Page 1

P4 • P5/EP5

alve Control System

IOM Instructions

Page 2

Contents

1. Introduction ..............................................................................................4

2. Storage instructions..................................................................................6

PMV Positioner and feedback module storage and handling procedures ....6

Warehouse storage ........................................................................................ 6

Field storage .................................................................................................6

Pneumatic positioners...................................................................................6

Potential damage mechanism .......................................................................6

Storage Seal (P5/EP5) ..................................................................................7

3. Function.....................................................................................................8

4. Installation.................................................................................................9

Air requirements ........................................................................................... 9

Installation ....................................................................................................9

5. Connections .............................................................................................10

6. Cam adjustment......................................................................................12

7. Calibration ..............................................................................................13

Calibration procedure .................................................................................13

8. Indicator adjustment..............................................................................14

9. Front cover and indicator cover............................................................14

10. Dampers.................................................................................................15

11. I/P Unit (P5/EP5)...................................................................................16

12. How to mount the I/P Unit to the positioner unit (P5/EP5) ..............17

13. Maintenance .......................................................................................... 18

Pilot valve ................................................................................................... 18

Diaphragm ..................................................................................................19

Feedback spring..........................................................................................20

Balance arm ................................................................................................20

Lower arm ..................................................................................................21

O-rings ........................................................................................................ 22

Filter plug (EP5) .........................................................................................22

14. Feedback unit (P5 or EP5)...................................................................23

15. T r ouble shooting ...................................................................................24

16. Technical data .......................................................................................25

Dimensional drawing (P4)..........................................................................27

17. Spare parts, P4......................................................................................28

17. Spare parts, P5/EP5..............................................................................30

18. Certificates ............................................................................................34

2

Page 3

Manufacturers declaration • Hersteller-Erklärung • Déclaration de fabricant

G B

Manufacturers declaration

in compliance with EC directive 89/ 392/ EEC, annex I I B and 89/ 336/ EEC.

We hereby confirm that the appliances described in this sheet has been manufactured in

compliance with the applicable standards and is intended for installation in a

machine/ application, and that commissioning is strictly prohibited until evidence has

been provided that the machine/ application in question is also in compliance

with EC directive 89/ 392/ EEC and 89/ 336/ EEC.

This manufacturers declaration is applicable to the following PMV-Positioner series:

P4, P5, EP5, F5.

D

Herstel ler-Erkärung

im sinne der EG-richtlinie 89/ 392/ EWG, A nhang I I B und 89/ 336/ EWG.

H iermit erklären wir, da§ die in diesem Blatt beschriebenen Geräte entsprechend den

gültigen Normen gebaut und zum Einbau in eine Maschine oder Applikation bestimmt

sind, sowie daß deren Inbetriebnahme so lange untersagt ist, bis festgestellt wurde, daß

diese Maschine/Applikation ebenfalls der EG-Richtlinie 89/ 392/ EWG und 89/ 336/

EWG entspricht. Diese H erstellererklärung hat für folgende PMV-Stellungsregler-Serien

Gültigkeit:

P4, P5, EP5, F5.

F

Déclaration de fabricant

au sens dela directive de la CE 89/ 392/ CEE, annexe I I B et CE/ 89/ 336/ CEE.

N ous déclarons par la présente que les appareils décrits sur cette page sont construits en

conformité avec les normes en vigueur et qu’ils sont destinés à être montés dans une

machine ou une application, nous déclarons également que leur mise en service est

interdite tant qu’il n’a pas été constaté que cette machine/application satisfait également à

la directive CE 89/ 392 CEE et CE/ 89/ 336/ CEE.

Cette déclaration de fournisseur est valable pour les types d’appareils PMV suivants:

P4, P5, EP5, F5.

Mr. Roland Wedebrand

President, Palmstiernas Instrument AB

3

Page 4

Special Conditions for Safe Use

The enclosure is made of aluminium and any impact or friction caused by external

objects shall be avoided in the application.

Rubbing of the window with dry fabrics shall be avoided when the positioner is used in

an hazardous atmosphere in order to avoid potentially incendive static discharges.

Always check www.pmv.nu for latest edition of manual.

1. Introduction

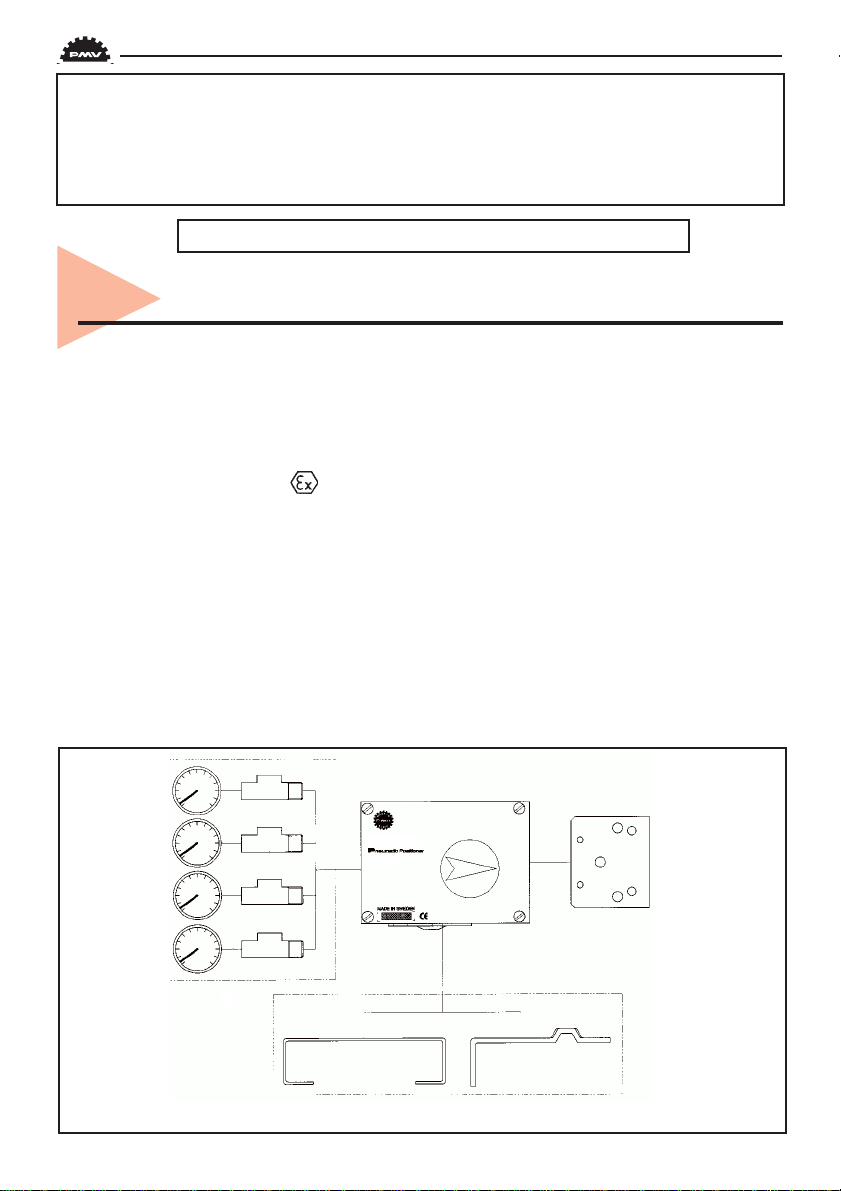

P4

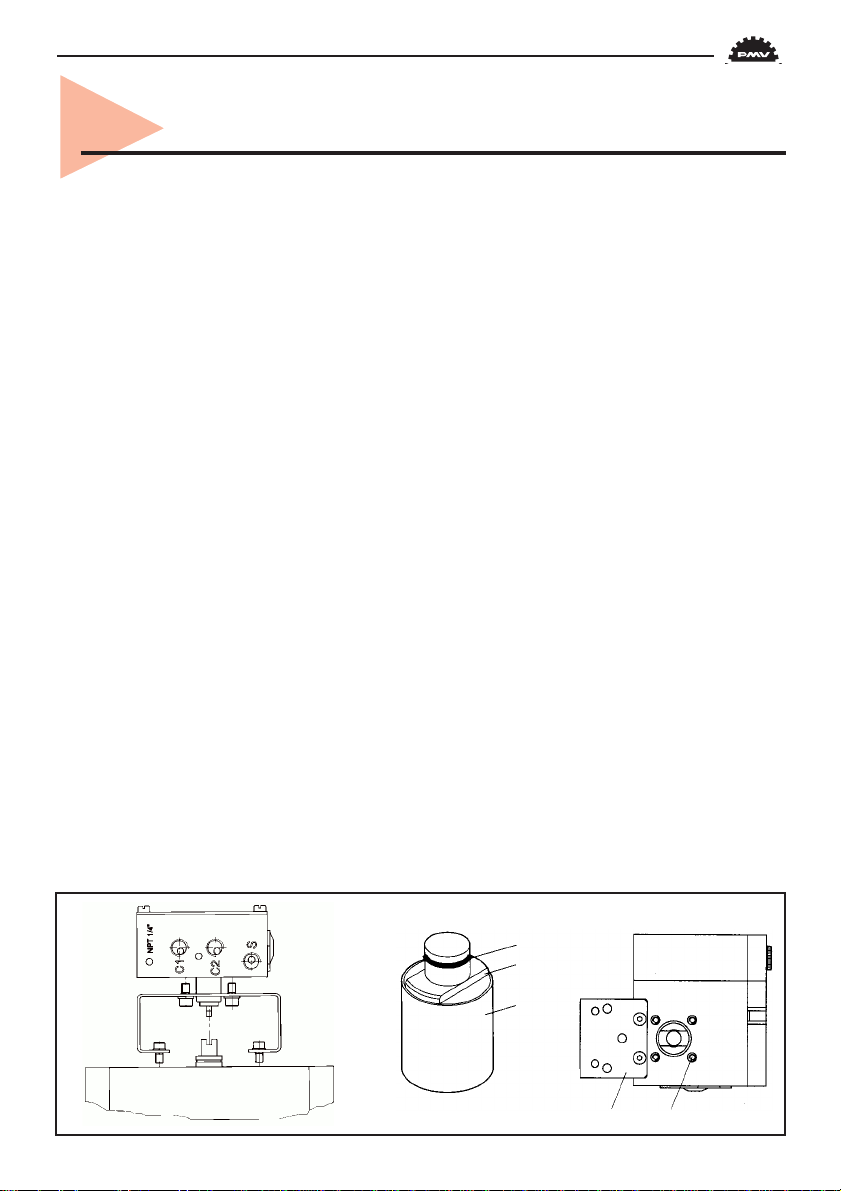

The P4 is a pneumatic valve positioner for double acting actuators, rotary or linear. It can

also be used for single acting applications by simply plugging one of the outlet ports, C1 or

C2.

ATEX: II 2 G

It features a standardized foot print, external zero adjustment, gold plated spool valve, positive

internal pressure and a bright visible position indicator. The simple, sturdy design with few

moving parts together with the well proven spool valve design provides long and trouble

free operation. T ogether with the unit, a wide range of mounting kits are of fered for quarter

turn and linear applications.

Calibration and set up is quick and simple, all done by thumb wheels. The unit requires a

minimum of maintenance and the only tool needed is a flat screw driver.

For installation of gauges T-connectors are required.

Option

4

Option

Page 5

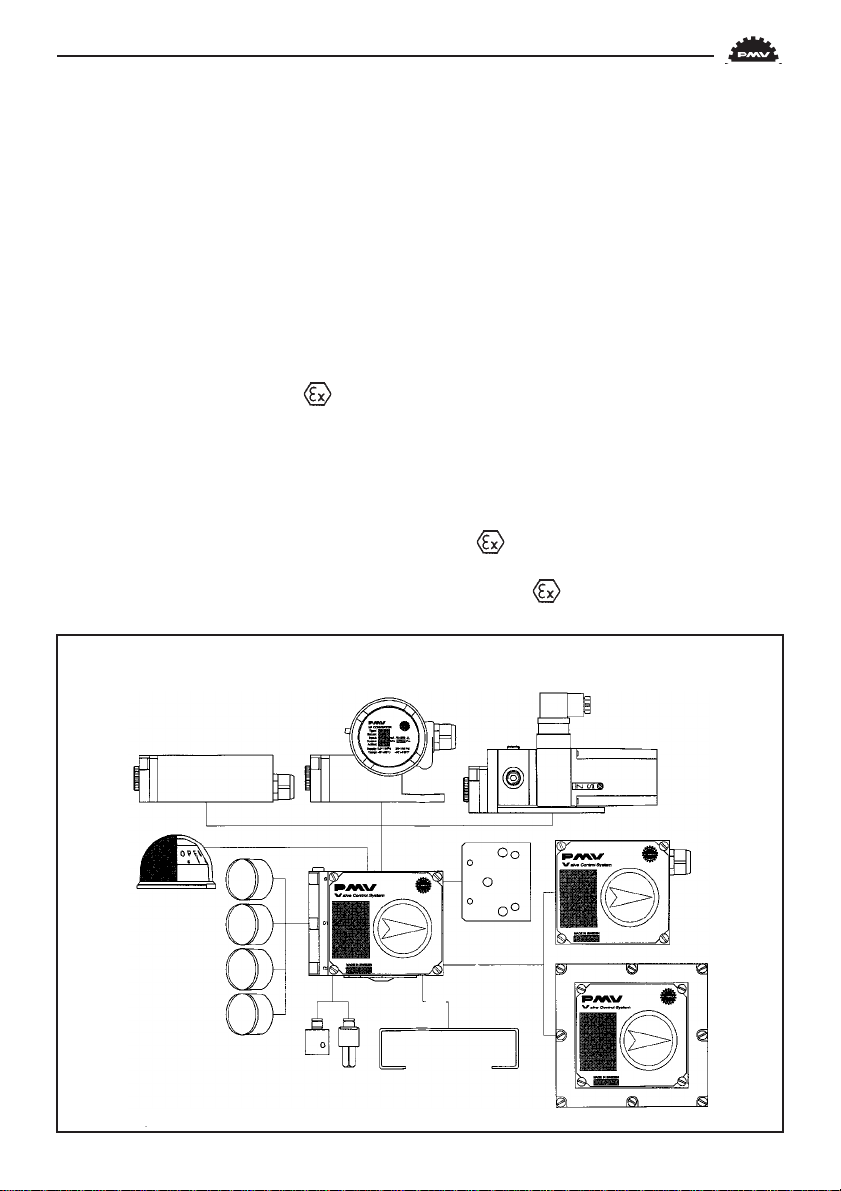

P5

The base unit of the system is the pneumatic positioner, used in either single or double acting

applications. P5 comes standard with built in dampers, a high gain spool valve assembly,

gauge ports and an O-ring sealed housing. The housing utilizes a unique O-ring seal that

can be adjusted to a sealed or drained position.

The modular design concept allows for easy addition of accessories such as I/P converter

and/or a feedback package, both which are isolated from the basic pneumatic unit. These

accessories can be factory or field mounted.

Ease of calibration and maintenance are built into to the design with easily accessible span

and zero adjustment, and very simple parts replacement.

ATEX: II 2 GD

EP5

The EP5 has same features and benefits as the P5 positioner. It’s modular to suit several

applications,

General applications, intrinsically safe, explosion proof and fail freeze versions are offered.

Intrinsically Safe: ATEX: EEX ia IIC T4 II 1 GD

CSA, FM Class I, Div, Group ABCD

Explosion proof: ATEX: EEX d IIB+H2, T4-T6 II 2 GD

CSA, FM Div I, Class 1,2 & 3 Group BCDEFG

Fail Freeze

I/P Module

Standard or I/S

I/P-converter

module

Explosion proof I/P module

Dome

indicator

Gauges

P5 pneumatic positioner

Spindles

Mounting bracket

Mounting

adapter

plate

F5 feedback module

F5 Explosion Proof

5

Page 6

2. Storage instructions

PMV Positioner and feedback module storage and handling pr ocedur es

PMV Positioners and feedback modules are precision instruments which should be stored

and handled accordingly to avoid problems or damage.

Electropneumatic positioners/feedback modules contain electronic components which can

be damaged by exposure to water. Appropriate precautions should be taken to protect units

while in storage.

Warehouse storage

Stored in original PMV shipping containers, units should be stored in an environmentally

controlled area, i.e. clean, cool (15-26°C, 60-80°F) and dry, out of direct sunlight or weather

exposure.

Field storage

Note: Once the air supply to the positioner is connected and turned on, internal air bleed

will prevent the ingress of moisture and protect the unit from corrosion. It is recommended

that the air supply be left on at all times.

• If units are installed immediately, turn, and leave on, the air supply.

• If positioners must be stored outdoors, tighten all covers which may have loosened in

shipment, make sure all open enclosure entry points are sealed.

Feedback modules should have cover tightened and conduits entries sealed. Positioners/

Feedback modules should be wrapped and sealed air and watertight with desiccant inside

the plastic, units should be securely covered with an opaque cover and not exposed to direct

sunlight, rain or snow.

Pneumatic positioners

Units should have all ports sealed and be protected from direct exposure to weather.

For long term storage (>1 month) or overseas shipment units should be protected with

plastic and desiccant.

Potential damage mechanism

When units are stored in hot, humid climates, the daily heating/cooling cycle will cause air

to expand/contract and be drawn in and out of the positioner/feedback housing.

6

Page 7

Dependent on the local temperature variations, humidity and dew points and time in storage

condensation could occur and accumulate inside on the I/P Converter causing erratic operation or failure due to water and corrosion. The potential for condensation damage is especially

high in southern climates and aggravated if units are exposed to direct sunlight.

For further assistance, please contact you nearest PMV office.

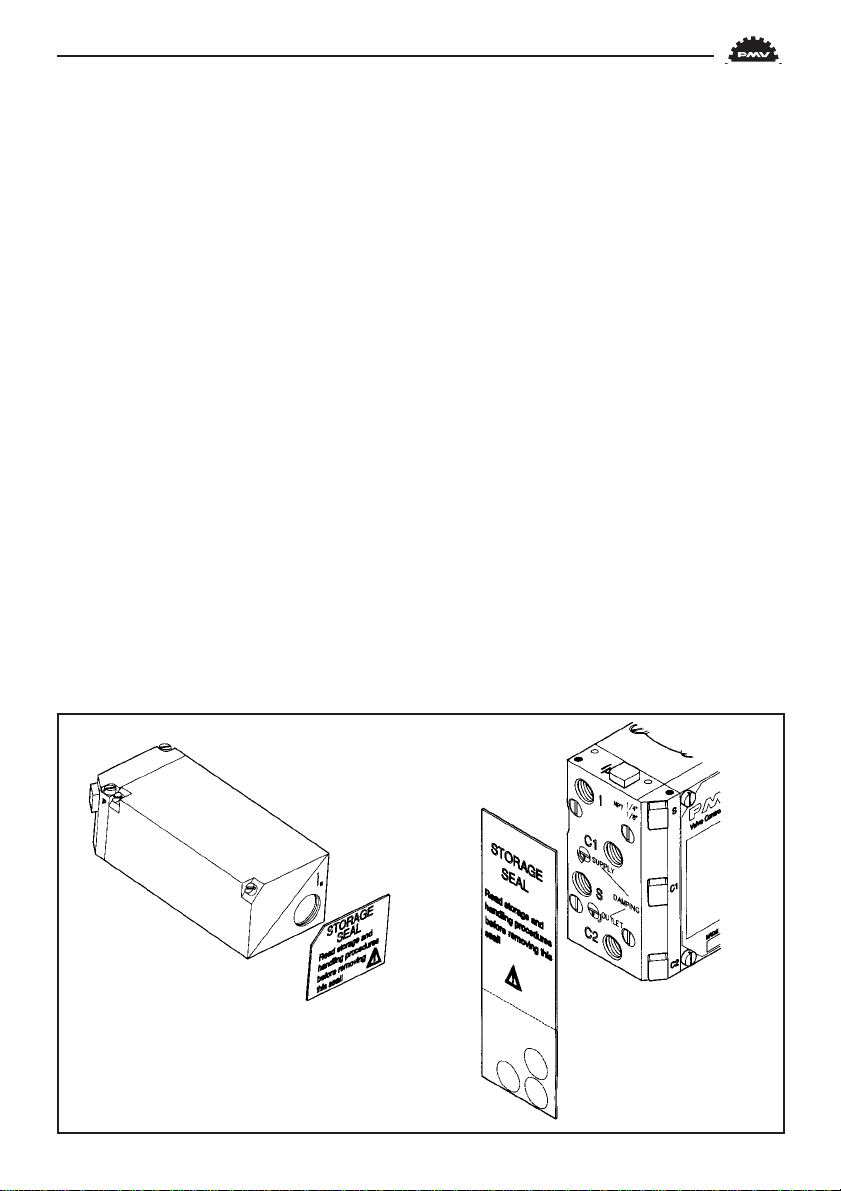

Storage Seal (P5/EP5)

P5/EP5 is supplied with all enclosure entry points sealed.The seal is only a storage seal, not

to be used as seal when P5/EP5 is in operation. If Storage Seal is removed or damaged, make

sure all open enclosure entry points are proper resealed before further shipping or storage.

Use circular stickers marked I, S and OUT, supplied on Storage Seal or vapour proof tape.

P5

Remove Storage Seal from connection block, mount positioner on actuator/valve, make

connections according to section 5, (Page 10). Calibrate span and Zero according to section

7, (Page 13).

Clean any oil/debris off the connecting block, then reseal open enclosure entry ports, use

circular stickers marked I, S and OUT, supplied on Storage Seal or vapour proof tape.

EP5

Follow P5 instructions as above. Remove Storage Seal for conduit entry IE, connect input

signal cable and install proper cable gland to secure the units sealing.

IP5-SEAL

IP5 seal

P5-SEAL

P5 seal

7

Page 8

3. Function

The P4 and P5/EP5 operates on a force balance principal. Force is originated by the signal

pressure transmitted through a diaphragm on to the balance arm. The opposing force is

achieved through the feedback spring and is proportional to the position of the lower arm.

The lower arm position is determined by the position of the cam which is secured to the

spindle and connected to the actuator shaft thus providing the feedback from the actuator/

valve. When these two forces are equal, the balance arm and the spool in the pilot valve are

in a neutral position — the complete unit is in a balanced position. Air is supplied to the

pilot valve through port S, and controls the air flow through ports C1 and C2

Assume an equilibrium position.

An increased control pressure will deflect the diaphragm 1 down, compressing the feedback

spring 3. The balance arm 2 moves the spool 7 in the pilot valve 8 furnishing supply air to

the actuator, while at the same time air is exhausted from actuator and is vented to atmosphere

through the pilot valve and the OUT port . W ith the increased supply air, the actuator rotates

(or moves linearly) moving the positioner spindle 6. The spindle and cam 5 rotate, forcing

the lower arm 4 upwards compressing the feedback spring 3. This motion will continue

until the two forces are equal and the unit is in an equilibrium position.

I

S

8

7312

856 4

Page 9

4. Installation

Air requirements

Maximum supply pressure is 1 MPa (150 psi). Supply air shall be clean, dry and free from

oil, water, moisture, foreign parts and debris.

The air shall be freeze-dried or similar to a dew point of at least 10°C (18°F) below lowest

expected ambient temperature.

A <40µ filter/regulator is recommended to be installed as close to P4/P5/EP5 as possible to

ensure proper supply air quality.

Before making pneumatic connections to the positioner, it is recommended that the supply

air lines are opened up and allowed to vent for 2-3 minutes to clear any debris from the line.

It is further recommended that a large paper bag is used to collect any oil or humidity that

may be present in the line during this purging, direct the air flow into the bag. Should exessive

amounts of oil and/or humidity be present at this stage, a review of the pneumatic system

should be carried out and the problem corrected.

Poor air quality is one of the major causes of pr emature failure of pneumatic equipment.

Installation

P4 and P5/EP5 mounts on to the actuator using either the ISO F05 holes 4 and a PMV ISO

mounting kit or by using the optional mounting adaptor and screws 5 to mount P5 on to

existing PMV mounting kits.

Proper alignment of the positioner spindle to the actuator shaft is very important since

improper alignment can cause excessive wear and friction to the positioner.

P5/EP5 only

The spindle/positioner shaft assembly allows for quick and simple spindle changes. T o ensure

the proper connection, the spindle 3 has a spring clip 2 that must be properly installed. A

solid ”click” should be felt when assembling the two pieces insuring that the two flats 1 are

engaged into the positioner shaft groove.

The spindle can be removed, by inserting two screwdrivers under the two tapered surfaces

of the spindle and bending carefully. When the spring clip releases the spindle will eject.

P4/P5 P5/EP5

2

1

3

5 4

9

Page 10

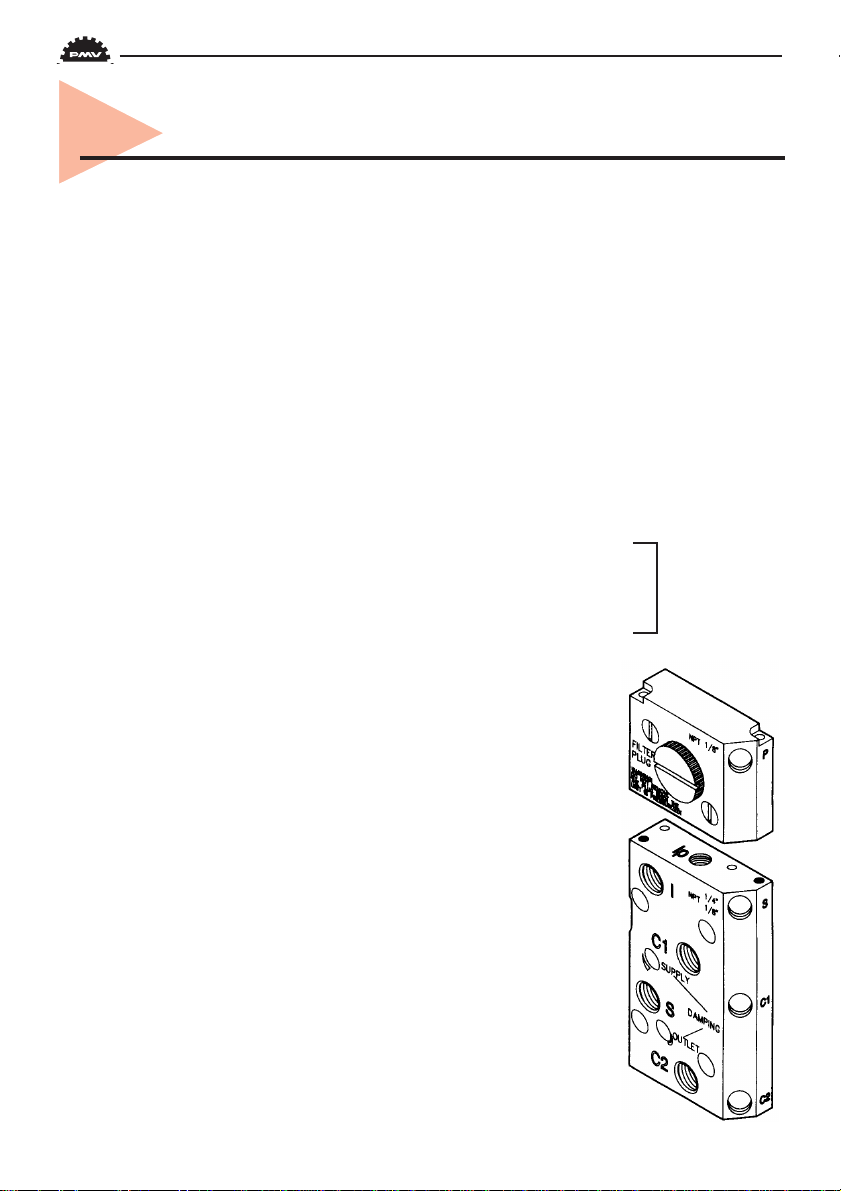

5. Connections

Air connections are tapped for 1/4" G or NPT male connectors and are clearly marked.

Gauge ports are for 1/8" G or NPT.

We recommend use of Loctite® 577 or similar user preferred for sealing.

Electrical connection on I/P unit accepts 1/2" NPT or PG 13,5 (M20) cable gland.

Port I Input instrument pneumatic signal 20-100kPa (3-15 psi)

Port S Supply air, maximum 1 MPa (150 psi) Minimum 0,15 MPa

(21 psi) for EP5

Port C1, C2 Actuator connections (0,2-1 MPa). C2 opening port.

For single acting operation plug port C1 for increasing signal to open valve. Plug C2 for

decreasing (reverse) signal to open valve.

OUT Exhaust air port. Do not block! Exhaust filter optional.

Port Ip Gauge port for pneumatic input signal.

Port I

E

Port P Gauge port for I/P unit output pressure ( On the I/P unit)

Ports Ip, P, S, C1 and C2 are sealed with plugs. To install gauges,

unscrew plugs and replace with gauges.

Input electric signal (4-20 mA) (On the I/P unit.)

P5/EP5 only

Port OUT is for venting the unit. All air from the positioner, actuator

and I/P unit is vented to atmosphere through this port. Do not block

this port. A high flow silencer or an exhaust pipe can be connected to

this port to prevent foreign objects from entering and blocking the

units exhaust. Connector in exhaust port must not have less than 9

mm (3/8“) orfice.

When using gases other than air for supply — Please contact PMV.

On EP5 (P5 with I/P unit installed) I/P unit is supplied with air from

port S. Port’I is automaticly sealed off and protected. No connection

shall be made to this port. See pages 13 and 14 for more information.

10

Page 11

C1

C2

S

I

C1

C2

II

S

C1

C2

S

X = Port plugged

Direct function

11

Page 12

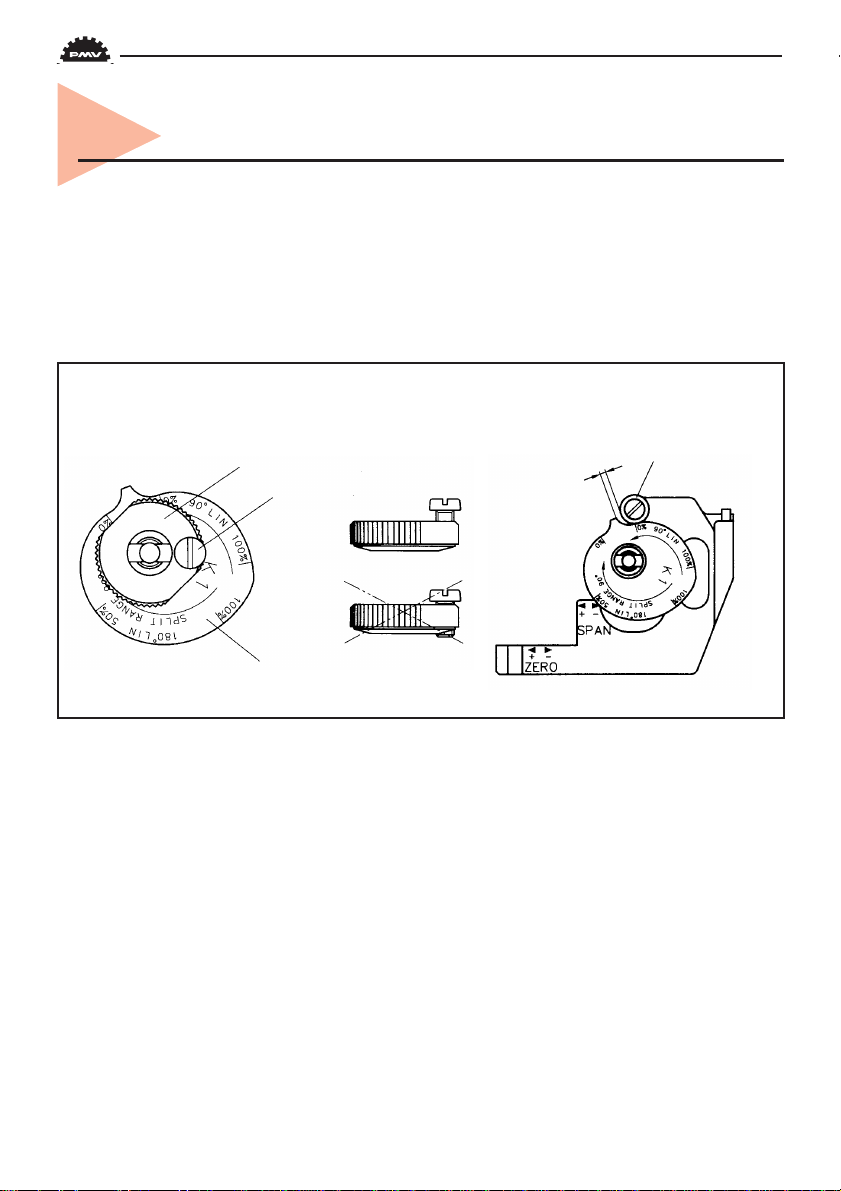

6. Cam adjustment

With the cover and indicator removed, loosen the screw 1 and turn the cam locking nut 2

counterclockwise until the cam loosens. Adjust the cam 3 as desired making sure that the

ball bearing 4 always is riding on an active lobe on the cam. To secure the cam, make sure

that screw 1 is backed out from the locking nut 2 then finger tighten the locking nut and

tighten screw 1. Install and adjust the indicator and reinstall cover.

2

4

1

correct

incorrect

3

1-2 mm (1/16")

12

Page 13

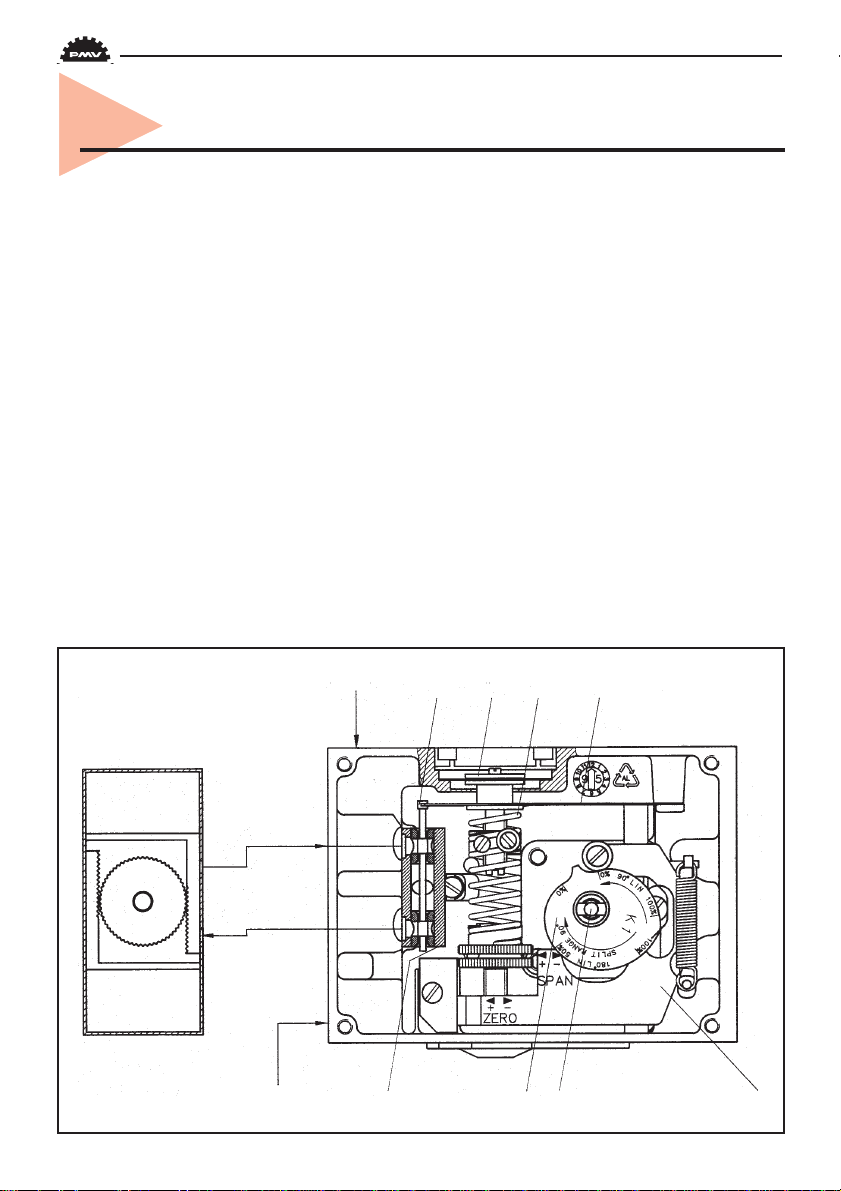

7. Calibration

P4/P5/EP5 is when shipped from PMV precalibrated for 90 ±0,5 deg rotation, (can also

be 30, 45 or 60 deg, see installed cam). For

most applications the valve closed position

is more critical than valve open position,

most attention should be paid at valve closed

position. Always start calibration procedure

by applying 0 % input signal, then adjusting

zero. P4/P5/EP5 is calibrated by turning

thumb wheels 1 & 4.

Arrows on arm 5 indicate turning direction

of thumb wheels.

< “+“ = Increase zero/span

> “–“ = Decrease zero/span

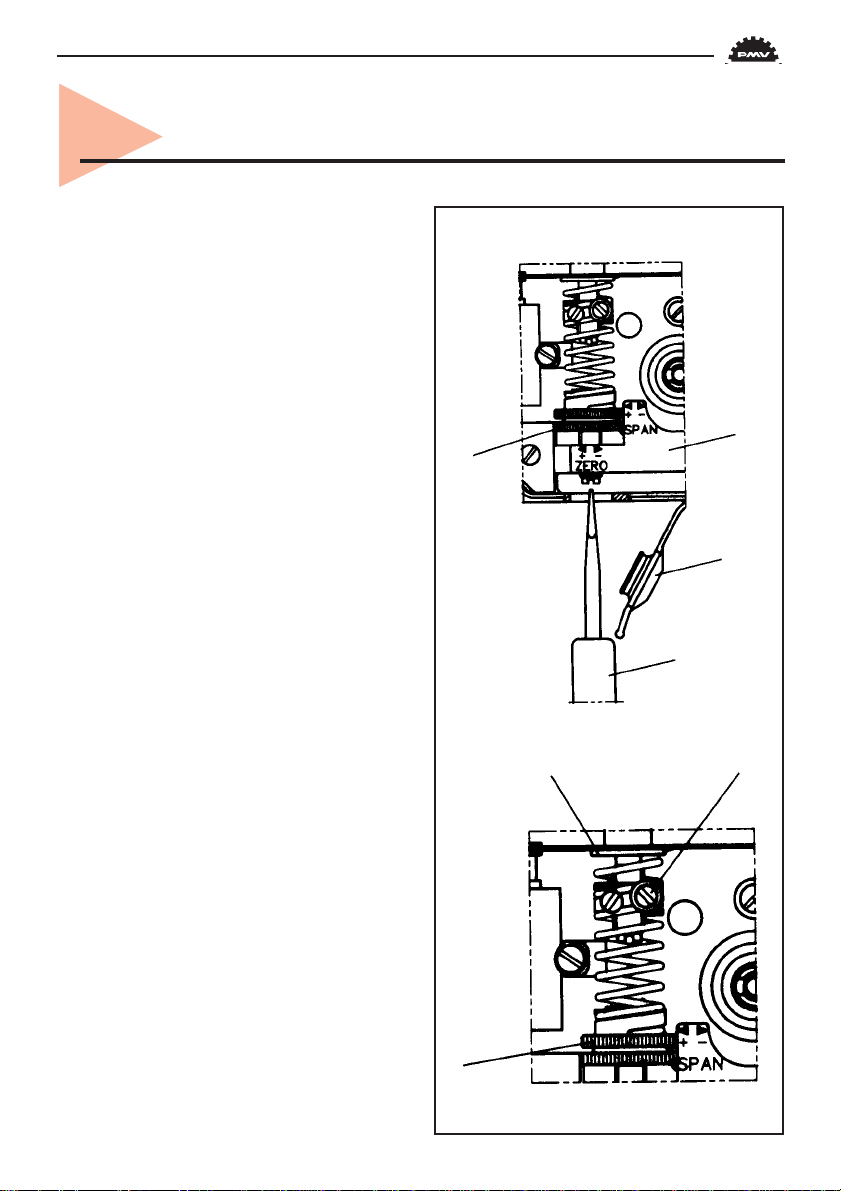

Calibration procedure

Check cam seating, section 6 before starting

calibration procedure.

1. Apply 0 % input signal (0% =

20 kPa/3 psi or 4 mA)

2. Wait for steady state.

3. Adjust zero by turning the silver (lower)

thumb wheel 4 with finger or with screw-

driver 7 from the outside.

4. Apply 100% input signal (100% =

100 kPa/ 15 psi or 20 mA)

5. Wait for steady state then memorize

result.

6. Apply 0% input signal.

7. Adjust span if necessary. This is done by

first loosing screw 2, then turning the

yellow (upper) thumb wheel 1 “+“ or

“–“ and finally tighten screw 2. Spring

top must not be in contact with spring

guide 3.

8. Check zero and adjust if needed.

9. Repeat steps 2 to 8 until desired

calibration is achieved.

5

4

6

7

3 2

13

Page 14

8. Indicator adjustment

P5/EP5: To adjust the indicator, take off front cover and pull the indicator upwards until it

comes off the Allen screw.

Before installing the indicator make sure that the Allen screw is tightened. Press the indicator

on the screw and adjust it by rotating clockwise to desired position.

P4: Loose screw, adjust indicator, tighten screw.

9. Front cover and indicator cover

The front cover of P5 is secured to the pneumatic unit with four captured screws and sealed

with an O-ring 1. The O-ring can be looped over notches 2 in the front cover to allow for

drainage. There are eight locations on the front cover where the O-ring can be looped. This

O-ring system is common to the Pneumatic unit , I/P unit and Feedback unit in the PMV

Valve Control System P5. This unique sealing system allows for complete sealing or draining

of the units by changing the position of the O-ring.

The indicator cover 3 is O-ring sealed and secured by a bayonet coupling. The indicator

cover is also used to secure the identification cover 4.

To remove the indicator cover turn it slightly counterclockwise until it loosens. Identification

cover and O-ring 5 are now removable.

When installing indicator cover and identification cover make sure that the O-ring is properly

engaged.

1

4315

14

2

Page 15

10. Dampers (P5/EP5)

The standard built in dampers 5 located on the connecting block prov-ide a simple means of

adjusting the actuator travel speed.

For maximum actuator travel speed dampers shall be adjusted to mini-mum damping position. (Fig).

Double acting actuators – adjust only OUTLET damper, set SUPPLY damper in minimum

damping position.

Single acting actuators – adjust both dampers for desired operation.

5

15

Page 16

11. I/P Unit (P5/EP5)

WARNING! Units installed in hazardous

areas must have proper approvals.

The I/P unit is mounted directly on top of

the positioner unit.

No external air supply is needed since the I/

P unit is supplied with air from the positioner unit.

Port I on the positioner unit will be plugged

when the I/P unit and the appropriate gauge

block gasket installed.The I/P unit accepts a

4-20 mA input signal.

1

2

The I/P unit is equipped with a built in 30

micron filter (Fig 4).

Caution: Do not operate the unit without filter and filterplug installed.

Ensure that wiring between I/P and terminals are properly seated in rubber clamp.

Do not unscrew filterplug when the positioner is pressurized.

Span and Zero for the I/P converter is factory

set and can not be adjusted

16

Fig 3

Page 17

12. How to mount the I/P Unit to

the positioner unit (P5/EP5)

Switch off supply air and disconnect input signal – port I.

Loosen screws 3 and remove connection block 1, the gauge or plug from port Ip, the fitting

from port I and existing gasket 4. Carefully install gasket 6 supplied together with I/P unit.

When correct installed port I will be blocked by the gasket.

Make sure that relief valve spring 5 is installed properly. Install the connection block 1 to

the positioner unit 2.

Remove cover on I/P unit.

Install the I/P unit to the top of the Positioner unit, making sure that the four O-rings are

present and properly seated. Tighten the unit with the three screws. (See fig. 1 and 2 page

16) Screw 1 first, screw 2 last.

WARNING! Units installed in hazardous areas must have proper approvals.

Connect input signal cable to port IE and tighten the cable gland (see fig 5 on page 16).

Adjust the O-ring on the I/P Unit housing to desired posi-tion - sealed or drained. (See fig 3

on page 16 or section 9 on page 14).

A gauge indicating output signal from the I/P converter can be installed in port P. Make sure

that the filter plug is tightened before supply air is switched on (Fig 4 on page 16).

6

2

4

1

3

5

17

Page 18

13. Maintenance

When upgrading electronically parts inside a PMV positioner appr oved for

installation in Hazardous locations special procedures apply , permission from

PMV is required prior to the start of work.

Please contact your local PMV Sales office for information r egarding

proper procedur es.

www.pmv.nu or info@pmv.nu

Pilot valve

To remove the pilot valve for cleaning or inspection, remove the screw 1 and carefully lift

out the complete assembly 2. Gently remove the spool 3 from the block and clean the parts,

using methylate cleaner or similar. Blow the parts dry with compressed air. Install the spool

into the pilot valve housing, place it on a flat surface, then lift it carefully in one end. Before

reaching 20 deg angle the spool should slide by itself.

Should the parts show signs of wear, a new assembly is recommended. Mixing spool valves

and valve bodies may result in very high bleed rates and poor performance. Check the Orings, then secure and install the pilot valve assembly into positioner unit, press it towards

the positioner housing wall and secure it with screw 1. Make sure that the leaf spring 4 on the

balance arm 5 is properly fitted in the groove on the spool 6. Check again to insure smooth

operation of the assembly.

To maintain original factory performance specifications, use only spool valve assemblies

supplied by PMV.

18

3

2

1

6

5

4

Page 19

Diaphragm

If P5 is equipped with I/P unit (EP5), the I/P unit must be removed to access the diaphragm.

When installing the diaphragm make sure to place one washer on each side of the diaphragm.

Put some Loctite 577 on the thread, install the screw 3 and tighten.

Make sure the diaphragm is centered.

Check the O-ring for the diaphragm cover 2, install the O-ring into the positioner housing,

then install cover 2. Secure crosswise with screws 1, first turn loosely. Torque shall be 4,5

Nm (40 in-lbs).

19

Page 20

Feedback spring

Once the front cover and indicator are removed, the feedback spring can be easily

accessed.

Hold the spring 1 from the top, pull down

and out.

When installing, hold the assembly at the top,

guide the lower part to position on the zero

screw , then press down until it fits easily under the balance arm 2. Make sure that the

assembly is aligned properly against the

lower arm and the notch is engaged in the

tab on the balance arm 2.

Balance arm

The balance arm 3 can only be removed after

I/P unit, diaphragm and feedback spring have

been removed. (See sections above and on

page 16, 18 and 19).

2

1

3

Loosen the screws 3 and the balance arm can

be removed.

installing the balance arm make sure that the

leafspring 4 on the underside of the balance

arm 5 is properly engaged into the groove 6

of the spool in the pilot valve. Tighten the

two screws 3 holding the balance arm to the

positioner.

20

6

5

4

Page 21

Lower arm

Once the front cover is removed, the lower arm can be easily accessed.

Remove the indicator, feedback spring and the cam.

Loosen screw 2 and remove twist stop 1.

Remove screw 3, lower arm 4, rod 5 and spring 6.

Check rod and lower arm for wear, replace if necessary. Clean the rod and install it in the

lower arm. The lower arm should move easily and smoothly.

Install the lower arm and rod assembly into the positioner housing, making sure that the

spring 6 is attached properly to the lower arm and positioner housing.

Secure the lower arm and rod assembly with the screw 3.

Check again that the lower arm moves smoothly.

Apply a small amount of grease on the small tongue on the lower arm, then install and secure

the twist stop.

Install cam, feedback spring, indicator and front cover.

4

3

6

2 1 5

2 1 5

P4 P5/EP5

4

3

6

21

Page 22

O-rings

With time and use, O-rings can become brittle. This can cause poor operation and even

failure of the positioner.

Always check O-rings when performing any work on the positioner and replace bad Orings.

A thin layer of silicon grease applied on the NBR (Black) O-rings prolongs their life. On Q

(red) O-rings, use a non silicon based grease.

Filter plug (EP5)

Caution! Do not operate the unit without filter and filter plug installed. Do not attempt

to unscrew filter plug while positioner is pressurized.

EP5 is equipped with a built in secondary filter located on the side of the I/P unit.

For replacement or inspection, make sure that positioner unit is not pressurized, then unscrew

filter plug 1. Remove filter 3 and install a new into the filter plug . Check condition of Oring 2 and filter compartment. If moisture is found, check upstream filters/oil-water separators.

Moisture can cause I/P failure.

Reinstall filter plug.

1

22

3

2

Page 23

14. Feedback unit (P5 or EP5)

See feedback module instructions for connections and calibration.

The P5 or EP5, Valve Control System, can easily be equipped with a Feedback unit, model

F5. This unit will mount directly on top of the Pneumatic positio-ner replacing the positioner front cover. The O-ring located on the bottom of the Feedback unit, F5, will provide the

same sealing or draining capabilities as the front cover. The indicator and front cover from

the positioner unit can then be installed on to the Feedback unit.

WARNING! Units installed in hazardous locations must have proper

approvals.

Installing the feedback unit.

— Remove the front cover, indicator, and Allen head screw from the top of the

positioner spindle.

— Install the drive coupling 4 and adjust the O-ring seal on the bottom in either

sealed or draining position. (See section 6, page 10).

— Install the Feedback unit 9 on top of the Positioner unit, making sure the

coupling is properly engaged before tightening the four screws 5.

—Make electrical connections and tighten cable glands. (See F5 manual for details).

— Adjust cams and/or potentiometer to desired position.

— Install the indicator and front cover.

9

5

O-ring seal

2

4

3

23

Page 24

15. Trouble shooting

Note: All PMV-positioners are serialized.

Please note down, and provide the serial

number when contacting the factory for trouble shooting or service.

Signal change has no effect on the actuator

position.

— Check indicator and screw.

— Check air supply to positioner and tubing

to the actuator.

— Check input signal to positioner.

— Check diaphragm for damage or leakage.

— Check pilot valve function.

— Check cam for correct setting.

— Check I/P output

Signal change results in actuator running to

end positions.

— Check coupling between positioner and

actuator.

— Check cam position and locking screw.

— Check input signal.

Inaccurate positioning.

— Dirty or worn pilot valve.

— Defective or leaking diaphragm.

— Input signal fluctuates.

— Incorrect sizing of actuator.

— Valve/actuator ”stiction”.

— High valve/actuator breakaway torque.

— Loose cam.

24

Page 25

16. Technical data

P4

Input Signal 20-100 kPa/3-15 Psi (6-30 Psi optional)

Linearity (%)* 0,7

Hysteresis+deadband (%)* 0,8

Repeatability (%)* 0,5

Pressure gain at load 20% (%/%) 20 %/% ISA 75.13 1989

(kPa/kPa) 300

Air consumption at supply pressure:

0,6 MPa/87 Psi 8 nl/min (0.31 SCFM)

Air delivery at supply pressure:

0,2 MPa/29 Psi 140 nl/min (5.46 SCFM)

0,4 MPa/58 Psi 245 nl/min (9.55 SCFM)

0,6 MPa/87 Psi 350 nl/min (13.65) SCFM

Supply Pressure Max 1 MPa/150 Psi

Temperature range -20°C to +85°C (-4°F to 185°F)

Connector threads 1/4" NPT

Weight std. 0,9 kg/2 lbs

* % of full scale.

25

Page 26

P5 EP5

Input Signal 20-100 kPa/3-15 Psi (6-30 optional) 4-20 mA

Linearity ≤ 0,5%* ≤ 0,5%*

Hysteresis ≤ 0,75%* ≤ 0,5%*

Repeatability ≤ 0,5%* ≤ 0,5%*

Gain (pressure 600 kPa/87 Psi)

1 000 (kPa/kPa)

Min 66%/% ISA S75.13

Air consumption at Supply pressure:

0,2 MPa/29 Psi 5,4 nl/min 0.19 SCFM 6,1 nl/min 0.22 SCFM

0,4 MPa/58 Psi 12,3 nl/min 0.43 SCFM 13,6 nl/min 0.48 SCFM

0,6 MPa/87 Psi 20 nl/min 0.71 SCFM 22 nl/min 0.78 SCFM

0,8 MPa/116 Psi 27,8 nl/min 0.98 SCFM 30,5 nl/min 1.08 SCFM

1 MPa/145 Psi 35,7 nl/min 1.26 SCFM 39 nl/min 1.38 SCFM

Air delivery at Supply Pressure:

0,2 MPa/29 Psi 200 nl/min 6.9 SCFM

0,4 MPa/58 Psi 370 nl/min 12.8 SCFM

0,6 MPa/87 Psi 540 nl/min 18.8 SCFM

0,8 MPa/116 Psi 710 nl/min 24.7 SCFM

1 MPa/145 Psi 880 nl/min 30.6 SCFM

Supply Pressure Max 1 MPa/150 Psi 0,15-1 MPa/21,8-150 Psi

Temperature range -20°C to +85°C (-4°F to 185°F)

Connector threads 1/4" NPT or G

Gauge threads 1/8" NPT or G

Weight std. 1,1 kg/2.4 lbs 1,5 kg/3.4 lbs

Weight with gauges 1,3 kg/2.9 lbs 1,8 kg/3.9 lbs

Ingress protection IP 66/NEMA 4

* Per cent of full scale.

(The information in this manual is subject to change without notice.)

26

Page 27

Dimensional drawing (P4)

27

Page 28

17. Spare parts

P4

20

18

21

1

21

3

21

20

20

11

21

20

20

12

8

7

9

15

6

16

20

20

10

17

13

19

20

2

20

28

Page 29

No Part no Qty Description Remarks

1. 1 Housing 1 N/A

2. P4-xx 1 Front cover

3. P4-7 1 Diaphragm cover incl. O-ring

4. P5-8 1 Diaphragm

5. P5-9 2 Diaphragm washer

6. P5-10 1 Balance arm

7. P5-AS13/315 1 Feedback spring 3-15 Psi assembly

7. P5-AS13/630 1 Feedback spring 6-30 Psi assembly (Green)

8. P4-AS18 1 Lower arm assembly

9. P5-19 1 Rod

10. P5-20 1 Spring

11. P5-24 1 Twist stop

12. P4-AS25 1 Pilot valve incl. O-rings

13. P5-27 1 Cam locking nut incl. screw

15. P5-31 1 Mounting adapter incl. screws

16 P5-32 1 Ball bearing

17. P5-K1 1 Cam K1 90°/180° Linear 0-100%,

split range 0-50-100% 1

17. P5-Kxx 1 Cam special, K2-K10 (ConsultPMV)

18. P4- 1 Cxx Spindle (Consult PMV)

19. 12013 1 Indicator Arrow type 1

20. P4-SCREW Screw set Set

21. P4-SEAL NBR Seal and O-ring set NBR, Nitrile rubber. Set (4, 21)

29

Page 30

Spare parts, P5/EP5

84

30

Page 31

Pos Part no Qty Description

11Housing

2 P5-2 1 Front Cover incl. O-ring

3 P5-AS3N 1 Connecting block NPT 1/4" assembly

3 P5-AS3G 1 Connecting block G 1/4" assembly

4 P5-4 1 Relief valve spring

6 P5-6P 1 Gasket for P5

6 P5-6EP 1 Gasket for EP5

7 P5-7 1 Diaphragm cover incl. O-ring

8 P5-8 1 Diaphragm

9 P5-9 2 Diaphragm washer

10 P5-10 1 Balance arm

13 P5-AS13/315 1 Feedback spring 3-15 psi assembly

13 P5-AS13/630 1 Feedback spring 6-30 psi assembly

18 P5-18 1 Lower arm assembly

19 P5-19 1 Rod

20 P5-20 1 Spring

21 P5-21A 1 Indicator Arrow

21 P5-21F 1 Indicator Flag

21 P5-21P 1 Indicator Pointer

22 P5-22T 1 Indicator cover Transparent incl. O-ring

22 P5-22F 1 Indicator cover Flag incl. O-ring

22 P5-22B 1 Indicator cover Blind incl. O-ring

24 P5-24 1 Twist stop

25 P5-25 1 Pilot valve incl. O-rings

26 P5-26 1 Shaft incl. O-rings, screw

27 P5-27 1 Cam locking nut incl. screw

29 P5-29 1 Zero cover

30 P5-30 1 Cover

31 P5-31 1 Mounting adapter, incl screws

32 P5-32 1 Ball bearing

35 P5-xx/xx 1 Identification cover

36 12047N 4 Plug NPT 1/8"

36 12047G 4 Plug 1/8" G

37 P5-Kxx 1 Cam

38-45, P5-Screws 1 Screw set P5/EP5

75-80

46-53 P5-Seal NBR 1 O-ring set P5/EP5

81-83, 6 , 67, 70 Nitrile, NBR

46-53 P5-Seal Q 1 O-ring set P5/EP5

81-83, 6 , 67, 70 Silicone, Q

54 P5-Sxx 1 Spindle adaptor

➜

31

Page 32

Spare parts, P5/EP5

84

32

Page 33

Pos Part no Qty Description

61 1 I/P box

62 E5-2 1 I/P cover incl. screws

63 E5-AS3N 1 I/P nose NPT 1/4" assembly

63 E5-AS3G 1 I/P nose G 1/4" assembly

64 P5-4 1 Relief valve spring

65 E5-5 1 Filter plug incl. Filter 66, O-ring, 81

66 E5-6 1 Filters (5 per package)

67 E5-7 1 Gasket I/P

71 E5-STD 1 I/P converter

73 E5 N-AS 11 1 Mounting bracket Round I/P

E5 G-AS 11 incl. screws, O-rings, I/P Nose

74 FU-STD 1 Enclosure incl. I/P converter Std.

74 E5-EX/EU 1 Enclosure incl. I/P converter, flameproof Cenelec

74 E5-EX/US 1 Enclosure incl. I/P converter,

Explosionproof FM, CSA

84 E5-FS 1 I/P converter fail in last position incl. bracket

33

Page 34

18. Certificates

34

Cenelec Atex, black label

Page 35

Cenelec Atex, black label

35

Page 36

36

Page 37

Cenelec Atex, white label

37

Page 38

WARNING!

These instruments must be installed in accordance with local and national codes of

practice, especially for hazardous area installations. The instruments are fully isolated

from ground and therefore grounding is unnecessary for functional purposes.

However, grounding may be necessary to conform to installation codes.

WARNING!

Installation of any hazardous area equipment should be made in accordance with

hazardous area installation codes and also of course to the installation to the installation

and operating instructions provided. The manufacturer cannot be held responsible for

incorrect installation or any customer modifications to, or repair of, a certified instrument

as this may invalidate the certified design. If a certified instrument shoult fail, no attempt

should be made by the user to effect repair. The unit should be returned to the factory.

Approvals EP5-IS

(I/P-converter with white label)

Page 39

FM

White label

Page 40

CSA

White label

Page 41

Page 42

Palmstiernas Instrument AB

Korta Gatan 9 • 171 54 Solna

Tel: +46 (0)8-555106 00 • Fax: +46 (0)8-555106 01

E-mail: info@pmv.nu • www.pmv.nu

PMV PN 22549/02

Loading...

Loading...