Page 1

injury and material damage. Read these instructions

thoroughly!

and comply with applicable safety directives when

working with hazardous or hot/cold medium.

is no risk of crush injuries. The risk is highest with

automatic valves.

unintentional manoeuvre - i.e to atmosphere.

ensuring that the line is free of pressure and any

content.

position to avoid trapping pressure and medium.

suitable for its intended use. This applies especially to

highly oxidising and corrosive medium. Observe also

the risk of erosion and explosion as well as decaying

medium. If in doubt, always request a written

recommendation from NAF AB.

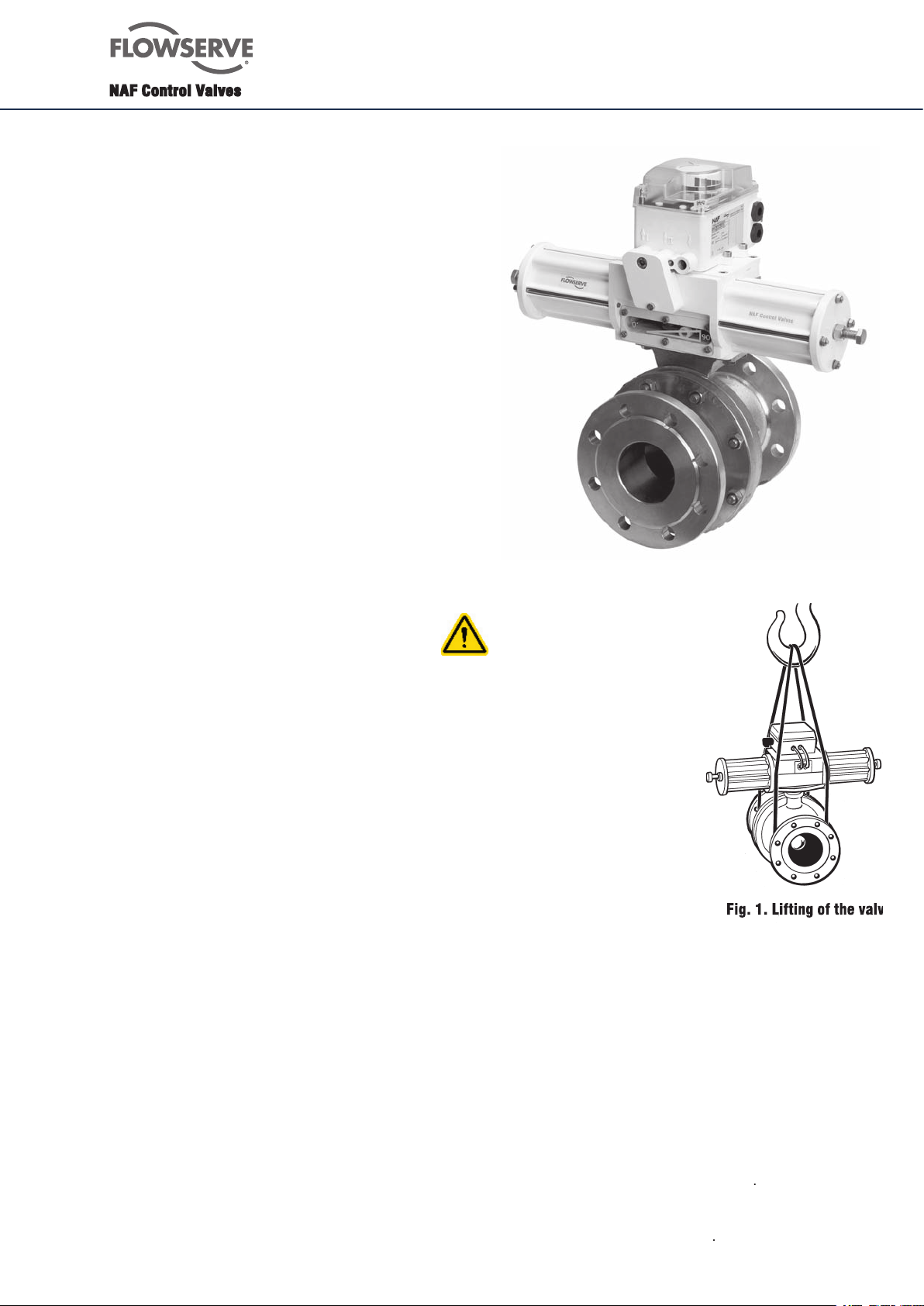

All lifting must be made in

the valve itself and not in the

the valve and the actuator

All valves leaving our works are inspected and tested

the pipework. However, in view of damage that may have

valve delivered is correct in

terms of type, size, equipment, etc

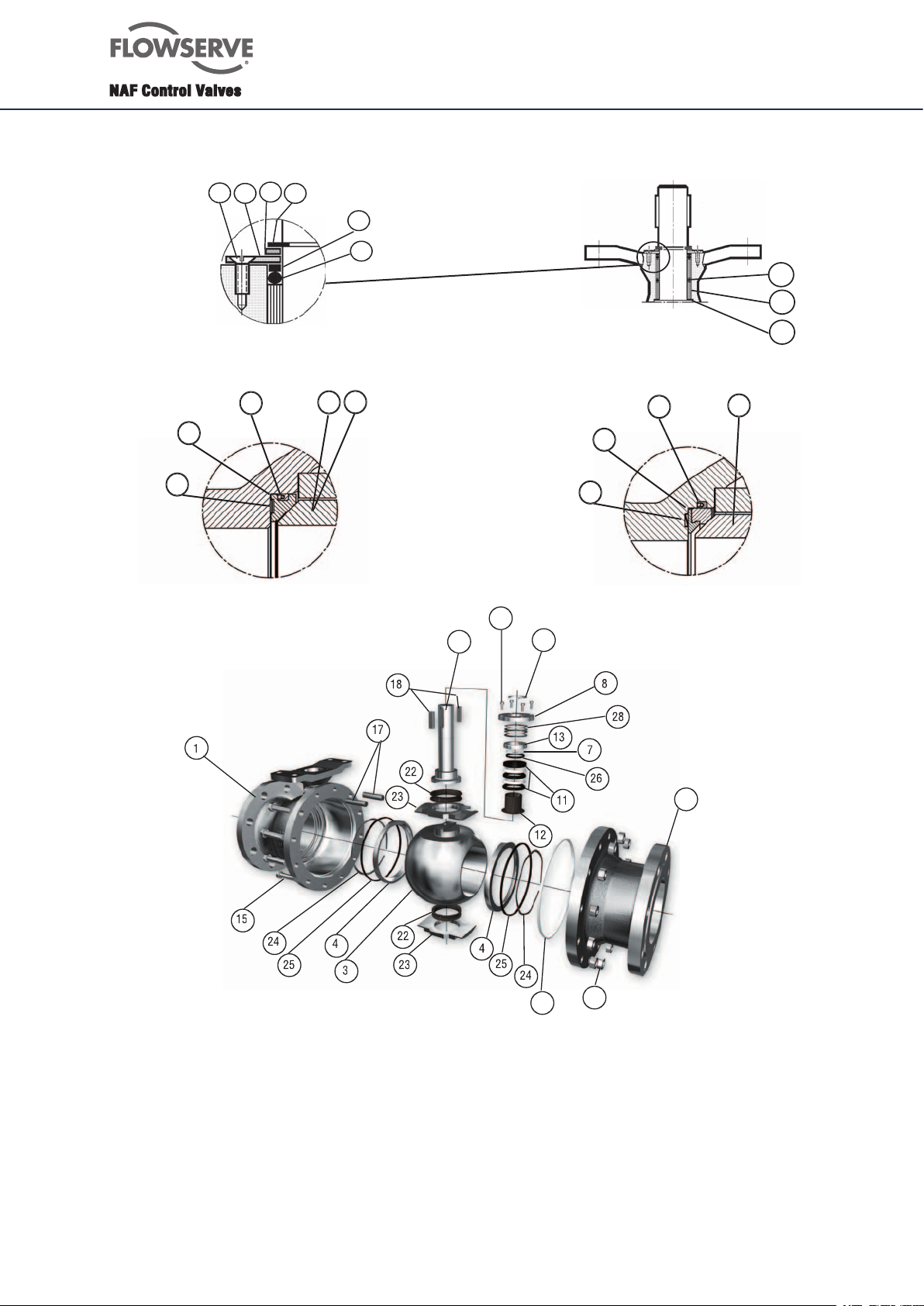

Page 2

the valve is to be installed are parallel and are correctly

valve must not be used for drawing together or aligning

as this will cause needless loads on

the valve and pipe which may lead to diffi cult damages

Wrong installation Correct installation

the pipework.

valve

Body EN 1.4408/CF8M

Body EN 1.4408/CF8M

Ball hard chrome EN 1.4408/CF8M/Hcr

Seat ring Alloy 6

Stem, assembly EN 1.4460

Circlip Spring steel

Backing ring PTFE

Upper lid EN 1.4436

Screw A4

Packing box PTFE/PTFE+25%C

Bushing PTFE+1.4401

Anti-friction washer EN 1.4436

Sealing ring PTFE

Screw A4-80

Nut A4

Screw A4-80

Key A4

Ball EN 1.4408/CF8M

Ball Alloy 6

Seatring EN 1.4436/PTFE+25%C

Bearing PTFE+1.4401

Trunnion plate EN 1.4470

Spring ASTM A316

Sealing ring PTFE+15%Graphite

O-ring FPM

Spring ASTM A316

Supporting ring Spring steel

Washer A4

Supporting ring PTFE

O-ring EPDM

Bushing PTFE reinforced carbon

Sliding washer PTFE reinforced carbon

Page 3

3

Alloy 6

with o-rings type 898X9X-XXXX

Page 4

Fk 41.66 and the manuf. No.specifi ed on the

identifi cation plate of the valve.

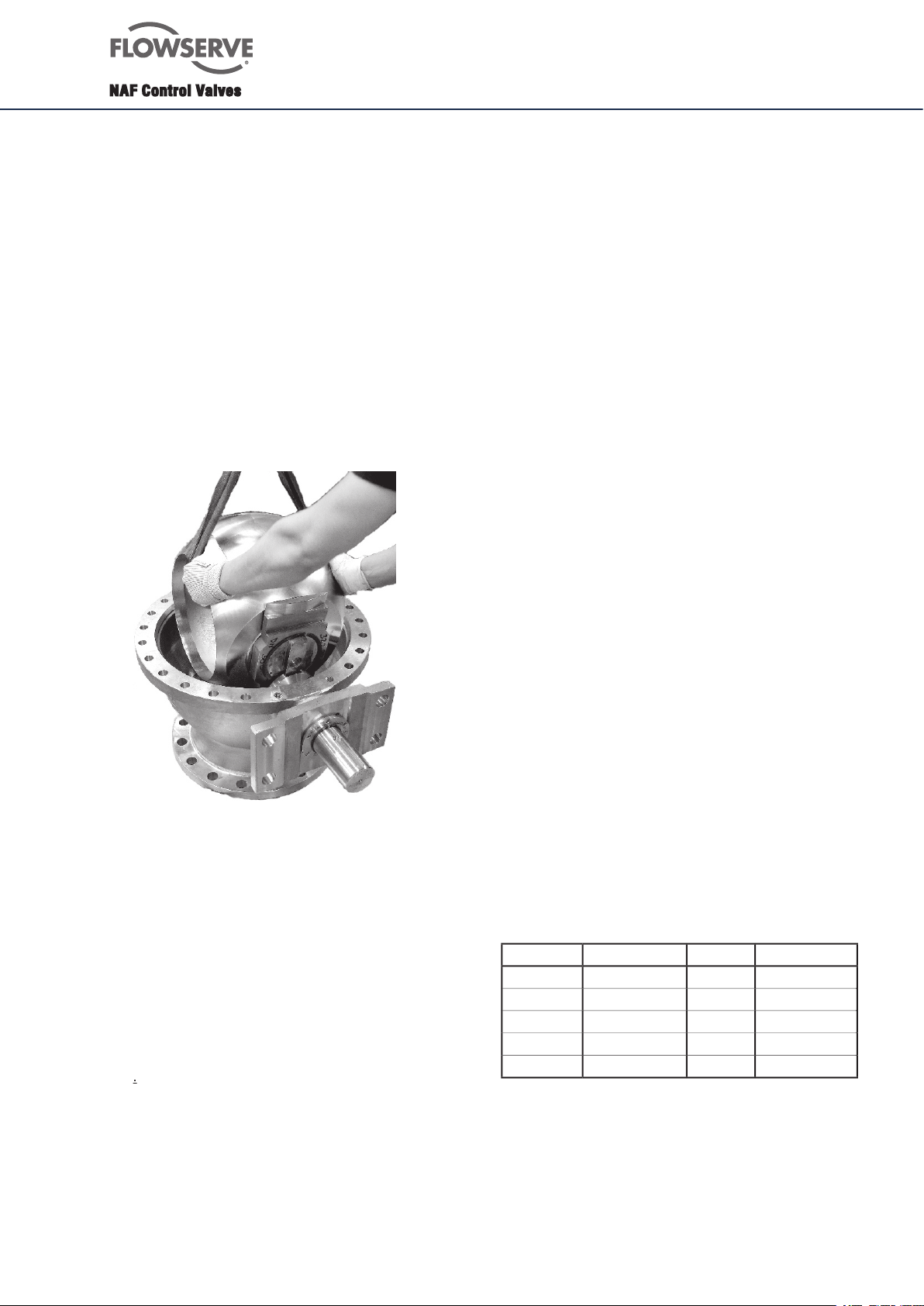

required - see table below.

Description Qty

6” 8” 10” 12” 16” 18” 20” 24” 28” 32

Wave spring

Page 5

isolate all electrical connections to the actuator.

cables connected to the actuator.

the pipework. Then lift out the valve. Don’t use

the actuator for lifting.

Apply all lifting forces to

the valve itself and not to the actuator

- Fig. 1.

In certain applications, the pipe can be discon-

nected from one side of the valve, and the body

half (2) - Fig. 3 - can be removed, without the

need for removing the whole valve from the

pipework.

by centre-punching before the dismounting

since the pattern of the holes drilled in the valve

fl ange and pipe fl ange may vary.

tion - here with the valve on a work bench.

It can also be done with mounted actuator

and the body (1) mounted in the pipework.

gaskets for the pipe fl anges are available.

Before dismounting the valve,

it is completely empty

times between the open and closed positions to

ensure that the space between the valve body and

ball is not under pressure.

for

replacing the seatring and ball.

completely empty

do when the valve is in closed position.

bearing from the bearing journal of the ball.

if necessary, some degreasing compound. Do not

scrape any machined surfaces with hard tools.

seatrings, wave springs and sealings if they are worn

or damaged.

25) behind the seatring (pos 20).

can be removed by polishing with fi ne emery cloth. If

the ball has major damages, it must be replaced to

ensure satisfactory tightness.

halves.

ball.

for service in an oxygen system, the ball can be coa-

ted with silicone grease, which is approved for oxygen

applications.

i.e. Crane Packings’s Thread-Grade or Gleitmo 600.

(1) and then the upper bodyhalf (2). Make sure that

the centrepunch marks made according to section 8.1

item 6 are lined up. Tighten the bolted joint of the two

bodyhalves alternately in several stages and tighten

them fi nally as per the table below.

its tightness - Fig. 5.

valve are properly fi lled

with water before the pressure

testing. The valve should be pressure tested as follows:

Open valve: PN x 1,5

Closed valve: Max dp x 1,1

Page 6

in alloy 6

A groove on the inside of the ring facilitates with-

drawal. Minor damage to the rings can be polished

with fi ne emery cloth. Check the rings on a face

plate to ensure that they are perfectly fl at. Do

not lap the rings and the chromium-plated ball

together. Change the rings if they are severely

damaged.

damage may be polished with fi ne emery cloth.

If the existing ball must be used for a further

period of time, remove all sharp edges, dents and

irregularities with a fi ne fi le or emery cloth. Check

the circularity of the ball. The tolerance is

If the ball is seriously damaged, it must be

replaced.

and 25) behind the seatring.

bodyhalves.

Molykote U.

section 8.3

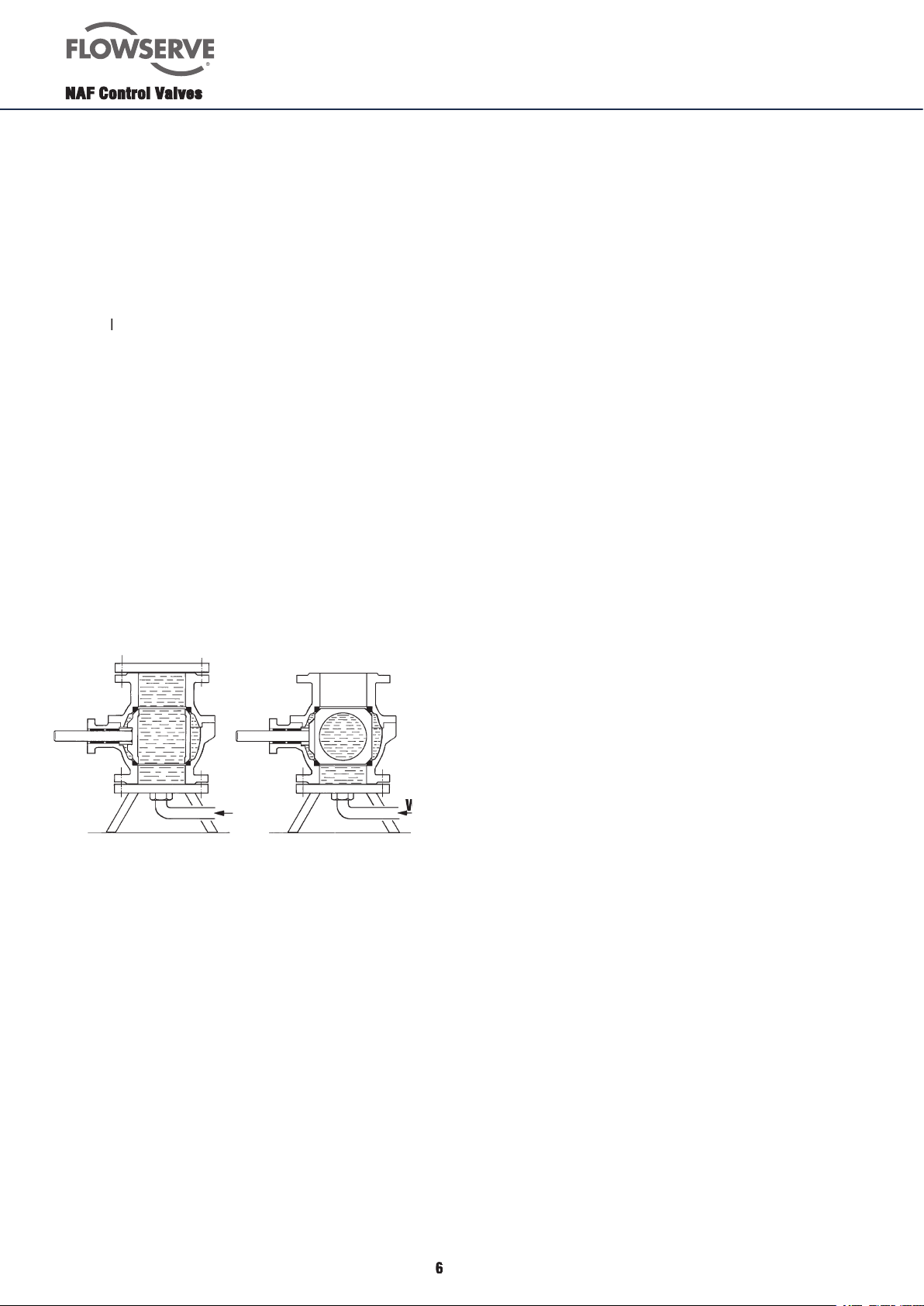

Valve open Valve closed

Water

valves with packing box type PSDCL

(DN150-DN400) i.e. type

8982EF-XXXX-BABADA

from the underside of the mounting plate of the

valve keeps the actuator in place.

keys.

and remove the upper lid (8). Note! The upper

lid is prespringloaded.

it.

ring (7), o-ring (26) and packing box (11).

the body.

through the body.

grease before you press it down into the body.

Note that the broadest of the 5 rings should be

on top, see fi g 3 on page 3.

the body and out.

washer (13), lubricate a new o-ring (26) with

silicone grease and mount it in the anti-friction

washer. Mount the anti-friction washer with the

o-ring downwards against the valve.

item 5 to 1.

those in section 8.4 above.

mend that the valve is returned to NAF for repair.

This applies especially if the ball must be ground

before lapping. Assemble the valve before dispat-

ching it to NAF.

ted by lapping them together. This can be done

manually with a compound with grit size 200. Take

great care to ensure that the ball and seat rings do

not become oval.

lubricated before they are mounte

solvent for cleaning. Then lubricate the ball with

silicone grease, such as Molykote Dow Corning

FS3452. The coat of grease must be very thin.

Then polish the ball with chamois leather or a

piece of soft cloth.

Water

Page 7

(DN450-DN800) i.e. type 898295-XXXX

from the underside of the mountingplate of the

valve keeps the actuator in place.

keys.

(29).

(30) and the anti-friction washer in PTFE (31).

the new ring with silicone grease before it is

mounted.

(

8.7, item 1 and 2.

(30) and the anti-friction washer of PTFE (31).

it.

intermediate o-ring (32).

been lubricated with Silicone grease. Change

also the sliding washer (34) on the stem.

reverse order.

Before that consider to change the seatrings or

lapping of the seatrings and ball.

the bolts according to section 8.3.

either in line with the connected pipes or transversely

to them. For mounting in line with the connected

pipes an intermediary plate is required

the closed position before mounting the actuator.

The valve is in the closed position when the

keyway on the stem is in the direction of fl ow.

(An actuator which uses compressed air to close

the valve and a return spring to open the valve

should be mounted with the actuator and valve in the

open position.)

The direction of closure must always be

clockwise, as viewed from the actuator.

actuator slides easily onto the stem when the

keys are not fi tted. Check also that the keys fi t

freely into the keyways in the hollow shaft of the

actuator. Deburr if necessary. Lubricate the hollow

shaft of the actuator and push it in over the

threaded sleeve. Mount the actuator onto the stem.

Mount the bolts and nuts, and tighten them.

have been correctly preset. If necessary, make

adjustments.

If any accessories such as valve positioner or

limit switches should be mounted, please see the

corresponding manufacturer’s instructions for

installation and adjustment.

Page 8

Loading...

Loading...