Page 1

TRG 5-5...

Installation Instructions 810428-03

Temperature Sensor TRG 5-53, TRG 5-54

TRG 5-55, TRG 5-56

TRG 5-57, TRG 5-58

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ...................................................................................... 7

Safety note ......................................................................................................................7

Danger ............................................................................................................................ 7

Ratings pursuant to article 9 of the PED .........................................................................7

Explanatory Notes

Scope of supply ..............................................................................................................8

System description .......................................................................................................... 8

Function .......................................................................................................................... 8

Design .............................................................................................................................8

Technical data ................................................................................................................. 9

Installation

TRG 5-53, TRG 5-54.....................................................................................................10

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58 ..................................................................17

Example of installation ..................................................................................................15

Wiring

TRG 5-5... ..................................................................................................................... 11

Commissioning

Measure fluid temperature ............................................................................................11

Table “Resistance values” .............................................................................................11

Operation

Replace temperature sensing element ......................................................................... 12

Annex

Fault finding list .............................................................................................................12

Declaration of conformity .............................................................................................. 14

2

Page 3

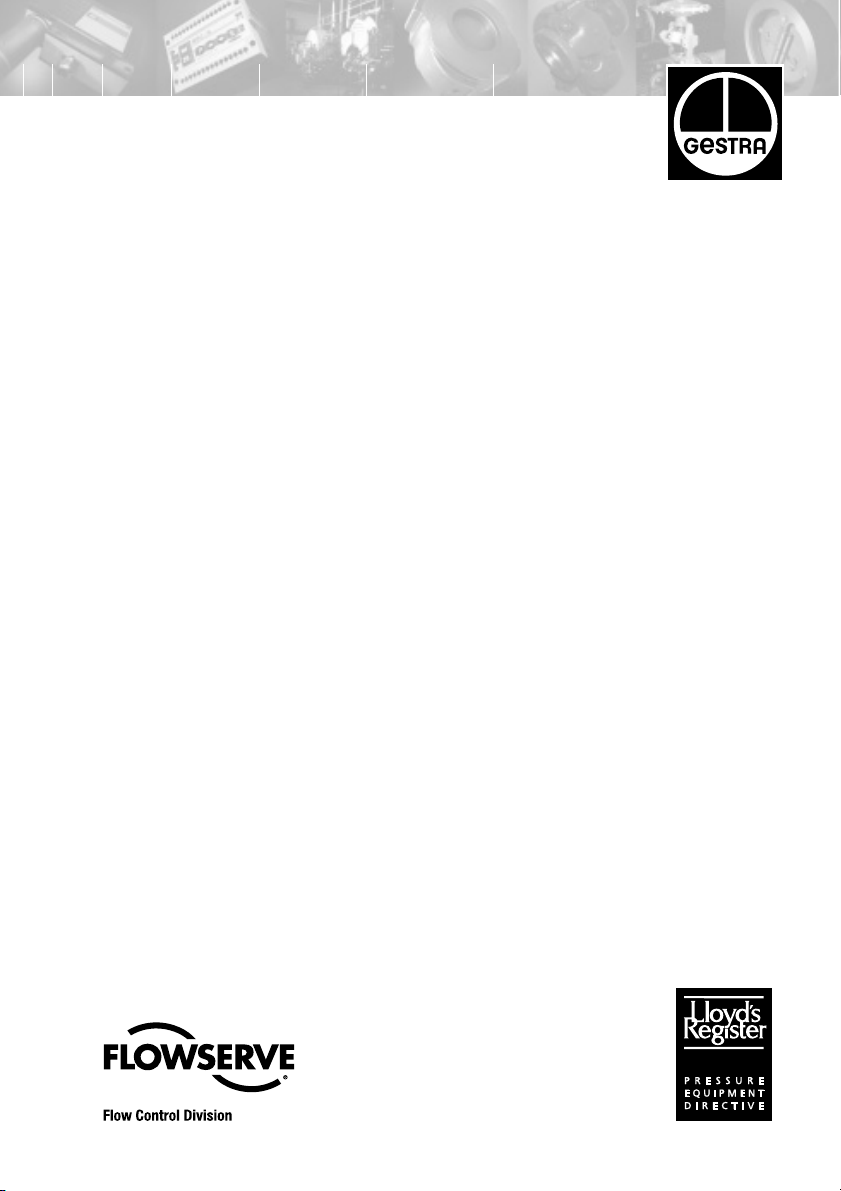

Wiring Diagram

10 12

H I

Red

11

White

ϑ

Fig. 1

10 12

Yellow

Red

Fig. 2

11

ϑ

Black

White

ϑ

3

Page 4

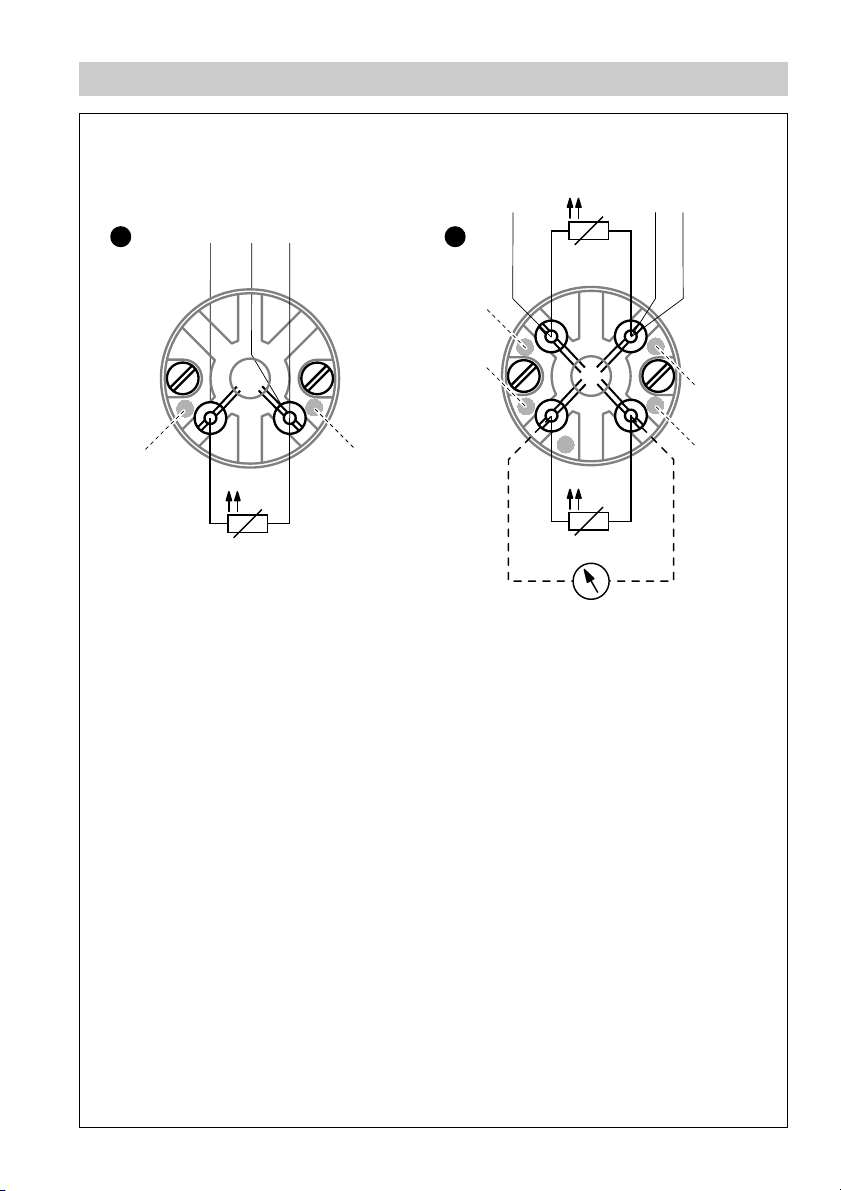

Dimensions

95120

∅ 26

Fig. 3

15

A

D

½" BSP

E

F

G

Fig. 4

∅ 11

TRG 5-53 TRG 5-54

A

D

100, 160, 250, 400

40

4

Page 5

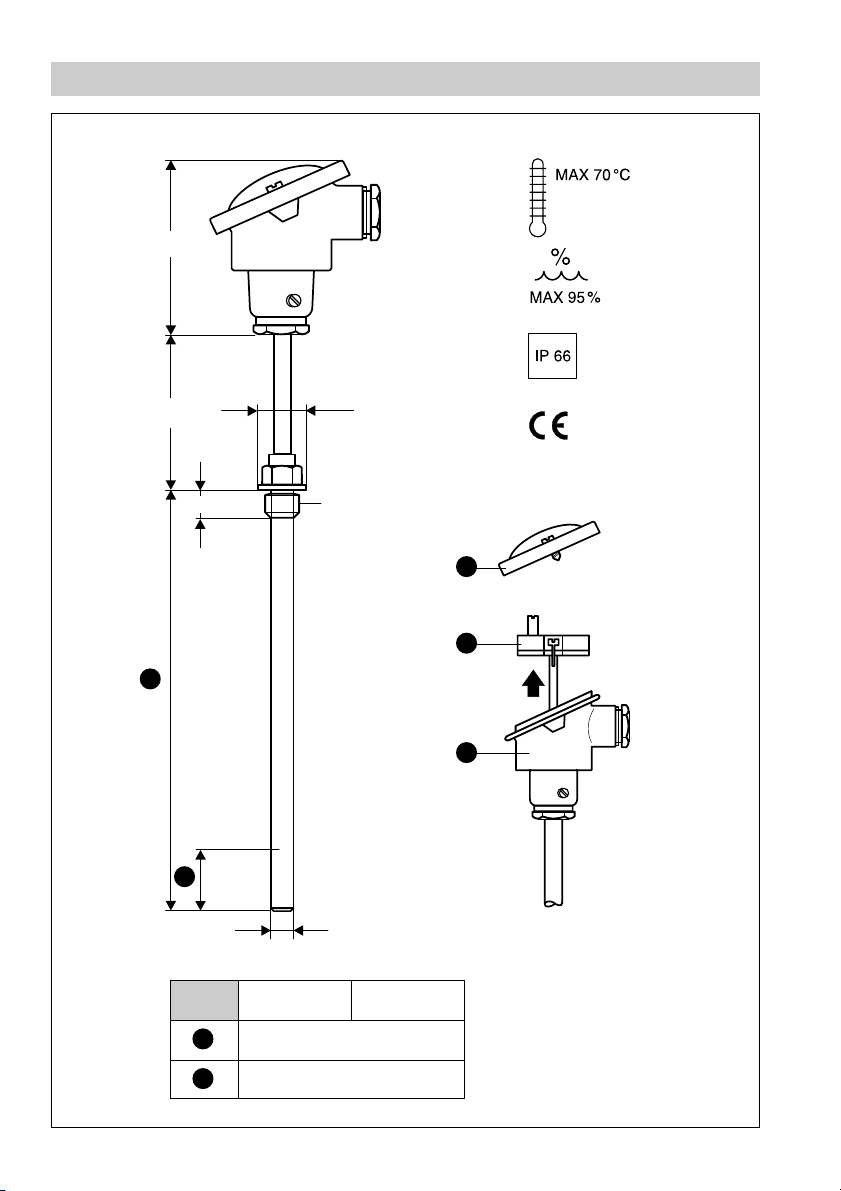

Dimensions

95140

∅ 11

E

25

F

Fig. 4

B

C

D

∅ 18

G

∅ 6

Fig. 5

B

C

D

TRG 5-55

TRG 5-56

115

40

TRG 5-57 TRG 5-58

140

65

30

5

Page 6

Key

A

Protection tube

B

Welding sleeve

C

Tapered part

D

Temperature-sensitive part

E

Cover

F

Temperature sensing element (removable)

G

Body

6

Page 7

Important Notes

Usage for the intended purpose

Use temperature sensors types TRG 5-53, TRG 5-54, TRG 5-55, TRG 5-56,

TRG 5-57 and TRG 5-58 only for measuring temperatures in conjunction with the

associated GESTRA temperature switches.

Safety note

The temperature sensors must only be installed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance with

regulations concerning electrical safety systems, and first aid & accident

prevention – have achieved a recognised level of competence appropriate

to the installation and commissioning of this device.

Danger

The temperature sensors TRG 5-53 and TRG 5-54 are screwed into

tanks or pipes. When loosening the equipment hot water, steam,

corrosive or poisonous fluids may escape. This presents the danger of

poisoning or severe scalding and acid burns to the whole body.

Installation and maintenance work should only be carried out when the

system is depressurized. Wear protective clothing.

The temperature sensor is hot during operation. This presents the risk

of severe burns to hands and arms.

Installation and maintenance work should only be carried out when the

equipment is cold.

Ratings pursuant to article 9 of the PED1)

Category IV

Description Equipment with safety function

CE marking yes

1

) PED = Pressure Equipment Directive

7

Page 8

Explanatory Notes

Scope of supply

TRG 5-53, TRG 5-54, TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58

1 Temperature sensor

1 Installation manual

System description

The equipment TRG 5-53, TRG 5-54, TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58 are

temperature sensors according to DIN 3440.

The temperature sensing element Pt 100 integrated in the protection tube has

temperature-dependent resistance values. The temperature switch TRS 5-6/TRS 5-8

measures the resistance values and raises a temperature alarm correponding to the

adjusted limit.

Application in steam boilers and pressurized hot-water plants acc. to TRD 604 and

other heat-generating units.

Function

The temperature sensors TRG 5-53, TRG 5-54, TRG 5-55, TRG 5-56, TRG 5-57,

TRG 5-58 feature standardized platinum resistance thermometers Pt 100 according

to DIN IEC 751. The temperature sensor in combination with temperature switches

TRS 5-6 or TRS 5-8 are used for temperature monitoring. The power source is

equipped with an adjustable resistor and supplies the resistance thermometer

Pt 100 with a constant current. The desired switch-off temperatures are adjusted with

the aid of the 8 pole code switch on the temperature switch. To ensure a fail-safe

alarm in the event of excessively high temperatures the circuit features relays of the

normally-closed type. In the event of a power failure the temperature switch will raise

an alarm.

Design

TRG 5-53, TRG 5-54:

Temperature sensor with protection tube and ½" screwed terminal box to DIN IEC 751.

The temperature sensing element can be removed.

F

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58:

Temperature sensor with protection tube and socket-weld end to DIN IEC 751.

The temperature sensing element can be removed.

F

8

Page 9

Technical Data

Type approval

DIN STW (STB) 98698 S

GL 99251-96 HH

DIN TW 10 6895

EG 01 202931-B-010008

Temperature sensing element

Pt 100 to DIN IEC 751, class B

Service pressure/service temperature

TRG 5-53, TRG 5-54:

nominal length 100/160/250 mm

40 barg (580 psig), 251°C (484 °F)

36 barg (522 psig), 400°C (752 °F)

nominal length 400 mm

18 barg (261 psig), 400°C (752 °F)

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58:

160 barg (2321 psig), 345 °C ( 653 °F)

120 barg (1741 psig), 540 °C (1004 °F)

Admissible flow velocity

TRG 5-53, TRG 5-54:

Air 25 m/s

Superheated steam 25 m/s

Water 3 m/s

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58:

Air 60 m/s

Superheated steam 60 m/s

Water 5 m/s

Connections

TRG 5-53, TRG 5-54:

Screwed socket ½" BSP

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58:

Socket-weld end ∅ 18 mm

Length of protection tube

see “Dimensions”

Materials

TRG 5-53, TRG 5-54:

Protection tube made of S.S.X 6 CrNiMoTi 1712 2 (1.4571)

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58:

Protection tube made of forged alloy steel 13 CrMo44 (1.7335)

Weight

TRG 5-53, TRG 5-54:

1.3 kg

TRG 5-55, TRG 5-56, TRG 5-57, TRG 5-58:

0.8 kg

9

Page 10

Installation

TRG 5-53, TRG 5-54

1. Clean sealing surfaces.

2. Put gasket 13 x26 onto the sealing surface (choose the material of the gasket

according to the respective application).

3. Screw in temperature sensor and tighten with spanner when cold (torque 50 Nm).

TRG 5-55, TRG 5-56, TRG-5-57, TRG 5-58

1. Remove socket-weld end from temperature sensor.

2. Clean welding surfaces.

3. Arc-weld trap manually (welding process 111 complying to DIN EN 24063) or use

gas-welding process (welding process 3 complying to DIN EN 24063).

4. After welds have cooled down screw in temperature sensor and tighten with

spanner when cold.

Note

■ To install the temperature sensor in a pipe, weld knee bend to the pipe

such that the measuring tip is immersed in the fluid against the

D

direction of flow. Fig. 8, Fig. 9

■ Make sure that the measuring tip of the installed temperature sensor is

always in contact with the fluid. Fig. 3, Fig. 4

■ The temperature sensors must not be completely insulated. For more

details see examples of installation Fig. 6, Fig. 7

Tools

■ Open-end spanner (A.F. 22 mm or A.F. 27 mm)

■ Torque spanner (A. F. 22 mm or A.F. 27 mm)

K

D

10

Page 11

Wiring

TRG 5-5...

Use four-core cable for wiring:

1. Connect terminal strip acc. to wiring diagram. Fig. 1, Fig. 2

2. You can connect additional equipment to the terminals marked in yellow and black

of the TRG 5-54, TRG 5-56 and TRG 5-58. Fig. 2

Wiring diagram

See wiring diagram on page 3.

Tools

■ Screwdriver for slotted screws, size 2.5, completely insulated to VDE 0680

Commissioning

Measure fluid temperature

Use the following table indicating the resistance of the Pt 100 to ascertain the current

temperature of the fluid.

1. Connect the test wire direct to the terminal box.

2. Measure the resistance with an ohmmeter.

3. Find the corresponding value in the table below, read off the temperature and, if

necessary, determine the exact value by interpolation.

°C 0 102030405060 708090100 Ω/

10

0 100.00 103.90 107.79 111.67 115.54 119.40 123.24 127.07 130.89 134.70 138.50 0.385

100 138.50 142.28 146.06 149.82 153.57 157.32 161.04 164.76 168.47 172.16 175.84 0.373

200 175.84 179.51 183.17 186.82 190.46 194.08 197.70 201.30 204.88 208.46 212.03 0.361

300 212.03 215.58 219.13 222.66 226.18 229.69 233.19 236.67 240.15 243.61 247.06 0.350

400 247.06 250.50 253.93 257.34 260.75 264.14 267.52 270.89 274.25 277.60 280.93 0.338

500 280.93 284.26 287.57 290.87 294.16 297.43 300.70 303.95 307.20 310.43 313.65 0.327

600 313.65 316.86 320.05 323.24 326.41 329.57 332.72 335.86 338.99 342.10 345.21 0.315

700 345.21 348.30 351.38 354.45 357.51 360.55 363.59 366.61 369.62 372.62 375.61 0.304

800 375.61 378.59 381.55 384.50 387.45 390.38 0.295

Basic resistance values according to DIN 43760 for Pt 100

deg

11

Page 12

Operation

Replace temperature sensing element

If necessary the temperature sensing element can be replaced during operation.

F

1. Cut off power supply to temperature sensor.

2. Remove cover . Fig. 4, Fig. 5

E

3. Disconnect wires from terminals.

4. Unscrew the temperature sensing element with a screwdriver.

F

5. Insert new temperature sensing element and fasten with a screwdriver.

6. Connect terminals according to wiring diagram. Fig. 1, Fig. 2

7. Install cover .

E

Annex

Fault finding list

Fault:

Remedy:

Remedy:

If faults occur that are not described here, please contact our subsidiary or agency in

your country.

The temperature switch gives an alarm during normal operation.

Check whether the cable leading to the resistance thermometer is

damaged.

Check the resistance thermometer for correct measuring results

(basic resistance values according to DIN 43760 for Pt 100).

12

Page 13

For your notes

13

Page 14

Annex – continued –

Declaration of conformity

We hereby declare that the equipment TRG 5-53, TRG 5-54, TRG 5-55, TRG 5-56,

TRG 5-57 and TRG 5-58 conform to the following European guidelines:

■

LVD guideline 73/23/eec version 93/68/eec

■

EMC guideline 89/336/eec version 93/68/eec

■

Pressure Equipment Directive (PED) 97/23/EC of 29 May 1997

which are based on the following harmonised standards:

■

LV standard EN 50 178

■

EMC standard EN 50 081-2, EN 50 082-2

■

DIN standard 3440 (relevant for PED)

EC Type Examination (Module B) and Production Quality Assurance (Module D)

according to PED 97/23/eec.

This declaration is no longer valid if modifications are made to the equipment without

consultation with us.

Bremen, 12th June 2001

GESTRA GmbH

Head of the Design Dept.

Uwe Bledschun

Academically qualified engineer

Key

Measuring tip

D

J

Insulating seal

K

Screwed socket

14

Quality Assurance Representative

Lars Bohl

Academically qualified engineer

Page 15

Examples of installation

J J

J

≥ 100

J

Fig. 7

Fig. 6

D

≥ 100

D

Fig. 8

K

K

Fig. 9

15

Page 16

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: sales@flowserve.com

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 0034 91 /5152032

Fax 003491/4136747; 5152036

E-mail: gestra@gestra.es

Italia

Flowserve S.p. A.

Flow Control Division

Via Prealpi, 30 – 20032 Cormano (MI)

Tel. 0039 02 /6632 51

Fax 00 39 02 /66 32 55 60

E-mail: infoitaly@flowserve.com

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/6198770

Fax 00351 22 /6107575

E-mail: gestra@gestra.pt

®

GESTRA GmbH

P. O. Box 10 54 60, D-28054 Bremen, Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03- 0, Fax +49 (0) 421 35 03 -393

E-Mail gestra.gmbh@flowserve.com, Internet www.gestra.de

A Unit of Flowserve Corporation

810428-02/803c · © 1998 GESTRA GmbH · Bremen · Printed in Germany

16

Loading...

Loading...