Page 1

USER INSTRUCTIONS

PLEUGER® standard submersible

motor pumps

Installation

Operation

Maintenance

Submersible motor pumps with water filled motor

for deep-well installation

PCN=71569293 01-13 (E) (Based on 1042.277/7.)

Original instructions.

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

CONTENTS

Page

1 INTRODUCTION AND SAFETY ............................ 3

1.1 General ........................................................... 3

1.2 CE marking and approvals .............................. 3

1.3 Disclaimer ....................................................... 3

1.4 Copyright ......................................................... 3

1.5 Duty conditions ................................................ 3

1.6 Safety .............................................................. 4

2 TRANSPORT AND STORAGE .............................. 9

2.1 Consignment receipt and unpacking............... 9

2.2 Handling and lifting.......................................... 9

2.3 Storage .......................................................... 10

2.5 Recycling and end of product life .................. 10

3 DESCRIPTION .................................................... 10

3.1 Technical data ............................................... 10

3.2 Delivery contents ........................................... 10

3.3 General data ................................................. 11

3.4 General description ....................................... 11

3.5 Submersible motor ........................................ 12

3.6 Pump and check valve .................................. 13

4 INSTALLATION .................................................... 14

4.1 Hydraulic installation ..................................... 14

4.2 General advice for installation ....................... 14

4.3 Flexible hose riser pipe ................................. 14

4.4 Centralizers ................................................... 14

4.5 Checks before installation ............................. 14

4.6 Installation of pre-assembled pump units ..... 15

4.7 Riser pipes with flange connections.............. 15

4.8 Riser pipe with pipe socket ........................... 15

4.9 Assembly of submersible motor pumps

before installation ........................................ 15

Page

6 MOTOR FILLING ................................................ 21

6.1 Antifreeze ...................................................... 21

6.2 Type of use ................................................... 22

6.3 Filling quantities ............................................ 22

6.4 Accessories and hardware for filling

and topping up ............................................ 22

6.5 General information about filling ................... 22

6.6 Filling instructions ......................................... 23

7 COMMISSIONING, START-UP

AND SHUTDOWN ........................................... 31

7.1 Commissioning ............................................. 31

7.2 Operation ...................................................... 31

7.3 Switching off the unit ..................................... 32

8 MAINTENANCE .................................................. 32

8.1 General information ...................................... 32

8.2 Pump units .................................................... 32

8.3 Measuring insulation ..................................... 32

8.4 Removal of the pump unit ............................. 33

8.5 Overhaul of the pump unit ............................ 33

9 FAULTS; CAUSES AND REMEDIES .................. 35

10 CERTIFICATION ............................................... 37

5 ELECTRICAL CONNECTIONS ........................... 16

5.1 Motor ............................................................. 16

5.2 Protective measures against

shock-hazard voltage .................................. 16

5.3 Motor protection ............................................ 17

5.4 Short circuit protection .................................. 17

5.5 Motor connection diagrams ........................... 18

5.6 Adjustments for soft-starter and

soft stop devices ......................................... 20

5.7 Operation of submersible motors with

static frequency converter ........................... 20

5.8 Resistance sensor PT100 (RTD) .................. 21

Page 2 of 40 flowserve.com

Page 3

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilising sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not take

into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

These instructions should be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety noted in the

instructions, have been met.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic

Compatibility (EMC), Pressure Equipment Directive

(PED), minimum efficiency for some water pumps

(Ecodesign) and Equipment for Potentially Explosive

Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions.

Where applicable this document incorporates

information relevant to these Directives and Approvals.

To confirm the Approvals applying and if the product is

CE marked, check the serial number plate markings

and the Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be reliable. In spite of all the efforts of

Flowserve Corporation to provide sound and all

necessary information the content of this manual

may appear insufficient and is not guaranteed by

Flowserve as to its completeness or accuracy.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organisations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use.

As Flowserve cannot test parts and accessories

sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety features

of the products. The failure to properly select, install

or use authorised Flowserve parts and accessories is

considered to be misuse. Damage or failure caused

by misuse is not covered by the Flowserve warranty.

In addition, any modification of Flowserve products or

removal of original components may impair the safety

of these products in their use.

The operational safety of the delivered unit is only

guaranteed for use according to the limitations

described in section 3.1, Technical data. The limits

given in the data sheet may not be exceeded.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application.

If there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

Page 3 of 40 flowserve.com

Page 4

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

If the conditions of service on your purchase order are

going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user seeks

the written agreement of Flowserve before start up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction would

cause hazards. The specific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and could

result in loss of life.

This symbol indicates “hazardous and toxic fluid”

safety instructions where non-compliance would affect

personal safety and could result in loss of life.

This symbol indicates safety instructions

where non-compliance will involve some risk to safe

operation and personal safety and would damage the

equipment or property.

This symbol indicates explosive atmosphere zone

marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This sign is not a safety symbol but indicates

an important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the personnel

in question do not already possess the necessary

knowledge and skill, appropriate training and instruction

must be provided. If required the operator may

commission the manufacturer/supplier to provide

applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

Before maintenance and repair work is started the

motor of the pump unit must first be completely

isolated from the electrical power supply.

The procedure to shut down the unit described in

section 7.3, Switching off the unit, must be followed

without fail.

Danger from electricity must be

eliminated. (For details see, for example, the

regulations of the VDE and local power supply

companies.)

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS IN OPERATION

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

DISMOUNTING PUMP UNITS

Before dismounting one pump unit, the pump must be

separated from the motor and drained. In case of

dangerous delivery fluids, suitable safety measures

must be made.

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should be

avoided.

HOT (and cold) PARTS

If hot or cold components, or heater or cooler units,

can cause a danger for the operating staff or persons

in the immediate vicinity, measures must be taken to

prevent possible contact, eg by protective gratings.

Page 4 of 40 flowserve.com

Page 5

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

If complete protection is not possible, access to such

devices must be limited to the maintenance staff who

must be informed specifically about the special

dangers by warnings and corresponding signs.

The measures listed above must be applied if the

temperatures in a limited access zone exceed

80 ºC (175 ºF) or fall below -5 ºC (23 ºF), or if the

regional limit values are exceeded.

ADDITIONAL SAFETY NOTES

In addition to the safety notes listed in the main Safety

section, special safety notes in all other sections must

also be observed, eg those for private use.

COMMISSIONING

Prior to each commissioning after installation,

maintenance or repair, follow the instructions and

notes in section 8, Commissioning, switching on,

operation and switching off.

Notes directly attached to the unit must be observed

without fail. These include:

Marking of connections

Rating plate

Rotational direction

HAZARDOUS LIQUIDS

Units handling hazardous liquids must be

decontaminated.

INFLAMMABLE FLUIDS

When the pump is handling hazardous liquids care must

be taken to avoid exposure to the liquid by appropriate

siting of the pump, limiting personnel access and by

operator training. If the liquid is flammable and or

explosive, strict safety procedures must be applied.

When pumping dangerous fluids, no packing

seals must be used.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

In horizontally arranged pump units, the pump must not

be used as support for suction or pressure pipework.

Arrange compensators in such a way that the forces

caused by internal pressure do not act upon the pump

flange unless approved in writing by Flowserve.

ROTATIONAL DIRECTION OF THE

MOTOR

The rotational direction of each motor can be found in

the data sheet and or the connection data sheet.

As testing the rotational direction by short startup in

dry conditions is not permitted and as by design the

rotational direction of the motor cannot be determined

when the pump unit is completely mounted, the

rotating field of the power supply must be known. If

necessary, it must be determined using a rotating

field measurement device.

If the pump unit is operated with incorrect rotational

direction, the delivery output is reduced and pump

damage is possible.

OPERATION OF THE PUMP UNIT

The pump unit may only be operated if the unit is

completely mounted, the motor is completely filled

with the prescribed amount of filling fluid and it is

submerged sufficiently into the delivery medium.

Never let the submersible motor pump run dry.

Switching on, including for test purposes, is never

allowed if the pump is not submerged.

For the minimum submersion depth in the delivery

medium, refer to the provided data sheet or ask

Flowserve.

Non-observance can cause the following dangers:

Failure of important system functions

Failure of prescribed methods for maintenance

and upkeep

Danger to persons due to electrical, mechanical

or chemical impact

Danger to the environment by leakage when

delivering hazardous media

OPERATION OF THE PUMP UNIT

Operation with a flow volume that is above average

or does not cause counter-pressure to the pump can

cause a motor overload and cavitation in the pump.

Low flow rates can cause shortened service life of the

pump, overheating of the pump, instability, cavitation

and vibration.

The duty point for which the pump unit has been

designed can be found in the data sheet of the pump.

SWITCHING ON THE PUMP UNIT

After having completely installed the pump unit, close

the outlet valve apart for a small gap to bleed the

riser pipeline. (If the system is equipped with an airrelease valve at the highest point of the riser pipeline,

the outlet valve remains closed.) After switching on,

the pressure at the pressure gauge must be higher

than the pumping head specified in the data sheet,

minus the water depth.

Page 5 of 40 flowserve.com

Page 6

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Because of the risk of motor overload, S-series units

(pumps with axial impellers) must never be started

against a closed slider!

In order to avoid overheating the pump, a pump must

never be operated for more than 2 minutes against a

closed outlet valve.

In the time during which the empty riser is filled, the

ampere meter can display a higher current after

switch-on than specified in the data sheet, even after

the starting current has subsided.

Afterwards, the operating current must be lower than

the maximum permitted current as specified in the

data sheet.

SLOWLY open the outlet valve so as to not cause

overload to the well due to excessive delivery flow.

Open the slider slowly until the ampere meter displays

the operating current as specified in the data sheet.

After reaching the operating point for which the unit has

been designed, the current intake must approximately

match the one specified in the data sheet.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

Avoid excess temperature

Prevent build up of explosive mixtures

Prevent the generation of sparks

Prevent leakages

Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

For ATEX, both electrical and non-electrical equipment

must meet the requirements of European Directive

94/9/EC. Always observe the regional legal Ex

requirements eg Ex electrical items outside the EU may

be required certified to other than ATEX eg IECEx, UL.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the motor and pump

equipment are suitably rated and/or certified for the

classification of the specific atmosphere in which they

are to be installed.

Where Flowserve has supplied only the bare shaft

pump or motor, the Ex rating applies only to that.

The party responsible for assembling the ATEX pump

set shall select any instruments or devices and the

motor cable and joint design and cable protection

suitable to the Ex environment according to ATEX

and IEC 60079-14. Fully submerged submersible

pump sets like electric cables are exempt from ATEX

Ex Marking. IEC 60079-14 requires that the cable

passing through an Ex Zone such as Zone 0, 1, 2, 20,

21 or 22 is correctly rated and protected by a suitable

Conduit or Armour design. Flowserve must be

advised the Ex Zone and area ATEX Classification in

any Caisson or atmosphere so that the appropriate

cable and pump set design is provided for the

application. If the Zone is Zone 0 or 20 a Flowserve

ATEX Category 2 or 3 Marked Pleuger CAVERN

design must not be used. All Pleuger CAVERN

designs use a liquid filled Conduit containing the

electric cable. Any additional applicable equipment

for ATEX must be provided with the necessary CE

Certificate/Declaration of Conformity establishing it is

suitable for the area in which it is to be installed.

The output from a variable frequency drive (VFD) can

cause additional heating effects in the motor and so, for

pump sets with a VFD, the ATEX Certification for the

motor must state that it is covers the situation where

electrical supply is from the VFD. This particular

requirement still applies even if the VFD is in a safe area.

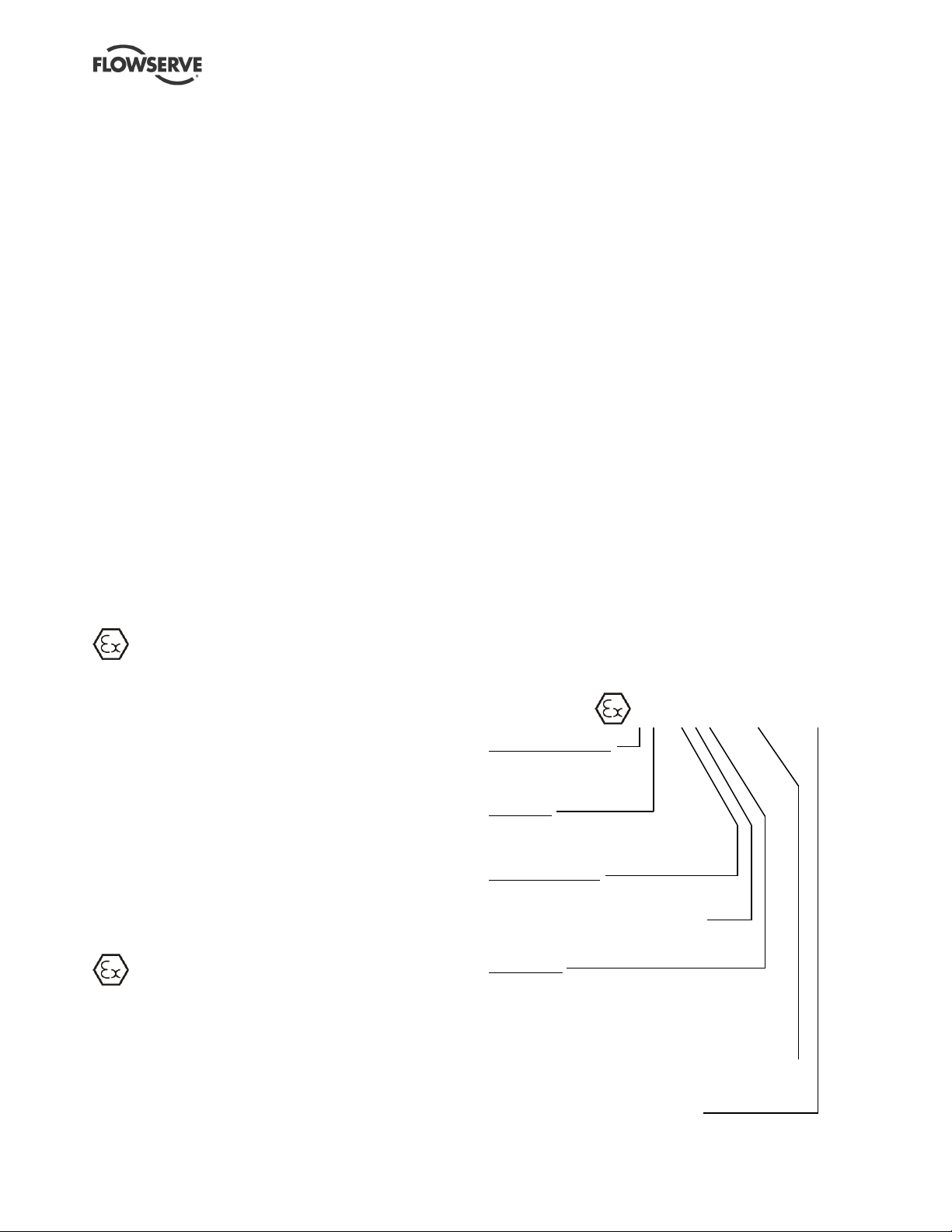

1.6.4.2 Marking

An example of ATEX CAVERN equipment marking is

shown below. The actual classification of the pump

will be engraved on the nameplate.

II 2 GD k IIC T4 T135ºC IP68

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas, D = Dust

k = Liquid encased protection

(in accordance with EN13463-8)

Gas Group

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

No gas group means suitable for all

Maximum surface temperature (Temperature

Class, see table 1, section 1.6.4.3.)

Protection type when applicable

Page 6 of 40 flowserve.com

Page 7

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Temperature class

to EN13463-1

Maximum surface

temperature permitted

Temperature limit of

liquid handled *

T6

T5

T4

T3

T2

T1

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximum ambient of 40 ºC (104 ºF); refer to

Flowserve for higher ambient temperatures.

The surface temperature on the pump is influenced

by the temperature of the liquid handled. The

maximum permissible liquid temperature depends on

the ATEX temperature class and must not exceed the

values in the table that follows:

Table 1: Maximum permitted liquid temperature for

pumps

* The table only takes the ATEX temperature class into consideration.

Pump design or material, as well as component design or material,

may further limit the maximum working temperature of the liquid.

The temperature rise at the seals and bearings and

due to the minimum permitted flow rate is taken into

account in the temperatures stated.

The operator is responsible for ensuring that the

specified maximum liquid temperature is not

exceeded.

Temperature classification “Tx” is used when the liquid

temperature varies and when the pump is required to be

used in differently classified potentially explosive

atmospheres. In this case the user is responsible for

ensuring that the pump surface temperature does not

exceed that permitted in its actual installed location.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitors or a

power monitor and make routine vibration monitoring

checks.

A vibration check must be carried out routinely. We

recommend a measurement every 4 weeks.

In dirty or dusty environments, make regular checks

and remove dirt from areas around close clearances,

bearing housings and motors.

Where there is any risk of the pump being run against a

closed valve generating high liquid and casing external

surface temperatures fit an external surface

temperature protection device.

For pumps with key drive impellers only

If an explosive atmosphere exists during the

installation, do not attempt to check the direction of

rotation by starting the pump unfilled. Even a short

run time may give a high temperature resulting from

contact between rotating and stationary components.

1.6.4.4 Preventing the build-up of explosive

mixtures

ENSURE THE PUMP IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented.

In addition it is essential to make sure that seal

chambers, auxiliary shaft seal systems and any

heating and cooling systems are properly filled.

If the operation of the system cannot avoid this

condition, fit an appropriate dry run protection device

(for example liquid detection or a power monitor).

To avoid potential hazards from fugitive emissions of

vapour or gas to atmosphere the surrounding area

must be well ventilated.

1.6.4.5 Preventing sparks

To avoid the potential hazard from random

induced current generating a spark, the baseplate

must be properly grounded.

Avoid electrostatic charge: do not rub non-metallic

surfaces with a dry cloth; ensure cloth is damp.

1.6.4.6 Preventing leakage

The pump must only be used to handle liquids

for which it has been approved to have the correct

corrosion resistance.

Avoid entrapment of liquid in the pump and associated

piping due to closing of suction and discharge valves,

which could cause dangerous excessive pressures to

occur if there is heat input to the liquid. This can occur if

the pump is stationary or running.

Page 7 of 40 flowserve.com

Page 8

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Bursting of liquid containing parts due to freezing

must be avoided by draining or protecting the pump

and ancillary systems.

Locking system for mechanical seals must be

monitored for leaks of the delivery medium and the

locking medium.

Where there is the potential hazard of a loss of a seal

barrier fluid or external flush, the fluid must be monitored.

If leakage of liquid to atmosphere can result in a

hazard, install a liquid detection device.

1.6.4.7 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions. Where there

is a risk from such tools or materials, maintenance

must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (See section 8, Maintenance.)

1.7 Nameplate and safety labels

1.7.1 Nameplate

For details of nameplate, see the Declaration of

Conformity, or separate documentation included with

these User Instructions.

1.7.2 Safety labels

Oil lubricated units only:

1.8 Specific machine performance

1.8.1 General

For performance parameters see section 1.5, Duty

conditions. Where performance data has been supplied

separately to the purchaser these should be obtained

and retained with these User Instructions if required.

1.8.2 Ecodesign

EU regulation 547/2012 of the Directive

2009/125/EC, for the minimum efficiency of defined

classes of water pumps requires that products must

show their Minimum Efficiency Index (MEI) value.

The EU benchmark MEI ≥ 0.70. Also product

information must be available to users.

Performance curves will have been provided with the

quotation or order or are available at flowserve.com.

The efficiency of a pump with trimmed impeller is

usually lower than that of a pump with the full impeller

diameter. Trimming of the impeller will adapt the

pump to a fixed duty point, leading to reduced energy

consumption. The minimum efficiency index (MEI) is

based on the full impeller diameter.

The operation of this water pump with variable duty

points may be more efficient and economic when

controlled by, for example, by the use of a variable

speed drive that matches the pump duty to the system.

Page 8 of 40 flowserve.com

Page 9

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Information on benchmark efficiency is available at;

www.europump.org/efficiencycharts

EU Regulation 547/2012 requires the statement on a

product nameplate:

MEI ≥ 0.10 [--.-]. (Between 01 January 2013 and

31 December 2014.)

MEI ≥ 0.40 [--.-]. (From 01 January 2015.)

1.9 Noise level

In principle, any noise emission should be avoided as

far as possible at the location of origin. If the noise

protection cannot be reduced by suitable measures to

the values approved by regional laws, the concerned

staff must be provided with personal hearing protection.

Attention must be given to the exposure of personnel

to the noise, and local legislation will define when

guidance to personnel on noise limitation is required,

and when noise exposure reduction is mandatory.

This is typically 80 to 85 dBA.

Submerged motor pumps are in principle submerged

in fluid during operation. This fluid jacket has a

dampening impact so that the noise pressure level of

the units is lower or equal to 70 dB(A). Noise

generation from pipelines and valves must be

evaluated by the operator

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Submersible pumps are subjected to a thorough

inspection before leaving the factory and are supplied

with operating instructions for fitting, starting, care etc

that conform to international safety regulations.

Immediately after receipt of the equipment it must be

checked against the delivery and shipping documents

for its completeness and that there has been no

damage in transportation. Any shortage and or damage

must be reported immediately to Flowserve and must

be received in writing within one month of receipt of the

equipment. Later claims cannot be accepted.

Check any crates, boxes and wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling and lifting

Take special care when handling the

pump unit. Make certain that it does not hit against

walls, steel structures or floors etc.

2.2.1 Erection of long units

For transport, ensure that the hoist

has an adequate carrying capacity.

Units less than 1 000 kg (2 200 lb.) do not

carry any weight information.

Units that are delivered or stored in several sub-

assemblies due to extreme length must be

assembled during installation into the well. Special

fitting instructions must be requested from the

manufacturer for this.

A unit that is shipped on a transport rail due to its

extreme length must be lifted into the vertical position on

this rail (ie an auxiliary carrier) before fitting into the well.

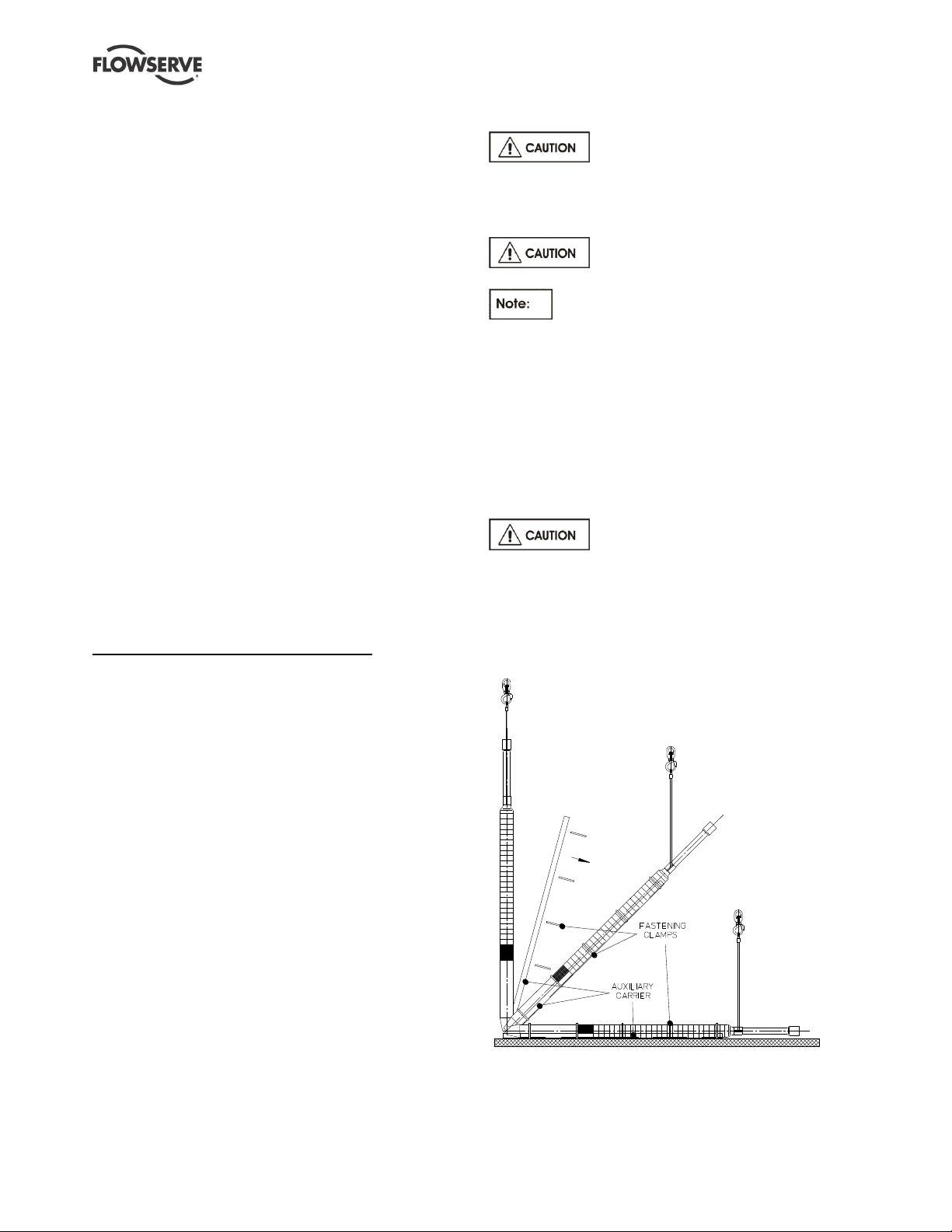

Due to the danger of sagging, pump

units that exceed the permissible length must be

supported by an auxiliary carrier (U or H carrier) when

lifted into the vertical position. This carrier may only be

removed after the pump unit is hanging vertically from

the crane or lifting block. (See figure 2-1.)

Figure 2-1

When assessing the diameter of the unit, use the

smaller size from the pump and motor. This can be

found on the rating plate or the data sheet.

Page 9 of 40 flowserve.com

Page 10

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Rated diameter

Permissible length

6 in. (152 mm)

3.3 m (10.8 ft)

8 in. (203 mm)

3.5 m (11.5 ft)

10 in. (254 mm)

4.4 m (14.4 ft)

12 in. (305 mm)

4.7 m (15.4 ft)

Table 2-1

Under no circumstances must the

power cables be used for lifting or moving the motor.

2.3 Storage

Store the pump unit vertically in a dry,

well ventilated location. If it cannot be foreseen when

the unit will be installed, the following instructions

must be followed:

2.3.1 General remarks

Submersible pump units need special

storage conditions. For functional reasons some

inner parts (eg the stator and rotor plates) cannot be

produced from corrosion-resistant materials and are

therefore sensitive to any type of air humidity.

All units may basically be stored either in a filled or

unfilled condition; however these two types of storage

require different treatment of the unit.

All units must be stored vertically,

secured appropriately in this position to prevent

tipping over.

The leads of the power cables must

be protected from moisture. Ensure that the power

cables and, if applicable, the signal cables are not

bent during storage.

2.3.2 Requirements for the storage area

The storage area must be well ventilated.

Air humidity should be in a range of 40 to 60 %.

Temperatures:

+50 to -25 °C (+122 to -13 °F) for units with

unfilled motors

+50 to 0 °C (+122 to +32 °F) for units with MX

type motors (water-filled without antifreeze)

+50 to -15 °C (+122 °F to +5 °F) for units with

motors originally filled by the manufacturer

For temperatures down to -15 °C, (+5 °F) see the

guidelines in the instructions for filling submersible

pump motors in section 0, 6.1 Antifreeze.

2.3.3 Storing for up to four weeks

No special arrangements are required.

2.3.4 Storing between one and 24 months

For storage between one and 24 months, it is

recommended that the shaft of the unit be turned at

intervals of approximately 8 weeks. For this it may be

necessary to remove a mounted pressure housing,

including the check valve. On pump units where this is

not possible, the pump and motor must be separated.

If needed, separate instructions should be requested

from the manufacturer.

2.3.5 Storing for over 24 months

If the pump unit is stored for more

than 24 months a complete visual inspection at the

Flowserve manufacturing plant is recommended. An

authorised Flowserve factory representative can also

carry out this inspection.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local requirements.

If the product contains substances that are harmful to

the environment, these should be removed and

disposed of in accordance with current regulations.

This also includes the liquids and or gases that may

be used in the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3 DESCRIPTION

3.1 Technical data

Each unit is individually manufactured to the special

requirements of the customer. The specific technical

data regarding head, delivery rate, current requirement,

minimum permissible flow velocity on the external motor

surfaces etc can be found in the data sheet delivered

with the unit or in the order confirmation.

3.2 Delivery contents

Pump unit

These User Instructions

Technical data sheet

Page 10 of 40 flowserve.com

Page 11

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

3.3 General data

3.3.1 Normal operating conditions

Temperature: see data sheet

Sand content: max. 25 mg/l (0.03 oz/fl.oz)

Water velocity along motor surface: see data

sheet

No impurities that could lead to deposits and

blockages within the pump or to deposits on the

motor surface

No water hammer

Maximum 3 minutes operation against closed

slide valve

Refer to section 7.1.2., First

switching on.

Operation within prescribed voltage tolerances

Permissible operational range: 50 to 120 % of the

best efficiency point (BEP)

Correctly selected and adjusted motor protection

Observation of the maximum permissible starting

frequency

If other working conditions are

required please contact Flowserve for advice.

Other uses or applications must be agreed by the

manufacturer.

Power cables and, if applicable, signal cables are

fixed to the riser pipes by means of cable clips.

The ideal construction of a water supply system is

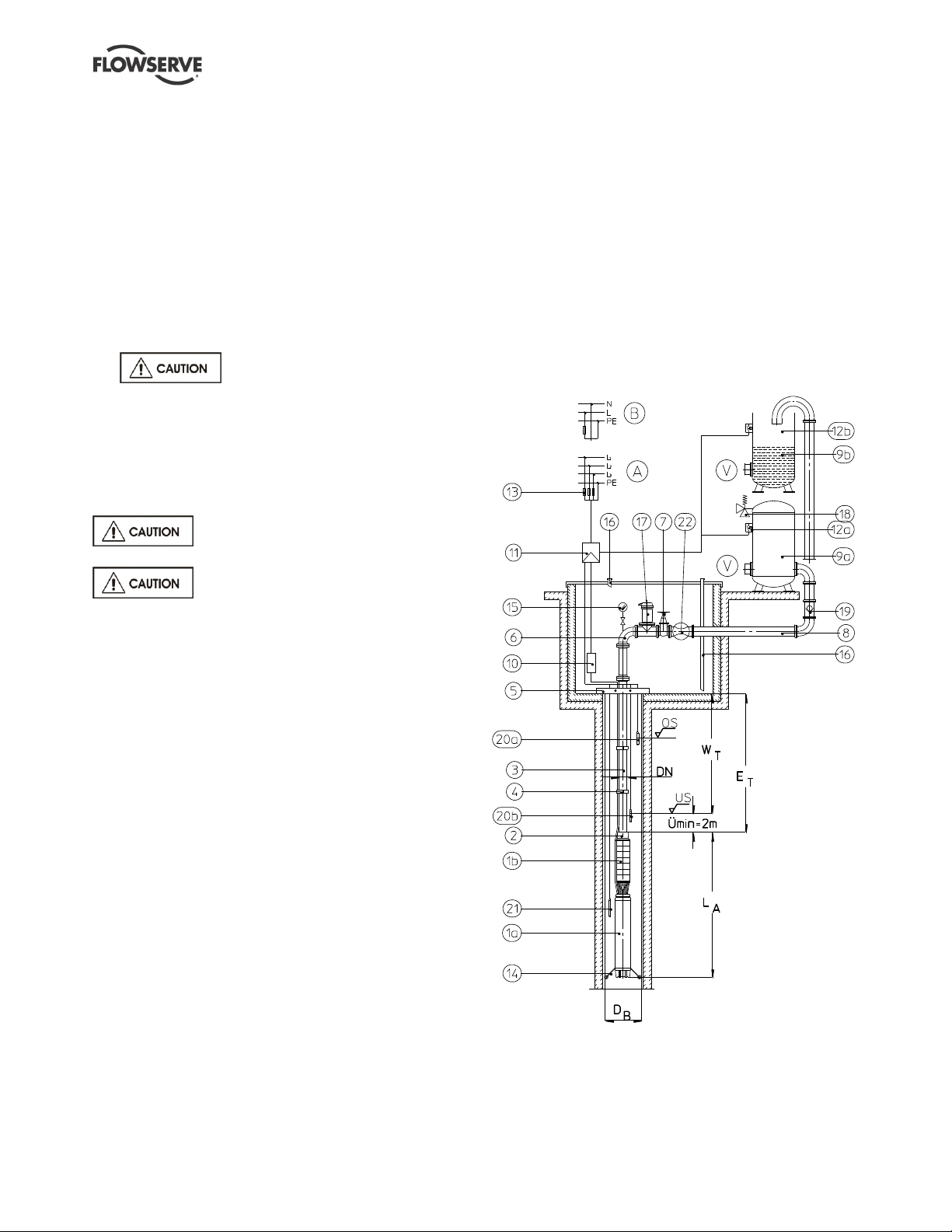

shown in figure 3-1. Since this shows a basic

arrangement, the actual layout must be adapted to

local and technical conditions.

The additional listed components are

recommendations for operational safety and the

protection of the pump unit.

Figure 3-1: Water supply system

At higher ambient temperatures

and/or lower flow velocities on the external motor

surfaces, or if there is risk of clogging, special

measures for heat dissipation are required. This

must be checked with the manufacturer by indicating

the ambient conditions. In this case the suitability of

the unit for its planned application must be confirmed

by the manufacturer.

3.4 General description

Submersible-motor pumps are subjected to a thorough

inspection before leaving the factory and are supplied

with operating instructions for fitting, starting and care

that conform to general safety regulations.

Standard submersible-motor pumps are used to

transport cold clean water under normal operating

conditions.

The Pleuger submersible-motor pump has been

developed for installation in wells and as a result has a

distinctive slim design. The Pleuger submersible-motor

pump, because of its various features, can also be used

for other applications with different design modifications.

The submersible motor pump consists of a submersible

motor, a submersible pump and usually a check valve.

The complete pump unit is freely suspended on the

rising main which is supported at the wellhead.

Page 11 of 40 flowserve.com

Page 12

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Ref.

Description

1a

Submersible motor

1b

Submersible pump

2

Check valve

3

Riser pipe

4

Cable clips

5

Support clamp

6

Elbow

7

Control valve

8

Delivery pipe

9a

Pressure vessel

9b

High level tank

10

Terminal box for power cable

11

Switchgear or switchboard

12a

Pressure switch

12b

Float switch

13

System fuses

14

Centering device

15

Pressure gauge

16

Well shaft vents

17

Double orifice air valve

18

Safety valve

19

Check valve (optional)

20a

Water level detector, upper

20b

Water level detector, lower

21

Pressure sensor for water level measuring system

22

Flowmeter

As the motor is hermetically sealed and equipped

with a pressure/volume compensating device the

motor filling remains in the motor for the duration of

operation.

On motors larger than 10 in. (254 mm) an impeller

fitted on the motor shaft provides an internal water

circuit for better cooling.

When the unit is operating, the motor filling-water

becomes warm and increases in volume. Excess water

is released through a vent valve/pressure relief valve

located at the top of the motor. After the unit is switched

off, the filling-water cools down and the volume

decreases. A breather diaphragm compensates for the

lower pressure resulting from the decrease in volume.

This arrangement avoids under-pressure in the motor

and the ingress of pumped medium. The change of

volume by varying temperatures continues over the

For safe operation, the following are also

recommended:

entire lifetime of the pump unit.

Although the motor filling-water and the pumped

liquid surrounding the motor will mix if there is

leakage from the seals, the motor remains operative

due to its water-lubricated journal bearings.

Explanations and abbreviations:

DB Well diameter

ET Installation depth

LA Unit length incl. check valve

US Lower operating level = dry running protection

OS Upper operating level (only for automatic operation

Ü Minimum water level above pump outlet

V To the consuming device

WT Minimum (dynamic) water level

(depending on NPSH)

A Connection for a three-phase motor

B Connection for a single-phase motor

3.5 Submersible motor

The so-called “wet” electric motor is a water-filled

three-phase AC squirrel-cage motor with a watertight

winding, which is operating in water and is designed

especially for direct drive of submersible pumps. The

motor filling-water cools the winding and bearings as

well as lubricating the thrust and radial bearings.

The submersible-motor-pump is connected to the

lower end of a riser pipe and submerged in the

pumped medium. The power supply is through water

resistant power cables fastened to the riser pipes with

cable clips.

For operation the motor must be filled with potable

At lower installation depth the motor can, on

customer request, be equipped with a header tank

connected to the motor with a filling and venting

pipeline instead of a pressure compensating system.

Basically, “wet” motors operate maintenance-free

with the ammeter acting as a monitoring device.

The internal temperature of the motor can be

monitored with one or two additional temperature

sensors mounted inside the end coils of the motor

winding. These sensors can trigger a high

temperature warning signal or switch off the motor.

3.5.1 Stator winding

The stator winding consists of winding wire provided

with special insulation.

The power cables are connected to the winding by a

special watertight splice and leave the motor through

stuffing boxes.

The winding and cable connections are tested at high

voltage according VDE 0530 IEC60034-1 immersed

in water, at twice the operating voltage plus 1 000

volts, or a minimum of 2 000 volts.

water. Antifreeze can be added to the potable water

if there is a risk of freezing.

Page 12 of 40 flowserve.com

Page 13

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

3.5.2 Rotor

The rotor winding consists of induction welded copper

bars with short-circuit rings. The rotors are

dynamically balanced and are protected against

corrosion by a protective varnish. The drive shaft end

is made of stainless steel.

3.5.3 Bearings

The "Michel type" axial thrust bearing is located in the

motor base and is designed to handle very high thrust

loads; it is dimensioned so that it can support the

axial thrust of the pump rotating assembly as well as

all hydraulic loads.

The thrust bearing is bi-directional. A fixed counterthrust bearing is also provided. The journal bearings

are slide bearings.

The motor filling liquid lubricates the journals and

thrust bearings.

3.5.4 Mechanical seal

The motor is equipped with a single directional

operating mechanical seal, which can operate in both

directions of rotation.

3.5.5 Starting procedures

The motors can have different operating modes and

starting procedures. Essentially, these are:

Direct-on-line (DOL)

Star-delta starting

Starting via an auto-transformer

Starting via soft-starter. (See also section 3.5.6,

Starting via soft-starter.)

Static-frequency converter operating. (See also

section 3.5.7, Static-frequency converter operating

with submersible motors.)

Single-phase motor - refer to Flowserve

For direct-on-line (DOL), Star-delta starting and starting

via an auto-transformer the electrical data and the

connection diagram for the motor have to be followed.

These are marked in the technical data sheet.

For all other operating modes special procedures

have to be followed that are described in detail below.

3.5.6 Starting via soft-starter

Pleuger submersible motors can be operated via

“soft-start and soft-stop devices”. These instructions

relate to radial and mixed flow pumps.

Axial flow pumps must be referred to the

manufacturer on an individual basis.

A compensation-capacitor must not be installed at the

junction between soft-start and soft-stop devices and

the motor.

Power output reduction is not necessary if the

conditions in section 5.6, Adjustments for soft-starter

and soft stop devices, are observed.

Soft-start ramp up and soft-stop ramp down times

must be clarified with the manufacturer after the

hydraulic system data is finalised.

3.5.7 Static-frequency converter operating with

submersible motors

Technical data needs to be taken from the

specific data sheet.

For submersible motors that are later converted to

static-frequency converter operation, the required

data must be requested from the manufacturer.

3.5.8 Direction of rotation

The direction of rotation depends on the pump type.

Reversing two phases of the power supply will

change the direction of rotation of all three-phase

squirrel-cage motors. (Changing the direction of

rotation of a single-phase motor is not possible.)

3.5.9 Resistance thermometer PT100 (RTD)

Either one or two temperature sensors PT100 (RTD)

are installed with pressure and watertight connections

to a signal cable. As the temperature sensors are

mounted on the winding head they can only be

removed after dismantling the motor.

3.6 Pump and check valve

Radial or semi-axial centrifugal pumps are used as

single or multistage pumps. The pump stages of

pump types NB6 and NB8 are bolted together with

tie-bolts. The pump bowls of all other types of pumps

are bolted together one by one.

The dynamically balanced impellers are fixed to the

pump shaft by means of keys. The pump shaft runs

in journal bearings that are lubricated by the pumped

medium.

Power transmission for 6 in. (152 mm) and 8 in.

(203 mm) motors is via a spline coupling; on all other

motors a keyed coupling is used.

The check valve of pump types NB6 and NB8 is an

integral part of the pump. On all other pump types

the check valve is an independent part, mounted onto

the discharge casing of the pump.

Page 13 of 40 flowserve.com

Page 14

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

4 INSTALLATION

4.1 Hydraulic installation

A typical design for a water supply system is shown

in figure 3-1, Water supply system. As this shows a

basic arrangement, the actual layout must be

adapted to local conditions. (The additional

components listed are recommendations for

operational safety and protection of the pump unit.)

4.2 General advice for installation

The following criteria must be taken into account to

determine the installation position and depth:

Vertical installation in the well above the filter line,

so that an adequate motor cooling flow is

guaranteed along the external motor surface

Sufficient water cover

Static water level at least 2 m (6.6 ft.) above the

pump outlet

A dynamic water level above the suction housing,

taking into account the required NPSH for the

pump. (See pump characteristic curve.)

Flow rate. (See pump characteristic curve.)

Supply conditions of the pumping medium

(depends on the installation conditions)

Regardless of the above, the pump

unit should be installed above the well screen

whenever possible, to avoid foreign matter being

drawn directly into the pump inlet, and also to ensure

that there is sufficient water flowing across the motor

to assist heat transfer. If this is not possible a flow

shroud should be provided to induce the flow of water

over the motor.

Pump units can only be operated with

a completely filled and immersed motor. The liquid

level of the motor must always be checked before

installation and, if necessary, adjusted according to the

information on the data card supplied with the motor.

4.3 Flexible hose riser pipe

If a flexible hose is used instead of

steel pipes, these will twist against the direction of

rotation of the motor when it is switched on,

depending on the locked rotor torque of the motor. In

this case, the power cable (and, if provided, the

signal cable) fastened to the riser hose would also

twist and tighten. To prevent the cables being pulled

out of their junction boxes, they should not be laid

parallel to the riser hose but wound around it in the

opposite direction to the rotation of the motor. The

number of turns required will depend on the length

and stiffness of the riser hose line and the locked

rotor torque of the motor. The exact operating

characteristics will need to be requested from the

hose manufacturer.

4.4 Centralizers

When pump units are installed in narrow wells the

risers, whether steel pipes or hose lines, will need to

be centralized to prevent them from touching the wall

of the well which could cause damage to any cables

fastened to them.

4.5 Checks before installation

Before beginning installation, check the

dependability of auxiliary equipment, particularly

hoists, as well as comparing the information on the

data sheet with that on the rating plate on the motor.

Ensure that the line voltage (measured between two

phases) is equal to the motor voltage shown on the

rating plate.

The maximum permissible voltage fluctuation can be

seen in the data sheet. Greater voltage and frequency

fluctuations must be stated in the order and confirmed by

the factory. In case of doubt, contact Flowserve or the

nearest factory representative before starting up the unit.

Before installing, the insulating resistance of the

motor must be measured as shown in section 8.3,

Measuring insulation.

Ensure that the well diameter is large enough down

to the installation depth, so that the pump unit can be

installed without difficulties. If the riser connections

are made of pipes with flanges, these must have cut

outs for the cable if the well diameter is narrow.

When lowering the unit, ensure the power cable is

neither squeezed nor scraped. To protect the power

cables, we recommend that the well head is lined

with a rubber sheet at the entry point of the power/

signal cable into the well pipe and it is fed into the

well shaft using a cable roller. (See figure 4-1.)

During lowering, the unit must always hang freely and

must not become wedged in the well shaft. Always

ensure that the pump can be rotated freely. If

needed, attach a cable clip every 3 m (approx. 10 ft.)

of pipe length.

For especially narrow and deep wells, the insulating

measurements shown in section 8.3, Measuring

insulation, should be repeated to determine possible

damage to the power cables in time.

Page 14 of 40 flowserve.com

Page 15

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

g) When this has been completed lift the unit

sufficiently to enable the supporting clamp to be

removed.

Do not allow the pipe to be lowered or to

slip whilst carrying out this operation. This could

result in damage to hands and in extreme cases

loss of fingers.

h) Install the remaining riser pipes as described

from point b) to e).

i) Finally mount the wellhead support plate onto the

last length of riser pipe. Feed the power cables

and, if necessary, the control lines and/or

instrument leads through the corresponding holes

in the wellhead support plate and connect them

to the junction box or control panel.

4.8 Riser pipe with pipe socket

(Reference “B” in figure 4-1.)

a) Connect a lifting clamp underneath the pipe

socket of the screwed riser pipe and lift the

complete pump unit with a suitable hoist.

b) Lower the pump unit into the well as far as the

installation clamp mounted underneath the socket

of the riser pipe.

c) Lower the unit and rest it on the well rim flange.

Figure 4-1

4.6 Installation of pre-assembled pump

units

Mount the first length of pipe, which should not be

longer than 1 m (39 in.), onto the assembled pump unit.

Fasten the power cables, control lines and instrument

leads (if any) with cable clips onto the pipe.

4.7 Riser pipes with flange connections

(Reference “A” in figure 4-1.)

a) Mount a "lifting dolly” to the riser pipe flange, and

hang the complete unit on a suitable hoist.

b) Lower the pump unit into the well, allowing

sufficient pipe to protrude above the well to

enable the installation clamp to be mounted onto

the riser pipe.

c) Continue to lower the unit until the installation

clamp rests on the well rim flange.

d) Remove the lifting dolly, and attach it to the next

riser pipe to be installed.

e) Fasten the power cable, control lines and

instrument leads (if any) with cable clips to the

riser pipe.

f) Lift the next pipe to be installed into a vertical

position and bolt it to the pipe resting on the well

rim flange.

Do not let the pump unit slip

through the installation clamp.

j) Remove the lifting clamp and attach it to the next

riser pipe and connect this to the pipe already

installed.

k) Fasten the power cables and, if necessary, the

control lines and/or instrument leads with cable

clips onto the riser pipe.

l) Lift the unit and remove the resting supporting

clamp.

m) Install the remaining riser pipes as described

from point b) to f).

n) Finally mount the wellhead support plate onto the

last riser pipe. Feed the power cables and, if

necessary, the control lines and/or instrument

leads through the corresponding holes in the

wellhead support plate and connect them to the

junction box or control panel.

4.9 Assembly of submersible motor

pumps before installation

Submersible motor pump units that are delivered in

sub-assemblies have to be assembled during or

before installation. For assembly of these submersible

motor pump units the specific installation instructions

have to be requested from the manufacturer if they

have not been delivered with the unit.

Page 15 of 40 flowserve.com

Page 16

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

5 ELECTRICAL CONNECTIONS

5.1 Motor

All work on the electrical system must

be performed by a qualified Electrician in accordance

with relevant local, national and international

regulations.

The connection diagrams in the following sections

show the basic structure of the connection

possibilities and the line arrangement of the mains

and motor power cable.

Detailed information about the connection of

motors and, if necessary, of control and monitoring

devices can be taken from the appropriate circuit

diagrams from the control panel manufacturer.

To ensure a good connection with the least possible

contact resistance when connecting the power lines,

the conductor ends should not be tin-plated. If the

conductor ends are tin-plated, these should be

removed. The exposed fine-strand wires must be

connected to the electrical supply with suitable

terminal screws or by crimping or soldered cable lugs.

5.1.1 Labelling of conductor ends and rotation

direction of three-phase motors

The conductor ends of the power cables are labelled

so that all three-phase motors rotate clockwise (seen

from the coupling ends and towards the shaft) when

connected to a clockwise rotating system according

to figure 5-1 to 5-5.

Counter clockwise rotation occurs if two phases of

the main connection are transposed from that shown

in the clockwise connection diagrams (compare

figures 5-7 to 5-11).

Power supply cables with round or flat cross-sections

are connected to the motor. Depending on power

consumption or if the installation circumstances are

restricted then several single core cables can be

used.

5.1.2 Single-phase motors

The direction of rotation of single-phase motors

(alternating current motors) is pre-set by the

manufacturer and cannot be changed. The rotation

direction pre-set by the manufacturer can be seen in

the data sheet. Connection can only be made using

the switching device accompanying the motor for

which the labelling of the leads can be found in figure

5-6 or 5-12.

5.1.3 Motors with one power cable

One four lead power cable is connected to the motor

for direct-on-line starting, also auto transformer

starting, starting via soft-start and soft-running-out

devices as well as for static-frequency operating

(compare figures 5-1 and 5-7), if the current load of

the leads allow it.

5.1.4 Motors with two power supply cables,

parallel connection

See attachment TI 01-04 E for the

interim solution for motors with old and new coloured

power supply cables until 01 April 2006.

When the rated current of a motor cannot be supplied

by one cable it is equipped with two parallel cables.

The connections for a motor with two power cables,

with parallel connection, as well as the colour and

letter labelling of the conductor ends, is shown in

figure 5-2 or 5-8.

5.1.5 Motors with two power supply cables,

parallel connection (open delta-connection)

See attachment TI 01-04 E for the

interim solution for motors with old and new coloured

power supply cables until 01 April 2006.

For motors with star-delta starting (figure 5-3 or 5-9),

motors whose star connection (figure 5-4 or 5-10) and

or delta connection (figure 5-5 or 5-11) is in the control

panel, as well as for motors provided with two different

voltages, two three-lead and or one three- and one

four-lead power cables are connected to the motor.

5.2 Protective measures against shockhazard voltage

Protective measures against shock-hazard voltages

must be taken according to IEC regulations and the

local electricity supply company ordinances.

According to IEC-regulations the protective conductor

must be connected directly to the motor on new

systems. This also applies when the unit is installed

in an inaccessible well.

If there is no earth lead on the motor, a

separate earth lead must be connected to the motor

using the earth screw supplied. This is labelled with a

symbol.

Page 16 of 40 flowserve.com

Page 17

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

IA

t

L

100 mm (4 in.)

150 mm (6 in.) or larger

1.05 x IE

> 2 hours

cold

1.,20 x IE

< 2 hours

warm

5 x IE

6 x IE

10seconds

cold

5.3 Motor protection

To protect the motor against current overload, a

thermal overload relay must be provided. The

tripping time of the relay should have temperature

compensation to allow for variations in ambient

temperature. It should also have accelerated tripping

under single-phase conditions.

Trip reset should only be possible manually.

The setting of the thermal overload relay must be

chosen according to the data sheet provided with the

pump.

For star-delta motor starters, it is important that the

protection relay is in the motor line (see figure 5-3 or

5-9). The adjusted current level will then be 58 % of

the operational current. If the protection relay has

been installed in the power line in exception to this

rule, the adjusted current is the same as the

operational current.

Table 5-1; Overload relay tripping characteristic

5.4 Short circuit protection

To prevent a short circuit in the power cable and the

motor, safety precautions must be taken according to

local regulations.

Guide values for safety fuse sizes can be found in the

data sheet.

IA = Release current

IE = operational current (rated current)

t = Delay time until release

L = Operational temperature before overload

The adjustment of the motor protection relay

(thermally delayed over current release) must be set

according to the value given in the data sheet.

The value given in the data sheet is a standard value

for the operating point. If the actual operational

current in the operating point of the pump is less than

this given value, the motor protection must be

adjusted lower so that there is effective protection

and malfunctions can be indicated in time.

The motor protection adjustment must

never be set higher than the highest permissible

value given in the data sheet. Testing the correct

operation of a motor protection switch by deliberate

single phasing is not permitted!

Page 17 of 40 flowserve.com

Page 18

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Old

New

U

=

black

V = light blue

brown

W = brown

grey

PE = green/yellow

Old

New

U1/U2 = black

V1/V2 = light blue

brown

W1/W2 = brown

grey

PE = green/yellow

Old

New

U1/U2 = black

V1/V2

=

light blue

brown

W1/W2 = brown

grey

PE = green/yellow

Old

New

U

=

black

V = light blue

brown

W = brown

grey

PE = green/yellow

Old

New

U1/U2 = black

V1/V2 = light blue

brown

W1/W2 = brown

grey

PE = green/yellow

V = light blue

UV = brown

Z

=

black

PE = green/yellow

5.5 Motor connection diagrams

5.5.1 Clockwise rotation

Figure 5-1: Direct-on-line-starting

- one power supply cable

Figure 5-3: Star-delta-stating

Figure 5-5: Direct-on-line-starting delta-connection in control panel

Figure 5-2: Direct-on-line-starting

- two power supply cables

Page 18 of 40 flowserve.com

Figure 5-4: Direct-on-line-starting

- star-connection in control panel

Figure 5-6: Single-phase motor

Page 19

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Old

New

U

=

black

V = light blue

brown

W = brown

grey

PE = green/yellow

Old

New

U1/U2 = black

V1/V2 = light blue

brown

W1/W2 = brown

grey

PE = green/yellow

Old

New

U1/U2 = black

V1/V2 = light blue

brown

W1/W2 = brown

grey

PE = green/yellow

Old

New

U

=

black

V = light blue

brown

W = brown

grey

PE = green/yellow

Old

New

U1/U2 = black

V1/V2 = light blue

brown

W1/W2 = brown

grey

PE = green/yellow

V = light blue

UV = brown

Z

=

black

PE = green/yellow

5.5.2 Counter-clockwise rotation

Figure 5-7: Direct-on-line-starting

- one power supply cable

Figure 5-9: Star-delta-stating

Figure 5-11: Direct-on-line-starting

- delta-connection in control panel

Figure 5-8: Direct-on-line-starting

- two power supply cables

Page 19 of 40 flowserve.com

Figure 5-10: Direct-on-line-starting

- star-connection in control panel

Figure 5-12: Single-phase motor

Page 20

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Motor type

Minimum permitted current limit as

% of motor rated current

M6

250

M8 up to VNI 14

300

MI 16

350

> MI 16

On request

Motor type

Maximum starts and run-outs per hour

M6

8

M8 to MI16

6

> MI16

On request

Ambient temperature

Minimum flow velocity

30 °C (86 °F)

0.5 m/s (1.64 ft/sec)

20 °C (68 °F)

0.2 m/s (0.66 ft/sec)

5.6 Adjustments for soft-starter and soft

stop devices

5.6.1 Minimum permissible current limits

Table 5-2

5.6.2 Minimum start-up voltage

On adjustable devices do not adjust the start-up

voltage lower than 55 % of the rated voltage.

5.6.3 Permissible ramp-up time

To avoid thermal overload and damage to the bearings

DO NOT adjust the ramp-up time above 5 seconds.

On units with a dual ramp-time function or pump

function the sum of the dual ramp-time must not

exceed 5 seconds. Any other ramp-up time above 5

seconds must be referred to Flowserve for approval.

Should external guidelines state differing values than

those stated above, the above values must take

precedent. This function should not be used for

speed adjustment of the motor.

5.6.4 Permissible ramp-down time

The maximum ramp-down time must not exceed 20

seconds.

On units with a dual ramp-time-function or pumpfunction the total amount of ramp-time must not exceed

20 seconds. The amount of running-out voltage in this

case must not be less than 45 % of the rated voltage.

Any other ramp-down time above 20 seconds must

be referred to Flowserve for approval.

Should external guidelines state differing values than

those stated above, the above values must take

precedent. This function should not be used for

speed adjustment of the motor.

5.6.5 Starting frequency

Table 5-3

The number of starts per hour should be spread

equally over the hour.

In addition, pay attention to the starting frequency of

the soft-start device, which could possibly be less.

5.6.6 Soft starter current limit

To have sufficient reserve for any required additional

acceleration torque, the choice of the soft-start device

must be carefully considered to ensure that the

starter can deliver at least four times the motor rated

current.

5.7 Operation of submersible motors

with static frequency converter

5.7.1 General

Motors for operation with a static frequency converter

are specially designed. Major operating criteria are

the temperature rise of the motor depending on

additional losses and the higher voltage stress on

static frequency converter operation.

5.7.2 Cooling

Generally, the flow velocity along the motor must be

guaranteed for the nominal condition according to

table 5-4.

Table 5-4

5.7.3 Starting conditions

The minimum frequency of 10 Hz must be reached

within 0.5 seconds.

5.7.4 Permissible operating frequency range

The acceptable operating frequency is from a

minimum of 10 Hz up to a maximum of the nominal

frequency. (Refer to the data card.)

In this case the allowable pumping

capacity range must be observed. (See section

3.3.1, Normal operating conditions.) This may result

in a minimum operating frequency above 10 Hz.

5.7.5 Maximum voltage stress

The rise in voltage should be less than 500 V/µs and

be limited to 1.5 UN.

5.7.6 Power cable

Shielded power cables should be used at the top of the

borehole/well. The cables between the submersible

motor and the surface connections must be installed in

an adequate Cu-mesh shield that is extensively earthed

on both sides.

Page 20 of 40 flowserve.com

Page 21

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Motor filling

type

“FSM1”

% volume

Water

% volume

Protection

down to:

MF 15 *

35

65

- 15 °C (5 °F)

MF 20

40

60

- 20 °C (-4 °F)

MF 25

45

55

- 25 °C (-13 °F)

MF 30

50

50

- 30 °C (-22 °F)

Filled

Unfilled

M 6

MX6

M 8

MX8

MI 10

MIX10

VNI 12

VNI 14

MI 16

MI 19

VNI 22

MI 26

VNI 30

Any power supply cables must be sized for this higher

voltage, depending on the static frequency converter.

Follow the instructions of the manufacturer of

the frequency converter regarding the maximum

length of the power cables.

The signal cables for temperature sensors should be

installed at a distance as far as possible from the high

voltage power cables.

5.8 Resistance sensor PT100 (RTD)

Figure 5-13: Standard connection diagram for one

PT100 (RTD)

Figure 5-14: Standard connection diagram for two

PT100 (RTD)

regions only) filled only with drinking water. For

specifically ordered units filled only with drinking

water the client is responsible for ensuring that

storage and use do not permit freezing.

This standard concentration is always the same

unless the customer or operator expressly states a

different preference.

For units supplied with a header tank, the fitting of an

audible or visual alarm is recommended to monitor the

filling level of the motor in case of leakage. This can be,

for example, a float switch installed in the overhead tank.

6.1 Antifreeze

Only MF-type motor filling should be

used as antifreeze.

6.1.1 Motor filling - MF-type

MF-type motor filling is a liquid consisting of “FSM1”

antifreeze and water. “FSM1” antifreeze is

manufactured based on propylene-glycol. The mixing

ratios must be prepared according to table 6-1.

Table 6-1

5.8.1 Adjustment of motor temperature

protection relay

The adjustment of the motor temperature protection

relays depends on the rated output and the flow

conditions along the motor surface. The permissible

temperatures are shown on the enclosed data sheet

as far as the motor is equipped with Pt100 resistance

sensors. Examples of values are:

At 60 °C (140 °F) high temperature: early warning

At 65 °C (149 °F) high temperature: motor shut down

6 MOTOR FILLING

The motor must be filled with clean, oil-free and

grease-free drinking water, to which antifreeze can be

added if there is a risk of freezing.

Never use distilled water.

All motors delivered ready-filled by the manufacturer

have antifreeze added which gives protection down to

-15 °C (5 °F) unless specifically ordered (certain

* Standard filling

6.1.2 As-delivered state

These instructions apply to the motor types listed in

table 6-2. They are also applicable to Polder pumps,

prefixed with a “P”. As a general rule, all motors are

delivered as shown in table 6-2.

Table 6-2

Every motor carries a label indicating its state of filling

on delivery.

Yellow label = filled

Green label = unfilled

In all cases the state of filling stated on the label must

be observed.

Page 21 of 40 flowserve.com

Page 22

PLEUGER STANDARD USER INSTRUCTIONS ENGLISH 71569293 01-13

Motor type

Filling quantity

litres

US gal

M 6

MX6

4 to 4.5

1 to 1.2

M 8

MX8

8.5 to 9

2.2 to 2.4

MI 10

MIX10

15 4 VNI 12

35 to 40

9 to 11

VNI 14

53 to 60

14 to 16

MI 16

75

20

MI 19

150

40

VNI 22

200

53

MI 26

300

80

VNI 30

360

95

Designation

Diagram

Size

Part. no.

Vent valve

< 0.3 bar

B6523

> 0.8 bar

Filling valve

R³/8 in.

B6514

R³/4 in.

Screw plug

R³/8 in.

6780

R³/4 in.

M16 x 1.5

Filling screw

- -

- -

Protection cap

- -

0236

Filling nipple

M10

(2)

M16

6.1.3 Topping up of pre-filled motors

Topping up of pre-filled motors can be done with

potable water without antifreeze if the quantity of

topping up liquid is relatively small (1-2 %).

6.2 Type of use

The filling of motors depends not only on the motor

size and type, but also on the type of use. The

standard uses are described below.

6.2.1 Vertical installation

Normal design

Normal design in cooling/suction shroud

Normal design in closed shroud

Polder pump

Cavern pump

6.2.2 Horizontal installation

Normal design

Normal design in closed shroud

Pumping station

Heeling pump

6.3 Filling quantities

The filling quantities stated in table 6-3 are

approximate and may vary slightly due to differing

lamination lengths.

Table 6-3

Table 6-4: Accessories and hardware

6.5 General information about filling

The 6.5 General information about filling in this

section applies to all motor types, unless stated

otherwise in the individual descriptions. If units that

require filling are not mentioned in these instructions,

special instructions must be requested from the

manufacturer.

6.5.1 Filling pressure

6.4 Accessories and hardware for filling

and topping up

Motors must be filled and topped up as shown in the

descriptions and accompanying diagrams from

section 6-6, Filling instructions, onwards.

The various components referred to in the individual

descriptions and diagrams are summarized here for