Page 1

Worcester Controls

CONTENTS

Page

1. STORAGE INSTRUCTIONS........................................................................................................................................................................2

2. INSTALLATION..........................................................................................................................................................................................2

A. Mounting Guide....................................................................................................................................................................................2

B. Mounting Instructions ..........................................................................................................................................................................3

C. Connections..........................................................................................................................................................................................4

3. OPERATION ..............................................................................................................................................................................................4

4. AIR REQUIREMENTS................................................................................................................................................................................4

5. SPAN AND ZERO ADJUSTMENT...............................................................................................................................................................5

6. CAM ADJUSTMENT ..................................................................................................................................................................................6

7. REVERSE-ACTING AND SPLIT-RANGE.....................................................................................................................................................6

8. MAINTENANCE .........................................................................................................................................................................................7

A. Pilot Valve.............................................................................................................................................................................................7

B. Diaphragm............................................................................................................................................................................................7

C. Feedback Spring...................................................................................................................................................................................8

D. Balance Arm.........................................................................................................................................................................................8

E. Lower Arm............................................................................................................................................................................................9

F. O-Rings ................................................................................................................................................................................................9

9. TROUBLESHOOTING ..............................................................................................................................................................................10

10. TECHNICAL DATA ...................................................................................................................................................................................10

11. SPARE PART LIST ..................................................................................................................................................................................11

12. EXPLODED DRAWING ............................................................................................................................................................................11

WCAIM2016

(Part 12506)

PM15 Pneumatic Valve Positioner

Installation, Operation and Maintenance Instructions

Page 2

1. STORAGE INSTRUCTIONS

PM15 Positioner Storage and Handling Procedures

PM15 positioners are precision instruments which should be stored

and handled accordingly to avoid problems or damage.

Warehouse Storage

Stored in original shipping containers, units should be stored in an

environmentally controlled area, i.e., clean, cool (15–26°C, 60–80°F)

and dry, out of direct sunlight or weather exposure.

Field Storage

NOTE: Once the air supply to the positioner is connected and turned on,

internal air bleed will prevent the ingress of moisture and protect the unit

from corrosion. It is recommended that the air supply be left on at all

times.

• If units are installed immediately, turn, and leave on, the air

supply.

• If positioners must be stored outdoors, tighten all covers which

may have loosened in shipment, make sure all open enclosure

entry points are sealed.

Positioners should be wrapped and sealed air and watertight with

desiccant inside the plastic, units should be securely covered with an

opaque cover and not exposed to direct sunlight, rain or snow.

Units should have all ports sealed and be protected from direct

exposure to weather. For long term storage (>1 month) or overseas

shipment, units should be protected with plastic and desiccant.

Potential Damage to Mechanism

When units are stored in hot, humid climates, the daily

heating/cooling cycle will cause air to expand/contract and be drawn

in and out of the positioner housing.

Dependent on the local temperature variations, humidity and dew

points and time in storage, condensation could occur and accumulate

inside pilot valve causing erratic operation or failure due to water and

corrosion. The potential for condensation damage is especially high in

southern climates and aggravated if units are exposed to direct

sunlight.

For further assistance, please contact your nearest Worcester

distributor.

2. INSTALLATION

Before mounting the positioner, the relationship of the actuator to the

valve must be determined. The actuator can be mounted inline or

cross-line to the valve. In addition, the actuator can be mounted rightside-up or inverted. If a spring-return actuator is used, the actuator

can be set up to fail with the valve closed or with the valve open. This

gives the end user a total of eight possible set-up configurations.

A. MOUNTING GUIDE

The following notes pertain to Positioner Mounting Guide on next

page:

1. “Inverted” Actuator Position and “Cross-Line” Actuator

Mounting applies to sizes 10-20 39 Series actuators only. On

sizes 25 and larger, the output shaft is square, which allows

for the coupling to be indexed 90˚ to the actuator shaft.

Normal actuator position means that the actuator is mounted

“right-side-up”.

2. For Spring-Return actuators only. “Fail-Open” actuators have

a “9” in position 3 of the ordering code.

3. To change cam to Reverse-Acting, remove and reinstall

upside down (see Section 7).

4. For Double-Acting actuators only. Normal hose positions refer

to those described in Section 2.C, Connections.

B. MOUNTING INSTRUCTIONS

Mounting instructions for a Direct-Acting PM15 to a SpringReturn or Double-Acting 39 Actuator:

The most common installation configuration is with the actuator

mounted inline, direct-acting, and with spring-return set for failclosed. Direct-acting means that as the signal increases, the valve

travels in the open direction.

1) Close the valve/actuator assembly if it is not already closed

(fully CW).

2) Remove the position indicator, if any, from the actuator shaft.

3) Attach the mounting bracket to the top of the actuator such

that the indicating scale is upright and on the same side of

the actuator as the actuator nameplate. Use four (4) screws

and lockwashers supplied with mounting kit.

4) Place coupling on actuator shaft. DO NOT tighten set screws

at this time.

5) Install the indicating arm and locknut on the coupling such

that the end of the arm points downward.

6) Place the positioner on the bracket so that the actuator

nameplate and the side of the positioner with the zero

adjustment are on the same side. Positioner is mounted to

bracket using mounting adapter and screws (5).

2 PM15 Pneumatic Valve Positioner Installation, Operation and Maintenance Instructions WCAIM2016

Flow Control Division

Worcester Controls

5

Installation

Page 3

WCAIM2016 PM15 Pneumatic Valve Positioner Installation, Operation and Maintenance Instructions 3

(

Flow Control Division

Worcester Controls

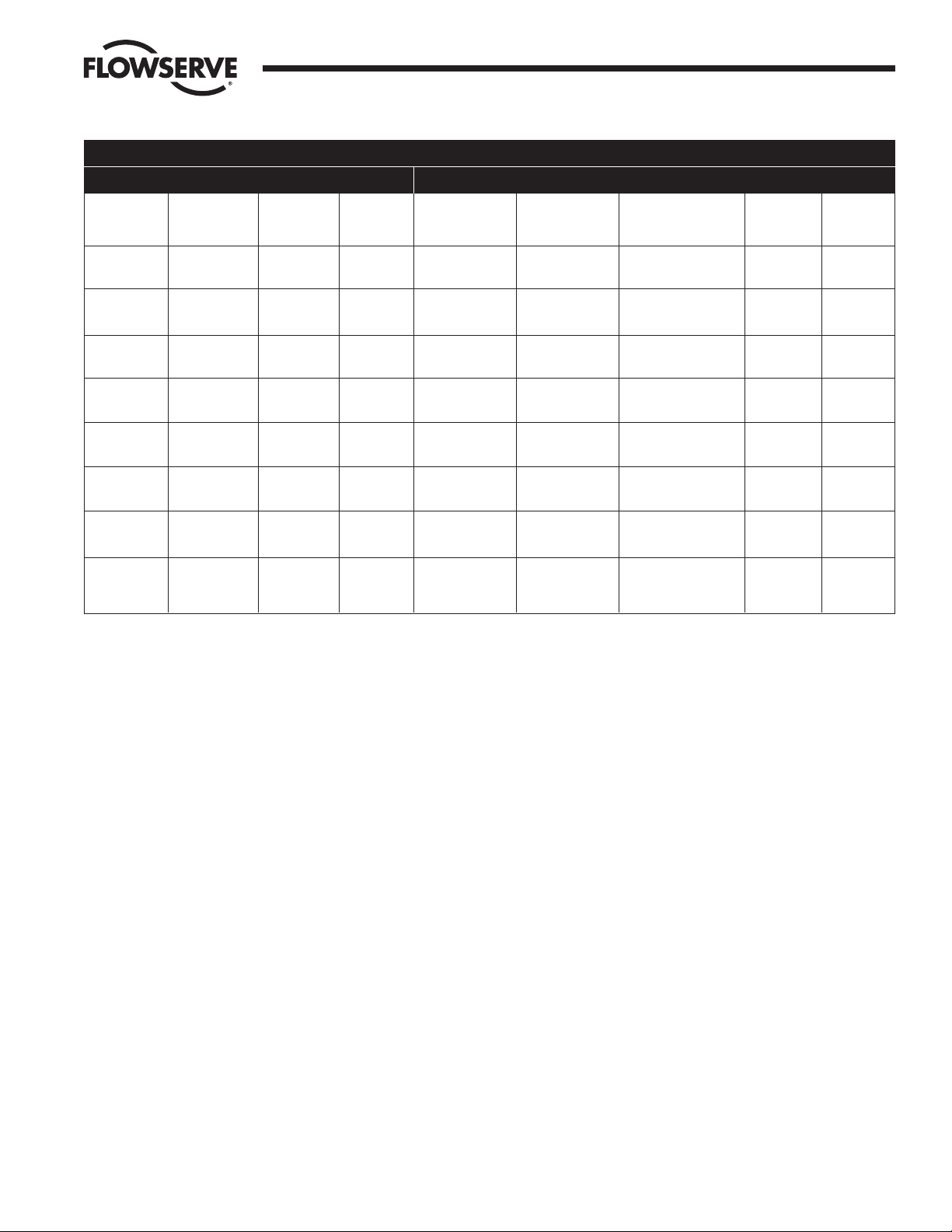

POSITIONER MOUNTING GUIDE

ACTUATOR POSITIONER

Actuator

Mounting

(Note 1)

Inline

Inline

Cross-Line

Cross-Line

Inline

Inline

Cross-Line

Cross-Line

Failure

Mode

(Note 2)

Fail-Close

Fail-Close

Fail-Close

Fail-Close

Fail-Open

Fail-Open

Fail-Open

Fail-Open

Actuator

Position

(Note 1)

Normal

Normal

Inverted

Inverted

Inverted

Inverted

Normal

Normal

Rotation

to

Open

CCW

CCW

CW

CW

CCW

CCW

CW

CW

Positioner

Operation

Direct-Acting

Reverse-Acting

Direct-Acting

Reverse-Acting

Direct-Acting

Reverse-Acting

Direct-Acting

Reverse-Acting

Cam

(Note 3)

Direct-Acting

Reverse-Acting

Reverse-Acting

Direct-Acting

Direct-Acting

Reverse-Acting

Reverse-Acting

Direct-Acting

Cam Setting

0˚ (Min. Signal)

When Valve is Closed

90˚ (Max.Signal)

When Valve is Closed

0˚ (Min. Signal)

When Valve is Closed

90˚ (Max.Signal)

When Valve is Closed

90˚ (Max.Signal)

When Valve is Open

0˚ (Min. Signal)

When Valve is Open

90˚ (Max.Signal)

When Valve is Open

0˚ (Min. Signal)

When Valve is Open

Actuator

Supply Hoses

(Note 4)

Normal

Reverse

Reverse

Normal

Normal

Reverse

Reverse

Normal

Valve

Position at

Min. Signal

Closed

Open

Closed

Open

Closed

Open

Closed

Open

7) Align the mounting holes and then use the two

5

/

16-18 socket

head cap screws, lockwashers, hex nuts, and rubber washers

(between bracket and positioner) supplied with the mounting

kit to fasten the positioner to the bracket.

8) Tighten the set screw at the upper end of the coupling to the

positioner shaft (seat the set screw in the positioner shaft

groove). The other two set screws will be tightened after the

actuator is cycled 90˚. Proper alignment of the positioner spindle

to the actuator shaft is very important since improper alignment

can cause excessive wear and friction to the positioner.

C. CONNECTIONS

Air connections are tapped for

1

/

4" NPT male connectors and are

clearly marked. We recommend use of tape, Loctite®577 or

similar user preferred for sealing.

Port I Input instrument pneumatic signal 20–100 kPa (3–15 psi)

Port S Supply air, maximum 0.9 MPa (125 psi)

Port C1, C2 Actuator connections (0.2–0.9 MPa). C2 opening port.

Connect the air supply line to port S.

For double-acting operation, connect the right-hand and left-hand

ports of the actuator end cap (right-hand end cap when facing

actuator nameplate) to port C2 and C1 respectively.

For single-acting operation, plug port C1 for increasing signal to

open or close. Plug port C2 for decreasing (reverse) signal to

close.

3. OPERATION

The PM15 operates on a force balance principal. Force is originated

by the signal pressure transmitted through a diaphragm onto the

balance arm. The opposing force is achieved through the feedback

spring and is proportional to the position of the lower arm. The lower

arm position is determined by the position of the cam which is

secured to the spindle and connected to the actuator shaft thus

providing the feedback from the actuator/valve. When these two

forces are equal, the balance arm and the spool in the pilot valve is in

a neutral position — the complete unit is in a balanced position. Air is

supplied to the pilot valve through port S, and controls the air flow

through ports C1 and C2.

Assume an equilibrium position.

An increased control pressure will deflect the diaphragm (1) down,

compressing the feedback spring (3). The balance arm (2) moves the

spool (7) in the pilot valve (8) furnishing supply air to the actuator,

while at the same time air is exhausted from actuator and is vented to

atmosphere through the pilot valve.

With the increased supply air, the actuator rotates (or moves linearly)

moving the positioner spindle (6). The spindle and cam (5) rotate,

forcing the lower arm (4) upwards compressing the feedback spring

(3). This motion will continue until two forces are equal and the unit

is an equilibrium position.

Page 4

4 PM15 Pneumatic Valve Positioner Installation, Operation and Maintenance Instructions WCAIM2016

Flow Control Division

Worcester Controls

1

7

8

3

5

6

4

2

1

3

2

4

7

6

5

Correct

Incorrect

3

2

1

1-2 mm (

1

/

16

")

4

Operation Span and Zero Adjustment

Cam Adjustment

4. AIR REQUIREMENTS

Maximum supply pressure is 0.9 MPa (125 psi).

Supply air shall be clean, dry and free from oil, water, moisture,

foreign parts and debris.

The air shall be freeze-dried or similar to a dew point of at least 10˚C

(18˚F) below lowest expected ambient temperature.

A <40 micron filter/regulator is recommended to be installed as close

to PM15 as possible to ensure proper supply air quality.

5. SPAN AND ZERO ADJUSTMENT

Span is adjusted with the brass-colored (upper) thumb wheel (1)

located on the feedback spring.

To adjust the span, always return to minimum input signal first, then

loosen the locking screw (2) and turn thumb wheel (1). Tighten screw

(2) when span is set. Do not allow the top of the spring to contact the

spring guide (3).

Always check zero after adjusting span.

Zero is adjusted by turning the silver (lower) thumb wheel (4) located

on the lower arm (5) or externally with a screwdriver (7), through the

zero adjustment opening. Remember to install cover (6) to ensure the

units sealing.

6. CAM ADJUSTMENT

With the cover and indicator removed, loosen the screw (1) and turn

the cam locking nut (2) counterclockwise until the cam loosens.

Adjust the cam (3) as desired making sure that the ball bearing (4)

always is riding on an active lobe on the cam. To secure the cam,

make sure that screw (1) is backed out from the locking nut (2) then

finger tighten the locking nut and tighten screw (1). Install and adjust

the indicator and reinstall cover.

Page 5

WCAIM2016 PM15 Pneumatic Valve Positioner Installation, Operation and Maintenance Instructions 5

Flow Control Division

Worcester Controls

7. REVERSE-ACTING AND SPLIT-RANGE

Reverse-Acting

For reverse-acting operation, invert cam. Also reverse connections

C1 and C2. For single-acting actuators, move actuator connection

from C2 to C1 and plug C1.

Split-Range

For split-range, reposition the cam, noting the markings on the cam—

for 3–9 psi use initial 50% zone; from 9–15 psi, use 51–100% zone.

8. MAINTENANCE

A. PILOT VALVE

To remove the pilot valve for cleaning or inspection, remove the

screw (1) and carefully lift out the complete assembly (2). Gently

remove the spool (3) from the block and clean the parts, using

methylate cleaner or similar. Blow the parts dry with compressed

air.

Should the parts show signs of wear, a new assembly is

recommended. Mixing spool valves and valve bodies may result

in very high bleed rates and poor performance. Check the O-rings,

then secure and install the pilot valve assembly to the positioner

unit and secure it with the screw (1). Make sure that the leaf

spring (4) on the balance arm (5) is properly fitted in the groove

on spool (6). Check again to ensure smooth operation of the

assembly.

To maintain original factory performance specifications, use only

Worcester spool valve assemblies.

B. DIAPHRAGM

Loosen screws (1) and remove the diaphragm cover (2).

Loosen screw (3), diaphragm (4) and washers (5) can be

removed.

When installing the diaphragm, make sure to place one washer on

each side of the diaphragm. Make sure that the raised circle on

the washer is facing the diaphragm.

Install the screw (3) and tighten.

Check the O-ring on the diaphragm cover (2), then install

and secure the cover with screws (1).

C. FEEDBACK SPRING

Once the front cover and indicator are removed, the

feedback spring can be easily accessed.

Hold the spring (1) from the top, pull down and out.

When installing, hold the assembly at the top, guide the lower

part to position on the zero screw, then press down until it fits

easily under the balance arm (2). Make sure that the assembly is

aligned properly against the lower arm and the notch is engaged

in the tab on the balance arm (2).

D. BALANCE ARM

The balance arm can only be removed after diaphragm and

feedback spring have been removed. (See Section 8.C. and

Section 8.B.)

Loosen the screws (3) and the balance arm can be removed.

When installing the balance arm make sure that the leaf spring (4)

on the underside of the balance arm (5) is properly engaged into

the groove (6) of the spool in the pilot valve.

Tighten the two screws (3) holding the balance arm to the

positioner.

Maintenance — Pilot Valve

Maintenance — Diaphragm

Maintenance — Feedback Spring

3

2

1

6

5

4

2

1

3

5

4

2

1

Page 6

6 PM15 Pneumatic Valve Positioner Installation, Operation and Maintenance Instructions WCAIM2016

E. LOWER ARM

Once the front cover is removed, the lower arm can be easily

accessed. Remove the indicator, feedback spring and the cam.

Loosen screw (2) and remove twist stop (1). Remove screw (3),

lower arm (4), rod (5) and spring (6).

Check rod and lower arm for wear, replace if necessary. Clean the

rod and install it in the lower arm. The lower arm should move

easily and smoothly.

Install the lower arm and rod assembly into the positioner

housing, making sure that the spring (6) is attached properly to

the lower arm and positioner housing.

Secure the lower arm and rod assembly with the screw (3). Check

again that the lower arm moves smoothly.

Apply a small amount of grease on the small tongue on the lower

arm, then install and secure the twist stop.

Install cam, feedback spring, indicator and front cover.

F. O-RINGS

With time and use, O-rings can become brittle. This can cause

poor operation and even failure of the positioner.

Always check O-rings when performing any work on the

positioner and replace bad O-rings.

A thin layer of silicon grease applied on the Buna N (Black) Orings prolongs their life. On Q (Red Silicon) O-rings, use a

non-silicon based grease.

9. TROUBLESHOOTING

NOTE: All PM15 positioners are serialized and date coded. Please note

and provide the serial number when contacting the factory for

troubleshooting or service.

Signal change results in actuator running to end positions:

• Check coupling between positioner and actuator.

• Check cam position and locking screw.

• Check input signal.

Signal change has no effect on the actuator position:

• Check indicator and screw.

• Check air supply to positioner and tubing to the actuator.

• Check input signal to positioner.

• Check diaphragm for damage or leakage.

• Check pilot valve function.

• Check cam for correct setting.

Inaccurate positioning:

• Dirty or worn pilot valve.

• Defective or leaking diaphragm.

• Input signal fluctuates.

• Incorrect sizing of actuator.

• Valve/actuator “stiction”.

• High valve/actuator breakaway torque.

• Loose cam.

Flow Control Division

Worcester Controls

Maintenance — Balance Arm

Maintenance — Lower Arm

3

6

5

4

2

1

5

4

3

6

Page 7

WCAIM2016 PM15 Pneumatic Valve Positioner Installation, Operation and Maintenance Instructions 7

Flow Control Division

Worcester Controls

Exploded Drawing

10. TECHNICAL DATA

Input Signal 20–100 kPa/3–15 psi

Linearity < 0.5%*

Hysteresis < 0.5%*

Repeatability < 0.5%*

Gain Factor at:

80% Load

(Supply Pressure 0.6 MPa/87 psi) 250 kPa/kPa psi/psi +20%

50% Load

(Supply Pressure 0.6 MPa/87 psi) 500 kPa/kPa psi/psi +20%

Air Consumption at Supply Pressure: ± 20%

0.6 MPa/87 psi 7.5 nl/min (0.27 scfm)

Air Delivery at Supply Pressure: ± 20%

0.2 MPa/29 psi 135 nl/min (4.7 scfm)

0.4 MPa/58 psi 240 nl/min (8.4 scfm)

0.6 MPa/87 psi 340 nl/min (11.9 scfm)

Supply Pressure Max 0.9 MPa/125 psi

Temperature Range -20˚C to +85˚C (-4˚F to 185˚F)

Connector Threads

1

/

4" NPT

Weight 1.1 kg/2.4 lb

Housing Die Cast Aluminum

Surface Treatment Epoxy Painting

*Percent of full scale.

Item Qty Description

2, 4, 9, 15, 1 Set P4 Screw Set

18, 19, 20,

27, 30

3 1 P4-3 Front Cover

5 1 P4-5 Indicator Arrow-Standard

6 1 P4-6 Cam Locking Nut

7 1 P4-K1 Cam

8 1 P4-8 Lower Arm Spring

12 1 P4-12 Balance Arm

13, 14 1 P4-13 Adapter Plate

16, 17 1 P4-17 Diaphragm Cover with Nitrile O-Ring

Item Qty Description

20, 21 1 P4-20 Diaphragm Assembly/Nitrile

23 1 P4-C3 Spindle

24 1 P4-24 Mounting Hole Sealing Cap

25 1 P4-25 Zero Adjust Cover

26 1 P4-26 Lower Arm Stop Plate

28 1 P4 O-Ring Set, Nitrile

29 1 P4-29 Pilot Valve Assembly

31, 10, 11 1 P4-31 Lower Arm Assembly

32 1 P4-32 P4 Spring Assembly, 12 psi

33 1 P4-33 Guide Rod

11. SPARE PARTS LIST

Page 8

Flow Control Division

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone 931 432 4021

Fax 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. WCAIM2016 10/03 Printed in USA

Loading...

Loading...