Page 1

USER INSTRUCTIONS

PolyChem GRP

Installation

Operation

Maintenance

ANSI B73.5M standard horizontal and self-priming

non-metallic, frame-mounted pump

PCN=71569132 12-04A (E). Original instructions.

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

CONTENTS

Page

1 INTRODUCTION AND SAFETY ........................... 4

1.1 General ......................................................... 4

1.2 CE marking and approvals ............................. 4

1.3 Disclaimer...................................................... 4

1.4 Copyright ....................................................... 4

1.5 Duty conditions .............................................. 4

1.6 Safety ............................................................ 5

1.7 Nameplate and safety labels .......................... 8

1.8 Specific machine performance ....................... 9

1.9 Noise level ..................................................... 9

2 TRANSPORT AND STORAGE ........................... 10

2.1 Consignment receipt and unpacking ............ 10

2.2 Handling ...................................................... 10

2.3 Lifting .......................................................... 10

2.4 Storage........................................................ 10

2.5 Recycling and end of product life ................. 11

3 DESCRIPTION .................................................. 11

3.1 Configurations ............................................. 11

3.2 Name nomenclature .................................... 11

3.3 Design of major parts ................................... 12

3.4 Performance and operating limits ................. 12

4 INSTALLATION .................................................. 13

4.1 Location....................................................... 13

4.2 Part assemblies ........................................... 13

4.3 Foundation .................................................. 13

4.4 Grouting ...................................................... 15

4.5 Initial alignment............................................ 16

4.6 Piping .......................................................... 17

4.7 Electrical connections .................................. 23

4.8 Final shaft alignment check .......................... 23

4.9 Protection systems ...................................... 23

Page

6 MAINTENANCE ................................................ 31

6.1 General ....................................................... 31

6.2 Maintenance schedule ................................ 32

6.3 Spare parts ................................................. 32

6.4 Recommended spares and

consumable items ..................................... 33

6.5 Tools required ............................................. 33

6.6 Fastener torques ......................................... 33

6.7 Setting impeller clearance ........................... 34

6.8 Disassembly ............................................... 35

6.9 Examination of parts ................................... 38

6.10 Assembly of pump and seal ....................... 40

7 FAULTS; CAUSES AND REMEDIES ................. 45

8 PARTS LISTS AND DRAWINGS........................ 48

8.1 PolyChem GRP pump, Group 1................... 48

8.2 PolyChem GRP pump, Group 2................... 49

8.3 PolyChem GRP pump, Group 3................... 50

8.4 General arrangement drawing ..................... 51

9 CERTIFICATION ............................................... 51

10 OTHER RELEVANT DOCUMENTATION

AND MANUALS ............................................. 51

10.1 Supplementary User Instruction manuals .. 51

10.2 Change notes............................................ 51

10.3 Additional sources of information ............... 51

5 COMMISSIONING, START-UP, OPERATION

AND SHUTDOWN .......................................... 24

5.1 Pre-commissioning procedure ...................... 24

5.2 Pump lubricants ........................................... 24

5.3 Impeller clearance ....................................... 26

5.4 Direction of rotation ...................................... 27

5.5 Guarding ..................................................... 27

5.6 Priming and auxiliary supplies ...................... 28

5.7 Starting the pump ........................................ 29

5.8 Running or operation ................................... 29

5.9 Stopping and shutdown ............................... 30

5.10 Hydraulic, mechanical and electrical duty ... 30

Page 2 of 52 flowserve.com

Page 3

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

INDEX

Page

Additional sources (10.3) ....................................... 51

Alignment (see 4.3, 4.5 and 4.8)

Assembly (6.10) ..................................................... 40

ATEX marking (1.6.4.2) ............................................ 7

CE marking and approvals (1.2) ............................... 4

Certification (9) ...................................................... 51

Change notes (10.2) .............................................. 51

Clearances, impeller (6.7) ...................................... 34

Commissioning and operation (5) ........................... 24

Compliance, ATEX (1.6.4.1) ..................................... 7

Configurations (3.1) ............................................... 11

Copyright (1.4) ......................................................... 4

Design of major parts (3.3) ..................................... 12

Direction of rotation (5.4) ........................................ 27

Disassembly (6.8) .................................................. 35

Disclaimer (1.3)........................................................ 4

Dismantling (6.8, Disassembly) .............................. 35

Drawings (8) .......................................................... 48

Duty conditions (1.5) ................................................ 4

Electrical connections (4.7) .................................... 23

End of product life (2.5) .......................................... 11

Examination of parts (6.9) ...................................... 38

Fastener torques (6.6)............................................ 33

Faults; causes and remedies (7) ............................ 45

Foundation (4.3) .................................................... 13

General arrangement drawing (8.4) ........................ 51

General assembly drawings (8) .............................. 48

Grouting (4.4) ........................................................ 15

Guarding (5.5) ....................................................... 27

Handling (2.2) ........................................................ 10

Hydraulic, mechanical and electrical duty (5.10) ..... 30

Impeller clearance (see 5.3 and 6.7)

Inspection (6.2.1 and 6.2.2) .................................... 32

Installation (4) ........................................................ 13

Lifting (2.3)............................................................. 10

Location (4.1) ......................................................... 13

Lubrication (see 5.2) .............................................. 24

Maintenance (6) ..................................................... 31

Maintenance schedule (6.2) ................................... 32

Name nomenclature (3.2)....................................... 11

Nameplate (1.7.1) .................................................... 8

Operating limits (see 3.4) ....................................... 12

Ordering spare parts (6.3.1) ................................... 32

Part assemblies (4.2) ............................................. 13

Parts lists (see 8) ................................................... 48

Performance (3.4) .................................................. 12

Piping (4.6) ............................................................ 17

Pre-commissioning (5.1) ........................................ 24

Priming and auxiliary supplies (5.6) ........................ 28

Protection systems (4.9) ........................................ 23

Page

Reassembly (see 6.10, Assembly) ......................... 40

Receipt and unpacking (2.1) .................................. 10

Recommended fill quantities (figure 5-2) ................ 25

Recommended oil lubricants (figure 5.3) ................ 25

Recommended spares (6.4) .................................. 33

Recycling (2.5) ...................................................... 11

Replacement parts (see 6.3 and 6.4) ................. 32/33

Running the pump (5.8) ......................................... 29

Safety action (1.6.3) ................................................ 5

Safety labels (1.7.2) ................................................ 8

Safety markings (1.6.1) ........................................... 5

Safety, protection systems (see 1.6 and 4.9)

Sectional drawings (8) ........................................... 48

Setting impeller clearance (6.7) ............................. 34

Sound pressure level (1.9, Noise level) .................... 9

Sources, additional information (10.3) .................... 51

Spare parts (6.3) ................................................... 32

Specific machine performance (1.8) ........................ 9

Starting the pump (5.7) .......................................... 29

Stopping and shutdown (5.9) ................................. 30

Storage, pump (2.4) .............................................. 10

Storage, spare parts (6.3.2) ................................... 32

Supplementary manuals or information sources..... 51

Supplementary User Instructions (10.1) ................. 51

Tools required (6.5) ................................ ............... 33

Torques for fasteners (6.6) .................................... 33

Trouble-shooting (see 7) ....................................... 45

Vibration (5.8.8) ..................................................... 30

Page 3 of 52 flowserve.com

Page 4

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilising sophisticated quality techniques and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety, noted in the

instructions, have been met. Failure to follow and

apply the present user instructions is considered

to be misuse. Personal injury, product damage,

delay or failure caused by misuse are not covered

by the Flowserve warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and equipment

put into service within certain regions of the world shall

conform with the applicable CE Marking Directives

covering Machinery and, where applicable, Low Voltage

Equipment, Electromagnetic Compatibility (EMC),

Pressure Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions. Where

applicable this document incorporates information

relevant to these Directives and Approvals.

To confirm the Approvals applying and if the product is

CE marked, check the serial number plate markings

and the Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be reliable. In spite of all the efforts of

Flowserve Corporation to provide sound and all

necessary information the content of this manual

may appear insufficient and is not guaranteed by

Flowserve as to its completeness or accuracy.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organisations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use.

As Flowserve cannot test parts and accessories

sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety features

of the products. The failure to properly select, install

or use authorised Flowserve parts and accessories is

considered to be misuse. Damage or failure caused

by misuse is not covered by the Flowserve warranty.

In addition, any modification of Flowserve products or

removal of original components may impair the safety

of these products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve Pump Division.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application.

If there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

Page 4 of 52 flowserve.com

Page 5

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

If the conditions of service on your purchase order are

going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user seeks

the written agreement of Flowserve before start up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction would

cause hazards. The specific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and could

result in loss of life.

This symbol indicates “hazardous and toxic fluid”

safety instructions where non-compliance would affect

personal safety and could result in loss of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This sign is not a safety symbol but indicates

an important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the personnel

in question do not already possess the necessary

knowledge and skill, appropriate training and instruction

must be provided. If required the operator may

commission the manufacturer/supplier to provide

applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to help

prevent injury to personnel and damage to the

environment and to equipment. For products used

in potentially explosive atmospheres section 1.6.4

also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

DRAIN THE PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of fluoroelastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

NEVER APPLY HEAT TO REMOVE IMPELLER

Trapped lubricant or vapour could cause an explosion.

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators and

persons entering the immediate area action must be

taken to avoid accidental contact. If complete

protection is not possible, the machine access must

be limited to maintenance staff only, with clear visual

warnings and indicators to those entering the

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be hot.

If the temperature is greater than 80 ºC (175 ºF) or

below -5 ºC (20 ºF) in a restricted zone, or exceeds

local regulations, action as above shall be taken.

Page 5 of 52 flowserve.com

Page 6

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should be

avoided.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate siting of the pump, limiting personnel

access and by operator training. If the liquid is

flammable and or explosive, strict safety procedures

must be applied.

Gland packing must not be used when pumping

hazardous liquids.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump as a support for piping. Do not mount

expansion joints, unless allowed by Flowserve in

writing, so that their force, due to internal pressure, acts

on the pump flange.

ENSURE CORRECT LUBRICATION

(See section 5, Commissioning, startup, operation and

shutdown.)

THE PUMP SHAFT MUST TURN

CLOCKWISE WHEN VIEWED FROM THE MOTOR

END

It is absolutely essential that the rotation of the motor

be checked before installation of the coupling spacer

and starting the pump. Incorrect rotation of the pump

for even a short period can unscrew the impeller,

which can cause significant damage.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

Avoid excess temperature

Prevent build up of explosive mixtures

Prevent the generation of sparks

Prevent leakages

Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

Both electrical and non-electrical equipment must meet

the requirements of European Directive 94/9/EC.

1.6.4.1 Scope of compliance

NEVER EXCEED THE MAXIMUM

DESIGN PRESSURE (MDP) AT THE

TEMPERATURE SHOWN ON THE PUMP

NAMEPLATE

See section 3 for pressure versus temperature

ratings based on the material of construction.

NEVER OPERATE THE PUMP WITH

THE DISCHARGE VALVE CLOSED

(Unless otherwise instructed at a specific point in the

user instructions.) See section 5, Commissioning

start-up, operation and shutdown.

NEVER OPERATE THE PUMP WITH

THE SUCTION VALVE CLOSED

It should be fully opened when the pump is running.

NEVER RUN THE PUMP DRY OR

WITHOUT PROPER PRIME (Casing Flooded)

NEVER OPERATE THE PUMP AT

ZERO FLOW OR FOR EXTENEDED PERIODS

BELOW THE MINIMUM CONTINUOUS FLOW

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of the

specific atmosphere in which they are to be installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The party

responsible for assembling the pump set shall select the

coupling, driver and any additional equipment, with the

necessary CE Certificate/ Declaration of Conformity

establishing it is suitable for the area in which it is to be

installed.

The output from a variable frequency drive (VFD) can

cause additional heating effects in the motor and so,

for pumps sets with a VFD, the ATEX Certification for

the motor must state that it is covers the situation

where electrical supply is from the VFD. This

particular requirement still applies even if the VFD is

in a safe area.

Page 6 of 52 flowserve.com

Page 7

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Temperature class

to EN13463-1

Maximum surface

temperature permitted

Temperature limit of

liquid handled

T6

T5

T4

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

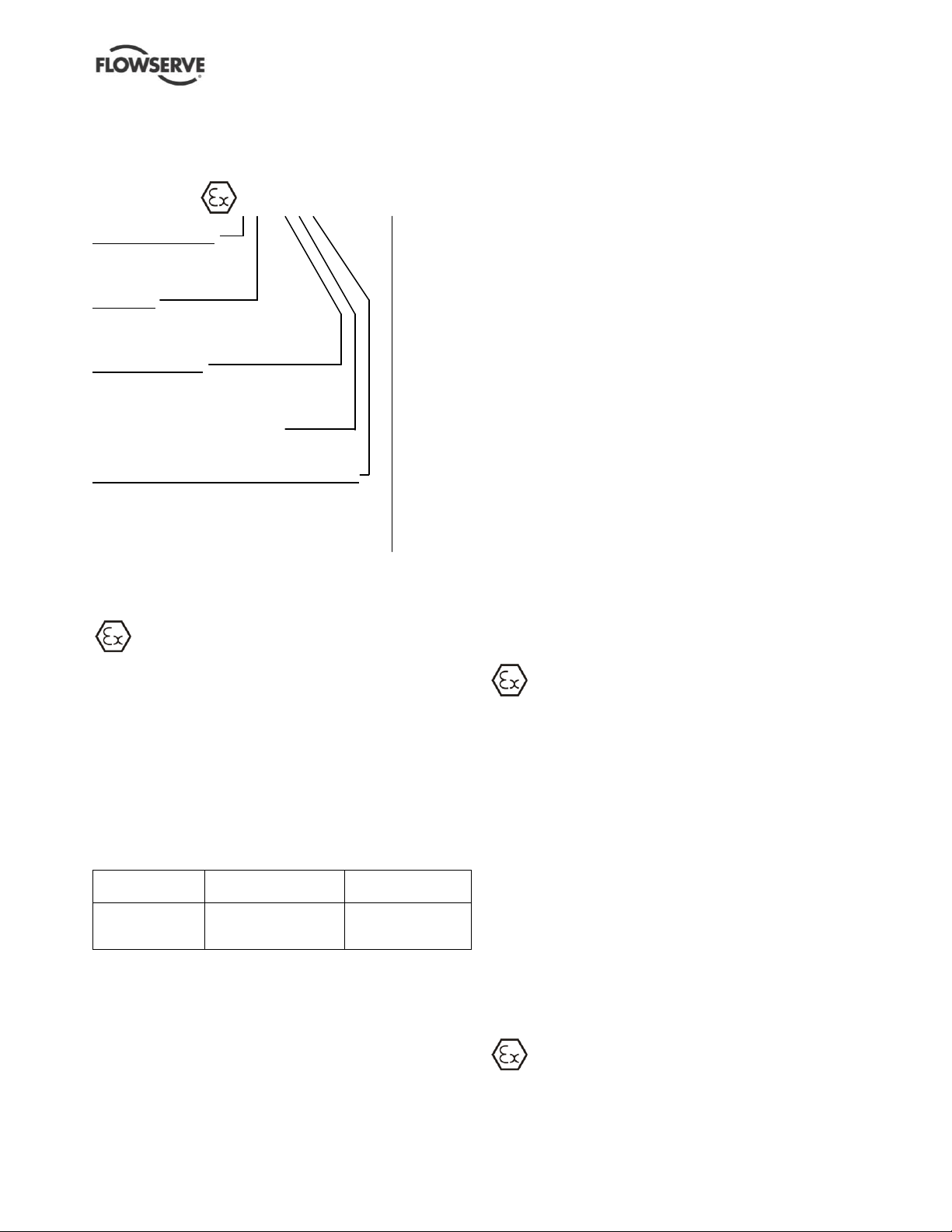

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC 135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with EN13463-5)

Gas Group (Equipment Category 2 only)

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3.)

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximum ambient of 40 ºC (104 ºF); refer to

Flowserve for higher ambient temperatures.

The surface temperature on the pump is influenced

by the temperature of the liquid handled. The

maximum permissible liquid temperature depends on

the ATEX temperature class and must not exceed the

values in the table that follows:

* The table only takes the ATEX temperature class into

consideration. Pump design or material, as well as component

design or material, may further limit the maximum working

temperature of the liquid.

The temperature rise at the seals and bearings and

due to the minimum permitted flow rate is taken into

account in the temperatures stated.

The responsibility for compliance with the specified

maximum liquid temperature is with the plant

operator.

Temperature classification “Tx” is used when the liquid

temperature varies and when the pump is required to be

used in differently classified potentially explosive

atmospheres. In this case the user is responsible for

ensuring that the pump surface temperature does not

exceed that permitted in its actual installed location.

Do not attempt to check the direction of rotation with the

coupling element/pins fitted due to the risk of severe

contact between rotating and stationary components.

Where there is any risk of the pump being run against a

closed valve generating high liquid and casing external

surface temperatures fit an external surface

temperature protection device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitor or a

power monitor and make routine vibration monitoring

checks.

In dirty or dusty environments make regular checks

and remove dirt from areas around close clearances,

bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE THE PUMP IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation so that an explosive

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heating and cooling systems are

properly filled.

If the operation of the system cannot avoid this

condition, fit an appropriate dry run protection device

(for example liquid detection or a power monitor).

To avoid potential hazards from fugitive emissions of

vapour or gas to atmosphere the surrounding area

must be well ventilated.

1.6.4.5 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking for

Category 2.

Page 7 of 52 flowserve.com

Page 8

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

To avoid the potential hazard from random induced

current generating a spark, the baseplate must be

properly grounded.

Avoid electrostatic charge: do not rub non-metallic

surfaces with a dry cloth; ensure cloth is damp.

For ATEX, the coupling must be selected to comply

with 94/9/EC. Correct coupling alignment must be

maintained.

Additional requirement for metallic pumps on

non-metallic baseplates

When metallic components are fitted on a nonmetallic baseplate they must be individually earthed.

1.6.4.6 Preventing leakage

A pump with mechanical seal must only be

used to handle liquids for which it has been approved

to have the correct corrosion resistance.

Avoid entrapment of liquid in the pump and associated

piping due to closing of suction and discharge valves,

which could cause dangerous excessive pressures to

occur if there is heat input to the liquid. This can occur if

the pump is stationary or running.

Bursting of liquid containing parts due to freezing

must be avoided by draining or protecting the pump

and ancillary systems.

Where there is the potential hazard of a loss of a seal

barrier fluid or external flush, the fluid must be monitored.

If leakage of liquid to atmosphere can result in a

hazard, install a liquid detection device.

1.6.4.7 Maintenance to avoid the hazard

1.7 Nameplate and safety labels

1.7.1 Nameplate

For details of nameplate, see the Declaration of

Conformity and section 3.

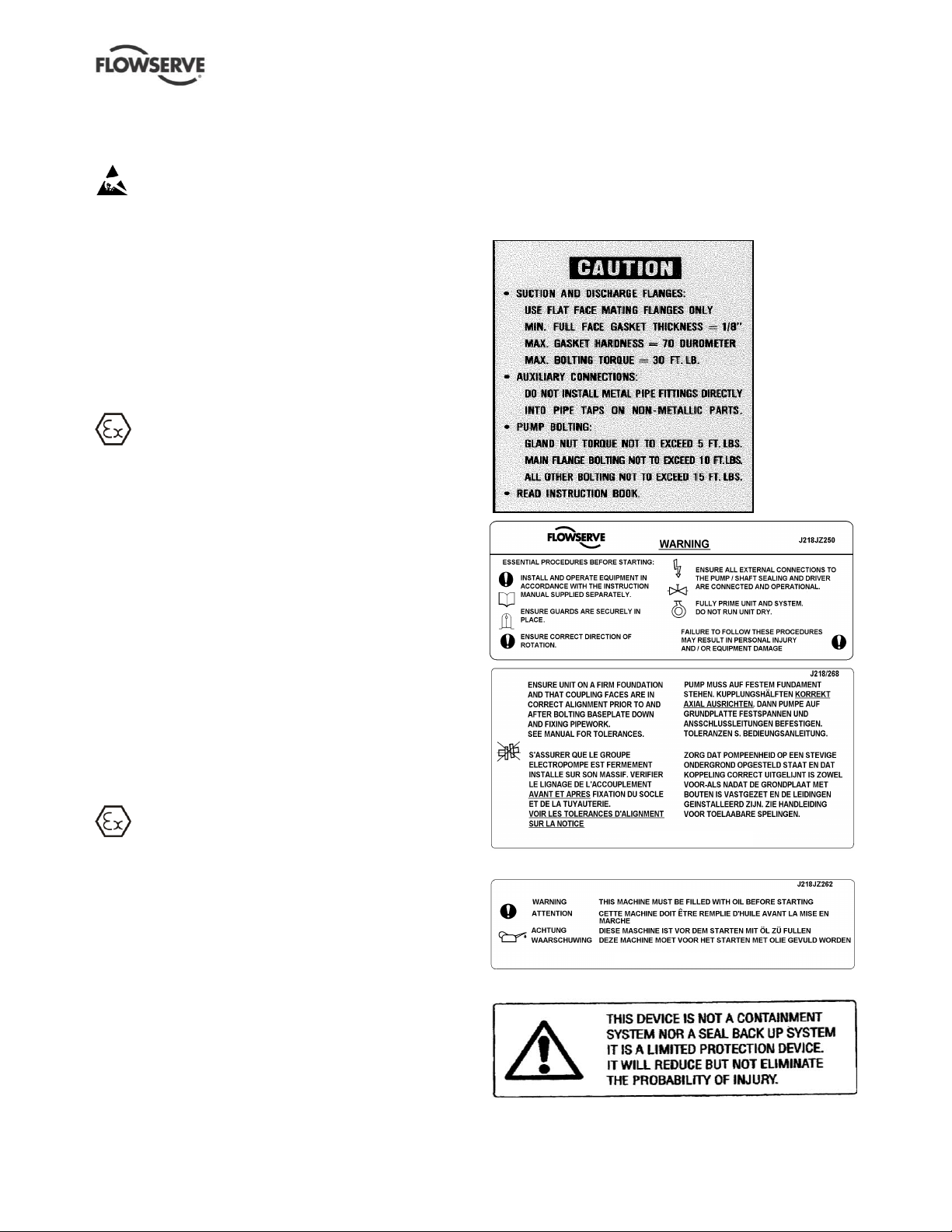

1.7.2 Safety labels

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

Oil lubricated units only:

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

DurcoShieldTM (splash/shaft guard

adversely affect the ambient conditions. Where there

is a risk from such tools or materials, maintenance

must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (See section 6, Maintenance.)

Page 8 of 52 flowserve.com

Page 9

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

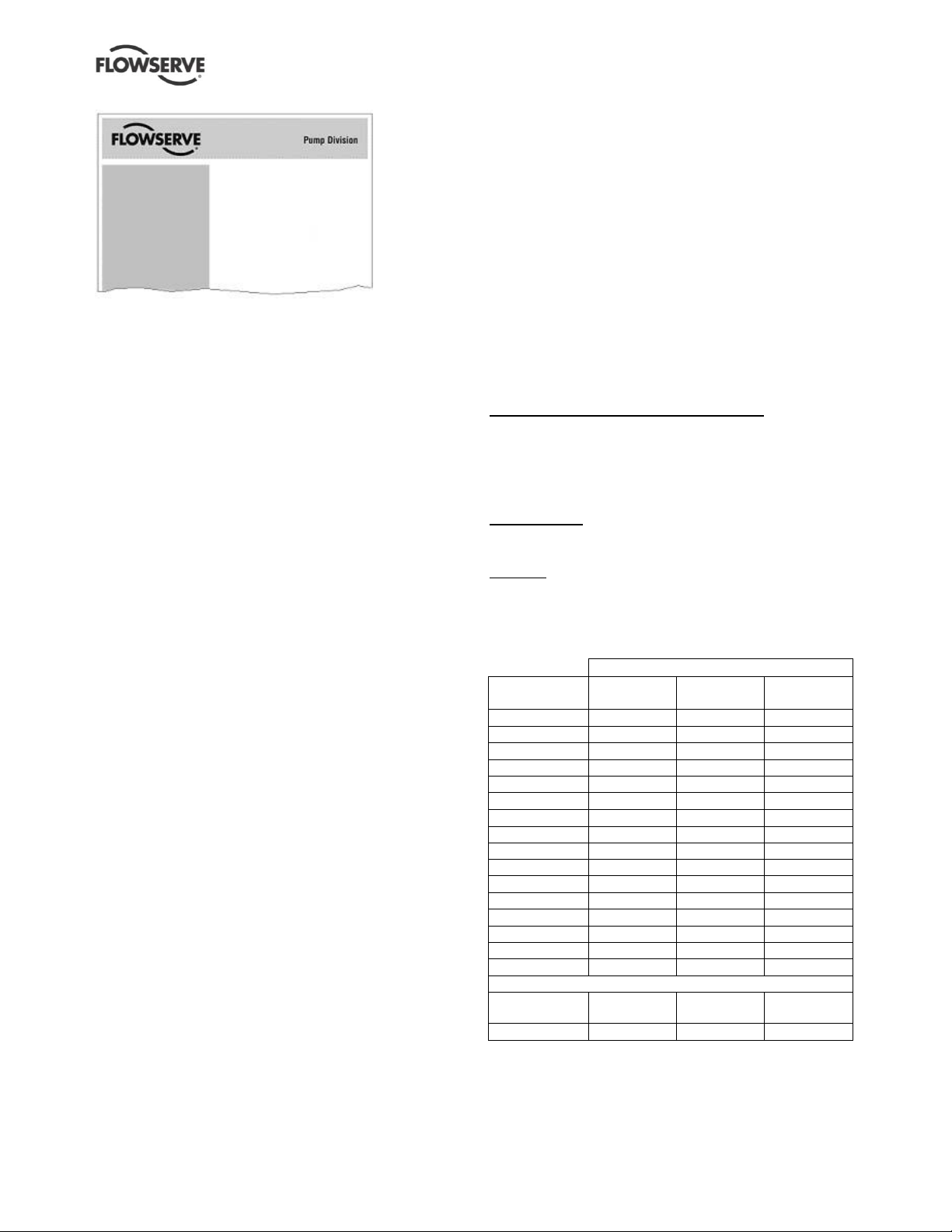

Motor size

and speed

kW (hp)

Typical sound pressure level LpA at 1 m reference 20 μPa, dBA

3 550 r/min

2 900 r/min

1 750 r/min

1 450 r/min

Pump

only

Pump and

motor

Pump

only

Pump and

motor

Pump

only

Pump and

motor

Pump

only

Pump and

motor

<0.55(<0.75)

72

72

64

65

62

64

62

64

0.75 (1)

72

72

64

66

62

64

62

64

1.1 (1.5)

74

74

66

67

64

64

62

63

1.5 (2)

74

74

66

71

64

64

62

63

2.2 (3)

75

76

68

72

65

66

63

64

3 (4)

75

76

70

73

65

66

63

64

4 (5)

75

76

71

73

65

66

63

64

5.5 (7.5)

76

77

72

75

66

67

64

65

7.5 (10)

76

77

72

75

66

67

64

65

11(15)

80

81

76

78

70

71

68

69

15 (20)

80

81

76

78

70

71

68

69

18.5 (25)

81

81

77

78

71

71

69

71

22 (30)

81

81

77

79

71

71

69

71

30 (40)

83

83

79

81

73

73

71

73

37 (50)

83

83

79

81

73

73

71

73

45 (60)

86

86

82

84

76

76

74

76

55 (75)

86

86

82

84

76

76

74

76

75 (100)

87

87

83

85

77

77

75

77

90 (120)

87

88

83

85

77

78

75

78

110 (150)

89

90

85

87

79

80

77

80

150 (200)

89

90

85

87

79

80

77

80

200 (270)

85

87

83

85

300 (400)

–

87

90

85

86

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. Where performance data has been supplied

separately to the purchaser these should be obtained

and retained with these User Instructions if required.

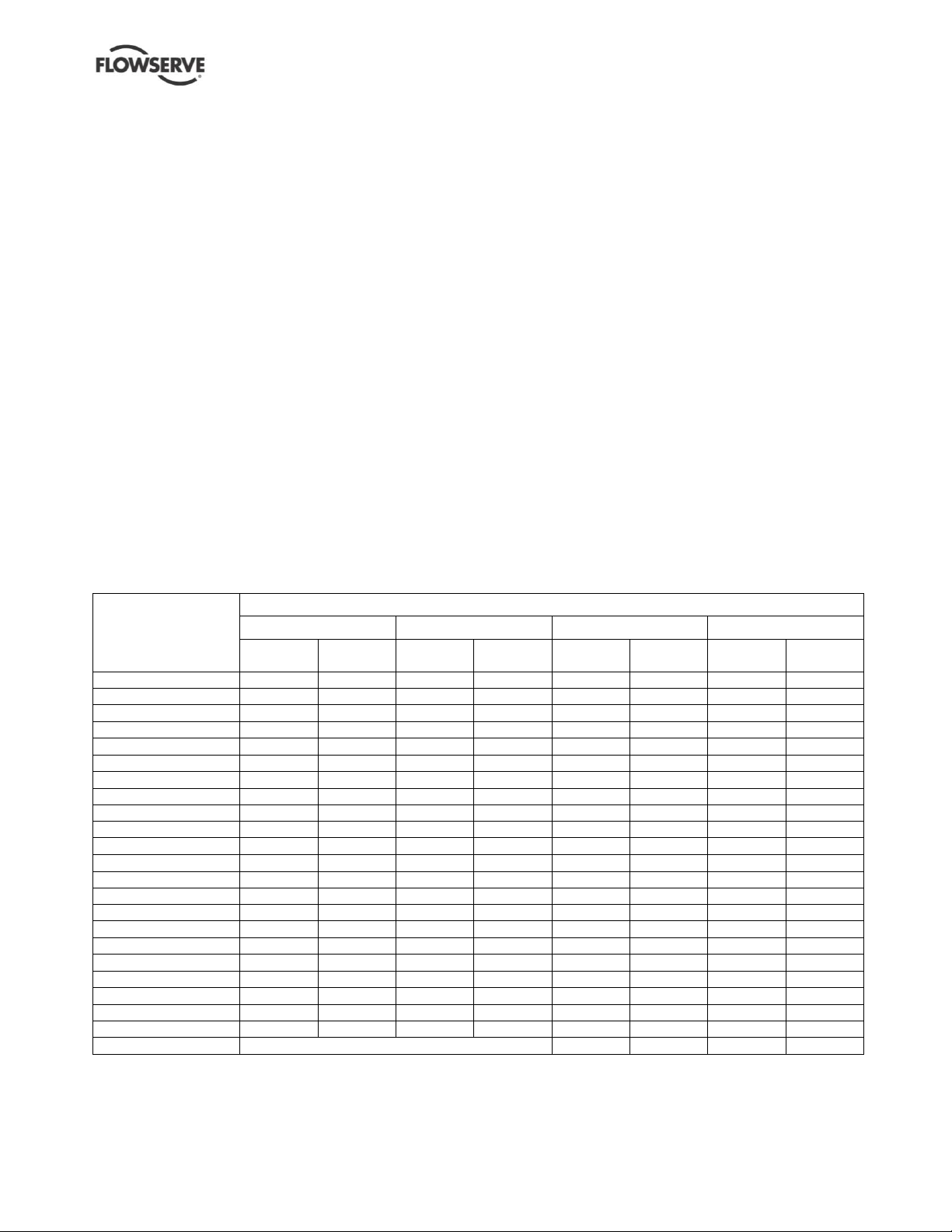

1.9 Noise level

Attention must be given to the exposure of personnel

to the noise, and local legislation will define when

guidance to personnel on noise limitation is required,

and when noise exposure reduction is mandatory.

This is typically 80 to 85 dBA.

The usual approach is to control the exposure time to

the noise or to enclose the machine to reduce emitted

sound. You may have already specified a limiting

noise level when the equipment was ordered,

however if no noise requirements were defined, then

attention is drawn to the following table to give an

indication of equipment noise level so that you can

take the appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipework design and

acoustic characteristics of the building, and so the

values given are subject to a 3 dBA tolerance and

cannot be guaranteed.

Similarly the motor noise assumed in the “pump and

motor” noise is that typically expected from standard

and high efficiency motors when on load directly driving

the pump. Note that a motor driven by an inverter may

show an increased noise at some speeds.

If a pump unit only has been purchased for fitting with

your own driver then the “pump only” noise levels in

the table should be combined with the level for the

driver obtained from the supplier. Consult Flowserve

or a noise specialist if assistance is required in

combining the values.

It is recommended that where exposure approaches

the prescribed limit, then site noise measurements

should be made.

The values are in sound pressure level LpA at 1 m

(3.3 ft) from the machine, for “free field conditions

over a reflecting plane”.

For estimating sound power level LWA (re 1 pW) then

add 14 dBA to the sound pressure value.

The noise level of machines in this range will most likely be of values which require noise exposure control, but typical values are inappropriate.

Note: for 1 180 and 960 r/min reduce 1 450 r/min values by 2 dBA. For 880 and 720 r/min reduce 1 450 r/min values by 3 dBA.

Page 9 of 52 flowserve.com

Page 10

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and/or damage must

be reported immediately to Flowserve Pump Division

and must be received in writing within one month of

receipt of the equipment. Later claims cannot be

accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their

size and construction.

2.3 Lifting

A crane must be used for all pump sets in

excess of 25 kg (55 lb). Fully trained personnel must

carry out lifting, in accordance with local regulations.

The driver and pump weights are recorded on their

respective nameplates.

Pumps and motors often have integral

lifting lugs or eye bolts. These are intended for use in

only lifting the individual piece of equipment.

2.3.1.2 Rear cover [1220]

Use a choker hitch slung through the central seal

chamber hole to lift large rear covers.

2.3.1.3 Bearing housing [3200]

Group 1. Insert a sling between the upper and lower

support ribs between the housing barrel and the

casing attachment flange. Use a choker hitch when

slinging. (Make sure there are no sharp edges on the

bottom side of the ribs which could cut the sling.)

Group 2 and 3. Insert either a sling or hook through

the lifting lug located on the top of the housing.

2.3.1.4 Power end

Same as bearing housing.

2.3.1.5 Bare pump

Horizontal pumps. Sling under the casing and

around the outboard end of the bearing housing with

separate slings. Choker hitches must be used at

both attachment points and pulled tight. The sling

lengths should be adjusted to balance the load before

attaching the lifting hook.

2.3.2 Lifting pump, motor and baseplate assembly

If the baseplate has lifting holes cut in the sides at the

end (type A Group 3, type D, and type E bases) insert

lifting S hooks at the four corners and use slings or

chains to connect to the lifting eye. Do not use slings

through the lifting holes because of sharp edges.

Other styles of baseplates can be lifted by placing

slings slightly outboard from the center of mass of the

motor and pump. A spreader bar may be required to

maintain the sling spacing during lifting.

2.4 Storage

Do not use eye bolts or cast-in lifting

lugs to lift pump, motor and baseplate assemblies.

To avoid distortion, the pump unit

should be lifted as described in this section.

Care must be taken to lift components

or assemblies above the center of gravity to prevent

the unit from flipping.

2.3.1 Lifting pump components

2.3.1.1 Casing [1100]

Use a choker hitch through the suction hole and

around the casing body.

Page 10 of 52 flowserve.com

location away from vibration. Leave piping

connection covers in place to keep dirt and other

foreign material out of pump casing. Turn pump at

intervals to prevent brinelling of the bearings and the

seal faces, if fitted, from sticking.

The pump may be stored as above for up to six

months. Consult Flowserve for preservative actions

when a longer storage period is needed.

2.4.1 Short term storage and packaging

Normal packaging is designed to protect the pump

and parts during shipment and for dry, indoor storage

for up to six months or less. The following is an

overview of our normal packaging:

Store the pump in a clean, dry

Page 11

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

All loose unmounted items are packaged in a

waterproof plastic bag and placed under the

coupling guard. Larger items are boxed and

metal banded to the baseplate. For pumps not

mounted on a baseplate, the bag and/or box is

placed inside the shipping container.

Inner surfaces of the bearing housing, shaft (area

through bearing housing) and bearings are

coated with Cortec VCI-329 rust inhibitor, or

equal. (Note: bearing housings are not filled with

oil prior to shipment.)

Regreasable bearings are packed with grease.

(EXXON POLYREX EM for horizontal pumps.)

Exposed shafts are taped with Polywrap.

Flange covers are secured to both the suction

and discharge flanges.

Assemblies ordered with external piping, in some

cases components may be disassembled for

shipment.

The pump must be stored in a covered, dry location.

2.4.2 Long term storage

Long term storage is defined as more than six

months, but less than 12 months. The procedure

Flowserve follows for long term storage of pumps is

given below. These procedures are in addition to the

short term procedure.

Each assembly is hermetically (heat) sealed from

the atmosphere by means of tack wrap sheeting

and rubber bushings (mounting holes).

Desiccant bags are placed inside the tack

wrapped packaging.

A solid wood box is used to cover the assembly.

This packaging will provide protection for up to twelve

months from humidity, salt laden air, dust etc.

After unpacking, protection will be the responsibility of

the user. Addition of oil to the bearing housing will

remove the inhibitor. If units are to be idle for

extended periods after addition of lubricants, inhibitor

oils and greases should be used. Every three

months, the pump shaft should be rotated

approximately 10 revolutions.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local requirements. If the

product contains substances that are harmful to the

environment, these should be removed and disposed

of in accordance with current regulations.

This also includes the liquids and or gases that may

be used in the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3 DESCRIPTION

3.1 Configurations

PolyChem GRP chemical process pumps are end

suction, single stage, centrifugal pumps. The GRP

family conforms to ASME B73.5M as a non-metallic

wet end, end suction, centerline discharge

arrangement. There is also a self-priming option

available. These pumps are made of a glassreinforced polymer that is designed to handle a wide

range of chemicals. PolyChem GRP pumps may

often be used as a cost-effective solution where

stainless steel, Alloy 20, Monel, Nickel, Hastelloy ™,

and even titanium metal pumps are used.

3.2 Name nomenclature

The pump size will be engraved on the nameplate

typically as below:

2K 4 X 3G – 13 / 12.5

Frame size:

“2K’ indicates a medium size pump frame with a

Mark3 power end - in this example, a Group 2.

1J or 1K = Group 1 (small frame)

2K = Group 2 (medium frame)

3J = Group 3 (large frame – 2 ⅜ in. shaft)

4J = Group 4 (large frame – 2 ¾ in. shaft)

Power end:

Mark 3A – Standard

ANSI 3A – Optional (3 year guarantee)

“4” = Nominal suction port size.

“3” = Nominal discharge port size.

“G” = PolyChem GRP pump line

“GS” = Self-primer version

Nominal maximum impeller diameter:

“13” = 13 in. diameter

Actual impeller size:

“12.5” = 12 ½ in. diameter

An example of the nameplate used on the PolyChem

GRP pump is shown below. This nameplate, which is

always mounted on the Mark 3 bearing housing, is

shown in figure 3-1.

Page 11 of 52 flowserve.com

Page 12

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Figure 3-2

Bar (psi)

Size

-46 °C

(-50 °F)

66 °C

(150 °F)

121 °C

(250 °F)

1J1.5x1G-6

13.79 (200)

13.79 (200)

10.34 (150)

1J3x1.5G-6

13.79 (200)

13.79 (200)

10.34 (150)

1J3x2G-6

13.79 (200)

13.79 (200)

10.34 (150)

1J1.5x1G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K3x1.5G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K3x2G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K4x3G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K2x1G-10

17.24 (250)

17.24 (250)

13.79 (200)

2K3x1.5G-10

6.89 (100)

6.89 (100)

5.17 (75)

2K4x3G-10

6.89 (100)

6.89 (100)

5.17 (75)

2K6x4G-10

6.89 (100)

6.89 (100)

5.17 (75)

2K3x1.5G-13

8.62 (125)

8.62 (125)

6.89 (100)

2K4x3G-13

8.62 (125)

8.62 (125)

6.89 (100)

3J8x6G-13

10.34 (150)

10.34 (150)

8.62 (125)

3J12x10G-15

6.89 (100)

6.89 (100)

5.17 (75)

4J12x10G-15B

6.89 (100)

6.89 (100)

5.17 (75)

Size

-29 °C

(-20 °F)

66 °C

(150 °F)

107 °C

(225 °F)

1K3x2GS-7

9.31 (135)

9.31 (135)

9.31 (135)

2K4X3G-13/12.5

Serial No.

Equipment No.

Purchase Order

Model

Size

MDP

Material

Date DD/MMM/YY

3.3.8 Driver

The driver is normally an electric motor. Different drive

configurations may be fitted such as internal combustion

engines, turbines, hydraulic motors etc driving via

couplings, belts, gearboxes, drive shafts etc.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

Figure 3-1

3.3 Design of major parts

3.3.1 Pump casing

The pump casing is designed with a horizontal

centerline suction inlet and a vertical centerline top

discharge which makes it self venting.

Removal of the casing is not required when

performing maintenance of the rotating element. The

pump is designed with a gasket perpendicular to the

shaft allowing the rotating element to be easily

removed (back pull out).

3.3.2 Impeller

An open impeller design is the only offering.

3.3.3 Shaft/sleeve

The pump shafts are sleeved, supported on rolling

element bearings, with both threaded and polygon

3.4 Performance and operating limits

This product has been selected to meet the

specification of your purchase order. (See section 1.5.)

Typical materials used in the PolyChem GRP include:

Casing, impeller, rear cover, and glands. Glass

reinforced plastic (GRP) composed of chopped

fiberglass strands in a Derakane 470™ vinyl ester

resin. (Durcon 730, a glass reinforced thermo-setting

epoxy resin, is used for the 1K3x2GS-7.)

Shaft sleeves. Ryton plastic (Polyphenylene

sulfide) or high alloy steels are available.

Shafting. 4140 carbon steel as standard with 17-4

PH stainless steel as an option. (Superchlor 77 is the

standard shaft material for the 1K3x2GS-7 pump.)

3.4.1 Pressure-temperature ratings

drive ends for the impeller and a keyed drive end.

3.3.4 Pump bearings and lubrication

Ball bearings are fitted as standard and may be either

oil or grease lubricated.

3.3.5 Bearing housing

Options include a large reservoir for oil bath

lubrication or the use of zerk fittings for regreasable

bearings. A micrometer shaft adjustment allows

external setting of the impeller gap.

3.3.6 Seal chamber (cover plate)

The seal chamber has a spigot (rabbet) fit between

the pump casing and bearing housing (adapter) for

optimum concentricity. The design enables a number

of sealing options to be fitted.

3.3.7 Shaft seal

The mechanical seal(s), attached to the pump shaft,

seals the pumped liquid from the environment. Gland

packing may be fitted as an option.

Page 12 of 52 flowserve.com

Page 13

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Figure 3-3

MCF (% of BEP)

Size

3 600

r/min

3 000

r/min

1 800

r/min

1 200

r/min

1J1.5x1G-6

10

10

10

10

1J3x1.5G-6

10

10

10

10

1J3x2G-6

10

10

10

10

1J3x2GS-7

10

10

10

10

1J1.5x1G-8

10

10

10

10

2K3x1.5G-8

10

10

10

10

2K3x2G-8

10

10

10

10

2K4x3G-8

20

20

20

20

2K2x1G-10

10

10

10

10

2K3x1.5G-10

N/A

10

10

10

2K4x3G-10

N/A

25

25

25

2K6x4G-10

N/A

25

25

25

2K3x1.5G-13

N/A

N/A

25

25

2K4x3G-13

N/A

N/A

25

25

3J8x6G-13

N/A

N/A

25

25

3J12x10G-15

N/A

N/A

N/A

25

4J12x10G-15B

N/A

N/A

25

25

The pressure-temperature charts for PolyChem GRP

pumps are shown in figure 3-2. Maximum fluid

temperature for Derakane 470™ material is 121 °C

(250 °F) and for Durcon 730 is 107 °C (225 °F).

The following data are typical, and factors such as

liquid being pumped, temperature, and seal type may

influence them. If required, a definitive statement for

your application can be obtained from Flowserve.

3.4.2 Minimum continuous flow

The minimum continuous flow (MCF) is based on a

percentage of the best efficiency point (BEP). Figure

3-3 identifies the MCF for all PolyChem GRP pump

models.

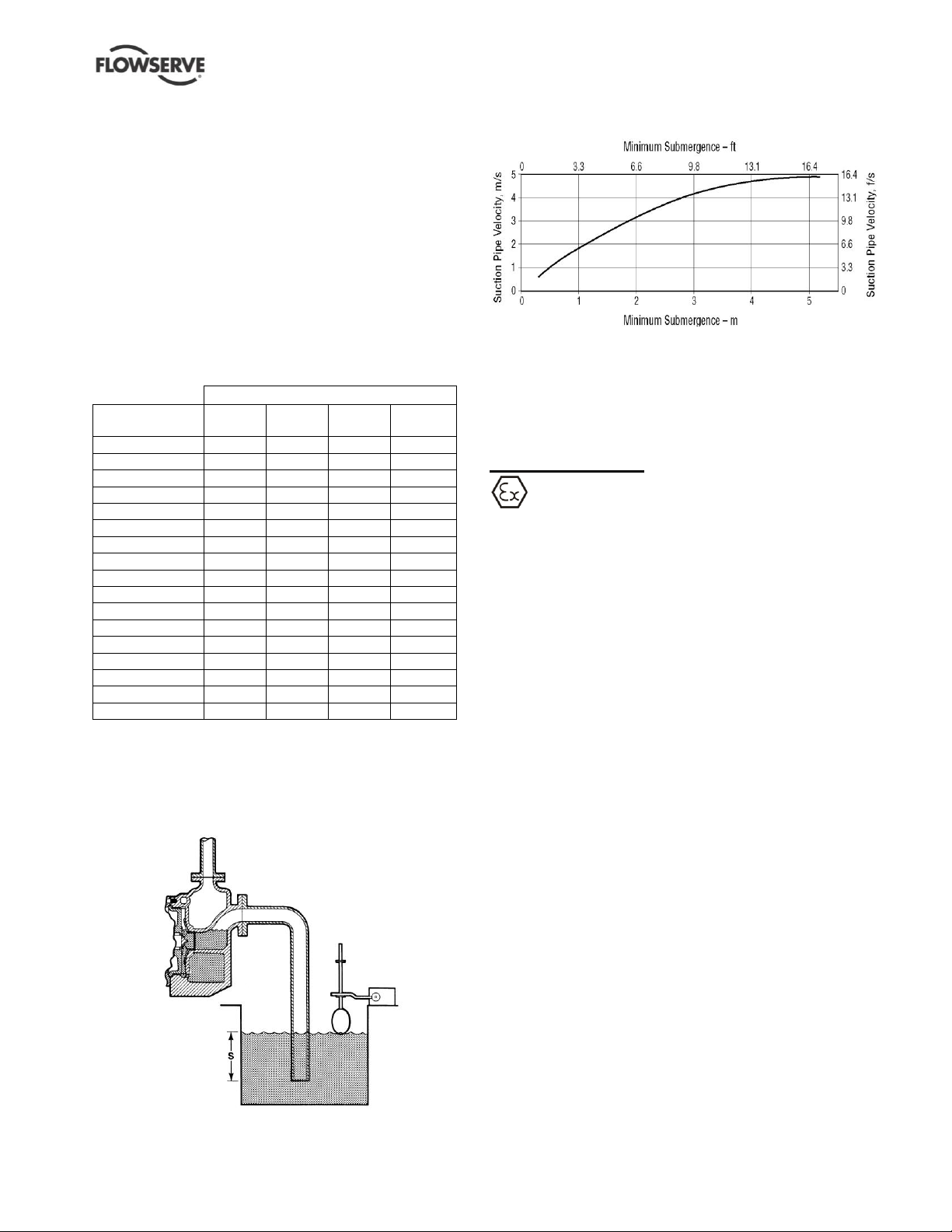

3.4.3 Minimum suction pipe submergence

The minimum submergence is shown in figure 3-4 and

3-5 for the 1K3x2GS-7 unitized self-priming pump.

Figure 3-4: Minimum submergence

Figure 3-5: Minimum submergence

3.4.4 Suction pressure limits

Open style impellers typically create a thrust load

towards the suction of the pump. This reduces the axial

loading on the bearings so that the suction pressure

limit is equal to the pressure-temperature rating.

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4, Products used in

potentially explosive atmospheres.

4.1 Location

The pump should be located to allow room for access,

ventilation, maintenance and inspection with ample

headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped. Refer

to the general arrangement drawing for the pump set.

4.2 Part assemblies

The supply of motors and baseplates is optional. As

a result, it is the responsibility of the installer to

ensure that the motor is assembled to the pump and

aligned as detailed in sections 4.5 and 4.8.

4.3 Foundation

4.3.1 Protection of openings and threads

When the pump is shipped, all threads and all

openings are covered. This protection/covering

should not be removed until installation. If, for any

reason, the pump is removed from service, this

protection should be reinstalled.

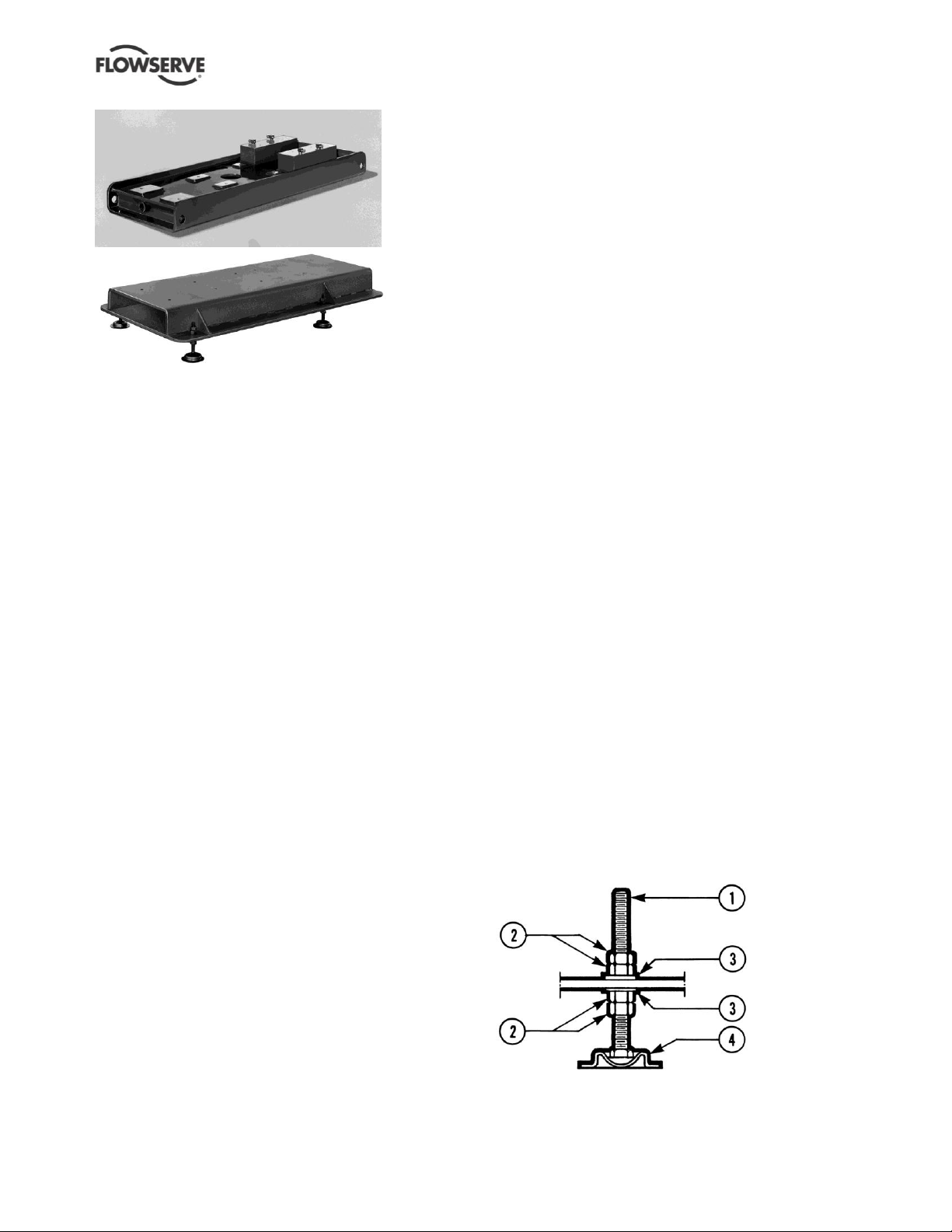

4.3.2 Rigid baseplates - overview

The function of a baseplate is to provide a rigid

foundation under a pump and its driver that maintains

alignment between the two. Baseplates may be

generally classified into two types:

Foundation-mounted, grouted design (figure 4-1)

Stilt mounted, or free-standing (figure 4-2)

Page 13 of 52 flowserve.com

Page 14

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

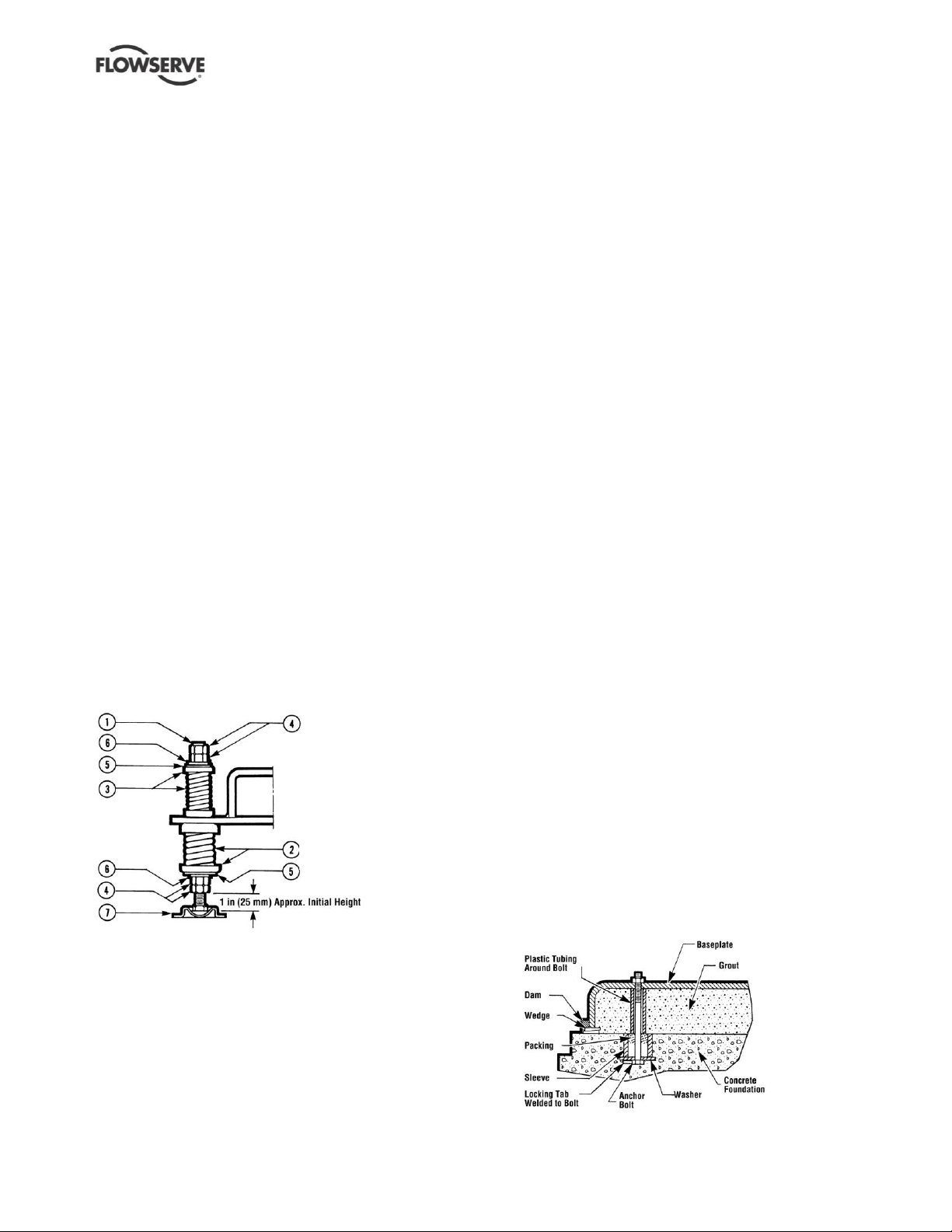

Figure 4-3

1. Stilt bolt

2. Nuts

3. Lock washer

4. Floor cup

capability at the motor to obtain a “perfect” final

alignment when the installer puts the baseplate

assembly into its original, top leveled, unstressed

condition.

4.3.3 Stilt and spring mounted baseplates

Flowserve offers stilt and spring mounted baseplates.

Figure 4-1

(See Figure 4-2 for stilt mounted option.) The low

vibration levels of PolyChem GRP pumps allow the use

of these baseplates - provided they are of a rigid design.

The baseplate is set on a flat surface with no tie down

bolts or other means of anchoring it to the floor.

Figure 4-2

Baseplates intended for grouted installation are

designed to use the grout as a stiffening member.

Stilt mounted baseplates, on the other hand, are

designed to provide their own rigidity. Therefore, the

designs of the two baseplates are usually different.

Regardless of the type of baseplate used, it must

provide certain functions that ensure a reliable

installation. Three of these requirements are:

The baseplate must provide sufficient rigidity to

assure the assembly can be transported and

installed, given reasonable care in handling,

without damage. It must also be rigid enough

when properly installed to resist operating loads.

The baseplate must provide a reasonably flat

mounting surface for the pump and driver.

Uneven surfaces will result in a soft-foot condition

that may make alignment difficult or impossible.

Flowserve experience indicates that a baseplate

that has a top surface flatness of 1.25 mm/m

(0.015 in./ft) across the diagonal corners of the

baseplate provides such a mounting surface.

Therefore, this is the tolerance to which we supply

our standard baseplate. Some users may desire

an even flatter surface, which can facilitate

installation and alignment. Flowserve will supply

flatter baseplates upon request at extra cost. For

example, mounting surface flatness of 0.17 mm/m

General instructions for assembling these baseplates

are given below. For dimensional information, please

refer to the appropriate Flowserve “Sales Print.”

4.3.3.1 Stilt mounted baseplate assembly

instructions

(Refer to figure 4-3.)

a) Raise or block up baseplate/pump above the floor

to allow for the assembly of the stilts.

b) Predetermine or measure the approximate

desired height for the baseplate above the floor.

c) Set the bottom nuts (item 2) above the stilt bolt

head (item 1) to the desired height.

d) Assemble lock washer (item 3) down over the stilt

bolt.

e) Assemble the stilt bolt up through hole in the

bottom plate and hold in place.

f) Assemble the lock washer (item 3) and nut (item 2)

on the stilt bolt. Tighten the nut down on the lock

washer.

g) After all four stilts have been assembled, position

the baseplate in place, over the floor cups (item 4)

under each stilt location, and lower the baseplate

to the floor.

h) Level and make final height adjustments to the

suction and discharge pipe by first loosening the

top nuts and turning the bottom nuts to raise or

lower the baseplate.

i) Tighten the top and bottom nuts at the lock

washer (item 3) first then tighten the other nuts.

(0.002 in./ft) is offered on the Flowserve Type E

“Ten Point” baseplate shown in figure 4-1.

The baseplate must be designed to allow the user

to final field align the pump and driver to within

their own particular standards and to compensate

for any pump or driver movement that occurred

during handling. Normal industry practice is to

achieve final alignment by moving the motor to

match the pump. Flowserve practice is to confirm

in our shop that the pump assembly can be

accurately aligned. Before shipment, the factory

verifies that there is enough horizontal movement

Page 14 of 52 flowserve.com

Page 15

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

1. Stilt bolt

2. Bottom spring 3 ¼ in.

(83 mm) OD x 4 in.

(102 mm) floor cups

3. Top spring 2 in. (51 mm)

OD x 4 in. (102 mm) floor

cups

4. Nuts

5. Flat washer

6. Lock washer

7. Floor cup

j) It should be noted that the connecting pipelines

must be individually supported, and that the stilt

mounted baseplate is not intended to support

total static pipe load.

4.3.3.2 Stilt/spring mounted baseplate assembly

instructions

(Refer to figure 4-4.)

a) Raise or block up baseplate/pump above the floor

to allow for the assembly of the stilts.

b) Set the bottom nuts (item 4) above the stilt bolt

head (item 1). This allows for 51 mm (2 in.)

upward movement for the final height adjustment

of the suction/discharge flange.

c) Assemble the lock washer (item 6) flat washer

(item 5) and bottom spring/cup assembly (item 2)

down over the stilt bolt (item 1).

d) Assemble the stilt bolt/bottom spring up through

hole in the bottom plate and hold in place.

e) Assemble top spring/cup assembly (item 3) down

over stilt bolt.

f) Assemble flat washer (item 5), lock washer (item 6)

and nuts (item 4) on the stilt bolt.

g) Tighten down top nuts, compressing the top

spring approximately 25 mm (1 in.).

h) After all four stilts have been assembled, position

the baseplate in place, over the floor cups (item 7)

under each stilt location, and lower the baseplate

down to the floor.

i) Level and make final height adjustments to the

suction and discharge pipe by first loosening the

top nuts, and turning the bottom nuts to raise or

lower the baseplate.

j) To make the stilt bolts more stable, tighten down

on the top nuts, compressing the top spring

approximately 25 mm (1 in.), and lock the nuts in

place.

k) It should be noted that the connecting pipelines

must be individually supported, and that the

spring mounted baseplate is not intended to

support total static pipe loads.

Page 15 of 52 flowserve.com

Figure 4-4

4.3.3.3 Stilt/spring mounted baseplates - motor

alignment

The procedure for motor alignment on stilt or spring

mounted baseplates is similar to grouted baseplates.

The difference is primarily in the way the baseplate is

leveled.

a) Level the baseplate by using the stilt adjusters.

(Shims are not needed as with grouted

baseplates.) After the base is level, it is locked in

place by locking the stilt adjusters.

b) Next the initial pump alignment must be checked.

The vertical height adjustment provided by the

stilts allows the possibility of slightly twisting the

baseplate. If there has been no transit damage

or twisting of the baseplate during stilt height

adjustment, the pump and driver should be within

0.38 mm (0.015 in.) parallel, and 0.0025 mm/mm

(0.0025 in./in.) angular alignment. If this is not

the case, check to see if the driver mounting

fasteners are centered in the driver feet holes.

c) If the fasteners are not centered there was likely

shipping damage. Re-center the fasteners and

perform a preliminary alignment to the above

tolerances by shimming under the motor for

vertical alignment, and by moving the pump for

horizontal alignment.

d) If the fasteners are centered, then the baseplate

may be twisted. Slightly adjust (one turn of the

adjusting nut) the stilts at the driver end of the

baseplate and check for alignment to the above

tolerances. Repeat as necessary while maintaining

a level condition as measured from the pump

discharge flange. Lock the stilt adjusters.

e) The remaining steps are as listed for new grouted

baseplates.

4.4 Grouting

a) The pump foundation should be located as close to

the source of the fluid to be pumped as practical.

There should be adequate space for workers to

install, operate, and maintain the pump. The

foundation should be sufficient to absorb any

vibration and should provide a rigid support for the

pump and motor. Recommended mass of a

concrete foundation should be three times that of

the pump, motor and base. (Refer to figure 4-5.)

Figure 4-5

Page 16

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

baseplate or if they were not removed from the

Foundation bolts are imbedded in the

concrete inside a sleeve to allow some

movement of the bolt.

b) Level the pump baseplate assembly. If the

baseplate has machined coplanar mounting

surfaces, these machined surfaces are to be

referenced when leveling the baseplate. This may

require that the pump and motor be removed from

the baseplate in order to reference the machined

faces. If the baseplate is without machined

coplanar mounting surfaces, the pump and motor

are to be left on the baseplate. The proper

surfaces to reference when leveling the pump

baseplate assembly are the pump suction and

discharge flanges. DO NOT stress the baseplate.

Do not bolt the suction or discharge flanges of the

pump to the piping until the baseplate foundation

is completely installed. If equipped, use leveling

jackscrews to level the baseplate. If jackscrews

are not provided, shims and wedges should be

used (see figure 4-5). Check for levelness in both

the longitudinal and lateral directions. Shims

should be placed at all base anchor bolt locations,

and in the middle edge of the base if the base is

more than 1.5 m (5 ft) long. Do not rely on the

bottom of the baseplate to be flat. Standard

baseplate bottoms are not machined, and it is not

likely that the field mounting surface is flat.

c) After leveling the baseplate, tighten the anchor

bolts. If shims were used, make sure that the

baseplate was shimmed near each anchor bolt

before tightening. Failure to do this may result in

a twist of the baseplate, which could make it

impossible to obtain final alignment. Check the

level of the baseplate to make sure that

tightening the anchor bolts did not disturb the

level of the baseplate. If the anchor bolts did

change the level, adjust the jackscrews or shims

as needed to level the baseplate. Continue

adjusting the jackscrews or shims and tightening

the anchor bolts until the baseplate is level.

d) Check initial alignment. If the pump and motor

were removed from the baseplate proceed with

step e) first, then the pump and motor should be

reinstalled onto the baseplate using Flowserve’s

factory preliminary alignment procedure as

described in section 4.5, and then continue with

the following. As described above, pumps are

given a preliminary alignment at the factory. This

preliminary alignment is done in a way that

ensures that, if the installer duplicates the factory

conditions, there will be sufficient clearance

between the motor hold down bolts and motor foot

holes to move the motor into final alignment. If the

pump and motor were properly reinstalled to the

baseplate and there has been no transit damage,

and also if the above steps where done properly,

the pump and driver should be within 0.38 mm

(0.015 in.) FIM (Full Indicator Movement) parallel,

and 0.0025 mm/mm (0.0025 in./in.) FIM angular.

If this is not the case, first check to see if the driver

mounting fasteners are centered in the driver feet

holes. If not, re-center the fasteners and perform

a preliminary alignment to the above tolerances by

shimming under the motor for vertical alignment,

and by moving the pump for horizontal alignment.

e) Grout the baseplate. A non-shrinking grout

should be used. Make sure that the grout fills the

area under the baseplate. After the grout has

cured, check for voids and repair them.

Jackscrews, shims and wedges should be

removed from under the baseplate at this time. If

they were to be left in place, they could rust,

swell, and cause distortion in the baseplate.

f) Run piping to the suction and discharge of the

pump. There should be no piping loads

transmitted to the pump after connection is made.

Recheck the alignment to verify that there are no

significant loads.

4.5 Initial alignment

Pump and driver must be isolated

electrically and the half couplings disconnected.

The alignment MUST be checked.

4.5.1 Horizontal initial alignment procedure

The purpose of factory alignment is to ensure that the

user will have full utilization of the clearance in the

motor holes for final job-site alignment. To achieve

this, the factory alignment procedure specifies that

the pump be aligned in the horizontal plane to the

motor, with the motor foot bolts centered in the motor

holes. This procedure ensures that there is sufficient

clearance in the motor holes for the customer to field

align the motor to the pump, to zero tolerance. This

philosophy requires that the customer be able to

place the base in the same condition as the factory.

Thus the factory alignment will be done with the base

sitting in an unrestrained condition on a flat and level

surface. This standard also emphasizes the need to

ensure the shaft spacing is adequate to accept the

specified coupling spacer.

The factory alignment procedure is summarized

below:

a) The baseplate is placed on a flat and level

workbench in a free and unstressed position.

Page 16 of 52 flowserve.com

Page 17

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

b) The baseplate is leveled as necessary. Leveling

is accomplished by placing shims under the rails

of the base at the appropriate anchor bolt hole

locations. Levelness is checked in both the

longitudinal and lateral directions.

c) The motor and appropriate motor mounting

hardware is placed on the baseplate and the motor

is checked for any planar soft-foot condition. If any

is present it is eliminated by shimming

d) The motor feet holes are centered on the motor

mounting fasteners. This is done by using a

centering nut as shown in figure 4-6.

Figure 4-6

e) The motor is fastened in place by tightening the

nuts on two diagonal motor mounting studs.

f) The pump is put onto the baseplate and leveled.

The foot piece under the bearing housing is

adjustable. If an adjustment is necessary, add or

remove shims [109A] between the foot piece and

the bearing housing.

g) The spacer coupling gap is verified.

h) The parallel and angular vertical alignment is

made by shimming under the motor.

i) The motor feet holes are again centered on the

motor mounting studs using the centering nut.

At this point the centering nut is removed and

replaced with a standard nut. This gives

maximum potential mobility for the motor to be

horizontally moved during final, field alignment.

All four motor feet are tightened down.

j) The pump and motor shafts are then aligned

horizontally, both parallel and angular, by moving

the pump to the fixed motor.

k) The pump feet are tightened down.

l) Both horizontal and vertical alignment is again

final checked as is the coupling spacer gap.

See section 4.8 for Final Shaft Alignment

4.6 Piping

Protective covers are fitted to the pipe

connections to prevent foreign bodies entering during

transportation and installation. Ensure that these

covers are removed from the pump before connecting

any pipes.

4.6.1 Suction and discharge pipework

Never use pump as a support for

piping.

All piping must be independently supported,

accurately aligned and preferably connected to the

pump by a short length of flexible piping. The pump

should not have to support the weight of the pipe or

compensate for misalignment. It should be possible

to install suction and discharge bolts through mating

flanges without pulling or prying either of the flanges.

All piping must be tight.

Pumps may air-bind if air is allowed to leak into the

piping. If the pump flange(s) have tapped holes,

select flange fasteners with thread engagement at

least equal to the fastener diameter, but that do not

bottom out in the tapped holes before the joint is tight.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. To

minimize these forces and moments that may, if

excessive, cause misalignment, hot bearings, worn

couplings, vibration and the possible failure of the

pump casing, the following points should be strictly

followed:

Prevent excessive external pipe load

Never draw piping into place by applying force to

pump flange connections

Do not mount expansion joints so that their force,

due to internal pressure, acts on the pump flange

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is arranged

to allow pump flushing before removal of the pump.

The GRP suction and discharge flanges require full

flat face gaskets with a minimum thickness of 3.2 mm

(0.125 in.) and a hardness 70 durometer (Shore A).

Check that the gasket material is compatible with the

fluid and that the inner diameter of the gasket is

centered before assembly.

Use flat washers behind the pump flanges and do not

exceed 41 Nm (30 lbf•ft) torque on the flange bolting.

4.6.2 Suction piping

To avoid NPSH and suction problems, suction piping

must be at least as large as the pump suction

connection. Never use pipe or fittings on the suction

that are smaller in diameter than the pump suction size.

Page 17 of 52 flowserve.com

Page 18

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Figure 4-7 illustrates the ideal piping configuration

with a minimum of 10 pipe diameters between the

source and the pump suction. In most cases,

horizontal reducers should be eccentric and mounted

with the flat side up as shown in figure 4-8 with a

maximum of one pipe size reduction. Never mount

eccentric reducers with the flat side down.

Horizontally mounted concentric reducers should not

be used if there is any possibility of entrained air in

the process fluid. Vertically mounted concentric

reducers are acceptable. In applications where the

fluid is completely de-aerated and free of any vapor

or suspended solids, concentric reducers are

preferable to eccentric reducers

Figure 4-7 Figure 4-8

Avoid the use of throttling valves and strainers in the

suction line. Start up strainers must be removed

shortly before start up. When the pump is installed

below the source of supply, a valve should be

installed in the suction line to isolate the pump and

permit pump inspection and maintenance. However,

never place a valve directly on the suction nozzle of

the pump.

Refer to the Durco Pump Engineering Manual and

the Centrifugal Pump IOM section of the Hydraulic

Institute Standards for additional recommendations

on suction piping, section 10. Refer to section 3.4 for

performance and operating limits.

4.6.3 Discharge piping

Install a valve in the discharge line. This valve is

required for regulating flow and or to isolate the pump

for inspection and maintenance.

When fluid velocity in the pipe is high,

for example, 3 m/s (10 ft/sec) or higher, a rapidly

closing discharge valve can cause a damaging

pressure surge. A dampening arrangement should

be provided in the piping.

A non-return valve should be located in the discharge

pipework to protect the pump from excessive back

pressure and hence reverse rotation when the unit is

stopped.

4.6.4 Allowable nozzle loads - PolyChem GRP

pumps (ASME B73.5)

Flowserve chemical process pumps meet or exceed

the allowable nozzle loads given by ANSI/HI 9.6.2.

The following paragraphs describe how to calculate

the allowable loads for each pump type and how to

determine if the applied loads are acceptable.

The following steps are based upon ANSI/HI 9.6.2.

All information necessary to complete the evaluation

is given below. For complete details please review

the standard.

a) Find the “Baseplate Correction Factor” in figure

4-10. The correction factor depends upon how

the baseplate is to be installed

b) The casing material correction factor for the GRP

material is 0.9.

c) Select the lowest correction factor from steps a)

and b). For example:

If the pump is mounted on a Type A grouted

baseplate, the correction factor used is 0.9.

If the pump is mounted on a Type D stilt

mounted baseplate, the correction factor is 0.75.

d) Locate the pump model being evaluated in

figures 4-12 through 4-15 and multiply each load

rating by the lowest correction factor. Record the

adjusted loads for each table.

e) Calculate the applied loads at the casing flanges

according to the coordinate system depicted in

figure 4-9. The 12 forces and moments possible

are Fxs, Fys, Fzs, Mxs, Mys, Mzs, Fxd, Fyd, Fzd,

Mxd, Myd and Mzd. For example, Fxd

designates Force in the “x” direction on the

discharge flange. Mys designates the Moment

about the “y”-axis on the suction flange.

f) Figure 4-11 gives the acceptance criteria

equations. For long coupled pumps, equation

sets 1 through 5 must be satisfied.

g) Equation set 1. Each applied load is divided by

the corresponding adjusted figure 4-12 value.

The absolute value of each ratio must be less

than or equal to one.

h) Equation set 2. The summation of the absolute

values of each ratio must be less than or equal to

two. The ratios are the applied load divided by

the adjusted figure 4-13 values.

i) Equation sets 3 and 4. These equations are

checking for coupling misalignment due to nozzle

loading in each axis. Each applied load is divided

by the corresponding adjusted load from figure 4-14

and 4-15. The result of each equation must be

between one and negative one.

j) Equation set 5. This equation calculates the total

shaft movement from the results of equations 3 and

4. The result must be less than or equal to one.

Page 18 of 52 flowserve.com

Page 19

USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Base type

Grouted

Bolted

Stilt

mounted

Type A

1.0

0.7

0.65

Type B - Polybase

1.0

n/a

0.95

Type C

n/a

1.0

1.0

Type D

1.0

0.8

0.75

Type E - PIP

1.0

0.95

n/a

Polyshield - baseplate

/foundation

1.0

n/a

n/a

Set

Equations

Figure

Remarks

1

0.1,0.1,0.1,0.1,0.1,0.1

,0.1,0.1,0.1,0.1,0.1,0.1

______

______

adjzd

zd

adjyd

yd

adjxd

xd

adjzd

zd

adjyd

yd

adjxd

xd

adjzs

zs

adjys

ys

adjxs

xs

adjzs

zs

adjys

ys

adjxs

xs

M

M

M

M

M

M

F

F

F

F

F

F

M

M

M

M

M

M

F

F

F

F

F

F

Adjusted

4-12

Maximum

individual

loading

2

0.2

______

______

adjzd

zd

adjyd

yd

adjxd

xd

adjzd

zd

adjyd

yd

adjxd

xd

adjzs

zs

adjys

ys

adjxs

xs

adjzs

zs

adjys

ys

adjxs

xs

M

M

M

M

M

M

F

F

F

F

F

F

M

M

M

M

M

M

F

F

F

F

F

F

Adjusted

4-13

Nozzle stress,

bolt stress,

pump slippage

3

adjzd

zd

adjyd

yd

adjxd

xd

adjyd

yd

adjzs

zs

adjys

ys

adjxs

xs

adjys

ys

M

M

M

M

M

M

F

F

M

M

M

M

M

M

F