Page 1

P3/EP3

Modular Linear Positioner

Installation

Operation

Maintenance

Page 2

2

Contents

1. Introduction ................................................................................................................... 3

Safety instruction ............................................................................................................... 3

2. Storage ............................................................................................................................ 4

General .............................................................................................................................. 4

Storage indoors .................................................................................................................. 4

Storage outdoors or for a longer period ............................................................................. 4

Storage in a warm place .................................................................................................... 4

3. Design.............................................................................................................................. 5

4. Variants ........................................................................................................................... 6

Standard designs ................................................................................................................ 6

Optional equipment ........................................................................................................... 6

5. Function .......................................................................................................................... 7

General .............................................................................................................................. 7

Increase in signal pressure ................................................................................................. 7

Decrease in signal pressure ............................................................................................... 7

6. Installation...................................................................................................................... 8

Air supply requirements .................................................................................................... 8

Mounting ........................................................................................................................... 9

Connections ..................................................................................................................... 11

Direct / Reverse function ................................................................................................. 11

Single acting positioner ................................................................................................... 12

Electrical connections ...................................................................................................... 13

Control drawing ...............................................................................................................14

7. Adjustments..................................................................................................................15

Gain ................................................................................................................................. 15

Default settings ................................................................................................................ 15

Setting the zero position and span ................................................................................... 15

8. Maintenance/service .................................................................................................... 16

Valve block ...................................................................................................................... 16

Flapper nozzle ................................................................................................................. 17

Gain screw ....................................................................................................................... 17

Integral I/P converter ....................................................................................................... 17

Feedback arm / Spindle ................................................................................................... 18

9. Trouble shooting .......................................................................................................... 19

10. Technical data ............................................................................................................ 20

11. Spare Parts List .......................................................................................................... 22

Page 3

1. Introduction

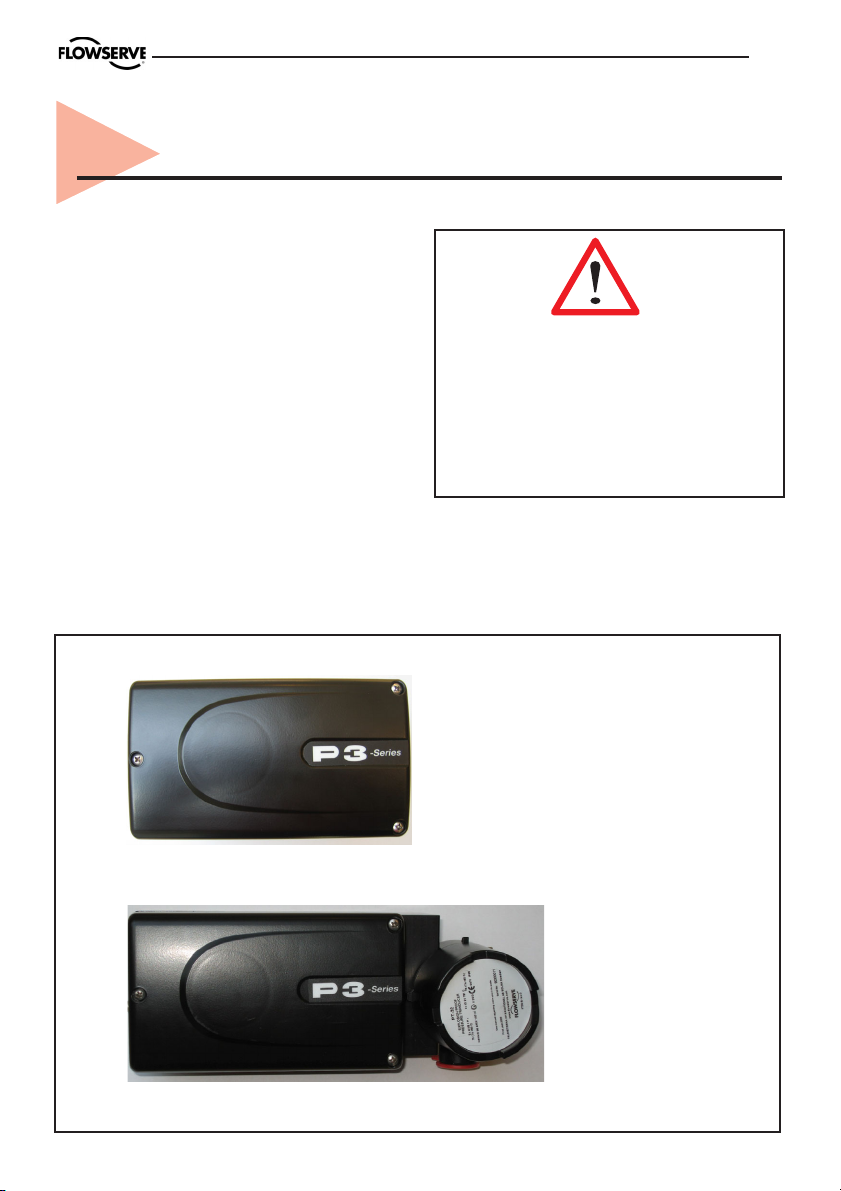

The PMV P3 is a modular Positioner system designed for use on control valves with

linear motion. The basic unit is the P3 positioner, which is available for single acting.

The I/P converter can be integral, located in

a separate mounted module (Ex), or located

elsewhere. The P3 can be equipped with

connection blocks for pressure gauges to

indicate:

- actuator pressure

- air supply pressure

- input signal pressure

3

Safety instruction

Read the safety instructions in this

manual carefully before using the product.

The installation, operation, and

maintenance of the product must be done

by staff with the necessary training and

experience.

PMV P3 basic unit

PMV P3 with

explosion proof I/P

Page 4

4

2. Storage

General

The PMV positioner is a precision instrument. Therefore it is essential that it is

handled and stored in the correct way.

Always follow the instructions below!

N.B. As soon as the positioner is

connected and started, an internal air bleed

will provide protection against corrosion

and prevent the ingress of moisture. For this

reason, the air supply should always be kept

on.

Storage indoors

Store the positioner in its original

packaging. The storage environment must

be clean, dry and cool, (15 to 26°C,

59 to 79°F).

Storage outdoors or for a

longer period

If the positioner must be stored

outdoors, it is important that all the cover

screws are tightened and that all connections

are properly sealed. The unit should be

packed with a desiccant in a plastic bag or

similar, covered with plastic, and not exposed

to sunlight, rain, or snow.

This is also applicable for long-term

storage (more than 1 month) and for long

transport by sea.

Storage in a warm place

When a positioner is stored in a warm

place with a high relative humidity and is

subjected to daily temperature variations, the

air inside the unit will expand and contract.

This means that air from outside the unit

may be drawn into the positioner. Depending

on the temperature variations, relative

humidity, and other factors, condensation and

corrosion can occur inside the unit, which in

turn can give rise to functional disorders or

a failure.

Page 5

3. Design

5

The P3 positioner comprises a basic

module with a single acting valve block. It

also includes a sealed chamber with terminals for the electrical input signals.

The I/P unit can be built into the main

housing (as shown in the figure below) or

I/P

converter

Feedback arm

Feedback spring

located externally (explosion proof), see

section ”Variants”.

The adjusting screws and knobs are

accessible under the removable sealed aluminium cover.

Balance arm

Flapper nozzle

C+

➠

➠

Supply

Input

3-15 psi

Electrical

connection

Figure shows P3 positioner with integral I/P converter and cover removed

Zero position

adjustment

Adjusting screw,

damping

Span

adjustment

Adjusting

screw, gain

Page 6

6

4. Variants

Standard designs

P3/EP3 is available single acting.

I/P converter can be integral or located

elsewhere.

P3

Pneumatic, single acting, to be

connected to an external I/P converter.

EP3, EP3IS

Electro-pneumatic, single , with integral

I/P converter. Intrinsically safe model also

available.

EP3EX

Explosion proof model, I/P converter

located in separate, sealed enclosure.

Optional equipment

P3 / EP3 positioner can be equipped

with connection blocks and pressure gauges

for:

- input signal pressure

- input air supply pressure

- output pressure

P3/EP3

EP3 EX

Page 7

5. Function

General

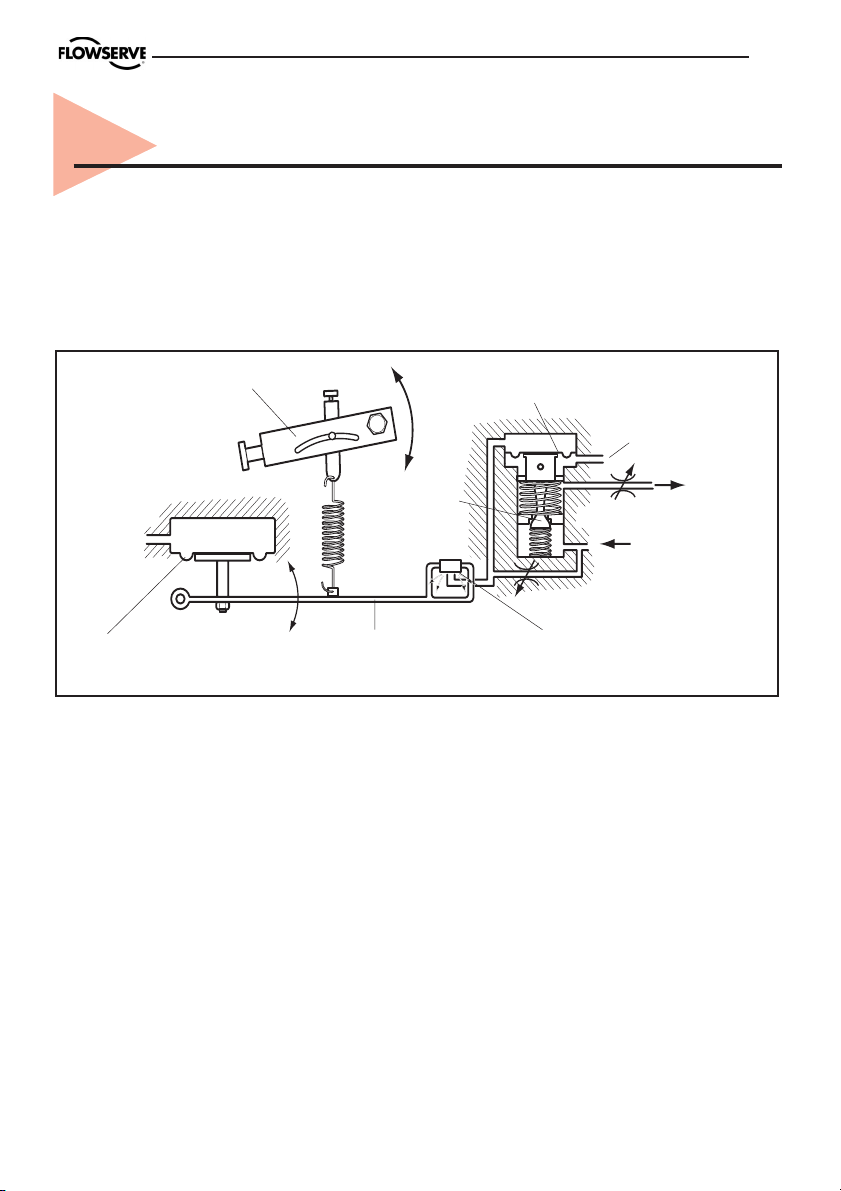

The P3 positioner operates on the force balance principle. Changes are initiated by the

signal pressure from the I/P converter. The functionality is described briefly below.

Single action

7

Feedback arm

Plug

Signal

pressure

Signal diaphragm Balance arm Flapper nozzle

Increase in signal pressure

When the air pressure on the signal

diaphragm increases, the balance arm is pressed down and the flapper nozzle closes. The

pressure on the relay diaphragm then

increases and the plug valve opens.

Air is now supplied to the actuator, the

spindle movement rotates the feedback arm,

the balance arm is lifted, and the flapper

nozzle opens. The pressure on the relay

diaphragm is reduced and the plug valve

reduces the air flow to the actuator. An

equilibrium position is thus reached and the

valve being controlled is in the desired position.

valve

Decrease in signal pressure

diaphragm is reduced, the balance arm is

lifted and the flapper nozzle opens. The

pressure on the relay diaphragm is then

reduced and the plug valve upper seal opens

and vents.

and its spindle moves. The actuator

movement goes back through the arm

mechanism (see figure) to the positioner

spindle, which rotates the feedback arm. The

balance arm is now lowered by the reduced

spring force and closes the flapper valve. An

equilibrium position is thus reached and the

valve being controlled is in the desired position.

Relay

diaphragm

Venting

When the air pressure on the signal

Air is now ventilated from the actuator

To/from

actuator

Air

supply

Page 8

8

6. Installation

Air supply requirements

Max. air supply pressure, see the section

Technical Data on page 20.

The supply air must be free from

moisture, water, oil, and particles.

The supply air must be dried or be treated

in such a way that its dew point is at least

10°C (18°F) below the lowest expected

ambient temperature.

Before the air supply is connected to the

positioner, we recommend the hose is opened

freely for 2 to 3 minutes to allow any contamination to be blown out. Direct the air jet

into a large paper bag to trap any water, oil,

or other foreign materials. If this indicates

that the air system is contaminated, it should

be properly cleaned.

To ensure a stable and problem-free ope-

ration, we recommend the installation of a

filter/pressure regulator <40µ as close to the

positioner as possible.

WARNING. Do not direct the

open air jet towards people or

objects because it may cause

personal injury or damage.

Poor air quality is the main source of

problems in pneumatic systems.

Page 9

Mounting according to IEC 534-6

9

N.B. If the positioner is installed in a

hazardous environment, it must be of a

type approved for this purpose.

The positioner has an ISO F05 footprint

(A). The holes are used to attach it to the

mounting bracket (B), which is suitable for

most types of linear actuators.

The arm (C) is graduated in mm and

AB

inches. The scale is used to adjust the pin

(D) so its position corresponds to the stroke

of the valve stem.

It is important that the positioner’s

spindle and the arms, that transfer the

actuator movements, are correctly mounted.

Any tension between these parts can cause

incorrect operation and abnormal wear.

C D

Page 10

10

Mounting instructions for P3/EP3 with mounting kit 30168S

Page 11

Connections

11

Air:

Port S Supply air

Port C+ Connection to actuator

Port IPPneumatic input signal

(external I/P)

Electrical connection

Port I

E

Dimensions

Air connections: 1/4" NPT alt. G 1/4"

Electrical connection: M20 x 1.5 alt.

NPT 1/2"

Loctite 577 or equivalent is

recommended as a sealant.

Direct / Reverse function

It is simple to adapt the positioner for

direct or reverse function. Unscrew the

flapper valve nozzle and reverse it, and

change the mounting on the actuator. See

figure page 12.

Electric input signal

4-20 mA

Data for air and electrical

connections, see section

Technical Data on page 20.

Flapper valve position

➠

C+

➠

Supply

Input

3-15 psi

Page 12

12

Single action positioner

Actuator with closing spring, flapper

nozzle set for reverse function

When the signal from the I/P unit

increases, the pressure C+ to the actuator is

increased. The valve stem moves upwards.

Actuator with closing spring, flapper

nozzle set for direct function

When the signal from the I/P unit

increases, the pressure C+ to the actuator is

reduced. The spring forces move the valve

stem downwards.

S

C+

S

C+

Actuator with opening spring, flapper

nozzle set for reverse function

When the signal from the I/P unit

increases, the pressure C+ to the actuator is

increased. The valve stem moves

downwards.

Actuator with opening spring, flapper

nozzle set for direct function

When the signal from the I/P unit

increases, the pressure C+ to the actuator is

reduced. The spring forces move the valve

stem upwards.

S

C+

S

C+

Page 13

Electrical connections

On positioners with an integral I/P unit,

the electric cables are connected to the

terminals as shown in the figure.

Terminals in

positioner EP3

+

–

13

Output signal

from controller

+

–

Warning! In a hazardous

Hazardous areas

environment where there is a

risk of explosion, electrical

connections must comply

with the relevant regulations.

copies of certificates for hazardous

approvals.

Model code

A= Model no

PP3XX Linear positioner, Pneumatic

EP3XX Linear positioner, Electropneumatic

EP3IS Linear positioner, Electropneumatic, Intrin.Safe ATEX, IEC

EP3EX Linear positioner, Electropneumatic, Explosion proof ATEX, IEC, FM

B= Function

S Single acting

C= Connections Air - Electrical

M 1/4" NPT - M20x1,5

N 1/4" NPT - 1/2" NPT

D= Surface treatment

U Powder epoxy, black

E= Spindle

05Male dia. 10 mm

39Male D type incl nut

F= Cover

PV PMV cover, black, no indicator

G= Input signal

3 3-15 psi

4 4-20 mA

H= Temperature

Z -40 to + 85 deg C

I= Option

X No gauge block

M Gauge manifold 1/8" G

N Gauge manifold 1/8" NPT

P3 - U- PV- Z

Please see www.pmv.nu/products/ for

PP3 EP3

Signs

Logotype

II 2G Ex ia IIC T6/T5/T4

NEMKO 08ATEX1144X

Intrinsically safe when installed

according to document: IP-653

Type: E5-IS

Input Signal:

Input Pressure:

Output Pressure:

Temp. Range:

Action:

Flowserve Sweden, Palmstierna International Solna Sweden

www.flowserve.com

36

Type

0470

25

Prod. year:xxxx

Page 14

14

Control drawing

Page 15

7. Adjustments

Gain

Default settings

The positioner is supplied from the

factory with default settings.

If the settings have been changed, the

default settings can be reset as follows:

• Apply an input signal equivalent to maximum stroke (100%).

• Screw in (clockwise) the setting screw A

for gain to its bottom position.

• Unscrew (counter clockwise) the same

screw until the actuator is at max. stroke and

then a further 1/4 of a turn.

• Press on the flapper nozzle lightly (see

arrow) to ensure that it is sealing properly.

• Adjust the input signal to approx. 50%. If

resonance occurs, turn the setting screw A

counter clockwise a little more. The

adjusting screw for damping B can also be

screwed in a little if necessary. However,

this will slow down the actuator movements.

15

B

➞

A

D

Setting the zero position and span

If the zero position and span have been

changed, adjust them as follows:

• Apply an input signal equivalent to the zero

position.

• Turn the setting screw C for zero position

until the actuator is at its zero position.

• Apply the maximum input signal.

• Turn the adjusting screw D for range until

the actuator moves to max. stroke

• Adjust the input signal again to minimum

and check the zero position.

C

Page 16

16

8. Maintenance/service

When service or rebuilding is required,

it may be necessary to remove and refit

various parts of the positioner. This is

described on the following pages.

Valve block

The valve block is mounted on the base

with three screws. It is sealed against the air

ducts in the base with O-rings.

Remove the valve block as follows:

• Remove the spring from its attachment hole

A in the balance arm.

• Unscrew the screws holding the block assy.

Cleanliness is essential when working

with the positioner. Contamination in

the air ducts will lead to operational

disturbances. Do not disassemble the

unit further than that described here.

Do not take the valve block apart

because its function will be impaired.

Do not remove any screws other than

those described here.

A

• Lift the lower edge of the valve block and

pull it away from the base in the direction of

the arrow in the figure.

• Check all the O-rings on the rear side of

the valve block and replace if necessary.

• Refit in the reverse order.

Page 17

Flapper nozzle

The flapper valve holder can be mounted

in two different ways, depending on the

required function. This is described on page

11. Change the function or replace the Orings as follows:

• Unscrew the screws C and D and remove

the holder E. Check both the O-rings and

replace them if necessary.

• Replace the holder in the desired position

and tighten the screws.

17

C

E

D

Gain screw

The sleeve F can be unscrewed to replace

the O-ring G. Let the adjusting screw remain

in the sleeve.

Integral I/P converter

The I/P converter can be removed if it is

necessary to replace it, to replace the O-rings,

or to rebuild the positioner.

• First unscrew the two screws H that hold

the terminal block. Release part of the rubber

seal so that the cables to the terminal block

can be pulled free from the grommet and the

terminal block can be pulled through.

• Remove the I/P unit with its cable and terminal block.

• Replace the O-rings if necessary and refit

the I/P unit or the rebuilding parts.

F

G

H

Page 18

18

Feedback arm / Spindle

The feedback arm is mounted on the

spindle with a friction clutch comprising

several disc springs. Remove the feedback

arm/spindle as follows:

• Remove the circlip J, the washer K behind

it, and the O-ring L.

• Release the spring from its upper

attachment M.

• Pull out the spindle with the feedback arm.

Remove the feedback arm as follows:

• Clamp the spindle in such a way that its

surfaces cannot be damaged.

• Undo the bolt N and remove the feedback

arm and the seven disc springs O.

• Refit in the reverse order. The disc springs

O must be fitted in the way shown in the

figure below. Lubricate the O-ring L with

silicone grease.

J, K, L

M

• Check whether there is any play on the

spindle. If so, replace the teflon bushes P.

J K L O

PN

Page 19

9. Trouble shooting

19

Fault symptom

Change in input signal to positioner does

not affect actuator position.

Change in input signal to positioner makes actuator move to its end position.

Inaccurate positioning.

Action

• Check air supply pressure and connection

between positioner and actuator.

• Check input signal to positioner.

• Check output signal from I/P converter.

• Check mounting and connections of positioner and actuator.

• Check function of diaphragm block.

• Check input signal.

• Check mounting and connections of positioner and actuator.

• Uneven air supply pressure.

•Uneven input signal.

• Wrong size of actuator being used.

• High friction in actuator/valve package.

• Excess play in actuator/valve package.

• Excess play in mounting of positioner

on actuator.

• Defect or leaking diaphragm block.

Page 20

20

10. Technical data

Common data

Repeatability <0,3%

Air delivery Supply at 600 kPa 125 nl/min

Air delivery Exhaust at 600 kPa 125 nl/min

Air supply pressure range 140-600kPa

Gain % / % acc. to ISA S75 5 to 30 %/%

Temperature range -40°C to +85°C

Temperature sensitivity < 0.4% per 10°C

Stroke length 6 - 60 mm, option 3 mm

Other data

P3

Linearity <±1%

Hysteresis + Deadband <0.5%

Deadband <0.15%

Air consumption (depending on gain setting) 2-8 nl/min

Supply pressure sensitivity <0.20%

Input signal 0.2 - 1 bar (3 - 15 psi)

EP3

Linearity <±1.5%

Hysteresis + Deadband <1%

Deadband <0.2%

Air consumption (depending on gain setting) 4-10 nl/min

Supply pressure sensitivity <0.3%

Input signal 4 - 20 mA

EP3EX

Linearity <±1.5%

Hysteresis + Deadband <1%

Deadband <0.2%

Air consumption (depending on gain setting) 4-10 nl/min

Supply pressure sensitivity <0.3%

Input signal 4 - 20 mA

Page 21

21

Page 22

22

11. Spare Parts List

1

4 3 2

Page 23

Pos. Part no. Description

1 E5-STD I/P Converter general purpose

1 E5-IS I/P Converter intrinsically safe

2 E3-EX I/P Converter explosion proof, incl bracket

3 P3-SP15 Air relay module, single acting

4 7-SP25B Cover incl screws

23

Page 24

Palmstierna International AB

Korta Gatan 9

SE-171 54 Solna

SWEDEN

Tel: +46 (0) 8 555 106 00

Fax: +46 (0) 8 555 106 01

E-mail: infopmv@flowserve.com

www.pmv.nu

Germany

Flowserve

Sperberweg 16

D-41468 Neuss

GERMANY

Tel: +49 (0) 2131 795 74 80

Fax: +49 (0) 2131 795 74 99

E-mail: pmvgermany@flowserve.com

UK

Flowserve

Abex Road

Newbury, Berkshire, RG14 5EY

UK

Tel: +44 (0) 1635 46 999

Fax: +44 (0) 1635 36 034

E-mail: pmvukinfo@flowserve.com

Scandinavia

Palmstiernas Svenska AB

Box 21

663 21 Skoghall

Sweden

Tel: +46 (0)54 52 14 70

Fax: +46 (0)54 52 14 42

e-mail: info@palmstiernas.se

Italy

Flowserve Spa

Via Prealpi, 30

20032 Cormano (Milano)

ITALY

Tel: +39 (0) 2 663 251

Fax: +39 (0) 2 615 18 63

E-mail: infoitaly@flowserve.com

USA, Mexico

PMV-USA

1440 Lake Front Circle, Unit 160

The Woodlands, TX 77380

USA

Tel: +1 281 292 7500

Fax: +1 281 292 7760

E-mail: pmvusa@flowserve.com

Canada

Cancoppas Limited

2595 Dunwin Drive, Unit 2

Mississuga, Ont L5L 3N9

CANADA

Tel: +1 905 569 6246

Fax: +1 905 569 6244

E-mail: controls@cancoppas.com

Asia Pacific Headquarters

Flowserve Pte Ltd.

No. 12 Tuas Avenue 20

REPUBLIC OF SINGAPORE 638824

Tel: +65 (0) 687 98900

Fax: +65 (0) 686 24940

E-mail: fcdasiaprocess@flowserve.com

South Africa

Flowserve

Unit 1, 12 Director Road

Spartan Ext. 2

1613 Kempton Park, Gauteng

SOUTH AFRICA

Tel: +27 (0) 11 397 3150

Fax: +27 (0) 11 397 5300

The Netherlands

Flowserve Flow Control Benelux

B.V

Postbus 1501

4700 Roosendaal

THE NETHERLANDS

Tel: + 31 (0)165 598898

Fax: + 31 (0)165 555670

China

Flowserve

Hanwei Building

No. 7 Guanghua Road

Chao Yang District

100004 Beijing

CHINA

Tel: +86 (10) 6561 1900

Fax: +86 (10) 6561 1899

FCD PMENIM0012-02

Loading...

Loading...