Page 1

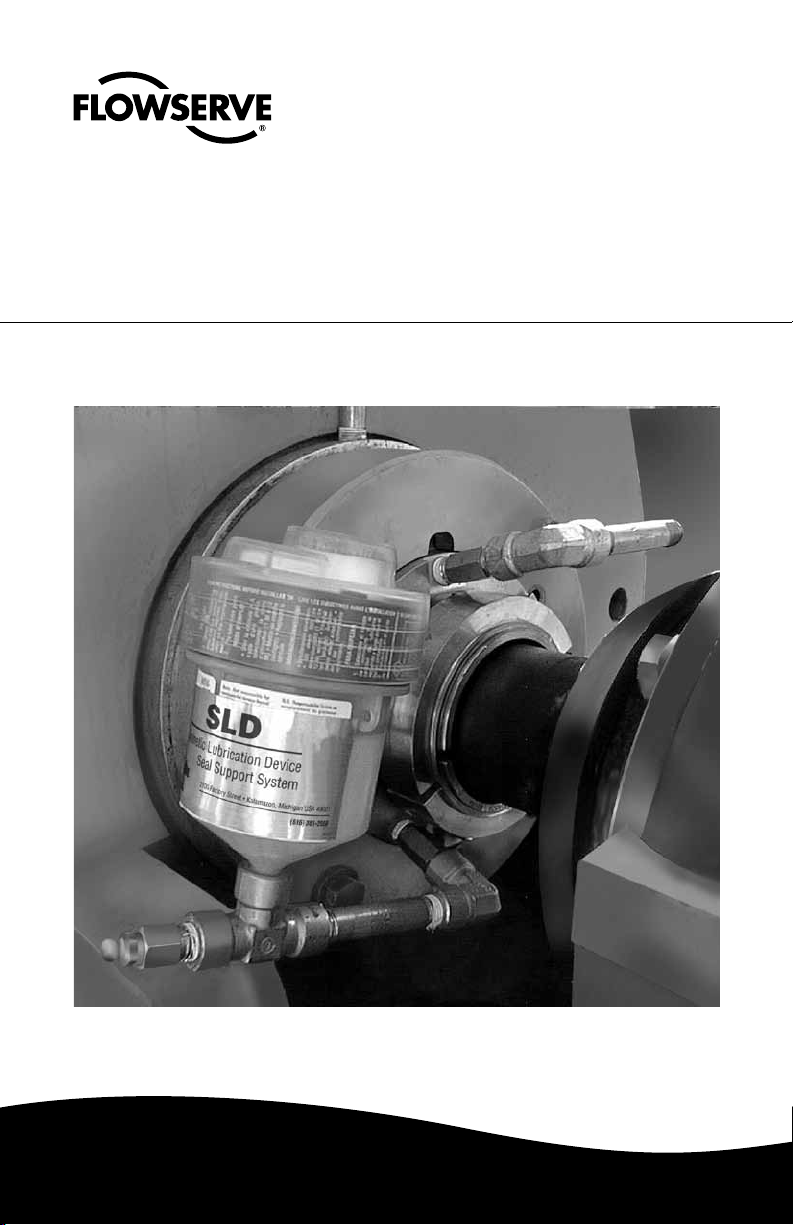

SLD

Synthetic Lubrication Device

Seal Support System

Installation

Instructions

Experience In Motion

Page 2

SLD Installation Instructions

The following instructions are designed to simplify the installation of a typical

SLD (Synthetic Lubrication Device) seal support system. By reading this manual

and following its guidelines, seal performance can be improved by helping to

reduce the chances of premature failure attributed to improper installation or

use. In addition to these instructions, consult the seal assembly drawing included

for your specic seal design, materials of construction, critical dimensions,

and any auxiliary piping connections. If any problems arise during installation,

Do Not Try to Force Anything.

These instructions are written for trained, experienced technicians who are

familiar with the basic principles and tools involved in the installation, care

and service of mechanical seals and seal support systems.

A complete reading of these instructions by personnel in contact with

the equipment is essential to safety. Incorrect installation, operation

or maintenance can result in personal injury or death to personnel and

damage to the equipment.

Description

The SLD Seal Support System is a stand-alone system that dispenses a supply

of synthetic lubricant to the atmospheric side of mechanical seal faces during

periods of marginal equipment operation. Ideally suited for single mechanical

end face seals incorporating two hard carbide faces and a quench containment

device (QCD), it is primarily utilized in water based slurry applications when

operating ushless mechanical seal designs. The SLD Seal Support System

allows synthetic lubricant to be wicked between the faces due to centrifugal

action during periods of uncontrolled equipment cavitation or periods of

unintentional dry running. When proper dispensing rate is selected the SLD Seal

Support System may be able to take the place of a continuous water quench

traditionally used only as a means to help prevent seal face damage associated

with periods of starved operation. The SLD Seal Support System is not intended

to supply added cooling or able to dissolve scaling products that a continuous

water quench may provide. With a properly installed and functioning SLD Seal

Support System, friction generated heat levels leading to face damage have not

been observed in laboratory tests for periods of up to 30 minutes when normal

liquid pumpage is not present.

The SLD Seal Support System does not require compressed air, electricity, or

external water in order to function correctly. This makes it ideal for equipment

having frequent automatic start/stop sequences or for installations at remote

eld locations. The SLD Seal Support System should be a consideration for

use with new equipment that will be sitting at a job site for extended periods of

time prior to being placed into operation. The SLD allows for hand rotation of

shafts as requested by many bearing manufacturers to reduce scoring effects

to mechanical seal faces during the procedure. The SLD Seal Support System

can also help keep dirt, dust, and moisture debris from the atmosphere from

2

Page 3

contaminating the seal quench chamber. The SLD Seal Support System is a

single point lubricator and is not designed to supply more than one seal quench

cavity at a time.

Synthetic Lubricant

The specially formulated Flowserve lubricant (DS-920-OG) lubricant has been

selected because of its inert nature to acids and caustics and proven ability to

promote seal face survivability during periods of marginal hydraulic equipment

operation. The lubricant complies with Occupational Safety and Health Standards

(OSHA) regulations 29 CFR 1910.120 related to "Hazardous Waste Operations

and Emergency Response". To obtain best seal life, alternative lubricants

are not recommended. Contact your nearest Flowserve Sales and Service

Representative or Authorized Distributor for possible substitutes that will not

invalidate your mechanical seal warranty when used.

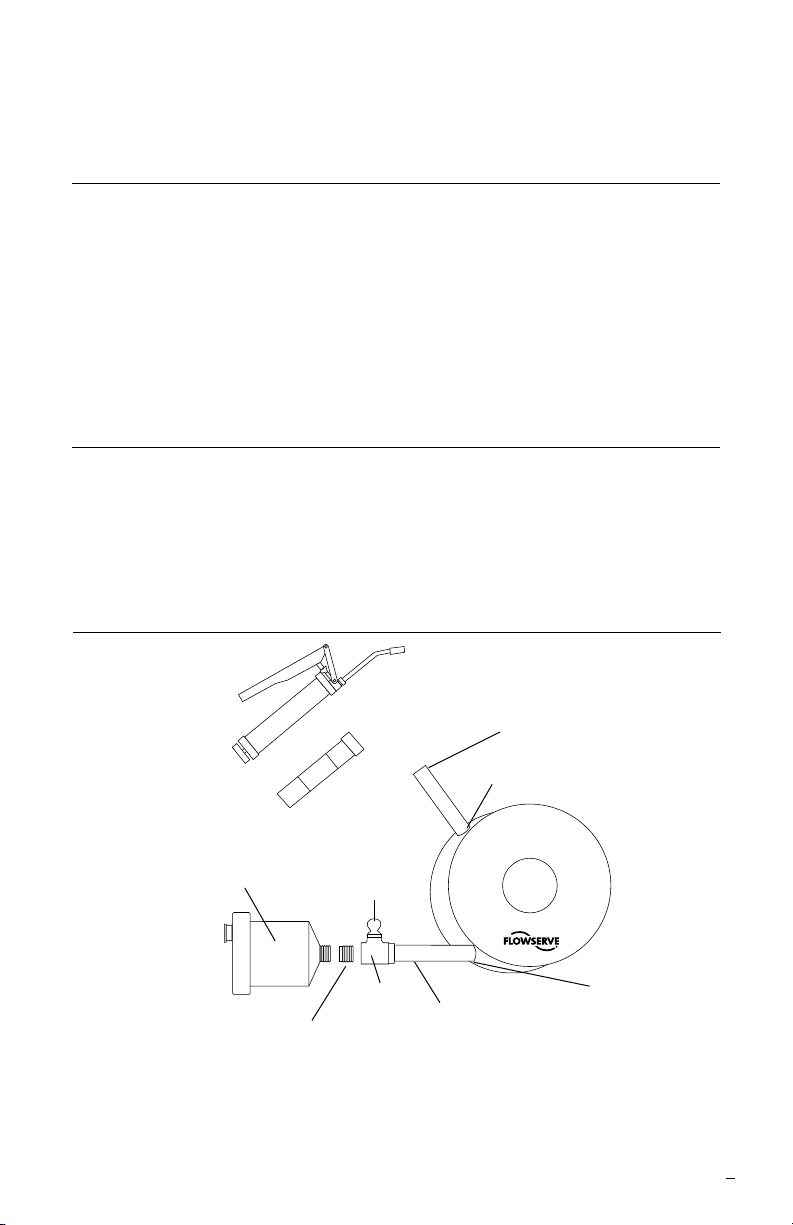

1 Initial Filling and Installation

1.1 Install mechanical seal cartridge in equipment with INLET quench

connection located towards the bottom and the OUTLET quench

connection located towards the top to allow for proper venting of seal

quench cavity. See Figure 1.

Mounting Details

SLD Seal Support System

Figure 1

6.4 mm ID (.25 inch ) x 125 mm (5 inch)

SLD grease gun

SLD grease

cartridge

Auto-Luber Unit

Temporary Plug

used for initial grease

gun lling

SLD

Grease Fitting

Pipe tee

6.4 mm ID (.25 inch) x 460 mm (18 inch)

Minimum pipe diameter and maximum

pipe length

Minimum pipe diameter and maximum

pipe length

Quench Chamber

Outlet Port

Cartridge

Mechanical Seal

End View

Quench Chamber

Inlet Port

1.2 Install INLET piping using 1/4 inch NPT [6.4mm (0.25 inch) minimum pipe ID]

to connect the pipe tee with the hydraulic lube tting to the bottom INLET

quench connection of the seal. The maximum length of pipe from SLD autoluber to INLET quench connection of the seal should be 460 mm (18 inches).

3

Page 4

It is recommended that the shortest possible pipe length be used. The

piping should be installed with good design and minimal bends from the

SLD to the seal. It should be lled with clean grease prior to start up and

vented to make sure no air has been trapped prior to start up.

Additional support to the SLD auto-luber may be required for pipe lengths

over 100mm (4 inch). High vibration levels or improper support of the SLD

auto-luber unit can cause threaded tting fracture or failure. The unit should

be monitored carefully to ensure that it does not experience excessive

vibration caused by pump operation. If vibration is observed due to inadequate support from the piping alone, additional bracing should be used to

support the unit. The bracing should connect directly to the tting near the

SLD auto-luber, not directly to the unit.

The SLD auto-luber should be located so that it will not be impacted during

normal pump operation and maintenance. Excessive or sudden force on

the threaded ttings may lead to a fracture or failure.

Take care using tube ttings or special connectors as they may have an ID

smaller than the 6.4 mm (.25 inch) recommended. Restrictions in the INLET

or OUTLET lines may create back pressure in the system affecting performance of the SLD auto-luber.

1.3 Temporarily plug the pipe tee with a pipe plug prior to initially lling the seal

quench cavity by use of the SLD grease gun.

1.4 Fill the seal quench cavity with SLD synthetic lubricant supplied using

the specied grease gun until lubricant expels from the OUTLET quench

connection located towards the top of the seal. This step does not need to

be repeated later when only replacing an empty SLD auto-luber unit.

1.5 Install OUTLET piping using 1/4 inch NPT [6.4 mm (0.25 inch) minimum

pipe ID] to the OUTLET quench connection of the seal. Piping should have

no restrictions and be a maximum length of 125 mm (5 inch). The piping

should expel the lubricant to a safe location. For dusting or blowing sand

environments, a 90 degree elbow can be connected with the opened end

facing down.

1.6 Remove the pipe plug from the pipe tee and thread the SLD auto-luber unit

in place to nish installation.

1.7 Set the dispensing rate of the SLD auto-luber unit by clicking the

appropriate DIP (direction input postioner) switch or switches located

through the top access port. See Figure 2. It is recommended that the

initial dispensing rate should be between 1-2cc per day (2-3 month setting

for Mini Luber or 8-12 month setting for Jumbo Luber) to start with. Be

sure to also click on the “Blip” light switch. See paragraph 4 Maintenance

for blip light indicators. The visual presence of the blip light every 15 to

20 seconds indicates that the SLD system is functioning and operational.

Be sure to replace the DIP switch access cap and weather proof cover to

protect the SLD auto-luber unit against dust and moisture contamination.

Lubricant dispensing rate may vary depending on atmospheric pressures,

temperatures, and seal size. Please see Section 3 for appropriate

considerations.

4

Page 5

2 Normal Operation

2.1 Once the SLD auto-luber unit is switched on, an electro-chemical reaction

cell is activated that creates inert nitrogen gas. This produces an internal

pressure of up to 345 kPa (50 psi) that expands a bladder that acts against

a piston to force the lubricant out of the dispensing cylinder at a controlled

rate according to the specic time period previously selected. This is an

automatic operation.

2.2 After initial activation, there is a delay before enough nitrogen gas is

generated to start moving the piston to dispense lubricant. The longer the

dispensing period selected the longer the delay before lubricant is dispensed.

See Figure 3. If immediate dispensing is desired, prestart the SLD autoluber unit 12 hours prior to installation by moving all DIP switches to the “On”

position. After this period of time, return all DIP switches to “Off” and reselect

desired dispensing

period. If this step

is not done and all

switches are left

on, then the entire

contents will be

dispensed in only

14 days.

N

I

G

H

1M 2 M 3 M CM 12M B O

O

N

T

OFF

Dispensing

*cc per day

0.25 - 0.3

0.1 - 0.15

*Note that one stroke from a typical hand grease gun is approximately

equal to one cubic centimeter (cc) at normal (101 KPa and 20°C, 14.7

psia and 68°F) atmospheric conditions

Set Dispensing Rate Figure 2

Rate

30 - 32

14 - 15

7 - 8

4 - 5

3 - 4

2.5 - 3

2 - 2.5

1 - 2

1 - 1.4

0.8 - 1

0.7 - 0.8

0.5 - 0.7

125cc Mini Luber

Setting to Empty

Unit Life Switch Setting Unit Life Switch Setting

14 days

123612 B

1 month

123612 B

2 months

123612 B

3 months

123612 B

4 months

123612 B

4.5 months

123612 B

6 months

123612 B

12 months

123612 B

24 months

123612 B

Not Recommended over 24 months

475cc Jumbo Luber

Setting to Empty

14 days

1 month

2 months

3 months

4 months

4.5 months

6 months

8 months

12 months

24 months

123612 B

123612 B

123612 B

123612 B

123612 B

123612 B

123612 B

123612 B

123612 B

123612 B

5

Page 6

Time Delay to Dispense Figure 3

Time Delay to Dispense

Month Switch 1 mo. 2 mo. 3 mo. 6 mo. 12 mo. B

Days Delay 1 2 3 5 10 20

to Start

2.3 If it is desired to decrease or increase the rate of lubricant dispensing after

initial setting, simply click all the DIP switches to “Off” and reselect the new

dispensing period desired.

2.4 To turn off the SLD auto-luber unit during periods of extended equipment

shutdown (months), click all the DIP switches, including the “Blip” light,

to “Off”. Reactivate settings prior to placing equipment back into normal

operation. See paragraph 4 Maintenance for blip light indicators.

3 Dispensing Variations

Variables can be considered when selecting the dispensing rate based on the

operating environment. The SLD auto-luber dispensing rates are based on seal

quench chamber parameters found at normal sea level atmospheric conditions

of 101 kPa and 20°C (14.7 psia and 68°F) and for equipment shaft diameters of

100 mm (4 inch). In general, it is a good practice to rst select a faster dispensing

rate than anticipated and make adjustments based on actual eld observations.

Because of the wide number of variables found with each application, the

following information is being provided only as a guide for making an informed

decision when selecting the appropriate dispensing rate. There is an additive

effect of variables that can cancel or compound with each other. This may help

explain why grease consumption varies between installations, seasons, or from

published rates.

3.1 Altitude Effect

The rate of dispensing will increase at higher altitudes and decrease at lower

altitudes because of the difference in atmospheric pressure acting against

the SLD auto-luber unit. For every change in elevation of 305 meters (1000

feet) from sea level, the discharge rate will naturally increase or decrease

by an additional 5%. For example, at 610 meters (2000 feet) above sea

level, the dispensing rate will be 10% faster. Similarly, at 305 meters (1000

feet) below seal level, the dispensing rate will be 5% slower. Installation

at high altitude may require selection of a slower dispensing rate to help

compensate.

3.2 Temperature Effect

The rate of dispensing will increase at higher temperatures and decrease

at lower temperatures because of the change in lubricant viscosity.

For every change in temperature of 5.5°C (10°F) above or below ambient,

the discharge rate will naturally increase or decrease by an additional 4%.

6

Page 7

For example, at 37°C (98°F), the dispensing rate will be 12% faster.

Similarly, at 9°C (48°F), the dispensing rate will be 8% slower. Installationat

high or low temperature may require selection of a slower or faster dispensing

rate to help compensate.

3.3 Shaft Diameter Effect

The rate of dispensing will need to be increased for large equipment shaft

diameters and can be decreased for small equipment shaft diameters

because of the change in mechanical seal face surface area. For every

change in shaft diameter of 50 mm (2 inch) above or below 100 mm

(4 inch), the discharge rate should be increased or decreased by an additional

3%. For example, a piece of equipment having a shaft diameter of 200 mm

(8 inch), the dispensing rate should be 6% faster. Similarly, for a piece of

equipment having a shaft diameter of 50 mm (2 inch), the dispensing rate can

be 3% slower. Installation for larger or smaller shaft diameters may require

selection of a faster or slower dispensing rate to help compensate and provide

adequate protection from damage to seal faces.

Please contact your Flowserve Sales and Service Representative or Authorized

Distributor for applications at extreme elevations above 3050 meters (10,000 feet)

or atmospheric temperatures above 55°C (130°F) or below -20°C (-4°F) and for

equipment shaft diameters larger than 250 mm (10 inch).

4 Maintenance

The Flowserve SLD Seal Support System components are relatively maintenance

free. Check frequently to be sure that the synthetic lubricant is being expelled by

observing the end of the stand pipe connected to the OUTLET quench chamber

connection and also take notice that the SLD auto-luber is becoming empty.

When the SLD auto-luber is empty, replace with a new one. Never try to rell

the SLD auto-luber or inject lubricant into the grease tting by means of the

grease gun while the auto-luber is installed. There are no user replaceable or

serviceable components located inside of the SLD auto-luber unit itself.

Blip Light Indicators

Flashing Green Light: The system is purging. This means the SLD auto-luber is

functioning but lubricant is not yet being delivered beyond the end of the canister.

Flashing Red Light: The system is functioning normally. The lubricant is now

exiting the SLD auto-luber and is pressurized properly, supplying lubricant at the

current setting.

Steady Red Light: The system battery is dead and the SLD auto-luber is no longer

pressurizing. The SLD auto-luber should be replaced immediately.

No Light: The system is off, or battery is completely dead (if the system switches

are in the “on” position). If the battery is dead, the unit must be replaced.

Steady Red and Green Light: There is a system error. There is an electrical error

in the SLD auto-luber and the unit needs to be replaced.

Note: An empty SLD auto-luber might still have a ashing red light. There is no light

pattern that indicates that the SLD auto-luber is empty. Level must be checked by

a periodic visual inspection on the side of the canister.

7

Page 8

TO REORDER REFER TO

flowserve.com

B/M #

F.O

.

5 Specications

The Flowserve SLD Seal Support System is designed to work best in temperature

environments between minus -20°C (4°F) and plus 55°C (130°F).

Mini Luber dimensions: 117.5 mm high X 79.5 mm diameter

(4.625 inch X 3.125 inch)

nipple 1/4 inch NPT

Mini Luber grease capacity: 125 cc (approximately 4 oz.)

Jumbo Luber dimensions: 168.5 mm high X 120.5 mm diameter

(6.625 inch) X (4.750 inch)

nipple 1/2 inch NPT

Jumbo Luber grease capacity: 475 cc (approximately 16 oz.)

For special problems encountered during installation or for further information

regarding applications outside of specications, contact your nearest Flowserve

Sales and Service Representative or Authorized Distributor.

FIS119eng REV 03/13 Printed in USA

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this

Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve

products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service

conditions. Although Flowserve can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The

purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance

of Flowserve products. The purchaser/user should read and understand the Installation Instructions included with the product, and train its

employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes

only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to

be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is

continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to

change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation

at any one of its worldwide operations or offices.

© 2013 Flowserve Corporation

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Roosendaal, the Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

Loading...

Loading...