Page 1

Durametallic® SLM-6000, SLM-6100

Self contained cartridge

medium duty slurry seal

Installation

Instructions

Experience In Motion

Page 2

1 Cartridge Installation Instructions

The following instruction manual is designed to simplify the installation of a typical

SLM-6000 or SLM-6100 slurry seal. The SLM-6000 is a single seal with no quench port

connections, the SLM-6000 QCD adds an elastomer type quench containment device

(V-ring or lip seal) and 2 quench port connections to the single seal and the SLM-6100

adds a basic end face quench containment mechanical seal to make a tandem design

with a circulating device and 2 quench port connections to the single seal.

By reading this manual and following its guidelines, seal performance can be improved

by eliminating the chances of premature failure due to improper installation. In addition to

these instructions, consult the seal assembly drawing included for your specic seal design,

materials of construction, critical dimensions, and any auxiliary piping connections.

As you go through this manual you will nd some of the instructions referenced with gure

numbers. These illustrations are provided to help you visualize what the instruction is trying

to explain. If these instructions are followed faithfully, the seal installation will be successful,

and maintenance personnel will understand the proper procedures to follow when pump

adjustment is necessary.

For special problems encountered during installation, contact your nearest Flowserve Sales

and Service Representative or Authorized Distributor.

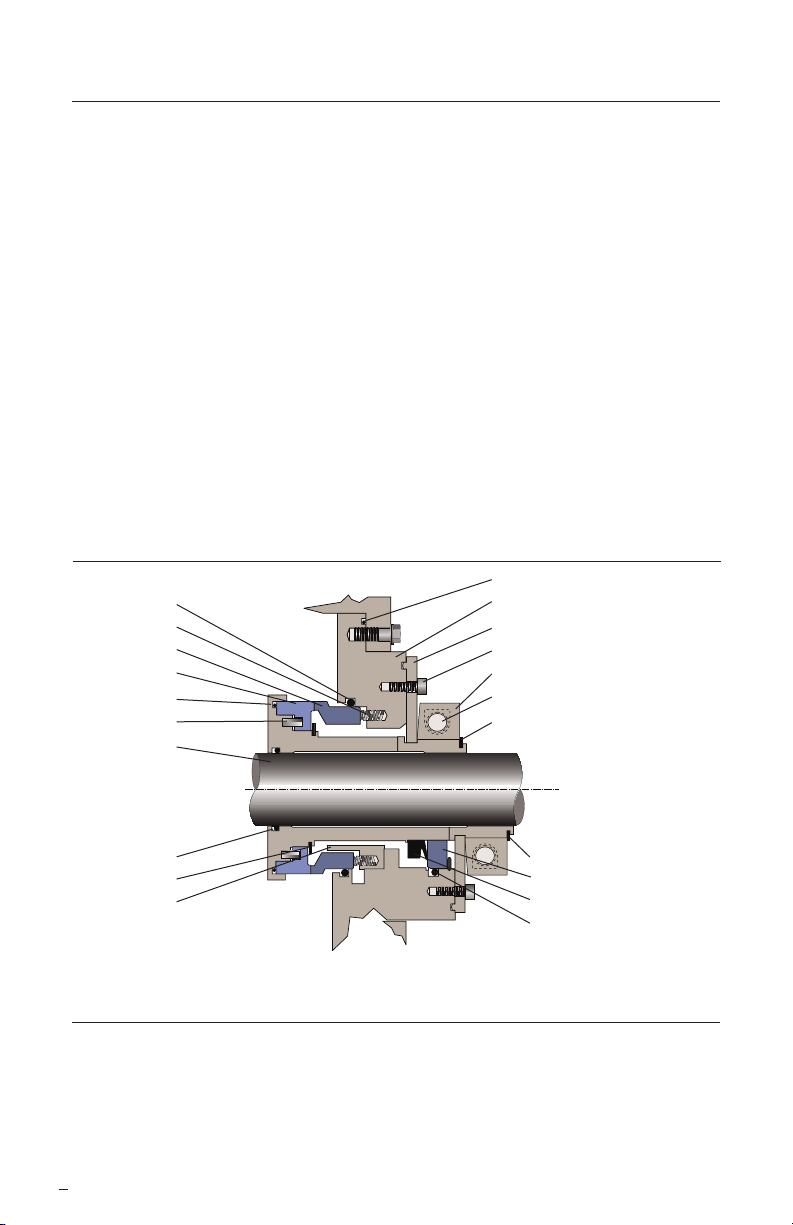

Typical Single SLM-6000 Cartridge Seal Figure 1

Gland O-ring

Stator O-ring

Spring

Stator

Rotor

Rotor O-ring

Rotor Pin

Sleeve

Sleeve O-ring

Snap Ring

Flow Guide

Gland

Centering Plate

Centering Plate Locking Screws

Sleeve Collar

Collar Cap Screw

Snap Spring

without QCD

(top view)

with QCD

(bottom view)

Snap Ring

QCD Stator

V-ring

QCD Stator O-ring

2 Recommendations

To ensure that your SLM-6000 Mechanical Seal will provide you with the longest possible

life, we recommend the following:

2.1 New radial and thrust bearings be installed in the pump.

The images of parts shown in these instructions may differ visually from the actual

2

parts due to manufacturing processes that do not affect the part function or quality.

Page 3

2.2 The saddle ts of the bearing assembly should not be worn.

2.3 The axial end oat of the pump shaft must not exceed 0.25 mm (0.010"). See Figure 2.

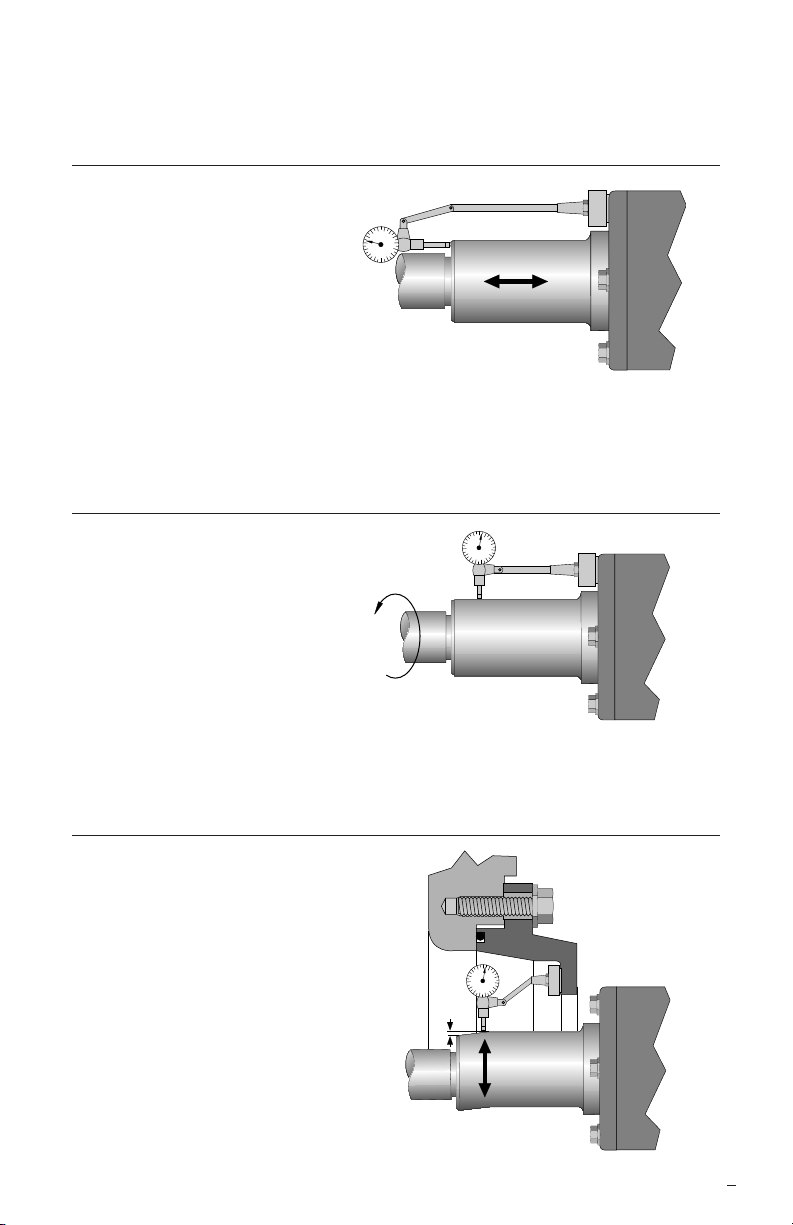

Check Axial Shaft Travel Figure 2

0.25 mm (0.010") Maximum

Acceptable Axial Movement

2.4 Shaft radial runout should be less than 0.0005 mm per mm (0.0005" per inch) of

shaft/sleeve diameter. See Figure 3. Turn the shaft through 360° and observe the

range of indicator movement.

Check Radial Shaft Runout Figure 3

Maximum Acceptable Radial

Run Out 0.0005 mm per mm

(0.0005" per inch) of shaft

diameter

2.5 The shaft should deect no more than 0.30 mm (0.012") at the seal chamber face.

See Figure 4.

Check Radial Shaft Deection Figure 4

Shaft should Deect no more

than 0.30 mm (0.012")

3

Page 4

2.6 Ensure that the shaft or shaft sleeve has a 1.6 mm (0.06") x 30° chamfer on the

leading edge to prevent O-ring damage at seal installation.

2.7 Hardened shaft sleeves must not be used when cartridge sleeve locking is

accomplished by set screws bearing directly into the shaft sleeve. Any of the sleeve

collars that clamp the cartridge sleeve to the shaft sleeve may be used on hardened

shaft sleeves.

3 General Instructions

3.1 Ensure that the bearing assembly is mounted correctly (central and square) to the

pump pedestal and securely fastened.

3.2 Ensure that all t locations on the pedestal are clean and free of burrs.

3.3 Clean the pump shaft/sleeve surface, making sure it is clean of product and rust

and has no burrs.

3.4 If the pump design requires it, bolt seal adapter plate to equipment case/pedestal

(hand tighten only).

3.5 Locate the seal t of the adapter to the shaft by use of a dial indicator or centering jig.

The equipment shaft must be concentric to the seal adapter bore to within 0.38 mm

(0.015"). See Figure 5.

Center Adapter Plate to Shaft Figure 5

Centering Jig

Adapter to be Concentric with

Shaft within 0.38 mm (0.015")

3.6 For adapters provided with a centering jig, simply insert the centering jig into the

adapter and tighten adapter bolts alternately, adjusting the cover location until the

centering jig can be removed by hand without binding.

3.7 Apply a light coat of O-ring lubricant to the seal sleeve O-ring. (Silicone grease must

be used with EPDM gaskets.)

Warning: Do not apply anti-seize or other lubrication to the pump shaft/sleeve. Keep

the shaft/sleeve clean and dry. The use of lubricants will cause improper clamping

pressure by the clamp collar.

4

Page 5

3.8 If the seal is tted with quench ports, orient the ports as illustrated in Figure 6.

Quench Port Orientation Figure 6

Quench Outlet

Quench Inlet

4 Wet-Side (Impeller-Side) Installation

The following steps describe installation of the seal cartridge mounted on the wet,

or impeller, side of the equipment case. If your cartridge is designed to mount on the dry,

or bearing, side of the equipment case, skip to section 5.

4.1 Seal chamber face runout (perpendicularity) should be less than 0.001 mm per mm

(0.001" per inch) of indicated diameter. See Figure 7.

Check Seal Chamber Face Runout Figure 7

Maximum Acceptable Runout

0.001 mm per mm (0.001" per inch)

of indicated diameter

4.2 Seal chamber concentricity should be less than 0.38 mm (0.015").

See Figure 8. Seal life varies with alignment. Poor shaft alignment can reduce

seal life.

5

Page 6

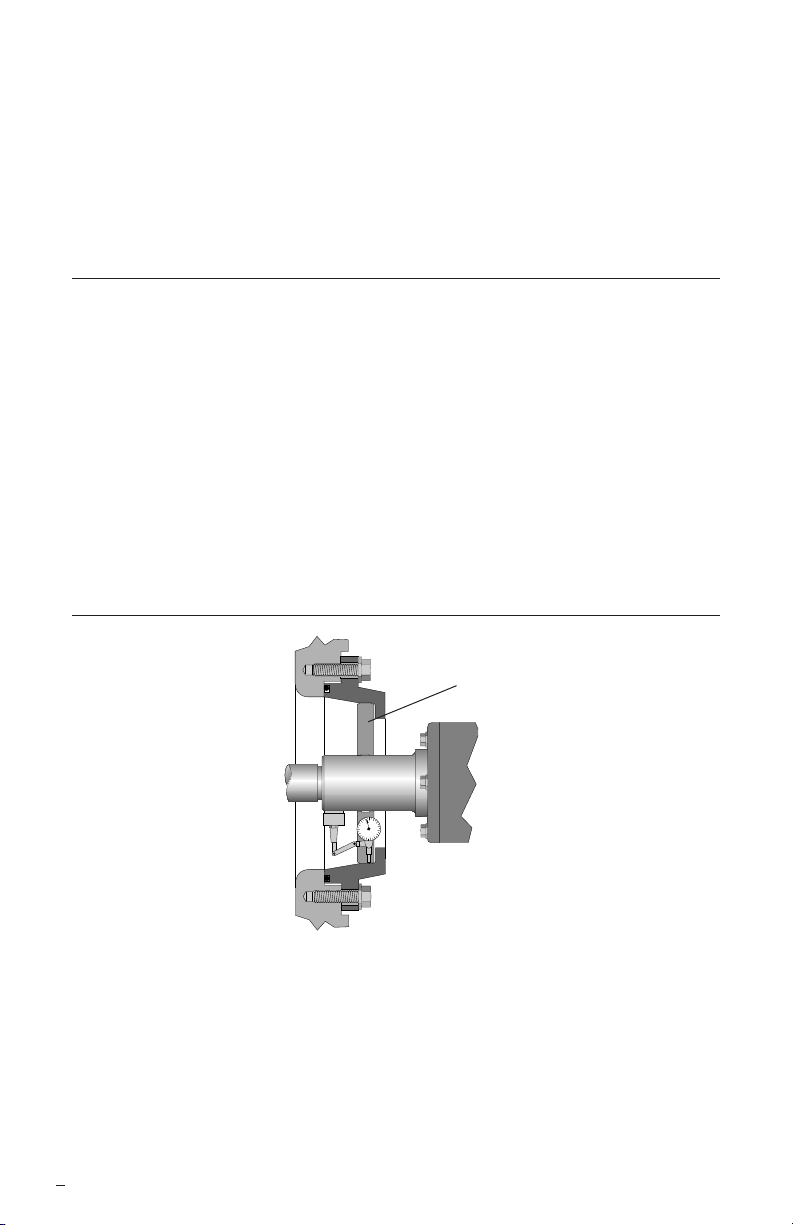

Check Seal Chamber Concentricity Figure 8

0.38 mm (0.015") Maximum Seal

Chamber Concentricity Runout

4.3 It is advisable to hold the gland gasket in place in the gland groove with contact

adhesive, #404 “super glue” (in spots only), or vacuum grease. With the seal clamp

collar facing toward the bearing assembly, slide the complete cartridge over the

pump shaft/sleeve and push back into the pump case. See Figure 9.

Warning: Do not hammer on or push against the cartridge sleeve.

Do not secure the gland retaining screws to the equipment casing at this time.

Inserting Cartridge Figure 9

Push on Gland to Slide the

Seal over the Shaft/Sleeve

Do Not Hammer or

Push on Seal Sleeve

Do Not Hammer or

Push on Seal Sleeve

Push on Gland to Slide

the Seal over the Shaft/Sleeve

4.4 If the seal is mounted directly on the shaft, rather than on the equipment sleeve, install

the impeller spacer sleeve (possibly modied).

4.5 Install the impeller and case.

4.6 Make any necessary impeller adjustments.

Warning: Loosen the bearing assembly and drive belts only enough to make the

adjustments. Fully retighten the bearing assembly and belts after adjustment.

6

Page 7

4.7 Insert the retaining screws through the rear face of the pump case and screw into the

seal gland. Tighten the retaining screws evenly to pull the seal into the pump case.

See Figure 10.

Cartridge in Place (Wet Side) Figure 10

5 Dry-Side (Bearing-Side) Installation

The following steps describe installation of the seal cartridge mounted on the dry,

or bearing, side of the equipment case. If your cartridge is designed to mount on the wet,

or impeller, side of the equipment case, refer to section 4. If you have completed section 4,

skip to section 6.

5.1 With the seal clamp collar facing toward the bearing assembly, slide the complete

cartridge over the pump shaft/sleeve and push back toward the bearing housing.

See Figure 11.

Warning: Do not hammer on or push against the cartridge sleeve.

Slide Cartridge onto Shaft Figure 11

Push on Gland to Slide the

Seal Over the Shaft/Sleeve

Do Not Hammer or

Push on Seal Sleeve

Do Not Hammer or

Push on Seal Sleeve

Push on Flange/Gland to Slide

the Seal Over the Shaft/Sleeve

7

Page 8

5.2 Position and lightly secure the equipment casing in place.

5.3 Seal chamber concentricity should be less than 0.38 mm (0.015").

Poor shaft alignment can reduce seal life. See Figure 12.

Check Seal Chamber Concentricity Figure 12

0.38 mm (0.015") Maximum Seal

Chamber Concentricity Runout

5.4 Seal mounting runout (perpendicularity) should be less than 0.001 mm per mm

(0.001" per inch) of indicated diameter. See Figure 13. When the equipment case

and shaft are properly aligned, secure the case in place.

Check Seal Chamber Face Runout Figure 13

Maximum Acceptable Runout

0.001 mm per mm (0.001" per inch)

of indicated diameter

5.5 If the seal is mounted directly on the shaft, rather than on the equipment sleeve,

install the impeller spacer sleeve (possibly modied).

5.6 Install the impeller and case.

5.7 Make any necessary impeller adjustments.

Warning: Loosen the bearing assembly and drive belts only enough to make the

adjustments. Fully retighten the bearing assembly and belts after adjustment.

5.8 Slide the seal cartridge up to the equipment case. Insert the retaining bolts through

the gland holes and screw into the threaded holes on the face of the equipment case.

Tighten the retaining bolts evenly in opposing pairs. See Figure 14.

8

Page 9

Cartridge in Place (Dry Side) Figure 14

6 Completing Installation

6.1 Evenly tighten the Socket Head Cap Screws of the 2-piece split clamp collar, the Hex

Head Cap Screws of the 3-piece shrink disk collar, or the Set Screws of the 1-piece

sleeve collar to the proper torque values listed below.

TORQUE VALUES

ft-lbs

(N-m)

Split Clamp Shrink Disk Set Screw Set Screw Penetrating

Clamp Clamping (Cup Point)

(Dog Point)

Fastener Alloy Steel Alloy Steel Alloy Steel Stainless Alloy

Size Steel Steel

1/4” 10-12 4-6 7-8

(14-16) (5-8) (9-11)

5/16” 24-26 20-22 10-12 13-15

(33-35) (27-30) (14-16) (18-20)

3/8” 40-45 24-27 18-20 22-25

(54-61) (33-37) (24-27) (30-34)

1/2” 90-100 50-55

(122-136) (68-75)

9

Page 10

6.2 Remove the setting plate locking screws. With a screwdriver, pry the setting plates

clear of the gland and remove them. Keep the setting plates and locking screws with

seal at all times. See Figure 15.

Remove Centering/Setting Plates Prior to Operation Figure 15

Centering/setting plate shown in the

installed position for shipping, seal

installation and maintenance.

A screwdriver is used to lever

the centering/setting plate out.

Centering/Setting plate shown in

the stored position for equipment

operation.

Centering Plate

7 Support Systems

7.1 For seal tted with quench ports and lip seal (SLM-6000 QCD):

7.1.1 Connect clean, low-pressure water to the quench inlet. See Figure 6. Water

ow must be regulated to 1-2 liter/min (1/4-1/2 gpm) at 35 kPa (5 psi)

maximum.

7.1.2 Quench outlet should be connected to plant drain.

7.1.3 Quench water must ow at all times when pump is in operation.

7.2 For seal tted with quench ports and basic end face seal (SLM-6100 with Plan 52):

7.2.1 Supply tank inlet should be located vertically 1 meter (3 feet) above centerline

of equipment shaft and the outlet horizontally within 1-2 meters (3-6 feet) of

seal quench inlet port. See Figure 16.

7.2.2 Connect lower supply tank outlet port to seal quench inlet port. See Figure 16.

7.2.3 Seal quench outlet port should be connected to upper supply tank inlet port.

See Figure 16.

API Plan 52 (ANSI Plan 7352) Figure 16

Fill Connection

10

Primary

Seal

Secondary

Seal

1 meter

(3 feet)

minimum

1-2 meters

(3-6 feet)

maximum

Supply Tank Assembly

(with Cooling Coil Option)

.500” OD minimum tubing

(.750” OD recommended)

Drain Connection

Page 11

7.2.4 Supply tank “Buffer” uid level must be maintained at all times when

equipment is pressurized and in operation. Fresh buffer uid should be used

when it becomes cloudy or contaminated with process uid. Quench supply

tank should have a drain connection located on the bottom and a ll

connection on the top that can be used when adding or exchanging buffer

uid. Supply tanks may or may not also have cooling coil connections. Buffer

uid ow is a function of the seal circulation device and thermosyphoning

created by proper location of supply tank. Buffer uid must always be kept at

0-69 kPa maximum (0-1 psig maximum).

7.3 Your SLM-6000 Mechanical Seal is now ready for operation.

Warning: To ensure that the mechanical seal does not run dry, leave motor v-belts or

drive coupling off the pump until the motor has been tested for rotation.

Note: For any subsequent impeller or bearing adjustment, reverse steps 6.1, and 6.2.

8 Start Up and Shut Down Procedures for the SLM-6000

Slurry Seal

Because the seal has no ush and relies on the product for seal face lubrication, the pump

cavity must be completely full of liquid before start up. Take the following steps to ensure

dry running does not occur:

8.1 Pump Start-Up

8.1.1 Open the suction valve.

8.1.2 Open the discharge washout/bleed valve to release any air that may be

trapped in the piping. Close the valve after a steady stream of liquid ows

from it. If little or no liquid appears, do not start the pump. This means that

part of the piping system is blocked with product.

8.1.3 Partially open the discharge valve to ensure that water hammer or cavitation

does not occur at start up.

8.1.4 After start up, slowly open the discharge valve. This will keep a false head

on the pump until the line lls.

8.2 Pump Shut-Down

8.2.1 Stop the pump.

8.2.2 Close the discharge valve.

8.2.3 Close the suction valve.

8.2.4 Drain all product from the pump seal chamber or ush with clean water or

process uid to prevent solids in the slurry (either free solids or dissolved

solids that will precipitate out when temperature is reduced during standby)

from setting in the seal chamber or volate.

9 Normal Operation

Never allow equipment to run dry during operation, as this will certainly result in premature

seal failure.

9.1 Do not allow equipment to cavitate, as this will shorten seal life.

9.2 Do not induce water hammer in the pipeline, as this can place undo strain on the

seal components.

9.3 Do not allow the seal chamber pressure to drop below 5 psi while equipment is in

operation as this may prevent lubrication from reaching the seal faces.

11

Page 12

flowserve.com

TO REORDER REFER TO

B/M #

F.O

.

10 Repair

This product is a precision sealing device. The design and dimension tolerances are critical

to seal performance. Only parts supplied by Flowserve should be used to repair a seal.

To order replacement parts, refer to the part code and B/M number. A spare backup seal

should be stocked to reduce repair time.

When seals are returned to Flowserve for repair, decontaminate the seal assembly and

include an order marked “Repair or Replace.” A signed certicate of decontamination

must be attached. A Material Safety Data Sheet (MSDS) must be enclosed for any

product that came in contact with the seal. The seal assembly will be inspected and, if

repairable, it will be rebuilt, tested, and returned.

For technical assistance or additional seal sizes and conditions not listed, contact your local

Flowserve Sales and Service Representative or Authorized Distributor.

FIS134eng REV 08/12 Printed in USA

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly

selected, this Flowserve product is designed to perform its intended function safely during its useful life. However,

the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous

applications under a wide variety of industrial service conditions. Although Flowserve can provide general guidelines,

it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume

the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve

products. The purchaser/user should read and understand the Installation Instructions included with the product, and

train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for

informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance

thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design,

the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of

its worldwide operations or offices.

© 2012 Flowserve Corporation

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Roosendaal, the Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

Loading...

Loading...