Page 1

Manual F5

PMV Valve Control System

Manual F5

alve Control System

– 1 –

Page 2

Manufacturers declaration • Hersteller-Erklärung • Déclaration de fabricant

GB

Manufacturers declaration

in compliance with EC directive 89/392/EEC/91/368/EEC, 89/336/EEC, 73/23/EEC

and 93/68/EEC.

We hereby confirm that the appliances described in this sheet has been manufactured in compliance

with the applicable standards and is intended for installation in a machine/application, and that

commissioning is strictly prohibited until evidence has been provided that the machine/application in

question is also in compliance with

EC directive 89/392/EEC/91/368/EEC, 89/336/EEC, 73/23/EEC and 93/68/EEC.

This manufacturers declaration is applicable to the following PMV series:

F5.

D

Hersteller-Erklärung

im Sinne der EG-Richtlinie 89/392/EWG/91/368/EWG, 89/336/EWG, 73/23/EWG

und 93/68/EWG.

Hiermit erklären wir, daß die in diesem Blatt beschriebenen Geräte entsprechend den gültigen Normen

gebaut und zum Einbau in eine Maschine oder Applikation bestimmt sind, sowie daß deren

Inbetriebnahme so lange untersagt ist, bis festgestellt wurde, daß diese

Maschine/Applikation ebenfalls der EG-Richtlinie

89/392/EWG/91/368/EWG, 89/336/EWG, 73/23/EWG und 93/68/EWG entspricht.

Diese Herstellererklärung hat für folgende PMV-Serien Gültigkeit:

F5.

F

Déclaration de fabricant

au sens dela directive de la 89/392/CEE/91/368/CEE, 89/336/CEE, 73/23/CEE et 93/68/CEE.

Nous déclarons par la présente que les appareils décrits sur cette page sont construits en conformité

avec les normes en vigueur et qu'ils sont destinés à être montés dans une machine ou une application,

nous déclarons également que leur mise en service est interdite tant qu'il n'a pas été constaté que cette

macine/application satisfait

également à la directive 89/392/CEE/91/368/CEE, 89/336/CEE, 73/23/CEE et 93/68/CEE.

Cette déclaration de fournisseur est valable pour les types d'appareils PMV suivants:

F5.

Mr. Jan-Eric Andersson

President, Palmstiernas Instrument AB

Manual F5

– 2 –

Page 3

PMV Feedback module storage and handling procedures

PMV feedback modules are precision instruments which should be stored

and handled accordingly to avoid problems or damage.

Feedback modules contain electronic components which can be damaged by

exposure to water. Appropriate precautions should be taken to protect units

while in storage.

Warehouse storage

-Stored in original PMV shipping containers, units should be stored in an

environmentally controlled area, i.e. clean, cool (15-26°C, 60-80°F) and dry,

out of direct sunlight or weather exposure.

Field storage

- If feedback units must be stored outdoors, make sure front covers are

tightened, all conduits entries are sealed and that units not are exposed to

direct sunlight, rain or snow.

Potential damage mechanism

When units are stored in hot, humid climates, the daily heating/cooling cycle

will cause air to expand/contract and be drawn in and out of the feedback

housing through ports left open. Dependent on the local temperature

variations, humidity and dew points and time in storage, condensation could

occur and accumulate inside causing erratic operation or failure due to water

and corrosion. The potential for condensation damage is especially high in

southern climates and aggravated if units are exposed to direct sunlight.

For further assistance, please contact you nearest PMV office.

Storage Seal

F5 is supplied with conduit entry points sealed.

The seal is only a storage seal, not to be used as seal

when F5 is in operation.

If Storage Seal is removed or damaged, make sure

conduit entry points are resealed before further

shipping or storage.

Use proper cable glands or vapour proof tape.

Mount F5 on positioner P5/EP5 or actuator/valve

package. Remove Storage Seal for conduit entry E

& E2, make electrical connections, install proper

cable glands or plugs to ensure the units sealing.

1

Manual F5

– 3 –

Page 4

Description

The PMV F5 is a feedback unit uniquely designed to mount on top of the PMV

P5, EP5 or P-2000 positioners with minimum parts required. The F5 can also

be mounted on actuators with an additional mounting kit. The F5 is available

in two different enclosures, standard or explosion proof.

The standard enclosure for F5 offers a gasketed NEMA 4/ IP66 enclosure with

optional American and European intrinsically safe approvals. The explosion

proof version is approved NEMA 7 / IP66 and carries North American and

European approvals. Both enclosures can be furnished with Namur sensors,

mechanical or proximity switches, potentiometer or 4-20 mA position transmitter or a combination of these items.

Manual F5

– 4 –

Page 5

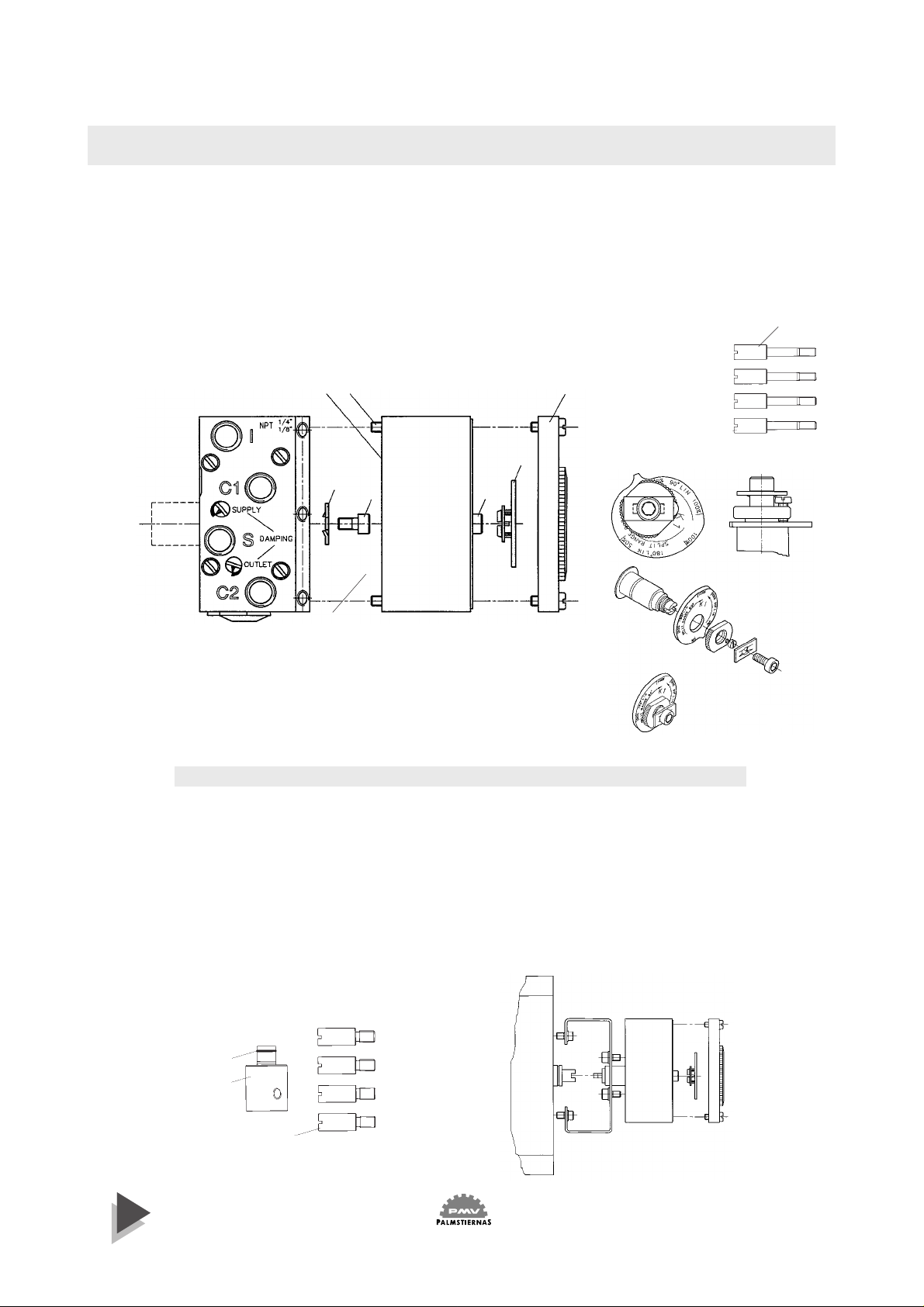

Mounting on P5 or EP5

– Remove the front cover and the indicator from the positioner.

– Loosen and remove the Allen head screw (3) (5mm hex-wrench)

– Install drive coupling (4) on the positioner shaft, secure it with screw (3)

– Check that F5is fitted with 4 nos of screws 5 and O-ring 9, install the F5 on

top of the positioner unit, make sure that the coupling is properly engaged

before tightening the four screws 5.

– Make connections and calibrate.

– Reinstall indicator 2 and front cover 1 on the F5.

5

9

4

3

1

2

5

O-ring seal

Mounting F5 on actuator

Install the spindle adaptor 1 into F5 shaft, make sure that a spring clip 2

is fitted. A solid click should be heard when the spindle adaptor is

properly installed into the F5 shaft.

Mount F5 on the actuator using a mounting kit and the ISO F05 mounting

holes on the bottom of the F5. Make sure that the F5 spindle is properly

alligned on top of the actuator.

Check that the four fasteners 3 are installed into F5.

2

1

(On/Off control valves)

Manual F5

3

– 5 –

Page 6

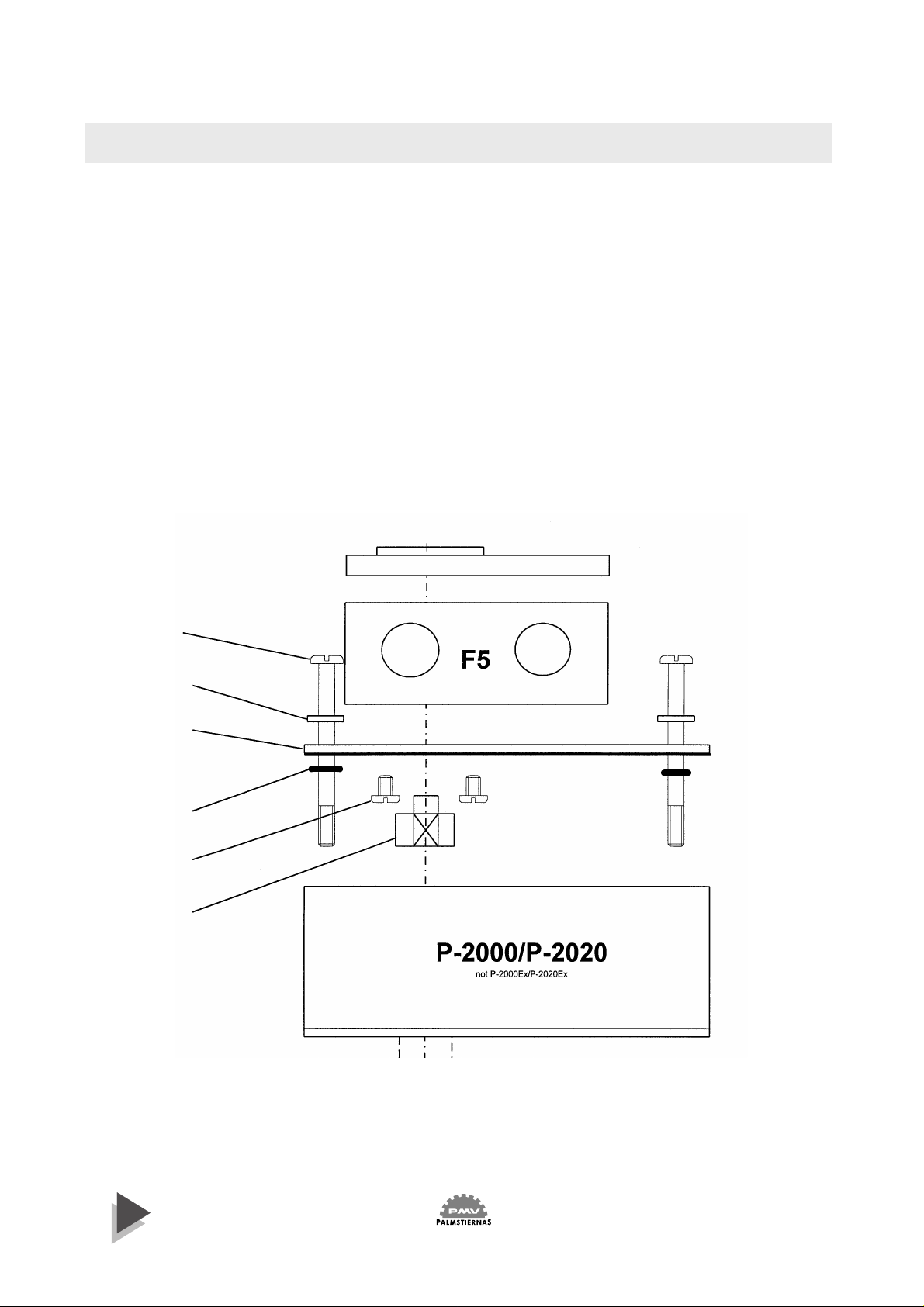

Mounting on P-2000/P-2020

– Remove front cover, indicator and cam nut from the positioner

– Replace the cam nut with coupling 1, calibrate the positioner.

– Check that the gasket is fitted to the bottom of plate 2, install screws 5 (3x

long, 1x short) plastic washer 6 and O-rings 7.

– Secure the F5 to the plate 2 with screws 3.

– Install assembly onto the positioner, make sure that coupling 1 is properly

engaged.

– Make electrical connections and calibrate.

5

6

2

7

3

1

Manual F5

– 6 –

Page 7

F5-EX

The F5-EX is approved explosion proof by CSA, FM and CENELEC.

Front cover screws shall be tightened 7 Nm (5,2 lbf x ft).

Approvals:

CSA, FM Div. 1, Class 1,2 & 3 Group BCDEFG T4-T6

CENELEC EEx d IIB + H2 T4-T6 LCIE 97.D6140

Manual F5

– 7 –

Page 8

Installing F5-EX on P5/EP5

– Remove front cover, indicator and Allen head screw from the positioner.

– Install drive coupling 4 and secure it with the Allen head screw.

– Remove front covers and indicator from the F5-EX unit.

– Remove screws 3.

– Install F5-EX on P5/EP5, , make sure drive coupling is properly engaged

before tightening screws 5.

– Reinstall and tight screws 3. Connect and calibrate.

– Reinstall front covers and indicator.

– Front cover screws 2 shall be tightened to 7 Nm (5,2 lbf x ft)

5

4

3

2

Installing on an actuator

– Remove front covers and indicator from the F5-EX unit.

– Remove screws 3 and (5). Reinstall and tight screws 3.

– Install drive shaft into F5-EX, a solid click should be heard when spindle

adapter is properly installed.

– Mount F5-EX on the actuator using the F05 holes and a mounting kit.

– Connect and calibrate, reinstall front covers and indicator.

– Front cover screws 2 shall be tightened to 7 Nm (5,2 lbf x ft).

3

2

Manual F5

– 8 –

Page 9

Connections

WARNING!

Units installed in hazardous locations must have proper agency approvals

and be installed according to installation drawing F5-2-4-9516.

Conduit entries are PG13,5 (M20) or NPT 1/2“

Make electrical connections according to wiring diagrams and tighten cable

glands. Terminals are 2.5 mm2 (AVG 14) screw terminals.

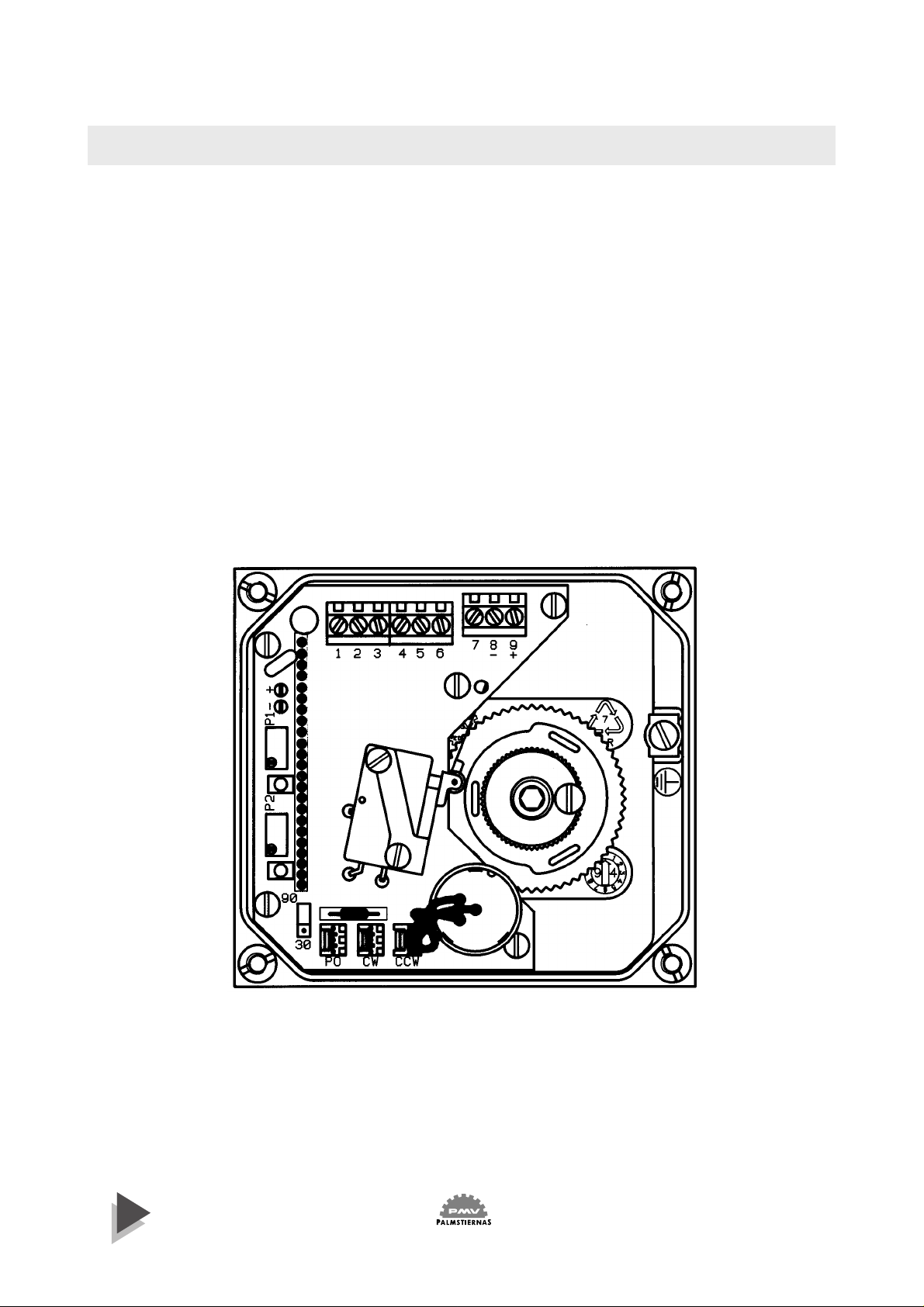

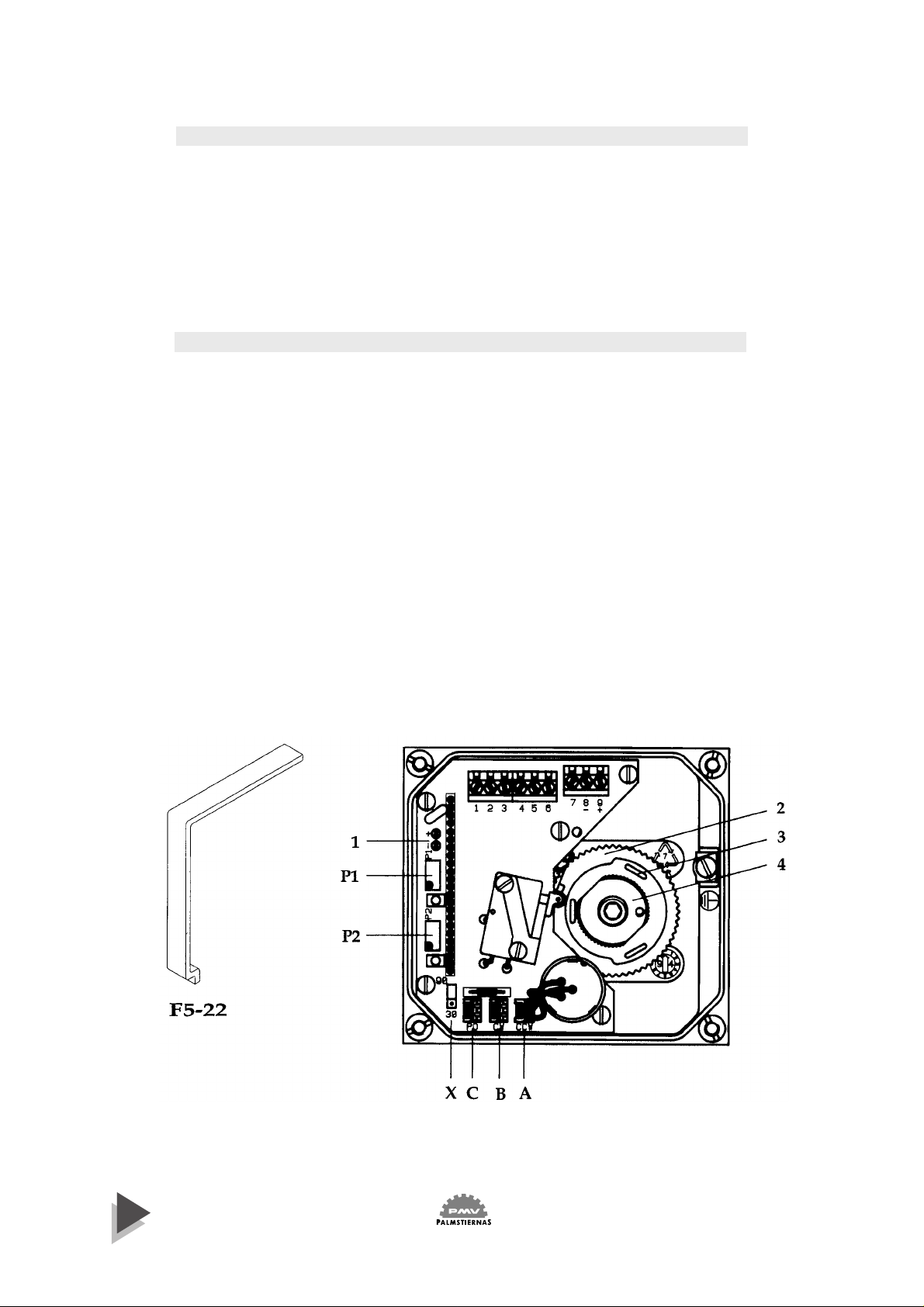

Adjustments

CAUTION! Moving parts – risk of injury.

The cams/gear wheel are secured in position by friction provided from the

cam/shaft assembly. To adjust switches and/or position transmitter, rotate

gear wheel 2 and cams 3 to desired position using tool F5-22 or tip of a screw

driver that fits snuggly in one of the slotted holes. Start calibration procedure

by adjusting position transmitter first, then continue with the lower switch

and complete with the upper switch.

If cams exhibit high stiction, rotate them back and forth rapidly several times.

Do not adjust nut 4 or lubricate cams, call PMV for assistance.

Manual F5

– 9 –

Page 10

Calibration

Potentiometer

1. Make electrical connections to terminals 7,8 and 9. Check that the

potentiometer is connected to connector C on the printed circuit board.

2. Stroke the actuator to check direction of travel indicated by the potentio-

meter. To change direction of travel, swap wires at terminals 7 and 9.

3. Stroke the actuator to the position where the minimum potentiometer

resistance is desired.

4. Adjust the potentiometer output reading to approx. 50 Ohm by

rotating gear wheel 2 with special tool F5-22 or tip of a screw driver

placed in one of the slotted holes.

5. Stroke the actuator to desired

maximum resistance position and

check reading.

6. Repeat steps 3-5 if necessary to

obtain desired resistance change.

7. Set switches or install frontcover.

4-20 mA position transmitter

1. Set direction of rotation by placing potentiometer jumper in location A or

B. (Location A for counter clockwise CCW valve/actuator rotation (Direct),

location B for clockwise CW valve/actuator rotation (Reverse).

2. Set jumper X to the desired valve rotation angle, for 30 deg or 45 deg

rotation choose position 30,

For 60 deg or 90 deg rotation choose position 90, for 180 deg rotation choose

position 30 and for 270 deg rotations choose position 90.

For 30° deg - 45° deg choose pos 30.

3. Make electrical connections according to wiring diagram. Power supply

should be >9 to <28 VDC (24 VDC recommended).

4. Connect a 4-20 mA meter to testoutlet 1. Adjust potentiometer P1 20

revolutions CW & P2 20 revolutions CCW. Stroke actuator to the desired 4

mA position and check that current deflection is correct. Rotate gear wheel

2 with tool F5-22 or tip of a screw driver placed in one of the slotted holes

until minimum valve is reached.

Potentiometer

7

8

9

5. Adjust the output signal 4,0 mA with potentiometer P2. LED will illuminate when out put is 4

mA (±1%) or less. Stroke actuator to the desired 20

mA position and adjust the output to 20,0 mA with

potentiometer P1. LED will illuminate when out

put is 20 mA (±1%) or more.

6. Stroke actuator again, check and adjust 4 mA and

20 mA readings. Install front cover or set switches

first, as follows:

Manual F5

4-20 mA position transmitter

4-20 mA

position

transmitter

+

89-

Display

4-20 mA

+-

Power

+

Supply

-

24 VDC

– 10 –

Page 11

Switches & Sensors

NAMUR switches

2

3

5

6

Upper

switch

Lower

switch

+

-

+

-

Limit switches cams must be adjusted separately with valve in an open and

closed position. With the valve in fully open or closed position adjust the

lower cam 3 to desired position by rotating it with special tool F5-22 or by the

tip of a screw driver placed in one of the slotted holes on the cam. Stroke the

valve fully and repeat the procedure above to set the upper cam.

Stroke valve open/closed to check proper limit switch operation.

Upper

switch

Lower

switch

Proximity switches

Mechanical switches

C

NC

NO

NO

NC

C

1

2

3

6

5

4

Upper

switch

Lower

switch

C

C

Mechanical switches

Mechanical switches

Technical specifications

General

Conduit entries 2x 1/2 NPT or 2x PG 13,5 (M20)

Housing material Die cast aluminum

Surface treatment ED painting

Mounting According to VDI/VDE 3845

Fasteners Stainless steel A2/A4

Terminals 2,5 mm

Enclosure IP66, NEMA 4

Switches, mechanical

Type Mechanical SPDT V3

Rating *6/2,5A 250 VAC *Res/Ind

Approvals CSA,UL,VDE

Temp range -20°C to 80°C (-4°F to 185°F)

Sensors, Namur

Type Proximity DIN 19234 NAMUR

Load Current ≤ 1mA ≥ 3mA

Voltage range 5-25 VDC

Hysteresis 0,2%

Temp range -20°C to 80°C (-4°F to 185°F)

2

(AVG 14)

Namur sensors

NC

NO

NO

NC

1

2

3

6

5

4

Weight

Standard enclosure 0.7 kg (lbs 1.5)

Explosion proof 2.1 kg (lbs 4.6)

Switches proximity

Contact rating 2 W or 2 VA @ 30 VDC/

VAC, 0.1 A

Maximum operating time 0.5 miliseconds

Breakdown voltage 200VDC

Contact resistance 0.2 Ohms

Switch type SPDT hermetically sealed

in one unit

Mechanical and

electrical life >10 million operations

Potentiometer

Out put 5kΩ (4kΩ at 90°)

Elements Conductive plastic

Power rating at 70° 1 W

Linearity 1%

Resolution Essentially infinite

Temp range -20°C to 80°C (-4°F to 185°F)

4-20 mA position transmitter

Power supply 9-28 VDC (24VDC recommended)

Out put signal 4-20 mA

LED indication at 4 mA ±1%

LED indication at 20 mA ±1%

Resolution Infinite

Minimum rotation travel 30°

Maximum rotation travel 90°

Linearity <1% of full scale

Hysteresis <0,5% of full scale

Out put current limit 24 mA DC

Load impedance 800 Ω at 24 VDC

Temp range -20°C to 80°C (-4°F to 185°F)

Manual F5

– 11 –

Page 12

F5 IS

Manual F5

– 12 –

Page 13

F5 IS

Manual F5

– 13 –

Page 14

Connection of F5 intrinsically safe version

Manual F5

– 14 –

Page 15

F5-EX

Manual F5

– 15 –

Page 16

F5-EX

Manual F5

– 16 –

Page 17

Spare Parts

10-13

10-13

14

14

1

10-13

17

15

15

2-9

16

14

16

15

14

16

16

Manual F5

– 17 –

Page 18

Spare Parts List

Manual F5

– 18 –

Page 19

Dimension drawing

Manual F5

– 19 –

Page 20

T rouble shooting

Switches

Check electrical connections and cam settings.

Potentiometer

If there is no output signal, check electrical connections and for open circuit, check that potentiometer is not out of it´s mechanical range.

If output deflection is wrong reverse connection

terminals 7 and 9.

4-20 mA position transmitter

If there is no output signal, check electrical

connections, polarity, loop power supply, and

that the potentiometer is within its range.

Palmstiernas Instrument AB

Korta Gatan 9

SE-171 54 Solna

SWEDEN

Tel: +46 (0) 8 555 106 00

Fax: +46 (0) 8 555 106 01

E-mail: info@pmv.nu

Internet: www.pmv.nu

SUBSIDIARIES:

If full output signal cannot be achieved by

adjustment, check supply voltage and jumper X

settings.

If output signal increases and decreases in the

wrong direction, move connector from A to B or

vice versa.

If the 4 mA fine adjustment P2 does not have

enough span, zero must be mechanically realigned as follows: Turn P2 20 revolutions counter

clockwise, then repeat the transmitter calibration

procedure.

Distributor

PMV Controls Ltd

Headlands Business Park

Ringwood

Hampshire BH24 3PB

ENGLAND

Tel: +44 (0) 1425 48 08 88

Fax: +44 (0) 1425 48 08 89

E-mail: sales@pmv-controls.ltd.uk

Internet: www.pmv-controls.ltd.uk

PMV-USA, Inc

1440 Lake Front Circle

Unit 160

The Woodlands, Texas 77380

USA

Tel: +1 281 292 7500

Fax: +1 281 292 7760

E-mail: pmvusa@pmvusa.com

Internet: www.pmvusa.com

(The information in this brochure is subject to change without notice.)

PMV GmbH

Postfach 2310

D-41554 Kaarst

GERMANY

Tel: +49 (0) 2131 667 081/82

Fax: +49 (0) 2131 667 083

E-mail: info@pmv-germany.de

Internet: www.pmv-germany.de

Palmstiernas Svenska AB

Box 21

SE-663 21 Skoghall

SWEDEN

Tel: +46 (0) 54 52 14 70

Fax: +46 (0) 54 52 14 42

E-mail: info@palmstiernas.se

Internet: www.palmstiernas.se

23744/2001.6 Ekvator

Manual F5

– 20 –

Loading...

Loading...