Page 1

Segmented V-port Ball Valves

FCD VLENIM4152-01 07.09

USER INSTRUCTIONS

Experience In Motion

Page 2

Contents

General 1

Lifting 2

Receiving inspection 3

Installation 4

Flange gaskets 5

Starting up 6

List of materials and spare parts 7

Ordering of spare parts 8

Maintenance 9

To remove the valve from the pipework 9.1

To inspect the ball sector and seat ring 9.2

To inspect and replace the upper shaft

seal of Safeguard type 9.3

To inspect and replace the upper shaft

seal of ZebraCL™ type 9.4

To change the gasket at the lower stem 9.5

Fitting the actuator to the valve 10

1. General

The instructions and list of spare parts are applicable to

ShearStream SB ball sector valves in accordance with

catalogue sheet FCD NFEETB4152-01.

2. Lifting

All lifting must be carried out on the valve itself and not

on the actuator. The joint between the valve and the actua-

tor is designed for carrying the operating torque and the

weight of the actuator - see Fig. 1.

Fig.1 Lifting of the valve

3. Receiving Inspection

All valves leaving our plant are inspected and tested in

accordance with the relevant requirements or in accor-

dance with the requirements specifi ed by the purchaser.

Valves equipped with actuators are subject to functional

testing and are adjusted in such a manner that every unit

during transport, it is advisable that receiving inspection

We would suggest the following inspection procedure:

- Check that

the valve delivered is correct in

terms of type, size, equipment

- Examine the valve, actuator and valve positioner

regarding possible damages

Page 3

3

4. Installation

the pipework is

free from impurities

the valve is to be installed are parallel and are correctly

aligned, and that the distance between the pipe ends

corresponds to the valve length, including gaskets.

The

valve could not be used for forcing together or aligning

as this will cause loads on the valve

and pipe which may lead to diffi cult damages during

operation. See Fig. 3.

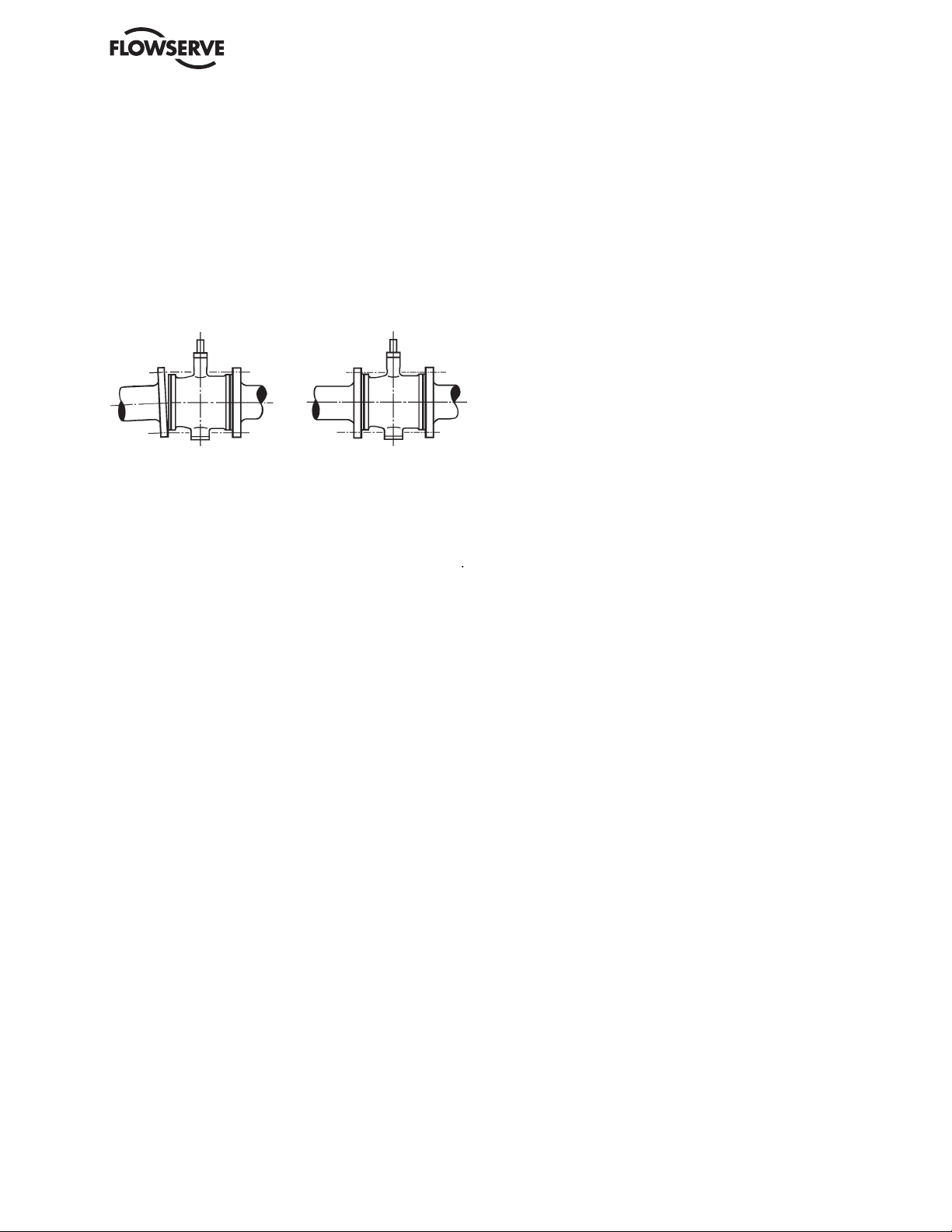

Wrong installation Correct installation

ShearStream SB

valves can be installed in any position

opposite direction.

We also recommend that the valve is mounted with

the stem pointing vertically upwards when the valve is

The pipes should be supported on each side of the

valve

vibrations.

for

with a pneumatic actuator and valve positioner.

5. Flange Gaskets

Gaskets with sizes according to ANSI B16.5, Table E1

6. Starting up

damage the sealing surfaces of the valve and impede its

operation will be fl ushed away.

Page 4

2

29

20

6

4

4

22

3

23

30

33

31

34

32

Fig. 4. ShearStream SB - spare parts, types of stem sealings and seat rings

Seat ring

Stem sealing

13

13

13

9

22

8

5

5

1

1

8

9A

21

Zebra-CL

Safeguard

Metal

Soft

Item

Qty

Part

Material

1

1

EN1.4408/CF8M

1

1

EN1.0619/WCB

2

1

EN1.4408/CF8M HCP

EN1.4408/CF8M

3

Stem, upper

EN1.4460

Stem, lower

EN1.4460

5

1

Gland cover

EN1.4408/CF8M

6

1

EN1.4408/CF8M

7

1

Gasket

Graphite

81EN1.4436

9

EN1.4460

10

Wave spring

EN1.4436

Seat ring

Alloy 6

12

1

Seat seal

13

1

O-ring

FPM

14

1

17

2

Screw

A4

18

19A

Safeguard

V-ring PTFE liveloaded

19B

Zebra-CL

V-ring PTFE

20

4

A4

21

1

Cap spring

EN1.4310

22

1

Steel

23

1

SS

26

Washer

Thread insert

Stainless

28

29

1

Seat ring/Back-up ring

30

1

Stem bearing

Metaloplast

31

1

Stem bearing

Metaloplast

321Washer

A4

33

Cylindrical pin

EN1.4460

34

Washer

Metaloplast

7. List of Materials and Spare Parts

8

9

9

8

27

28

26

2

Page 5

5

8. Product code for important spare parts and spare parts sets

8.1 Ordering of Spare Parts

When placing orders for spare parts, specify:

specifi ed on the identifi cation plate of the valve.

2. Description of the part, its item No. or spare

parts set number, and the quantity required.

Ordering example

or

9. Maintenance

to impurities in the pipework or for some other reason, or

decisive importance

to the entire

any faults should immediately be corrected

9.1 To remove the valve from the pipework

The procedure for inspection and maintenance, for

which no special tools are necessary, is as follows:

also the gaskets - important - for the pipe

fl anges are available.

2. Close the valve.

3. Shut off all compressed air connections

and isolate all electrical connections to the

actuator.

4. Disconnect all compressed air lines and electric

cables connected to the actuator.

5. Release the fl anged joint between the valve

and the pipework. Then lift out the valve. Don’t

use the actuator for lifting.

Apply all lifting

forces to the valve itself and not to the actuator

- see fi g. 1.

which is shown by an

arrow on the valve body.

9.2 To inspect the ball sector and seat ring

section 9.3, items 1 and 2.

2. Remove the indicating pin (23 - fi g. 4).

3. Turn the ball sector through more than 90°, until

it is no longer in contact with the seat ring.

4. Push the seat ring out of its seat at the valve

body inlet. Withdraw it past the ball sector -

between the ball sector and the inside

of the valve body - towards the outlet, and

remove it from the body.

Set or detail

Stem sealing set

Seat ring set

Other spare parts

Type

Zebra CL

Safeguard

Alloy 6

PTFE

Item No

19A

19B

11, 12

12, 29

7

10

DN

25

349 08 050

349 25 540

349 08 080

349 17 460

348 88 295

333 98 460

0040

349 08 050

349 25 540

349 08 08

349 17 46

348 88 295

333 98 46

0050

349 08 050

349 25 540

349 08 08

349 17 46

348 88 295

333 98 46

0065

349 08 050

349 25 540

349 06 089

349 17 469

348 88 295

333 98 46

9

0080

349 08 050

349 25 540

349 08 08

3

349 17 46

3

348 88 29

333 98 46

3

0100

349 08 050

349 25 540

349 08 08

4

349 17 46

4

348 88 29

4

333 98 46

4

0150

349 08 05

349

25 500

349 08 08

5

349 17 46

5

348 88 29

0

333 98 46

5

0200

349 08 05

349 25 720

349 08 08

6

349 17 46

6

348 88 29

333 98 46

6

0250

349 08 05

3

349 25 760

349 08 08

7

349 17 46

7

348 88 29

2

333 98 46

7

0300

349 08 05

349 25 140

349 08 08

8

349 17 46

8

348 88 29

3

333 98 46

8

0350

349 25 180

349

349 20 030

349 15 260

333

00 430

0400

349 25 180

349

7 431

349 20 03

349 15 260

333 00 431

0500

349 25 180

349

7 432

349 20 03

2

349 15 26

333

00 432

Page 6

6

5. Remove the compression spring (10) in the

same way.

6. Carefully wash all parts with warm water and

then, if necessary, with a suitable solvent. Never

scrape the sealing surfaces with hard tools.

7. Examine the surface of the ball sector (2).

Remove any deposits and clean the ball sector

as described in item 6 above.

sur

face of the ball sector.

8. Inspect the seat ring (11) and clean it as

described in item 6 above.

9. Inspect the sealing ring (12) - it need not be

removed from its groove in the body. Fit a new

sealing ring if the original one is damaged.

lubricant, such as Molykote Paste U, Gleitmo

700 or similar.

with a silicone-base grease, such as Silicone

grease DC 111, Silicone grease TKM 1011 or

similar.

Turn the ball sector (2) until it is in contact with

seat ring (11). Use a soft object to press the

seat ring towards the compression spring (10)

to enable the ball sector to move into its proper

position. Continue turning the sector to the

closed position.

pin is to restrict the travel of the ball segment

to 95 - 100°, so that it will always remain in

contact with the seat ring.

9.3 To inspect and replace the upper shaft seal of

Safeguard type

The stuffi ng box usually requires inspection and adjust-

After a certain period of time in service, it may some-

times also be necessary to replace the packing.

Begin by removing the valve positioner. This

can easily be done after the plastic cover of the

valve positioner has been removed. Remove the

four bolts securing the valve positioner to the

actuator. Then remove the nuts securing the

actuator to the valve mounting plate and dismantle

the actuator.

2. Remove the key.

3. Remove the nuts (18). Remove the gland (5).

Then remove the packing (19).

4. Clean the surfaces of the stem, gland (5) and

packing area in the valve body.

5. Carefully examine the surface of the stem which

must be completely free from marks and

scratches.

6. Grease the stem with a suitable grease, such as

Silicone grease.

7. Mount new packing (19). Then mount the gland

(5) and the nuts (18).

8. Tighten the nuts (18) suffi ciently to ensure that

the packing is correctly seated.

valve has been taken into service, retighten the

nuts (18), if necessary.

9.4 To inspect and replace the upper shaft seal of

Zebra CL

type

The stuffi ng box usually requires inspection and adjust-

After a certain period of time in service, it may some-

times also be necessary to replace the packing.

tems 1. Remove the keys (22) and the indicator

pin (23).

2. Remove the nuts (18), spring cups and gland (5).

Then remove the packing (19).

3. Clean the surfaces of the stem, gland (5) and

packing area in the valve body.

4. Carefully examine the surface of the stem which

must be completely free from marks and

scratches.

5. Grease the stem with a suitable grease, such as

Silicone grease.

6. Mount new packing (19) when mounting the

gland (5) and the spring cups and then the

nuts (18).

7. Tighten the nuts (18) suffi ciently according to the

torque table in catalogue sheet FCD NFEETB4152-01

to ensure that the packing is correctly seated.

valve has been taken into service.

9.5 To change the gasket at the lower stem

with the inspection of the seat ring (11).

2. Remove the bolts (20) and the cover (6).

3. Withdraw the stem (4) and remove the gasket (7).

4. Carefully clean the inside of the cover (6) and the

stem (4).

5. Fit a new gasket (7) and lubricate the small end

of the stem with a suitable lubricant, such as

Molykote Paste U or Gleitmo 700.

6. Fit the stem (4) with the gasket (7).

7. Spray the bolt threads with locking compound,

such as Loctite 641.

8. Fit the cover (6) and tighten the bolts (20).

Page 7

3

2

10. Fitting the Actuator to the Valve

valve. The mounting fl ange and the valve stem

follow the NAF standard for securing the

actuator.

2. Turn the valve to the closed position. The key

should face towards the inlet.

3. Fit the actuator.

4. Connect the compressed air supply to the

actuator - applies to pneumatic actuators. If the

end position stop is correctly set, the ball

segment will not move when compressed air

pressure is applied.

5. If moving - adjust the end position stop until the

actuator has turned the ball segment to the

closed position.

6.

The actuator may be fi tted either in line with the

connected pipes or transversely to them. An

intermediate plate is necessary for mounting the

actuator in line with the pipework.

the actuator fi ts the stem. First try without key to check

that the drive slips onto the shaft. Also check that the

actuator shaft entry. Push the actuator onto the stem.

The travel of the ball sector should be restricted to 90°

which is the travel necessary between fully open and

fully closed. If the sector is turned beyond this range,

the sealing surfaces of the sector and seat ring may

will come into contact with the bolts retaining the top

cover if an attempt is made to turn the ball sector outside

the range between fully open and fully closed. When

adjusting the actuator, make sure that, in the closed posi-

tion, the sphere of the ball sector (2) is located opposite

the seat ring (11), i.e. that the sphere projects beyond the

seat ring by equal amounts on each side of the seat as

shown in Fig. 5.

clockwise, as viewed from the actuator.

Fig. 5. Locating of the ball sector sphere when

adjusting the actuator

Page 8

To fi nd your local Flowserve representative:

F

or more information about Flowserve Corporation, visit

www.fl owserve.com or call USA 1 800 225 6989

To fi nd your local Flowserve representative:

F

www.fl owserve.com or call USA 1 800 225 6989

All data subject to change without notice

©08. 000 Flowserve Corporation. Flowserve is a trademark of the Flowserve Corporation

Flowserve Corporation

Springville, UT 84663

Flowserve Flow Control

5114 Railroad Street

Flowserve Pte Ltd.

Singapore 638824

Singapore

Flowserve India Controls Pvt. Ltd.

tefi eld

+91-80-2841028

6

Flowserve Linköping

Gelbgjutaregatan 2

58187 Linköping

Sweden

Flowserve Essen GmbH

45141 Essen

Germany

Flowserve S.A.S.

91965 Courtaboeuf Cedex

Flowserve (Austria) GmbH

9500 Villach

Austria

fl owserve.com

Loading...

Loading...