Page 1

SAMPLE AIRPLANE SETUP INSTRUCTIONS

Airplane Section

The

following example shows how the PCM

1024Z may be programmed for a pattern airplane.

The settings presented here are for a typical

model. Your model's settings are likely to vary

from these, but the procedures given will still be

applicable.

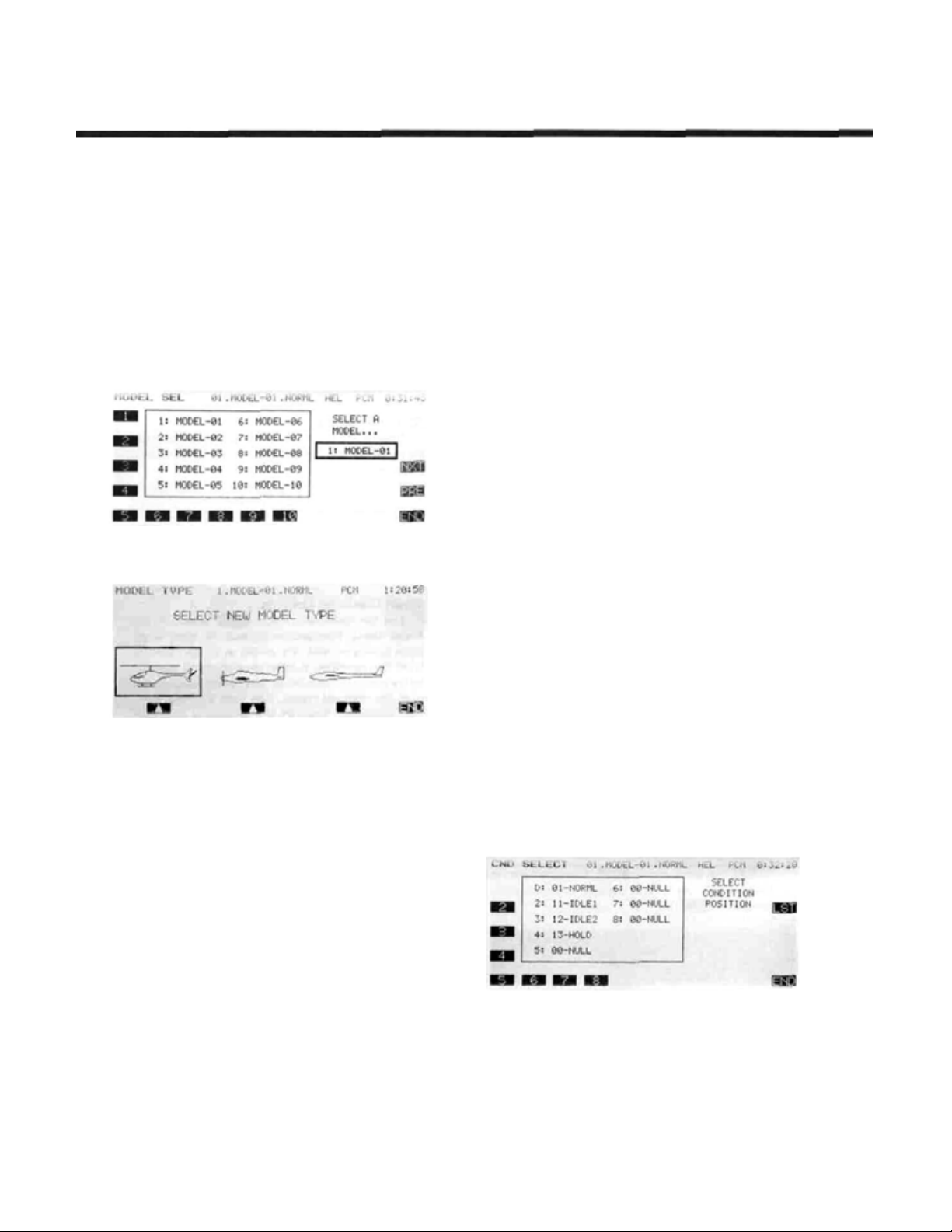

1. Model Selection

Use the Model Select function MSL to select a

vacant model memory (or one you don't mind erasing)

and choose the AIRPLANE Setup using the Type

TYP

function from Model menu.

2. Name The New Model

Rename the model using the Model Name MNA

function in the model menu. Switch to the Condition

menu

CND

(we recommend NORM L). Later you may add other

flight conditions, which may also be named to make

them easier to identify.

3. Activate Special Mixing

Activate Flaperon

ADF

choose one; both require two aileron servos). FPN is

suggested since it can accommodate differential

through end point adjustments, and has Flap mixing.

The Flap mixing is used to have the ailerons behave as

flaps as well, which can be used to make tighter loops

and squarer corners in maneuvers. Use ALV to get

elevators that act as ailerons (two servos are required

for ALV function). You need not adjust the throws

and mixing ratios at this time.

4. Reset Control Order

If necessary, reset the Control Order using the

Function Control

may choose what sticks and sliders control the different functions. If you use the ALV function, move

the retrac t operation to another switch, perhaps CH7

orCH8.

5. Connect Servos

Plug Servos into Correct Channel Numbers

1. AIL Aileron (Ail 1 if FPN or ADF on)

2. ELE Elevator

3. THR Throttle

4. RUD Rudder

5. G EA Landing Gear (Elev 2 if A LV on)

6. FLP Flap ( Ail 2 if FPN activated)

7. AU1

8. AU2 Collective Pitch

9. CH9

6. Set Neutral Points

Use the Subtrim function

servo to its neutral position. If the amount of subtrim

is large, you should reset the subtrim to zero and move

the splined servo arm to a position that is as close to

the desired neutral as possible. Then use the subtrim

to get the neutral position "right on." Repeat with the

remaining channels.

and name the default flight condition

FPN

if you desire these functions (you may only

FNC

Spoiler (Ail 2 if ADF is used)

Channel 9

or Aileron Diferential

in the model menu. Here you

STM

to move each

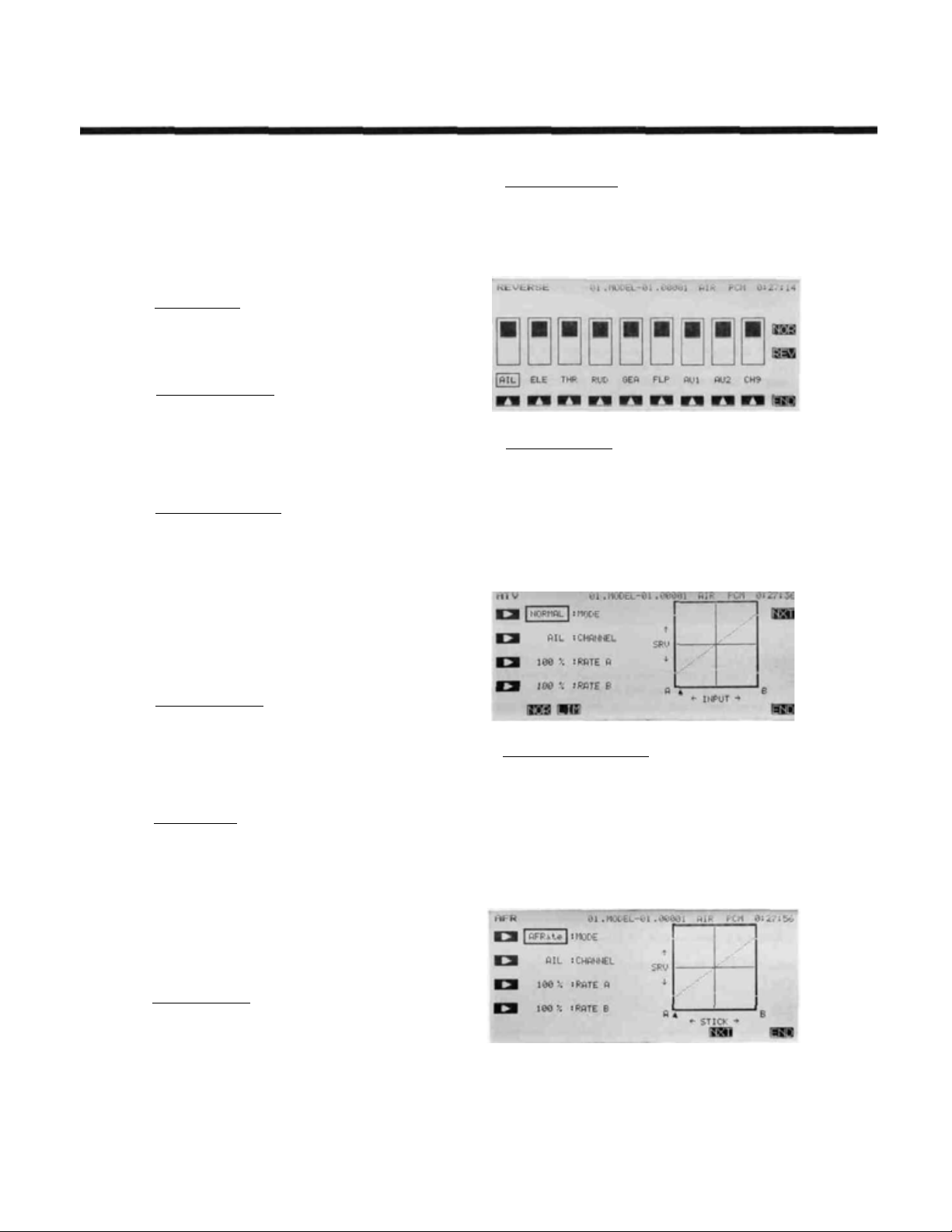

7. Adjust Servo Throws

Check the proper direction of throw for each

servo. Use Reversing Function

menu to set proper throw directions for each servo.

Double check that each servo moves the proper direction.

8. Limit Servo Throws

Now use the ATV function to limit servo throws.

The travel of the ailerons should be limited to roughly

10—12° maximum in both directions with the ATV

function. Repeat for elevator. Adjust rudder lateral

motion to about ±45°. Be sure that no servo "bottoms

out" at maximum control throw. After setting maximum throws, ATV is rarely used. Instead use AFR in

the different flight modes.

9. Changing The Control Feel

If you would like to soften the control feel for

ailerons, use the AFR menu. Press the

then the

rate of -15% to -25%. E X2 is used for throttle only.

AF R to get slightly more up than down travel, and use

EX 1 with a -10% setting.

EX1

EX1

key to get exponential curve. Set a

Change to Elevator using the Channel key. Use the

Change to Rudder with the Channel key, and set

for-10%.

REV

in the Model

NXT

key,

Airplane Section, Page 77

Page 2

Airplane Section

10. Set Flaperon Throws

Now go back to the FPN (Flaperon) menu. Set

differential by limiting the down aileron throws on

both sides. The down throw should be set between

70% and 95% of the up throw. This setting depends on

the individual model and its particular flight character-

istics, so make changes after flight testing. Be sure

that the flap mixing settings are the same (default is

±100%).

Move to the E->F menu to set up how much the

ailerons move due to elevator. Approximately 1030% up and down mixing should be used (be sure that

up elevator causes the ailerons to drop, and down

elevator raises the ailerons up). The amount of aileron

droop at neutral elevator may be set with the A knob.

You may adjust this travel by adjusting the trim rate —

it can be set to zer o to prevent accidental changes (be

sure this knob is zeroed before resetting subtrims).

Using the

to turn the elevator-flaperon mixing on and off.

11. Setting Up Airbrakes

move both the elevators and flaps to a preset position

for an airbrake effect. Normally, the ailerons are raised

5—10° and the elevator is offset to cancel any trim

change.

dition menu. Select the Manual mode by pressing the

MAN

mode. To select the operating switch, press the

key. The display shows that the default airbrake con-

trol switch is the C switch, ON in the lower position.

You may choose another switch or direction at this

time. Verify proper operation of the switch by activating it and watching the servos move.

key. If you have spoilers, they may be actuated also.

Read the section on AB K f or more details.

SWT

button, you can also define a switch

To make landings easier, you may set a switch to

Call the Airbrake

key. Auto is available.

This system should normally be used in manual

Press the

PRE

ABK

function from the con-

key to get back to the preceding

SWT

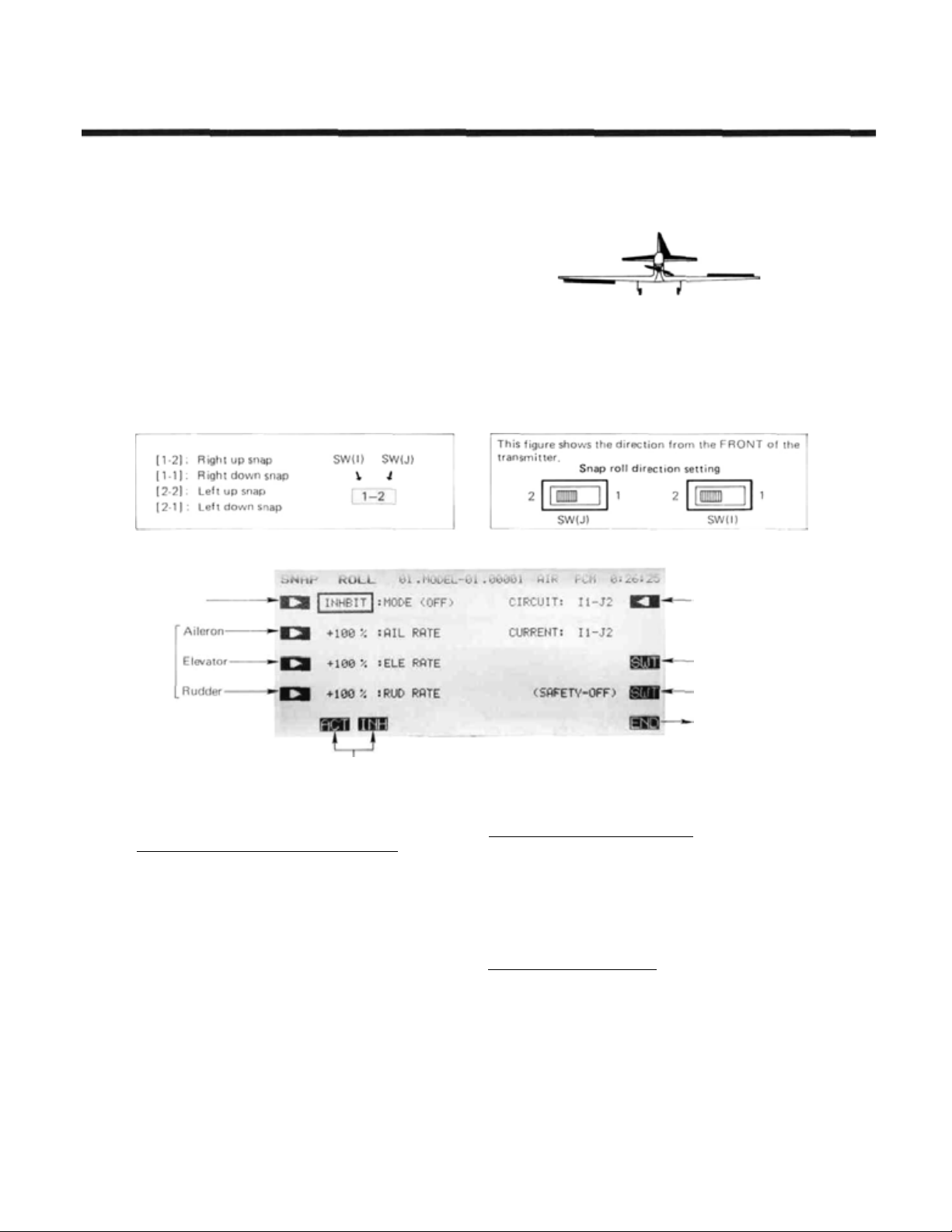

12. Snap Roll Setup

You may have any switch activate the Snap Roll

function (the spring-loaded switch is strongly recommended!). Call the Snap Roll function

the Condition menu. Activate it with the

Set the deflection for each switch position: ailerons

±100-110%, elevator ±80-100%, rudder ±70-80%.

Be sure to choose the correct directions with the

For safety, you may also turn on the safety switch

using the O button. This safety inhibits the activation

of snap roll if the landing gear are down. Check to

mak e su re the s wi t c h is set fo r th e correct direction.

13. Setting Up Differential Elevator

Your PCM 1024Z system has a unique function

called ALV for "Ailevators," or differential elevators.

This function provides roll control whenever the

propeller slipstream is acting on the tail, and is effective at low airspeeds.

Press the

with the

A-3 and A -4 settings. We recommend starting out with

small deflections at first. Be sure that the settings for

ELE are 10 0 % to get full elevator authority.

ALV

key to enter the menu. Activate

ACT

key , then adjust the rates given by the

SNP

ACT

form

key.

Airplane Section, Page 78

Page 3

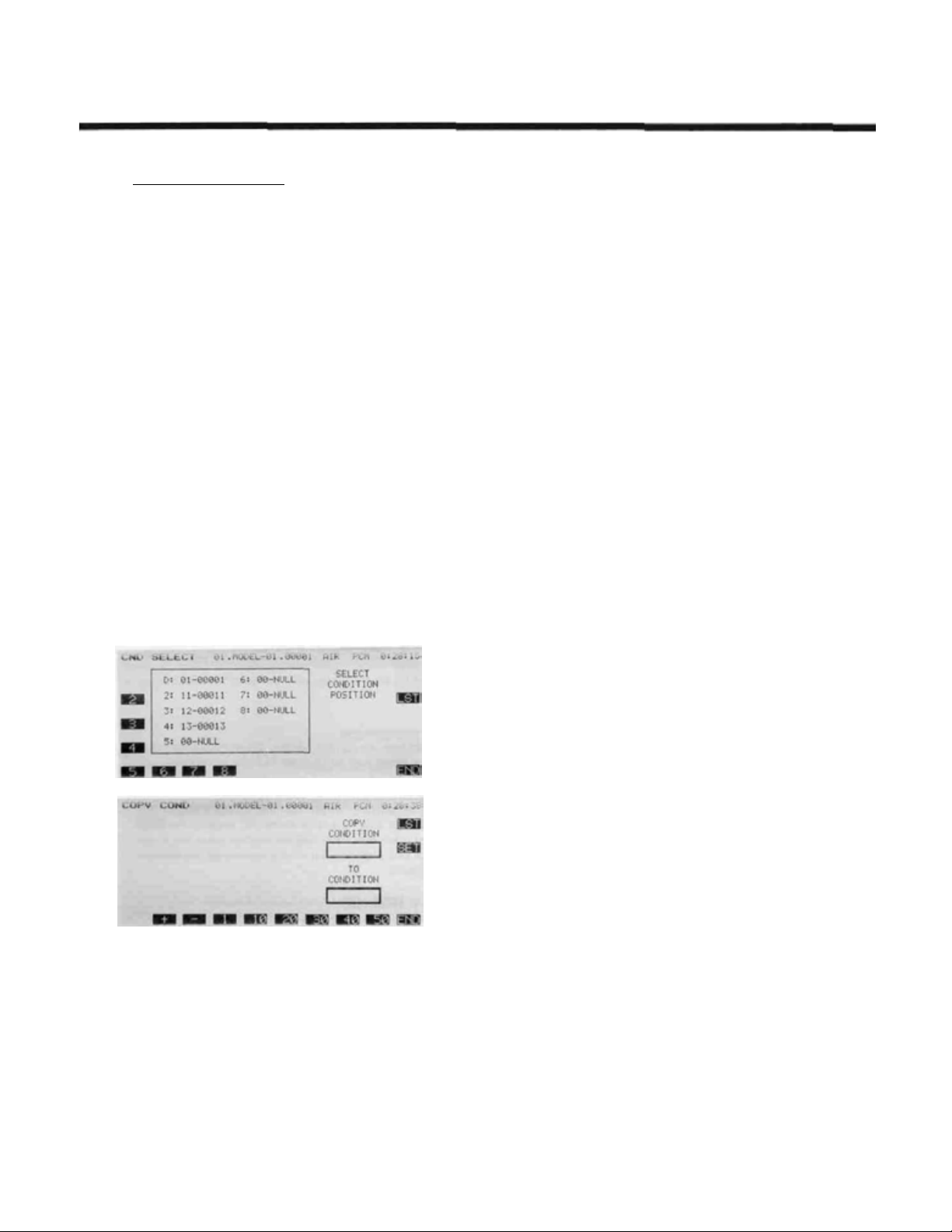

14.

Flight Conditions Switching

If yo u li ke, you may set up the system to call up

more than one function or switch to a new set of trims

or control settings simultaneously by moving a single

switch. You can have different subtrims, coupling,

differential, exponentials, and throw volumes. In fact

you may change EVERY parameter between flight

modes.

We recommend that you fly the model and adjust

trims and control responses to your liking before

defining another flight condition. Any bad tendencies

may be corrected with custom programmable mix

settings

a new flight condition, where they may be modified

for the new desired conditions. After copying you

may add new functions as necessary.

Model Menu. This function allocates the necessary

number of flight conditions to the model memory.

Note the condition number next to the D (default) in

the display. This is the set of conditions that wi ll be

copied into a new condition and modified. Also note

the number after the next display. You will copy to

this condition.

menu. This function copies the contents of on e condition into another. Choose the default flight condition

number, press the SET button, then choose the second

condition number in the lower box "TO CONDITION." Give the command to copy.

PMX

. Then, copy the set of adjustments to

Use the Condition Select

Use the Copy Condition

CSL

CPC

from the System

button in the

Airplane Section

15.

Volume Setting

Some functions can have their mixing ratio vary

with the motion of another slider or knob: use the

VOL key O to get to this choice (for example, see

AD F) . Move the selected control to determine how it

affects the mix. You can also add a time delay on

many of the menus: look fo r a DELAY setting.

16. Programmable Mixers

Up to five mixers are available in all flight condi-

tions. These may be used to enhance flight capabilities

or to correct bad tendencies by adjusting mixing from

one control to another. For example, you may use

Elevator->Flap coupling to tighten up the corners on

square loops, Throttle->Rudder coupling to correct

for torque tendencies, etc. There is no limit to the

number of corrections that can be made.

Your PCM 1024Z system is filled with powerful,

predefined mixing functions. Be sure to browse through

the various function menus in the Aircraft section follow-

ing this example.

The switch that calls the flight conditions should

be selected. Return to the Condition Select

function, press the desired flight condition number,

and use the SWT button to choose the desired switch

location. Once you have selected a condition, use the

CNA (Condition NAme) button to label the new conditi on (yo u may have to flip the chosen switch to the

correct position to get the desired condition). Now,

you may go through the Condition menu items to get

the desired settings in the new mode. Read the condition name after the model name to be sure you are

changing the condition you want.

CSL

Airplane Section, Page 79

Page 4

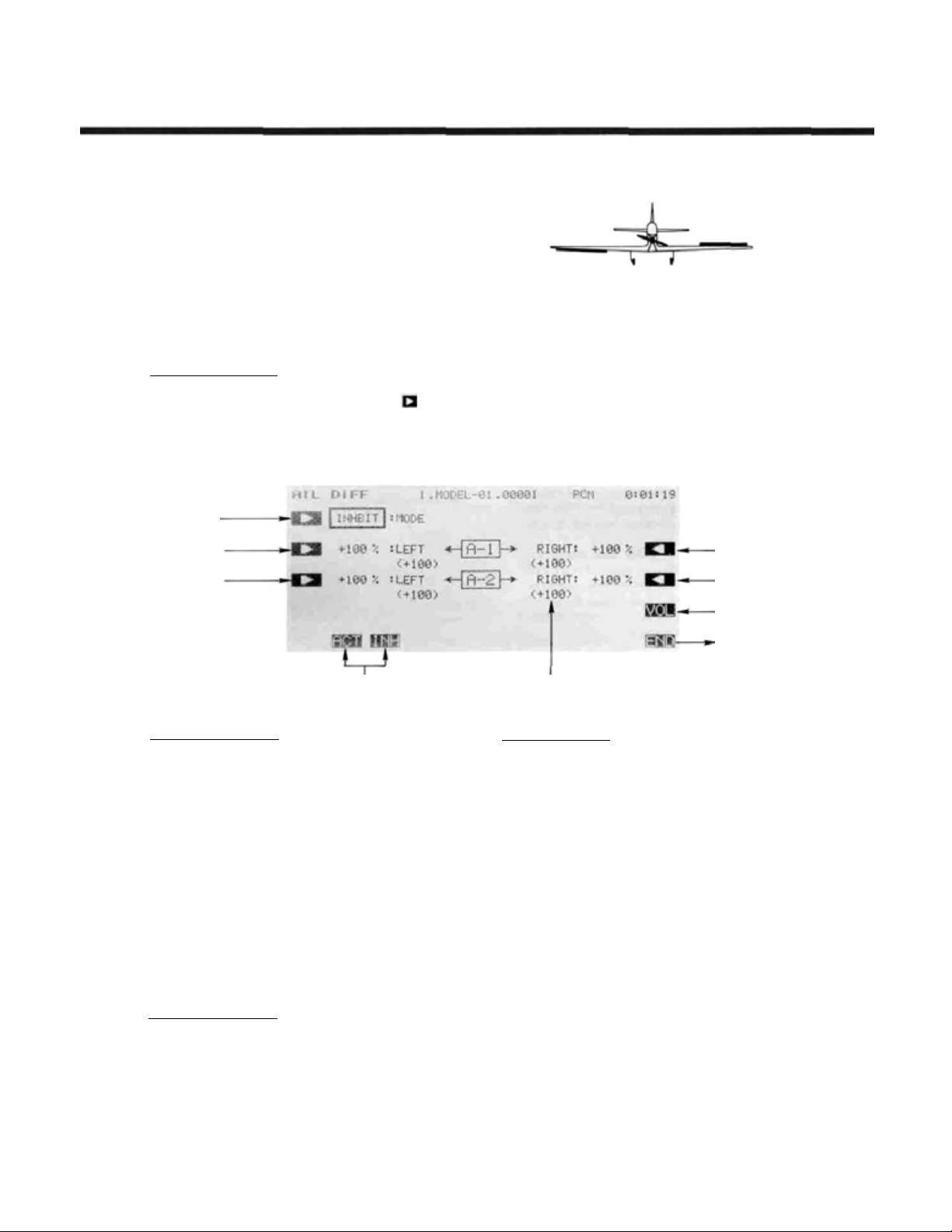

AlLERON DIFFERENTIAL (ADF)

This

function

to independently correct yaw tendencies during

rolls. It is possible to adjust each aileron's positive

and

negative

is activated, receiver outputs CH1 and CH7 are

used for the two aileron channels. This function

may not be used if Flaperon (FPN) is chosen. If

desired, the amount of down aileron deflection

may be trimmed in flight with a knob or trimmer.

Setting Up Aileron Differential

Activation of command

In the Condition Menu, press the ADF key to get the

AIL DIFF menu shown below. Use the A ( ) key to

activate mode setting, then press the

keys (F

and G) to

ferential function.

Mode setting

Aileron 1

Left Side rate

Aileron 2

Left Side rate

uses

deflection

activate or

two

separate

angles.

inhibit

aileron

When

the aileron

Mode selection Values in ( ) are the mixing rate, including the trim volume.

servos

this

function

ACTorINH

dif-

Airplane Section

Aileron 1

Right Side Rate

Aileron 2

Right Side Rate

Trimming volume

Setting

Return to

Condition screen

Aileron 1 Travel Setting

You now set the amount of servo throw for Aileron 1.

Press the B key to activate travel setting for the Left

direction and set the throw with the numeric keys. The

number keys 0 through 100 input the value directly.

The + and - keys increase or decrease the value by 1.

The +/- key may be used to reverse the throw direction.

If you are not sure what you are changing, hold the

stick to one side and press different keys — if there is no

effect, move the aileron stick to the other side and con-

tinue. Your setting may vary from -120 to +120%, the

initial value is+100%.

Now set the travel for the Right throw on Aileron 1.

Press the Q key to activate travel setting fo r the Right

direction and set the throw with the numeric keys as

before.

Aileron 2 Travel Setting

The setting process given above is repeated for Aileron

2. Press the C key to activate travel setting for the Left

direction and set the throw with the numeric keys.

Finally, set the travel for the Right throw on Aileron

2. Press the P key to activate travel setting for the Right

direction and

before.

set

the throw with the numeric keys as

Airplane Section, Page 80

Trim volume setting

You may set up the Aileron Differential function so

that its effect may be changed in flight by moving a trim

control. The trim control adjusts the volume within ±25%

of the set differential rate. This option is not activated at

init i al setup.

Call the volume setting screen by pressing the VOL

O key, and select the desired control using the screen

menus (for a description of the volume setting method,

see page 37).

Use the END (N)

key

to

leave

this

menu.

Page 5

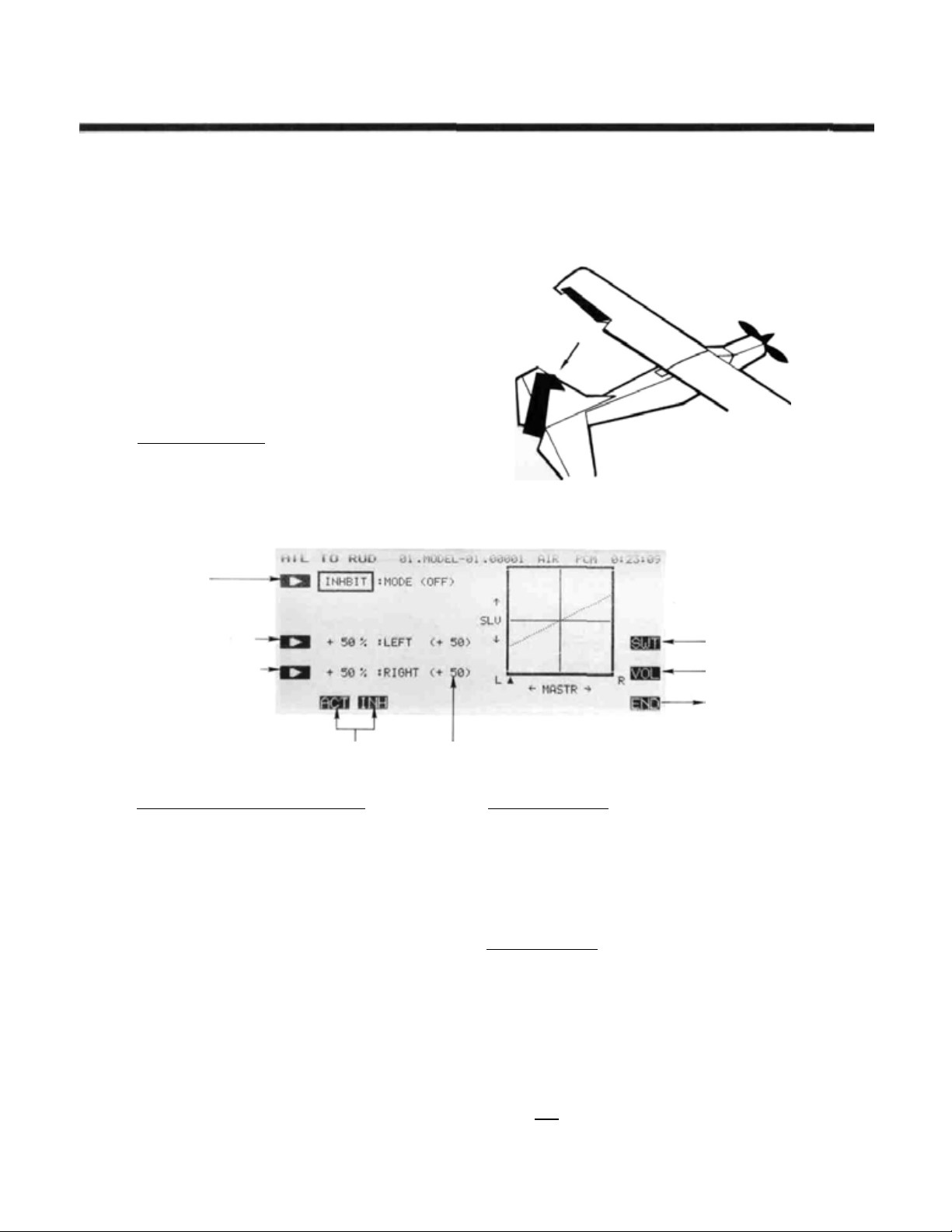

RUDDER COUPLING (A->R)

Airplane Section

This function is used to mix rudder operation

with aileron operation automatically, to make

realistic, coordinated turns. It is especially effective when turning and banking scale models or

large models tha t resemble full -size d aircraft. This

mixing

keeps

the

fuselage aligned

and helps to make what is called "coordinated

turns."

The function allows you to set up the left and

right mixing rates independently. Furthermore,

mixing can be turned on and off during flight by

setting a switch, or it may be set to stay on all the

Setting Up Rudder Coupling

Activation o f command

In the Condition Menu, press the

AI L TO RUD menu, as shown below. Use the A

key to activate mode setting, then press the ACT or

INH

keys ( F and G ) to activate or inhibit rudder

coupling.

Mode setting

into

A->R

key to get the

the

wind

time if the function is activated (ACT) without

setting an ON/OFF switch. Also, it is possible to

adjust the amount of rudder coupling in-flight, by

setting a volume control.

Mixing i—— Left side

rate

setting I—— Right side

Mode Selection Values in ( ) are the mixing rate, including the trim volume.

Setting the Mixing Ratio — Left and R ight

You now set the amount of mixing for left aileron

command. Press the C key to activate mixing ratio for

the Left direction and set the value with the numeric keys

F to M . The number keys 0 through

value directly. The + and - keys increase or decrease

the value by 1. The +/- key may be used to reverse the

throw direction.

If you are not sure what you are changing, hold the

stick to one side and press different keys — if there is no

effect, move the aileron stick to the other side and continue. Your setting may v ary from -100 to +100%. the

initial value is+50%.

Now set the amount of mixing for the Right aileron

command. Press theDkey to activate mixing ratio for

the Right direction and set the throw with the numeric

keys as before.

100

input the

ON/OFF switch

setting

Trimming volume

setting

Return to

Condition screen

On/Off Switch Setting

On initial setting, an activation switch for rudder

coupling is not set. meaning that once activated, it is on

all the time. If y o u would li ke to set a switch to turn it on

and off, call the Switch Setting screen by pressing the

SWT P

switch location and on direction. For more information

on the switch setting method, see page 37).

Trim Volume setting

its effect may be changed in flight by moving a trim control. The trim control adjusts the volume withi n ±25% of

the set mixing rate. This option is not activated at initial

setup.

O

menus (for a description of the volume setting method,

see page 37).

key. Then use the keys to choose the desired

You may set up th e Rudder coupling function so that

Call the volume setting screen by pressing the

key, and select the desired control using the screen

VOL

Use the END (N) key to leave this menu.

Airplane Section, Page 81

Page 6

V-TAIL (VTL)

Airplane Section

This

function

1024Z to

control a V-tail airplane with combined

elevator

servos, one hooked up to receiver output CH2

Setting Up V-Tail Mixing

Activation of command

V-TAIL Mixing menu shown below. Use the A key

to activate mode setting, then press the ACT or INH

keys ( F and G) to activate or inhibit V-Tail Mixing.

Mode setting

Elevator 1

deflection angle

Rudder 1

deflection angle

and rudder functions. It requires two

In the Condition Menu, press the

automatically

sets

VTL

up the PCM

key to get the

(elevator 2/rudder) and the second plugged into

CH4 (elevator 2/rudder 1). The elevator and rudder deflection can be adjusted independently.

Elevator 2

deflection

Rudder

deflection angle

Return to

condition screen

angle

2

Mode selection

Setting the Elevator Rates - 1 and 2

You now set the rate for Elevator 1. Press the B key

to activate rate setting for Elevator 1 and set the r at e with

the numeric keys E to M . The number keys 0 through

100

input the value directly. The + and - keys increase or decrease the value by 1. The +/- key may be

used to reverse the throw direction.

If you are not sure what you are changing, hold the

stick to one side and press different keys — if there is no

effect, move t he elevator stick to the other side and con-

tinue. Your setting may vary fr om —10 0 to +100%, the

initial value is +50%.

Now set the rate for Elevator 2. Press the Q key to

activate Elevator 2 rate setting and set the rate with the

numeric keys as before.

Setting the Rudder Rates - 1 and 2

You now set the rate for Rudder 1. Press the C key to

activate rate setting for Rudder 1 and set the rate with the

numeric keys E to M as before.

If you are not sure what you are changing, hold the

rudder stick to one side and press different keys — if there

is no effect, move the rudder stick to the other side and

continue. The initial value is +50%, but your setting may

vary from -100 to +100%.

Now set the rate for Rudder 2. Press the P key to

activate Rudder 2 rate setting and set the rate with the

numeric keys as before.

Checking Your Work

After you have set up the V-Tail rates, be sure that

they move the correct directions. For up elevator command, both V-tails should move upward. For right rudder

command, the trailing edge of both surfaces should move

to the right. If they do not, use the +/- to reverse the

direction as needed.

Use the

END ( N)

key to leave this menu.

Airplane Section, Page 82

Page 7

Airplane Section

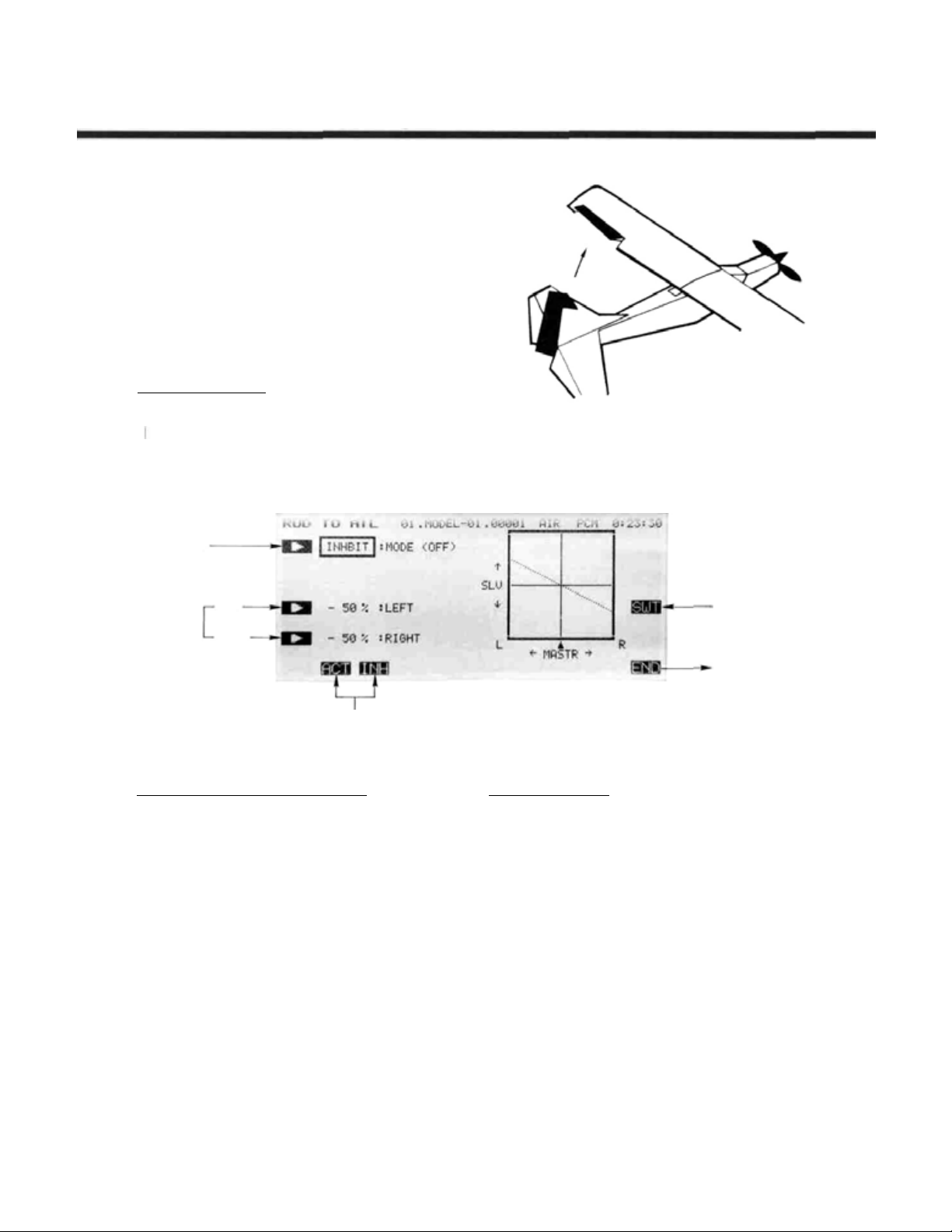

RUDDER—AILERON

Rudder to aileron coupling may be used for

correcting unwanted tendencies with aerobatic

planes. For example, this mixing can be used to

cancel out any rolling that occurs during knife

edge

flight.

The

rates

for

travel can be set independently. Mixing can be set

to be turned on and of f during flight by setting a

switch (if no ON/OFF switch is set, mixing remains on all the time).

Setting Up Rudder-Aileron Mixing

Activation of command

In the Condition Menu, press the A->R key to get the

RUD TO

key to activate mode setting, then press the ACT

or INH

to-aileron coupling.

Mode setting

AIL

mixing menu shown below.

keys(F

andG)

to

activate

(R->A)

left

and

or

inhibit

right

rudder

Use the A

rudder-

Mixing rate

setting

Setting the Mixing Ratio - Left and Right

You now set the amount of mixing for Left rudder

command. Press the C key to activate mixing ratio for

the Left direction and set the value with the numeric keys

E to M

value directly. The + and - keys increase or decrease

the value by 1. The +/- key may be used to reverse the

throw direction.

If you are not sure what you are changing, hold the

stick to one side and press different keys — if there is no

effect, move the rudder stick to the other side and continue. Your setting may vary from -100 to +100%, the

initial value i s -50%.

Now set the amount of mixing for the Right rudder

command. Press the D key to activate mixing ratio for

the Right direction and set the throw with the numeric

keys as before.

Left

Right

Mode selection

The number k eys 0 through 100 input the

ON/OFF switch

setting

Return to

Condition screen

On/Off Switch Setting

On initial setting, an activation switch for rudder to

aileron coupling is not set , meaning t h at once activated, it

is on all the time. If you would like to set a switch to turn

it on and off, call the Switch Setting screen by pressing

SWT P

the

desired switch location and on direction. For more information on the switch setting method, see page 37).

Use the

key. Then use the keys to choose the

END (N

) key to leave this menu.

Airplane Section, Page 83

Page 8

Airplane Section

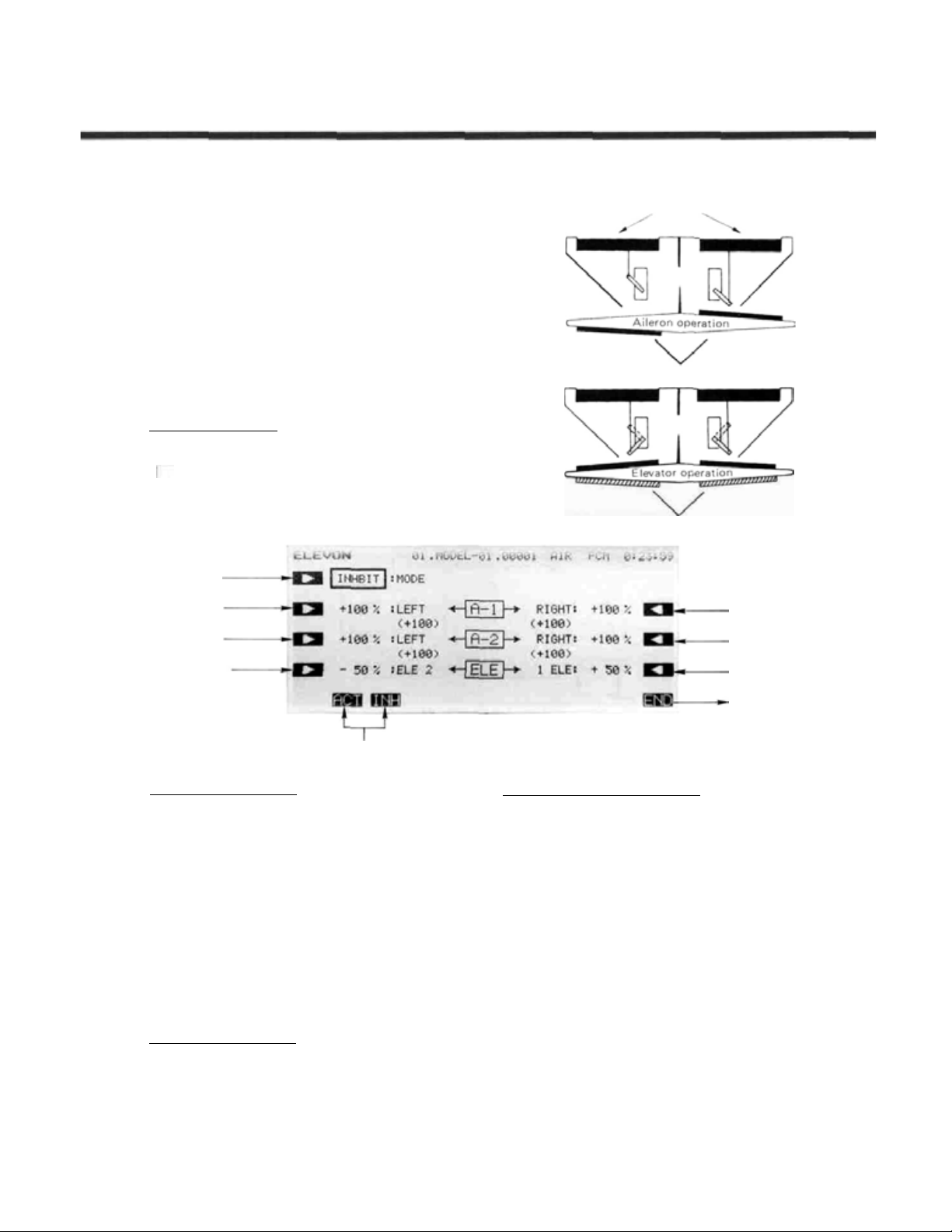

ELEVONS

This function may be used to set up the controls for delta wings, flying wings, and other tailless

aircraft

elevator functions. Receiver CH1 and CH2 are

made the operating channels for the two elevons,

and differential operation is possible.

The elevator deflection angle and operating

direction can be set for each servo. For conve-

nience, the elevon deflection angles can be trim-

med in flight when a volume-setting lever is activated (this setting is performed by the aileron

differential

Setting Up Elevon Mixing

Activation of command

In the Condition Menu. press the

the ELEVON Mixing menu as shown below. Use the

key to activate mode setting, then press the

or INH keys ( F and G ) to activate or inhibit Elevon

Mixing.

ADF

which

(EVN)

need

function

combined

on

page

125).

EVN

aileron

key to get

ACT

and

Delta-Wing Aircraft

Elevons

A

Mode setting

Aileron 1 left

side rate

Aileron 2 left

side rate

Elevator 2 rate

Mode Activation

Setting the Aileron 1 Rates

You now

B

key to activate left rate setting for Aileron 1 and set

the rate with the numeric keys E to M . The number

keys 0 through

and - keys increase or decrease the value by 1. The

+/-

If you are not sure what you are changing, hold the

stick to one side and press different keys — if there is no

effect, move the a ileron stick to the other side and continue. Your setting may vary from —120 to +120%, the

initial value is +100%.

Now

key to activate Aileron 1 right rate setting and set the rate

with the numeric keys as before.

Setting the Aileron 2 Rates

This

key to activate left rate setting for Aileron 2 and set the

rate with the numeric keys E toMas before.

Now set the right-side rate for Aileron 2. Press the

P key to activate Aileron 2 right rate setting and set the

rate as before.

set

the

left-side

100

key may be used to reverse the throw direction.

set

the

right-side

procedure

is

rate

for

Aileron

1.

Press

input the value directly. The +

rate

for

Aileron

1.

Press

repeated fo r Aileron 2.

Press

Airplane Section, Page 84

theQ

theC

the

Aileron 1 right

side rate

Aileron 2 right

side rate

Elevator 1

Return to

condition menu

Setting the Elevator Rates — 1 and 2

You now set the rate for Elevator 2. Press the D key

to activate rate setting fo r Elevator 2 and set the rate with

the numeric keys

Now set the rate for Elevator 1. Press the O key to

activate Elevator 1 rate setting and set its rate with the

numeric keys.

Checking Your Work

After you have set up the Elevon rates, be sure that

they move the correct directions. For up elevator command, both elevons should move upward. For right

aileron command, the trailing edge of the right-hand

surface should move up, and the trailing edge o f the lefthand surface should move down. I f they do not, use the

+/- to reverse the direction as needed.

Use the END ( N ) key to leave this menu.

E toM

.

rate

Page 9

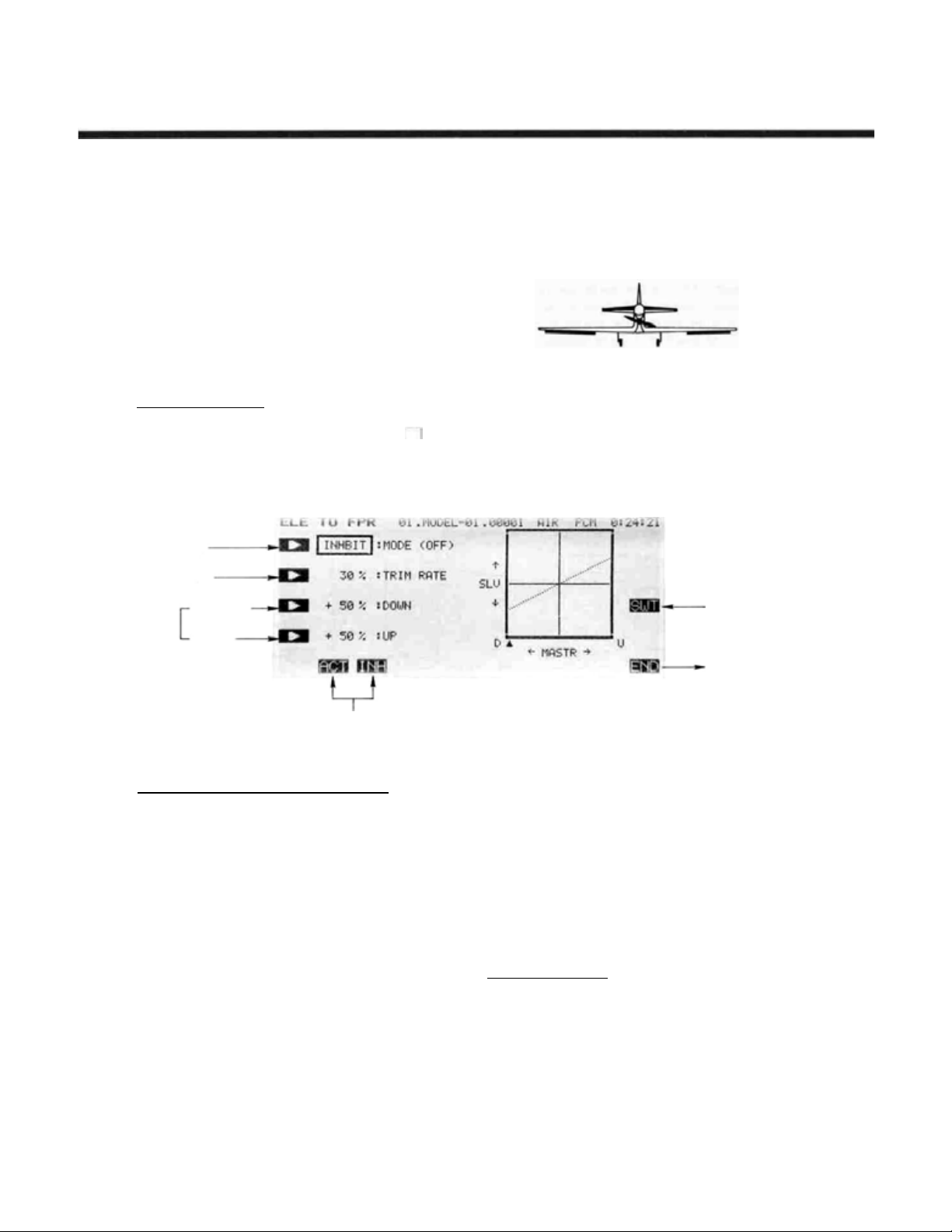

ELEVATOR- FLAP (E-F)

Airplane Section

This mixing is used to droop the flaps whenever

an up elevator command is given (and may be set

up for down elevator as well, helpful during

'outside' maneuvers). It helps to eliminate 'bucking,' and makes tight, square corners in maneuvers

for acrobatic aircraft.

Elevator-to-flap mixing can be set up to be

turned on and of f during flight by a switch (if no

switch is activated, this mixing remains on all the

time).

You

can

also

set

the

flap

trim

rate

in

this

Setting Up Elevator-to-Flap Mixing

Activation of command

In the Condition Menu, press the

ELE TO FPR menu shown below. Use the A key

to

activate

keys ( F and G) to activate or inhibit Elevator-to-Flap.

Mode setting

Flap trim rate

Mixing

rate

setting

mode setting, then

Down side

Up side

E->F

press

the ACT or INH

key to get the

function. If the flaperon function is activated, the

elevators are mixed with the ailerons, otherwise,

the

mixing

is

with

the

flaps

only.

ON/OFF switch

setting

Mode Selection

Setting the Mixing Ratio — Down and Up Side

You now set the amount of mixing for down elevator

command. Press the C key to activate mixing ratio for

the Down direction and set the value with the numeric

keys E to

the value directly. The + and - keys increase or decrease the value by 1. The +/- key may be used to

reverse the throw direction. Your setting may vary from

-100 to +100%, the initial value is set to +50%.

Now set the amount of mixing for the up elevator

command. Press the D key to activate mixing ratio for

the Up direction and set the throw with the numeric key s

as before.

M

The number keys 0 through

100

input

Return to

Condition screen

Flap Trim Rate Setting

You may choose any value for the Flap Trim Rate.

Knob (A) is used to trim the position of the flap servo,

and the trim value controls the authority of the knob.

The authority may be set anywhere from 0% to 100%,

and the initial setting is 30%.

Call the flap trim setting screen by pressing the TRIM

RATE B key, and select the desired trim rate using the

screen menus. You may want a small number fo r th i s rate,

so that an accidental movement of the knob doesn't give a

large flap deflection.

On/Off Switch Setting

On initial setting, the activation switch for Elevator-toFlap mixing is set as SW (C) on at the upper position. If

you would li ke to change the switch or turn mixin g on all

the time, call the Switch Setting screen by pressing the

SWT P

key. Then use the keys to choose the desired

switch location and on direction. For more information

on the switch setting method, see page 37).

Use th e

END ( N )

key to leave this menu.

Airplane Section, Page 85

Page 10

Airplane Section

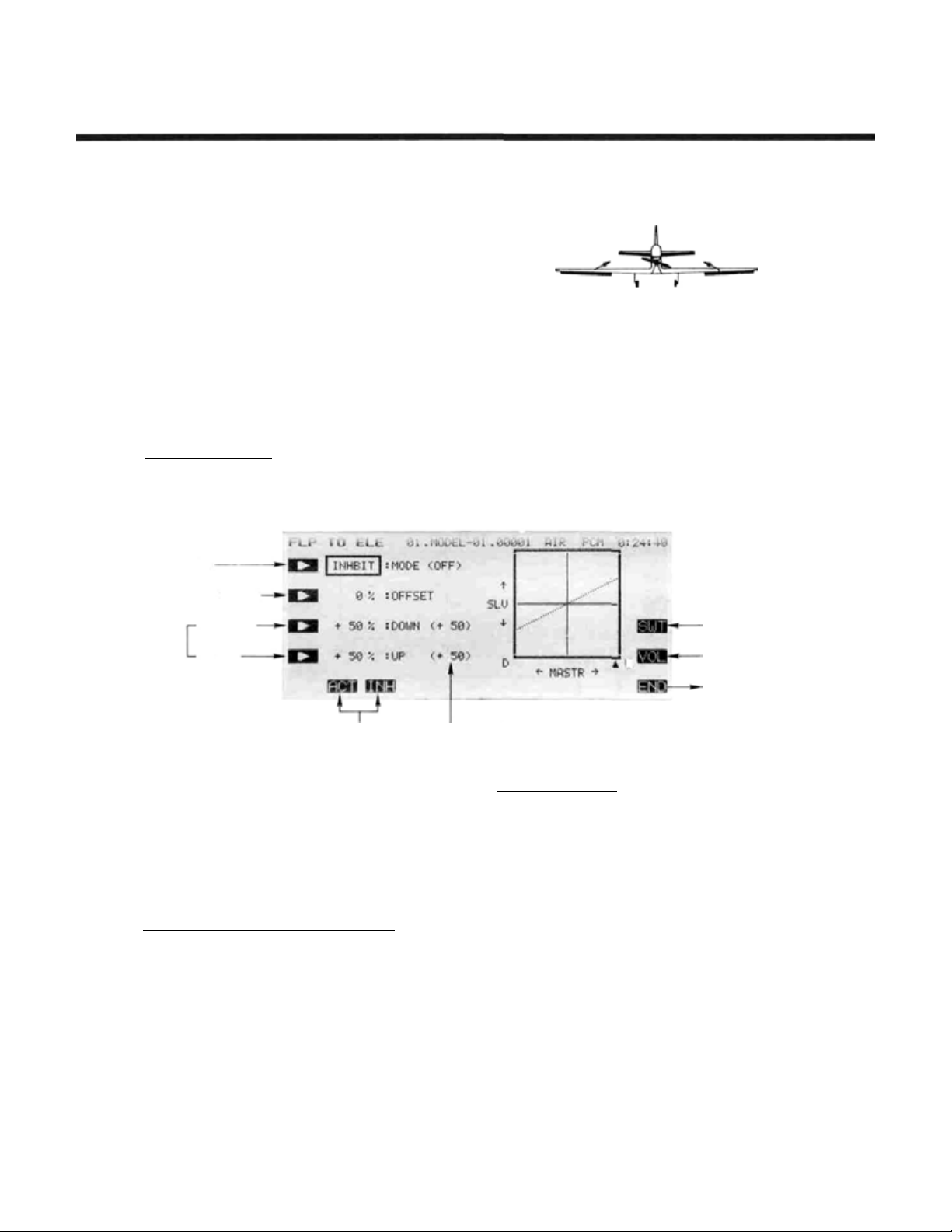

FLAP-ELEVATOR

This

function

changes when flaps are deployed for show fli g h t or

landing by mixing in a small movement of elevator.

The elevator should be adjusted to move only a

small deflection amount: too much elevator can

make the model difficult to control.

The amount of correction can be adjusted sepa-

rately for both positive and negative flap inputs,

and the neutral mixing position can be offset from

the flap neutral position. Flap-to-elevator mixing

can be turned on and off during flight by setting a

switch, but if an ON/OFF switch is not set, it

remains on al l the time. The amount of mixing can

be changed by setting a volume control.

Setting Up Flap-to-Elevator Mixing

Activation of command

In the Condition Menu, press the

FLP TO ELE menu shown below.

Mode setting

is

used

Mix (F-E)

to

compensate

F-E

for

trim

key to get the

Offset amount setting

Mixing

rate

setting

Use the A ( ) key to activate mode setting, then press

the ACT or INH

inhibit flap-to-elevator coupling.

Offset Position Setting

Then set the flap control to the offset position, and

press the SET key F to store the desired position in

memory.

Setting the Mixing Ratio — Down and Up Side

mand. Press the C key to activate mixing ratio for the

down direction and set the value with the numeric keys

E to M .

value directly. The + and - keys increase or decrease

the value by 1. The +/- key may be used to reverse the

throw direction. Your setting may vary from —100 to

+100%, the initial valu e is set to +50%.

command. Press the D key to activate mixing ratio fo r

the Up direction and set the throw with the numeric keys

as before.

Down side

Up side

Mode Selection Rate including volume adjustment

keys

(F and G)

Use the B key to activate offset setting mode.

You now set the amount of mixing for down fla p com-

The number keys 0 through

Now set the amount of mixing for the up elevator

to

activate

or

100

input the

ON/OFF switch

setting

U

On/Off Switch Setting

Initially an activation switch for is not set, meaning

tha t once activated, this function is on all the time. If you

would like to set a switch to turn it on and off, call the

Switch Setting screen by pressing the

Then use the keys to choose the desired switch location

and on direction. For more information on the switch

setting method, see page 37.

Trim volume setting

You may set up the Flap-to-Elevator mixing so that its

effect may be changed in flight by moving a trim control.

The trim control allows you to adjust the volume within

±25% of the set mixing rate, which can be handy for

getting the best value while flying the model. This option

is not activated at initial setup.

Call the volume setting screen by pressing the VOL

O key, and select the desired control using the screen

menus (for a description of the volume setting method,

see page 3 7 ).

Use the

END

N key to leave this menu.

Trimming volume

setting

Return to Condition

screen

SWT P

key.

Airplane Section, Page 86

Page 11

COLLECTIVE PITCH FUNCTION (CPT)

(DIVING

AIR

BRAKE,

HIGH

PITCH

TRIM)

Airplane Section

This function allows diving airbrake ("minus

pitch") adjustment at low throttle and high pitch

adjustment at high throttle for consistent model

speed during vertical aerobatics. This mixing can

be turned on and off during flight with a switch.

Air brake, engine idle-up trim , and t he high-side

pitch control trim can be set independently.

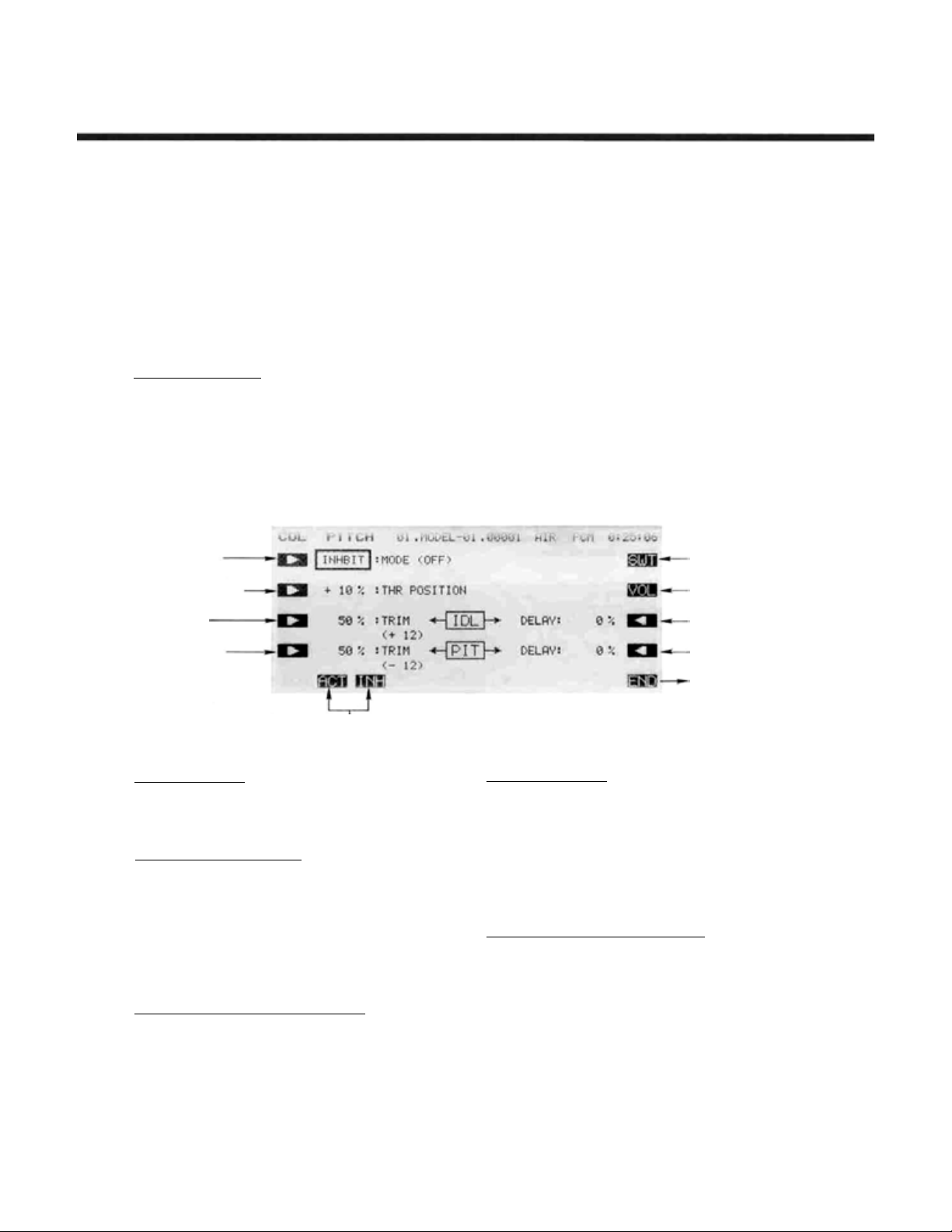

Setting Up Collective Pitch Function

Activation of command

In the Condition Menu, press the

COL PITCH menu shown below. Use the

key to activate mode setting, then press the ACT or

INH keys ( F and G ) to activate or inhibit the func-

tion.

Mode setting

Mixing operation

point setting

Idle-up

High pitch

Trim Rate setting

CPT

Mode selection

The

key to get the

A

mixing switching point (minus pitch/high pitch

switching point) can be set at a selected throttle

stick position, and each trim rate can be adjusted.

The throttle delay when switching from minus

pitch to high pitch and the pitch delay when

switching from high pitch to minus pitch can also

be adjusted independently.

ON/OFF switch

setting

Trimming volume

setting

Throttle delay

setting

Pitch delay

setting

Return to

Condition screen

Switch Point Setting

Press the B key to enter the thro ttle position setting

function. Then set t he throttle stick to the desired switch

key

to enter the

SET (F)

point, and press the

Idle-up Trim and Delay Setting

Press the C key to enter the Idle-Up Trim rate setting

function, and set the rate with the numeric keys F to

M. The range may be set from 0 to 100%, and the initial

value is set to 0%.

Next, press the P key to enter the Throttle delay

setting function, and set the delay with the numeric keys.

The setting range is 0 to 100%, an d the initial value is set

to0%.

Pitch Control Trim Rate and Delay Setting

Press

the D

function. Set the desired rate with the numeric keys F to

M.

The range may be set from 0 to 100%, and t he initial

value is set to 50%.

Press the O key to activate the Pitch Delay setting

menu, and set the delay with the numeric keys

The range may be set from 0 to 100% (initial setting is

0%).

key.

Pitch

Trim

Rate

setting

F to M .

Airplane Section, Page 87

On/Off Switch Setting

On initial setting, the activation switch for the Collective Pitch function is set as SW (E) ON at the lower position. If you would like to change the switch or turn

mixing on all the time, call the Switch Setting screen by

pressing the

choose the desired switch location and on direction. For

more information on the switch setting method, see page

37).

Idle-Up Trim/Pitch Co ntrol Trim Setting

You may set up the Collective Pitch function so that

its effect may be changed in fli ght by moving a trim control. The trim control allows you to adjust the volume by

moving a slider. A t initial setting, the left-side lever is set

for idle-up trim and the right-side lever is set for pitch

control trim.

Call the volume setting screen by pressing the

O key, and select the desired control using the screen

menus (for a description of the volume setting method,

see page 37).

Use t he

SWT(R)

END

(N) key to leave this menu.

key. Then use the keys to

VOL

Page 12

AlLEVATORS/COMBINED AlLERONS & ELEVATORS (ALV)

This

function

tor surface on each side of the airplane independ-

ently,

so

mode) and differentially (aileron mode). This

function,

give aileron control even at low speeds, because

the

propeller

surfaces and may be used f or rolling commands.

This function requires two elevator servos connected to receiver output channels 2 and 5. In this

manual (see diagram), the rear control su r faces are

referred to as Aileron 3 and Aileron 4. With this

function, all control deflections — left and right

ailerons,

adjusted. You may even add differential to the rear

ailerons.

and

allows

you

that

they

operate

sometimes called

wash

is

always passing over

elevator

on

to

hook

together

"ailevators"

both

sides

up

the

(elevator

(ALV)

—

the

can

eleva-

will

tail

be

Airplane Section

Setting Up Differential

Activation of command

In the Condition Menu, press the ALV key to get the

AILVATOR menu shown below. Use the A key to

activate mode setting, then press the ACT or INH

keys (F andG)to activate or inhibit the function.

Mode setting

Aileron 3 Left.

Side Rate

Aileron 4 Left

Side Rate

Elevator 1 Rate

Setting

Setting the Aileron 3 Rates

You now set the left-side travel for Aileron 3. Press the

B ke y to activate left rate setting fo r Aileron 3 and set

the rate with the numeric keys E to M . The number

keys 0

through 100

and - keys increase or decrease the value by 1. The

+/-

key may be used to reverse th e throw direction.

Your setting may vary from -100 to +100%,the initial

value is-50%.

Now set the right-side rate fo r Aileron 3. Press the Q

key to activate Aileron 3 right rate setting and set the rate

with the numeric keys as before.

Setting the Aileron 4 Rates

This procedure

key to activate left rate setting for Aileron 4 and set the

rate with the numeric keys E to M as before. The max

values and initial setting are t he same as for Aileron 3.

Now set the right-side rate for Aileron 4. Press the 13

key to activate Aileron 4 right rate setting and set the rate

as before.

input

is

repeated

Elevators

Mode Activation

the

value

for

directly. The +

Aileron

4.

Press

the C

Aileron 3 Right

Side Rate

Aileron 4 Right

Side Rate

Elevator 2 Rate

Setting

Return to

condition menu

Setting the Ele va to r Rates - 1 and 2

You now set the rate for Elevator 1. press the D key

to activate rate setting for Elevator 1 and set the rate with

the numeric keys E to M . The initial rate is 100%, but

you may vary your setting between -100 and +100%.

Now set the rate for Elevator 2. Press theOkey to

activate Elevator 2 rate setting and set its rate with the

numeric keys. Settings have the same range as Elevator 1.

Checking Your Work

After you have set up the Ailevator rates, be sure that

they move the correct directions. For up elevator command, both elevators should move upward. For right

aileron command, the trailing edge of the right-hand

surface should move up. and the trailing edge o f the lefthand surface should move down. I f they do not, use the

+/- to reverse the direction as needed. Adjust the

travels on either side to get the differential effect, if you

wish.

Exiting

Use the

END ( N

) key to leave this menu.

Airplane Section, Page 88

Page 13

Airplane Section

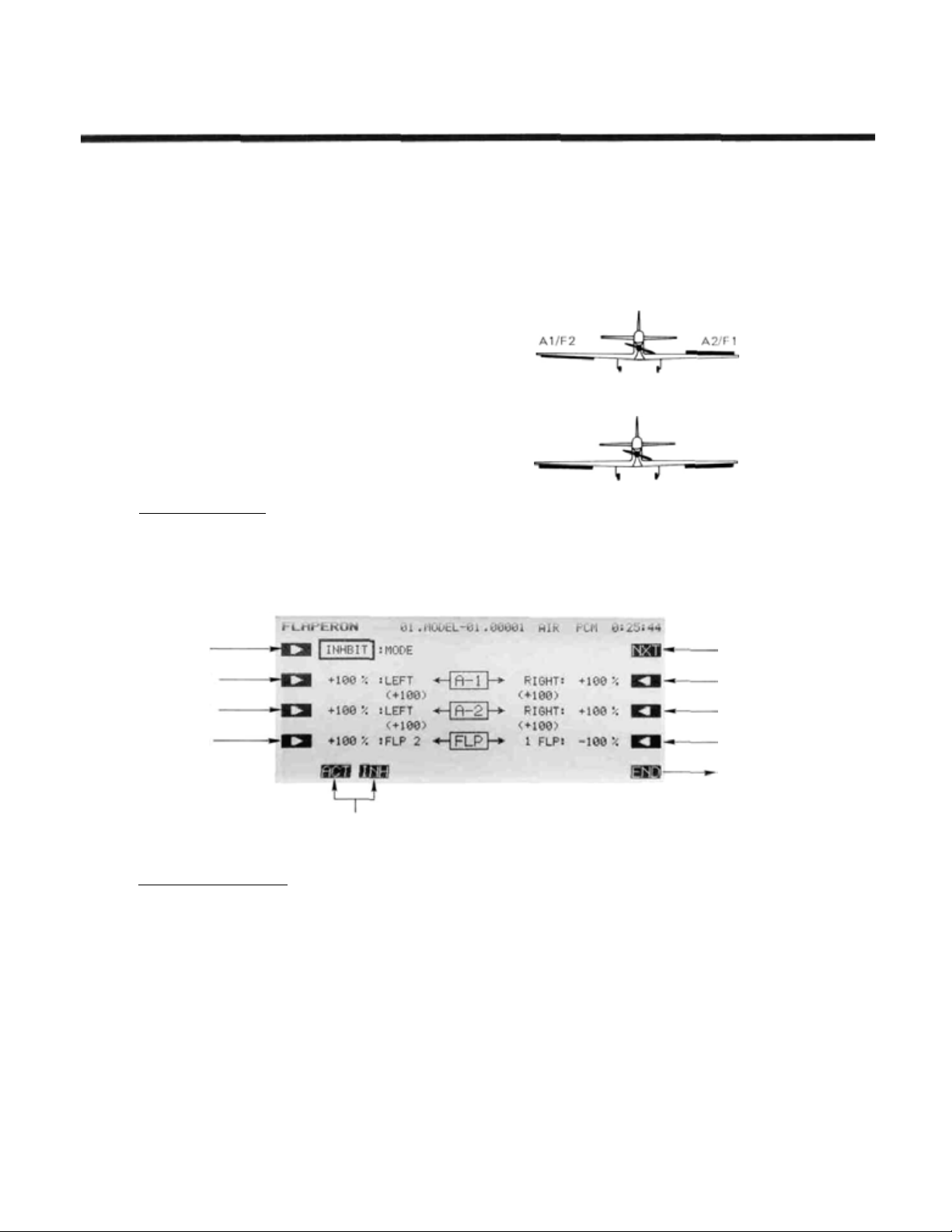

FLAPERONS

This function allows you to program the

ailerons to work in the same direction, giving a

flap response as well as aileron control (see figure).

For good square maneuvers, and landing, both

ailerons can be raised and lowered simultaneously.

While this function is on, regular aileron operation

is always present.

The Flaperon function requires two separate

channels: Receiver CH1 (aileron 1/flap 2) and CH6

(aileron 2/flap 1) are the operating channels. The

Aileron 1 and Aileron 2 left and right deflection

angles can be adjusted independently, making it

easy to apply differential to the ailerons. With

differential, the up side travel is set to around 5%

larger than the down travel.

Setting Up Flaperons

Activation of command

In the Condition Menu, press the

FLAPERON menu as shown below. Use the A ke y

to activate mode setting, then press the

keys

(F and G) to

activate or

(FPN)

inhibit

the

FLP

function.

key to get the

ACTorINH

You may also adjust the

throws independently, and you can set the flap

trim

rate

as

large

or

small

flap trim offset can be adjusted, allowing you to

freely change the flap neutral angle.

Aileron operation

Flap operation

as

Flap

you

like.

1 and Flap 2

Also,

the

Mode setting

Aileron 1 Left

Side Tra ve l

Aileron 2 Left

Side Travel

Flap 2 Travel

Setting

Mode Selection

Setting the Aileron 1 Travel

You now set the left-side travel for Aileron 1. Press the

B

key to activate left travel setting for Aileron 1 and set

the travel with the numeric keys E to M . The number

keys 0

through 100 input the

and - keys increase or decrease the value by 1. The

+/- key may be used to reverse the throw direction.

If you are not sure what yo u are changing, hold the

stick to one side and press different keys — if there is no

effect, move the aileron stick to the other side and continue. Your setting may vary from —120 to +120%, wit h

an initial value of +100%.

Now set the righ t-side travel f or Aileron 1. Press the

Q

key to activate Aileron 1 right travel setting and set

the travel with the numeric keys as before.

value

directly. The +

To Next Screen

Aileron 1 Right

Side Travel

Aileron 2 Right

Side Tra vel

Flap 1 Travel

Setting

Return

to

condition menu

Setting the Aileron 2 Travels

This procedure

key to activate left travel setting for Aileron 2 and set the

travel with the numeric keys E to M as before.

Now set the right-side travel for Aileron 2. Press the

P key to activate Aileron 2 right travel setting and set

the travel as before.

Setting the Flap Travels — 1 and 2

You now

activate travel setting for Flap 2 and set the travel with

the numeric keys E to M . Your setting may va ry fro m

-100 to +100%, with an initial value of +100%.

Now set the travel for Flap 1. Press the

activate Flap 1 travel setting and set its travel with the

numeric keys. I ts initial value is -100%.

is

repeated for Aileron 2.

set

the

travel

for

Flap

2.

Press

Press

the D key

O

theC

to

key to

Airplane Section, Page 89

Page 14

Flap Trim Authority Setting

In the Flaperon mode. Flap Trim moves both ailerons

upwards or downwards together. To input the Flap Trim

Authority, move to the next screen by pressing the

R key. Then press theDkey and set the rate with the

numeric keys F to M. You may choose any value from

0% to 100% f or the Flap Trim Authority. The initial

setting is 30%, but a smaller number is recommended.

Flap Trim Offset Setting

Flap trim offset sets the flap position from which

motion occurs. To input the flap trim offset amount

setting, press th e B key, then set the flap trimmer to the

position to be set and press the

can be anywhere between ±(trim authority setting).

Checking Your Work

After you have set up everything, be sure the controls

move the correct directions. If they do not, use the +/-

to reverse the direction as needed.

SET

F key. The offset

NXT

Airplane Section

Use the

to get to the previous menu.

END

( N) key to leave this menu, or hit PRE

Airplane Section, Page 90

Page 15

Airplane Section

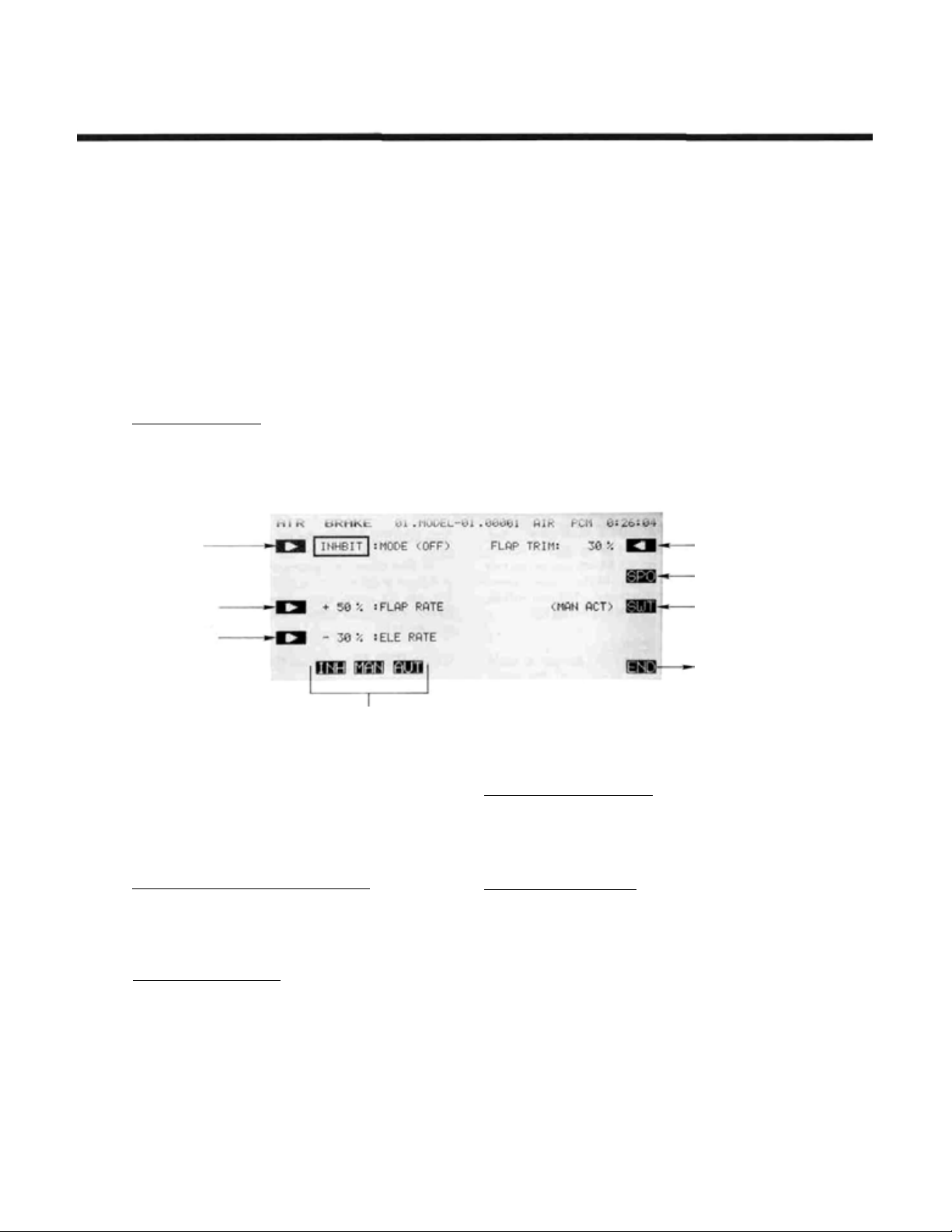

AIRBRAKE

Airbrake presets are used to set up preset

deflections of the elevators, flaps, and (optionally)

spoilers for landing precision or for constant speed

during vertical flight maneuvers. Airbrake presets

can be turned on and off during flight by ON/OFF

switch, or you may define an AUTO mode where

mixing is turned on and off automatically by

throttle stick position.

The AUTO mode, if used, may be turned on

and off with a switch. However, a command on

Setting Up The Airbrake Presets

Activation of command

In the Condition Menu, press the

AIR BRAKE menu as shown below.

Mode setting

Flap Preset

Position Setting

Elevator Preset

Position Setting

(ABK)

ABK

key to get the

the

air

brake

has

priority

of the position of the AUTO mode ON/OFF

switch.

Suggested settings for the Airbrake function are

a flap deflection of +50%. The elevators will need

to be set to about -20 to 23%. Of course, the

elevators should be adjusted so that the model

maintains

is operated.

level

flight

when

and

is

followed

the

Airbrake

Flap Trim Rate

Setting

Spoiler Setting

Air brake ON/OFF

Switch Setting

regardless

function

Airbrake Mode Selection

Use the A key to activate mode setting, and

press the ACT F key to activate the function. Now

you must decide on Manual or Auto operation. Select the

manual mode by pressing the MAN ( G) key. Select the

AUT

auto mode by pressing the

Throttle Position Setting (Auto Mode Only)

For the Auto mode, you need to input the position at

which the function will take effect. Press t h e B key, then

move the throttle stick to the desired position, and press

SET

the

Flap Preset Position Setting

the C key and use the rate setting keys

setting may vary from -100 to 100%, and is initially set

to

( F ) key to memorize the position.

To set the position that the fla ps will move to, press

50%.

H key.

E to M

. This

Return

to

condition menu

Elevator Preset Position Setting

To set the position that the elevators will move to,

press the D key and use the rate setting keys E to M .

This setting may vary from -100 to 100%, and is initially

set to -30% by the system.

Flap Trim Authority Setting

Flap Trim moves both ailerons upwards or downwards

together. To input the Flap Trim Authority, press the

NXT R

key. Then set the rate with the numeric keys

E to M. You may choose any v alue from 0% to 100%

for the Flap Trim Authority. The initial setting is 30%,

but a smaller number is recommended. If you input a

number here, it will override whatever value was input in

the Flaperon menu.

Airplane Section, Page 91

Page 16

Airplane Section

Spoiler setting: Press the

menu below.

Spoiler Activate

Spoiler Preset

Setting

Use the A () key to activate mode setting, then

press the

or inhibit the function. Press the B key and set the rate

with the numeric keys E to M . The initial spoiler preset

is 50%, but you may set it between -100 and +100%.

Return to preceding screen by pressing the Q key.

Airbrake ON/OFF Switch Definition

SW (C ) is turned ON at the lower position at initial

setting. If you'd like another switch, call the switch

setting menu by pressing the SWTPkey. For a description of the switch setting method, see page 37.

Caution: if the ON/OFF switch is disabled with NUL, the

Airbrake function remains on all the time.

ACTorINH

SPO Q

key to get to the

Spoiler Mode Selection

keys ( F andG)to activate

To Preceding

Screen

Auto ON/OFF Airbrake Switch Definition (AUTO mode

only)

At first setting, the automatic airbrake control switch

is defined as SW (E), ON at the lower position. To change

this, call the switch setting menu by pressing the

O

key. For a description of the switch setting method,

seepage37.

Use the

END N

key to exit this menu.

SWT

Airplane Section, Page 9 2

Page 17

Airplane Section

SNAP ROLL

Your PCM 1024Z system may be programmed

to perform snap rolls by flipping a switch. Four

snap roll directions can be defined, and the preset

positions of the aileron, elevator, and rudder

servos can be set f or each one.

You may activate a safety switch to ensure that

snap rolls are not accidentally commanded while

the

landing

switch is turned on accidentally.

Setting Up The Snap Roll Presets

Activation of command

In the Condition Menu, press the

SNAP ROLL menu as shown below.

Snap Roll Directions

(Note: These snap roll direction se tt i ng switches are only present on the T9ZAP systems, not on the T9ZHP)

gear

(SIMP)

is

down,

even

if

the

SNP

snap

roll

key to get the

Direction Switches

Mode setting

Rate

setting

Mode selection

Use the

press the

or inhibit the function.

Inputting the Snap Roll Preset Control Positions

We'll start with the 1-2 direction (Right/Up) snap

roll setting. Press the R key to get to the setting menu,

then press the

To

key. Use the numeric keys

preset condition. The default is +100%, but you may use

anything between -110 and +110%.

Now we'll set the Elevator servo preset. Press the C

key. and set the preset with the numeric keysEtoM.

This also has a default of +100%, but you may use anything between -110 and +110%.

The last part of the setting is for the rudder position.

Press the D key, and enter the rate that you want the

rudder to move with the numeric keys E to M. This

setting also has a default of +100%, and may be set anywhere between -110 and +110%.

This procedure should be repeated for the

direction (Rright/Down) snap roll setting,

A

ACTorINH

set

the Aileron

key to activate mode setting, then

keys ( F and G ) to activate

1-2

F key.

servo

throw setting,

E to M

press

to input the desired

2-2

direction

theB

-Th row setting

ON/OFF switch

setting

Safety switch setting

Return to condition

menu

(Left/Up) snap roll setting, and 2-1 direction (Left/

Down) snap roll setting.

Snap Roll Switch ON/OFF Definition

SW (H) is defined to be the Snap Roll switch, and is

turned ON at the forward position at initial setting. If

you'd like another switch, call the s witch setting menu by

pressing the

switch setting method, see page 37. Caution: if you define

a switch that doesn't have a spring return, the Snap R oll

function will remain on all the time!

Snap Roll Safety switch setting

A safety switch should be used to prevent accidental

operation of the snap roll function. To examine the snap

roll safety switc h settings, call up the switch setting screen

by pressing the SWT

defines SW (F) for Mode I, (G) for Mode II to be the

safety switch. You should set the ON direction of the

safety switch to match the landing gear switch position

when the landi ng gear is down. When this switch is ON,

1-1

the snap roll function is inhibited.

Use the

SWT

P key. For a description of the

END N

key to exit this menu.

O

key. The function initially

Airplane Section, Page 93

Page 18

Airplane Section

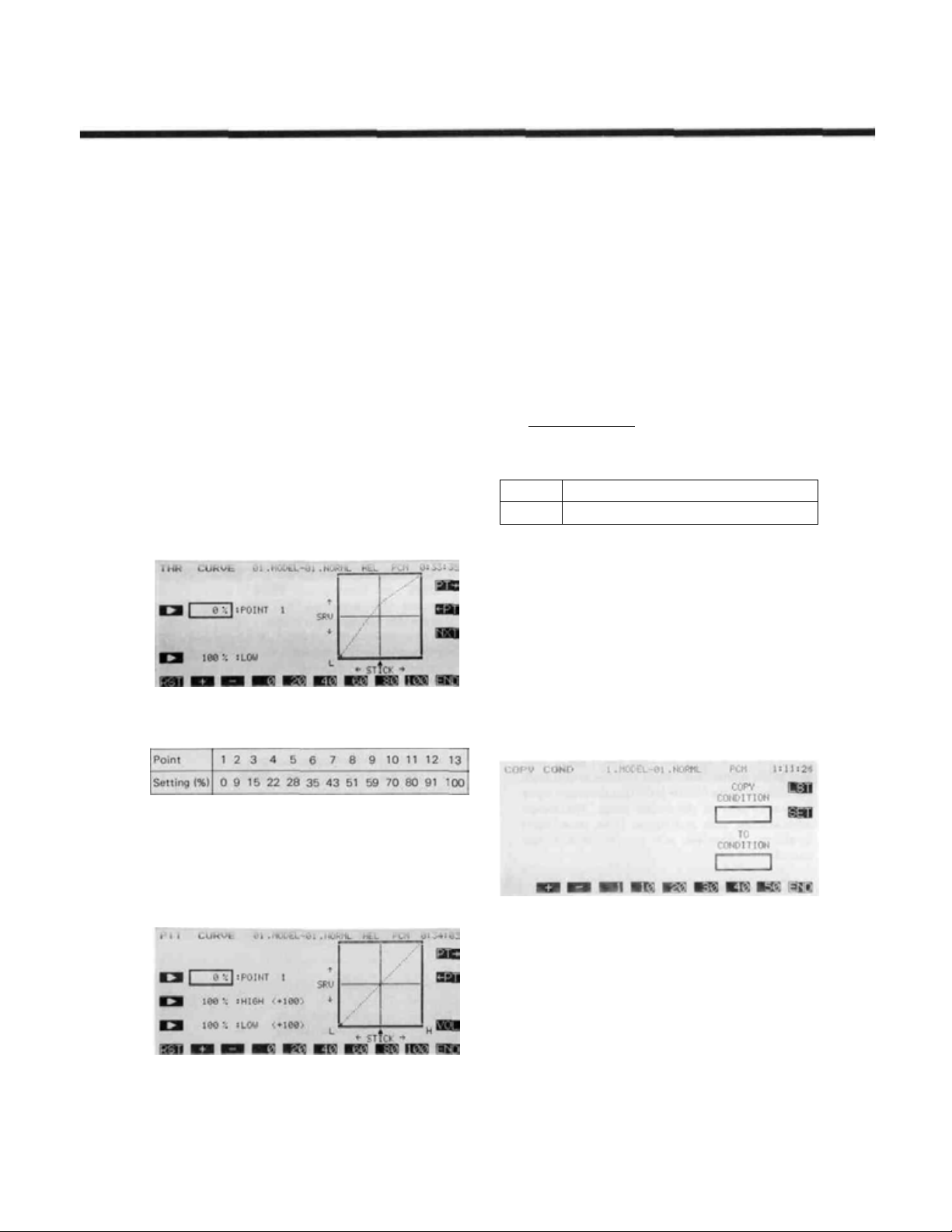

THROTTLE CURVE

This function programs throttle curves for dif-

ferent

flight

modes.

servo

response

by a 13-point curve. The low side rate can be adjusted with a volume control (point 7 is the refer-

Setting Up The Throttle

Throttle Curve Inputting

In the Condition Menu, press the

the THR CURVE menu shown in the figure below.

Curve setting

Low Side

Rate Setting

over

The

full

ADJ. (TCV)

throttle

stroke

Curve Function

of

curve

the

throttle

TCV

sets

the

stick

key to get

ence).

The

servo

delay

at

flight

condition

can also be programmed. You need to activate the

Model menu throttle curve [THR] function (page

53) to allow the Throttle curve function to work

properly.

switching

Point Movement

Trim Volume

Setting

Low Side Rate Set Value, Including Trim Volume

Setting Point Selection (Points 1 to 13)

Press

the Bkey

function. Use the movement keys Q and R to select the

point whose value is to be set. The

the poin t number by one, and the

point number by one. The active point on the curve is

shown as a black dot.

Once you have selected the desired point on the curve,

you may input the rate with the rate setting keys E to

M.

The number keys 0 through

directly. The

value by 0.5 with each button pressing (so it takes two

hits to see a number change because of numeric rounding).

You may set or reset each point on the curve by

repeating these steps for each point.

Low-Side Rate Adjustment

Press

the D

numeric keys E to M . You may set anywhere in the

range fro m 0 to 110% (initially the rate is set to 100%).

to

tur n on the curve

+

and - keys increase or decrease the

key

and you may

<-PT

input

inputting

PT->

key increases

key reduces the

100

input the value

the rate

with

the

Return To

Condition Menu

Low-Side Volume Control Assignment

No volume controller is defined when TCV is first

activated. To set the control and direction of the volume

adjuster, call the volume setting screen by pressing the

VOL O

key. Use the buttons to selec t the control and

direction you desire. For a description of the volume

setting method, see page 37.

Use the

or use the END

to the Condition menu.

Curve Setting Note

If you change Point 7 after setting the low side rate,

other points in the throttle curve also change, because

Point 7 is the reference point for the curve.

PRE N

key to return to the previous menu,

N

key to leave this menu and return

Airplane Section, Page 94

Page 19

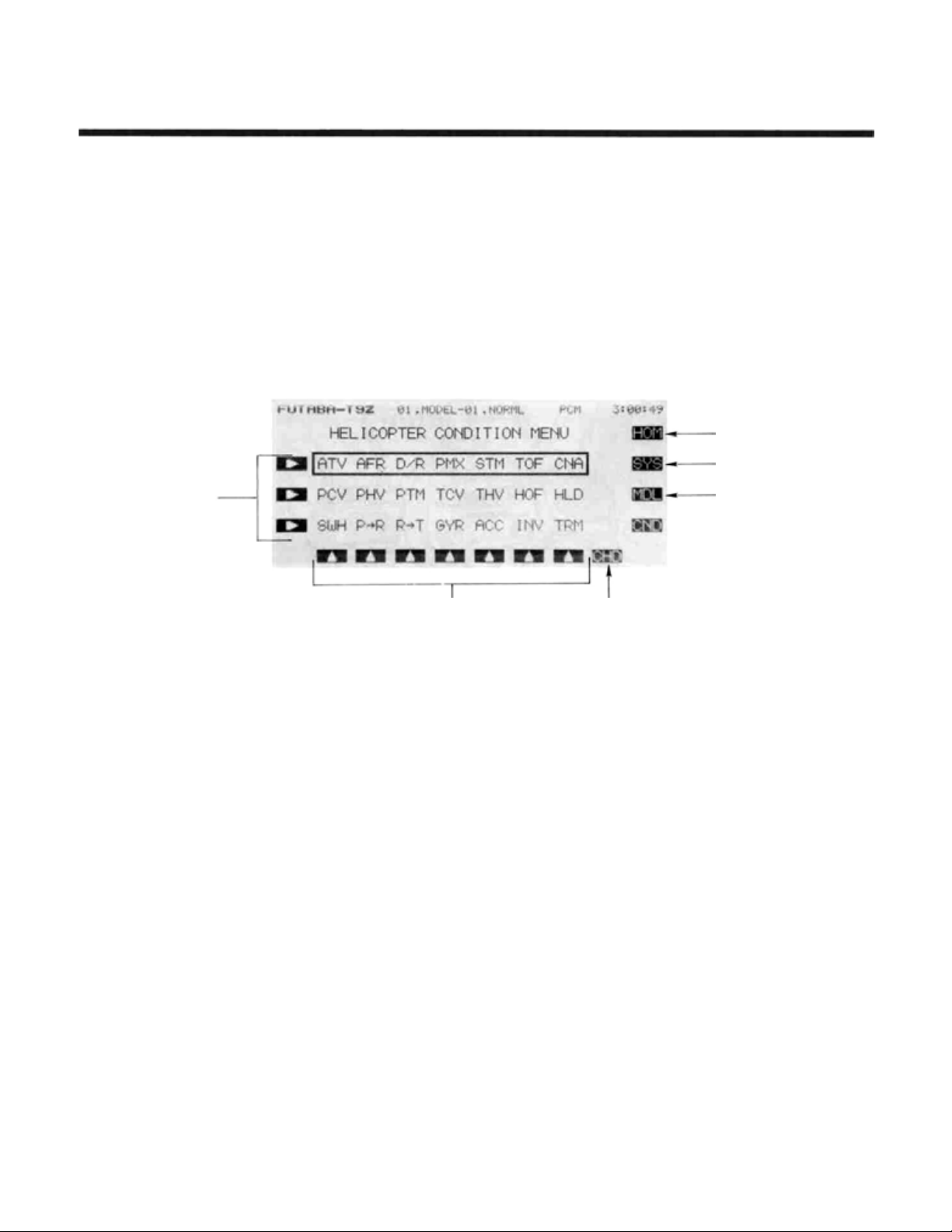

HELICOPTER SECTION

This section contains information on the commands that apply to

helicopters only. Each of these functions can be set independently for

different flight conditions.

To get to these settings, press the MDL key from any menu in a

Helicopter setup. To select one, first select the line containing the

desired function with the B , C, or D keys. Then use the F to

L keys to select the function to be entered.

For conditions that apply to all models (ATV, AFR, D/R, PMX,

STM, TOF, CNA, and TRM functions), refer to the Common Condi-

tions section. For instructions on Airplanes and Sailplanes, refer to

the sections pertaining to those airc raft.

Select Desired

Line With

These Keys

Helicopter Section

To Home Screen

To System Menu

To Model Menu

Function Selection Keys Activates Condition Hold Function

Helicopter Section Table of Contents

Helicopter Transmitter Controls and Functions.

Helicopter Receiver and Servo Connections.

Helicopter Setup Example.

Specific Control Setup Definitions

PCV.

. .

.Pitch Curve

PHV. .

.Hovering

PTM

. .

.Pitch

Trim

TCV

. .

.Throttle

THV

. .

.Hovering

HOF

. . .Hovering

HLD. .

SWP. . .

P->R

R->T

GYR. .

ACC .

INV. . . .Inverted

.Throttle Hold

.Swashplate Type

. . .Pitch->

. . .Rudder -> Throttle

.Gyro

.

.Acceleration.

Rudder

Sensitivity.

............................

..........

Pitch.

........

...........

Curve.

........

Throttle.

Offset.

Pitch . ......

......

.......

......

.......

........

......

.......

.........

.Adjusts

flight conditions

.Used

around hover

.Allows pitch

without changing curve

.Program

throttle response

.Can adjust

around hover

.Programs

point

.Moves

during autorotation

.Compensates

cyclic applied

.Handles torque changes

pitch angle inputs

.Accounts

to rudder

.Used

.Cancels torque due

throttle commands

Sets

flight

to

to

pitch

................ 96

.................. 98

99

response

trim

the

for

switch

pitch

the

throttle

pitch

throttle

power

rates

in

different

response

trim

offset

shape of

response. . . .

mix

to

for

power

change

gyro

to

for

inverted

. . . 104

. . . .

......

the.

.....

hovering

...

idle

.....

loss

when 111

from . . . 112

due. . .

sensitivity . .

sudden

. . .

....

105

106

107

108

109

110

.113

114

116

117

Helicopter Section, Page 95

Page 20

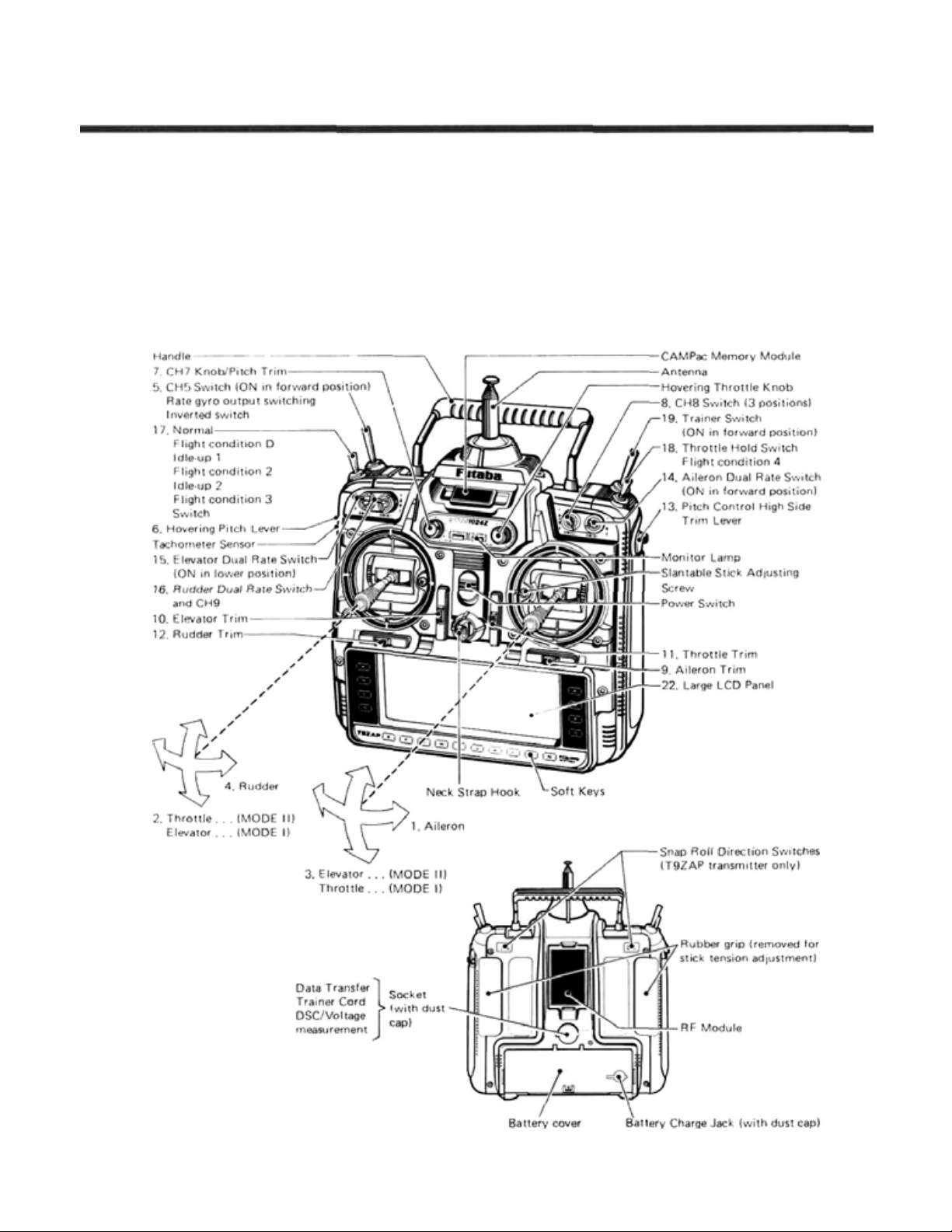

HELICOPTER TRANSMITTER CONTROLS AND FUNCTIONS

Functions and locations given in this drawing are

the factory default positions, which occur upon

startup. Each setting can be easily changed as the

owner desires. The Function Change menu [FNC]

may be used for this purpose.

Helicopter Section

Helicopter Section, Page 96

Page 21

Note that all stick & switch positions may be

changed

1.

Aileron control

2.

Throttle control . . . (MODE II)

Elevator control . . . (MODE I)

3.

Elevator control . . . (MODE II)

Throttle control

4.

Rudder control

5.

CH 5 switch

Rate gyro output switching/inverted switch.

6.

Hovering rate lever (CH6)

Adjusts the hovering point pitch

independently from the thr o t tle.

pitch trimming when hovering. When t h e

throt t le stic k is at the SLOW or HIGH side,

the pitch servo does not operate ev en if this

lever is moved.

7.

CH7/pitch trim knob

Used as a spare channel, or as the pitch

trimmer.

8.

CH8 switch

Used as a spare channel (3 positions).

9.

Aileron trim lever trims the ailerons.

10.

Elevator

11. Throttle trim lever (with ATL) Adjustable

throttle limiter type trim lever. Operates at

the throttle stick SLOW side. Movement is

maximum at maximum slow. Since the HIGH

side does not change even if the SLOW si de is

adjusted, it is very convenient when

connecting the linkage, etc.

trim

. . . (MODE I)

lever

trims the

Used in

elevators.

Helicopter Section

12. Rudder trim lever trims the rudder.

13. Pitch control HIGH side trim lever.

Pitch control servo HIGH pitch trimmer.

Adjusted for optimum pitch during flight.

14. Aileron dual rate switch.

Aileron deflection angle

15. Elevator dual rate switch.

Elevator deflection angle

16. Rudder dual rate switch.

Rudder deflection angle switch.

Can also be used as the CH9 switch.

17. Normal/idle-up 1/idle-up 2 switch.

Idle-up ON/OFF switch.

The On direction is set by condition

(CSL) function (page 40).

(Flight condition switch.)

18. Throttle hold switch.

This switch is used during auto rotation.

The ON direction is set by condition select

(CSL) function (page 40).

(Flight condition switch)

19. Trainer switch.

This switch is turned on in the forward

position. It is spring loaded and is turned off

when released. It can also be changed to an

alternate switch (page 29).

switch.

switch.

select

Helicopter Section, Page 97

Page 22

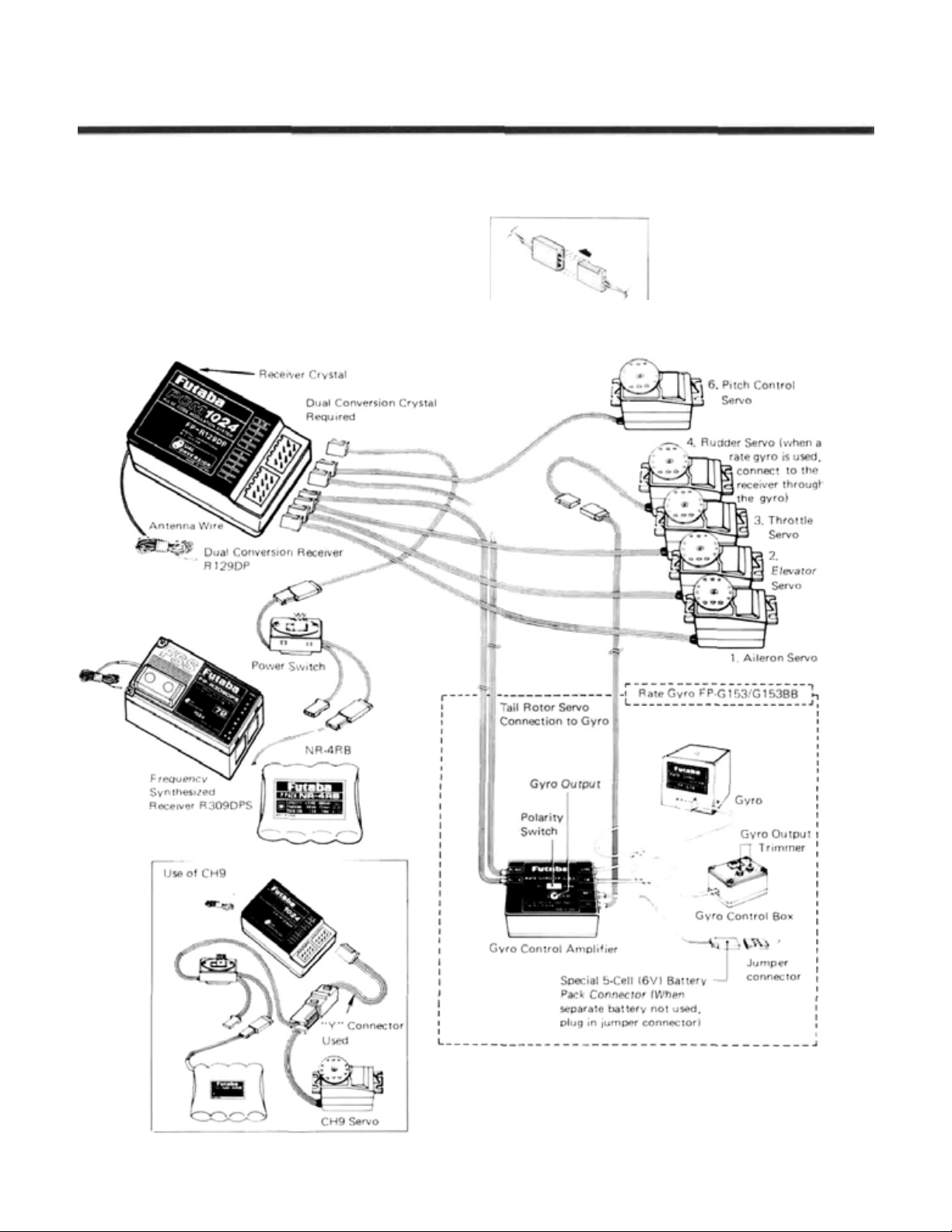

HELICOPTER RECEIVER AMD SERVO CONNECTION

The receiver output order is shown below:

1. AIL Aileron

2. ELE Elevator

3. THR Throttle

4. RUD Rudder

5. GYR Rate Gyro Sensitivity Switching

6. PIT Pitch

7. AU1

8. AU2

9. CH9 Channel 9

(Spare)

(Spare)

Be sure to insert proper

direction

Helicopter Section

Five Servos are supplied

as standard

Helicopter Section, Page 98

Page 23

SAMPLE HELICOPTER SETUP INSTRUCTION

Helicopter Section

The following example shows how the PCM

1024ZH may be programmed for a contest helicopter model, although for completeness we have

added other functions (these will be marked by a

"t" sign). The settings presented here are for a

typical model. Your model's settings are likely to

vary

from

these,

but

the

procedures

given

will

still

be applicable.

1 Memory Selection

Use the Model Select function

model memory.

Choose the Helicopter Setup using the Type

function from Model menu.

2 Model Naming

Name the model using the Model Name

tion in the model menu. Not e that the default flight

condition is named "NORML" (the condition name

is located next to the model name). The system

automatically adds and names three other flight

conditions, which you will program later in this

example.

MSL

to select a

TYP

MNA

func-

5 Plug Servos Into Receiver

Plug Servos into Correct Channel Numbers

1 .. . .AIL. .. .

2 ... .E LE. ... .Elevator

3 .. . .THR . . . .Throttle

4 ... .RUD . . . .Rudder

5 ... .GYR . . . .Rate Gyro Sensitivity

6 ... .PIT .... .Pitch

7 ... .AU1 . . . .(Spare)

8 ... .AU2 . . . .(Spare)

9 .. . .CH9. . . . .Channel 9

6 Set

Servo Throw Direction

Check the proper direction of throw for each

servo. Use Reversing Function

menu to set proper throw directions. Reverse channels as necessary to correct throws. Link the carburetor to the throttle servo so that the carb may be

fully closed to shut off engine.

7 Flight Conditions Switching

You may set up the system to call up more than

one function or switch to a new set of trims or control settings simultaneously by moving a single

switch. This is very convenient f or loading different

flight conditions such as Idle-up 1

IDL2

, and Throttle Hold

normal flight condition. You may change EVERY

parameter between flight modes.

We recommend that you fly the model and adjust

trims and control responses to your liking before

defining another flight condition. Then, as described

below, you will copy the set of adjustments to a new

flight condition (this will maintain all trim settings

between the different conditions), and define the

condition switches that activate them. Each may be

modified for the new desired conditions, and you

may add new functions as necessary.

Use the Condition Select

Model Menu. The four flight conditions listed above

have already been allocated. The position and ON

direction of each flight condition call switch are set

as follows:

.Aileron

HOLD

REV

IDL1

in

addition to the

CSL

button in the

in the Model

, Idle-up

2

3t Set Control Order

If desired, reset the Control Order usi ng the Function Control

may choose what sticks, sliders, and tr ims control

the different functions.

FNC

in the model menu. Here you

4 Hook Up Controls

Hookup the aileron, elevator, throttle, and rudder

servos in accordance with the model's instructions

or plans.

1. Normal. . . .

2. Idle-up

Helicopter Section. Page 99

.Operation when. .

all switches OFF etc.

1 .. . .ON at SW (E ) . .. . .For 540° stall

Center position turns, looping,

. .Used in hovering,

rolling stall turns

Page 24

Helicopter Section

3. Idle-up 2 . . . .ON at SW (E) . . . . .Used fo r rolling

4. Throttle . . . .ON at SW (G) .... .Activate for

Hold Forward position autorotation.

In

4>3>2>D,

means that if the Idle-Up 1 switch is on, and Throttle

hold is turned on, the system will use the Throttle

hold settings.

To set the condition data for each flight condition, be sure that you call the appropriate condition

by turning on the correct switch (as given above).

Read the condition name after the model name to be

sure you are changing the condition you want.

Forward position aerobatics.

the

case

above,

the

with 4 having the highest

flight

condition

priority

priority.

This

8 Normal Flight Programs

Select the Normal flight settings by turning off

all the flight condition switches.

9 Throttle Curve Setting

Call the Throttle Curve

Model Menu. Check to see that it is activated ACT .

Next, move to the condition menu and press

TCV

to get the setting menu. Set the t hrottle curve

to the values shown in the table below:

THA

function from the

is

The following settings assume a semi-symmetrical

rotor blade with no twist. For the pitch curve, the

initial LOW rate is 100% and the HI G H r at e is 100%.

Set the maximum pitch angle in advance. The pitch

angle is -4° to +12°.

When setting the pitch angle, set the hovering

pitch lever and the HIGH side pitch lever to the

center positions. These levers may be activated in

flight to make adjustments. Next, input the data so

that the normal pitch used in hovering becomes

-2.5° to+10° by LOW/HIGH side rate setting.

Although unimportant in calm conditions, the

pitch angle should be set to that the High side pitch

rate is large. This provides high collective sensitivity

to help cope with windy conditions.

Pitch Curve Setting.

Move to the Condition menu, and select the pitch

curve PCV ke y. Set the pitch curve to the follow-

ing values:

Point

Setting (%)

1

9218

The rise at the low end is fast, and then the rise

rate

is reduced at the high end. We recommend

setting the hovering pitch to +4.5°.

27

4

3

5

35

43

6

52759

67

8

97310

11

78 82

11 Flight Condition Copying

Use the Condition Select

Model Menu. This function displays the flight conditions associated with the model in active memory.

Note the condition number next to the D (default)

in the display. This is the set of conditions associated

with the trimmed model. Also note the three num-

bers following: these are the conditions associated

with Idle-up 1&2 and Throttle Hold, that will be

copied into and modified.

CSL

button in the

11

86

13

88

The throttle responds slowly at first and then the

response rate increases at the top end.

10

Pitch Curve Setting

Call the pitch curve PIT function from the

model menu. Verify that the PIT curve function is

activated (

ACT ).

Use the Copy Condition CPC from the System

menu. This function may be used to copy the con-

tents of one condition into another. Choose the

default flight condition number (next to the D),

press the

condition number in the lower box "TO CONDITION." Give the command to copy. Repeat for

Idle-up 2 and Throttle-hold conditions.

Normal->-ldle-up 1

Normal->ldle-up 1

Normal->Throttle Hold

Helicopter Section, Pag e 10 0

SET

button, then choose the Idle-up 1

Page 25

12

Idle-Up 1 Setting

The switch that calls the Idle-up 1 conditions

(SW-E, center position) is not yet activated. In the

Model menu, press the Condition Select

then select the condition position. Press the Switch

button

SWT

selected), and press the center position button ( Q).

Hit the previous key

Move the Idle-up 1 switch to its ON position and

verify that the condition name after the model name

refers to Idle-up 1. Then you may go through the

Condition menu items to revise the desired settings

in the new mode.

Throttle Curve Setting:

and press TCV to get the setting menu. Change the

first seven Idle-up 1 throttle curve points to the

values shown in the table below:

, select SW-E (if it is not already

PRE

and

END

move to the condition menu

CSL

key,

to finish.

Helicopter Section

14

Throttle Hold Setting

Now the Throttle Hold conditions are set for use

in autorotation. Call up the Throttle Hold conditions by setting SW-G to the 1 (forward) position.

Now you will set the Throttle Hold O N /OFF switch

so that SW (G) is turned on in the 1 (forward)

position, the same as th e flight condition call switch:

HLD

Call the Throttle Hold

condition menu. Set the condition switch SW (G) to

the 1 (forward) position. Select the Manual mode

MAN and activate the throttle hold function. Press

the SWT button to get to the Switch menu, and

activate the SW (G)-1 position. Hit

to exit.

function from the

PRE

and

END

Pitch Curve Setting:

key. The Normal curve copied already appears on

the screen. The Idle-up 1 pitch curve uses the same

curve as the normal condition, but the maximum

HIGH side pitch angle should be 8° to 10°, depending on the engine used. Set the pitch angle by curve

or rate.

Idle-Up 2 Setting

13

Call up the Idle-up 2 conditions by setting SW-E

to the 1 (forward) position. Be sure that the switch

is defined using CSL as in the previous case. Now,

you may go through the menu items to revise the

desired settings in the new mode (be sure that the

condition name after the model name refers to Idle-

up 2).

Throttle Curve Setting:

and press TCV to get the setting menu. Change the

first seven Idle-up 2 throttle curve points to the

values shown in the table below:

Pitch Curve Setting: Select the pitch curve

key. The Normal curve copied already appears on

the screen. Set the HIGH side pit c h th e same as Idle-

up 1. Values may be easily compared by switching

between Idle-up 1 & 2 with the condition switch, so

settings may be easily matched. Set the LOW side

pitch curve to the follow ing values:

Select the pitch curve PCV

move to the condition menu

PCV

When SW (G ) is in the 1 (forward) position, the

throttle hold function is turned on and when SW ( G )

is in the 2 (rear) position, the function is turned off.

In throttle hold, set the throttle to move th e servo to

engine idle (approximately 15%).

Pitch Curve Setting:

key. The Normal curve copied already appears on

the screen. During autorotation. maximum pitch is

used at both the HIGH and LOW sides. Therefore,

normally set the HI GH and LOW rates to 100% each.

The curve must be set so th at the r ise matches the

rotor near points 2 to 6. The rotor blade pitch angle

is-4° to+12°.

The pitch angle for each flight condition is shown

below:

.......

Normal

Idle-up 1 ....... -2.5° ~ 4.5° ~ 8°

Idle-up 2

Throttle Hold . .. . -4° ~ 4.5° ~ 12°

15

Pitch-rudder Mix Setting

Pitch->Rudder

to suppress the torque reaction of the main rotor

due to changes in collective pitch. The shape of the

mixing curve may be set independently for each

flight condition.

.......

Select the pitch curve PVC

-2.5° ~ 4.5° ~ 10°

-4° ~ 4.5° ~ 8°

P->R

mixing

uses

the

tail

rotor

Adjust the pitch curve low side to -4°

Helicopter Section, Page 101

Page 26

Helicopter Section

To set this feature, call the Pitch->R udder P->R

from the Condition Menu. The Normal setting is

used during hover, so it should be set to match takeoff, landing, and constant speed vertical climbing.

Normal Setting:

Select the normal flight conditions by turning off

all the flight condition switches. Set th e rudder mi x -

ing curve to the following values (initial settings):

Idle-up 1 Setting:

These settings are used in 540° stall turns, loop-

ing, and rolling stall turns and is set to be straight

ahead when the model is pointing directly into or

away from the wind. Call the Idle-up 1 flight conditions by moving swi tch E to the 0 (center) position.

Set the rudder mixing curve to the following values:

When these values are input, the rudder is offset

at the half-throttle position.

Idle-up 2 Setting:

These settings are used in rolls. Acti vate the Idleup 2 flight conditions by moving switch E to the 1

(forward) position. Set the rudder mixing curve to

the following values:

17 Rudder->Throttle Mix Setting

Rudder->Throttle

hovering eight, nose in circle, top hat, pirouette, an d

other aerobatics. It should be set so that at halfthrottle, if the rudder stick is operated, the rotor

speed is maintained to keep altitude constant.

For normal models, commanding right rudder

should increase throttle slightly, while using left

rudder should decrease throttle slightly.

To set this feature, return to the Normal flight

condition.

the Condition Menu. Press the

vate it, and set the Left value to -10%, and the

Right value to +10%.

Press

R->T

mixing is effective in

the Rudder->Throttle

ACT

button to acti-

18 Trim Offset Setting

The Tri m Offset

ed for Idle-up 1 and Idle-up 2. Aileron, elevator, and

rudder are offset so that the model flies straight

ahead during normal flight.

TOF

setting should be adjust-

R->T

from

The rudder is offset at the half-throttle position.

Throttle Hold Setting:

Throttle Hold settings are intended to keep the

model pointed str a ig ht ahead during linear autorotation. The tail rotor pitch angle is nearly 0°. Set t he

Throttle Hold flight conditions by moving switch G

to the 1 (forward) position. Set the rudder mixing

curve to the following values:

Delay Settings

Set the amount of delay for each flight condi-

tion. We recommend the following settings:

Normal .......

Idle-up 1 .......

Idle-up

2. ......20%

Throttle Hold . . . . 60%

The delay for Throttle hold should be large, because the rudder angle changes significantly during

flight condition changes.

20%

20%

Helicopter Section, Page 102