Frigidaire CFLE3900UW3, FFLE3900UW2, FFLE3900UW3, FFLG3900UW2, FFLG3900UW5 Installation Guide

All about the

Installation

of your Laundry Center

TA B L E O F C O N T E N T S

Important Safety Instructions |

.....................2 |

Installation Instructions............................ |

14 |

Installation Requirements........................... |

4 |

Accessories and Replacement Parts........... |

20 |

Unpacking Laundry Center........................ |

13 |

|

|

www.frigidaire.com USA 1-800-944-9044 |

www.frigidaire.ca Canada 1-800-265-8352 |

2019) (February A11270803

IMPORTANT SAFETY INSTRUCTIONS

WARNING

WARNING

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent property damage, personal injury or loss of life. Save these instructions.

WARNING - RISK OF FIRE

WARNING - RISK OF FIRE

•Ensure the entire dryer exhaust system is clean and free of lint and debris prior to the installation of your new laundry center. The entire exhaust system should be inspected and cleaned a minimum of every 18 months with normal usage. Failure to comply with cleaning your exhaust system will increase the RISK of FIRE.

•DO NOT install a clothes dryer with flexible plastic or flexible foil venting material. Flexible venting materials are known to collapse, be easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

•DO NOT screen the exhaust ends of the vent system, or use any screws, rivets or other fasteners that extend into the duct to assemble the exhaust system. NO screen or grate of any mesh size is allowed to cover the outdoor exhaust opening.

•Install the laundry center according to the manufacturer’s instructions and local codes.

•Laundry Center installation and service must be performed by a qualified installer, service agency or the gas supplier.

•The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the National Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian Electrical Code CSA C22.1 part 1.

•The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas Code ANSI Z223.1/NFPA 54, or in Canada, the Natural Gas and Propane Installation Code, CSA B149.1. An individual manual shutoff valve must be installed within 6 ft. (1.83 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

•The laundry center is designed under ANSI Z21.5.1/CSA 7.1 or UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE only. This laundry center is not recommended for commercial applications such as restaurants, beauty salons, etc.

•Destroy the carton and plastic bags after the laundry center is unpacked. Children might use them to play. Cartons covered with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a garbage container or make materials inaccessible to children.

The instructions in this manual and all other literature included with this dryer are not meant to cover every possible condition and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and maintaining any appliance.

Definitions

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

CAUTION

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

WARNING

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

IMPORTANT

IMPORTANT

IMPORTANT indicates installation, operation or maintenance information which is important but not hazard-related.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

2

IMPORTANT SAFETY INSTRUCTIONS

For your Safety

•DO NOT store or use gasoline, or other flammable liquids in the vicinity of this or any other appliance. Read product labels for warnings regarding flammability and other hazards.

•DO NOT operate the appliance in the presence of explosive fumes.

•Remove all staples from the carton. Staples can cause severe cuts, and also destroy finishes if they come in contact with other appliances or furniture.

CAUTION

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more than one person move or lift the appliance.

Child Safety

Destroy or recycle the carton, plastic bags, and any exterior wrapping material immediately after the appliance is unpacked. Children should never use these items for play. Cartons covered with rugs, bedspreads, plastic sheets or stretch wrap may become airtight chambers, and can quickly cause suffocation.

WARNING

WARNING

ELECTRIC SHOCK HAZARD

Certain internal parts are intentionally not grounded and may present a risk of electrical shock if contacted during installation. Do

not contact the following parts while the appliance is energized:

•Pump

•Drive Motor

•Electronic control boards

•Water valve

Installation Checklist

Installation Checklist

Shipping Hardware

Foam shipping restraint (inside wash tub) removed and stored

Foam shipping support (underneath appliance) removed and stored

Leveling

Laundry center is level, side-to-side and front-to-back

Cabinet is setting solid on all corners

Water Supply

Use only new hoses and verify rubber sealing washers are installed

HOT supply is connected to HOT inlet and COLD supply is connected to COLD inlet

HOT and COLD water supply turned on

No leaks present at water supply connections or appliance inlet connections -recheck in 24 hours

Drain

Stand pipe or wall drain height min. 33”

Drain hose secured in place with cable tie (shipped in drum)

Exhaust Venting

Free-flowing, clear of lint buildup

4 inch (102 mm) rigid or semi-rigid ducting of minimal length and turns

NO foil or plastic venting material

Approved vent hood exhausted to outdoors

Gas Supply (Gas Dryer)

Manual shutoff valve present in supply

All connections sealed with approved sealer and wrench tight

Conversion kit for LP systemGas supply turned on

No leaks present at all connections - check with soapy water, NEVER check with flame

240v Electric Supply

(Electric Dryer)

Approved NEMA 10-30R or 14-30R service cord with all screws tight on terminal block

Approved strain relief installed

Terminal access cover installed before initial operation

Electrical Power

House power turned onLaundry Center plugged in

Final Checks

Installation Instructions and Use and Care Guide read thoroughly

Water enters drum when cycle starts with lid lowered. Dryer door latches and drum tumbles when cycle starts.

Registration card sent in

3

INSTALLATION REQUIREMENTS

Pre-Installation Requirements

Tools and materials needed for installation:

•Adjustable pliers

•Phillips, straight, & square bit screwdrivers

•Adjustable wrench

•Pipe wrench for gas supply (gas dryer)

•LP-resistant thread tape (for natural gas or LP supply, gas dryer)

•Carpenter’s level

•External vent hood

•4-inch (102 mm), rigid metal or semirigid metal exhaust duct work

•3-wire or 4-wire 240 volt cord kit (electric dryer)

•4 in. (102 mm) clamp

•Gas line shutoff valve (gas dryer)

•½ NPT union flare adapters (x2) and flexible gas supply line (gas dryer)

•Metal foil tape (not duct tape)

•Inlet hoses (x2)

NOTE

Hoses are not included with washer purchase. See “Accessories” section for various inlet hose kits to fit your specific installation.

NOTE

Because of potentially inconsistent voltage capabilities, the use of this dryer with power created by gas powered generators, solar powered generators, wind powered generators or any other generator other than the local utility company is not recommended.

Electrical requirements for Laundry Center with electric dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers.

POWER SUPPLY - 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

IMPORTANT

IMPORTANT

This laundry center is internally grounded to neutral unless it was manufactured for sale in Canada.

Only a 4-conductor cord shall be used when the appliance is installed in a location where grounding through the neutral conductor is prohibited. Grounding through the neutral link is prohibited for: (1) new branch

circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes DO NOT permit grounding through the neutral.

OUTLET RECEPTACLE - NEMA 10-30R or NEMA 14-30R receptacle to be located so the power supply cord is accessible when the dryer is in the installed position.

GROUNDING CONNECTION - See “Grounding requirements” in Electrical Installation section.

WARNING

WARNING

Improper grounding of the laundry center may cause serious injury or death. Check with a licensed electrician if you are in doubt as to whether the appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances, cut, remove,

or bypass the grounding prong.

Power cord with 3-prong grounded plug

3-WIRE POWER SUPPLY CORD KIT

(not supplied)

3-wire receptacle (NEMA type 10-30R)

The dryer MUST employ a 3-conductor power supply cord NEMA 10-30 type SRDT rated at 240 volt AC minimum, 30 amp, with 3 open end spade lug connectors with upturned ends

4

INSTALLATION REQUIREMENTS

or closed loop connectors and marked for use with clothes dryers. For 3-wire cord connection instructions see ELECTRICAL CONNECTIONS FOR A 3-WIRE SYSTEM.

4-WIRE POWER SUPPLY CORD KIT

(not supplied)

4-wire receptacle (NEMA type 14-30R)

The dryer MUST employ a 4-conductor power supply cord NEMA 14-30 type SRDT or DRT (as required) rated at 240 volt AC minimum, 30 amp, with 4 open end spade lug connectors with upturned ends or closed loop connectors and marked for use with clothes dryers. For 4-wire cord connection instructions see ELEC-

TRICAL CONNECTIONS FOR A 4-WIRE SYSTEM.

NOTE

Laundry centers manufactured for sale in Canada have factory-installed, 4-wire power supply cord (NEMA 14-30R).

Electrical requirements for Laundry Center with gas dryer

WARNING

WARNING

Improper grounding of the laundry center. may cause serious injury or death. Check with a licensed electrician if you are in doubt as to whether the appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances, cut, remove,

or bypass the grounding prong.

Power cord with 3-prong grounded plug

CIRCUIT - Individual, properly polarized and grounded 15 amp. branch circuit fused with 15 amp. time delay fuse or circuit breaker.

POWER SUPPLY - 2-wire, with ground, 120 volt, single phase, 60 Hz, Alternating Current.

POWER SUPPLY CORD - The dryer is equipped with a 120 volt 3-wire power cord.

GROUNDING CONNECTION - See “Grounding requirements” in Electrical Installation section.

Gas supply requirements

WARNING

WARNING

EXPLOSION HAZARD

Uncoated copper tubing will corrode when subjected to natural gas, causing gas leaks. Use ONLY black iron, stainless steel, or plastic-coated brass piping for gas supply.

1.Installation MUST conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition).

2.The gas supply line should be 1/2 inch (1.27 cm) pipe.

3.If codes allow, flexible metal tubing may be used to connect your dryer to the gas supply line. The tubing MUST be constructed of stainless steel or plastic-coated brass.

4.The gas supply line MUST have an individual shutoff valve installed in accordance with the B149.1, Natural Gas and Propane Installation Code.

5.A 1/8 inch (0.32 cm) N.P.T. plugged tapping, accessible for test gauge connection, MUST be installed immediately upstream of the gas supply connection to the dryer.

6.The dryer MUST be disconnected from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures in excess of 1/2 psig (3.45 kPa).

7.The dryer MUST be isolated from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa).

8.Connections for the gas supply must comply with the Standard for Connectors for Gas Appliances, ANSI Z21.24 - CSA 6.10.

5

INSTALLATION REQUIREMENTS

Water supply requirements

Hot and cold water faucets MUST be installed within 42 inches (107 cm) of your washer’s water inlet. The faucets MUST be 3/4 inch (1.9 cm) with threading for laundry hose connection. Water pressure MUST be between 10 psi

(0.69 bars) and 120 psi (8.27 bars). Pressure difference between hot and cold cannot be more than 10 psi. Your water department can advise you of your water pressure.

NOTE

Washers connected to water supplies with lower inlet pressure will experience longer filling times and may not complete cycles as quickly.

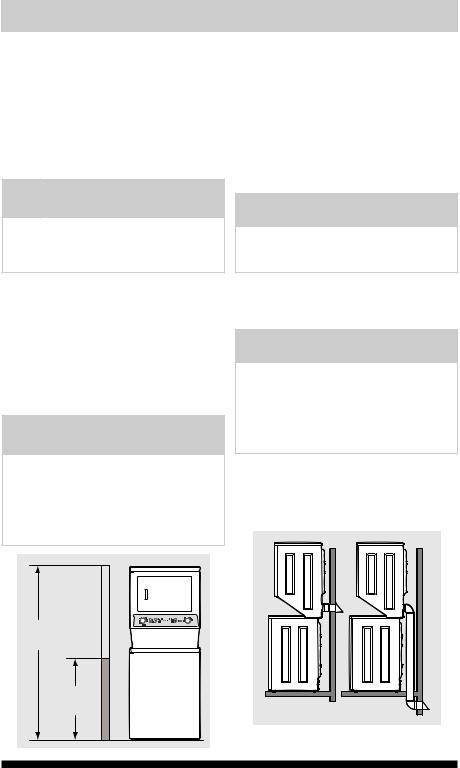

Drain system requirements

1.Drain capable of eliminating 17 gals (64.3 L) per minute.

2.A standpipe diameter of 1-1/4 in. (3.18 cm) minimum.

3.Standpipe height above the floor should be:

Minimum height: 33 in. (84 cm) Maximum height: 96 in. (244 cm)

NOTE

For installations requiring a longer drain hose, have a qualified technician install a longer drain hose (according to your model number) available from an authorized parts distributor. For drain systems in the floor, install a syphon break kit available from your local hardware store.

96"

(244cm)

max.

33"

(84cm)

min.

Exhaust system requirements

Use only 4 inch (102 mm) diameter rigid or flexible metal duct and approved vent hood which has a swing-out damper(s) that open when the dryer is in operation. When the dryer stops, the dampers automatically close to prevent drafts and the entrance of insects and rodents. To avoid restricting the outlet, maintain a minimum of 12 inches (30.5 cm) clearance between the vent hood and the ground or any other obstruction.

WARNING

WARNING

FIRE HAZARD

Failure to follow these instructions can create excessive drying times and fire hazards.

The following are specific requirements for proper and safe operation of your dryer.

WARNING

WARNING

FIRE HAZARD

DO NOT install a clothes dryer with flexible plastic or metal foil venting materials. Flexible venting materials are known to collapse, be easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

If your present system is made up of plastic duct or metal foil duct, replace it with a rigid or semi-rigid metal duct. Also, ensure the present duct is free of any lint prior to installing dryer duct.

Correct

6

INSTALLATION REQUIREMENTS

Incorrect

WARNING

WARNING

FIRE HAZARD

A clothes dryer must be exhausted outdoors. DO NOT exhaust dryer into a chimney, a wall, a ceiling, an attic, a crawl space or

any concealed space of a building. A clothes dryer produces combustible lint. If the dryer is not exhausted outdoors, some fine lint will be expelled into the laundry area. An accumulation of lint in any area of the home can create a health and fire hazard.

The dryer must be connected to an exhaust outdoors. Prior to installing your new

dryer, inspect the outdoor exhaust opening and remove any accumulation of lint around the outdoor exhaust opening and in the surrounding area.

WARNING

WARNING

FIRE HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property damage.

DO NOT install a booster fan in the exhaust duct.

Install ALL clothes dryers in accordance with the installation instructions in this manual.

WARNING

WARNING

FIRE HAZARD

•DO NOT allow combustible materials (for example: clothing, draperies/ curtains, paper) to come in contact with exhaust system. The dryer MUST NOT be exhausted into a chimney, a wall,

a ceiling, or any concealed space of a building which can accumulate lint, resulting in a fire hazard.

•DO NOT screen the exhaust ends of the vent system, or use any screws, rivets

or other fasteners that extend into the duct to assemble the exhaust system. No screen, grate, or guard of any mesh size is allowed to cover

the exhaust opening.  Lint can become caught

Lint can become caught

in the screen, grate,

guard, or on the screws or rivets, clogging the duct work

and creating a fire hazard as well as increasing drying times. Use an

approved vent hood to terminate the duct outdoors, and seal all joints with metal foil tape. All male duct pipe fittings MUST be installed downstream with the flow of air.

WARNING

WARNING

FIRE HAZARD

Exceeding the length of duct pipe or number of elbows allowed in the “MAXIMUM LENGTH” charts can cause an accumulation of lint in the exhaust system. Plugging the system could create a fire hazard, as well as increase drying times.

ofNumber |

|

|

|

|

|

|

|

|

MAXIMUM LENGTH |

||||||||||||||

|

|

|

|

|

|

(Preferred) |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

of 4” (102 mm) Rigid Metal Duct |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

VENT HOOD TYPE |

||||||||||||||

turns 90° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

4” (10.2 cm) |

louvered |

2.5” (6.35 cm) |

|||||||||||||||||||||

|

|||||||||||||||||||||||

0 |

|

|

|

|

56 ft. (17 m) |

42 ft. (13 m) |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1 |

|

|

|

|

48 ft. (14.5 m) |

34 ft. (10.5 m) |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2 |

|

|

|

|

40 ft. (12 m) |

26 ft. (8 m) |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

3 |

|

|

|

|

32 ft. (9.5 m) |

18 ft. (5.5 m) |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

Loading...

Loading...