want it to go past the 1"

2-2

Page 16

(in which case chose limiter) or you may want to allow it to pass the 1" measurement (in which case

choose normal). The limiter setting in ATV would not allow your elevator servo to move any further

than that set amount (in this example 1"), even when called from dual rate (D/R), AFR, or any mix,

such as a flap-to-aileron mix.

I want to change the operation speed of one of my servos (for example, slowing the opening of my

gear doors). How can I do this?

You can control the servo speed via the channel delay function, which is in the ATV section of the

condition menu. To do so, select ATV from the conditions menu. Go to the next screen, and there is

your condition channel delay. Note that these are settable for each condition, and affect the speed of

the servo response when ENTERING this condition from other conditions. However, this is NOT

effective in the base condition. For a specific programming example of slow-lower gear and slow-close

doors, please see the specific programming examples section, P. 2-17. (A detailed explanation of conditions

and condition use is covered in Chapter 2 Section E.)

What are cross trims? Why does the trim beside the throttle adjust the elevator and vice versa?

The default setting on the 9Z is for cross trims, which means the trim next to the throttle adjusts the

elevator and the trim next to the elevator adjusts the throttle. This is an excellent set-up option

because this way the modeler can adjust the elevator trim with the left hand while the right hand is

holding the necessary elevator inputs. However, if you prefer “conventional trims”, you can reverse

the cross trim set-up in each model as follows (note that you must adjust this in each model memory

and any time you completely reset a model):

2-3

Reset the Cross Trims to

Same Side Trims

Open Function (FNC) and Reassign

the Elevator and Throttle Trims

PBKOFQ

GOGQH

NR

Reset the Trim Type to Operate

Properly for Throttle and Elevator

EGEN

FFNN

Page 17

C. Multiple Servos for One Control Type and Other Set-up Options

What are twin aileron servos, aileron differential and flaperons? When do I use which?

When a manufacturer or modeler talks about twin aileron servos, they usually mean the model has

one servo operating each aileron and each is plugged into a separate channel on the receiver. Twin

aileron servos allow the modeler more precise aileron control. They also provide the option of

flaperons (FPN) (the coordinated movement of both aileron servos as flaps) and aileron differential

(ADF) (the ability to have a lesser amount of down travel aileron than up travel aileron to help keep

rolls straight.)

The 9Z flaperon programming gives aileron with differential (ADF) if desired, and ailerons as flaps,

along with the option to trim the two ailerons’ up or down travel together as a flap trim. If you don’t

want flap action from the two ailerons, then aileron differential (ADF) is a simpler set-up.

What about twin elevator servos? What are ailevators?

Ailevators (ALV) is programming specifically designed to command twin elevator servos. Basically, it

is “setting up twin elevator servos made easy”. It assigns the second elevator servo to channel 5,

turning off other control of channel 5, and has channel 5 always obey the same commands as channel 2

(elevator). In addition, it is called ailevators (ALV) because it also has programming to let the elevator

servos operate in unison with the ailerons to increase roll responsiveness, especially at slow speeds.

Don’t want the aileron action? Don’t worry, just set the aileron left and right settings (keys B, C, P and

Q) to 0.

What are elevons?

Elevon (ELV) are for flying wing models where 2 servos work together to create both roll and pitch

functions (aileron and elevator). On right roll command the right surface goes up and the left down;

on up elevator command the right surface again goes up but the left now goes up as well.

What about v-tail programming?

V-tail (VTL) programming is for models with v-tails – two tail surfaces that are both angled equally to

the fuselage, not horizontal and vertical. The programming is similar to elevons (ELV) in that the tail

servos do 2 jobs, elevator and rudder. For example, on right rudder, both servos move right; on up

elevator, both servos move “up” – the left surface moves right and the right surface left.

Can I assign flaperons, elevons, or ailevators to a switch so they're only functional sometimes?

(I want to use them for special stunts but not the rest of the time.)

Using conditions, ABSOLUTELY! You can create one condition which has flaperons (FPN), and one

which does not, or set flaperons (FPN) in each condition but set the flap action differently in each, etc.

(A detailed explanation of conditions and condition use is covered in Section E .) Without conditions, no, you

can’t assign these features to a switch. However, you COULD manually create any of them with

mixes as described in this chapter.

I am setting up flaperons on my 9Z, but I’m confused about how to operate them as flaps.

When flaperons (FPN) is activated, the two ailerons operate normally with aileron input. By default,

the flap action is set to zero to avoid any accidental adjustments to flap position in flight.

2-4

Page 18

If you want to operate the flaperons as flaps, you will now use airbrake (ABK) or a mix to move the

flaps a certain distance when the switch is moved.

If you want to be able to TRIM your flaps, go back into flaperon and set the maximum % of the total

flap throw you want available on the trim. Now you can trim the flaps that percentage up or down on

the slider or whatever control you assign channel 6 (flaps) to in the function (FNC) menu.

I want to move a function from one control input to a different one. For example, I want to move

flaps from the slider onto the throttle stick on a 2-servo glider. How can I do this?

This is an easy change. This is just what the function (FNC) menu is designed for. You simply need to

go into the model menu, into function (FNC), and select the channel you want to reassign. Then select

where you want it controlled, then how you want it to be trimmed, if at all. Here is your example:

I want to set up two servos to operate a single surface, but can not use a preset feature like

flaperons or ailevators to do so because of the specific servo assignment I need or the number of

channels on my receiver. How can I do this with a mix?

You can use a free mix to set up the twin elevator servos, or any other two-servo combination by

simply doing a pmix (PMX) of the primary (master) channel to the secondary (slave) channel at 100%

with trim on and link on, offset off and switch assignment NULL so that the mix is always active.

Here is an example of mixing channel 2 to 7 for twin elevator servos:

Set up flaperons (FPN), set a flap

trim rate of 5% on the leftt slider

(LS), and deploy flaps 60% on the

airbrake (ABK) switch (switch C)

down position.

Now the twin aileron servos

operate as ailerons, and also act

as deployed flaps at 60% throw

when the airbrake switch is

deployed. Last, the flaperons can

be trimmed as flaps with the left

slider (LS).

Make Flaperons (FPN) Active O D H A F

Set up Flap Trim at 5% R C F (x5) N R

Assign Flap Trim to Left slider (LS) P B K O J P E

NR

Select and Activate (ACT)

Airbrake (ABK)

OD I AG

Set 60% Flap Drop Rate and

0% Elevator Rate

C K E (if rate is not already +)

DH

Confirm Assigned to Switch C

down Position

P (confirm switch is C and active in

down position. If not, press C then

R Q or P as needed)

NNR

Use function (FNC) control to

move flap control to the throttle

stick and move airbrake (ABK) to

left slider (LS).

Select Function (FNC) Control P B K

Set the Flap Control to the

Throttle Stick (J3)

OJ PK

Move Airbrake (ABK) off Throttle

Stick onto Left slider (LS)

OG P E

Pmix (PMX) channel 2 to 7 at 100% link on,

trim on, switch null.

Thus, whenever channel 2 is instructed to

move (whether by stick movement or by

another mix @ that’s what the link on

does), channel 7 will move exactly equal to

channel 2. Trim on means that channel 7

will also be trimmed when channel 2 is

trimmed, and switch null means this mix is

always active as long as the aircraft is in

the condition in which this mix operates.

From the Condition Menu Select Pmix (PMX) 1 O B I F

Make the Mix Active A F

Set the Master Channel ELE and Link on B F M

Set the Slave Channel Aux 1 C K

Set Type Linear D E

Make Trim Active R F

Go to next Screen and Set Rate to 100% for Both Sides O C M D M N

Set Switch Assignment to Null and Close the Menu P I N N N R

2-5

Page 19

I want to know about triple rates in conditions and over-riding one channel within a condition for a

higher rate. (A detailed explanation of conditions and condition use is covered in Section E.)

There are several separate ways to create a triple rate on the 9Z: two dual rate (D/R) circuits, a dual

rate (D/R) circuit and a mix, a dual rate (D/R) circuit and a condition, and multiple conditions. Let’s

work through a specific example. First, set the model’s elevator servo’s ATV to 95% to get rid of

binding. Now, remember, do not adjust ATV once the setup has begun or it will negatively affect your

other functions. From here on use AFR to adjust your high rates. High rate is 90%, low rate is 60%,

and ultra-low rate is 20%.

OPTION 1, Two Dual Rate Circuits, If you do not need dual rates on 3 channels, you can use a second circuit to set up a third rate.

For example, triple rate on elevator and no dual rate on rudder.

Set ATV: Set base travel of the elevator servo,

from which all mixes, etc will operate.

Open ATV and Select ELE O B F B F

Set First rate: “high” or primary rate is AFR. Open AFR and Select ELE O B G B F

Set Elevator High Rate to 90% of the ATV

Positive and Negative and Close Menu

C G (x10)

D G (x10) N R

Set Second rate: "low" or dual rate is set

in D/R. Remember, dual rates aren't

preassigned for aileron, elevator, rudder.

You can use these D/R circuits for any

channel, including, in this situation, to create

3 or even 4 rates for one surface.

Set Third rate: In this approach, "ultra-low"or

third rate is also set in D/R.

Select Dual Rate (D/R) Circuit A and Make it Active O B H A A F

Select Elevator and Set 60% Travel for

Up and Down Elevator

BFCKDK

Assign the Dual Rate to Switch A in the

Center Position Only and Close the Menu

OAQP

NNN R

Select Dual Rate Circuit B for the Third Rate and Make it Active O B H B A F

Again Select Elevator and Set 20% Travel for Each B F C I D I

Confirm Switch A Down Assignment and Close the Menu O A (Confirm P reads ON,

if not press P) N N

NR

Set Elevator Travel to 95% Positive

and Negative and Close ATV Menu

C M G (x5)

D M G (x5)

NR

OPTION 2, Using a Mix. The Mix Option is a choice if you do not wish to use up a second dual rate (D/R) circuit to create the third rate for the particular

channel. Set your ATV, AFR and D/R as described above (Set ATV, first rate and second rate). Set the switch for the dual rate (D/R) to the middle position

only, as you did above. Then:

OPTION 3, Using a Condition. A condition allows you to edit nearly ALL parameters, rather than just set up a single rate onto the switch.

However, setting up a condition is far more complex, and requires significant steps.

First, set your ATV, AFR and D/R as described above (set ATV, first rate and second rate). Set the switch for the Dual rate (D/R)

to the middle position only, as you did above.

Create a condition (for information on setting up a condition see section E) and assign it to the third switch position. In part 3, select switch A

and press P to assign the condition to the 3rd position of this switch. In part 4, name the new condition "trple" for triple rate.

Set the third rate with a mix: Use a mix to

mix elevator to itself, -80% (decreasing the

throw by 80%, down to 20%) which is only

active in the Switch A down position, just like

the third rate circuit above.

Select Pmix (PMX) 1, Make it Active, and Assign Elevator as

the Master and Slave

OB I F

AFBFCF

Confirm Mix, Trim, Master Settings R G Q F D E

Set the Rate at -80% (Decreasing 80%) Each Direction

(Leave Offset at 0)

OC E L

DE LN

Set Switch A Down as Active Position and Close Menu A P A P N N

NR

Confirm switch A is down

then: C I D I N R

OBGB F

BE SURE that you have this condition active by having the A switch in the lowest position. Remember, you can confirm what condition you are editing by

looking at the top of your screen and checking the condition name.

Now adjust the AFR of the elevator IN THIS CONDITION as follows. This will be the rate which is active when you move the switch A to the third position.

Set up a lowered AFR in the new condition only Open AFR and Select Elevator

Set Each Direction to 20% and Close Menu

(Remember, this is a whole new condition, so from here you could create a 4th rate, or you could put this condition's control on a different switch,

and then have dual rates or even triple rates created on the A switch. The sky's practically the limit with the 9Z!)

2-6

Page 20

Let’s take another look at triple rates...is a condition what you really wanted?

Now that we have you thinking about conditions.....do you REALLY want three triple rates? Or are

you trying to set up your aircraft, for example, to do 3D, and old habits have you thinking you need to

throw 3 switches to get “hyper rates” on all 3 surfaces? If so, we'd like to suggest you rethink this

mind set. Instead of using up 3 dual rate (D/R) circuits and 3 mixes and having to throw 3 switches to

get to a really high performance rate (or a really low one, or otherwise specialized set-up), consider

instead creating a 3D (or a precision) condition and throwing a single switch which puts all your

proper mixes, rates, exponentials, everything at your finger tips in a single flick of a switch, AND

expands your flexibility in that set up dramatically. Just create a new condition, be sure you're in it

from the home screen, and go to town! Set the ATVs, AFR, expo, etc., to fit your needs. See Section E

for more information on creating a condition.

2-7

Page 21

D. P-Mix Features

What are the various Mix Types? When would I use them?

Linear mixes: Linear mixes are proportional to the movement of the master channel. For

example, the rudder-to-aileron (R-A), rudder-to-elevator, and flap-to-elevator

(F-E) mixes are all Linear Mixes.

Offset mixes: Offset mixes move the slave channel a preset distance when the mix is

activated, rather than moving it proportionally. For example, full smoke on

when throttle passes a certain point is an offset mix.

Hovering-type mixes: Hovering mixes are designed to fine tune another mix around the center stick

of the primary control. That is, the slave channel has maximum input when

the master channel is centered, and becomes gradually less as the master

channel control input increases in either direction. For an example of using

hovering mix to fine tune another mix, see “hovering throttle” and “hovering

pitch” in the glossary.

Curve mixes: Curve mixes are similar to linear mixes but have 7 adjustable points along the

mix. For example, a manually-created throttle curve would be a throttle-tothrottle mix on a 7 point curve.

Control mixes: Control mixes are linear mixes which have the volume of the mix adjusted by

the motion of an additional channel. For example, the amount of rudder-toaileron (R-A) mix needed to counteract roll coupling may vary based upon

throttle position. Rather than setting a mix which is right for one throttle

setting and fighting the mix at other settings, a control mix allows 7 separate

mix amounts (“volumes”) to be set based upon 7 stick positions of the control

channel.

What does the programmable mix “trim” feature do?

With trims inhibited, the second servo is not trimmed when the first servo is trimmed. For example, a

rudder-to-elevator mix would not want the mix trim active because then adjusting your rudder trim

would also automatically adjust your elevator trim! Conversely, when 2 servos are being used to

operate one surface or one axis, such as twin elevator servos or twin rudder servos, then having the

trim feature active is critical to be able to trim the aircraft in flight.

What is “master mixed” mode?

“Master Mixed” means the mix refers to the master channel’s AFR (high rate) or D/R (low rate)

currently active. For example, we have two rudder servos mixed to operate a single giant scale

rudder. Rudder AFR is set to 80% and Rudder D/R is set to 60%. With master mix mode ON and

2-8

Page 22

rudder D/R off, both servos would move 80% of the ATV. With master mix OFF, the primary servo

(channel 4) would move 80% of the ATV setting; the slave servo would move 100% of the ATV setting.

For example, this unique mix type is valuable with a 4-control wing on a funfly or other aerobat. The

outboard surfaces are ailerons. The inboard surfaces are flaps. The mix from ailerons to flaps for full

wing ailerons would be UnMixed. Then the inboard ailerons “the ones in the prop blast” always have

maximum possible throw, even when you’re using low rates on the outboard ailerons to avoid tip

stalling. This could be very helpful when doing 3D manuevers where tip stalling and “wing rocking”

is a problem.

Another example is a giant scale military aircraft which requires full rudder availability at all times

but less tail wheel deflection sometimes. By plugging the tailwheel servo into channel 4, rates are

easily available to the tailwheel. Mix the rudder servo into the tailwheel servo, master mode unmixed,

and no matter if the tailwheel dual rate (D/R) is high or low the rudder still has full deflection

available to it.

What does the “link” option do? Why can it be set separately for master and slave channels?

Link tells the radio to look at the channel link is tagged to, and says, “is there any other mix related to

this servo already?” If link is ON then the radio will also obey this other mix. If the link is OFF then

the radio ignores any other mixes commanding this servo. In MOST cases you will want the link to be

ON because your mix is making two servos operate in unison to do a particular job, but you may not

wish to have this occur in some other cases.

Why set it separately for the master and slave? If you want a pre-programmed mix (such as A-R) to

also respond when a programmable mix commands aileron movement, you must set the link on the

slave (aileron) portion of the programmable mix, since you can not adjust link in the preprogrammed

mixes.

Still not sure whether you want link on or off? Let’s look at 2 examples.

1) Elevator-to-flap (E-F) mix with flaperons (FPN): the flap channel (ch6) already has a mix associated

with it (the flaperon mix). If you did an elevator-to-flap (E-F) mix with link off, only the ch6 servo

would move. With link ON, not only will this mix cause the ch6 servo to move in response to the

elevator-to-flap (E-F) mix, but the aileron servo (ch1) will now also move in response to the elevator

motion because the flaperon mix is also being commanded.

2) Elevator-to-flap (E-F) mix with a rudder-to-elevator mix: when you operate elevator, you want the

flaps to move; however, when you move rudder you want it to compensate with elevator BUT NOT

also move the flaps. So, when you set up the rudder-to-elevator mix, you want link OFF on the

slave (elevator) so that it doesn't command the elevator-to-flap (E-F) mix.

Another example would be a 4-wing-servo aircraft with flaps-to-flaperons mix and elevator-to-flap (EF) mix. The flaps-to-flaperons mix is giving you crow behavior when you use the flaps. You'll want

the elevator mix just to call the flaps, not the flaperons as well, because you're trying to do tight loops

but need the wingtips to stay stable, so you don't want the ailerons to respond in that circumstance. In

that case you would leave link OFF on the flaperon side of the flaps-to-flaperon mix so that it did not

automatically also activate the flap-to-elevator (F-E) preprogrammed mix.

2-9

Page 23

E. Understanding the Basics of Conditions

A WORD OF CAUTION: Each model MUST have a base condition which must be accessible to open

the model, even if you do not use it (see the gear door example on P. 2-17).

What is a Condition and How Do I Set up a Condition on My 9Z?

Your 9Z has a very unique ability - you can have up to 8 model memories for ONE MODEL, all of

which are interchangeable IN FLIGHT! These “model memories” are called conditions and allow the

flexibility to change nearly everything. Before setting up additional conditions, always set up

everything you want the same across all conditions – servo directions, basic dual rate (D/R), etc. Also

for clarity, be sure the model has a name (in model menu, MNA.)

* (Note: Copy from will depend on the model number you are using because your base condition number is always the model number. Look at the top center of your

screen. Right after COPY COND it says xx.(name).NRML, xx being the model number, which is the number you need in the copy from box.) Select a condition

number to copy to, choosing a blank condition. To find a blank one, choose list (.R). The first 10 listed are your base models (your 10 model memory) and can not

be used as conditions. Press Next (P) and find the first condition which has # in its name and 00 in its model # OR the same model # as the model you are

working in. For example, from model 1, conditions 11-13 are preassigned to this model.)

What is “condition hold (CHD)”? When would I use this?

Condition hold (CHD) is a great time-saving feature. This feature allows you to edit conditions which

you are not actually operating at the time. For example, you can land, set condition hold (CHD), and

the model now obeys the commands of the condition you were in when you set condition hold (CHD);

now you can open and make changes, for example, to an idle-up condition (otherwise impossible with

a helicopter on the ground). Then release condition hold (CHD), and go back to flying! For an aircraft

example, adjustments can be made to your gear-up or bomb release condition, without the gear

actually retracting, etc.

2-10

Name the base condition to help keep track.

The base condition is the “normal” flight

mode, so name it “normal”.

Open Condition name (CNA), Name the Condition

“Norml” and Close the Menu

OB L

QMMH MH

MM M H K K

KKKHKH

NR

Copy normal condition* into 2nd condition

(make sure it is blank and not in use.)

Open Copy Condition (CPC), Copy Condition 1* into

Condition 11* and Close

QC F HQ

IFOLL

NR

Now select the copy as the second condition

& assign to a switch so you can use it.

Verify that it works: View the model’s name at top center: 01.modelname.NORML. (where 01 is your model's # and “modelname”

is the model's name). Pull switch C to 2 position. See the name changed to 01.modelname.00011? You did it!

Now you can decide its use and name (condition menu, select CNA, name like you did the base condition NORML). From here, it is entirely

up to you to set up anything you want condition #2 to do. It can nearly do ANYTHING except change the basic stick assignments (throttle left

elevator right, etc). (Items in the System and Model menus can not be different between conditions.) REMEMBER! Whenever you're making

any types of changes, you HAVE to be in the proper condition that you're changing. Don't have the switch in the normal condition then think

you're changing throws, etc., in the new condition you made.

Open Condition Select (CSL), 2nd, Select #11 P B F B I O

Assign to Switch C and Close P C P N N R

Page 24

I am interested in using conditions, but what about trims? If I trim the model in one condition,

will the trim “follow” through all conditions or do I have to re-trim in each condition? Also,

what if I need a difference in trim between two conditions, but want any changes to follow from

then on?

When I set up varied conditions, my trims don't have the same amount of effect in each condition.

In an aerobatic 3D condition, for example, the trim has a much larger effect than in my normal

flight condition. How can I fix that?

Like most issues, this can be resolved in more than one manner, but there is definitely a preferred

approach. This is an example where modifying ATV instead of AFR has caused an undesired effect.

[For an explanation of the differences between ATV/AFR/Dual rate (D/R), please see P. 2-2.] By

resetting the ATVs to the same percentage in each condition, then adjusting the AFR to give more or

less throw on each surface's high rate, the radio will maintain a consistent trim adjustment. You

COULD simply adjust the size of the step of the trim in each condition until it feels comfortable, but

this is putting a band-aid on a poor programming set up. Instead, correct the ATVs so your conditions

match properly.

I want to have very fine trim adjustment in my base conditions, but for the first flight of the model

I want to have a condition I can go to which has higher trim adjustment in case the model is farther

out of trim than the fine-setting trims will allow. How can I do that?

To have trim changes made in one condition

affect all conditions, combine all trims.

Want to set all trims back to center for all conditions? Combine the trims, and move digital trim levers to 0. Nothing more is needed.

Go to the Trim (TRM) Menu and Combine All Trims,

Close Trim (TRM) Menu

EE I NFI N

GINHINN

Want to remember your current trim setting

before going to fly a modified plane so you

can tell exactly what trim the model took?

Go to Trim (TRM) Menu, and Save this Current

Trim Setting to Memory

E (physically move all digital trim

levers until left digit reads 0)

KIN

Need an offset of trim between conditions?

For example, having a small amount of down

elevator trim in your gear-down condition?

You can do this without needing a mix and

still having trim follow each condition.

Trim the Aircraft in the Normal Condition, Then Separate

the Elevator Trim for Each Condition

EF INN

Re-fly the Aircraft and Trim it for Gear-down While in the

Gear-down Condition, Then Recombine the Elevator Trim

EFHNN

In general, the stock trim throw settings would be plenty for your high trim condition, but too much for your fine tuning base set up.

Create your conditions, name them normal and HiTrim. In this example, switch C down position is HiTrim Condition On.

In the normal condition, reduce the amount

the trims effect the servo position on each

click. Note that moving the condition

switch to normal and back to HiTrim will

allow you to adjust the trim effectiveness

in each condition.

In the Normal Condition, Go to Trim (TRM) Menu (with switch C up or center) E

Choose Elevator Trim and Adjust Step 1 to 1

and Step 2 to 3

FRH

PH FFN

Choose Rudder Trim, Then Aileron Trim, and Adjust Step

1 to 1 and Step 2 to 3 and Close the Menu

ERH

PHF FN

HRH

PHF FNN

2-11

Page 25

F. Specific Programming Examples

Let’s take a complex model and walk through the basics of set up from servo connections through

mixing. Remember: we’ve provided the actual keystrokes to use here, ASSUMING you began with a

blank model. Always double-check every step to ensure proper set up and verify that the desired end

result is reached. We can provide the guidance, but you are ultimately responsible for the usability of

your programming.

How do I program a four-servo delta wing set up on the 9Z? I want to make all four wing servos

respond as both elevator and aileron.

You want both of the controls on the left side to go the opposite direction from those on the right side

when aileron stick is commanded, and all four servos to go up and down together for elevator stick. You

can't use the default delta set-up, as it uses a maximum of three servos, and you want to use four.

Programmable mixers will do the job, but you'll have to spend some time working with them to get the

trim settings to work properly with all the servos. The easiest way is to use both the Flaperon and

Ailevators (ALV) pre-programmed mixing functions.

Let’s do this example right from the start. Select model 1 in the radio, clearing anything in its memory,

and do all set-ups.

Select the desired model. Select Model 1 and Close the Menu Q B F A L L

NR

Reset the model menu.

Select Model Reset and Reset All, Close the Menu P B L O I I

NR

Set the model type (TYP) as Acro.

Select Model type (TYP) and Select Acro, Close the Menu Q C H I R N R

Reset cross trims to same-side trims.

Plug in your servos as follows, and complete basic set-ups:

CH1 = Right aileron (outboard) CH2 = Right elevator (inboard) CH3 = throttle

CH4 = Rudder CH5 = Left elevator (inboard) CH6 = Left aileron (outboard)

Open Function (FNC) and Reassign the Elevator

and Throttle Trims

PBKOFQ G

OGQHNR

Check servo direction and close the menu.

(For example, reverse aileron.)

Select Servo Reverse (REV), Select Aileron,

Reverse It, Close the Menu

PBJEP

NR

Set desired ATVs and adjust as needed. (For

example, set elevator to 80% up 82% down.)

Select ATV, Select Elevator, Set Desired Percentages,

Close the Menu

OB F B F

CLDL FF

NR

Set desired high rates (AFR). (for example

rudder 85%.)

Select AFR, Select Rudder, Set Desired Percentage,

Close the Menu

OBGB H

C L F(x5)

D L F(x5) N R

Set desired low rates (D/R). (for example,

aileron 60%.)

Now Set up Flaperons (FPN) and Ailevators (ALV) to Create the Desired Flying Wing Operation.

Select D/R, Select Aileron, Set Desired Percentage,

Assign Switch A Position 2, Close the Menu

OBHA F

BECK

D K O A (Confirm P

says “on”) N N N R

Set up flaperons (FPN) with 100%

flap trim motion.

Open Flaperon and Make it Active O D H A F

Set up Ailevators (ALV).

Open Ailevators (ALV) and Make it Active O D F A F N

R

Operate the flap action of the ailerons in

conjunction with elevator movement.

Note: Using the elevator trim will only trim the two inboard, elevator servos, not the outboard aileron servos. Similarly, using the aileron trim will trim only the two outboard aileron servos.

*Remember, there are lots of different ways to obtain the same end result. For example, this could be done without turning the flap trim movement to 100% and without the

function (FNC) menu action, but instead by using flap-to-elevator (F-E) mixing.

Open Function (FNC) Menu and Select Flap, Set to J2* P B K

OJ PJNR

Set the Flap Movement from Flap Command to 100% R C M N R

Reset the Trim Type to Operate Properly for

Throttle and Elevator

EGEN

FFNN

2-12

Page 26

On my helicopter, I want to set up a “throttle cut” condition which only operates in normal, but not

in any of my other conditions. How can I do this? (I am Afraid I'll bump the throttle cut when

reaching for certain other switches--for example, in inverted flight.)

The standard throttle cut (CUT) function is set from the Model Menu, and all the functions listed on

the Model Menu are not "condition" switchable, so it can't do specifically what you're requesting.

There are several ways you CAN achieve this, however.

First, you can set the minimum stick position above which the throttle cut (CUT) function will not

operate. For example, you can set it to a point where the throttle cut (CUT) will not operate if the stick

is any place above about 1/8 throttle. This way, unless you do a lot of full throttle inverted work, even

if you accidentally bump the switch, you shouldn't have a problem.

Second, you can simply set up a mix in your base condition which offsets throttle to whatever negative

percent will shut off your engine without overcamming your servo (you'll need to experiment to find

this point). Let’s work through this example.

(Note: You could create a similar mix also for idle down by simply setting the % for the throttle to decrease and again experimenting until it idles your

engine down to the desired point.)

On my aircraft, I want to set up the left slider as throttle trim.

Note that this can only be done in an aircraft model type. Note that the digital trim also remains

active unless you deactivate it in the FNC menu.

I am setting up a twin-engined model and want to command the engines separately at certain times.

Specifically, I want the engines to respond to the throttle stick (never knobs); the left engine to

operate alone if the C switch is up (the right engine idles); both engines to operate together in the C

center position; the right engine to operate alone in the C down position (left engine idles.)

Absolutely! Like most things with the 9Z, there are many ways to tackle this task. We'll give you 3

options here. There are many more.

Create a Pmix (PMX) which offsets throttle

20% to shut the engine off when at idle. Note

that this switch will idle the engine down but

not necessarily shut it off at higher throttle

settings. (Select the desired percent based on

running the engine at idle and adjusting the

percent until the engine shuts off.)

Select Pmix (PMX) 1 and Make it Active

OB I F A F

Set the Mix Type as Offset

DF

Set the Slave as Throttle

CG

Set the % as 20%

OD I N

Assign the Switch to H and Close the Menu

PHPN

NNR

Select throttle curve activation, make it active,

go to throttle curve and set the volume on the

left slider.

Activate Throttle Curve (TCV)

PCL FNR

Select Throttle Curve and Assign Volume to Left Slider

OD KOF

Change Direction ONLY IF NEEDED

P

Close Volume

N

Adjust Curve If Desired

(adjust if desired)

Close the Menu

NR

2-13

Page 27

FIRST OPTION: "I have a spare channel on my 8-ch receiver, or am using a 7-ch receiver" (so channel 8 can be used to set up the mixes).

Servo Set-up: channel 3 = left throttle channel 7 = right throttle

Open Function (FNC) Menu, Assign Channels 3 and 7

Controls and Trims to Null, Channel 8 Control to Throttle

Stick and Trim to Trim 2 for Cross Trims or Trim 3 If You

Have Reversed Cross Trims and Close the Menu

Assuming your spare channel is channel 8,

assign channel 8 to throttle stick, and attach

the throttle trim to channel 8. Set channels 3

and 7 to null so no knob, slider or switch

controls those two servos directly – they move

only by mix commands.

PBK

OG PMME

QE

OK PMME

QE

OL PKQG

NR

Open and Activate (ACT) Pmix (PMX) 1Create a pmix (PMX), mixing channel 8 to 3 at

100% with trim on, Switch C in up and center

positions. This will move servo 3 in unison

with throttle stick movement, including trims,

when Switch C is in up and center positions,

but not when Switch C is in down position.

OB I F A F

Open Pmix (PMX) 2 and Make it ActiveCreate a pmix (PMX), mixing channel 8 to 7 at

100% with trim on, Switch C in center and

down positions. This will move servo 7 in

unison with throttle stick movement, including

trims, when Switch C in center and down

positions, but not when Switch C is in up

position.

OB I GAF

Set Type Linear, Trim Active, Master Mixed, Switch C

Ctr/dwn

DERFQF

PCPQN

Master Aux2 Slave Aux1

BLCK

Set 100% Both Directions and Close the Menu

OCMDMN

NNR

Set Type Linear, Trim Active, Master Mixed, Switch C

Up/Ctr

DERFQF

PCRQN

Master Aux2 Slave Throttle

BLCG

Set 100% Both Directions and Close the Menu

OCMDMN

NNR

SECOND OPTION: “I am using an 8-ch receiver and do not have a spare channel.”

Servo Set-up: channel 3 = left throttle channel 7 = right throttle

Open and Activate (ACT) Pmix (PMX) 1Set switch C up position:

Pmix (PMX) throttle to 7, 100%, trims follow,

with the mix activated by switch C position

center and down, then Pmix (PMX) offset

channel 7 to bring it to idle at the up position.

(Note that this set-up mix is offsetting the

servo 50%. You may need to adjust this

percent to get a proper idle and not

accidentally shut down the second engine.)

OB I F A F

Select Pmix (PMX) 3 and Make it ActiveSet switch C down position:

Pmix (PMX) throttle-to-throttle -100% which

turns off throttle but leaves it at neutral. Again,

like we did with mix 2 above, do an offset to

take throttle to idle. Set switch C down.

Note: to trim the channel 7 engine by itself,

use the right dial. Or turn off the dial

assignment in Function (FNC).

Open Function (FNC) Menu and Set Aux1 Assignment

to Null and Close the Function (FNC) Menu.

OB I HA F

Set Type Linear, No Trim, Master Mixed, Switch C down

DERGQF

PCPN

Master Throttle Slave Throttle

BGCG

Set Percent -100% Each Way

Offset to Idle and Close the Menu

OCME

D M E (Move throttle

to idle position) B F

NNN R

PBKOK

PMMENR

Type Linear, Trim Active, Master Mixed, Sw C Up/ctr

DERFQF

PCPQN

Master Throttle Slave Aux1

BGCK

Set 100% Both Directions and Close the Menu

OCMDMN

NNR

Open and Activate (ACT) Pmix (PMX) 2

OB I GAF

Set Type Offset, Switch C up

DFPCRN

Slave Aux 1

CK

Set 50% and Close the Menu

O D J F(x10)

NNN R

2-14

Page 28