Page 1

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East 1978 Foreman Dr.

Flow Control Division Provo, Utah 84606 Cookeville, TN 38501

www.flowserve.com Phone: 801 373 3028 Phone: 931 432 4021

SR Limit Switch Method

3-Position Control/Dribble Control SR Limit Switch Method

Introduction

The Automax UltraSwitch XLA series limit switch is designed to

operate an automated valve package through three distinct

positions with the mid position fully adjustable. The XLA series

can be easily mounted to an Automax SuperNova spring return

actuator with line mounted 3-way and 2-way solenoid valves

mounted in series for a complete 3-position control package. In

the event of electrical or pneumatic failure, the springs return the

actuator to the fail position. The XLA UltraSwitch utilizes

adjustable cams for precise mid-position calibration. Stopping in

the center for a 3-way valve or stopping near the end of travel for

tank topping dribble control is easily accomplished by adjusting

the pinpoint accurate cams.

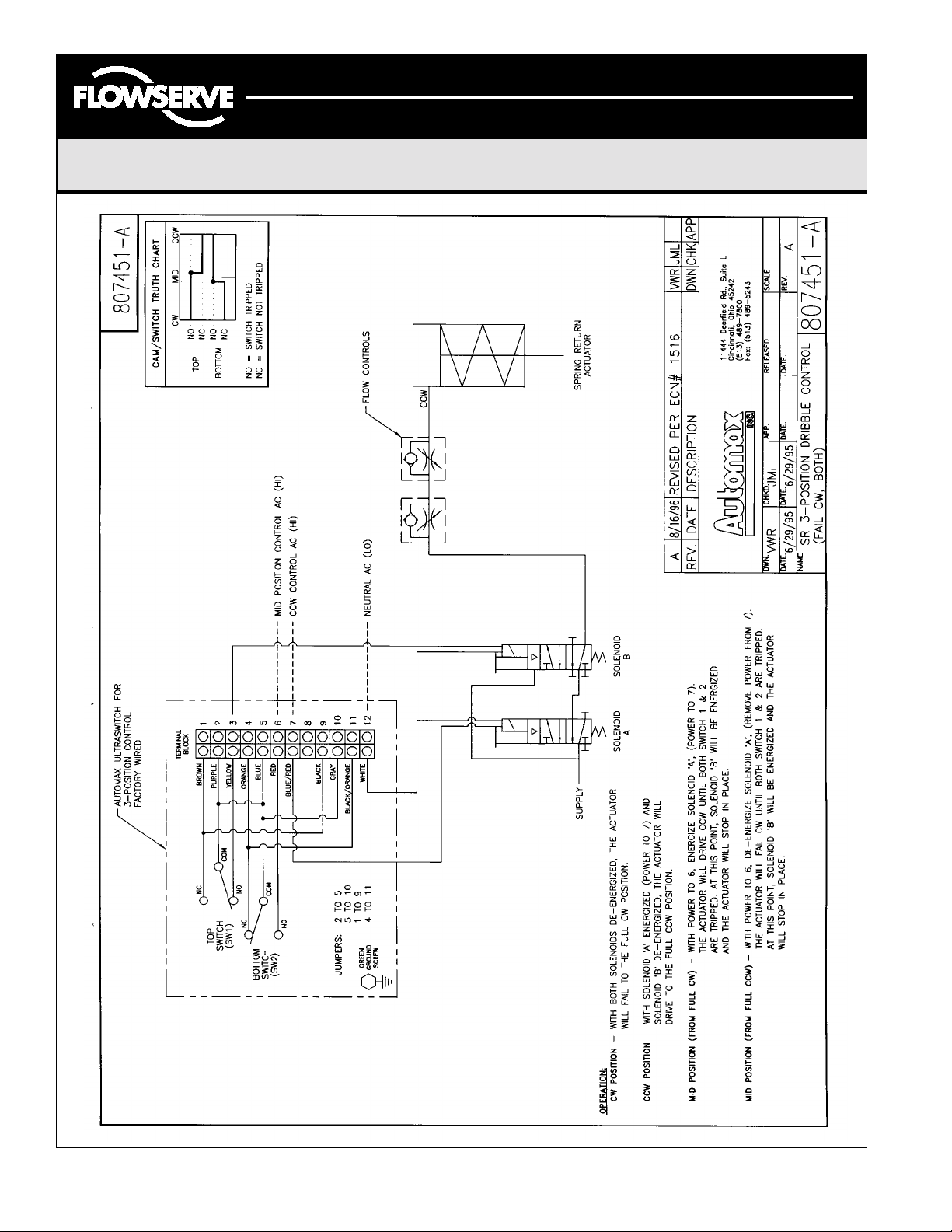

Operation (see schematic 807451 on back)

The Spring Return limit switch method 3-position control package

utilizes the Automax UltraSwitch XLA series limit switch complete

with a 3-way and a 2-way solenoid valve. The XLA series limit

switch contains (2) 15 amp SPDT mechanical switches with an

integral cam assembly for mid-position control. Power to terminal

block connection #7 will drive the actuator counterclockwise

(CCW). Power to terminal block connection #6 and #7 will drive

the actuator to the mid position from the clockwise (CW) position.

Power to terminal block connection #6 will drive the actuator to the

mid position from the CCW position. With both solenoids

de-energized, the springs will fail the actuator to the full CW

position. At the preset mid-position, the top and bottom switches

will trip simultaneously, energizing the 2-way solenoid valve and

locking the actuator in place.

6. Loosen the lock-down screw on the top cam.

7. Adjust the bottom cam to trip the switch. The switch should

remain tripped from the mid to the full CCW position.

8. Tighten the lock-down screw to secure the position of the

bottom cam.

9. For accurate setting of the mid position, see calibration notes

below.

10. Clean the base and lid flanges of the UltraSwitch and replace the

lid on the base. Make sure the wires are not caught between

the flanges, and tighten the captive cover screws.

Calibration Notes

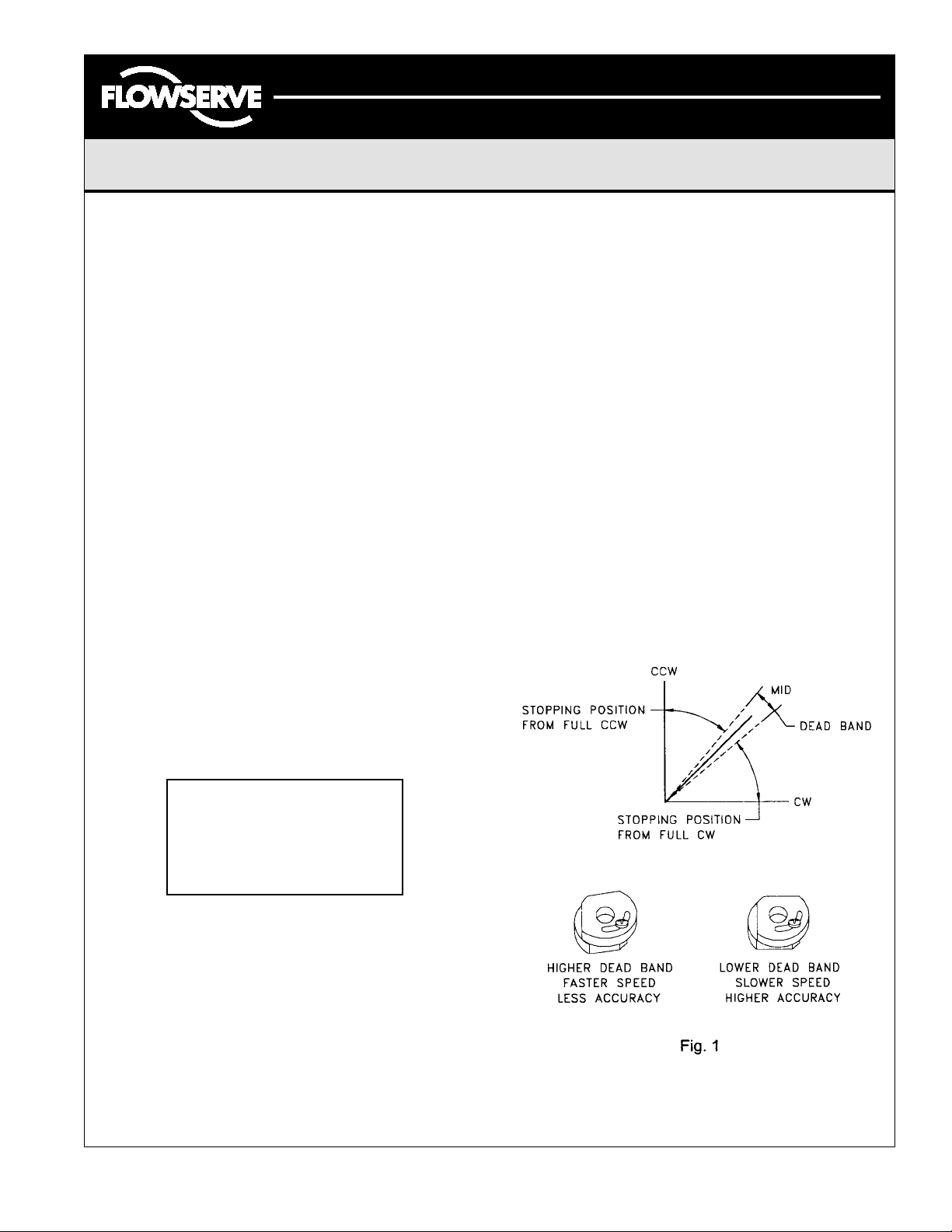

The accuracy of the mid position and speed of operation are

interdependent. If a more precise location of the mid position is

required, then the speed of operation must be reduced through the

adjustment of the speed controls. If a faster speed of operation is

required, the mid position must be calibrated with a higher dead

band, thus reducing the accuracy of the mid position. (Dead band is

the overlap between the switches.) (see Fig. 1).

CAUTION:

To prevent ignition of hazardous

atmospheres, keep unit tight while

circuits are alive. Disconnect supply

circuit before opening.

Calibration

1. Loosen the (4) captive cover screws of the UltraSwitch and

remove the lid, turning slightly while lifting.

2. Loosen the setscrews in the top cam to allow free rotation of

the integral cams.

3. Jog the actuator to the desired mid-position by depressing

the solenoid override or applying power to the solenoid.

Energizing the 2-way solenoid valve will block air in the

actuator at the desired mid position.

4. Adjust the top cam to trip the switch. The switch should

remain tripped from the full CW to the mid position.

5. Tighten the setscrews in the top cam.

LML0004-0 (AUTO-34) 3/02

©

2002, Flowserve Corporation, Printed in USA

Page 1 of 2

Page 2

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East 1978 Foreman Dr.

Flow Control Division Provo, Utah 84606 Cookeville, TN 38501

www.flowserve.com Phone: 801 373 3028 Phone: 931 432 4021

SR Limit Switch Method

LML0004-0 (AUTO-34) 3/02

©

2002, Flowserve Corporation, Printed in USA

Page 2 of 2

Loading...

Loading...