Page 1

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 2233 Phone: 931 432 4021

SNA250 / SNA300

All actuators are factory lubricated for life, but still should be

protected from the elements and stored indoors until ready for

use. The ports of the actuator are plugged as supplied from

the factory. If actuators are stored for a long period of time

prior to installation, the units should be stroked periodically

to prevent the seals from taking a set.

Prior to assembly, check the mounting surfaces, the stem

adaptor and the bracket to assure proper fit. Manually open

and close the valve to insure freeness of operation. Be sure

the valve and Automax actuator rotate in the same direction

and are in the same position (i.e., valve open, actuator open).

Secure the valve with the stem vertical. Bolt the bracket to the

valve and place the stem adaptor on the valve stem. Position

the actuator over the valve and lower to engage the stem

adaptor to the actuator shaft.

Continue to lower until the actuator seats on the bracket

mounting surface. In order to align the bolt holes, it may be

L

L/2

necessary to turn or stroke the actuator a few degrees and/or

adjust the actuators travel stops. Bolt the actuator to the bracket.

After consulting the valve manufacturer’s recommendations,

adjust the travel stop bolts of the actuator for the proper open

or closed valve position. Adjust the Stop Bolt (8) until the

desired travel is obtained and reinstall O-ring (10) and Nut (9).

Pneumatically stroke the actuator several times to ensure

proper operation with no binding of the stem adaptor. If the

actuator is equipped with an UltraSwltch or other accessories,

adjust them at this time.

To prolong actuator life use only clean, dry plant air. Lubricated air is

not required, however it is recommended particularly for high cycle

applications.

CAUTION: Do not use lubricated air with positioners.

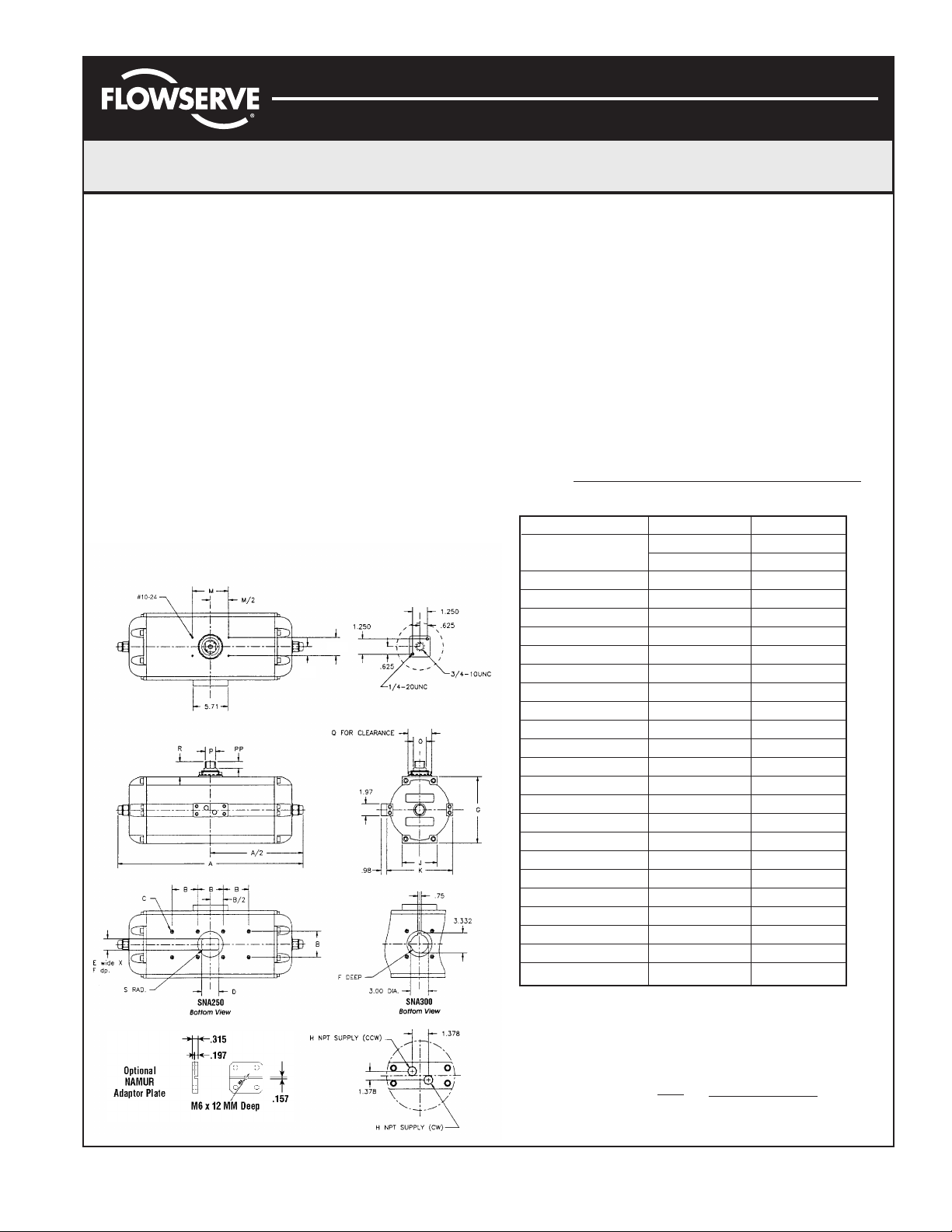

Dimensional Information

MODEL SNA250 SNA300

(DA & SR) 27.32 32.60

A

180° 39.14 44.00

B 4.250 5.000

C 5/8 - 11x.63 5/8 - 11x.86

D 2.87 N/A

E 1.850 N/A

F 1.81 2.50

G 11.02 13.39

H(NPT) 1/2 1/2

J 5.91 6.30

K 11.02 13.39

L 1.181 1.181

M 5.118 5.118

N➁➂ 10 - 24 10 - 24

OØ 2.20 2.44

P 1.969 1.969

PP 0.98 0.98

QØ 3.75 3.75

R 1.65 1.65

S 0.24 N/A

Wts. lbs. (DA) 137 217

Wts. lbs. (SR) 172 288

Volume (IN

Volume (IN

Notes:

➀ Actuators shown in the full clockwise (CW) position as viewed from

the accessory side.

➁ Accessory mounting holes not for gear override or stop block.

Consult factory.

➂ Use studs only to mount. Bolts are not recommended.

④ Air consumption per 90° = V Supply Pressure + 14.7

(Standard cubic feet) 1728 14.7

3

) CW 757 1403

3

) CCW 720 1019

(

)

FCD AXAIM0005-00 (LMR0014-1) (AUTO-5) 03/05 Page 1 of 4

©

2005, Flowserve Corporation, Printed in USA

Page 2

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 2233 Phone: 931 432 4021

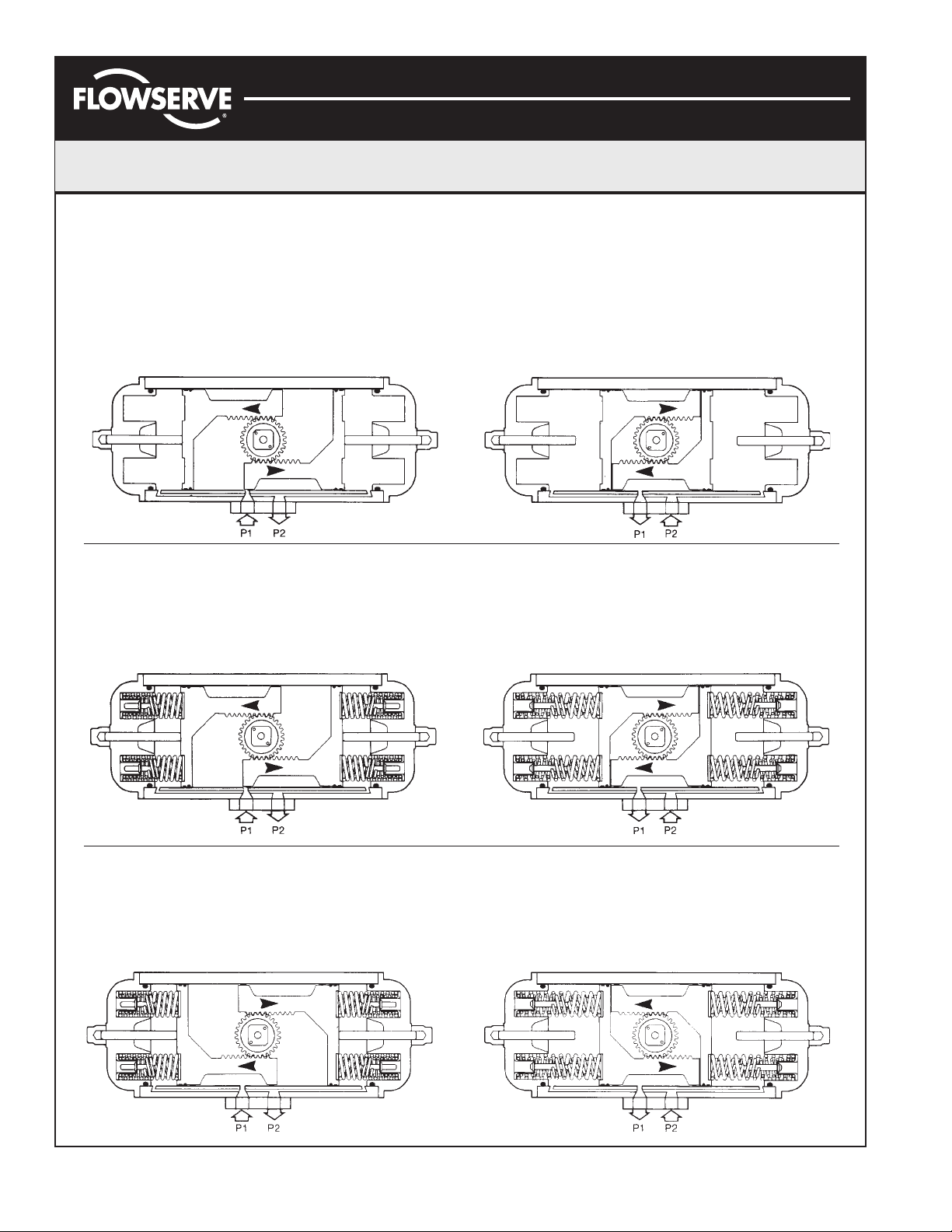

Operation (as viewed from top of actuator)

Double Acting

Applying air pressure to Port 1 drives the pistons Applying air pressure to Port 2 drives the pistons

outward, which turns the pinion counterclockwise as inward, which turns the pinion clockwise as the air

the air volume on the outside of the pistons exhausts volume on the inside of the pistons exhausts through

through Port 2. Port 1.

Spring Return (Fail CW)

Applying air pressure to Port 1 drives the pistons Exhausting the air pressure from Port 1 allows

outward, which compresses the springs and turns stored energy of the springs to drive pistons inward,

the pinion counterclockwise as the air volume on the turning the pinion clockwise. Air volume on outside

outside of the pistons exhausts through Port 2. of pistons vents through Port 2.

Spring Return (Fail CCW)

Applying air pressure to Port 1 drives the pistons Exhausting the air pressure from Port 1 allows stored

outward, which compresses the springs and turns energy of the springs to drive pistons inward, turning

the pinion clockwise as the air volume on the outside the pinion counterclockwise. Air volume on outside of

of the pistons exhausts through Port 2. pistons vents through Port 2.

FCD AXAIM0005-00 (LMR0014-1) (AUTO-5) 03/05 Page 2 of 4

©

2005, Flowserve Corporation, Printed in USA

Page 3

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 2233 Phone: 931 432 4021

Maintenance Instructions

Disassembly Procedures

1. Disconnect all air and electrical supplies from actuator.

2. Remove all accessories from actuator and dismount

actuator from valve.

3. Remove the 16 Endcap Screws (11, 12). When

removing endcap screws on the supply side, apply low

heat to loosen. Failure to apply heat may result in

broken bolts.

WARNING: Loaded Springs in Endcaps, should be

removed with caution.

4. SR - The Springs (21-24) will push the Endcaps off, releasing the spring load prior to the disengagement of

the Endcap Screws (11, 12). Remove the Endcaps (2)

and Spring Cartridge (21-24).

DA- Remove the Endcaps (2). Step 6 will push the

Endcaps (2) from the Body (1).

5. Rotate Pinion (3) counterclockwise (DA & SR-FCW) or

clockwise (DR & SR-FCCW) to drive the Pistons (16) off

the end of the rack. Pull the Left Piston (16) from the

Body (1).

6. Remove the Right Piston (16) by pushing out through

inside of Body (1).

7. Remove the Pinion Snap Ring (7), and pinion washer

(6).

8. Tap Pinion (3) lightly with plastic mallet to remove.

Reassembly Procedures

1. Inspect all parts for wear and replace any worn parts

as needed. Replace all ‘O’-rings.

2. Clean all components and lightly grease cylinder bore,

pinion and seals per temperature rating notes. See

page 4.

3. Reverse the disassembly procedures to reassemble.

4. The standard Pinion (3) orientation is with the drive

pocket parallel with the Body (1) in the CW position.

5. When fitting the Pistons (16) ensure the teeth engage

the Pinion (3) at the same time by measuring in from

the edge of the Body (1) the same distance from each

end. Note: the orientation of the pistons will determine

the operation of the actuator. Refer to the diagrams

under “Operation” for correct piston position.

6. When assembling a spring return actuator, stand

actuator cylinder vertical when inserting spring

cartridges. If this is not possible, make sure spring

cartridges are fully seated in piston pockets when

installing Endcap.

7. Adjust the Stop Bolt (8) until the desired travel is

obtained and reinstall O-ring (10) and Nut (9).

8. Test the actuator for smooth operation and air leakage

at service pressure before reinstalling.

Changing Number of Springs

Changing Pinion Orientation

1. Disconnect all air and electrical supplies from actuator.

2. Remove all accessories from actuator and dismount

actuator from valve.

3. Remove the Pinion Snap Ring (7) and Pinion Washer

(6).

4. Tap Pinion (3) lightly with plastic mallet to remove.

5. Reverse Steps 3 & 4 with new Pinion (3) orientation.

FCD AXAIM0005-00 (LMR0014-1) (AUTO-5) 03/05 Page 3 of 4

©

2005, Flowserve Corporation, Printed in USA

1. Follow the Disassembly Procedures through step 5.

2. Determine spring combination, consult catalog torque

charts, distributor or factory. Simply add or remove

one or more of the spring cartridges.

3. Reassemble the actuator, paying special note to step 6

in reassembling procedures.

Page 4

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 2233 Phone: 931 432 4021

Item

No.

1 Body 1 Extruded hard anodized aluminum

2 Endcap 2 Die Cast Aluminum.Electrostatic Poly

3 Pinion 1 Nickel Plated Steel

4 Upper pinion ‘O’-ring ➀ 1 Nitrile rubber

5 Lower pinion ‘O’-ring ➀ 1 Nitrile rubber

6 Pinion washer ➀ 1 Nylon

7 Pinion snap ring ➀ 1 Steel / plated

8 Stop bolt 2 Steel / plated

9 Stop bolt retaining nut 2 Steel / plated

10 Stop bolt ‘O’-ring ➀ 2 Nitrile rubber

11 Endcap screw 8 Stainless steel

12 Endcap screw 8 Stainless steel

13 Piston and Endcap seal ➀ 4 Nitrile rubber

14 Piston guide band 2 PTFE

15 Piston guide 2 PTFE

16 Piston 2 Extruded aluminum

17 Connection base 1 Extruded aluminum, anodized

18 Connection base seal ➀ 2 Nitrile rubber

19 Connection base screw 4 Stainless steel

20 Spring ➁ 12 Steel electrostatic resin coated

21 Spring ➁ 12 Steel electrostatic resin coated

22 Spring Cartridge ➁ 12 Steel / plated

23 Spring Cartridge ➁ 12 Steel / plated

24 Spring Cartridge ➁ 12 Steel / plated

25 NAMUR adaptor plate 1 Aluminum / Anodized

Part Description Qty. Materials

Note:

➀ Parts included in a Seal Kit

➁ See Torque Chart for available combinations

SNA250 / SNA300

Seal Kits

Buna Seal Kit Number NN - (Actuator Model No.) - SK B

Buna Seal Kit Number NN - (Actuator Model No.) - SK V

Seal kit consists of all sealing parts.

Pressure Rating

150 psig maximum

Temperature Ratings

1

Standard

High Temp

Low Temp

Notes:

1

For standard applications, use multi-purpose polymer

fortified grease, such as Dubois Chemicals MPG-2.

2

For low temperature and high temperature applications,

use special formulated grease such as Dow Corning

Nitrile -20° F to +175°F

2

Viton 0°F to +300°F

2

Silicon-based -55°F to +175°F

®

55.

FCD AXAIM0005-00 (LMR0014-1) (AUTO-5) 03/05 Page 4 of 4

©

2005, Flowserve Corporation, Printed in USA

Loading...

Loading...