Page 1

USER INSTRUCTIONS

Polybase baseplates

Non-metallic, solid polymer concrete

AMSE B73.1 and ISO 3661 dimensions

PCN=71569284 – 12-10 Original instructions

Installation

Operation

Maintenance

Page 2

Polybase Baseplate USER INSTRUCTIONS ENGLISH 71569284 USER – 12-10

CONTENTS

1 INTRODUCTION AND SAFETY.......................3

1.1 General.........................................................3

1.2 CE marking and approvals ...........................3

1.3 Disclaimer.....................................................3

1.4 Copyright ......................................................3

1.5 Duty conditions .............................................3

1.6 Safety............................................................4

1.7 Nameplate and safety labels........................6

2 TRANSPORT AND STORAGE.........................6

2.1 Consignment receipt and unpacking............6

2.2 Handling........................................................6

2.3 Lifting ............................................................6

2.4 Storage .........................................................8

2.5 Recycling and end of product life .................8

3 DESCRIPTION .................................................8

3.1 Configurations...............................................8

3.2 Nomenclature ...............................................9

3.3 Design of major parts....................................9

3.4 Performance and operation limits.................9

4 INSTALLATION ..............................................11

4.1 Location ......................................................11

4.2 Part Assemblies..........................................11

4.3 Foundation..................................................11

4.4 Grouting......................................................15

5 COMMISSIONING, STARTUP, OPERATION

AND SHUTDOWN...................................................16

6 MAINTENANCE..............................................16

6.1 Maintenance schedule................................16

6.2 Spare parts..................................................16

6.3 Recommended spares and consumable

items ...........................................................17

6.4 Tools required.............................................17

6.5 Field thread insert installation procedure....17

6.6 Field installed thread insert testing

(Optional)....................................................18

6.7 Recommended fastener mounting

torques........................................................19

7 FAULTS: CAUSES AND REMEDIES............. 20

8 PARTS LIST AND DRAWINGS...................... 21

9 CERTIFICATION ............................................22

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS ...............................................................22

10.1 Supplementary user instructions............22

10.2 Change Notes ........................................22

10.3 Additional sources of information...........22

Page 2 of 24 flowserve.com

Page 3

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety noted in the

instructions, have been met. Failure to follow and

apply the present user instructions is considered

to be misuse. Personal injury, product damage,

delay or failure caused by misuse are not covered

by the Flowserve warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and equipment

put into service within certain regions of the world shall

conform with the applicable CE Marking Directives

covering Machinery and, where applicable, Low Voltage

Equipment, Electromagnetic Compatibility (EMC),

Pressure Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable the Directives and any additional

Approvals cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions. Where

applicable this document incorporates information

relevant to these Directives and Approvals.

To confirm the Approvals applying and if the product is

CE marked, check the serial number plate markings

and the Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be complete and reliable. However, in spite of

all of the efforts of Flowserve Corporation to

provide comprehensive instructions, good

engineering and safety practice should always be

used.

Flowserve manufactures products to exacting

International Quality Management System Standards as

certified and audited by external Quality Assurance

organizations. Genuine parts and accessories have

been designed, tested and incorporated into the

products to help ensure their continued product quality

and performance in use. As Flowserve cannot test

parts and accessories sourced from other vendors the

incorrect incorporation of such parts and accessories

may adversely affect the performance and safety

features of the products. The failure to properly select,

install or use authorized Flowserve parts and

accessories is considered to be misuse. Damage or

failure caused by misuse is not covered by the

Flowserve warranty. In addition, any modification of

Flowserve products or removal of original components

may impair the safety of these products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

If the conditions of service on your purchase order

are going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user

seeks the written agreement of Flowserve before

start up.

Page 3 of 24 flowserve.com

Page 4

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction would

cause hazards. The specific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and

could result in loss of life.

This symbol indicates “hazardous and toxic fluid”

safety instructions where non-compliance would affect

personal safety and could result in loss of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This sign is not a safety symbol but indicates

an important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer/supplier

to provide applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

prevent injury to personnel and damage to the

environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

(Lock Out)

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

equipment can present a danger to operators and

persons entering the immediate area, action must be

taken to avoid accidental contact (such as shielding).

If complete protection is not possible, the machine

access must be limited to maintenance staff only with

clear visual warnings and indicators to those entering

the immediate area. Note: bearing housings must not

be insulated and drive motors and bearings may be

hot.

If the temperature is greater than 80°C (175 °F) or

below -5 °C (23 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump as a support for piping. Do not

mount expansion joints, unless allowed by Flowserve

in writing, so that their force, due to internal pressure,

acts on the pump flange.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate pump placement, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive, strict safety procedures

must be applied.

Page 4 of 24 flowserve.com

Page 5

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent build up of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

For ATEX, both electrical and non-electrical equipment

must meet the requirements of European Directive

94/9/EC. Always observe the regional legal Ex

requirements eg Ex electrical items outside the EU may

be required certified to other than ATEX eg IECEx,

UL/CSA.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of the

specific atmosphere in which they are to be installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The party

responsible for assembling the pump set shall select the

coupling, driver and any additional equipment, with the

necessary CE Certificate/ Declaration of Conformity

establishing it is suitable for the area in which it is to be

installed. That party are also responsible for CE

Marking the complete machine.

The output from a variable frequency drive (VFD) can

cause additional heating effects in the motor and so,

for pumps sets with a VFD, the ATEX Certification for

the motor must state that it is covers the situation

where electrical supply is from the VFD. This

particular requirement still applies even if the VFD is

in a safe area.

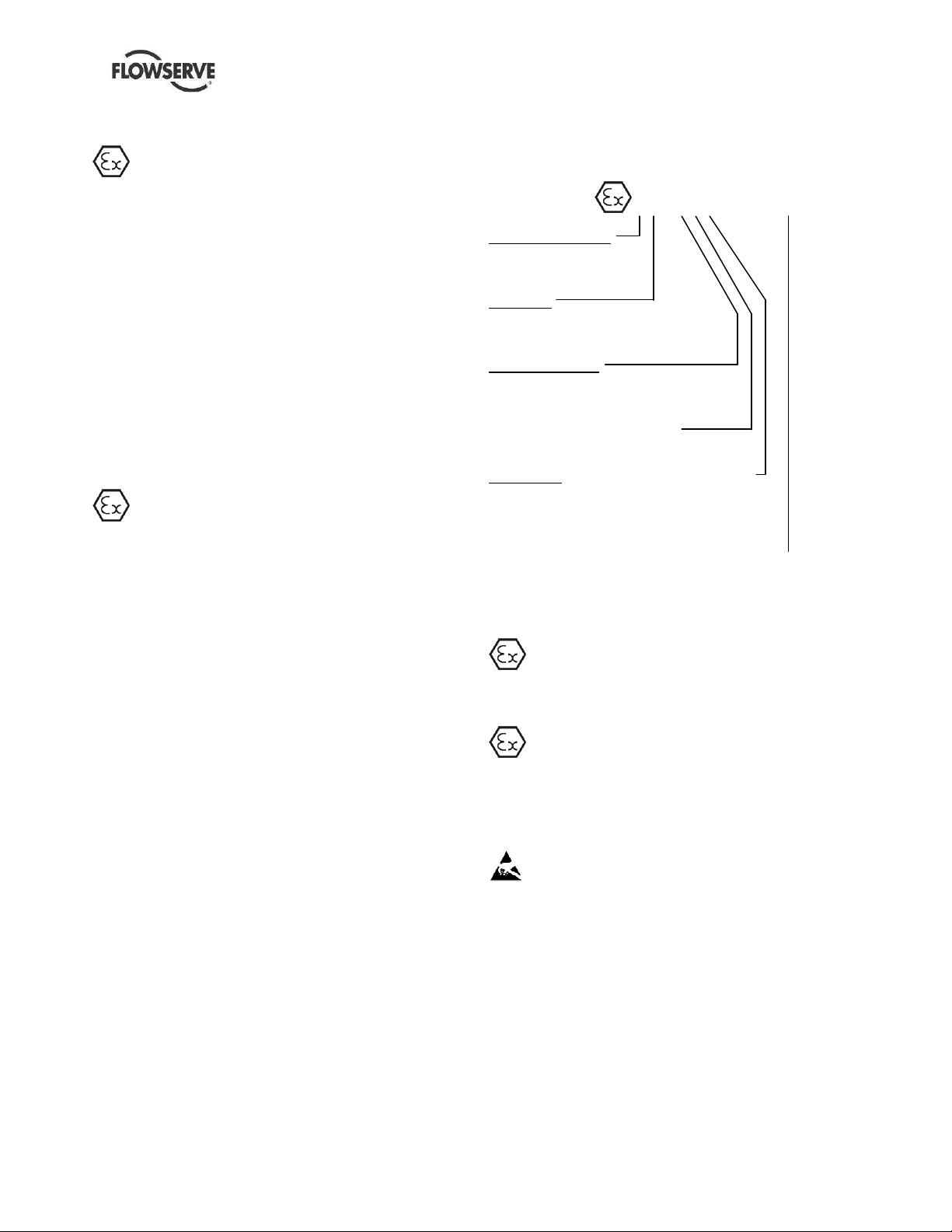

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC T135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with EN13463-5)

Gas Group

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3.)

1.6.4.3 Avoiding excessive surface

temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

1.6.4.4 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking.

To avoid the potential hazard from random induced

current generating a spark, the earth contact on the

baseplate must be used.

Avoid electrostatic charge: do not rub non-metallic

surfaces with a dry cloth; ensure cloth is damp.

The coupling must be selected to comply with 94/9/EC

and correct alignment must be maintained.

Additional requirement for metallic pumps on

non-metallic baseplates

When metallic components are fitted on a nonmetallic baseplate they must be individually earthed.

Page 5 of 24 flowserve.com

Page 6

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

1.6.4.5 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions. Where there

is a risk from such tools or materials, maintenance

must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (See section 6, Maintenance.)

1.7 Nameplate and safety labels

1.7.1 Safety labels

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and/or damage must

be reported immediately to Flowserve Pump Division

and must be received in within ten days of receipt of

the equipment. Later claims cannot be accepted.

Check all crates, boxes or wrappings for any

accessories or spare parts that may be packed

separately from the equipment or attached to side

walls of the box or equipment. After unpacking,

protection will be the responsibility of the user.

Each product has a unique serial number. Check

that this number corresponds with your order. Use

this number in correspondence as well as when

ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork-lift vehicles or slings depending on their

size and construction.

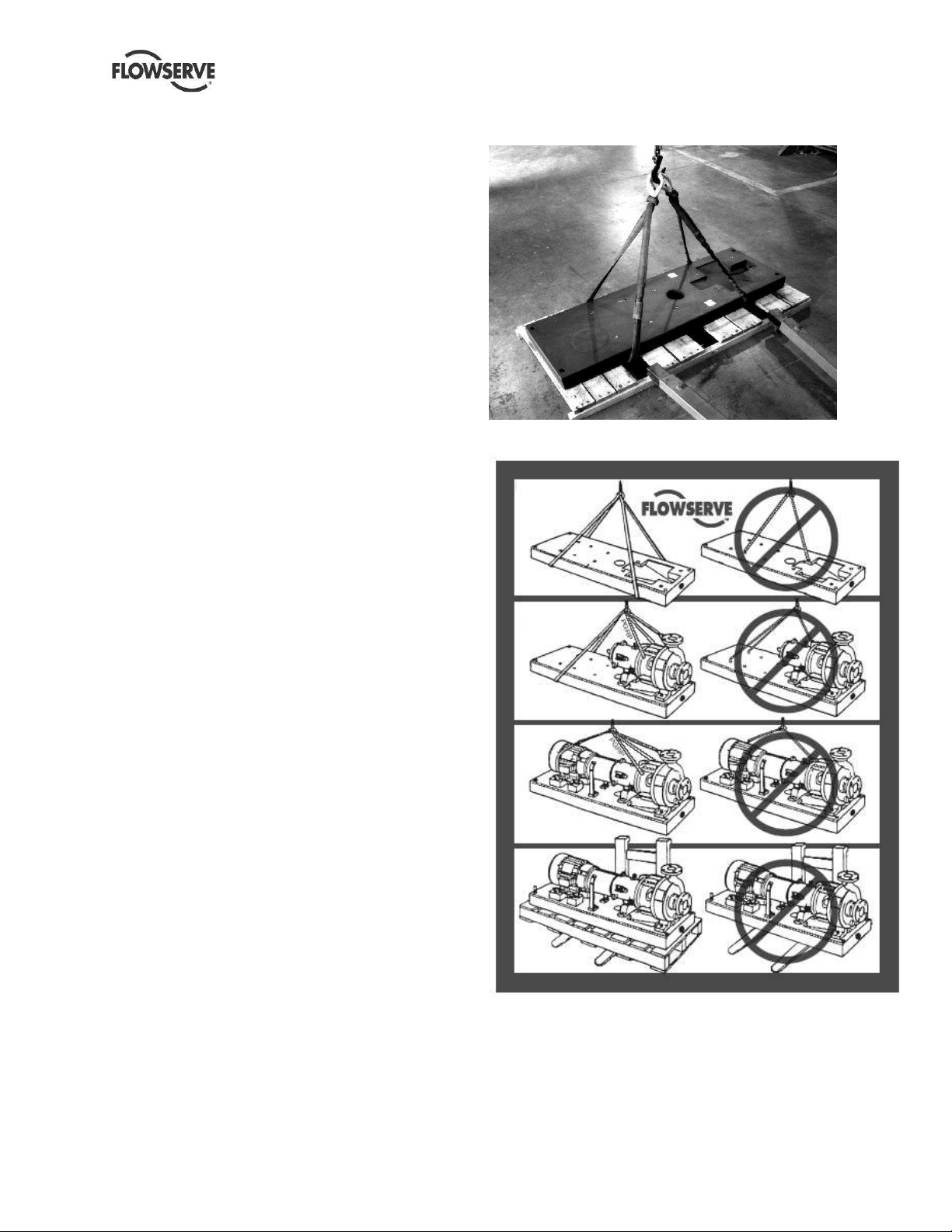

2.3 Lifting

Fully trained personnel must carry out lifting in

accordance with local regulations. The Polybase

baseplate dimensions and weights are shown in

Section 8 PARTS LIST AND DRAWINGS.

.Do not install eye bolts in the Polybase

thread inserts for the purpose of lifting the base. This

practice imposes lateral loads on the inserts which

they were not designed to withstand. Also, do not use

hooks in the baseplate anchor bolt holes.

Pumps and motors often have integral

lifting lugs or eye bolts. These are intended for use in

only lifting the individual piece of equipment.

Do not use eye bolts or cast-in lifting

lugs to lift pump, motor and baseplate assemblies.

Polybase units should be transported

via fork truck to the area of their intended installation

on the wooden pallets on which they were shipped.

Never transport a Polybase over long distances or

over rough terrain while it is suspended from slings.

Care must be taken to lift components

or assemblies above the center of gravity to prevent

the unit from flipping.

Page 6 of 24 flowserve.com

Page 7

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

2.3.1 Lifting Polybase baseplates with no

mounted equipment

a) Remove the fasteners that hold the Polybase to

the wooden pallet.

b) Slip two slings under the baseplate between

pallet cross-members as shown in Figure 2.1.

Slings should be positioned approximately onequarter to one-third the baseplate length from

each end.

c) Lift the Polybase a few inches off the pallet and

verify that it hangs reasonably level and that the

slings are not prone to slipping out of position.

d) If this slinging appears to be unstable, set the

baseplate back on the pallet and reposition the

slings. After satisfactory slinging has been

achieved, the baseplate may be hoisted onto its

foundation.

2.3.2 Lifting the Polybase baseplate with pump

and motor installed

a) Remove the fasteners that hold the Polybase to

the wooden pallet.

b) Install slings around the pump discharge nozzle

(except for PGRP pumps where the slings must

go around and through the adapter) and around

the outboard end of the motor frame using

choker hitches pulled tight. The motor sling

should be positioned so the weight is not carried

through the fan housing. Make sure the

completion of the choker hitch on the discharge

nozzle (or adapter arms) is toward the coupling

end of the pump shaft as shown in Figure 2.2.

2.3.3 Lifting the Polybase baseplate with only

the pump installed

a) Remove the fasteners that hold the Polybase to

the wooden pallet.

b) Install a sling around the pump discharge nozzle

using a choker hitch pulled tight (except for

PGRP pumps where the slings must go around

and through the adapter).

c) Install a second sling around the motor end of

the Polybase using a basket hitch (see Figure

2.2). Make sure the completion of the choker

hitch on the discharge nozzle is toward the

coupling end of the pump shaft. Refer to section

4.0 INSTALLATION for setting the base on the

foundation.

d)

Figure 2.1

Figure 2.2

Page 7 of 24 flowserve.com

Page 8

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

2.4 Storage

This section addresses the storage procedures for

the Polybase baseplate only. When storing a

Polybase baseplate with mounted pump assemblies,

it is extremely important that the proper storage

procedures for the pump be observed as well. Refer

to the User Instruction for the particular pump that is

mounted on your baseplate. Flowserve's normal

packaging is designed to protect the Polybase

baseplate during shipment and handling from the

time it is assembled at the factory to installation at the

end user's jobsite. If the Polybase baseplate is to be

stored for a period of time prior to installation, it is

recommended that the following procedures be

followed:

a) Leave the baseplate bolted to its wooden

shipping pallet.

b) Place the pallet on a solid, dry, level surface in a

location where the base cannot be struck by

passing fork trucks, falling objects, etc. Make

sure that the pallet does not rock.

c) Do not stack heavy objects on top of the

baseplate.

d) If the Polybase will be installed in an indoor

location, but is to be stored in an outdoor

location, cover the base completely with a

tarpaulin or dark plastic sheeting to prevent UV

degradation of the surface. NOTE: UV

degradation (bleaching) of the polymer concrete

is the normal result of exposure to sunlight. This

phenomenon is purely a visual change in the

color of the material which in no way

compromises the performance or corrosion

resistance characteristics of the Polybase

baseplate.

e) Multiple Polybase baseplates without installed

equipment may be stacked, provided the bases

are level and the stacking is done in a manner

which uniformly distributes the weight of the

upper base to the top surface of the base on

which it rests. A minimum of two pallet crossmembers should contact the entire width of the

lower base. Cross members must not rest on

fasteners or on the corners of the lower base.

Do not attempt to stand a Polybase

baseplate on end to make more efficient use of

storage space. Neither the base nor the fasteners

that hold the base to its wooden pallet have been

designed for vertical storage. Severe personal

injury or death, as well as irreparable damage to

Polybase baseplate, may result if it tips over.

f) After unpacking, protection will be the

responsibility of the user.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and in accordance with local

regulations. If the product contains substances that

are harmful to the environment, these should be

removed and disposed of in accordance with current

local regulations. This also includes the liquids

and/or gases that may be used in the "seal system"

or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

local regulations at all times.

3 DESCRIPTION

3.1 Configurations

The Flowserve Polybase baseplate is a solid,

polymer concrete baseplate that is manufactured in

versions that conform to both ASME B73.1 and ISO

3661.

ASME Polybase units are manufactured with integral

drain basin and grout hole. Integral leveling screw

thread inserts facilitate proper installation. Twelve

sizes are available ranging from 139 through 398.

ISO Polybase units are manufactured with integral

drain basin, and are available in sizes ISO 3, 4, 5, 6,

7 and 8.

Metallic thread inserts are provided in the mounting

surfaces for particular combinations of pump and

motors. Multiple motor insert patterns are also

available, and custom insert configurations can be

produced per customer specifications. The standard

thread insert material is 304SS (18.10 CrNi stainless

steel), with higher alloys available upon request.

Three different epoxy vinyl ester resin materials are

available to support the use of Polybase baseplates

in most chemical applications (see 3.3.2).

Additional available options include stilt mounting and

flush plan mounting.

Page 8 of 24 flowserve.com

Page 9

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

The Polybase baseplate utilizes as standard the

unique Polybloc mounting system. This system is

comprised of corrosion resistant polymer concrete

mounting blocks having surface flatness and

parallelism equivalent to machined steel blocks.

Motor mounting Polyblocs incorporate the unique

Bloc-loc™ counterbore/jam nut feature for positive

attachment to the baseplate (Figure 3.1).

The optional 8-point™ motor adjusters and the Blocloc™ features are joined to provide axial and

transverse motor adjustment (Figure 3.1).

Figure 3.1

Counterbore type Mounting Polyblocs are also totally

suitable if order requirements do not require that

motor Polyblocs must be independently locked to the

baseplate. In this case the polymeric block are fitted

with the counterbore side of the block facing the

surface of the baseplate.

3.2 Nomenclature

Individual baseplate sizes in the Polybase baseplate

product line are identified by the ASME B73.1 pump

group size they support and the length of the

baseplate. For example:

139 = Group 1 pumps; 39 inches long.

264 = Group 2 pumps; 64 inches long.

398 = Group 3 pumps; 98 inches long.

The length of the baseplate determines the motor

frame size that can be fitted. The longer baseplates

allow larger motors to be fitted.

3.3 Design of major parts

3.3.1 Baseplate materials of construction

The body of a Polybase baseplate is composed of an

epoxy vinyl ester resin with integral silica aggregate.

The threaded inserts are made of 304SS. The

inserts are retained in the Polybase baseplate by a

two-part industrial epoxy (Master Bond EP21LV or

equivalent).

3.3.2 Resin options

The standard epoxy resin is Derakane 411-50 (black

or gray in color). Novolac GT4500 resin is optional

for severe sulfuric acid services (red in color).

Novolac GT4000 resin is optional for chlorinated

solvent services (blue in color).

3.4 Performance and operation limits

This product has been selected to meet the

specification of your purchase order (see section 1.5).

The following data are included as additional

information to help with your installation. If required,

a definitive statement for your application can be

obtained from Flowserve.

3.4.1 Temperature ratings

The maximum equipment temperature that can be

tolerated by the various Polybase resins is listed

below:

Black bases (Derakane) = 149 °C (300 °F)

Red bases (GT 4500) = 82 °C (180 °F)

Blue bases (GT4000) = 104 °C (220 °F)

The minimum acceptable temperature for the

Polybase resins is -45 °C (-50 °F).

Page 9 of 24 flowserve.com

Page 10

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

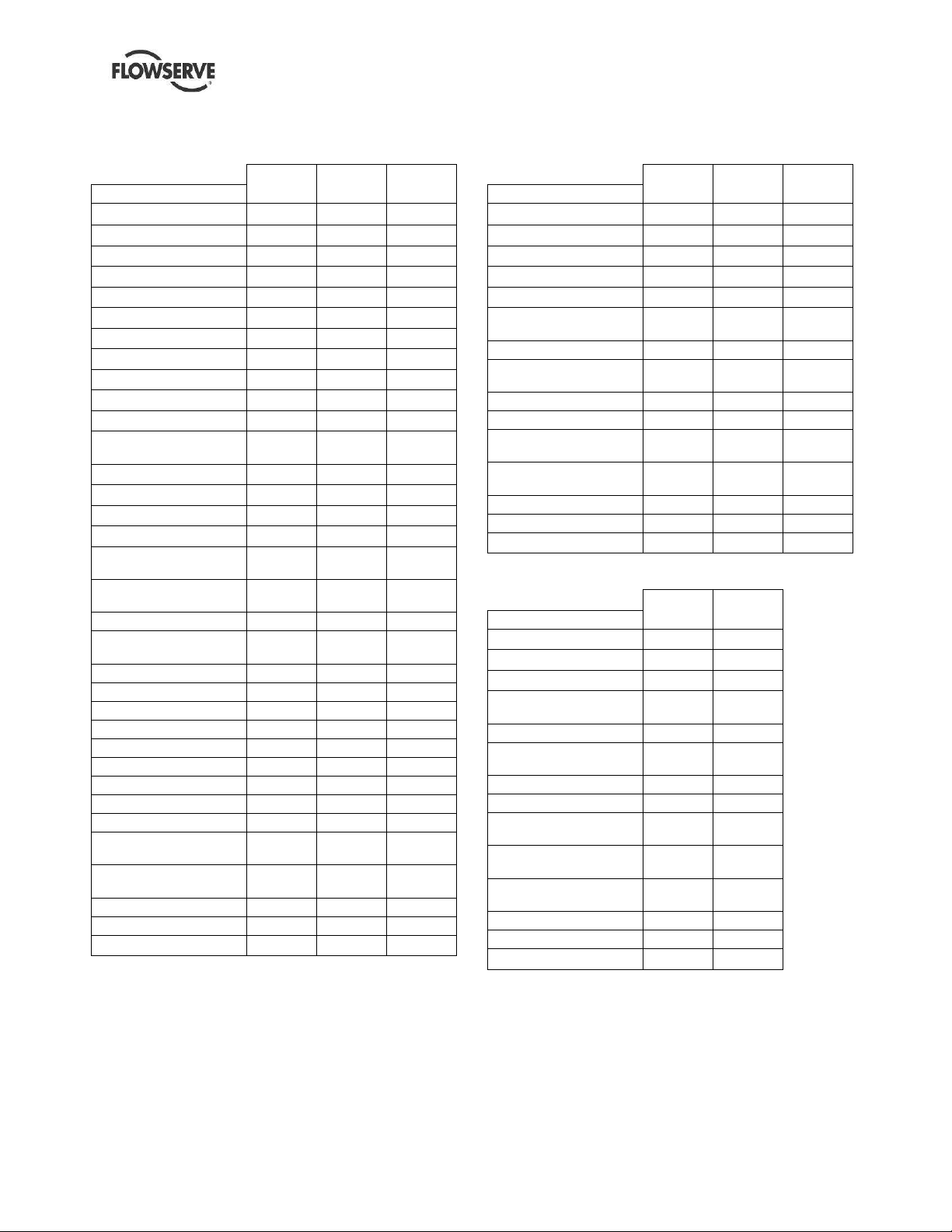

3.4.2 Polybase corrosion guide (abridged)

Table 3-1 Derakane resin (black)

Chemical

Acetic acid <75%

Acetic, glacial

Amines

Aromatic solvents

Benzene

Bleach

Bromine (dry)

Bromine (wet)

Calcium chloride

Chlorinated solvents

Chlorobenzene

Chlorine dioxide

<15%

Chromic acid <20%

Ferric chloride

Fluosilic acid <30%

Gasoline

Hydrobromic acid

<50%

Hydrochloric acid

=<20%

Hydrochloric >20%

Hydrofluoric acid

<20%

Methylene chloride

Nitric acid =<30%

Nitric acid >30%

Oil, mineral

Petroleum oil

Phosphoric acid

Seawater

Sodium chlorate

Sodium chloride

Sodium hydroxide

=<50%

Sodium hydroxide

>50%

Sulfuric acid <75%

75% to 93%

93% to 98+%

21 °C

(70 °F)

60 °C

(140 °F)

93 °C

(200 °F)

R R S

S NR NR

R S NR

S NR NR

NR NR NR

R R NR

R NR NR

R NR NR

R R S

NR NR NR

NR NR NR

R R S

R NR NR

R R R

R NR NR

R R NR

R R NR

R R S

R S NR

R S NR

NR NR NR

R S NR

NR NR NR

R R R

R R R

R R R

R R R

R R R

R R R

R R S

NR NR NR

R S S

NR NR NR

NR NR NR

Table 3-2 Novolac GT4000 resin (blue)

Chemical

Acetic acid <75%

Acetic, glacial

Benzene

Bleach =<18%

Chromic acid <20%

Hydrochloric acid

=<20%

Hydrochloric >20%

Hydrofluoric acid

<20%

Methylene chloride

Nitric acid to 69%

Sodium hydroxide

=<50%

Sodium hydroxide

>50%

Sulfuric acid <75%

75% to 93%

93% to 98+%

21 °C

(70 °F)

R R R

R R R

R R R

R R R

R R R

R R R

R R R

R S NR

S NR NR

R R R

R R R

NR NR NR

R R R

S NR NR

S NR NR

Table 3-3 Novolac GT4500 resin (red)

Chemical

Bleach to 12%

Chromic acid <20%

Gasoline

Hydrochloric acid

=<20%

Hydrochloric >20%

Hydrofluoric acid

<20%

Methylene chloride

Nitric acid to 50%

Phosphoric acid to

85%

Sodium hydroxide

=<50%

Sodium hydroxide

>50%

Sulfuric acid <75%

75% to 93%

93% to 98+%

21 °C

(70 °F)

R R

R R

R R

R R

R R

R S

NR NR

R R

R R

R R

NR NR

R R

R R

R R

R = Recommended.

S= Satisfactory for occasional contact at some

concentrations – consult Flowserve Materials

Engineering Department.

NR = Not recommended.

60 °C

(140 °F)

60 °C

(140 °F)

93 °C

(200 °F)

Page 10 of 24 flowserve.com

Page 11

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4, Products used in

potentially explosive atmospheres.

4.1 Location

The baseplate should be located to allow room for

access, ventilation, maintenance, and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Refer to the general arrangement drawing for the

pump set.

4.2 Part Assemblies

The supply of motors and pumps are optional. As a

result, it is the responsibility of the installer to ensure

that the motor is assembled to the pump and aligned

as detailed in section 4.5 and 4.8.

4.3 Foundation

4.3.1 Protection of openings and threads

When the baseplate is shipped, all threads and all

openings are covered. This protection/covering

should not be removed until installation. If, for any

reason, the baseplate is removed from service, this

protection should be reinstalled.

4.3.2 Rigid baseplates - overview

The function of a baseplate is to provide a rigid

foundation under a pump and its driver that maintains

alignment between the two. Baseplates may be

generally classified into two types:

• Foundation-mounted, grouted design (Figure 4-1)

• Stilt mounted, or free-standing (Figure 4-2)

Figure 4.1

Figure 4.2

Baseplates intended for grouted installation are

designed to use the grout as a stiffening member.

Stilt mounted baseplates, on the other hand, are

designed to provide their own rigidity. Therefore, the

designs of the two baseplates are usually different.

The Polybase baseplate is solid and has a thick

cross-section so it can be both grouted in place and

stilt mounted.

Regardless of the type of baseplate used, it must

provide certain functions that ensure a reliable

installation. Three of these requirements are:

• The baseplate must provide sufficient rigidity to

assure the assembly can be transported and

installed, given reasonable care in handling,

without damage. It must also be rigid enough

when properly installed to resist operating loads.

• The baseplate must provide a reasonably flat

mounting surface for the pump and driver.

Uneven surfaces will result in a soft-foot condition

that may make alignment difficult or impossible.

Flowserve’s experience indicates that a baseplate

that has a top surface flatness of 1.25 mm / meter

(0.015 inch / foot) across the diagonal corners of

the baseplate provides such a mounting surface.

Therefore, this is the tolerance to which we supply

our standard baseplate. Some users may desire

an even flatter surface, which can facilitate

installation and alignment. Flowserve will supply

flatter baseplates upon request at extra cost. For

example, mounting surface flatness of 0.42 mm/m

(0.005 in./ft) is offered on the Flowserve Polybase

baseplate.

• The baseplate must be designed to allow the user

to final field align the pump and driver to within

their own particular standards and to compensate

for any pump or driver movement that occurred

during handling. Normal industry practice is to

achieve final alignment by moving the motor to

match the pump. If a pump and motor assembly

is provided with the baseplate, Flowserve’s

Page 11 of 24 flowserve.com

Page 12

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

practice is to confirm in our shop that the pump

assembly can be accurately aligned. Before

shipment, the factory verifies that there is enough

horizontal movement capability at the motor to

obtain a “perfect” final alignment when the installer

puts the baseplate assembly into its original, top

leveled, unstressed condition.

4.3.3 Stilt mounted Polybase baseplates

Flowserve offers a stilt mounted option for Polybase

baseplates (See Figure 4-5). The baseplate is set on

a flat surface with no tie down bolts or other means of

anchoring it to the floor.

General instructions for assembling these baseplates

are given below. For dimensional information, please

refer to the appropriate Flowserve “Sales Print.”

Note: The following assembly procedure should be

carried out as closely to the final installation location

as possible. DO NOT remove the Polybase from its

shipping pallet until it is in the area of the installation

and you are ready to assemble the stilts.

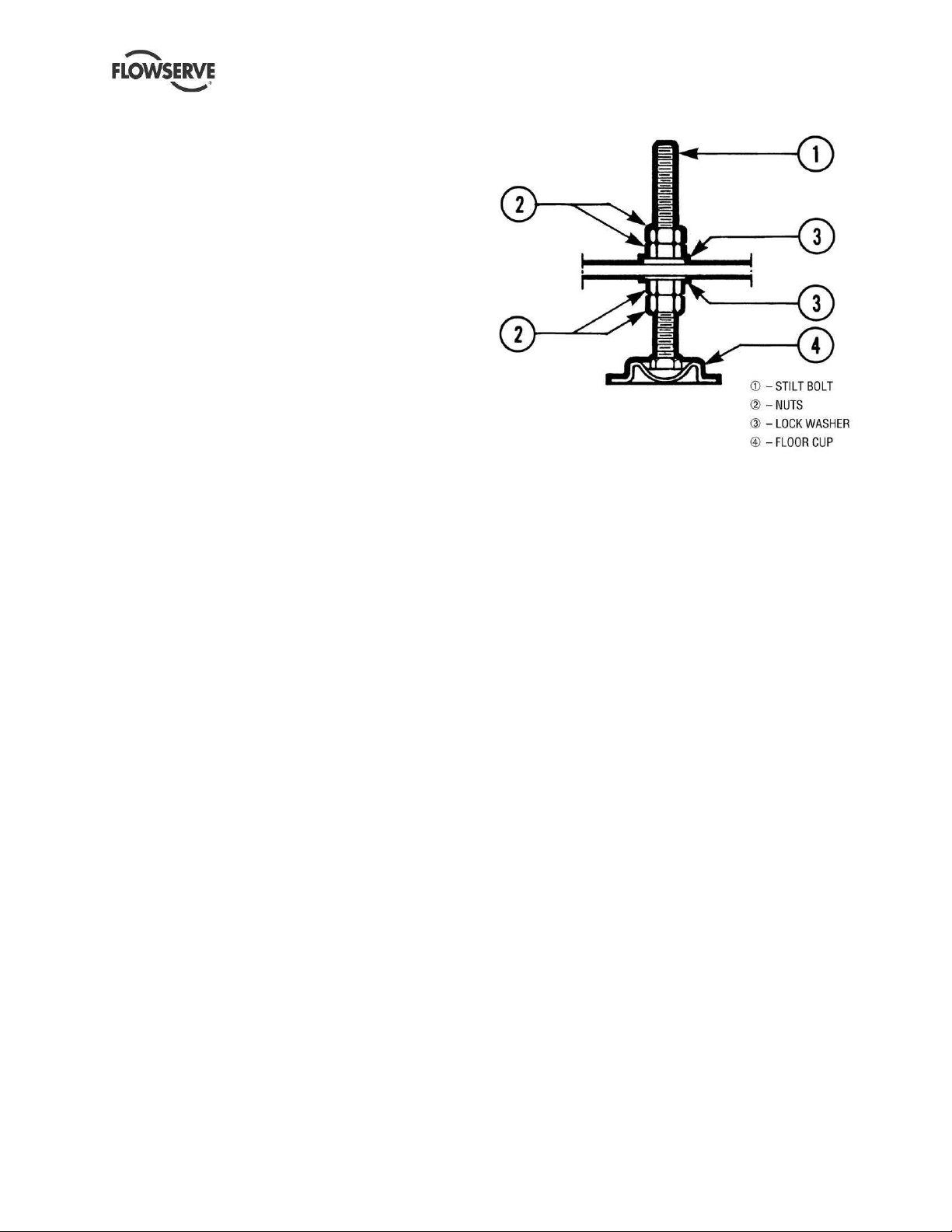

4.3.3.1 Stilt mounted baseplate assembly

instructions for 264 and shorter

Polybase baseplates (Refer to Figures 43 and 4-5)

a) Raise or block up baseplate/pump above the

floor to allow for the assembly of the stilts.

b) Bolt the cross bars onto the underside of the

Polybase baseplate.

c) Predetermine or measure the approximate

desired height for the baseplate above the floor.

d) Set the bottom nuts (item 2) above the stilt bolt

head (item 1) to the desired height.

e) Assemble lock washer (item 3) down over the stilt

bolt.

f) Assemble the stilt bolt up through hole in the

cross bar and hold in place.

g) Assemble the lock washer (item 3) and nut (item

2) on the stilt bolt. Tighten the nut down on the

lock washer.

h) After all four stilts have been assembled, position

the baseplate in place, over the floor cups (item

4) under each stilt location, and lower the

baseplate to the floor.

i) Level and make final height adjustments to the

suction and discharge pipe by first loosening the

top nuts and turning the bottom nuts to raise or

lower the baseplate.

j) Tighten the top and bottom nuts at the lock

washer (item 3) first then tighten the other nuts.

k) It should be noted that the connecting pipelines

must be individually supported, and that the stilt

mounted baseplate is not intended to support

total static pipe load.

Figure 4.3

Page 12 of 24 flowserve.com

Page 13

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

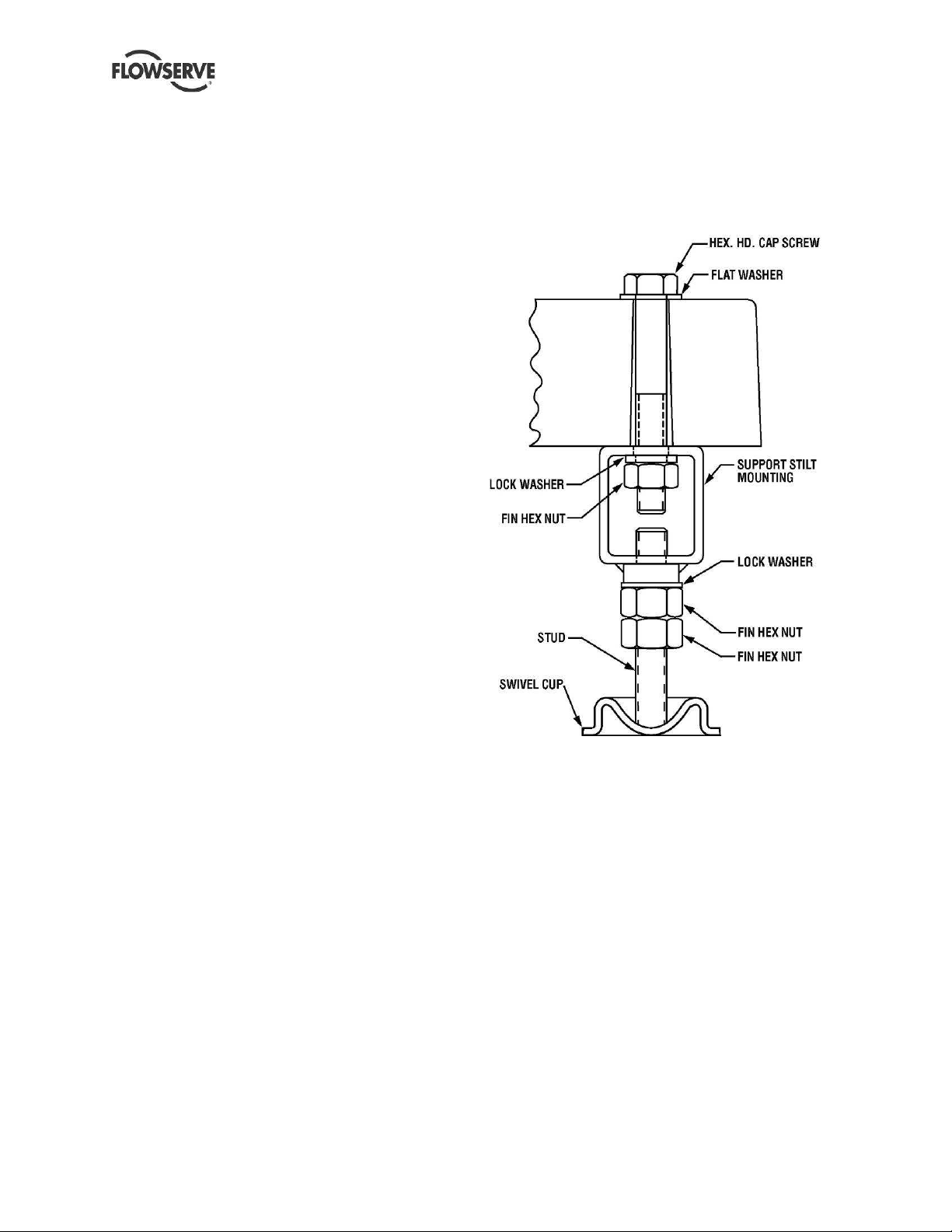

4.3.3.2 Stilt mounted baseplate assembly

instructions for 268 and longer Polybase

baseplates (Refer to Figures 4-4 and 4-5)

a) Determine or measure the approximate desired

height for the baseplate above the floor.

b) Sling and hoist the baseplate/pump assembly off

its shipping pallet in accordance with the

procedures shown in Section 2.3.

c) Bolt the stilt beams to the underside of the

Polybase using the fasteners provided as shown

in Figure 4.4. Torque the 7/8” bolts to 217Nm

(160 lbf*ft).

d) Thread two hex nuts onto each stud. Install one

internal-tooth lockwasher over the FLAT ends of

each stud. Thread the flat ends of the studs into

the weld nuts on the undersides of the

longitudinal support beams until the low point of

each SPHERICAL end is at the desired distance

from the bottom surface of the Polybase. Do not

tighten the nuts at this point.

e) After all four stilts have been assembled, position

the Polybase in place over the floor cups under

each stilt location, and GENTLY lower the

assembly to the floor.

f) Using two wrenches, lock the two hex nuts on

each stud together. Turn the studs by means of

these locked nuts to raise or lower the assembly.

When the desired leveling is achieved, unlock the

pairs of nuts and thread the upper ones (with

lockwashers on top) up until they make contact

with the weld nuts on the beams. Tighten

securely. Thread the lower nuts up and tighten to

lock the assembly in place.

g) Recheck levels and adjust if necessary.

h) It should be noted that the connecting pipe lines

must be individually supported, and that the stilt

mounted Polybase is not intended to support total

static pipe load.

4.3.3.3 Stilt mounted baseplates - motor

alignment

The procedure for motor alignment on stilt mounted

baseplates is similar to grouted baseplates. The

difference is primarily in the way the baseplate is

leveled.

a) Level the baseplate by using the stilt adjusters.

(Shims are not needed as with grouted

baseplates.) After the base is level, it is locked in

place by locking the stilt adjusters.

b) Next the initial pump alignment must be checked.

The vertical height adjustment provided by the

stilts allows the possibility of slightly twisting the

baseplate. If there has been no transit damage

or twisting of the baseplate during stilt height

adjustment, the pump and driver should be within

0.38 mm (0.015 in.) parallel, and 0.0025 mm/mm

(0.0025 in./in.) angular alignment. If this is not

the case, check to see if the driver mounting

fasteners are centered in the driver feet holes.

Figure 4.4

c) If the fasteners are not centered there was likely

shipping damage. Re-center the fasteners and

perform a preliminary alignment to the above

tolerances by shimming under the motor for

vertical alignment, and by moving the pump for

horizontal alignment.

d) If the fasteners are centered, then the baseplate

may be twisted. Slightly adjust (one turn of the

adjusting nut) the stilts at the driver end of the

baseplate and check for alignment to the above

tolerances. Repeat as necessary while

maintaining a level condition as measured from

the pump discharge flange. Lock the stilt

adjusters.

The remaining steps are the same as for new grouted

baseplates.

Page 13 of 24 flowserve.com

Page 14

Figure 4.5

Polybase Baseplate USER INSTRUCTIONS ENGLISH 71569284 USER – 12-10

Page 14 of 24 flowserve.com

Page 15

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

4.4 Grouting

a) The pump foundation should be located as close

to the source of the fluid to be pumped as

practical. There should be adequate space for

workers to install, operate, and maintain the

pump. The foundation should be sufficient to

absorb any vibration and should provide a rigid

support for the pump and motor. Recommended

mass of a concrete foundation should be three

times that of the pump, motor and base. Refer to

Figure 4-6 for a cross-section of the

recommended foundation and baseplate

arrangement. Note that foundation bolts are

imbedded in the concrete inside a sleeve to allow

some movement of the bolt.

Figure 4.6

b) Gently set the Polybase baseplate

down onto the foundation. Do not subject a

Polybase baseplate to heavy shock loading.

c) Level the pump baseplate assembly. The proper

surfaces to reference when leveling the pump

baseplate assembly are the pump suction and

discharge flanges.

DO NOT stress the baseplate.

DO NOT bolt the suction or discharge

flanges of the pump to the piping until the

baseplate grouting has been completed If

equipped, use leveling jackscrews to level the

baseplate. If jackscrews are not provided, shims

and wedges should be used. Check for

levelness in both the longitudinal and lateral

directions. Shims should be placed at all base

anchor bolt locations, and in the middle edge of

the base if the base is more than 1.5 m (5 ft)

long.

DO NOT RELY ON THE BOTTOM OF

THE POLYBASE BASEPLATE TO BE FLAT.

This is an as-molded surface which is not as flat

as the mounting (top) surface.

d) After leveling the baseplate, install flat washers

and nuts on the anchor bolts.

ENSURE THE NUTS HAVE A

SNUG FIT, BUT DO NOT TORQUE THEM AT

THIS POINT.

If shims are used, make sure to shim the

baseplate near each anchor bolt and snug the

nut firmly with a wrench. Failure to do this may

result in a twist of the baseplate, which could

make it impossible to obtain final alignment.

Check the level of the baseplate to ensure that it

was maintained, else adjust the jackscrews or

shims as needed until the baseplate is level

e) Check initial alignment. If the pump and motor

were removed from the baseplate, install them so

that prior to grouting it can be verified that

alignment can be achieved. If the pump and

motor were properly reinstalled to the baseplate

or if they were not removed from the baseplate

and there has been no transit damage, and also

if the above pre-grout steps where done properly,

the pump and driver should be within 0.38 mm

(0.015 in.) FIM (Full Indicator Movement) parallel,

and 0.0025 mm/mm (0.0025 in./in.) FIM angular.

If this is not the case, first check to see if the

driver mounting fasteners are centered in the

driver feet holes. If not, re-center the driver on its

fasteners and perform a preliminary alignment to

the above tolerances by shimming under the

motor for vertical alignment, and by moving the

pump for horizontal alignment.

f) Grout the baseplate. A non-shrinking grout

should be used. Make sure that the grout fills the

area under the baseplate. After the grout has

cured, check for voids and fill them if possible.

Jackscrews, shims and wedges should be

removed from under the baseplate at this time. If

they were to be left in place, they could rust,

swell, and cause distortion in the baseplate.

g) Lubricate the anchor bolt threads and torque the

nuts using a torque wrench to values noted in

table 4-1 below.

Table 4-1

Recommended

Bolt size

M12 & ½ in. 27(20)

M20 & ¾ in. 96 (70)

M22 & 7/8 in. 150 (110)

M24 & 1 in. 220 (160)

torque Nm (lbfft)

lubricated

Page 15 of 24 flowserve.com

Page 16

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

h) Tighten pump and motor hold

down fasteners using a torque wrench. Apply

recommended torque given in clause 6.7,

DO NOT exceed the maximum allowable torque

values provided.

i) Run piping to the suction and discharge of the

pump. There should be no piping loads

transmitted to the pump after connection is made.

Recheck the driver and pump alignment to verify

it is still acceptable. Significant loads being

carried through the pump connections can cause

misalignment.

5 COMMISSIONING, STARTUP,

OPERATION AND SHUTDOWN

Pre start-up checks

Prior to starting the equipment mounted on a

Polybase baseplate, it is essential that the following

pump-based checks be made.

• Pump and motor properly secured to the

baseplate

• All fasteners tightened to the correct torque

• Coupling guard in place and not rubbing

• Seal support system (if used) properly secured

to the baseplate

• Inspect the baseplate for cracks

• Ensure the mounted equipment is ready to run

6 MAINTENANCE

It is the plant operator's responsibility to ensure

that all maintenance, inspection and assembly work

is carried out by authorized and qualified personnel

who have adequately familiarized themselves with

the subject matter by studying this manual in detail.

(See also section 1.6)

Any work on the machine must be performed when it

is at a standstill. It is imperative that the procedure

for shutting down the machine is followed.

On completion of work all guards and safety devices

must be re-installed and made operative again.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and the

exterior of the machine.

If platforms, stairs and guard rails are required for

maintenance, they must be placed for easy access to

areas where maintenance and inspection are to be

carried out. The positioning of these accessories

must not limit access or hinder the lifting of the part to

be serviced.

Place a warning sign on the starting device:

"Machine under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning sign on

the fuse box or main switch:

"Machine under repair: do not connect".

Never clean equipment with flammable solvents or

carbon tetrachloride. Protect yourself against toxic

fumes when using cleaning agents.

6.1 Maintenance schedule

It is recommended that a maintenance plan and

schedule be implemented to support the equipment

mounted on a Polybase baseplate. The Polybase

baseplate does not require any maintenance, but the

following should be checked during routine

maintenance of the mounted equipment:

• clean the surface of the baseplate to prevent long

term chemical attack from degrading the surface

(refer to 1.6.4.4 to prevent sparks when product

must comply with ATEX)

• check that the mounted equipment is securely

fastened to the baseplate

• inspect the surface of the baseplate for any

cracks.

6.2 Spare parts

The Polybase baseplate does not require any spare

parts unless it is damaged. If one of the threaded

inserts in the Polybase baseplate comes loose, or the

owner needs to add additional inserts to an installed

Polybase baseplate, the inserts are available from

Flowserve. A two-part industrial epoxy (Master Bond

EP21LV, Loctite E-120HP, or equivalent) is required

to bond the inserts in place. Replacement parts for

stilt mounted assemblies can also be supplied by

Flowserve.

To order spare parts

Flowserve keeps records of all products that have

been supplied. Spare parts can be ordered from your

local Flowserve Sales Engineer or from a Flowserve

Distributor or Representative. When ordering spare

parts the following information should be supplied:

1) Baseplate size

2) Motor size

3) Material of construction (color)

4) For thread repairs -- insert size and

quantity required

Page 16 of 24 flowserve.com

Page 17

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

5) For stilt mounts, the type and number

must be specified

If the spare Polybase baseplate is intended to

be used with equipment which is or will be installed in

a potentially explosive atmosphere, Flowserve should

be given the complete ATEX classification of the

equipment in order to check compliance.

6.3 Recommended spares and

consumable items

There are no recommended spare parts for the

Polybase baseplate. In the rare instances when a

threaded insert needs to be replaced or a Polybase

baseplate needs to be drilled and inserted for a

different size motor, the following materials and

procedure would apply.

6.4 Tools required

For drilling holes in the Polybase material, use a

masonry bit or a carbine-tipped drill bit.

6.5 Field thread insert installation

procedure

The procedure detailed below may be used either to

replace a damaged original thread insert or to install

an insert in a new location.

Thread inserts properly installed in the field

will yield performance characteristics and service life

equivalent to inserts installed at the factory. Field

installation should only be undertaken when

absolutely necessary, and then only by qualified

personnel using suitable drilling equipment. In order

to achieve a successful installation the following

procedures must be followed PRECISELY and the

drilling operation must be carried out AS

ACCURATELY AS POSSIBLE.

a) Drill out the damaged insert (or drill a new hole in

a location that has been carefully laid out) taking

care not to enlarge or elongate the hole into

which the replacement insert will be installed. It

is critical that the hole be drilled perpendicular to

the surface of the Polybase and that the hole

center line location be maintained. The

recommended method for achieving this is to use

a carbide tipped bit with a magnetic base drill

mounted on a steel plate that has been bolted to

the adjacent inserts in the baseplate (see Figure

6.1). Correct drill diameters and depths are

shown in Table 6-1.

DO NOT USE OIL OR CUTTING FLUID -

HOLES MUST BE DRILLED DRY.

Figure 6.1

b) Remove all dust and metal chips from the drilled

hole using dry, oil-free compressed air.

c) If the drilled hole has become contaminated with

oil or other foreign substance, flush thoroughly

with acetone or ethyl acetate and dry completely

with oil-free compressed air.

d) If the replacement insert has been contaminated

with oil or other foreign substance, flush

thoroughly with acetone or ethyl acetate and dry

completely with oil-free compressed air.

e) Dispense adhesive into the drilled hole (see

Figure 6.2) following the instructions provided.

Fill the hole to within approximately 12 mm (1/2

inch) of the baseplate surface.

Figure 6.2

f) After applying oil to the threads of a properly

sized socket head cap screw (or hex head bolt),

thread it into the insert. Be careful not to get any

oil on the outside surfaces of the insert.

Page 17 of 24 flowserve.com

Page 18

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

g) Engage the blind end of the stainless steel insert

in the hole. Tap on the cap screw head with light

hammer or soft mallet to drive the insert into the

hole (see Figure 6.3). Hold the insert straight

until it has been driven in to approximately half its

length; the insert is self-aligning once it has

passed this point.

Figure 6.3

h) Drive the insert in slowly to give

the adhesive time to flow around the grooves in

the insert. Drive the insert in to the point where

its top surface is flush with or just below the

surface of the baseplate. Excess adhesive will

squeeze out and pool around the top of the insert

as shown in Figure 6.4. Do not remove this

excess material. As the adhesive cures, some of

this excess will draw down into the space

between the insert and the wall of the hole. Do

not remove the cap screw at this time.

Figure 6.4

l) The baseplate is now ready to be put back into

service. The equipment fasteners mounting

torques are given in clause 6.7 Table 6-3.

Do not exceed the maximum

torque value given in Table 6-3in relation to

fastener mechanical properties.

Table 6-1

Drill Diameter

Thread Size mm inches

5/16-18 UNC 18 45/64 (.703)

3/8-16 UNC 18 45/64 (.703)

M6 18 45/64 (.703)

M8 18 45/64 (.703)

M10 18 45/64 (.703)

1/2-13 UNC 21 53/64 (.828)

M12 21 53/64 (.828)

5/8-11 UNC 29 1-1/8 (1.125)

3/4-10 UNC 29 1-1/8 (1.125)

M16 29 1-1/8 (1.125)

M20 29 1-1/8 (1.125)

7/8-9 UNC 32 1-1/4 (1.250)

M24 32 1-1/4 (1.250)

Depth (all) 46 1-13/16 (1.81)

6.6 Field installed thread insert

testing (Optional)

If user elects to assess the validity of his installation

or replacement of thread inserts, here are provided

the necessary bolts torques for the axial pull-out

testing of the insert sample(s).

The torque values tabulated below are

maximums that the inserts in the Polybase baseplate

can withstand without any damage. These values

may exceed the material strength of the bolts being

used to do the test. The end user must consider the

type of bolt and lubrication used (if any) before

tightening.

i) Allow the adhesive to cure undisturbed for 48

hours.

j) Following cure remove the screw. Excess

adhesive may be chipped off with a putty knife. If

desired, lightly sand the surface of the baseplate

to a flat, smooth condition.

k) OPTIONAL. It is up to the user to decide if a

sample insert axial pullout test is needed using

torque values given in clause 6.6.

Page 18 of 24 flowserve.com

Page 19

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

Table 6-2 Insert testing unlubricated torque limits

Test boltsize Nm (lbf•ft)

M6 16 (12)

M8 and 5/16 in. 22 (16)

M10 and 3/8 in. 45 (33)

M12 and ½ in. 105 (77)

M16 and 5/8 in. 150 (111)

M20 and ¾ in. 220 (162)

7/8 in. 275 (203)

M24 and 1 in. 410 (302)

All torques in table are for dry threads.

Note: 1.) For lubricated threads, use 75% of the values.

2.) Excessive torque can damage the Polybase

baseplate by pulling out the inserts.

3) These are maximum values valid for testing the

inserts, Fastener torquefor mounting the

equipmentis given clause 6.7.

4) As a default, the bolts used for insert testing

should be scrapped. They must not be reused if

the torque during test has attained 90% or more

of the proof test value of the bolt material or 80%

of its yield strength, whichever is the lowe

r.

6.7 Recommended fastener mounting

torques

Tighten pump and motor hold down fasteners using a

torque wrench. Apply table 6-3 recommended

torques.

DO NOT EXCEED THE HIGHEST

TORQUE VALUE.

Any fastener material used for mounting the

equipment to the Polybase must have a minimum

yield strength of 210 MPa (30 KSI) at room

temperature.

Table 6-3 Equipment fasteners mounting torques

Fastener Mechanical Property

Fastener Size

X

Strength

(1)

Max Torque

(dry)

Nm (

lbf•ft)

Y

Max Torque

Strength

Nm (

(dry)

lbf•ft)

(2)

M6 8 (6) 12 (9)

5/16 in. 8 (6) 17 (13)

M8 11 (8) 17 (13)

M10 and 3/8 in.

M12 and ½ in.

M16 and 5/8 in.

M20 and ¾ in.

15 (11) 35 (25)

35 (26) 80 (60)

75 (55) 115 (85)

130 (95) 165 (125)

7/8 in. 185 (135) 205 (150)

M24 and 1 in.

280 (205) 310 (230)

Above torque values are for unlubricated threads. For

lubricated threads use 75% of tabulated torques.

(1) X STRENGTH fasteners materials have yield strengths

within 210 - 440 MPa (30 – 64 KSI) at room temperature.

They need to be tightened within +/-5% of the value given

in table above. THESE FASTENERS MUST NOT BE

TIGHTENED MORE THAN 105% OF THE X STRENGTH

FASTENER TORQUE VALUES PER TABLE 6-3.

Commonly used X strength hold down fasteners are:

• UNC fasteners in carbon steel per ASTM A307 Grades

A&B (SAE J429 Gr.1&2) and the common AISI 300

stainless steel series;

• Metric fasteners in carbon steel per ISO 898-1 Classes

4.6 and those in stainless steel per

ISO 3506 Gr. A1, A2 and A4, all in Class 50.

(2) Y STRENGTH fasteners materials have a minimum

yield strength of 450 MPa (65 KSI) at room temperature.

These Y strength fasteners need to be torqued to values

not lower than those for of the X strength fasteners, but

Y STRENGTH FASTENERS MUST NOT BE TIGHTENED

MORE THAN THE VALUES LISTED IN TABLE 6-3. The

Polybase baseplate material properties and the thread

inserts bonding are the limiting factors imposing the

tabulated ceiling values for torques.

Usual Y strength hold down fasteners include:

• UNC fasteners in carbon steel per SAE J429 Grades 4

and above, and per ASTM A193 Grade B7;

• Metric fasteners in carbon steel per ISO 898-1 Classes

8.8 and above, and in stainless steel per

ISO 3506 Gr. A1, A2 and A4, Classes 70 & 80.

Page 19 of 24 flowserve.com

Page 20

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

7 FAULTS: CAUSES AND REMEDIES

TROUBLESHOOTING

The following is a guide to troubleshooting problems with Flowserve Polybase baseplates. Common problems

are analyzed and solutions offered. Obviously, it is impossible to cover every possible scenario. If a problem

exists that is not covered by one of the examples, then contact a Flowserve Sales Engineer or

Distributor/Representative for assistance.

FAULT SYMPTOM

Threaded insert is chemically attacked

Threaded insert pulls out

⇓⇓⇓⇓

⇓⇓⇓⇓

Corner of baseplate breaks off

⇓⇓⇓⇓

⇓⇓⇓⇓

Baseplate breaks during rigging

⇓⇓⇓⇓

⇓⇓⇓⇓

Motor is bolt bound and alignment is not possible

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

PROBABLE CAUSES POSSIBLE REMEDIES

Leaking product.

High vibration combined with excessive

mounting forces.

Anchor bolts or nuts are tightened too much

prior to grouting.

Rough handling of the Polybase baseplate. Follow the handling recommendations in Section 2.

Piping loads are too large.

Motor studs are not perpendicular to the

baseplate.

Fix leak source. Replace the damage insert(s) per the

direction given in Section 6.3.

Reduce the amount of vibration energy in the system.

Only torque bolts to the values recommended in Section

6.5.

Do not tighten the anchor bolt or nuts prior to grouting.

Arrange the shims under the baseplate so that they are

directly under the anchor studs or bolts to prevent a

bending moment from over tightening.

Construct suction and discharge piping so that the

flanges mate to the pump without inducing high loads.

For small diameter studs, they can be lighted impacted

with a rubber mallet to bend them slightly (with the motor

removed) to facilitate alignment. Larger stud diameters

will require the motor foot holes be enlarged or the

baseplate to be reworked or replaced.

Page 20 of 24 flowserve.com

Page 21

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

8 PARTS LIST AND DRAWINGS

Polybase Dimensional and Weight Information

Baseplate

Size mm (in.)

ANSI 139 330 (13)

ANSI 148 413 (16.25)

ANSI 153 489 (19.25)

ANSI 245 330 (13)

ANSI 252 413 (16.25)

ANSI 258 489 (19.25)

ANSI 264 489 (19.25

ANSI 268 660 (26)

ANSI 280 660 (26)

ANSI 368 660 (26)

ANSI 380 660 (26)

ANSI 398 660 (26)

ISO 3 390 (15.35)

ISO 4 450 (17.72)

ISO 5 490 (19.29)

ISO 6 540 (21.26)

ISO 7 610 (24.02)

ISO 8 660 (26)

HA HB HE HF HG HH HP Weight

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) kg (lb)

990 (39) 114 (4.5) 927 (36.5) 92 (3.63) 19 (0.75) 32 (1.25) 59 (130)

1219 (48) 152 (6) 1156 (45.5) 102 (4) 19 (0.75) 32 (1.25) 100 (220)

1346 (53) 190 (7.5) 1283 (50.5) 102 (4) 19 (0.75) 32 (1.25) 132 (290)

1143 (45) 114 (4.5) 1080 (42.5) 92 (3.63) 19 (0.75) 32 (1.25) 68 (150)

1320 (52) 152 (6) 1257 (49.5) 102 (4) 19 (0.75) 32 (1.25) 109 (240)

1473 (58) 190 (7.5) 1410 (55.5) 102 (4) 25 (1) 32 (1.25) 143 (315)

1625 (64) 190 (7.5) 1562 (61.5) 102 (4) 25 (1) 32 (1.25) 159 (350)

1727 (68) 241 (9.5) 1664 (65.5) 108 (4.25) 25 (1) 32 (1.25) 243 (535)

2032 (80) 241 (9.5) 1968 (77.5) 108 (4.25) 25 (1) 32 (1.25) 286 (630)

1727 (68) 241 (9.5) 1664 (65.5) 108 (4.25) 25 (1) 32 (1.25) 243 (535)

2032 (80) 241 (9.5) 1968 (77.5) 108 (4.25) 25 (1) 32 (1.25) 286 (630)

2489 (98) 241 (9.5) 2426 (95.5) 108 (4.25) 25 (1) 32 (1.25) 350 (770)

900 (35.43) 175 (6.89) 600 (23.62) 73 (2.87) 19 (0.75) 150 (5.9) 56 (123)

1000 (39.37) 200 (7.87) 660 (25.98) 88 (3.46) 24 (0.94) 170 (6.69) 87 (191)

1120 (44.09) 220 (8.66) 740 (29.13) 88 (3.46) 24 (0.94) 190 (7.48) 106 (233)

1250 (49.21) 245 (9.65) 840 (33.07) 88 (3.46) 24 (0.94) 205 (8.07) 131 (288)

1400 (55.12) 275 (10.83) 940 (37.01) 110 (4.33) 28 (1.1) 230 (9.06) 207 (455)

1600 (62.99) 300 (11.81) 1060 (41.73) 110 (4.33) 28 (1.1) 270 (10.63) 250 (550)

Page 21 of 24 flowserve.com

Page 22

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

9 CERTIFICATION

Certificates, determined from the contract

requirements, are provided with these instructions

where applicable. If required, copies of other

certificates sent separately to the Purchaser should

be obtained from Purchaser for retention with these

User Instructions.

10 OTHER RELEVANT

DOCUMENTATION AND MANUALS

10.1 Supplementary user instructions

Supplementary instructions such as for a pump,

driver, instrumentation, controller, seals, sealant

systems etc are provided as separate documents in

there original format. If further copies of these are

required they should be obtained from the supplier for

retention with these user instructions.

10.2 Change Notes

If any changes, agreed with Flowserve Pump

Division, are made to the product after it is supplied,

a record of the details should be maintained with

these User Instructions.

10.3 Additional sources of information

The following are excellent sources for additional

information on centrifugal pumps in general.

Pump Engineering Manual

R.E. Syska, J.R. Birk,

Flowserve Corporation, Dayton, Ohio, 1980.

Specification for Horizontal End Suction Centrifugal

Pumps for Chemical Process, ASME B73.1

The American Society of Mechanical Engineers,

New York, NY.

American National Standard for Centrifugal Pumps

for Nomenclature, Definitions, Design and Application

(ANSI/HI 1.1-1.3)

Hydraulic Institute, 9 Sylvan Way, Parsippany,

New Jersey 07054-3802.

American National Standard for Centrifugal Pumps

for Installation, Operation, and Maintenance (ANSI/HI

1.4)

Hydraulic Institute, 9 Sylvan Way, Parsippany,

New Jersey 07054-3802.

RESP73H Application of ASME B73.1-1991,

Specification for Horizontal End Suction Centrifugal

Pumps for Chemical Process, Process Industries

Practices

Construction Industry Institute, The University of

Texas at Austin, 3208 Red River Street, Suite 300,

Austin, Texas 78705.

Pump Handbook

2nd edition, Igor J. Karassik et al, McGraw-Hill, Inc.,

New York, NY, 1986.

Centrifugal Pump Sourcebook

John W. Dufour and William E. Nelson,

McGraw-Hill, Inc., New York, NY, 1993.

Pumping Manual, 9th edition

T.C. Dickenson, Elsevier Advanced Technology,

Kidlington, United Kingdom, 1995.

International Standard for End-suction centrifugal

pumps -- Baseplate and installation dimensions, ISO

3661

1, rue de Varembé

Case postale 56

CH-1211 Genève 20

Switzerland

Page 22 of 24 flowserve.com

Page 23

NOTES:

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

Page 23 of 24 flowserve.com

Page 24

Polybase Baseplate INSTRUCTIONS ENGLISH 71569284 – 12-10

Fax +1 757 485 8149

Your Flowserve factory contacts:

Flowserve Pumps

Flowserve GB Limited

Lowfield Works, Balderton

Newark, Notts NG24 3BU

United Kingdom

Telephone (24 hours) +44 (0)1636 494 600

Sales & Admin Fax +44 (0)1636 705 991

Repair & Service Fax +44 (0)1636 494 833

E-mail newarksales@flowserve.com

Flowserve Pump Division

3900 Cook Boulevard

Chesapeake, VA 23323-1626 USA

Telephone +1 757 485 8000

Your local Flowserve representative:

To find your local Flowserve representative please

use the Sales Support Locator System found at

www.flowserve.com

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

Pump

5215 North O’Connor Blvd.,

Suite 2300

Irving, Texas 75039-5421 USA

Telephone 1 972 443 6500

Fax 1 972 443 6800

Europe, Middle East, Africa

Worthing S.P.A.

Flowserve Corporation

Via Rossini 90/92

20033 Desio (Milan) Italy

Telephone 39 0362 6121

Fax 39 0362 303396

Latin America and Caribbean

Flowserve Corporation

Pump

6840 Wynnwood Lane

Houston, Texas 77008 USA

Telephone 1 713 803 4434

Fax 1 713 803 4497

Asia Pacific

Flowserve Pte. Ltd

10 Tuas Loop

Singapore 637345

Telephone 65 6771 0600

Fax 65 6779 4607

Page 24 of 24 flowserve.com

Loading...

Loading...