Page 1

PMV D20

Digital Positioner

Installation

Operation

Maintenance

Page 2

2

Contents

1. General information ....................................................................... 3

1.1 Using ............................................................................................ 3

1.2 Terms concerning safety .............................................................. 3

1.3 Protective clothing ........................................................................ 4

1.4 Qualified personnel ...................................................................... 4

1.5 Installation .................................................................................... 4

1.6 Spare parts................................................................................... 4

1.7 Service/repair ............................................................................... 4

1.8 Storage......................................................................................... 5

1.9 Valve and actuator variations ....................................................... 5

2. Unpacking ....................................................................................... 5

3. PMV D20 Overview ......................................................................... 6

4. Specifications ................................................................................. 7

4.1 Technical data .............................................................................. 7

4.2 Mechanical switches .................................................................... 8

4.3 Type sign ...................................................................................... 9

4.4 D20 Model Code ........................................................................ 10

4.5 Control Drawing .......................................................................... 11

4.6 Certificates ................................................................................. 12

5. Principle of operation .................................................................. 16

6. Mounting and installation............................................................ 17

6.1 General ...................................................................................... 17

6.2 Mounting on a linear pneumatic actuator ................................... 17

6.3 Rotary actuators ......................................................................... 19

7. Tubing positioner to actuator ..................................................... 22

8. Wiring and grounding guidelines ............................................... 23

8.1 Grounding screw ........................................................................ 23

8.2 Electromagnetic compability ...................................................... 24

8.3 Compliance voltage.................................................................... 24

9. Operation ...................................................................................... 25

9.1 Operation ................................................................................... 25

9.2 Start up....................................................................................... 25

9.3 Calibration .................................................................................. 25

9.4 Set of Direct or Reverse action .................................................. 26

9.5 Show gain setting ....................................................................... 26

9.6 Change gain setting ................................................................... 27

10. Limit switches & 4 - 20 mA transmitter (Optional) .................. 28

10.1 General .................................................................................... 28

10.2 Model selection ........................................................................ 28

10.3 Principle of operation ............................................................... 28

10.4 Installation ................................................................................ 28

10.5 Calibration of 4 - 20 mA input signal and/or 4 - 20 mA

feedback transmitter................................................................. 29

11. Trouble shooting ........................................................................ 30

11.1 PMV D20 normal operation ...................................................... 30

11.2 PMV D20 error codes ............................................................... 30

11.3 PMV D20 symptoms and solutions .......................................... 31

12. Spare parts ................................................................................. 32

Page 3

1. General information

1.1 Using

The following instructions are designed

to assist in unpacking, installing and

performing maintenance as required on

FLOWSERVE products. Product users

and maintenance personnel should

thoroughly review this bulletin prior to

installing, operating or performing any

maintenance.

1.2 Terms concerning safety

The safety terms DANGER,

WARNING, CAUTION and NOTE

are used in these instructions to

highlight particular dangers and/

or to provide additional information on aspects that may not be

readily apparent.

DANGER: indicates that death,

severe personal injury and/or

substantial property damage will

occur if proper precautions are not

taken.

WARNING:

severe personal injury and/or

substantial property damage can

occur if proper precautions are not

taken.

indicates that death,

3

In most cases FLOWSERVE valves,

actuators and accessories are designed

for specific applications (e.g. with regard

to medium, pressure, temperature). For

this reason they should not be used in

other applications without first contacting

the manufacturer.

NOTE:

indicates and provides

additional technical information,

which may not be very obvious

even to qualified personnel.

Compliance with other, not particularly

emphasised notes, with regard to transport, assembly, operationand

maintenance and with regard to technical

documentation (e.g. in the operating

instruction, product documentation or on

the product itself) is essential, in order

to avoid faults, which in themselves might

directly or indirectly cause severe personal injury or property damage.

CAUTION:

indicates that minor

personal injury and/or property

damage can occur if proper

precautions are not taken.

Page 4

4

1.3 Protective clothing

FLOWSERVE products are often used

in problematic applications (e.g.

extremely high pressures, dangerous,

toxic or corrosive mediums). In particular

valves with bellows seals point to such

applications. When performing service,

inspection or repair operations always

ensure, that the valve and actuator are

depressurised and that the valve has

been cleaned and is free from harmful

substances. In such cases pay particular

attention to personal protection

(protective clothing, gloves, glasses etc.).

1.4 Qualified personnel

Qualified personnel are people who, on

account of their training, experience and

instruction and their knowledge of relevant standards, specifications, accident

prevention regulations and operating

conditions, have been authorised by

those responsible for the safety of the

plant to perform the necessary work and

who can recognise and avoid possible

dangers.

1.5 Installation

DANGER: Before installation

check the order-no, serial-no. and/

or the tag-no. to ensure that the

valve/actuator is correct for the

intended application.

Do not insulate extensions that are

provided for hot or cold services.

Pipelines must be correctly

aligned to ensure that the valve is

not fitted under tension.

Fire protection must be provided

by the user.

1.6 Spare parts

Use only FLOWSERVE original spare

parts. FLOWSERVE cannot accept

responsibility for any damages that occur

from using spare parts or fastening

materials from other manufactures. If

FLOWSERVE products (especially

sealing materials) have been on store for

longer periods check these for corrosion

or deterioration before using these

products. Fire protection for

FLOWSERVE products must be

provided by the end user.

1.7 Service / repair

To avoid possible injury to personnel or

damage to products, safety terms must

be strictly adhered to. Modifying this

product, substituting nonfactory parts, or

using maintenance procedures other

than outlined in this instruction could

drastically affect performance and be

hazardous to personnel and equipment,

and may void existing warranties.

Between actuator and valve there are

moving parts. To avoid injury

FLOWSERVE provides pinch-pointprotection in the form of cover plates,

especially where side-mounted positioners are fitted. If these plates are removed for inspection, service or repair special attention is required. After completing

work the cover plates must be refitted.

Apart from the operating instructions and

the obligatory accident prevention

directives valid in the country of use, all

recognised regulations for safety and

good engineering practices must be

followed.

Page 5

5

WARNING:

Before products are returned to

FLOWSERVE for repair or service

FLOWSERVE must be provided

with a certificate which confirms

that the product has been

decontaminated and is clean.

FLOWSERVE will not accept

deliveries if a certificate has not

been provided (a form can be

obtained from FLOWSERVE).

1.8 Storage

In most cases FLOWSERVE products

are manufactured from stainless steel.

Products not manufactured from

stainless steel are provided with an

epoxy resin coating. This means that

FLOWSERVE products are well

protected from corrosion. Nevertheless

FLOWSERVE products must be stored

adequately in a clean, dry environment.

Plastic caps are fitted to protect the

flange faces to prevent the ingress of foreign materials. These caps should not

be removed until the valve is actually

mounted into the system.

1.9 Valve and actuator

variations

These instructions cannot claim to cover

all details of all possible product

variations, nor in particular can they provide information for every possible

example of installation, operation or

maintenance. This means that the

instructions normally include only the

directions to be followed by qualified personal where the product is being used

for is defined purpose. If there are any

uncertainties in this respect particularly

in the event of missing product-related

information, clarification must be obtained

via the appropriate FLOWSERVE sales

office.

2. Unpacking

Each delivery includes a packing slip.

When unpacking, check all delivered

valves and accessories using this

packing slip.

Report transport damage to the carrier

immediately.

In case of discrepancies, contact your

nearest FLOWSERVE location.

Page 6

6

3.

PMV D20 overview

The PMV D20 is a two-wire loop

powered, 4-20 mA input digital valve

positioner.

The PMV D20 positioner controls

actuators with linear and rotary

mountings.

The PMV D20 is completely powered by

the 4-20 mA input signal. The minimum

input signal required to function is 3,6

mA. As an option the D20 can be

equipped with HART protocol to allow

bidirectional communication.

Since the positioner is insensitive to

supply pressure changes and can

handle supply pressures from 1,5 to 6

barg (22 to 105 psig), a supply regulator

is usually not required; however, in

applications where the supply pressure

is higher than the maximum actuator

pressure rating a supply regulator is

required to lower the pressure to the

actuator’s maximum rating (not to be

confused with operating range). A

coalescing air filter is recommended for

all applications due to the close

tolerances in the positioner.

PMV D20 positioner accessories:

Optional analog feedback system as well

as limit switch unit and a directly

attachable double acting module.

NOTE:

ISA 7.0.01 orIEC 770 (a dew point at

least 10°C/18°F below ambient temperature, particle size below five microns –

one micron recommended – and oil content not to exceed one part per million).

The air supply must conform to

Page 7

7

4. Specifications

4.1 Technical data

Input signal 4-20 mA

Current supply min. 3,6 mA

Current supply Max. 150 mA

Load Standard 400 ohm at 20mA

Load HART 470 ohm at 20mA

Voltage dropStandard 8 VDC at 20mA

Voltage dropHART 9.4 VDC at 20mA

Angle of rotation min 0-40°

Angle of rotation Max 0-90°

Air supply range 1.5 – 6 bar

Out put 0-100% of air supply pressure

Air supply quality Free from oil, dust and moisture IEC 770,

ISA 7.0.01

Air supply effect <0.1%FS for10% pressure change at 6 Bar

Ingress protection IP66 / Nema 4X

Operating humidity 0-100% rh non-condensing

Air connections 1/4” NPT

Cable entry 2 x 1/2” or 2 x M20x 1,5

Te rminals Screw terminals 2,5 mm2 (AWG 14)

Operating Temperature -20 to +85°C-40 to +85°C (optional)

Storage temperature -40 to +85°C

Air delivery capacity 7 Nm3/h @ 6 bar (3 bar diff pressure)

Air delivery capacity Double acting 7 Nm3/h @ 6 bar (3 bar diff pressure)

Air consumption Single acting 0,120 Nm3/h @ 6 bar

Air consumption Double acting 0,120 Nm3/h @ 6 bar

Cv air delivery Single acting 0,12

Cv air delivery Double acting 0,12

Cut off function Close 0.5% Open 99.5%

Linearity <1%

Sensitivity <0.05%

Resolution <0,1%

Repeatability <0.2%

Hysteresis + dead band <0.5%

Temp effect <0.1%/10K

Mounting position effect <0,2%

CE 93/68/EEC, 2004/108/EEC, 2006/95/EEC

Approvals Ex II G Ex ia IIC T4 Ta: 85°C

Certificate nr Nemko 08ATEX1362X

Housing material Die cast Aluminium

Surface treatment Powder coating

Soft goods Nitrile

Weight 1,5 kg

Page 8

8

4.2 Mechanical switches

Type SPDT

Size Sub Sub miniature

Rating 3A, 125 VAC / 2A, 30VDC

Mechanical life >1 x 106 operations

Namur sensors

Type P+F NJ2 V3 N Inductive DIN 19234

Load current <1mA>3mA

Voltage range 5-25 VDC

Hysteresis 3-15% (5% typical)

Temp range -25° to +100° C (-248° to 373° F)

Namur sensors

Type P+F SJ2-N

Normal Voltage 8 VDC

Load current 1mA<I<3mA

Voltage range (5-25 VDC)

Hysteresis (max) 0.2%

Temp range -25° to +100° C (-248° to 373° F)

Namur sensors

Type P+F SJ2-SN

Normal Voltage 8 VDC

Load current 1mA<I<3mA

Voltage range 5-25 VDC

Hysteresis (max) (0.2%)

Temp range -40° to +100° C (-233° to 373° F)

Namur sensors

Type P+F SJ2-S1N

Normal Voltage 8 VDC

Load current 1mA<I<3mA

Voltage range 5-25 VDC

Hysteresis (max) 0.2%

Temp range -25° to +100° C (-248° to 373° F)

Proximity switches

Type SPDT

Rating 10W

Voltage max 200VDC

Current max 500mA

Contact resistance max 0.2 ohm

Page 9

Operating time 1.0 ms

Transmitter

Power supply 12-28 VDC

Output 1-22 mA

Resolution 0.1%

Linearity ±0.5%

Load impedance 600 ohm at (12 VDC and 20mA)

Alarm Output

Supply 3-28 VDC

Output 20mA @ 24 VDC

4.3 Type sign

9

Page 10

10

4.4 D20 Model Code

A = Model no

D20 Digital compact positioner, General purpose, LED status

B = Approval, Certificate

D General purpose version

I Intrinsically safe version ATEX

C = Connections Air, Electrical

M 1/4" NPT air, M20 x 1,5 electrical x 2

N 1/4" NPT air, 1/2" NPT electrical x 2

D = Housing/Surface treatment

U Aluminium/Powder epoxy, black

E = Function

S Single acting

D Double acting, incl gauges (2) Stainless/Brass

F = Mounting options / Spindle

09 Double D type, adaptor spindle

12 Flowtop, D-style+ nut, direct mounting, Kit 30144 include

23 VDI/VDE 3845 rotary, Mounting kit not included

39 IEC 534-6, Flat D type, nut incl. Mounting kit not included

40 VDI/VDE 3847 Linear, Flat D, Mounting kit 30145 included

G = Cover and Indicator

PVA PMV,Black cover, Arrow indicator

PVB PMV, Black cover, No indicator

PVD PMV, Black cover, Dome indicator

H = Temperature/seals

Z Standard -20°C to 85°C (-4°F to 185°F)

Q Low temp -40°C to 85°C (-38°F to 185°F)

I = Input signal/Protocol

4 4-20 mA / none

5 4-20 mA, / HART

J = Feedback option, 4-20 mA transmitter, switches

X No feedback option

T 4-20 mA transmitter only

S Limit switches Mechanical SPDT + 4-20mA

N Namur V3 type sensor, P+F NJ2-V3-N + 4-20mA

P Limit switches Proximity SPDT + 4-20mA

4 Slot type Namur sensor, P+F SJ2-S1N + 4-20mA

5 Slot type Namur sensor, P+F SJ2-SN + 4-20mA

6 Slot type Namur sensor, P+F SJ2-N + 4-20mA

K = Options, Add in electronics

0 Standard diagnostics

L = Accessories

X No accessories

M Gauge block 1/8" G (2 x gauges included)

N Gauge block 1/8" NPT (2 x gauges included)

Example:

A A A B C D - E F F G G G - H I J K L

Page 11

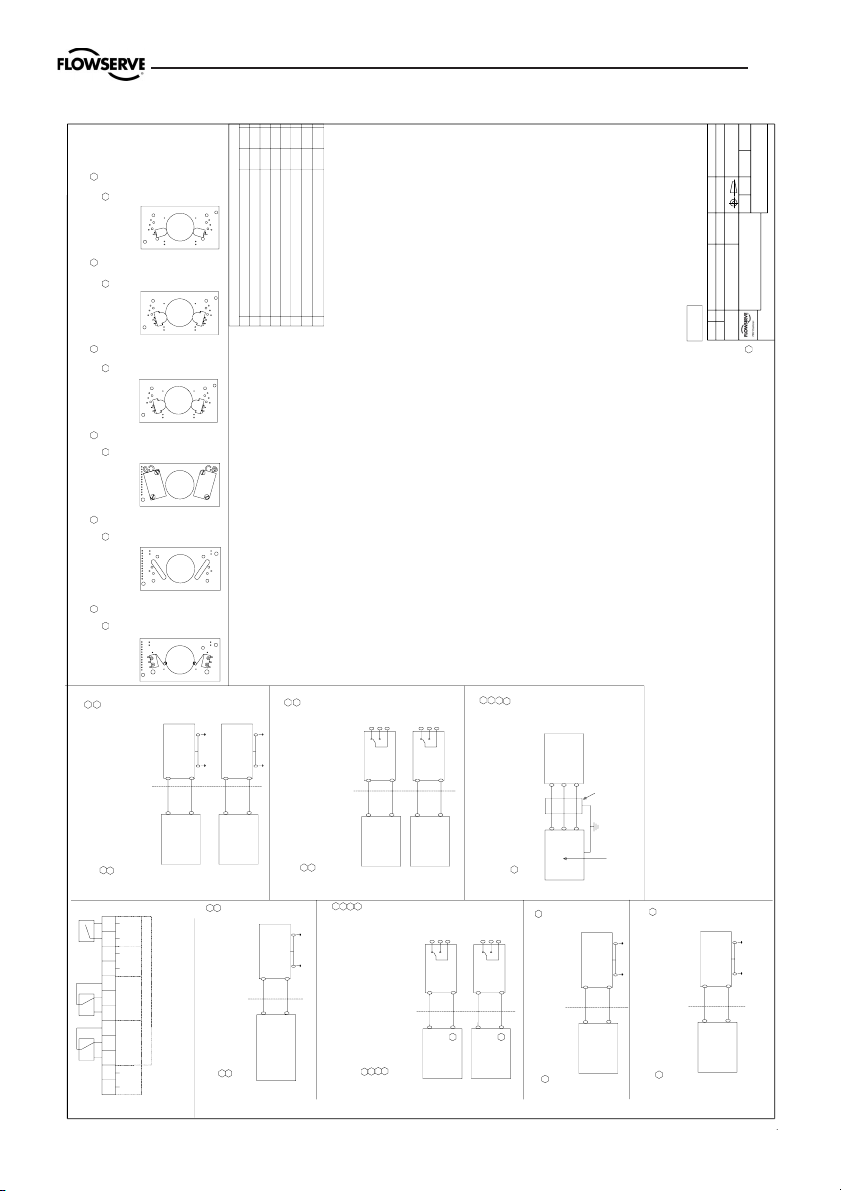

4.5 Control Drawing

UNCLASSIFIED AREA

Isolator

Isolator

4+

Postitioner

Ii : 29,7mA

Pi : 79mW

Ci : 40 nF

Ui : 10,6V

HAZARDEOUS AREA

7+

6-

Positioner

Ui : 10,6V

Pi : 79mW

Ci : 40 nF

Li : 100 µH

Ii : 29,7mA

HAZARDEOUS AREA

3-

Li : 100 µH

Pin 3;4 : Switch 1

Pin 6;7 : Switch 2

UNCLASSIFIED AREA

Pi : 653mW

D2xIxx-xxxxxx-xxTxx

Positioner

Model no: D3Ixx-xxxxxx-

xxTx/Logix 8xx-02-xxxxxx-xxx

-xxT

Pin 9;10

4-20 mA Output

UNCLASSIFIED AREAHAZARDEOUS AREA

Safety Barrier

/PA/PA

10-

Ii : 93mA

Ui : 28V

Li : 11,3 µH

Ci : 16,4 nF

9+

Ci : 5,64 nF

D2xIxx-xxxxx-xxTxx

Positioner

Model no: D3Ixx-xxxxxx-

xxTx/Logix 8xx-02-xxxxxx-xxx

-xxT

Alarm

Pin 11;12

/PA/PA

11+

12-

UNCLASSIFIED AREA

Safety Barrier

Ui : 28V

Pi : 315mW

Ii : 45mA

Li : 11,3 µH

HAZARDEOUS AREA

Pi : 315mW

Positioner

Positioner

Normally Closed

Pin 7;8 : Switch 2

Pin 4;5 : Switch 1

Safety Barrier

3 or 4

5

Pin 3;5 : Switch 1

Pin 6;8 : Switch 2

Normally Open

UNCLASSIFIED AREA

Ui : 28V

Ci : 1 nF

Ii : 45mA

HAZARDEOUS AREA

Pi : 315mW

/PA/PA

/PA/PA

Safety Barrier

6 or 7

8

UNCLASSIFIED AREA

Ui : 28V

Ci : 1 nF

Ii : 45mA

Li : 1 µH

HAZARDEOUS AREA

Li : 1 µH

UNCLASSIFIED AREA

Positioner

Positioner

Pin 7;8 : Switch 2

Pin 4;5 : Switch 1

Normally Closed

Pin 6;8 : Switch 2

Pin 3;5 : Switch 1

Normally Open

Isolator

Isolator

3 or 4

Ui : 10,6V

HAZARDEOUS AREA

5

8

6 or 7

Pi : 79mW

Ci : 1 nF

Li : 1 µH

Ui : 10,6V

Ii : 29,7mA

Ci : 1 nF

Li : 1 µH

Pi : 79mW

HAZARDEOUS AREA

Ii : 29,7mA

UNCLASSIFIED AREA

4

Remote unit output parameter

Po : 0,38W

Positioner

Shielded cable less than 10 metres

HAZARDEOUS AREA

It is only allowed to conne

ct the Pot. unit to the

positioners connectors 3, 4 and 5. The

connection requires a shielded cable less than 10

metres or less than 30 feet.

Pot.

Pin 3;4;5

4

3

55

3

D3Ixx-xxxxxx-xx6x

D2xIxx-xxxxxx-xx6xxD2xIxx-xxxxxx-xx5xxD2xIxx-xxxxxx-xx4xxD2xIxx-xxxxxx-xxNxxD2xIxx-xxxxxx-xxPxxD2xIxx-xxxxxx-xxSxx

Remove cover and innercover(see manual), visually verify Transmitter Board option.

4-20 mA Output

Mechanical Sw.

Transmitter Board Options

3-As81M 3-As81N3-As81P

All components need Saftey Barriers * except the Switches on transmitter board 3-As81N, 3-As81D4,

Explosion Hazard - Do not disconnect equipment unless area is known to be non-hazardous.

Substitution of the following components may impair suitability for Division 2 :

or; read, understand and adhere to the manufacturer's live maintenance procedures.

To prevent ignition of flammable or combustible atmospheres, disconnect power before servicing,

*Only CSA and FM

Substitution of components may impair Intrinsic Safety.

Warnings:

Non-Incendive:

Further requirements for FM:

- Associated apparatus manufacturer's installation drawing must be followed when installing this equipment.

- The Entity Concept allo

ws interconnections of int

rinsically safe apparatus with associated apparatus when the following is true:

Vmax or Ui larger than Voc, Vt or Uo;

Imax or Ii larger than Isc, It or Io

Pmax or Pi larger than Po

Ca larger than Ci + Ccable

La larger than Li + Lcable

- Dust-Tight conduit seal must be when installed in Class II and Class III environments.

- Control equipment connected to Associated Apparatus must not use or generate more than 250 Vrms or Vdc.

- Resistance between Intrinsically Safe Ground must be less than 1,0 Ohm.

- Installation should be in accordance with ANSI/ISA-RP12.06.01 "Installation of Intrinsically Safe Systems for Hazardous (Classified) Locations" and the National

Electric Code (ANSI/NFPA 70).

- The associated apparatus must be FM approved.

- The associated apparatus must be a resistively limited by a single or mult

iple channel FM Approved A

ssociated apparatus having parameters less than those quoted,

and for which the output and the combinations of output is non-ignition capable

for the Class, Divisio

n and Group of use.

Model no:

Logix 8xx-02-xxxxxx-xx1-xxx

4-20 mA Output

Namur Sw.

Proximity Sw.

4-20 mA Output

3-As81D4 3-As81D5 3-As81D6

Slotted Namur Sw.

4-20 mA Output

Slotted Namur Sw.

4-20 mA Output

Slotted Namur Sw.

4-20 mA Output

D3Ixx-xxxxxx-xxSx

Model no:

Logix 8xx-02-xxxxxx-xx2-xxx

D3Ixx-xxxxxx-xxPx

Model no:

Logix 8xx-02-xxxxxx-xx3-xxx

D3Ixx-xxxxxx-xxNx

Model no:

Logix 8xx-02-xxxxxx-xx4-xxx

D3Ixx-xxxxxx-xx4x

Model no:

Logix 8xx-02-xxxxxx-xx5-xxx

D3Ixx-xxxxxx-xx5x

Model no:

Logix 8xx-02-xxxxxx-xx6-xxx

3-As81D5, 3-As81D6, 3-As81P, D3-As38E N, D3-As38E D4, D3-As38E D5, D3-As38E D6 and D3-As38E P.

Pin 2: Irtn

Positioner

/PA

Safety Barrier

/PA

Pin 1;2

1+

2-

HAZARDEOUS AREA

Ui : 28V

Ii : 93mA

Pi : 653mW

Ci : 11,3 nF

Li : 11,3 µH

Pin 1: Isrc

UNCLASSIFIED AREA

REVISIONS

REV. DESCRIPTION DATE MOD. BY

1

"Old" Transmitter board a

ssemblies (D3-AS38E) omitt

ed.

Single acting remote added.

2006-11-14 KBM

2 11.3 was 5 (3x); 11.3 was 4; 16.4 was 4; 11.3 was 5; 5.64 was 5.7

Remote output parameter added.

2007-01-12 KBM

3Model code of Logix 500si added. 2007-11-13 KBM

4Redesigned 2008-03-04 JEE

50 change to x in

"Model no" to allow pressure sens

or option in code. 2008-04-24 MER

6

NAMUR switches, Li: 50

µH changed to

Li: 100

µH; Ci: 35 nF changed to Ci: 40 nF.

2008-04-29 MER

7

Document name changed to D3/D20. Model code for D20 upgraded.

Modelcode for Logix 5XXsi deleted.

2008-11-06 MRn

8. Switch 2 COM

1. Input signal

12. Alarm Output -

11. Alarm Output +

10. 4-20 mA -

9. 4-20 mA +

7. Switch 2 NC

6. Switch 2 NO

5. Switch 1 COM

4. Switch 1 NC

3. Switch 1 NO

2. Input signal

4-20mA input signal

Mechanical or Proximity switches

NAMUR switches

D3Ixx-xxxxxx-xx4x/Logi

x 8xx-02-xxxxxx-xxx-xx4

Model no: D3Ixx-xxxxxx-x4xx/Logix 81x-02-xxxxxx-xxx-xxx

Model no: D3Ixx-xxxxxx-

xxNx/Logix 8xx-02-xxxxxx-xxx

-xx3

1234 5 6789101112

- --

1

2

4-20mA

ALARM

OUTOUT

INPUT

OPTION

NO NC COM NCNO COM

SW1 SW2

(REMOTE)

SIGNAL

D3Ixx-xxxxxx-x5xx/Logi

x 82x-02-xxxxxx-xxx-xxx

D3Ixx-xxxxxx-xx5x/Logi

x 8xx-02-xxxxxx-xxx-xx5

D3Ixx-xxxxxx-xx6x/Logi

x 8xx-02-xxxxxx-xxx-xx6

Model no: D3Ixx-xxxxxx-

xxSx/Logix 8xx-02-xxxxxx-xxx

-xx1

D3Ixx-xxxxxx-xxPx/Logi

x 8xx-02-xxxxxx-xxx-xx2

Model no: D3Ixx-Mxxxxx-xxxx/Logix 8xx-02-xxxxxx-xMx-xxx

D3Ixx-Pxxxxx-xxxx/Logix

8xx-02-xxxxxx-xPx-xxx

to the Notified body

D3Ixx-Rxxxxx-xxxx/Logix

8xx-02-xxxxxx-xRx-xxx

D3Ixx-Qxxxxx-xxxx/Logix

8xx-02-xxxxxx-xQx-xxx

D2xIxx-xxxxxx-x4xxx

D2xIxx-xxxxxx-xxNxx

D2xIxx-xxxxxx-xxSxx

D2xIxx-xxxxxx-x5xxx

D2xIxx-xxxxxx-xx4xx

D2xIxx-xxxxxx-xx6xx

D2xIxx-xxxxxx-xx5xx

D2xIxx-xxxxxx-xxPxx

D3Ixx-xxxxxx-xxPx/Logi

x 8xx-02-xxxxxx-xxx-xx2

D2xIxx-xxxxxx-xxPxx

D2xIxx-xxxxxx-xxSxx

Model no: D3Ixx-xxxxxx-

xxSx/Logix 8xx-02-xxxxxx-xxx

-xx1

Mechanical or Proximity switches

D2xIxR-xxxxxx-xxxxx

No modification permitted without reference

7

Tested according to withstand dielectric strength requirement IEC EN 60079-11 6.3.12

Ingress Protection IP 66, NEMA 4X

Schedule drawing

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

7

Remote unit

5

5

6

7

5

6

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

PALMSTIERNA INTERNATIONAL AB

PALMSTIERNA INTERNATIONAL ABPALMSTIERNA INTERNATIONAL AB

PALMSTIERNA INTERNATIONAL AB

DRAWING NO.

DRAWING NO.DRAWING NO.

DRAWING NO.

DRW BY

DRW BYDRW BY

DRW BY APPR. BY

APPR. BYAPPR. BY

APPR. BY SCALE

SCALESCALE

SCALE DATE

DATEDATE

DATE

ANNOTATION

ANNOTATIONANNOTATION

ANNOTATION

DIMENSION

DIMENSIONDIMENSION

DIMENSION

MATERIAL

MATERIALMATERIAL

MATERIAL

DESCRIPTION

DESCRIPTIONDESCRIPTION

DESCRIPTION

PCS

PCSPCS

PCS

PART NO.

PART NO.PART NO.

PART NO.

HOLE TOL.

HOLE TOL.HOLE TOL.

HOLE TOL. UNSPECIFIED TOLERANCES ACCORDING TO:

UNSPECIFIED TOLERANCES ACCORDING TO:UNSPECIFIED TOLERANCES ACCORDING TO:

UNSPECIFIED TOLERANCES ACCORDING TO:

SURFACE

SURFACESURFACE

SURFACE

PROJECTION EUROPA

PROJECTION EUROPAPROJECTION EUROPA

PROJECTION EUROPA

KORTA GATAN 9 SE-171 54

SOLNA SWEDEN - Tel:+46(0)8

555 106 00-Fax:+46(0)8 555 106 01 - www.pmv.nu

KORTA GATAN 9 SE-171 54

SOLNA SWEDEN - Tel:+46(0)8

555 106 00-Fax:+46(0)8 555 106 01 - www.pmv.nuKORTA GATAN 9 SE-171 54

SOLNA SWEDEN - Tel:+46(0)8

555 106 00-Fax:+46(0)8 555 106 01 - www.pmv.nu

KORTA GATAN 9 SE-171 54

SOLNA SWEDEN - Tel:+46(0)8

555 106 00-Fax:+46(0)8 555 106 01 - www.pmv.nu

Control Drawing

Control DrawingControl Drawing

Control Drawing

-

--

-

-

--

-

imparted to

a third party nor be used for any unaut

horized purpose. Contravention will be prosecuted

imparted to

a third party nor be used for any unaut

horized purpose. Contravention will be prosecuted

imparted to

a third party nor be used for any unaut

horized purpose. Contravention will be prosecuted

imparted to

a third party nor be used for any unaut

horized purpose. Contravention will be prosecuted

3-86

3-863-86

3-86

-

--

-

-

--

-

-

--

-

KBM

KBMKBM

KBM

D3/D20

D3/D20D3/D20

D3/D20

PMV Positioner

PMV PositionerPMV Positioner

PMV Positioner

-

--

----

-

This document must not be

copied without our writte

n permission and the contents there of must not be

This document must

not be copied without our writte

n permission and the contents there of must not be

This docume

nt must not be copied without our writte

n permission and the contents there of must not be

This document must not be

copied without our writte

n permission and the contents there of must not be

051208

051208051208

051208

11

Always see www.pmv.nu for latest revision.

Page 12

12

4.6 Certificates

Page 13

131415

Page 14

Page 15

Page 16

16

1 Digital Control

Inner Loop

Piezo Control

Inner Loop

Position feed-

Micro-

Processor

Gain

Local

User

Figure 1.

5. Principle of operation

The PMV D20 positioner is a digital positioner with various options. The positioner consists of three main modules:

1. The microprocessor-based electronic

control module includes direct local user

interface switches

2. The piezo valve-based electropneumatic converter module

3. The infinite resolution valve position

sensor.

The basic positioner operation is best

understood by referring to figure 1. The

complete control circuit is powered by the

two-wire, 4-20 mA command signal. The

analog 4-20 mA command is passed to

the microprocessor, where it is compared

to the measured valve stem position. The

control algorithm in the processor

performs control calculations and

produces an output command to the

piezo valve, which drives the pneumatic

Piezo Valve

Pneumatic

3 Valve

Control

Valve

Stroke

amplifier. The position of the pilot valve

in the pneumatic amplifier is measured

and relayed to the inner loop control

circuit. This two-stage control provides

for more responsive and tighter control

than is possible with a single stage

control algorithm. The pneumatic

amplifier controls the airflow to the

actuator. The change of pressure and

volume of the air in the actuator causes

the valve to stroke. As the valve

approaches the desired position, the

difference between the commanded position and the measured position

becomes smaller and the output to the

piezo is decreased. This, in turn, causes

the pilot valve to close and the resulting

flow to decrease, which slows the

actuator movement as it approaches, the

new commanded position. When the

valve actuator is at the desired position.

the pneumatic amplifier output is held at

zero, which holds the valve in a constant position.

Page 17

6. Mounting and installation

6.1 General

Before starting installation, inspect the digital positioner for any transit damages.

The PMV D20 positioner is installed with a

mounting kit (according to NAMUR

specification) to the left-hand actuator support rod.

Generally, the unit can be installed in any

mounting position. The stroke feed-back

is realized by a follower arm and stem

clamps.

The mounting of rod actuators (according

17

to NAMUR) is described in Figure 3.

For the two mounting possibilities of cast

yoke actuators (according to NAMUR, lEC

534 part 6) refer to Figure 5.

After installation, ensure all screw

connections are tightened correctly and

all moving parts are free from excessive

friction.

Tighten front cover screws to 0.65 Nm to

ensure IP rating.

Figure 2. Dimensional drawing

6.2 Mounting of the PMV D20

positioner on a linear

pneumatic actuator

(NAMUR / IEC 534 part 6)

(See Figure 3)

The mounting of a rod actuator kit

(according to IEC 534 part 6) is described

in an example by using the following

equipment:

Valve: Standard globe valve or

equivalent

Actuator: Single-acting pneumatic

actuator

Positioner: PMV D20 with NAMUR

mounting kit.

Pre-assembly: Valve with actuator (valve

stroke is matched with the actuator

stroke).

Page 18

18

For mounting, proceed as follows:

Mounting the Follower Arm (Figures 3

and 6)

1. Unscrew the lock nut for the follower

arm attachment.

2. Place the follower arm on the shaft at

the back of the positioner and fasten it with

the lock nut. The follower pin should point

back from the positioner.

CAUTION: Maximum torque

0,25 Nm (0,18 ft-lbs).

Mounting the stem clamp bracket and

take-off arm (Figure 3)

1. Attach the stem clamp bracket to the

stem clamp and fasten it with two hexagon socket screws and lock washers.

2. Attach the take off arm to the stem clamp

bracket and fasten it with a hexagon

socket capscrew and a washer. Ensure

the take-off arm slot is centered.

Mounting the positioner (Figure 3)

1. Adjust the actuator to mid-stroke.

2. Pre-assemble the mounting bracket on

the left actuator

leg hand-tight with two U-bolts, nuts and

lockwashers.

3. Attach the positioner to the preassembled mounting bracket and fasten

it with two hexagon head screws and two

lock washers. Check that the follower pin

is inserted in the slot of the take-off arm

and the follower arm is positioned at a right

angle to the outer edge of the positioner.

4. Tighten all screws and nuts.

NOTE: A slight unsymmetrical

mounting increases the linearity

deviation but does not affect the

performance of the device.

Depending on the actuator size

and stroke it may be necessary to

flip the take-off arm (Figure 3) by

180° and attach it to the opposite

side of the stem clamp bracket.

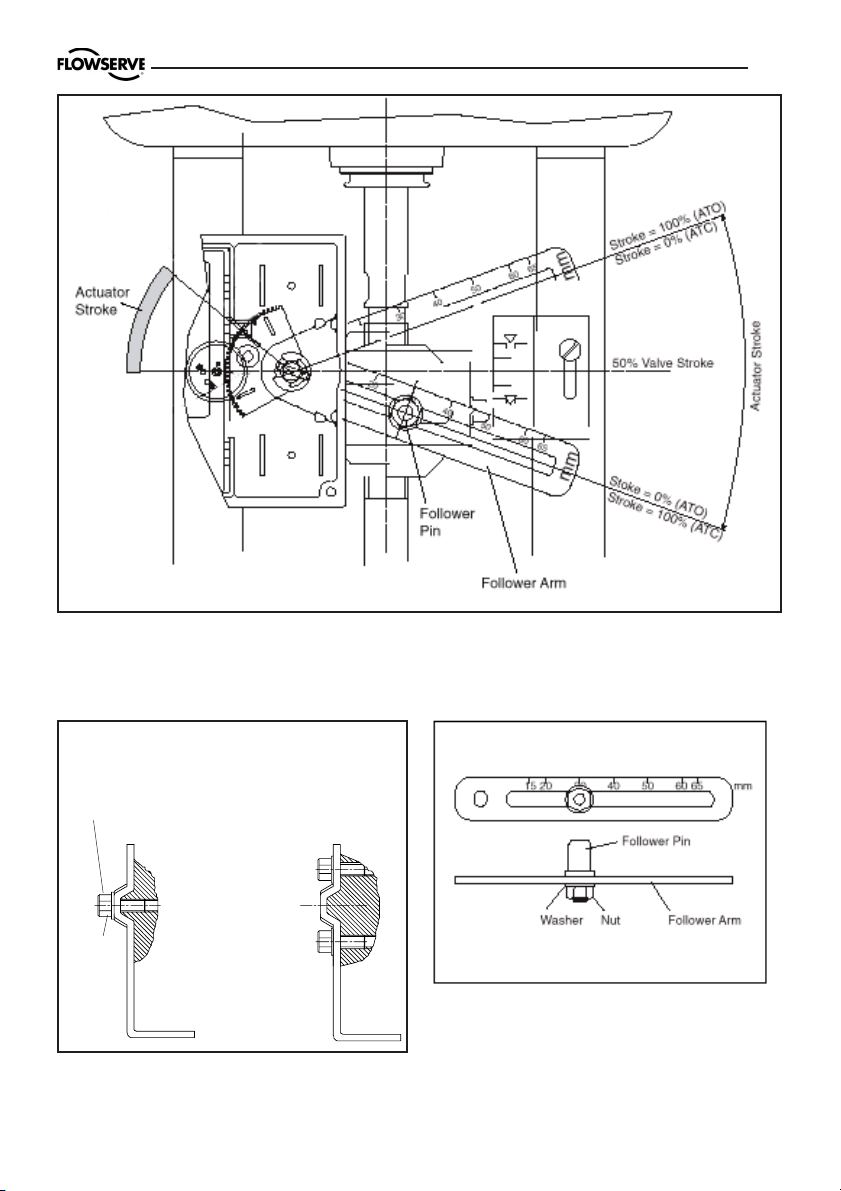

Follower pin adjustment (Figure 4)

The positioner follower pin must be

adjusted to match the valve stroke in the

following manner:

1. Adjust the follower pin (STROKE + 10

mm) as indicated on the follower arm’s

embossed scale (Figure 6).

2. Exhaust the actuator.

3. Loosen the follower pin and shift it along

the follower arm until the control marking

on the feedback gear (Figure 4) is horizontal (points to the center of the feedback potentiometer). Fasten the follower

pin in this position.

4. Adjust the actuator to full stroke and

check the follower pin adjustment the

same way as described in step 3. As the

actuator strokes, the rotation of the feedback gear should be between the inner

control markings. If the length of rotation

is outside the control markings, adjust the

Page 19

Figure 3. Mounting on a Rod Actuator (IEC 534 part 6)

19

follower pin farther out on the feedback

lever to reduce the angle of rotation.

NOTE: Stroke the actuator carefully and

ensure the follower arm does not

interfere with valve parts, actuator or

positioner. Do not adjust the follower pin

too near to the slot end of the take-off

arm.

The minimum lateral distance should be

approximately 5 mm (0,2 inches) to pre-

vent bending of the feed-back

mechanisim.

6.3 Rotary actuators

Mounting the PMV D20 positioner on

a quarter-turn actuator (closed or

open by spring)

The mounting of a pneumatic double-piston part-turn valve actuator (in

accordance with VDI/VDE 3845) is

described as an example by using the

following equipment:

Quarter-turn valve actuator: Rack &

pinion or scotch yoke, closed or open by

spring.

Page 20

20

Rotary actutaors VDI/VDE 3485

(Namur)

Mount bracket 1 to positioner. Secure

with 4 x M6 screws 2.

Fit positioner on actuator and secure

with 4 x screws 3.

Install tubing 4 between actuator and po-

sitioner.

See section 7.

Linear actuator “Flow act” (Direct

mounting, integrated tubing.

Check O-rings, Install bracket 1 to positioner and secure with screws.

Fit pin on valve stem.

Fit lever arm to positioner shaft.

Fit and check O-rings and positioner to

actuator and secure with 2 x screws 2.

No tubing needed, it’s integrated with

actuator, fit plug in positioner out port.

Linear actuator VDI/VDE 3847

(Direct mounting, integrated tubing.

4

1

3

2

1

2

Check O-rings, Install bracket

1 to positioner and secure with 2 x

screws 2.

Fit pin on valve stem.

Fit lever arm to positioner shaft.

Fit and check O-rings and positioner to

actuator and secure with 2 x screws 3.

No tubing needed, it’s integrated with

actuator.

1

2

3

Page 21

Figure 4. Basic Adjustment for a Linear Pneumatic Actuator

21

Mounting A Mounting B

Hexagon head screw

Lock

washer

Figure 5. Yoke Actuator Mounting

(according to IEC 534 part 6)

Figure 6. Follower Arm (standard)

Page 22

22

2 3

1

Mounting the positioner (Figure 7)

Place the positioner (1) onto the

mounting block (2) of the actuator using

four screws (3) Ensure the coupler fits

on to the shaft of the quarter-turn

connection on the part-turn valve

actuator.

7. Tubing positioner to actuator

Figure 7. Mounting a Part-turn

Valve Actuator in acc. with VDI/

VDE3845

After mounting has been completed,

tube the positioner to the actuator using

the appropriate compression fitting

connectors:

Air connections: 1/4” NPT (standard air

connection).

Auxiliary power: Pressurized air or

permissible gases, free of moisture and

dust in according with IEC 770 or ISA

7.0.01.

Pressure range: 1,5 – 6 bar (30 – 90 psi).

For connecting the air piping, the

following notes should be observed:

1. The positioner passageways are

equipped with filters, which remove medium and coarse size dirt from the

pressurized air. If necessary, they are

easily accessible for cleaning.

2. Supply air should meet IEC 770 or ISA

7.0.01 requirements. A coalescing filter

should be installed in front of the supply

air connection (Figure 8). Now connect

the air supply to the filter, which is

connected to the PMV D20 positioner.

3. With a maximum supply pressure of 6

bar (102 psi) a regulator is not required.

4. With an operating pressure of more

than 6 bar (90 psi), a reducing regulator

is required.

The flow capacity of the regulator must

be larger than the air consumption of the

positioner (7 Nm3 /h @ 6 bar / 4,12 scfm

@ 90 psi).

5. Connect the outlet connector (Figure

8) of the positioner with tubing, independent of the action (direct or reverse).

Page 23

2 - 6 bar

30 - 90 Psi

5 µ

ISO 8573 2.2.2

ISA 7.0.01.-1996 Class 2

8. Wiring and grounding guidelines

Electrical connections: signal cable

with cable passage (1/2” NPT, or M20 x

1,5) to terminals 2 x 2,5 mm.

Input signal: 4 – 20 mA

NOTE: Observe the minimum

requirements of voltage and equivalent

electrical load:

Figure 8. Connections

IN

+ –

4 - 20 mA

23

1 2

8 VDC at 20 mA

The performance is ensured only for a

minimum input current of 3,6 mA.

For wiring, the following notes should be

observed:

NOTE:

The input loop current signal to

the PMV D20 should be in shielded cable.

Shields must be tied to a ground at only

one end of the cable to provide a place

for environmental electrical noise to be

removed from the cable. In general,

shield wire should be connected at the

source. (Figure 8).

Connect the 4-20 mA current source to

terminals +1 and -2, see connection table.

Connection Description

+1 Input +4-20 mA

–2 Input –4-20 mA

Pneumatic output

signal (outlet)

Air supply

8.1 Grounding screw

The grounding screw, located inside the

positioner cover, should be used to provide the unit with an adequate and reliable

earth ground reference. This ground

should be tied to the same ground as the

electrical conduit. Additionally, the

electrical conduit should be earth

grounded at both ends of its run. The

grounded scrrew must not be used to

termingate signal shield wires.

Page 24

24

8.2 Electromagnetic compatibility

The PMV D20 digital positioner has been

designed to operate correctly in

electromagnetic (EM) fields found in

typical industrial environments. Care

should be taken to prevent the positioner from being used in environments with

excessively high EM field strengths

(greater than 10 V/m). Portable EM

devices such as hand-held two-way radios should not be used within 30 cm of

the device.

Ensure proper wiring and shielding

Current

Source

Compliance

Voltage

Figure 9. Compliance voltage

techniques of the control lines, and route

control lines away from electro-magnetic

sources that may cause unwanted noise.

An electromagnetic line filter can be used

to further eliminate noise.

In the event of a severe electrostatic discharge near the positioner, the device

should be inspected to ensure correct

operability. It may be necessary to

recalibrate the PMV D20 positioner to

restore operation.

If Present

R

Barrier

Current

R

Wire

8 VDC

PMV

D20

8.3 Compliance voltage

Output compliance voltage refers to the

voltage limit the current source can provide. A current loop system consists of the

current source, wiring resistance, barrier

resistance (if present), and the PMV D20

impedance.

The PMV D20 requires that the current

loop system allow for a 8.0 - 9.4 VDC

drop across the positioner at maximum

loop current.

CAUTION: Never connect a

voltage source directly across the

positioner terminals. This could

cause permanent circuit board

damage.

In order to determine if the loop will support the PMV D20, perform the following

calculation:

Voltage = Compliance Voltage(@Current

– Current

MAX(Rbarrier

+ R

wire

)

MAX

To support the PMV D20 the calculated

voltage must be greater than 9.4 VDC for

D20 HART and 8 VDC for non-HART.

)

Page 25

25

Example: DCS Compliance Voltage = 19 V

R

= 300Ω

barrier

R

= 25Ω

wire

CURRENT

= 20 mA

MAX

Voltage = 19 V – 0.020 A(300Ω + 25Ω) = 12.5 V

9. Operation

9.1 General

The D20 is operated by the yellow button.

Depending on desired action, press the

button:

- during a number of seconds (Ex: )

or

- a number of times. (Ex: )

x3

All operation steps are indicated by lit or

flashing LED(s).

9.2 Startup

Connect Air supply and a mA-simulator

to the positioner.

5 sec.

This system will support the PMV D20, as

the voltage 12.5 V is greater than the required

8 VDC for non-HART and 9.4 VDC for HART.

ALARM

OPEN/CLOSED

CONTROLLING

Calibration

button

The three LED:s will flash alternately

during calibration.

Warning: During calibration, the

actuator may stroke unexpectedly.

9.3 Calibration

Apply 4 mA current as input signal.

Press the button for 5 sec. (Release the button when the three

LED:s start to flash alternately).

5 sec.

The Calibration procedure will take

between 30 seconds and some minutes

depending on actuator size.

The calibration starts, the

actuator goes go to max. and

min. position and calculates the

control parameters.

After calibration all the three LED:s are

lit for a moment.

A successfull calibration is indicated by

yellow or green LED:

G

Green LED flashes = In service

Yellow LED flashes = In service.

Y

The unit vents in max or min posi-

tion.

An unsuccessfull calibration is indicated

by error codes:

R

D20 does not reach the setpoint.

For other indications, see Error codes,

page 30.

Page 26

26

9.4 Set of Direct or Reverse

action

Note! For safety reason, this operation has to be done max 5 minutes

after calibration. If time has run out,

or if power is disconnected during the

five minutes, perform a new calibration, before changing the

direction.

Run 4 mA. If valve is in right position,

then check the position over the whole

range (8, 12, 16 and 20 mA).

If the direction need to be

changed: press the button 3

x3

times and the direction will

change.

Check operation at 4 – 8 – 12 – 16 and

20 mA

9.5 Show gain setting

If the actuator position is unstable or

selfoscillating after calibration, the gain

can be adjusted.

Gain can be set from A (lowest) to G

(highest). Default is D.

To show the current gain

x4

To indicate the current setting, the LEDs

flashes according to the following:

LEDs show: G (Highest)

LEDs show: F

LEDs show: E

LEDs show: D Default

LEDs show: C

LEDs show: B

LEDs show: A (Lowest)

setting, press the button

four times.

Y R R

Y R Y

Y R G

Y G

Y G G

Y G Y

Y G R

The gain code sequence is repeated 5

times.

Page 27

Button functions:

Press 5 sec = Calibration

Press x3 = Direct/reverse action

Press x4 = Show gain setting

Press x5 - x11 = Change gain

setting

To indicate that a command is

accepted, the three LED:s

light up.

9.6 Change of gain setting

To lower the gain, press the button: 7, 6

or 5 times (5= lowest).

To increase the gain (if actuator is

moving to slow).

x11 G (Highest)

x10 F

x9 E

27

➾

Press the button: 9, 10 or 11 times (11=

highest) to increase the gain.

The LED:s flashes alternately when the

button is pressed. After gain change the

LED:s show the gain code (see 9.3) five

times.

The default value after first calibration is

D .

After this, the gain settings are finished.

x8 D Default

x7 C

x6 B

x5 A (Lowest)

Lower Higher

➾

Page 28

28

10. Limit switches & 4 - 20 mA transmitter (Optional)

Caution!

The installation of electrical

equipment in hazardous areas must

comply with the procedures contained

in the certificates of conformity. Country specific regulations may apply.

Electrical safety is determined only by

the power supply device.

10.1 General

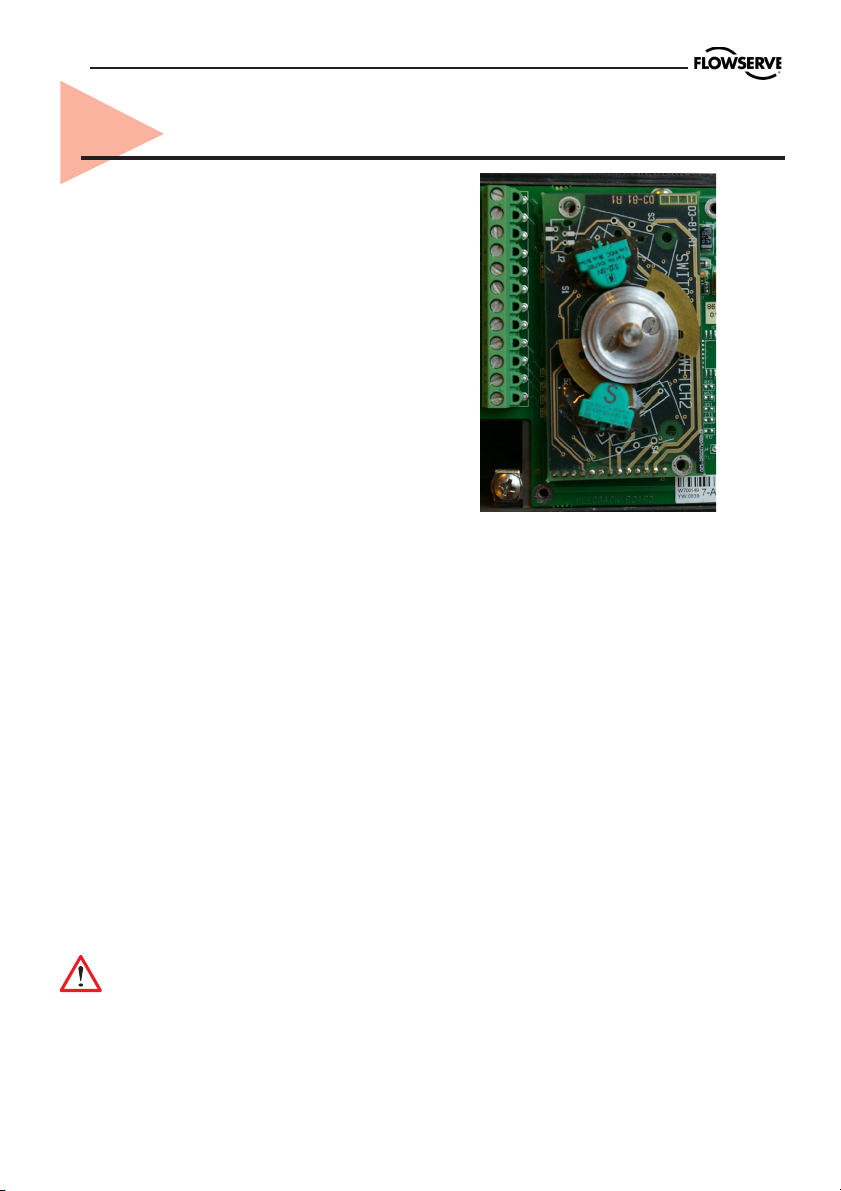

D20 can be equipped with optional plug

in modules for limit switches and/or 4-20

mA feedback transmitter

10.2 Model selection

See D20 model code

10.3 Priciple of operation

The stroke of the actuator/valve is picked

up by the potentiometer inside the D20.

Movement is transferred from actuator

via lever or shaft coupling. Cams/vanes

mounted on the positioner shaft actuate

limit switches 1 and 2. The switching point

can be adjusted on each cam/vane.

The position transmitter converts actual

position into a 4-20mA output signal. This

loop requires an external 12-25 VDC

power supply.

10.4 Installation

Caution! Turn off power and air

supply before starting the installation.

Important!

For D20 installed in hazardous areas,

maintenance and repair must only to be

made by authorized and trained staff.

-Remove cover, indicator if present and

inner plastic cover.

-Check that spacers are installed on the

printed circuit board.

-Carefully install feedback board into its

position on the pins.

-Secure it with two (2) screws.

-Install cam assembly on the shaft, if

feedback card has mechanical micro

switches, be careful to not damage

switch arms.

-Install plastic inner cover.

-Adjust cams/vanes to ensure proper

switching.

-Secure cam/van position by locking

them with two (2) screws.

-Calibrate 4-20 mA transmitter, (see next

page).

-Install cover.

Page 29

29

HARTconnection

12 3 4 5 9

+ – + – + –

Remote unit

10 11 12

Option

1 Input signal + 4-20 mA ,

Hart,

2 Input signal – 4-20 mA ,

Hart

3 Remote unit

4 Remote unit

5 Remote unit

9 4-20 mA + Feedback, 13-28 V DC

10 4-20 mA – Feedback, 13-28 V DC

11 Alarm output +, 8-28 V DC

12 Alarm output –, 8-28 V DC

10.5 D20 Calibration of 4-20 mA input signal and/or 4-20mA

feedback transmitter

• Press and hold button while switching

on power to the D20, keep the button

pressed for 6 sec. The eeprom will now

be erased, and then all three LEDs are

lighted. The LEDs will start to flash

yellow-red. This starts FACTORY MODE!

To calibrate 4-20 mA input signal

• Apply 4.0 mA input signal and then push

the button three (3) times until all LEDs

are lighted. The LEDs will now start flash

yellow-red again.

Apply 20.0 mA input signal and then push

the button three (3) times until all LEDs

are lighted.

To calibrate 4-20 mA transmitter

output signal

Note! If no transmitter board is installed

the LEDs will start flash yellow-yellow and

the unit is ready for continued calibration.

If there is a transmitter board installed

the LEDs will start flash yellow-green.

The feedback transmitter output signal

on pin 9 and 10 will now follow the input

signal instead of the position. Apply 4.0

mA input signal. Measure the output signal and adjust the input signal up/down

until the output signal is 4.0 mA. Push

the button three times until all LEDs are

lighted. The unit will now start to flash

yellow-green again.

The output signal on pin 9 and 10 will

continue to follow the input signal instead

of the position. Apply 20.0 mA input signal. Measure the output signal and adjust

the input signal up/down until the output

signal is 20.0 mA. Push the button three

times until all LEDs are lighted.

The LEDs will start flash yellow-yellow

and the unit is ready for continued

calibration.

Press the button for 5 sec until the LEDs

start alternating, D20 starts to calibrate

stroke.

After calibration the unit will start running

in normal operation.

Page 30

30

11. Trouble shooting

11.1 PMV D20 Normal operation

G

Y

Normal operation.

Valve fully closed or open

”Cut off” enabled.

11.2 PMV D20 error codes

An unsuccessful calibration is indicated by the LED:s. The type of error is shown

by the flash sequence.

Error code Probable Cause Action

R

(Alarm)

Calibration

R G

(No movement)

R Y G

Deviation between set value

and valve position.

No air supply or

shaft do not move.

Pot not calibrated.

Check air supply

Check shaft movement.

Calibrate the pot.

R G R

R R G

R Y R

Y R

Y G

Hallsensor value too low.

Hallsensor span too low.

Hallsensor value too high.

Unit in Factory Mode.

4 - 20 mA feedback installed.

Check hallsensor

connection.

Calibrate 4 - 20 mA

input signal.

Calibrate output.

Page 31

11.3 PMV D20 symptoms and solutions

Failure Probable Cause Corrective action

No LED is flashing. Current source below 3,6 mA . Verify current source

supplies at least 3,6 mA.

Incorrect wiring polarity. Check wiring for correct

polarity.

Valve position reading Stem position sensor mounting Reposition sensor.

is not what is expected. is off 180 degrees.

D20 not calibrated. Calibrate D20.

Tight shutoff MPC (Minimum No action.

position cutoff) is active.

D20 goes in wrong Change direction

direction. (Section 9.4).

31

D20 is oscillating. Decrese gain (Section 9.6).

D20 is responding slow. Increse gain (Section 9.6).

Page 32

32

12. Spare parts

12

9

11

7

8

16

15 19

18

4

17

1

3

5

14

2

21

Page 33

POS PMV P/N Description Remarks

33

1

2

3

3

4

4

5

5

5

5

7

8

9

11

12

14

14

14

14

14

14

14

15

15

15/16

15/16

15/16

15/16

17

18

19

31947

30116

D2-AS5D

D2-AS5N

D2-SP50 STD

D2-SP50 LT

7-SP80 1X

7-SP80-I 1X

7-SP80-H 1H

7-SP80-I-H 1H

30125

D2-SP17

7-SP25B

7-SP25BI

7-SP25

3-As81T

3-As81M

3-As81P

3-As81N

3-As81D4

3-As81D5

3-As81D6

D2-SP40

D2-SP40

D2-SP40

D2-SP40

D2-SP40

S2-SP40

30144

30145

30395

Housing

Lever arm set

Potentionmeter assy. Compl

Shaft D-type Linear, incl nut

Shaft VDI/VDE 3845 Rotary

Air relay assy. Ind. O-rings, screws, standard temp.

Air relay assy. Ind. O-rings, screws, low temp.

Electronics

Electronics, Intrinsically Safe

Electronics, HART

Electronics, HART Intrinsically Safe

Indicator, flat assy. Complete

Indicator, dome style assy. Complete

Front cover, no indicator, black, ind. screws

Front cover, for indicator/dome, black, ind. screws

Inner cover assy.

4-20 mA transmitter only

Mechanical switches assy. comp (incl. cams, screws)

Proximity switches assy. compl.

P+F NJ2-V3-N sensors assy. compl.

P+F SJ2 S1N sensors assy. compl.

P+F SJ2 SN sensors assy. compl.

P+F SJ2N sensors assy.comp.

Gauge block B 1/4" NPT, 1/4" NPT, 1/8" NPT, no gauges

Gauge block C 1/4" NPT, 1/4" NPT, 1/8" G, no gauges

Gauge block B 1/4" NPT, 1/4" NPT, 1/8" NPT, 1 gauge (SS/brass)

Gauge block C 1/4" NPT, 1/4" NPT, 1/8" G, 1 gauge (SS/brass)

Gauge block B 1/4" NPT, 1/4" NPT, 1/8" NPT, 2 gauges (SS/brass)

Gauge block C 1/4" NPT, 1/4" NPT, 1/8" G, 2 gauges (SS/brass)

Flowtop mounting kit incl. O-ring, screws

VDI/VDE 3847 mounting assy. incl. O-rings, screws

Double acting module incl. 2xGauges

N/A

EEx ia

HART

EEx ia, Hart

21

30738

30737

30135

Plug and cable gland kit, black

Seal and O-ring kit

Screw and washer kit

Page 34

Germany

Flowserve

Sperberweg 16

D-41468 Neuss

GERMANY

Tel: +49 (0) 2131 795 74 80

Fax: +49 (0) 2131 795 74 99

E-mail: pmvgermany@flowserve.com

UK

Flowserve

Abex Road

Newbury, Berkshire, RG14 5EY

UK

Tel: +44 (0) 1635 49 400

Fax: +44 (0) 1635 36 034

E-mail: pmvukinfo@flowserve.com

Italy

Flowserve Spa

Via Prealpi, 30

20032 Cormano (Milano)

ITALY

Tel: +39 (0) 2 663 251

Fax: +39 (0) 2 615 18 63

E-mail: infoitaly@flowserve.com

Palmstierna International AB

Korta Gatan 9

SE-171 54 Solna

SWEDEN

Tel: +46 (0) 8 555 106 00

Fax: +46 (0) 8 555 106 01

E-mail: infopmv@flowserve.com

www.pmv.nu

USA, Mexico

PMV-USA

1440 Lake Front Circle, Unit 160

The Woodlands, TX 77380

USA

Tel: +1 281 292 7500

Fax: +1 281 292 7760

E-mail: pmvusa@flowserve.com

Canada

Cancoppas Limited

2595 Dunwin Drive, Unit 2

Mississuga, Ont L5L 3N9

CANADA

Tel: +1 905 569 6246

Fax: +1 905 569 6244

E-mail: controls@cancoppas.com

Asia Pacific Headquarters

Flowserve Pte Ltd.

No. 12 Tuas Avenue 20

REPUBLIC OF SINGAPORE 638824

Tel: +65 (0) 687 98900

Fax: +65 (0) 686 24940

South Africa

Flowserve

Unit 1, 12 Director Road

Spartan Ext. 2

1613 Kempton Park, Gauteng

SOUTH AFRICA

Tel: +27 (0) 11 397 3150

Fax: +27 (0) 11 397 5300

The Netherlands

Fabromatic BV

Rechtzaad 17

4703 RC Roosendaal

THE NETHERLANDS

Tel: +31 (0) 30 6771946

Fax: +27 (0) 30 6772471

E-mail: fcbinfo@flowserve.com

China

Flowserve

Hanwei Building

No. 7 Guanghua Road

Chao Yang District

100004 Beijing

CHINA

Tel: +86 (10) 6561 1900

Fax: +86 (10) 6561 1899

FCD PMENIM0012-01

Loading...

Loading...