Page 1

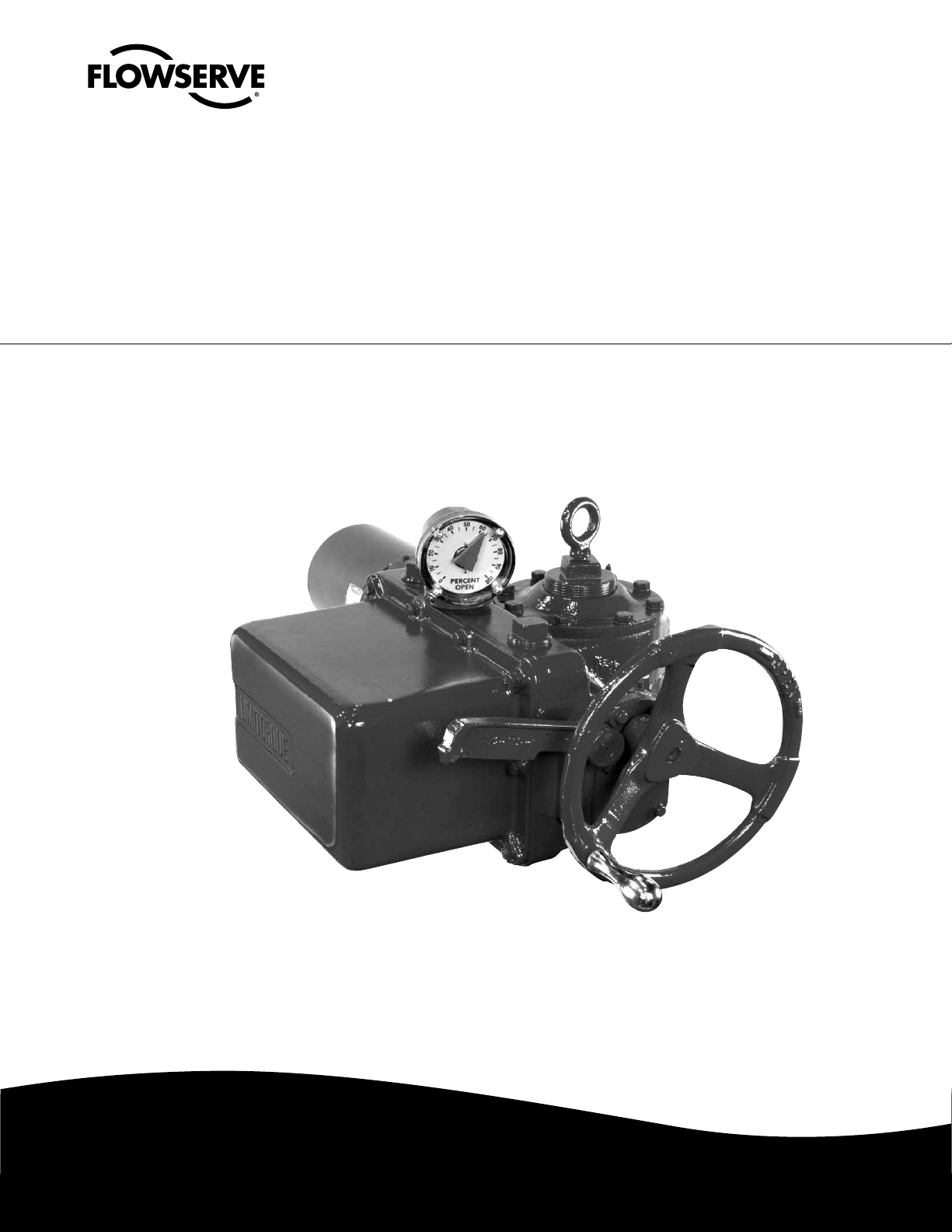

USER INSTRUCTIONS

Limitorque

FCD LMENIM1401-04-AQ – 1/15

®

SMB Series/SB Series

Installation

Operation

Maintenance

Experience In Motion

Page 2

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Contents

1 Introduction 6

2 Product Capabilities and Features 7

3 Actuator Weights 10

4 Installation Instructions 11

4.1 Safety Precautions 11

4.2 Safety Practices 12

4.3 Actuator Preparation 12

4.3.1 Mounting Base 13

4.3.2 Stem Acceptance 13

4.3.3 Terminal Connections 14

4.4 Setting The Limit Switch 14

4.4.1 Two-Train Geared Limit Switch 15

4.4.2 Four-Train Geared Limit Switch 18

4.5 Setting Torque Switch 20

4.5.1 SMB-000 “Cam Style” Double Torque Switch 20

4.5.2 SMB-000 and SMB-00 “C Style” Double Torque Switch 23

4.5.3 SMB-0 through SMB-5 Double Torque Switch 25

4.6 Position Indication 27

4.6.1 Local Position Indicator 27

4.6.2 Remote Position Indicator (50 ohm or 1000 ohm Potentiometer) 27

4.6.3 Remote Position Indicator (Resistance-to-Current Signal Converter) 28

4.7 Additional Electrical Components 30

4.7.1 Reversing Starter 30

4.7.2 Overload Relays 30

4.7.3 Control Station 31

5 Operation 32

5.1 Motor Operation 32

5.2 Manual Operation 33

5.2.1 SMB-000 and SMB-00 33

5.2.2 SMB-0 through SMB-4 34

5.2.3 SMB-5 through SMB-5T 34

6 Maintenance 35

6.1 Routine Maintenance 35

6.2 Major Maintenance 36

6.3 Lubrication 36

6.3.1 Lubrication Inspection 36

6.3.2 Standard Lubricant 37

6.3.3 Minimum Lubricant Qualities Required 38

7 SMB Disassembly and Reassembly 39

7.1 SMB-000 39

2

7.1.1 To Replace the Stem Nut Only 39

Page 3

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

7.1.2 SMB-000 Disassembly 40

7.1.3 SMB-000 Reassembly 41

7.1.4 Gasket Instructions 41

7.2 SMB-00 46

7.2.1 To Replace the Stem Nut Only 46

7.2.2 SMB-00 Disassembly 47

7.2.3 SMB-00 Reassembly 48

7.2.4 Gasket Instructions 49

7.3 SMB-0, 1, 2, 3 and 4 57

7.3.1 To Replace the Stem Nut Only 57

7.3.2 SMB-0, 1, 2, 3 and 4 Disassembly 58

7.3.3 Worm and Torque Spring Disassembly 59

7.3.4 SMB-0, 1, 2, 3 and 4 Reassembly 60

7.3.5 Gasket Instructions 60

7.4 SMB-5 (Thrust and Torque) and SMB-5T (Torque Only) 67

7.4.1 SMB-5 and SMB-5T Disassembly 67

7.4.2 SMB-5 and SMB-5T Reassembly 70

8 SB Disassembly and Reassembly 80

8.1 SB-00 80

8.1.1 SB-00 Disassembly/Stem Nut Removal 80

8.1.2 SB-00 Reassembly/Stem Nut Installation 81

8.2 SB-0 84

8.2.1 SB-0 Disassembly/Stem Nut Removal 84

8.2.2 SB-0 Reassembly/Stem Nut Installation 85

8.3 SB-1 88

8.3.1 SB-1 Disassembly/Stem Nut Removal 88

8.3.2 SB-1 Reassembly/Stem Nut Installation 88

8.4 SB-2 91

8.4.1 SB-2 Disassembly/Stem Nut Removal 91

8.4.2 SB-2 Reassembly/Stem Nut Installation 92

8.5 SB-3 95

8.5.1 SB-3 Disassembly/Stem Nut Removal 95

8.5.2 SB-3 Reassembly/Stem Nut Installation 96

8.6 SB-4 99

8.6.1 SB-4 Disassembly/Stem Nut Removal 99

8.6.2 SB-4 Reassembly/Stem Nut Installation 99

9 Troubleshooting 103

10 How to Order Parts 104

11 EC Declaration of Conformity 105

flowserve.com

3

Page 4

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Figures

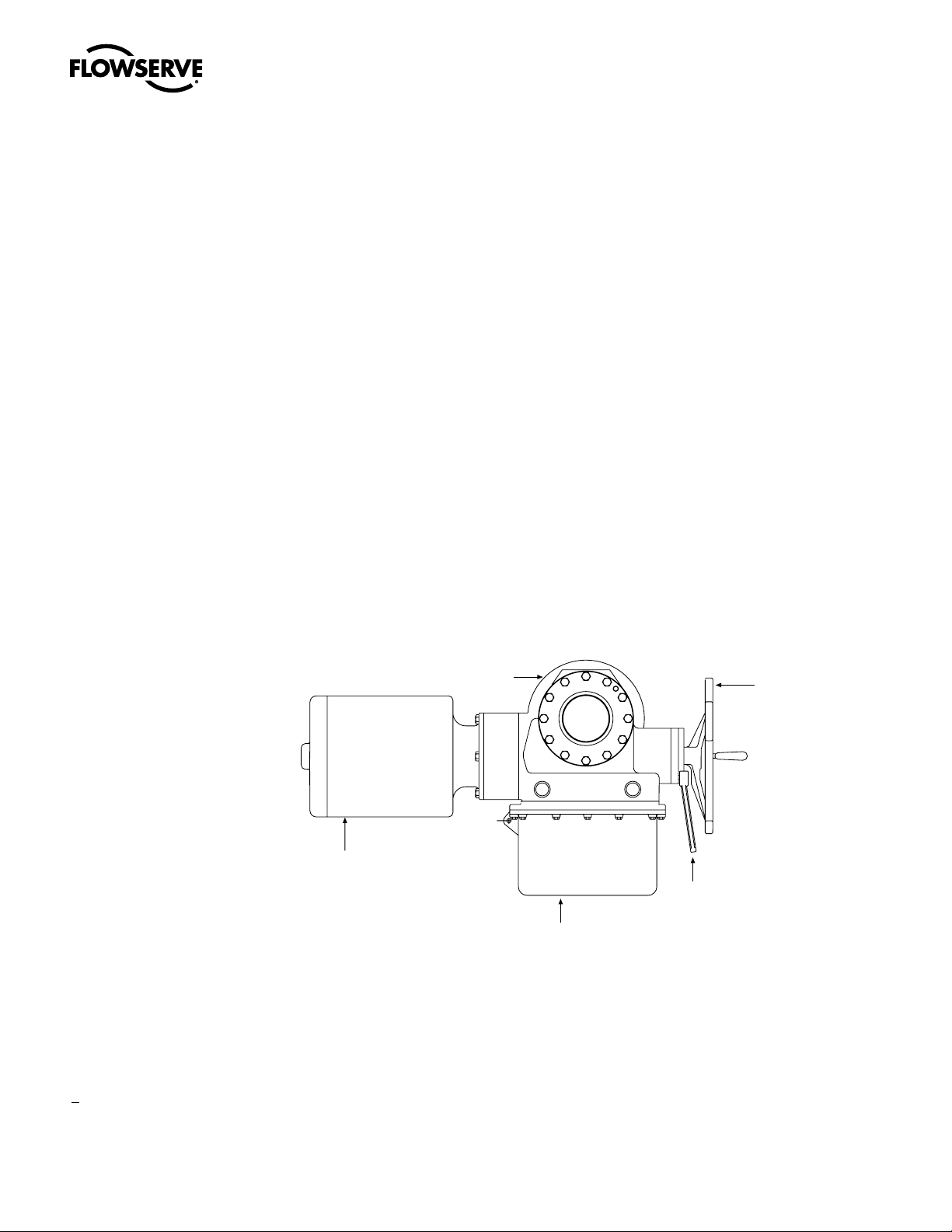

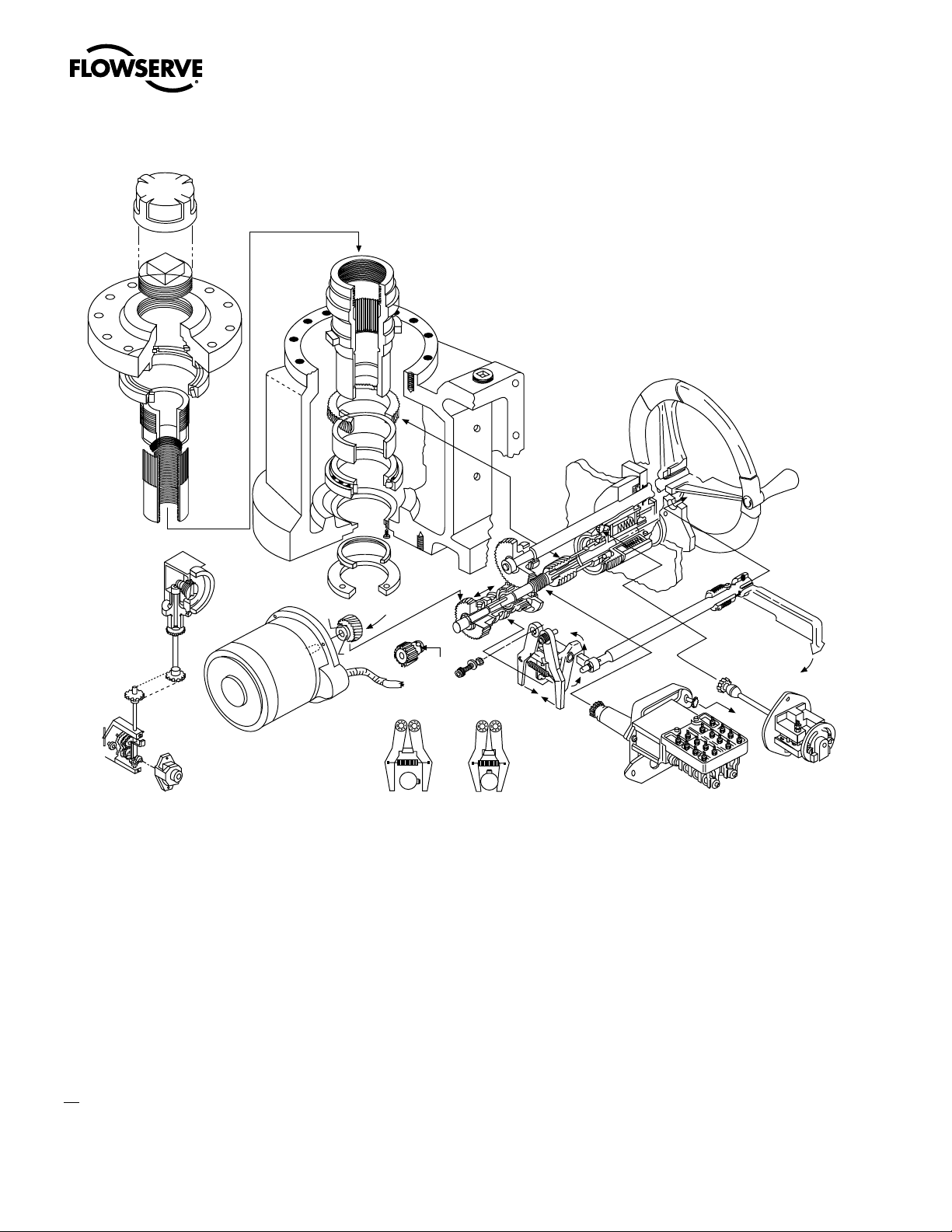

Figure 2.1 – Typical SMB (0 through 4) 8

Figure 4.1 – Wiring Connections 14

Figure 4.2 – Two-Train Geared Limit Switch – Rotor-Type 16

Figure 4.3 – Four-Train Geared Limit Switch – Rotor Type 18

Figure 4.4 – SMB-000 “Cam Style” Double Torque Switch 21

Figure 4.5 – SMB-000 and SMB-00 “C Style” Double Torque Switch 23

Figure 4.6 – SMB-0 through SMB-5 Double Torque Switch 25

Figure 4.7 – Typical Connection for a 50-ohm Potentiometer 29

Figure 4.8 – Typical Connection for a 1000-ohm Potentiometer 29

Figure 4.9 – Typical Connection for R/I Signal Converter (Older Version) 29

Figure 4.10 – Typical Connection for PT20SD R/I Converter 30

Figure 4.11 – Typical Wiring Diagram – Built-in Reversing Starter and Control Station for a

Three-Phase Power Supply 31

Figure 7.1 – SMB-000 Parts Diagram – Side View 42

Figure 7.2 – SMB-000 Parts Diagram – Top View 43

Figure 7.3 – SMB-000 Exploded View 44

Figure 7.4 – SMB-00 Parts Diagram – Motor End View 50

Figure 7.5 – SMB-00 Parts Diagram – Top View 51

Figure 7.6 – SMB-00 Parts Diagram – Side View 52

Figure 7.7 – SMB-00 Parts Diagram – Side Mounted Handwheel Detail 53

Figure 7.8 – SMB-00 Exploded View 54

Figure 7.9 – SMB-0 through SMB-4 Parts Diagram – Top View 61

Figure 7.10 – SMB-0 through SMB-4 Parts Diagram – Worm Shaft Side View 62

Figure 7.11 – SMB-0 through SMB-4 Parts Diagram – Drive Sleeve Side View 63

Figure 7.12 – SMB-0 through SMB-4 Exploded View 64

Figure 7.13 – SMB-5 and 5T Parts Diagram 73

Figure 7.14 – SMB-5 and 5T Parts Diagram– Top View 74

Figure 7.15 – SMB-5 and 5T Parts Diagram – Declutch Housing Detail 75

Figure 7.16 – SMB-5 and 5T Exploded View 76

Figure 8.1 – SB-00 Parts Diagram 82

Figure 8.2 – SB-0 Parts Diagram 86

Figure 8.3 – SB-1 Parts Diagram 89

Figure 8.4 – SB-2 Parts Diagram 93

Figure 8.5 – SB-3 Parts Diagram 97

Figure 8.6 – SB-4 Parts Diagram 101

4

Page 5

Tables

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

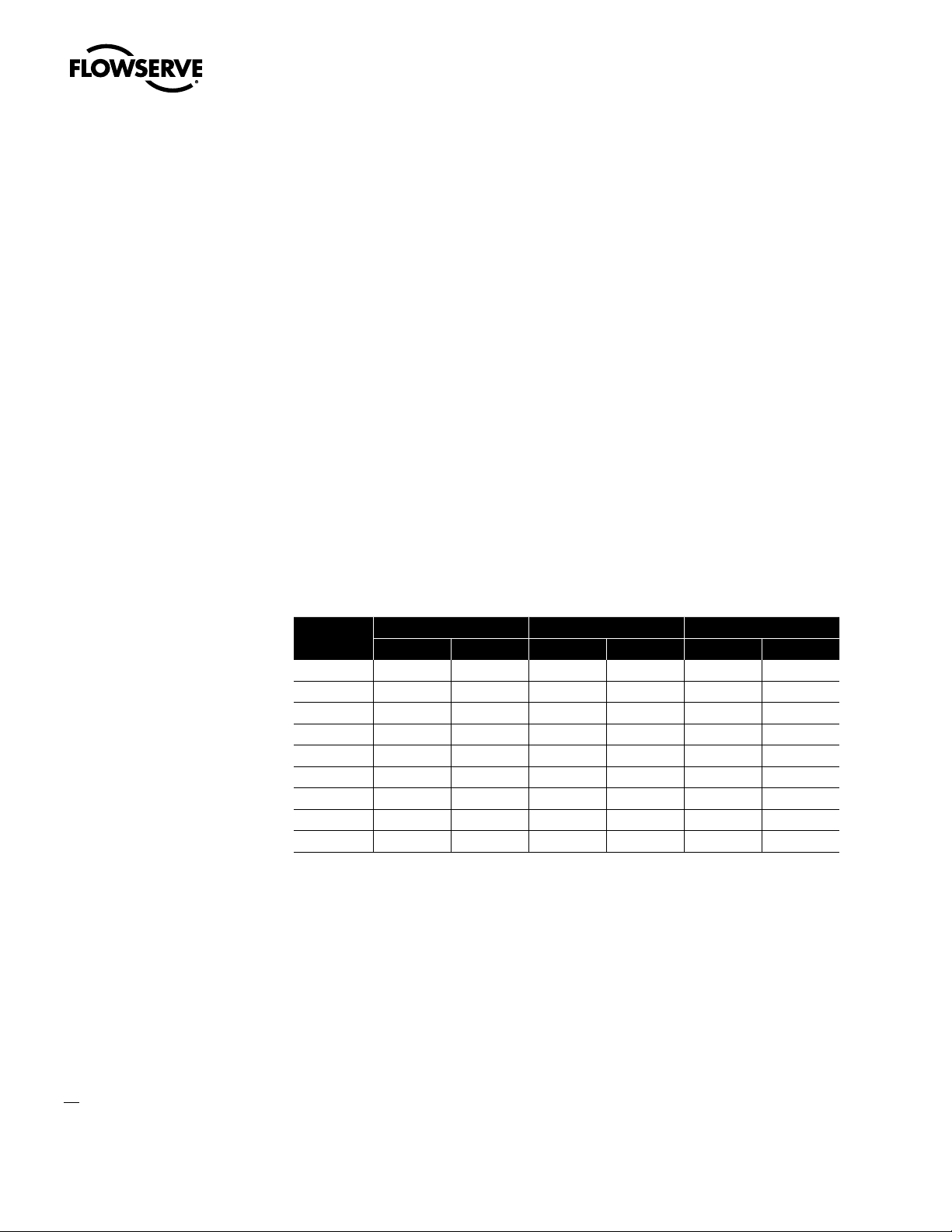

Table 3.1 – Actuator Weights

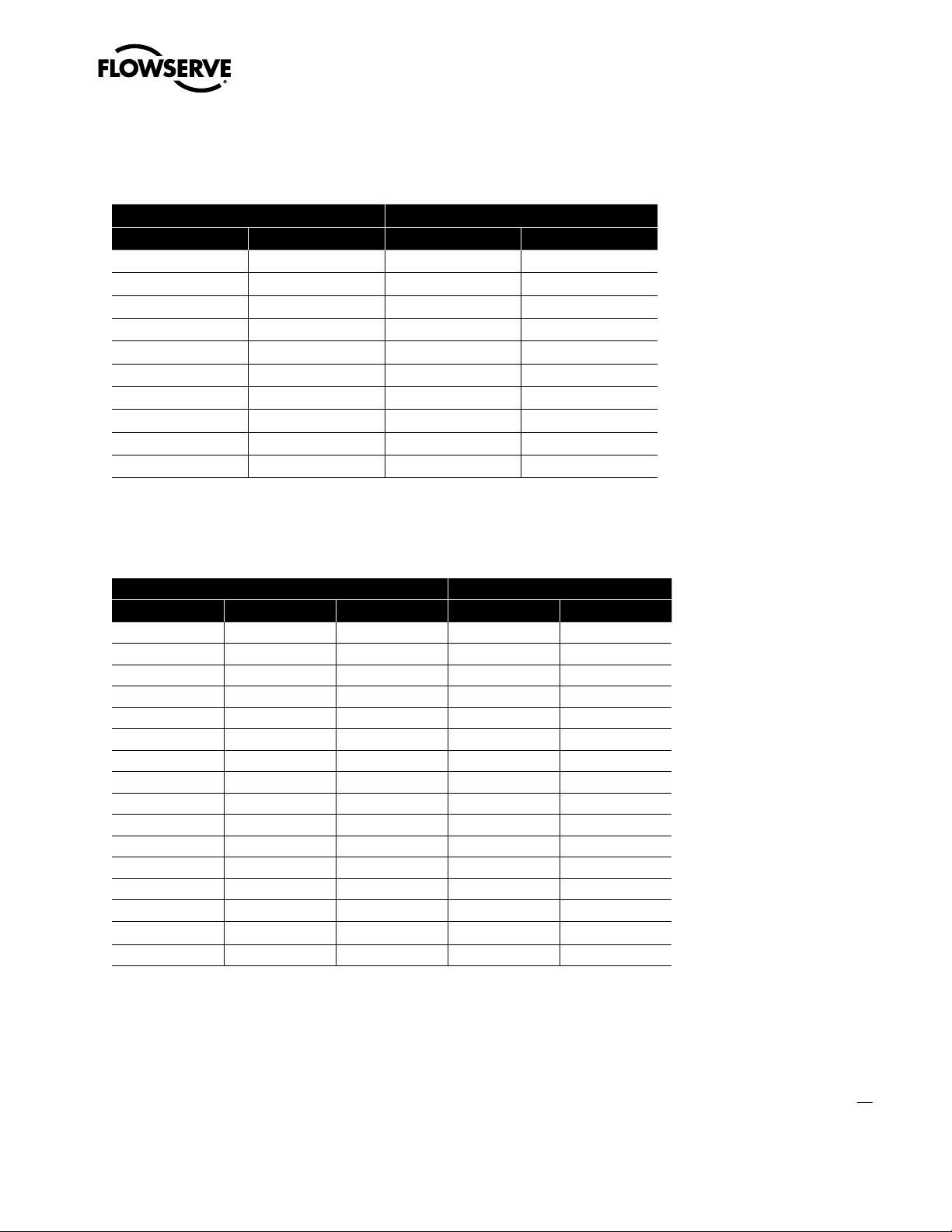

Table 4.1 – Mounting Base Dimensions 13

Table 4.2 – Maximum Stem Acceptance 13

Table 4.3– Terminal Connections 14

Table 4.4 – Two-Train Geared Limit Switch Parts List 17

Table 4.5 – Four-Train Geared Limit Switch Parts List 19

Table 4.6 – SMB-000 “Cam Style” Double Torque Switch Parts List 22

Table 4.7 – SMB-000 and SMB-00 “C Style” Torque Switch Parts list 24

Table 4.8 – SMB-0 through SMB-5 Double Torque Switch Parts List 26

Table 6.1 – Approximate Volume and Weights of Lubricants 37

Table 7.1 – SMB-000 Parts List 45-46

Table 7.2 – SMB-00 Parts List 55-57

Table 7.3 – SMB-0 through SMB-4 Parts List 65-67

Table 7.4 – SMB-5 and 5T Parts List 77-79

Table 8.1 – SB-00 Parts List 83-84

Table 8.2 – SB-0 Parts List 87

Table 8.3 – SB-1 Parts List 90

Table 8.4 – SB-2 Parts List 94

Table 8.5 – SB-3 Parts List 98

Table 8.6 – SB-4 Parts List 102

Table 10.1 – Space Heater Size per Voltage Rating 104

10

flowserve.com

5

Page 6

1

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Introduction

1.1 Purpose

This Installation and Maintenance Manual explains how to install and maintain SMB and SB actuators. Information on installation, operation, disassembly, lubrication, and spare parts is provided.

1.2 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal

injury and damage to the equipment. The user must read and be familiar with these instructions

before attempting installation, operation, or maintenance. Failure to observe these precautions could

result in serious bodily injury, damage to the equipment, void of the warranty, or operational difficulty.

Safety notices are presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning

notices could result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in

personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of actuator installation and

operation.

6

Page 7

2

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Product Capabilities and Features

SMB and SB Series actuators easily operate all types of valves: gate, globe, plug, ball, and butterfly

valves, and specialized valves and mechanisms.

The actuators meet rigid safety requirements. The housing is durable cast-iron or ductile iron,

acceptable for use in the nuclear power industry as well as other industries.

The actuators are available with optional integral controls and other features.

The actuators have a removable stem nut that allows transferring of the actuator from one valve to

another without major disassembly.

2.1 Initial Inspection and Storage Instructions

c WARNING: Read this Installation and Maintenance Manual carefully and completely before

attempting to install, operate, disassemble, or troubleshoot the actuator. Be aware of the electrical

hazards.

2.2 Product Identification

The actuator unit nameplate is located on the back of the unit opposite the limit switch compartment. The nameplate contains the following information:

• Point of Manufacture

• Unit Size

• Order Number

• Serial Number

• Customer Tagging

• CE Stamp

7

flowserve.com

Page 8

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

The motor nameplate is located on the motor. The nameplate contains the following information:

• ID Number

• Run Torque

• RPM

• Full Load Amps

• Insulation Class

• Horsepower

• Service Factor

• Hertz

• Ambient Temperature

• Start Torque

• Enclosure Type

• Volts

• Locked Rotor Amps

• Duty

• Phase

• Motor Code

• Connection Diagram

Figure 2.1 – Typical SMB (0 through 4)

Housing

Motor

Handwheel

Declutch lever

Switch compartment

8

Page 9

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

2.3 Inspection and Recording

Upon receipt of the actuator:

1. Carefully remove the actuator from the shipping carton or skid. Thoroughly examine the equipment for any physical damage that may have occurred during shipment. If damaged, immediately

report the damage to the transport company.

2. A nameplate is attached to each actuator. Record this information for future reference, i.e.

ordering parts or obtaining further information.

2.4 Storage Procedure

NOTE: The following is our recommended storage procedure to retain maximum product integrity

during storage. Failure to comply with recommended procedures will void the warranty. For longerterm storage, contact Limitorque for procedures and recommendations.

Storage (less than 1 year)

Actuators are not weatherproof until properly installed on the valve or prepared for storage.

Store actuators in a clean, dry, protected warehouse, away from excessive vibration and rapid

temperature changes. If the actuators must be stored outside, they must be stored off the ground,

high enough to prevent them from being immersed in water or buried by snow.

1. Position the actuator in storage with motor and switch compartment horizontal.

2. Connect the internal heaters (if supplied) or place desiccant in the switch compartment.

3. Replace all plastic caps or plugs with metal pipe plugs and ensure that all cover bolts are tight.

4. If the actuator is mounted on a valve and the stem protrudes from the actuator, a suitable stem

cover must be provided.

flowserve.com

9

Page 10

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

3

Actuator Weights

The approximate weights of the SMB actuators and SB and SBD options are provided below:

Table 3.1 – Actuator Weights

Actuator

SMB-000 135 62 N/A N/A N/A N/A

SMB-00 200 90 65 30 100 46

SMB-0 350 159 180 83 210 97

SMB-1 460 209 200 92 325 150

SMB-2 580 263 220 101 345 159

SMB-3 1200 553 500 230 825 380

SMB-4 2020 916 795 366 1285 591

SMB-5&5T 3375 1531 N/A N/A N/A N/A

SMB-5XT 5875 2665 N/A N/A N/A N/A

Note 1: With the largest motor, no integral controls, and standard compartment cover.

1

1

Weight

lb. kg lb. kg lb. kg

Adder for SB Adder for SBD

10

Page 11

4

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Installation Instructions

4.1 Safety Precautions

c WARNING: Read this Installation and Maintenance Manual carefully and completely before

attempting to install, operate, or troubleshoot the Limitorque actuator.

c WARNING: Be aware of electrical hazards. Turn off incoming power before working on the

actuator and before opening the switch compartment.

c WARNING: Potential HIGH PRESSURE vessel — be aware of high-pressure hazards associated

with the attached valve or other actuated device when installing or performing maintenance on

the actuator. Do not remove the actuator mounting bolts from the valve or actuated device unless

the valve or device stem is secured or there is no pressure in the line.

c WARNING: For maintenance and/or disassembly of the actuator while installed on the valve,

ensure that the actuator is not under thrust or torque load. If the valve must be left in service, the

valve stem must be locked in such a way as to prevent any movement of the valve stem.

c WARNING: Do not attempt to remove the spring cartridge cap, housing cover, or stem nut

locknut from the actuator while the valve or actuated device is under load.

c WARNING: Do not manually operate the actuator with devices other than the installed handwheel

and declutch lever. Using force beyond the ratings of the actuator and/or using additive force

devices such as cheater bars, wheel wrenches, pipe wrenches, or other devices on the actuator

handwheel or declutch lever may cause serious personal injury and/or damage to the actuator

and valve.

c WARNING: Do not exceed any design limitations or make modifications to this equipment

without first consulting Limitorque.

c WARNING: Actuators equipped with electrical devices (motors, controls) requiring field wiring

must be wired and checked for proper operation by a qualified tradesman.

c WARNING: Use of the product must be suspended any time it fails to operate properly.

flowserve.com

11

Page 12

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

a CAUTION: Do not use oversized motor overload heaters. Instead, look for the cause of the

overload.

a CAUTION: Do not operate the valve under motor operation without first setting or checking the

limit switch setting and motor direction.

a CAUTION: Do not force the declutch lever into the motor operation position. The lever returns to

this position automatically when the motor is energized.

a CAUTION: Do not depress the declutch lever during motor operation to stop valve travel.

a CAUTION: Do not use replacement parts that are not genuine Flowserve Limitorque parts, as

serious personal injury and/or damage to the actuator and valve may result.

a CAUTION: Do not lift actuator/gearbox or actuator/valve combinations with only the eye bolts in

the SMB actuator. These eye bolts are designed for lifting the SMB actuator only.

a CAUTION: Do not lift the actuator by the handwheel

4.2 Safety Practices

The following check points should be performed to maintain safe operation of the SMB or SB

actuator:

• Eye bolts in SMB and SB actuators are designed for lifting only the actuator and not associated

gearboxes or valves.

• Mount the actuator with the motor in a horizontal plane, if possible.

• Keep the switch compartment clean and dry.

• Keep the valve stem clean and lubricated.

• Set up a periodic operating schedule for infrequently used valves.

• Verify all actuator wiring is in accordance with the applicable wiring diagram.

• Carefully check for correct motor rotation direction. If the valve closes when open button is

pushed, the motor leads may have to be reversed.

• Verify the stem nut is secured tightly by the locknut and that the top thread of the locknut is

crimped or staked in two places.

• Use a protective stem cover. Check valve stem travel and clearance before mounting covers on

rising stem valves.

4.3 Actuator Preparation

Replace all molded plastic conduit and top protectors (installed for shipping purposes only) with

metal pipe plugs when installation wiring is complete.

12

Page 13

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

4.3.1 Mounting Base

Table 4.1 – Mounting Base Dimensions

Mounting Holes Tap Dimensions

Actuator Quantity Standard Optional

SMB-000 4

SMB-00 4

SMB-0 4 ¾-10 UNC x 1.00" deep M20-2.5 x 26 mm deep

SMB-1 8

SMB-2 8 ¾-10 UNC x 1.13" deep M20-2.5 x 29 mm deep

SMB-3 8

SMB-4 8 1¼-7 UNC x 2.00" deep M36-4 x 64 mm deep

SMB-5 12 1½-6 UNC x 3.00" deep N/A

SMB-5T 16 1-8 UNC x 2.00" deep N/A

SMB-5XT 16 Consult Factory N/A

5

⁄16-18 UNC x .63" deep N/A

5

⁄8-11 UNC x 1.13" deep M16-2 x 29 mm deep

5

⁄8-11 UNC x 1.00" deep M16-2 x 26 mm deep

7

⁄8-9 UNC x 1.75" deep M30-3.5 x 45 mm deep

4.3.2 Stem Acceptance

Table 4.2 – Maximum Stem Acceptance

Two-piece nut design (drive sleeve & stem nut) Max threaded Max bore & keyway

Actuator inch mm inch mm

3

SMB-000 1.375 35 1.125 w/ ¼ x

SMB-00 1.75 44 1.500 w/

SMB-0 2.375 60 1.875 w/ ½ x

SMB-1 2.875 73 2.438 w/

SMB-2 3.5 89 2.875 w/ ¾ x ¼ 73.0 w/ 20x6

SMB-3 5 127 4.250 w/ 1.0 x

SMB-4 5 127 4.500 w/ 1.0 x ½ 114.0 w/ 32x9

SMB-5 6.25 159 5.250 w/ 1¼ x

SMB-5T N/A N/A 6.000 w/1 ½ x ½ 152.0 w/ 40x11

SMB-5XT N/A N/A 10.000 w/ 1¼ x

SB-00 1.25 32

SB-0 2.375 60

SB-1 2.625 66

SB-2 3.50 89

SB-3 4.00 102

SB-4 5.00 127

⁄32 26.0 w/ 8x3.5

3

⁄8 x 1⁄8 37.0 w/ 10x4

3

⁄16 48.0 w/ 14x4.5

5

⁄8 x 7⁄32 62.0 w/ 18x5.5

3

⁄8 108.0 w/ 28x8

7

⁄16 133.0 w/ 36x10

5

/8 N/A

flowserve.com

13

Page 14

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

4.3.3 Terminal Connections

Wiring connections to the SMB geared limit switch, torque switch, and Marathon terminal strips are

to be made using ring-tongue terminals* as shown below:

Figure 4.1 – Wiring Connections

A

C

B

Table 4.3– Terminal Connections

AWG Screw Hole Insulation

22-16 #10 Vinyl 18RA-10 .97 .31 .27

18-14 #10 Vinyl 14RB-10 .97 .31 .27

12-10 #10 Vinyl 14RC-10 1.06 .31 .27

Note: Limit switch and torque switch contacts are rated 300 volts per NEMA ICS-2

Thomas &

Betts P/N

A B C

14

Terminals are to be crimped using Thomas & Betts crimping tool WT112M or ERG4001.

Manufacturer: *Thomas and Betts or equal

4.4 Setting The Limit Switch

c WARNING: Disconnect all incoming power before opening or replacing the limit switch compart-

ment cover.

a CAUTION: When wiring control circuits, distinguish between “normally open” and “normally

closed” terminals on the geared limit switch.

a CAUTION: Do NOT attempt to repair the limit switch gear box. Replace entire limit switch gear

box.

a CAUTION: Do NOT use abrasive cloth to clean the silver contacts on the limit switch. Contacts

should be burnished using appropriate burnishing tool.

a CAUTION: Before motor operation, reset the geared limit switch if the actuator has been

dismantled or removed from the valve.

NOTE: Clean the limit switch cover thoroughly and apply a thin coat of grease on machined flange

surfaces before mounting on an explosion proof actuator.

Page 15

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

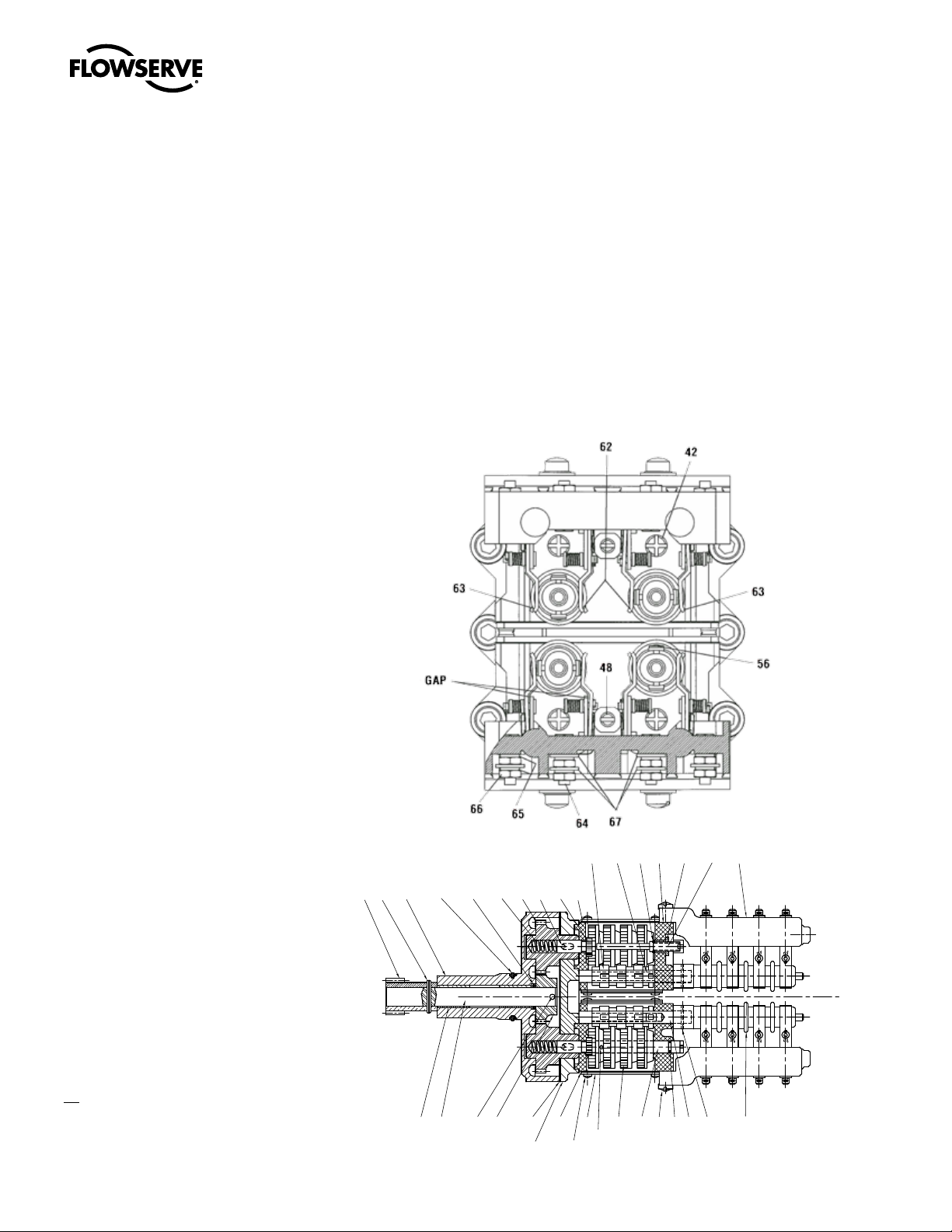

4.4.1 Two-Train Geared Limit Switch

The rotor-type, two-train geared limit switch employs two rotors. Each rotors contains four contacts.

When the rotor is properly set to trip at the desired position, two of these contacts open electric

circuits and two of the contacts close electric circuits. One rotor is normally set to trip at the full open

position of the valve, and the other rotor is normally set to trip at the full close position of the valve.

Each rotor may be adjusted independently of the other:

• First rotor—one circuit is used to open the “open” holding coil circuit of the motor controller, one

circuit is used to control the “open” indicating light.

• Second rotor—one circuit is used to open the “close” holding coil circuit of the motor controller,

one circuit is used to control the “closed” indicating light.

For the geared limit switches to trip at any desired position, follow the setting procedure below.

Piece numbers refer to Figure 4.2 and Table 4.4.

1. Verify all power is OFF.

2. Using the handwheel, manually open the valve to the full open position. See Section 5.2 Manual

Operation. Note the direction of rotation of the Intermittent Gear Shaft (piece #42), located over

the Rotor (piece #49) to be set.

3. Using a screwdriver, turn the Set Rod (piece #48) clockwise until it reaches a stop position.

4. If the Rotor (piece #49) you are setting has not turned 90° to open the contacts that should trip

open at this position, insert screwdriver on the Intermittent Gear Shaft (piece #42). Turn in the

direction noted in Step No. 4 until the Rotor (piece #49) turns and opens the contacts to be set.

5. If the Rotor (piece #49) has turned so that the contacts are already open, turn the Intermittent

Gear Shaft (piece #42) in the opposite direction as previously noted in Step No. 4 until the

contacts close. Turn the Intermittent Gear Shaft (piece #42) slightly in the direction noted in Step

No. 4 until the contacts open. The Rotor (piece #49) is set at the correct position for contact

opening.

Note: In the contact “Close” position, ensure a gap exists between the contact finger and the

L-bracket as seen in figure 4.2

6. Back off the Set Rod (piece #48) until it stops. Place the screwdriver on the Intermittent Gear

Shaft (piece #42) to ensure that the shaft is tight and will not rotate. Do not force.

7. Close the valve completely. Repeat Step No. 1 through 6 to set the tripping position for the other

Rotor (piece #49).

flowserve.com

15

Page 16

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

64 66 67

65

63

62

56

63

42 49

50 41 51 47 43 46 44 52 1

2

Figure 4.2 – Two-Train Geared Limit Switch – Rotor-Type

63

Contact Finger

62

42

56

GAP

GAP

65

64

5 10 3

67

66

L-Bracket

68

69

71

54

9

16

11 6 8 7 55 4 58 45 48 53

61

Page 17

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 4.4 – Two-Train Geared Limit Switch Parts List

Piece Description

1 Cartridge

2 Drive Sleeve and Shaft

3 Drive Pinion

4 Drive Pinion (Secondary)

5 Declutch Spring

6 Bushing

7 O-Ring

8 Pin

9 Groove Pin

10 Washer

11 Oil Seal

41 Gear Frame

42 Intermittent Gear Shaft

43 Intermittent Pinion Shaft

44 Geared Limit Frame Cover

45 Intermittent Gear

46 Intermittent Pinion

47 Stem Spur Pinion

48 Set Rod

49 Rotor

50 Groove Pin

51 Cover Gasket

52 Long Fillet Head Machine Screw

53 O-Ring

54 Setting Rod Bushing

55 Gear Frame Gasket

56 Insert (Rotor)

57 O-Ring (For Intermittent Gear Shaft piece #42) (Not shown)

58 Groove Pin

61 Finger Base

62 Right Hand Finger Assembly

63 Left Hand Finger Assembly

64 Long Hex Head Machine Screw

65 Lockwasher

66 Hex Nut

67 Washer

68 Long Fillet Head Cap Screw

69 Internal Tooth Lockwasher

71 Flat Washer

flowserve.com

17

Page 18

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

25

46

43

53 41

54

48

61

4.4.2 Four-Train Geared Limit Switch

The rotor-type, four-train geared limit switch employs four rotary drum switches. Each rotary drum

switch contains four contacts. When the rotor is properly set to trip at the desired position, two of

these contacts open electric circuits and two of the contacts close electric circuits. One rotor is set

to trip at the full open position of the valve, and one rotor is set to trip at the full close position of the

valve. The other two rotors are set at some intermediate position depending on the application.

For the geared limit switches to trip at any desired position, follow the steps in Section 4.4.1,

Two-Train Geared Limit Switch, with the exception that the piece numbers refer to Figure 4.3 and

Table 4.5.

NOTE: The upper Set Rod (piece #48) allows adjustment of the two adjacent upper rotors, and the

lower Set Rod (piece #48) allows adjustment of the two adjacent lower rotors.

Figure 4.3 – Four-Train Geared Limit Switch – Rotor Type

18

26

21

35

22 23

34

26

24

28

27

30

31

32

29

5552445845

42

57 47 50 49

68

69

71

01-472-0007-3

01-472-0007-3

Page 19

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 4.5 – Four-Train Geared Limit Switch Parts List

Piece Description

21 Cartridge

22 Oilite Bushing

23 Drive Shaft

24 Drive Pinion (Internal)

25 Helical Pinion

26 Groove Pin

27 Drive Sleeve and Gear

28 Declutch Spring

29 Drive Pinion Spur

30 Pin

31 Cartridge Gasket

32 Cartridge Mounting Plate

33 Long Socket Head Cap Screw and Lockwasher

34 O-Ring

35 O-Ring

36 Fillet Head Cap Screw and Lockwasher

41 Gear Frame

42 Intermittent Gear Shaft

43 Intermittent Pinion Shaft

44 Geared Limit Frame Cover

45 Intermittent Gear

46 Intermittent Pinion

47 Stem Spur Pinion

48 Set Rod

49 Rotor

50 Groove Pin

51 Cover Gasket

52 Long Fillet Head Machine Screw

53 O-Ring

54 Setting Rod Bushing

55 Gear Frame Gasket

56 Insert (Rotor)

57 O-Ring

58 Groove Pin

61 Finger Base

62 Right Hand Finger Assembly

63 Left Hand Finger Assembly

64 Long Hex Head Cap Screw

65 Lockwasher

66 Hex Nut

67 Washer

68 Long Fillet Head Cap Screw

69 Internal Tooth Lockwasher

71 Flat Washer

19

flowserve.com

Page 20

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

4.5 Setting Torque Switch

The torque switch is designed to protect the actuator in open and close directions.

c WARNING: Disconnect all incoming power before working on the torque switch.

c WARNING: Do not attempt to remove either the spring cartridge cap or the housing cover from

the actuator while the valve is torque-seated.

a CAUTION: Do not use abrasive cloth to clean the contacts on the torque switch.

a CAUTION: A maximum stop setting plate is furnished on all actuators. Do not exceed this

maximum setting without consulting Limitorque.

NOTE: See Section 4.3.3 for wiring connection requirements.

4.5.1 SMB-000 “Cam Style” Double Torque Switch

NOTE: Torque settings must be made with the switch mounted in the actuator.

Piece numbers correspond to Figure 4.4 and Table 4.6.

To set the torque switch:

1. Verify all electric power is OFF.

2. Loosen Pan Head Screws (piece #30).

3. For open or close operation, set Striker (piece #25) to the required torque setting. Match the edge

of the Striker with the desired number. The higher the number, the higher the torque output of the

actuator.

4. Tighten Pan Head Screws (piece #30).

5. For torque seated valves, operate the valve electrically to seat the valve. Ensure tight shut-off by

tripping the torque switch contacts.

20

Page 21

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

28

91211105 6481437

Figure 4.4 – SMB-000 “Cam Style” Double Torque Switch

5

4

3

2

1

1

5

2

4

3

7

38

39

25

27

23 21 321937 36

A

A

30 32 312522

20

27 24 25 26 25 23 22

44

17 11618333435

21 43 20

2

45

13

15

SECTION A-A

B

42

42

VIEW B-B

B

29

01-474-0056-4

01-474-0056-4

21

flowserve.com

Page 22

22

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 4.6 – SMB-000 “Cam Style” Double Torque Switch Parts List

Piece Description

1 Terminal Block

2 Contact Block

3 Contact Screw

4 Finger Holder

5 Finger

6 Shunt

7 Shunt Washer

8 Rivet

9 Finger Spring Stud

10 Compression Spring

11 Spring Cup Washer

12 Cotter Pin

13 Hex Head Machine Screw

14 Ring Tongue Connector

15 Shakeproof Lockwasher, Internal Teeth

16 Torque Switch Mounting Bracket

17 O-Ring

18 O-Ring

19 Socket Head Cap Screw

20 Cam

21 Torsion Spring

22 Spring Mandrel

23 Dial

24 Shaft

25 Striker

26 Torque Limiting Plate

27 Striker Hub

28 Roll Pin

29 Swage Nut

30 Pan Head Screw

31 Shakeproof Lockwasher, External Teeth

32 Flatwasher

33 Arm

34 Roller

35 Roller Pin

36 Groove Pin

37 Arc Barrier

38 Pan Head Screw

39 Lockwasher, External Tooth

42 Spring Pin

43 Cam Insert

44 Bushing (For piece #16)

45 Washer

Page 23

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

43

4.5.2 SMB-000 and SMB-00 “C Style” Double Torque Switch

NOTE: Torque settings must be made with the switch mounted in the actuator.

NOTE: See Section 4.3.3 for wiring connection requirements.

Piece numbers correspond to Figure 4.5 and Table 4.7.

To set the torque switch:

1. Verify all electric power is OFF.

2. For the open or close direction torque switch, loosen Machine Screw (piece #35) and set Pointer

(piece #7) at the desired torque setting. The higher the number, the higher the torque output of

the actuator.

3. Tighten Machine Screw (piece #35).

4. For torque seated valves, operate the valve electrically to seat the valve. Ensure tight shut-off by

tripping the torque switch contacts.

Figure 4.5 – SMB-000 and SMB-00 “C Style” Double Torque Switch

23

8

14

1

44

13

17

33

2

25

46

11

5

30

34

25

31

39

27

27

29 16

42

47

4

3

45

27

36

5

4

3

2

1

3

2

1

48

6

51

37

20

25

12

9

35

39/52

7

41

27/50

18

01-473-0056-3

01-473-0056-3

2122101528

23

flowserve.com

Page 24

24

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 4.7 – SMB-000 and SMB-00 “C Style” Double Torque Switch Parts List

Piece Description

1 Terminal Block

2 Contact Block

3 Hex Nut - Remove and discard

4 Contact Arm

5 Dial

6 Actuating Link

7 Pointer

8 Tripper Arm

9 Shaft

10 Contact Support

11 Torque Limiter Plate

12 Bushing (SMB-00 only)

13 Roller

14 Roller Pin

15 Contact Finger

16 Terminal Stud

17 Compression Spring

18 Torsion Spring

20 Bearing

21 O-Ring

22 O-Ring

23 Groove Pin

25 Thrust Washer

27 Lockwasher

28 Groove Pin

29 Hex Nut

30 Hex Nut

31 Cotter Pin

33 Pan Head Machine Screw

34 Hex Socket Set Screw

35 Round Head Machine Screw

36 Round Head Machine Screw

37 Insulating Material

39 Flatwasher

41 Round Head Machine Screw

42 Lockwasher, Internal Teeth

43 Socket Head Cap Screw

44 Lockwasher

45 Mounting Bracket

46 Dial Plate (SMB-00 only)

47 Socket Head Cap Screw

48 Lockwasher (SMB-000 only)

49 Insulator (SMB-000 only) - Not Shown

50 Lockwasher (SMB-000 only)

51 Lockwasher (SMB-000 only)

52 Lockwasher (SMB-000 only)

Page 25

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

01-473-0057-3

4.5.3 SMB-0 through SMB-5 Double Torque Switch

NOTE: Torque settings must be made with the switch mounted in the actuator.

NOTE: See Section 4.3.3 for wiring connection requirements.

Piece numbers correspond to Figure 4.6 and Table 4.8.

To set the torque switch:

1. Verify all electric power is OFF.

2. For the open or close direction torque switch, loosen Machine Screw (piece #35) and set Pointer

(piece #7) at the desired torque setting. The higher the number, the higher the torque output of

the actuator.

3. Tighten Machine Screw (piece #35).

4. For torque seated valves, operate the valve electrically to seat the valve. Ensure tight shut-off by

tripping the torque switch contacts.

Figure 4.6 – SMB-0 through SMB-5 Double Torque Switch

8

23

12

5

4

3

3

2

1

3

2

1

13

25

1

2

43

44

17

33

25

37

30

34

25

4

45

35

39

5

7

11

31

42

47

3

20

27

39

27

29 16

36

6

41

27

18

9

01-473-0057-3

2122101528

25

flowserve.com

Page 26

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 4.8 – SMB-0 through SMB-5 Double Torque Switch Parts List

Piece Description

1 Terminal Block

2 Contact Block

3 Hex Nut - Remove and Discard

4 Contact Arm

5 Dial

6 Actuating Link

7 Pointer

8 Pinion

9 Shaft

10 Contact Support

11 Torque Limiter Plate

12 Bushing

13 Spacer

15 Contact Finger

16 Terminal Stud

17 Compression Spring

18 Torsion Spring

20 Bearing

21 O-Ring

22 O-Ring

23 Pin

25 Thrust Washer

27 Lockwasher

28 Pin

29 Hex Nut

30 Hex Nut

31 Cotter Pin

33 Pan Head Self-Tapping Screw

34 Hex Socket Set Screw

35 Round Head Machine Screw

36 Round Head Machine Screw

37 Insulating Material

39 Flatwasher

41 Round Head Machine Screw

42 Lockwasher, Internal Teeth

43 Socket Head Cap Screw

44 Lockwasher

45 Mounting Bracket

47 Socket Head Cap Screw

26

Page 27

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

4.6 Position Indication

4.6.1 Local Position Indicator

NOTE: The local dial position indicator displays valve position. The position indicator can only be

adjusted when the actuator is mounted on the valve. See Figures 7.1-7.3 (SMB-000), 7.4-7.8 (SMB-

00), 7.9-7.12 (SMB-0 through 4), 7.13-7.16 (SMB-5).

To set the position indicator:

1. Disconnect all incoming power and open or remove the Limit Switch Compartment Cover.

2. Place the valve in the fully “close” position.

3. Loosen the round head machine screw that holds the pointer in place, move the pointer to the

“C” position, and retighten the screw.

The indicator is now set.

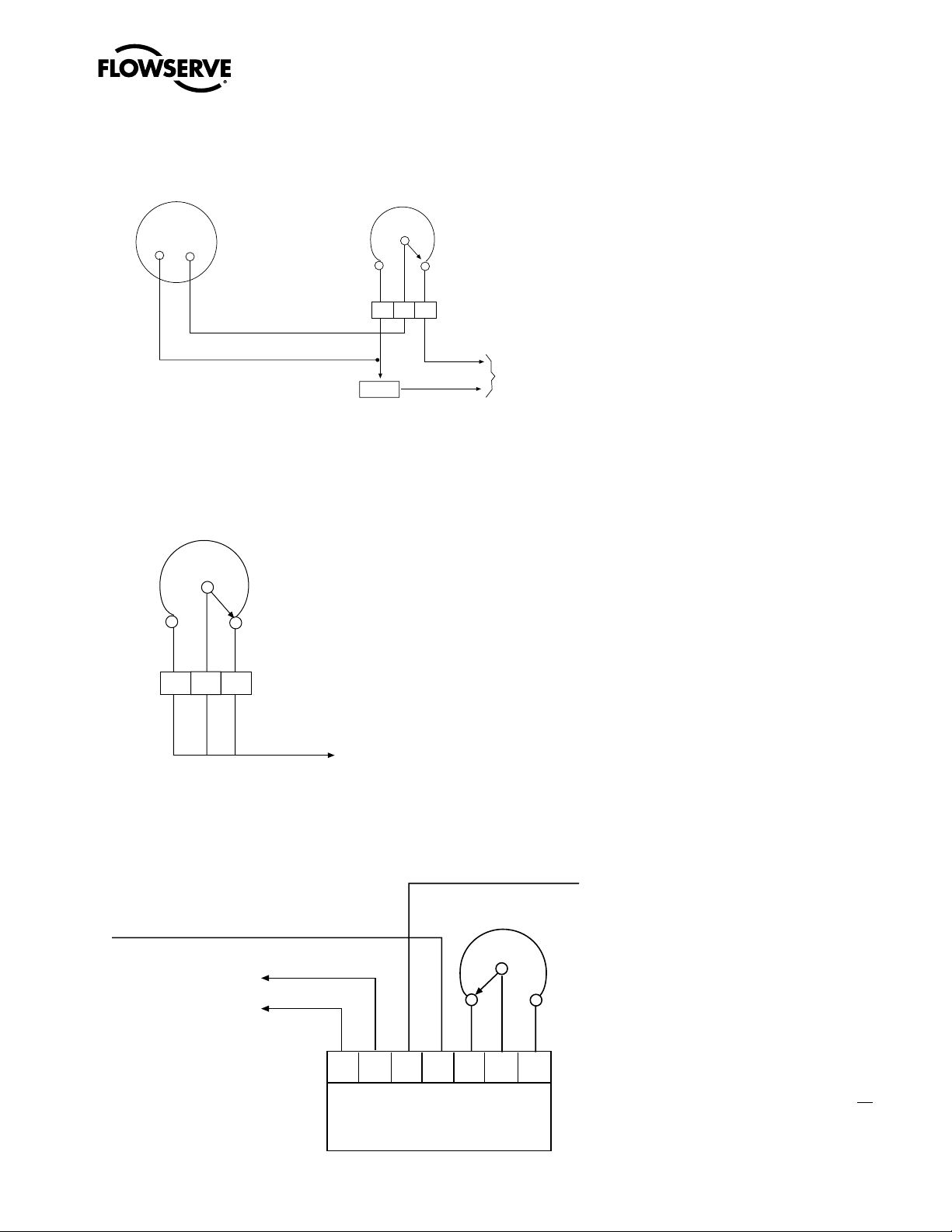

4.6.2 Remote Position Indicator

(50 ohm or 1000 ohm Potentiometer)

The SMB or SB actuator with a potentiometer installed, transmits a 0-10 VDC output signal to a

remote position indicator (meter). The potentiometer is powered by 120 VAC.

To set the potentiometer:

NOTE: The pinion has been disengaged to prevent damaging the potentiometer prior to setting the

valve.

1. Set the potentiometer by turning the pinion until the desired reading is obtained.

2. Loosen the hex nut on the back of the potentiometer and slide the potentiometer in the direction

of the idler pinion until the pinions are engaged.

3. Do not force the engagement of the pinions.

4. Retighten the hex nut on the back of the potentiometer.

5. Do not engage the pinion until the actuator and valve positions have been set.

To calibrate the potentiometer:

1. Position the valve at 50% of full travel.

2. Read the resistance from the wiper to either end of the potentiometer.

3. To set the potentiometer to the proper value, loosen the set screw on the potentiometer shaft

pinion and rotate the potentiometer shaft to a reading of ~500 ohms for the 1000-ohm potentiometer, or ~25 ohms for the 50-ohm potentiometer.

4. Tighten the set screw.

5. Run the actuator to the fully CLOSED position.

6. Adjust the CLOSED position setting to a value at or above 0 ohms.

7. Run the actuator to the fully OPEN position.

27

flowserve.com

Page 28

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

8. Adjust the OPEN position setting to a value at or below 1000 ohms for the 1000-ohm potentiometer; at or below 50 ohms for the 50-ohm potentiometer.

9. Repeat steps 5 through 8 and fine-tune as necessary.

4.6.3 Remote Position Indicator

(Resistance-to-Current Signal Converter)

The SMB or SB actuator with a signal converter installed transmits a 4-20 mA output signal to a

remote position indicator (meter). The signal converter responds to the input of a 1000-ohm

potentiometer and can be powered by 24 VDC or 120 VAC for the older version R/I converter; or

18 VDC, 24 VDC, or 120 VDC for the PT20SD style R/I converter.

To set the R/I signal converter:

NOTE: The pinion has been disengaged to prevent damaging the potentiometer prior to setting the

valve.

1. Set the potentiometer by turning the pinion until the desired reading is obtained.

2. Loosen the hex nut on the back of the potentiometer and slide the potentiometer in the direction

of the idler pinion until the pinions are engaged.

3. Do not force the engagement of the pinions.

4. Retighten the hex nut on the back of the potentiometer.

5. Do not engage the pinion until the actuator and valve positions have been set.

To calibrate the R/I signal converter:

1. Position the valve at 50% of full travel.

2. Read the ohms from the wiper to either end of the potentiometer.

3. To set the potentiometer to the proper value, loosen the set screw on the potentiometer shaft

pinion and rotate the potentiometer shaft to a reading of 500 ohms.

4. Tighten the set screw.

5. Run the actuator to the fully CLOSED position.

6. Adjust the ZERO control to an output of 4 mA.

7. Run the actuator to the fully OPEN position.

8. Adjust the SPAN control to an output of 20 mA.

9. Repeat steps 5 through 8 to fine-tune as necessary.

28

Page 29

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Remote position indicator

0-10 volts full scale deflection

Control voltage range

110 volts to 480 volts

Potentiometer 1000 ohm 2 Watt

customer’s equipment

terminal as valve opens

Figure 4.7 – Typical Connection for a 50-ohm Potentiometer

25 Watt, 50 OHM Potentiometer type

variable resistor mounted in SMB/SB housing

Voltmeter

type

P3P2P1

RES

175 Watt, 2500 ohm Adjustable resistor

to be located adjacent to remote position indicator

Figure 4.8 – Typical Connection for a 1000-ohm Potentiometer

for voltage adjustment

in limit switch housing

(CCW)

P1

Potentiometer slider rotates

toward counter clockwise (CCW)

Figure 4.9 – Typical Connection for R/I Signal Converter (Older Version)

4-20 mA

Output Signal

P2

P3

(CW)

To

91

(–)90(+)CL2CL1

1000 ohm

P1

POT

P2

P3

91 90 CL2 CL1 P1 P2 P3

(–) (+)

R to I

Signal Converter

PC Board

Connection

29

flowserve.com

Page 30

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

POT

24 VDC or

18 VAC

See comments

under Section

4.6.3,

Figure 4.10 – Typical Connection for PT20SD R/I Converter

1000 ohm

(S)

4-20 mA

Output

Signal

(+)

(–)

(+)

(–)

BLU

BLU

18V

115V

Black

Brown

Orange

Green

1

2

3

4

5

6

(CCW)

(+)m A

(–)m A

+V

COM

Signal Converter

1 BLK

3 RED

2 BRN

CCW SC W

1

2

3

LK2

1

AC

2

DC

3

LK3

(CW )

4.7 Additional Electrical Components

4.7.1 Reversing Starter

The reversing starter electrically changes the operation of the electric motor from one direction

of rotation to the other. The starter consists of two contactors mounted on a common base and

mechanically interlocked.

Each contactor consists of the following:

• three normally open power contacts

• one normally open circuit holding contact

• one normally closed interlock

• one magnetic holding coil.

30

The starter can be provided two ways:

• Mounted within the actuator limit switch compartment

• Supplied in a separate enclosure

4.7.2 Overload Relays

Overload relays de-energize the holding coils of the reversing starter, which open the power contacts

to de-energize the electric motor. The relays function at a predetermined current value and can reset

either automatically or manually as follows:

• Reset automatically if mounted as detailed in Figure 4.11.

• Reset manually if the reversing starter is furnished separately.

The relays are sized in accordance with full load (running) motor current.

Page 31

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

L1

M1

o

4.7.3 Control Station

The control station consists of

• a five-position Local-Stop-Off-Stop-Remote selector switch, padlockable in each position

• a spring return Open-Close selector switch

• green and red LED lights for position indication.

Typical wiring of the control station in conjunction with the motor control circuit is shown below in

Figure 4.11.

Figure 4.11 – Typical Wiring Diagram – Built-in Reversing Starter and Control Station for a

Three-Phase Power Supply

T1

L2

L3

o

o

C

M2

M3

OL

OL

OL

T2

Motor

T3

CL1

CL1

CL1

CL1

CL1

PB2

STOP

Black

LOCAL

Red

Green

4

8

53

C

C

18

43

17

To customer’s

equipment

45

5

55

1

Remote

indication

if required

HTR1

HTR2

C

o

White

47

57

CL2

CL2

CL2

2

OL

CL2

(H1)(H3) (H2)(H4)

CPT

(X1) (X2)

FUSE

SS

OFF

REMOTE

3

11

3

30

7

5

5

Purple

9

31

Gray

7

3

OPEN

5

5

Brown

Orange

Pink

70

60

PB1

41

Yellow

PB3

CLOSE

51

o

C

CLOSE (51)

COMMON (11)

STOP (9)

REMOTE (31)

REMOTE (30)

Blue

OPEN (41)

NOTE: Current design. Earlier control wiring varies slightly.

31

flowserve.com

Page 32

5

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Operation

c WARNING: See Section 4.1 and 4.2 on Safety Precautions and Safety Practices prior to

operation.

5.1 Motor Operation

Actuator motors are high-starting torque, totally enclosed motors. The motors are furnished in

weatherproof, explosionproof, or submersible enclosures. The motors are furnished with ball bearings and provided with grease seals. All three-phase AC motors are squirrel-cage design and all DC

motors are compound wound.

Piece numbers refer to Figure 7.9 through 7.11. However, this description is applicable to all models.

The piece numbers will differ for each model.

The electric motor has a Motor Pinion (piece #40) mounted on its shaft extension. This pinion drives

the Worm Shaft Clutch Gear (piece #41), which is engaged with the Worm Shaft Clutch (piece #50).

The Worm Shaft Clutch is splined to the Worm Shaft (piece #43). The Worm (piece #53) is splined to

the Worm Shaft (piece #43), and when it is rotated, it turns the Worm Gear (piece #16).

The Worm Gear has two lugs cast onto the top portion that engage the two lugs on the Drive Sleeve

(piece #11). These lugs are spaced so that when the Worm Gear begins to turn during motor operation there is a certain amount of lost motion before the lugs engage, causing the hammer blow effect

within the actuator.

32

As soon as the Worm Gear Lugs engage, the Drive Sleeve, splined internally with the Stem Nut (piece

#20), causes the stem nut to rotate and open or close the valve. The Stem Nut is threaded to fit the

thread of any rising stem valve. In the case of non-rising stem valves, the electric actuator may be

mounted in tandem with an additional gear drive, and the Stem Nut (piece #20) is bored and keyed to

fit the shaft.

Page 33

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

The thrust developed by the actuator is absorbed by the heavy-duty Bearings (piece #75, 76, 77,

78) on the top and bottom of the main Drive Sleeve. As the actuator develops greater torque, when

seating the valve, the Worm (piece #53) slides axially along the splines of the Worm Shaft (piece #43)

and compresses the Belleville Springs (piece #56) in the torque spring pack.

The Belleville Springs are calibrated springs. For every increment of compression from a given size

unit, a certain pre-determined amount of torque is developed. The Worm mechanically actuates

the Torque Switch. When the Worm moves back a preset distance and develops the torque output

required, the Torque Switch opens and a pair of electrical contacts that are wired into the motor

control circuit interrupt the circuit and stop the motor.

The Geared Limit Switch (piece #105) is directly geared to the Worm Shaft and is in step at all times

with the movement of the actuator. The switch cannot slip because no belts or other friction devices

are used in its operation. Once the Geared Limit Switch (piece #105) is set to trip at its proper position of valve travel, it will trip at the same point every time.

The Torque Switch (piece #104) is wired into the motor control circuit to stop the actuator in the full

closed position for any rising stem operation. The Geared Limit Switch (piece #105) is wired into

the motor control circuit to stop the operator at the full open position. For most 90° turn valves and

sluice gates, the Geared Limit Switch is wired into the motor control circuit to stop the actuator at

both the full open and full close position of the valve or gate. The Torque Switch is wired in series

with the Geared Limit Switch in both directions so that in the event of a mechanical overload, the

Torque Switch will open and cause the motor to stop.

Check the applicable wiring diagram to determine the correct wiring connections made for the torque

switch and geared limit switch.

5.2 Manual Operation

In the event of a power failure, the actuator can be operated by hand using the handwheel. The

actuator has an automatic handwheel declutching arrangement. For manual operation, the declutch

lever is pulled downward. This mechanically disconnects the electric motor from the handwheel

through the clutch assembly.

5.2.1 SMB-000 and SMB-00

The operation of the SMB-000 and SMB-00 are functionally the same. Due to a difference in piece

numbers between these actuators, the following description refers to the SMB-000 (Figures 7.1 to

7.3).

For the SMB-000 and the SMB-00, the Clutch Ring (piece #33) and the Clutch Keys (piece #23) are

moved upward until the Clutch Keys engage with the lugs on the bottom of the Handwheel (piece #5).

For the side-mounted Handwheel on the SMB-00, the Clutch Keys engage the lugs on the bottom of

the Bevel Gear (piece #100).

Trippers (piece #28, 29) hold the Clutch Keys in this position. The actuator will remain in hand operation indefinitely until the electric motor is energized and the Tripper Cams (piece #27) mounted on the

flowserve.com

33

Page 34

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Worm Shaft (piece #21) cause the trippers to release the Clutch Ring (piece #33) and the Clutch Keys

(piece #23) from their hand position. This is an automatic feature of the actuator.

5.2.2 SMB-0 through SMB-4

Piece numbers refer to Figures 7.9 to 7.11.

The declutching action is similar to that of the smaller SMB actuators. When the Declutch Lever

(piece #10) is depressed, the Declutch Shaft (piece #24) causes the Declutch Fork (piece #12) to

push the Worm Shaft Clutch (piece #50) out of engagement with the worm shaft clutch gear (piece

#41) and into engagement with the Handwheel Clutch Pinion (piece #42). The Clutch Trippers

(piece #32) lock the worm shaft clutch in this position. When the Handwheel (piece #5) is rotated,

the Handwheel Gear (piece #7) turns the Handwheel Clutch Pinion (piece #42) and the Worm Shaft

(piece #43), placing the actuator into manual operation.

When the electric motor is energized, the Tripper Pins (piece #51), which are part of the Worm Shaft

Clutch Gear (piece #41), cause the Trippers to be released, allowing the Worm Shaft Clutch (piece

#50) to be released from hand operation and engage in motor operation.

For all actuator sizes, when the handwheel is turned, the motor does not rotate; and when the motor

is in operation, the handwheel does not rotate in manual operation.

5.2.3 SMB-5 through SMB-5T

Piece numbers refer to Figures 7.13 to 7.16.

The declutching action is similar to that of the smaller SMB-0 through 4 actuators. When the

Declutch Lever (piece #9) is depressed, the rotation of the Declutch Shaft (piece #30) causes the

Declutch Fork (piece #14) to push the Sliding Gear Clutch (piece #51) out of engagement with the

Flexible Jaw Clutch Housing (piece #50) and into engagement with the Handwheel Gear (piece #6).

The Clutch Trippers (piece # 33, 34) lock the Drive Shaft Clutch in this position. When the Handwheel

(piece #10) is rotated, the Handwheel Shaft and Pinion (piece #40) turns the Handwheel Gear (piece

#6) and the Hollow Drive Shaft (piece #55), placing the actuator into manual operation.

When the electric motor is energized, the Motor Clutch Gear Cam Pins (piece #52), which are part

of the Flexible Jaw Clutch Housing (piece #50), causes the Clutch Trippers (piece #33, 34) to be

released, allowing the Sliding Gear Clutch to be released from hand operation and engage in motor

operation.

For all actuator sizes, when the handwheel is turned, the motor does not rotate; and when the motor

is in operation, the handwheel does not rotate.

34

Page 35

6

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Maintenance

6.1 Routine Maintenance

c WARNING: See Section 4.1 and 4.2 for Safety Precautions and Safety Practices before

performing maintenance.

NOTE: A routine maintenance check should be performed every 18 months as a minimum. The

frequency can increase based upon the frequency of operation and the ambient environmental

conditions.

The routine maintenance check consists of the following:

1. Remove the limit switch compartment and/or control cabinet cover. Inspect for moisture. If

moisture is present, dry the compartment and the components.

2. Inspect all electrical controls and contacts in the limit switch compartment and/or control

cabinet. Wipe clean all electrical contacts with electrical-type solvent cleaner similar to CRC

Lectra Clean and remove foreign residue.

3. Check armature brushes for proper contact and wear when DC motors are employed.

4. Verify all terminal connections are tight.

5. Clean gasketed surfaces on limit switch compartment and/or control cabinet cover. Inspect

gaskets and seals for damage. Replace all damaged gaskets or seals for weatherproof and

submersible units. Wipe a coating (approximately two mils) of lightweight bearing grease on

surfaces of explosionproof cover flanges for protection.

6. Inspect lubricant in accordance with Section 6.3.1, Lubrication Inspection. Visually check shaft

penetrations for indications of seal leakage. If abnormal leakage is found, replace the seal.

NOTE: Slight oil weepage is not a cause for seal replacement. See Section 6.2, Major Maintenance.

7. Megger test the motor—1 megaohm or higher is considered normal.

8. Clean and lubricate the valve stem for rising stem applications in accordance with the valve

manufacturer’s lubricant recommendation.

flowserve.com

35

Page 36

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

6.2 Major Maintenance

NOTE: Major maintenance is required when an operational deficiency is evident. The deficiency

should be thoroughly evaluated to determine the extent to which major maintenance should proceed.

Major maintenance consists of the following:

1. Perform all routine maintenance checks. See Section 6.1, Routine Maintenance.

2. Disassemble deficient portion of equipment.

3. Replace damaged or excessively worn components with new factory parts.

NOTE: Replace the Worm and Worm Gear as a set to ensure the greatest benefit from replacement.

Replace the entire limit switch gear box rather than attempt repairs in the field.

4. Replace all torn gaskets and seals.

5. Inspect stem and stem nut threads carefully for wear and/or damage.

6. Verify all electrical control components are operating before reinstallation.

6.3 Lubrication

Proper lubrication is essential to achieve the actuator design life. The actuator has been designed to

minimize maintenance and relubrication requirements. However, periodic inspection is a necessity.

The SMB and SB actuators have a totally sealed gear case, factory-lubricated with grease. The

gear case can be mounted in any position. However, those mounting positions that would result in

the actuator motor being saturated with lubricant if the seal failed should be avoided and are not

recommended.

No seal can remain absolutely tight at all times. Therefore, it is not unusual to find a small amount

of weeping around shaft seals—especially during long periods of idleness such as storage. Grease

lubrication minimizes this condition as much as possible. If a small amount is weeping at start-up,

remove it with a clean cloth. Once the equipment is operating on a regular basis, the weeping

should stop. Lubricant weeping is normal when there is infrequent operation and does not affect

the functionality of the actuator. Weeping is not covered by the standard warranty.

6.3.1 Lubrication Inspection

Inspect Limitorque SMB and SB actuators for correct lubrication prior to operating—particularly

following a long storage period.

Each application has its own effect on the actuator and the frequency of these inspections should be

based on the application and the operating experience. The following lubrication inspection schedule

is recommended until operating experience indicates otherwise.

36

Page 37

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Application Lubrication Recommendations

Main Gear Case

Inspect lubrication every 18 months or 500 cycles

– whichever occurs first.

Geared Limit Switch

Drive Sleeve Top Bearing

Inspect lubrication every 36 months or 1000 cycles

– whichever occurs first.

Lubricate every 6 months through housing cover

pressure fitting.

During an inspection, consider the following:

• Quantity—SMB and SB actuators are built to operate on the immersion principle.

a CAUTION: Ensure there is enough lubricant so that the Worm and the Worm Gear are totally

immersed in grease regardless of the position. Use the “fill” and “drain” plugs provided on the

actuator housing to verify this.

• Quality—Inspect lubricant for dirt, water, or foreign matter. If any of these are found, it is

recommended that the lubricant be replaced. This will require partial or complete mechanical

disassembly of the actuator. Repack the actuator with fresh lubricant, allowing room for thermal

expansion of the lubricant. See Section 10 for ordering replacement parts.

• Consistency—Ensure the lubricant is fluid, approximating a standard NLGI-0 grade consistency.

6.3.2 Standard Lubricant

• The SMB/SB actuator gear case is factory lubricated with an NLGI Grade 0 calcium sulfonate base

grease suitable for continuous ambient temperatures from -20°F (-29°C) to 150°F (66°C). Other

lubricants approved by Flowserve Limitorque may be used based on customer requirements. The

actuator nameplate states the original lubricant type supplied.

NOTE 1: For nuclear containment actuators, Exxon Nebula EP-0 and EP-1, or Crompton MOV-Long

Life, Grade 0 are the only approved lubricants for SMB/SB-000 through 5.

• Geared Limit Switch: Mobil 28.

• Motor Bearings: Motors furnished for Limitorque actuators are lubricated for life.

• Temperature rating is -20°F to 150°F (-29°C to 66°C).

NOTE 2: SMB/SB/SBD-000,00 standard lubricant was Sun Oil Co. (XC-421-39) for serial numbers up

to 295809. Sun 50EP (XC-421-39) should not be mixed with calcium base greases.

Table 6.1 – Approximate Volume and Weights of Lubricants

Actuator Size

SMB/SB-000 .32 1.2 2.7 1.2

SMB/SB/SBD-00 1.0 3.8 8.5 3.8

SMB/SB/SBD-0 1.2 4.5 10.0 4.5

SMB/SB/SBD-1 1.4 5.3 12.0 5.4

SMB/SB/SBD-2 2.7 10.2 22.3 10.1

SMB/SB/SBD-3 5.5 20.8 46.0 20.9

SMB/SB/SBD-4 9.4 35.6 75.0 34.0

SMB-5T 10.0 37.8 80.0 36.4

SMB-5 11.2 42.4 90.0 40.9

Approximate Volume Approximate Weight

gallons liters lb. kg

37

flowserve.com

Page 38

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

6.3.3 Minimum Lubricant Qualities Required

a CAUTION: Do not mix lubricants of a different chemical base. Mixing lubricant bases may cause

lubricant properties to be ineffective.

a CAUTION: Do not add a different lubricant to an actuator unless it consists of the same soap base

as the existing lubricant unless you have received lubricant manufacturer approval.

The standard lubricants used by Limitorque have been proven to be extremely reliable over the

years of service. Other lubricants may be used in place of the standard. Limitorque does require the

following lubricant qualities as a minimum.

The lubricant must:

• contain an “EP”additive.

• be suitable for the temperature range intended.

• be water and heat-resistant and non-separating.

• not create more than 8% swell in Buna N or Viton.

• not contain any grit, abrasive, or fillers.

• comply with Slump-prefer NLGI grades 00 to 1.

• not be corrosive to steel gears, ball or roller bearings, or yellow metals (bronze, brass,

or copper alloys).

• have a dropping point above 316°F (158°C) for temperature ranges of -20°F (-29°C)

to 150°F (66°C).

38

Page 39

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

SMB Disassembly

7

and Reassembly

NOTE: For explosion proof applications, brush-apply a thin coating of Mobil Infinitec 152 or

equivalent grease to the flanged surfaces of the gear housing and mating limit switch compartment

cover. Remove excess grease after bolting the cover in place. Mobil Infinitec 152 is a synthetic

automotive wheel bearing grease that is resistant to high temperatures and water wash-out.

7.1 SMB-000

c WARNING: See Section 4.1 and 4.2 on Safety Precautions and Safety Practices before

proceeding with disassembly.

7.1.1 To Replace the Stem Nut Only

c WARNING: Do not remove the Locknut (piece #30) with actuator under load or with the valve

under pressure.

a CAUTION: If valve must be left in service while the stem nut is replaced, the valve stem must be

locked in such a way as to prevent any movement of the valve stem.

1. Remove Locknut (piece #30). The locknut is staked in two places; locate the stakes and spot with

a drill.

2. Clean all metal particles.

3. Lift Stem Nut (piece #11) out of the top of the actuator.

If the actuator is mounted on a valve having a threaded stem and stem nut removal is required,

proceed as follows:

1. Remove the Locknut (piece #30).

2. Declutch actuator for manual operation.

3. Rotate the Handwheel (piece #5) to close the valve.

4. When the stem nut splines are free from the Drive Sleeve (piece #8), the Stem Nut may be

rotated by hand for the remainder of the length of the valve stem and replaced, if necessary.

flowserve.com

39

Page 40

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

To reinstall the Stem Nut onto the Keyed Shaft:

1. Lower the Stem Nut into the Drive Sleeve, aligning the splines, until the Stem Nut is seated.

2. Install the Key.

3. Install the Locknut.

4. Stake in two (2) places, 180° apart.

To reinstall the Stem Nut onto a Threaded Shaft:

1. Rotate the Stem Nut on the shaft until the Stem Nut splines engage the Drive Sleeve splines.

2. Rotate the Handwheel to open the valve until the Stem Nut is seated.

3. Install the Locknut.

4. Stake the top threads in two (2) places, 180° apart.

7.1.2 SMB-000 Disassembly

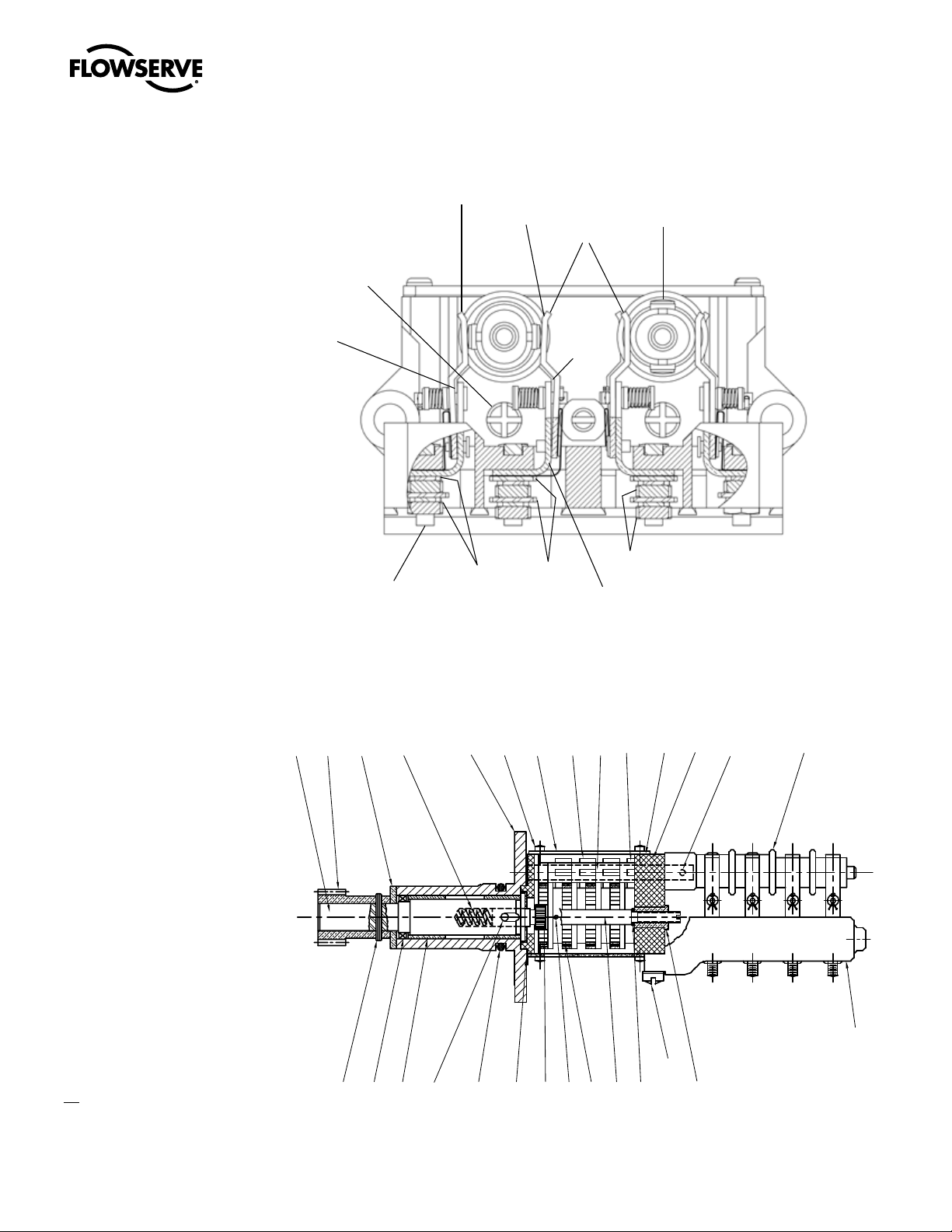

Piece numbers refer to Figures 7.1-7.2.

1. Verify power to actuator is OFF.

2. Remove or swing open the Limit Switch Compartment Cover (piece #3).

3. Disconnect the leads from the Geared Limit Switch (piece #95) and the Torque Switch (piece

#93). Verify the leads are marked for reconnecting to the terminals.

4. Remove the two screws each on the Geared Limit Switch and the Torque Switch. Remove the

Geared Limit Switch and the Torque Switch.

5. Remove the motor leads from the Motor Terminal (piece #91) inside the limit switch compartment. Remove the Motor Assembly (piece #92) and guide the motor leads through the conduit

opening.

NOTE: The Motor Pinion (piece #20) is keyed to the motor shaft and held there with a set screw to

retain the Motor Pinion in its proper position.

6. Verify actuator is in motor operation in order to unload tripper level (piece #15) assembly.

7. Remove Declutch Lever.

8. Remove Spring Cartridge Cap Cover (piece #43).

9. Remove Spring Cartridge Cap (piece #2).

10. Pull the Worm (piece #24) and Torque Spring Assembly directly out.

11. Remove Tripper Lever (piece #15) assembly.

NOTE: A hex head cap screw (piece #120) locates and secures the Tripper Lever (piece #15) on the

Declutch Shaft (piece #40) (end of shaft should be flush with tripper lever).

40

12. Remove Housing Cap (piece #6) and Handwheel Assembly (piece #5).

13. Remove Drive Sleeve Assembly completely including pieces #8, 10, 11, 17, 23, 30, 33, 34,

50, 67, and 69. Press off the lower drive sleeve Roller Bearing Cone (piece #67). Slide off all

remaining pieces.

14. Remove Flexloc Nut (piece #77). Remove Worm Shaft Gear (Piece #22).

Page 41

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

15. Remove Tripper Cam (piece #27) and Cam Spacers (pieces #31, 37).

16. Remove Worm Shaft (piece #21), Bearing (piece #70) and Worm Shaft Bearing Cap (piece #4).

17. Remove internal Retaining Ring (piece #74). Remove Worm (piece #24) from worm assembly.

18. Remove the Retaining Ring (piece #75) from declutch shaft. Pull the Declutch Shaft (piece #40)

and the Declutch Fork (piece #9) out of the actuator from the motor side of the actuator.

7.1.3 SMB-000 Reassembly

a CAUTION: Read gasket instructions 7.1.4 before replacing gaskets.

To reassemble, follow the disassembly procedure in the reverse order noting the following:

• Step 18 of Disassembly procedure—orient the Declutch Fork (piece #9) on the Declutch Shaft

(piece #40) as shown in Figures 7.1 and 7.2.

• Step 6 of Disassembly procedure - manually declutch unit and rotate Worm Shaft Gear (piece #22)

to verify proper tripper operation.

Adjust Clutch Trippers

1. Loosen lock screw (piece #113) on Tripper Adjustment Arm (piece #26).

2. Hold down Declutch Lever (piece #7). Lift Tripper Adjustment Arm up to touch Trippers (pieces

#28, 29). Tighten lock screw on Tripper Adjustment Arm.

3. Rotate Worm Shaft Gear (piece #22) to ensure actuator shifts into motor operation automatically.

4. Declutch actuator again and repeat Step 3.

7.1.4 Gasket Instructions

All gaskets except the housing cover gasket are 1⁄32" thick ASTM F104 synthetic fiber.

The housing gaskets vary in thickness. To determine the correct size, proceed as follows:

1. Clean the Housing Cap (piece #6) and main Housing (piece #1) gasket surface.

2. Install the actuator Drive Sleeve Assembly, including the Bearings.

3. Install the Housing Cap and measure the gap between the Housing Cap and the main Housing.

4. Take measurement and add 10%. Use the closest nominal gasket thickness or combination

available.

flowserve.com

41

Page 42

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Figure 7.1 – SMB-000 Parts Diagram – Side View

102

103

127

128

79

134

133 75 40

5

4

3

2

1

SMB

1

-

2

000

3

4

5

150

82 87 132 7

111

CLOSEOPEN

93

116

114

117

15

115

120

51

42

129

01-403-0034-3

01-403-0034-3

28

29

26

88

113

98

39156459

129

106

76

A

5

90

86 30

6

73

69

60

68

23

A

50

8

33

11

10

17

34

67

53

8532195

66

Page 43

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

108

Figure 7.2 – SMB-000 Parts Diagram – Top View

123

92

253926465820122105

24 71

250

44

62

2

41

35

77

22

27

37

31

4

70

21

81

112

118

42

43

19

78

16

63

88

49

74

59

111

CLUTCH FORK ASS'Y

A-A

110

01-403-0033-4

01-403-0033-4

43

flowserve.com

Page 44

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Slidewire

transmitter

Figure 7.3 – SMB-000 Exploded View

Local dial

indicator

44

Motor operation

position

Handwheel operation

position

08-403-0001-4

08-403-0001-4

Page 45

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 7.1 – SMB-000 Parts List

Piece Quantity Description

1 1 Housing

2 1 Spring Cartridge Cap

3 1 Limit Switch Compartment Cover

4 1 Worm Shaft Bearing Cap

5 1 Handwheel

6 1 Housing Cap

7 1 Declutch Lever

8 1 Drive Sleeve

9 1 Declutch Fork

10 1 Worm Gear

11 1 Stem Nut

14 1 Spacer (Deleted in 1975. Use piece #150)

15 1 Tripper Lever

16 1 Locknut

17 1 Drive Sleeve Bevel Gear

19 1 Bearing Cartridge

20 1 Motor Pinion

21 1 Worm Shaft

22 1 Worm Shaft Gear

23 2 Clutch Key

24 1 Worm

25 2 Clutch Roller Pin

26 1 Tripper Adjustment Arm

27 2 Tripper Cam

28 1 Tripper #1

29 1 Tripper #2

30 1 Locknut

31 1 Cam Spacer

32 1 Seal Cap

33 1 Clutch Ring

34 1 Spacer

35 1 Torque Limit Sleeve

37 1 Cam Spacer

39 2 Clutch Roller

40 1 Declutch Shaft

41 1 Thrust Washer

42 1 Thrust Collar

43 1 Spring Cartridge Cap Cover

44 1 Worm Bearing Nut

45 1 Terminal Mounting Bracket

46 1 Adjustable Arm Pivot Pin

49 1 Belleville Spring (Disc Spring)

50 1 Clutch Compression Spring

51 2 Tripper Spring

53 1 Bearing Shim

56 1 Shim Geared Limit Switch Cartridge Assembly

58 1 Gasket (Motor)

59 1 Gasket (Limit Switch Compartment.)

60 1 Gasket (Housing Cap)

62 1 Gasket (Spring Cartridge Cover)

63 1 Gasket (Spring Cartridge Cap)

66 1 Roller Bearing Cup

67 1 Roller Bearing Cone

68 1 Roller Bearing Cup

Continued on page 46

45

flowserve.com

Page 46

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

Table 7.1 – SMB-000 Parts List (continued)

Piece Quantity Description

69 1 Roller Bearing Cone

70 1 Ball Bearing

71 1 Ball Bearing

73 1 Retaining Ring

74 1 Retaining Ring

75 1 Retaining Ring

76 1 Grease Fitting

77 1 Flexloc Nut

78 1 Flexloc Nut

79 1 Roll Pin

81 1 Bushing

82 1 Bushing

85 1 Quad Ring

86 1 Quad Ring

87 1 Quad Ring

88 3 Pipe Plug

90 1 O-Ring

91 1 Terminal Strip

92 1 Motor Assembly

93 1 Torque Switch

95 1 Geared Limit Switch

98 1 Socket Head Set Screw

102 4 Hex Head Cap Screw

103 4 Lockwasher

105 1 Key

106 2 Socket Head Cap Screw

108 1 Guide Sleeve

110 1 Key

111 1 Key

112 1 Key

113 1 Socket Head Cap Screw

114 4 Socket Head Cap Screw

115 4 Lockwasher

116 4 Round Head Machine Screw

117 4 Lockwasher

118 1 Socket Head Set Screw

120 1 Hex Head Cap Screw

122 4 Hex Head Cap Screw

123 4 Lockwasher

127 4 Socket Head Cap Screw

128 4 Lockwasher

129 2 Pipe Plug

132 1 Socket Head Set Screw

133 2 Socket Head Cap Screw

134 2 Lockwasher

150 1 Declutch Shaft Spacer

250 1 Shim

46

7.2 SMB-00

c WARNING: See Section 4.1 and 4.2 on Safety Precautions and Safety Practices before

proceeding with disassembly.

7.2.1 To Replace the Stem Nut Only

c WARNING: Do not remove the locknut (piece #30) with the actuator under load or with valve

under pressure.

Page 47

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

a CAUTION: If valve must be left in service while the stem nut is replaced, the valve stem nut must

be locked in such a way as to prevent any movement of the valve stem.

1. Remove the Locknut (piece #30). The locknut is staked in two places; locate the stakes and spot

with a drill.

2. Clean all metal particles.

3. Lift the Stem Nut (piece #8) out of the top of the actuator.

If the actuator is mounted on a valve having a threaded stem, and stem nut removal is required,

proceed as follows:

1. Remove the Locknut (piece #30).

2. Declutch actuator for manual operation

3. Rotate the Handwheel (piece #89/99) to close the valve.

4. When the stem nut splines are free from the Drive Sleeve (piece #4), the Stem Nut may be

rotated by hand for the remainder of the length of the valve stem and replaced, if necessary.

To re-install the Stem Nut onto the Keyed Shaft:

1. Lower the Stem Nut into the Drive Sleeve, aligning the splines, until the Stem Nut is seated.

2. Install the Key.

3. Install the Locknut.

4. Stake in two (2) places, 180° apart.

To reinstall the Stem Nut onto a Threaded Shaft:

1. Rotate the Stem Nut on the shaft until the Stem Nut splines engage the Drive Sleeve splines.

2. Rotate the Handwheel to open the valve until the Stem Nut is seated.

3. Install the Locknut .

4. Stake the top threads in two (2) places, 180° apart.

7.2.2 SMB-00 Disassembly

Piece numbers refer to Figure 7.4 to 7.7.

1. Verify power to the actuator is OFF.

2. Remove or swing open the Limit Switch Compartment Cover (piece #2).

3. Disconnect the leads of the Geared Limit Switch (piece #85) leads and the Torque Switch (piece

#83). Verify the leads are marked for reconnecting to the terminals.

4. Remove the two screws each on the Geared Limit Switch and the Torque Switch. Remove the

Geared Limit Switch and the Torque Switch.

5. Remove the motor leads from the Motor Terminal (piece #77) inside the limit switch compartment. Remove the Motor Assembly (piece #84) and guide the motor leads through the conduit

opening.

NOTE: The Motor Pinion (piece #20) is keyed to the motor shaft and held there with a set screw to

retain the pinion in its proper position.

6. Verify actuator is in motor operation in order to unload tripper level (piece #10) assembly.

47

flowserve.com

Page 48

SMB Series/SB Series Installation and Maintenance FCD LMENIM1401-04-AQ – 01/15

7. Remove Declutch Lever.

8. Remove Spring Cartridge Cap Cover (piece #25).

9. Remove Spring Cartridge Cap (piece #3).

10. Pull the Worm (piece #19) and Belleville Spring assembly (piece #46) directly out.

11. Remove Tripper Lever (piece #10) assembly.

NOTE: A hex head cap screw (piece #173) locates and secures the Tripper Lever on the Declutch

Shaft (piece #34) (end of shaft should be flush with tripper lever).

12. For the top-mounted handwheel, remove the Housing Cover (piece #88) and the Handwheel

(piece #89) assembly.

13. For the side-mounted handwheel, remove the Bevel Gear Housing (piece #96) and the entire

handwheel assembly—including the Bevel Gear Cartridge (piece #98).

14. Remove the Drive Sleeve Assembly completely, including pieces #4, 7, 8, 12, 14, 28, 29, 30, 43,

64, and 66. Press off the Lower Roller Bearing Cone (piece #66). Slide off all remaining pieces

except Geared Limit Drive Hypoid Gear (piece #12) and Roller Bearing Cone (piece #64).

15. Remove the Locknut (piece #73) and remove the Worm Shaft Gear (piece #18).

16. Remove the Tripper Cams (piece #24), Bearing Spacer (piece #31), and Cam Spacers (piece

#36).

17. Remove the Worm Shaft (piece #17), Bearing (piece #67) and Worm Shaft Bearing Cap (piece

#35).

18. Remove the internal Retaining Ring (piece #71). Remove Worm (piece #19) from worm

assembly.

19. Remove the Retaining Ring (piece #70) on declutch shaft. Pull the Declutch Shaft (piece #34)

and the Declutch Fork (piece #6) out of the actuator from the motor side of the actuator.

20. Press off the Upper Roller Bearing Cone (piece #64). Slide the Geared Limit Drive Hypoid Gear