Page 1

Worcester Actuation Systems

WCAIM2026

DataFlo Digital Electronic Controller DFC17

Installation, Operation and Maintenance Instructions

MODELS:

10 - For

DataFlo

Boards Mounted Inside 10-23 75 Actuators.

25 - For

DataFlo

Boards Mounted Inside 25/30 75 Actuators.

Setpoint Inputs:

DFC17-1K (120A, 240A, or 24D) 1000 ohm Resistance

Setpoint Input

DFC17-13 (120A, 240A, or 24D) 135 ohm Resistance

Setpoint Input

DFC17-1 (120A, 240A, or 24D) 1 to 5 mA Setpoint Input

DFC17-4 (120A, 240A, or 24D) 4 to 20 mA Setpoint Input

DFC17-10 (120A, 240A, or 24D) 10 to 50 mA Setpoint Input

DFC17-5V (120A, 240A, or 24D) 0 to 5 VDC Setpoint Input

DFC17-XV (120A, 240A, or 24D) 0 to 10 VDC Setpoint Input

Voltages:

120A - 120 VAC Power Circuits

240A - 240 VAC Power Circuits

24D - 24 VDC Power Circuits

Page 2

2

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

TABLE OF CONTENTS

Page

1.0 GENERAL 4

1.1 Basic Design 4

1.2 Environmental Considerations 4

1.2.1 Temperature 5

1.2.2 Humidity 5

1.2.3 Input Circuit Noise Protection 5

2.0

DataFlo

ELECTRONIC POSITIONER CIRCUIT BOARD 5

2.1 General 5

2.2 Circuit Board Configurations 8

2.3 LED Indicators 8

2.4 Controls (Override) 8

2.5 AC Power Control 8

3.0 WIRING OF DIGITAL CONTROLLER AND SERIES 75 ELECTRIC ACTUATOR 8

3.1 Actuator Power 8

3.1.1 Wire Size 8

3.1.2 Termination and Voltage 8

3.1.3 Minimum Fuse Ratings 8

3.2 Input Signal Connections 9

3.2.1 Milliamp 9

3.2.2 Resistive 9

3.2.3 DC Voltage 9

3.3 4–20 mA (4–75) Position Indicator Option Connections 9

4.0 OPERATION OF THE DIGITAL CONTROLLER 12

4.1 Run Mode 12

4.1.1 Run Mode Menu 12

4.1.2 Mode Change Key Sequence 12

4.1.3 Alarm Displays 12

4.2 Calibration Mode 12

4.2.1 Calibration Mode Menu 12

4.2.2 Key Sequences for Calibrating Setpoint Lower Limit 12

4.2.3 Key Sequences for Calibrating Setpoint Upper Limit 12

4.2.4 Key Sequences for Calibrating Clockwise Position 12

4.2.5 Key Sequences for Calibrating Counter-clockwise Position 14

4.2.6 Key Sequences for Calibrating Analog Process #1 Lower Input Signal 14

4.2.7 Key Sequences for Calibrating Analog Process #1 Upper Input Signal 14

4.2.8 Key Sequences for Calibrating Single-Channel RTD Process Module 14

4.2.9 Key Sequences for Calibrating Optional Two-Channel RTD Process Module 15

4.2.10 Key Sequences for Calibrating Thermocouple Process Module 16

4.2.11 Key Sequences for Calibrating Cycle Time 17

4.3 Program Mode 17

4.3.1 Program Mode Menu 18

4.3.2 Instructions for Editing Parameters 18

4.3.3 Default Values for Process Control (factory installed) 18

4.4 Manual Setpoint Mode 18

4.5 Manual Position Mode 18

4.6 Positioner Mode 18

Flow Control Division

Worcester Actuation Systems

Page 3

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 3

4.7 Auto-Tuning Safety Considerations 21

4.7.1 Things to Know Before Tuning 21

4.7.2 Safety Concerns During Operation 21

4.8 Controller Setup 21

4.8.1 General Setup 21

4.8.2 Tuning the Controller Automatically (Open-Loop Tuning) 21

4.8.3 Tuning the Controller Manually 22

4.8.4 Some Guidelines for Control Parameters 22

5.0 TECHNICAL DATA 23

5.1 Allowable Supply Voltage Range 23

5.2 Analog Input Circuit Specifications 23

5.3 Output Circuit Specifications 23

5.4 Input Circuit Load Resistances 23

6.0 TROUBLESHOOTING 24

6.1 General 24

6.1.1 Cam Adjustment 24

6.1.2 Check Fuse F1 24

6.1.3 Check Basic Actuator for Proper Operation 24

6.1.4 Check for Noise Problems 24

6.1.5 Replace Circuit Board 24

6.2 Symptom Table 25

6.3 Troubleshooting Guidelines 26

Flow Control Division

Worcester Actuation Systems

Page 4

4

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

1.0 GENERAL

1.1 Basic Design

The Worcester/McCANNA

DataFlo

Digital Electronic Controller

(DFC17) was designed for use with the Worcester/McCANNA

Series 75 electric actuators. However, it may also be used with

other actuators or electrically operated rotary devices, provided

the specified load parameters as given in Section 5.3 are not

exceeded.

CAUTION: This controller is sensitive to electrical noise;

please see Section 1.2

PLEASE READ THIS SECTION

A. The 4–20 mA Setpoint signal input circuit of both the AC

and DC Digital Controller board is protected with a 62 mA

fuse (F1). The fuse is used to protect the input circuit

from an excessively high voltage. The fuse used in the

input circuit is a Littlefuse PICO II very fast-acting fuse

rated at 62 mA.

All DC Digital Controller boards also use a standard 1

1

/

4",

250 volt, 3 amp fuse (F2) to protect the circuit board and

the power source in case of a fault in the DC motor driver

integrated circuit on the circuit board.

CAUTION: It is important that the DC voltage power

source be connected properly to the actuator’s terminal

strip. Terminal one (1) of this strip is to have the

negative or common wire connected to it. Terminal two

(2) is to have the positive wire connected to it.

Note: All wiring to terminal strip should be inserted only

to mid-point of terminal strip.

For 240 VAC Digital Controller only, limit switches do not

directly control the motor(s). Therefore, the actuator will

not stop when the limit switches trip. Use care not to

drive the actuator past its normal limits.

B. The Digital Controller board requires both a setpoint input

signal and a process input signal.

C. The Digital Controller board can be set up in several ways

for normal operation. The board is designed to control in

90° quadrants only (with alternate potentiometer gearing,

180° of rotation is available). The number of quadrants

over which the board will control is determined by the

number of teeth on the feedback pot pinion gear.

D. Quite often when we receive an actuator for repair, we

find that the only thing wrong with the unit is that the

feedback potentiometer is out of calibration. It is very

important that the feedback pot be properly calibrated for

correct operation of the Controller board. It is also very

important that the actuator shaft not be rotated out of the

quadrant for which the feedback potentiometer has been

calibrated. Whenever you have a problem with the

Controller calibration, always check the feedback

potentiometer calibration first. See paragraph 6.3.6 in the

troubleshooting section.

1.2 Environmental Considerations

CAUTION: The

DataFlo

Digital Electronic Controller is sensitive

to electrical noise on signal, process, or supply lines and in

the environment. For maximum controller sensitivity, the

electrical noise level should be as low as possible. Follow

installation and calibration guidelines carefully and use

shielded wire as stated in paragraph 1.2.3.

Flowserve recommends that all products which must be stored

prior to installation, be stored indoors, in an environment

suitable for human occupancy. Do not store product in areas

where exposure to relative humidity above 85%, acid or alkali

fumes, radiation above normal background, ultraviolet light,

or temperatures above 120°F or below 40°F may occur. Do not

store within 50 feet of any source of ozone.

Temperature and humidity are the two most important factors

that determine the usefulness and life of electronic equipment.

Flow Control Division

Worcester Actuation Systems

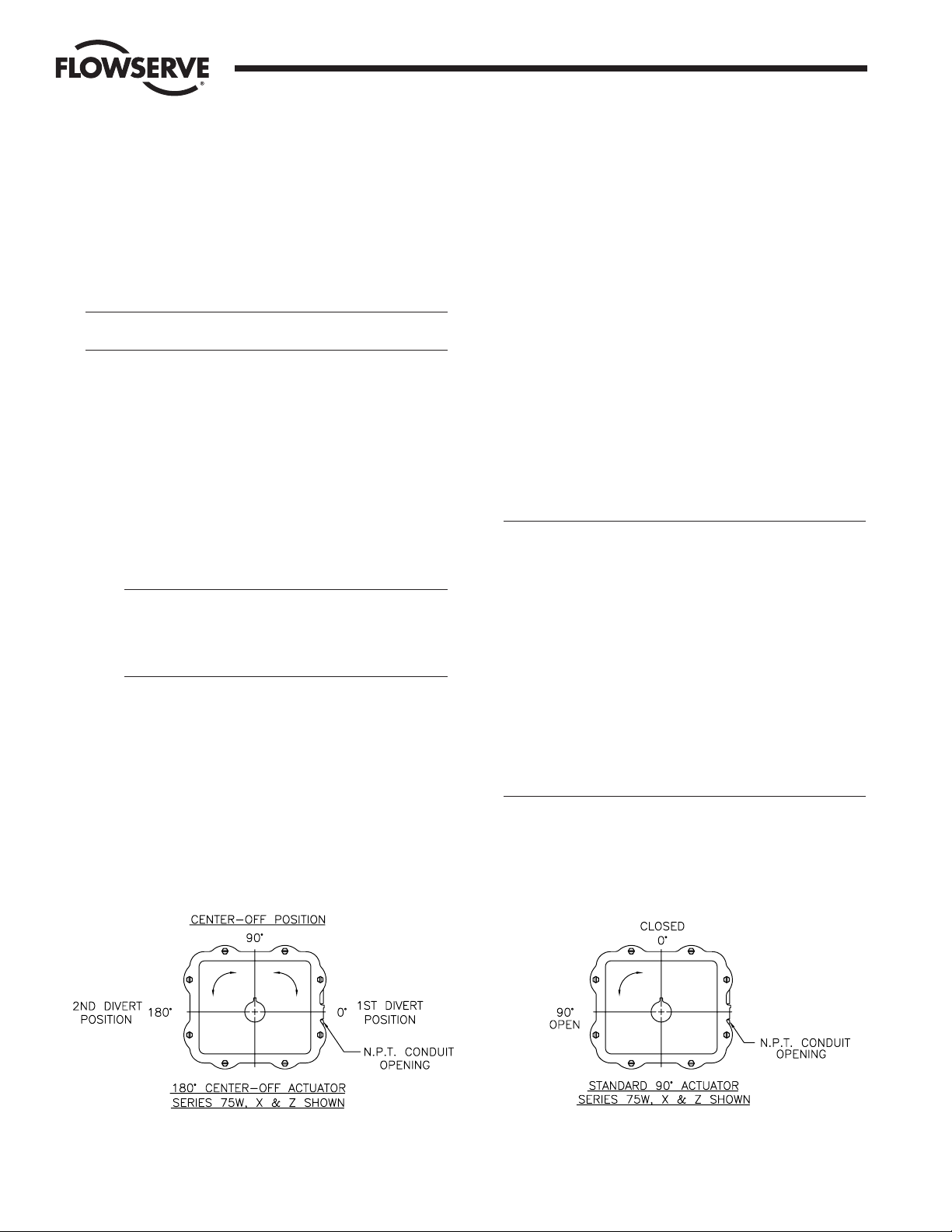

Quadrants of Operation

Page 5

WCAIM2026 DataFlo Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 5

1.2.1 Temperature

Operating solid state electronic equipment near or beyond

its high temperature ratings is the primary cause for most

failures. It is, therefore, very important that the user be

aware of and take into consideration, factors that affect the

temperature at which the electronic circuits will operate.

Operating an electronic device at or below its low

temperature rating generally results in a unit operating

poorly or not at all, but it will usually resume normal

operation as soon as rated operating temperatures are

reached. Low temperature problems can be easily cured

by addition of a thermostatically controlled heater to the

unit’s housing.

The Worcester/McCANNA

DataFlo

Digital Electronic

Controller is rated for operation between -40°F (with

heater and thermostat) and 160°F. When using the

Controller inside the Worcester/McCANNA 75 Series

actuators, a maximum ambient temperature of 115°F is

required to ensure the circuit board maximum

temperature of 160°F is not exceeded.

Temperature Ranging allows the user to specify the actual

process temperature conditions within the stipulated range

of the measuring element, i.e., RTD or thermocouple. The

control range can be as little as 50°C or 100°C

respectively, or to the full range of the measuring device.

For temperatures above 600°C, consult factory.

1.2.2 Humidity

Most electronic equipment has a reasonable degree of

inherent humidity protection and additional protection is

supplied by the manufacturer, in the form of moisture

proofing and fungicidal coatings.

Such protection, and the 3 to 4 watts of heat generated

by the circuit board assembly, will generally suffice for

environments where the average relative humidity is in

the area of 80% or less and ambient temperatures are in

the order of 70°F average. Where relative humidity is

consistently 80 to 90% and the ambient temperature is

subject to large variations, consideration should be given

to installing a heater and thermostat option in the

enclosure. The heater should not increase the enclosure

temperature to the point where the circuit board assembly

temperature rating of 160°F is exceeded.

In those instances where the internal heater would bring

the circuit board’s operating temperature near or above its

maximum rating, the user might consider purging the

enclosure with a cool, dry gas. The initial costs can

usually be paid off quickly in the form of greatly extended

equipment life, low maintenance needs, and much less

process downtime.

1.2.3 Input Circuit Noise Protection

Shielded wiring should be used for all setpoint and

process signal input circuit wiring regardless of length.

With separately housed Controllers, the wiring from the

feedback potentiometer to the remote Controller, would

be considered as signal input wiring

and should also be

shielded wire

.

The shields should never be used in place of one of the

input wires, and the shields should be grounded to

equipment housings at one end of the wiring run only.

Grounding both ends of shielding can eliminate the

shielding benefits because of current ground loops. If two

or more shielded cables come to the Controller from

different locations, ground the shields at the Controller.

2.0

DataFlo

ELECTRONIC

CONTROLLER CIRCUIT BOARD

2.1 General

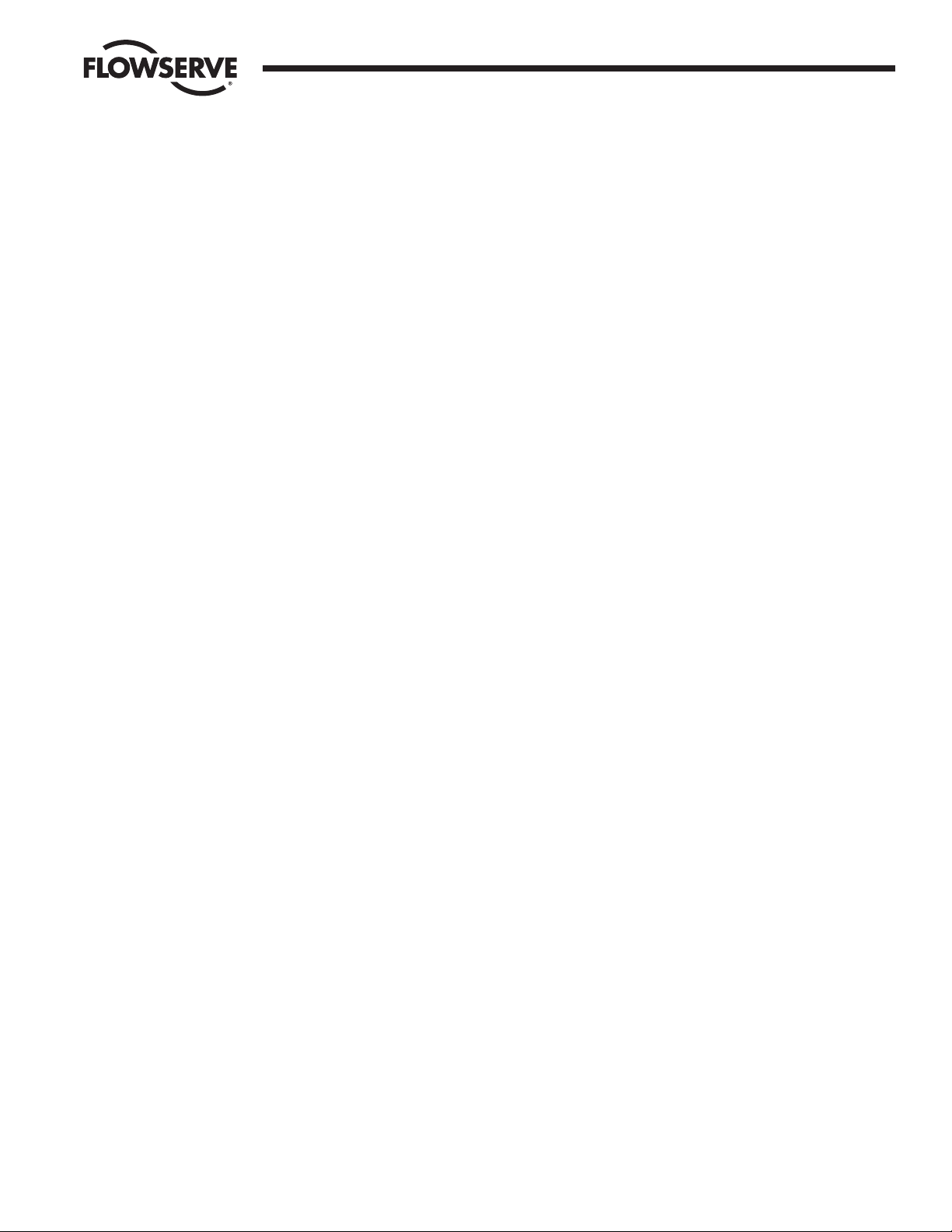

Figure 1 defines the location of major components and wires

from the Controller Board to terminal strip connections. The

Digital Controller Board is factory wired to the terminal strip

either per Figure 2, Figure 3, or Figure 4, as found in Section 3.0,

depending on power circuit voltage.

The feedback potentimeter leads are factory connected to the

terminal block (TB1) on the Digital Controller Board.

2.2 Circuit Board Configurations

The Controller circuit board is factory supplied in one of several

possible configurations:

A. The Controller circuit board will accept one of the

following setpoint signal inputs, depending on the circuit

board ordered:

• 4–20 mA

• 1–5 mA

• 10–50 mA

• 0–5 VDC

• 0–10 VDC

• 135 ohm pot

• 1000 ohm pot

In addition, the setpoint value can be set remotely via the

RS 485 interface, or locally with the circuit board

switches. When the setpoint is entered locally, all other

means of entering the setpoint are temporarily disabled.

Flow Control Division

Worcester Actuation Systems

Page 6

6

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

Flow Control Division

Worcester Actuation Systems

Figure 1 – Digital Electronic Controller Circuit Board, 120/240 VAC

Page 7

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 7

Flow Control Division

Worcester Actuation Systems

Figure 1 – Digital Electronic Controller Circuit Board, 24 VDC

Page 8

8

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

B. The Controller circuit board will accept one of the

following process signal inputs, depending on the circuit

board ordered:

One of the following analog inputs:

4–20 mA

1–5 mA

10–50 mA

0–5 VDC

0–10 VDC

135 ohm pot

1000 ohm pot

One 100 ohm Platinum RTDs – NOTE: A single channel is

standard. A two channel is available as a custom product

and must be hard wired to the red and two black leads

from circuit board identified as signal 2.

A single J, K, T, or E type Thermocouple

NOTE: Field changes to the Controller board are not

advised. Consult Flowserve before attempting any

modification.

2.3 LED Indicators

Light emitting diodes (LED) marked LD1 (CW) and LD2 (CCW)

are in the output circuits and when lit indicate which direction

the actuator is trying to drive. A third LED, LD3, is used to

indicate when an alarm condition exists. If LD3 is lit, the alarm

that caused it to light must be determined by looking at the

liquid crystal display (LCD) and finding the alarm parameter with

the UP or DN switch.

2.4 Controls (Override)

There are no adjustable controls provided on the circuit board

because none are necessary. All parameters are set through the

programming switches (keys) or the RS485 interface. Local

pushbutton control is provided at the actuator by simultaneously

pressing the SEL and UP switches (keys) for three seconds. At

this point the UP and the DN switches (keys) can be used to

manually position the actuator shaft. Pressing the SEL switch for

three seconds will return the Controller to the run mode.

2.5 AC Power Control

The AC output circuits are controlled by solid state switches

(triacs Q3, Q4), which will provide trouble-free operation for the

life of the equipment they are used with,

AS LONG AS THEY ARE

OPERATED WITHIN THEIR RATINGS

.

The ratings for the solid state switches used in the Worcester

DataFlo

Digital Electronic Controller are listed in part 5.3.

3.0 WIRING OF DIGITAL CONTROLLER

AND SERIES 75 ELECTRIC

ACTUATOR

See wiring diagrams located under actuator cover and/or Figures 2

through 4 for customer connections.

3.1 Actuator Power

CAUTION: Wiring should be inserted only to mid-point of

terminal strip.

3.1.1 Wire Size

Power to the Controller and from the Controller to the

actuator should be with wire no smaller than #18 gauge

and with insulation rated for the particular application.

The #18 gauge wire size is sufficient for all Worcester

Series 75 actuators. When using the Controller with other

makes of actuators, check the manufacturer’s current

rating to determine the correct wire size.

3.1.2 Termination and Voltage

Power connections are made to terminals 1 and 2 of the

terminal strip. The AC neutral or common, or DC

negative wire should be connected to terminal #1 and

the AC “Hot” or DC positive wire to terminal #2. Note

that the AC Controller requires a minimum of 110 VAC,

and a maximum of 130 VAC for the 120 VAC version and

a 220 VAC minimum, 250 VAC maximum for the

240 VAC version.

Grounding wires should be connected to green colored

grounding screw (if present) on actuator base or to any

base plate mounting screw in the actuator.

3.1.3 Minimum Fuse Ratings

See Minimum Fuse Rating table when overcurrent

protection is used in motor power circuit.

Minimum Fuse Rating for Overcurrent Protection

Actuator Size Voltage Fuse Rating

10-23 120 VAC 5 A

25/30 120 VAC 10 A

10-23 240 VAC 3 A

25/30 240 VAC 5 A

10-23 24 VDC 5 A

NOTE: This table shows the minimum rating to prevent inrush current

from blowing the fuse.

Flow Control Division

Worcester Actuation Systems

Page 9

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 9

3.2 Input Signal Connections

NOTES: The Digital Controller setpoint input signal circuit is

protected by

1

/

16 amp fuse, F1 (See Figure 1 and Paragraph A of

Part 1.1).

A label on the circuit board indicates the controllers setpoint and

process signal configurations. See Section 5.2 for input signal

specifications.

After input signal connections have been made, securely tighten

all terminal screws. Keep wiring away from all rotating parts and

ensure it will not be pinched when the actuator cover is installed.

3.2.1 Milliamp

DFC17-1, DFC17-4, DFC17-10 (Milliamp Setpoint Input

Signal for Digital Controller)

For a milliamp setpoint signal input, the more positive or

“High” signal lead should connect to actuator terminal 11.

The less positive or “Common” lead should connect to

actuator terminal 10. [Terminal 10 is (), Terminal 11

is (+).]

The Controller is available for use with the following

signals: 1 to 5, 4 to 20, and 10 to 50 milliamps. The

Controller board is factory calibrated for one of the three

milliamp signal ranges and field changes are not advised.

Part 5.4 gives the nominal resistance load, which the

Controller presents to the control circuit for the three

signal ranges.

Comparison of resistance measurements made at

terminals 10 and 11 (on the yellow and blue wires from

the circuit board) against the resistances shown in Part

5.4 provides a quick way to determine the milliamp range

for which a particular board is calibrated. If fuse F1 is

blown, an open circuit will be indicated.

NOTE: If the circuit board has an orange wire (See

Figure 1) attached to it, the board is set up for a

Potentiometer Setpoint Input. See paragraph 3.2.2.

3.2.2 Resistive

DFC17-13, DFC17-1K (Potentiometer Setpoint Input for

Digital Controller)

NOTE: The Setpoint Input Potentiometer is not the

Feedback Potentiometer, but is an additional

Potentiometer provided with the Controller, and externally

located by the end user. The acceptable potentiometer

values are 135 ohm for the DFC17-13 board and 1000

ohms for the DFC17-1K board.

For a potentiometer setpoint input signal, the usual

connections will be as shown in Figures 2 through 5 with

a “Low” setpoint command being generated when the

potentiometer is rotated to its full CCW position and a

“High” setpoint command when it is in the full CW

position.

If the setpoint command signal is derived from other than

a rotary potentiometer, it is only necessary to keep in

mind that a “Low” (full CCW) setpoint signal is called for

when the command potentiometer presents the least

resistance between terminals 10 and 11 and the most

resistance between terminals 11 and 12. A “High” (full

CW) setpoint signal would be the reverse condition; the

least resistance between terminals 11 and 12 and the

most resistance between terminals 10 and 11.

If the “Setpoint Command” potentiometer is reasonably

linear, the setpoint will be approximately 50% when the

potentiometer shaft is halfway through its travel.

3.2.3 DC Voltage

DFC17-5V, DFC17-XV (Direct Voltage Setpoint Input

Signal for Digital Controller)

For a voltage setpoint input signal, the more positive or

“High” signal lead should connect to terminal 11. The less

positive or “Common” lead should connect to terminal

10. (Terminal 10 is (), Terminal 11 is (+).)

The Controller is available for use with the following direct

voltage setpoint input signals: 0 to 5 VDC and 0 to 10

VDC. The Controller board is factory calibrated for one of

these two signal ranges and field changes are not advised.

Part 5.4 gives the nominal resistance load which the

Controller presents to the control circuit for the two

signal ranges.

3.3 4–20 mA (4-75) Position Indicator Option Connections

For units with a 4–20 mA (4–75) position indicator option

installed (indicator board installed over limit switches) the red

and black wires from the position indicator board will have to be

spliced directly to the external positive and negative output

(meter) wires respectively.

Note: Before wiring, calibrate indicator board per the following

paragraph. All other wiring of option, including the dual

potentiometer, has been done at the factory.

To obtain proper 4–20 mA output, the indicator board output has

to be calibrated prior to wiring red and black wires. Using an

ammeter connected to the red and black wires of the indicator

board, adjust the two potentiometers R4 and R5 on the board.

With the actuator in the closed position (0%), adjust R5

potentiometer (adjacent to the number “4” etched on the circuit

board and closest to terminal block) to obtain 4 mA on the

ammeter. Move the actuator to the open position (100%) and

adjust R4 potentiometer (adjacent to the number “20” etched on

the circuit board) to obtain 20 mA. Because adjustment of one

potentiometer affects the other, repeat the procedure several

times to obtain proper values.

NOTE: If a dual pot option only is installed, the “B” pot leads will

have to be wired directly to external device. The “A” pot leads

are factory connected to the terminal Block (TB1) on the Digital

Controller Board. Also, note that the “B” potentiometer has a

voltage limit of 30 volts maximum.

Flow Control Division

Worcester Actuation Systems

Page 10

10

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

Flow Control Division

Worcester Actuation Systems

Figure 2 Figure 3

NOTE: For all input signal circuit wiring, regardless of length, shielded wiring should be used. See Section 1.2

Page 11

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 11

Flow Control Division

Worcester Actuation Systems

Figure 4 – 24 VDC DFC17 Circuit Board Wiring

Figure 5

Model 485F9 (9 pin)

or 485F (25 pin)

485 Converter

1.5K

1.5K

PWR SUPPLY +9 VDC

PWR SUPPLY GND

TB2

TB2

2

1

9

8

Receive -

Receive +

Wht/Blk

Purple

Internal External

Actuator Terminal

Strip

(SHIELD)

(NO CONNECTION)

EN\

TX

TX\

RX\

RX

Sample RS-485 Connection

Controller Board

NOTE: If you are not using the RS-485 converter as shown in Figure 5, then refer to the documentation that came with your converter for proper

connections.

ICS

GND

GND

VDC

Page 12

12

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

4.0 OPERATION OF THE DIGITAL

CONTROLLER

Refer to RS485 Communications software diskette included with

controller for more information.

The DFC17 Controller is capable of being operated in several modes.

The normal mode of operation is the RUN mode. Following is a list of

the various modes and the key sequences necessary to enter each of

them and the function of each of the parameters within that mode:

4.1 Run Mode “run”

This is the normal operating mode.

While in the Run Mode momentarily pressing:

SEL Toggles between alternating name/value and continuous

value display.

UP Shows the next parameter.

DN Shows the previous parameter.

4.1.1 Run Mode Menu

Pressing SEL while the alarm condition is alternating on

the display will freeze the display with the highest priority

alarm showing. At that point, pressing SEL again will

attempt to reset the alarm display. If the alarm

condition(s) still exist after pressing SEL, the display will

continue to show the alarm(s).

See table on page 13.

4.1.2 Mode Change Key Sequence

See table on page 13.

4.1.3 Alarm Displays

See table on page 13.

4.2 Calibration Mode

Press SEL + DN keys for three seconds to enter Calibration Mode

CAL from Run Mode. A security code may be required for entry

to the Calibration Mode. If one is required, it is checked and

entered using the instructions below and for editing a numeric

value as described in paragraph 4.3.2.

Simultaneously press and hold the SEL and DN keys for three

seconds. CAL will be displayed for two seconds and the security

code will be checked. If the required security code is not zero

(“0000”), the display will begin alternating between “CodE” and

“0000”. If the required security code is zero, it will not need to be

entered, i.e., it will be bypassed and display will automatically

flash “SEtL”. Skip to paragraph 4.2.2.

Enter the security code, if necessary, as follows. (If the code is

forgotten, the special number 4800 can be used to gain entry).

Quick tap SEL key once. First 0 will flash. Quick tap UP key until

you reach code number. Quick tap the DN key once. The second

0 will flash Quick tap the UP key until the next code number is

reached. Continue this procedure as needed for the remaining

code numbers. Quick tap SEL to accept code.

Display now flashes between “SEtL” and a value.

Press SEL key for two seconds to return to the Run Mode.

For the Calibration Mode Menu table, press:

SEL To sequence through the calibration parameters.

SEL + UP To enable/start calibration of the selected parameter.

4.2.1 Calibration Mode Menu

See table on Page 14.

4.2.2 Key Sequences for Calibrating Setpoint Lower Limit

The lower setpoint parameter SEtL should be displayed.

Press SEL + UP to begin calibrating the parameter.

Attach an accurate current source to the setpoint signal

input and adjust the source to produce a 4 mA signal. The

voltage reading on the display should be less than 1 volt.

Press SEL

to accept the value shown and return to the

calibration menu.

4.2.3 Key Sequences for Calibrating Setpoint Upper Limit

Press DN to select the upper setpoint parameter SEtU

Press SEL + UP to begin calibrating the parameter.

Attach an accurate current source to the setpoint signal

input and adjust the source to produce a 20 mA signal.

The voltage reading on the display should be between

3.800 and 5.000 volts.

Press SEL to accept the value shown and return to the

calibration menu.

4.2.4 Key Sequences for Calibrating Clockwise Position

Press DN to select the clockwise setpoint parameter PoC

Press SEL + UP to begin calibrating the parameter.

1) Use either the UP or DN switches to manually rotate

the actuator to its full clockwise (CW) position.

2) With the actuator in the full CW position, adjust the

feedback potentiometer by rotating the face gear

located on the actuator shaft with your fingers, for a

reading between .200 and .400 volts.

NOTE: It is not necessary to loosen or remove face gear

snap ring(s) (if present) to rotate gear, it is a friction fit.

For gears that do have snap rings, and if for any reason

the snap ring(s) must be removed, do not overstretch

them. Use the minimum opening to allow the rings to slip

over the gear.

Press SEL to accept the value shown and return to the

calibration menu.

Flow Control Division

Worcester Actuation Systems

Page 13

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 13

Flow Control Division

Worcester Actuation Systems

Table 4.1.1 Run Mode Menu

Display Description Units

Pr1 Process #1 signal value. Engineering

Pr2 Process #2 signal value. Engineering

Pr12 Average of process #1 and process #2 signal values. Engineering

SEt - Setpoint value. Only one of the following will be displayed: Engineering

SEtA – analog setpoint; SEtP – digital setpoint;

SEtL – local manual setpoint.

PtEr Proportional term value.

itEr Integral term value.

dtEr Derivative term value.

ALr Alarm. Alarm shown is highest priority. See Mode Change

Key Sequence table.

POS Valve position. Percent

CYCn Number of cycles. Times 1000

cycles

PHi Highest recorded process value. Engineering

PLo Lowest recorded process value. Engineering

Table 4.1.2 Mode Change Key Sequence

Press Key(s) for Three Seconds Mode Entered

SEL Program Mode.

SEL + DN Calibration Mode.

SEL + UP Manual Setpoint Mode.

SEL + DN + UP Manual Position Mode (gives access to Auto Tuning).

Table 4.1.3 Alarm Displays

Display Description

PrHi Process high limit alarm.

PrLo Process low limit alarm.

Hi Shaft upper position alarm.

Lo Shaft lower position alarm.

SHFt Invalid shaft position alarm.

Pro Invalid process value alarm.

SEt Invalid setpoint value alarm.

thEr Motor driver circuit thermal warning alarm (DC motors only).

Page 14

14

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

4.2.5 Key Sequences for Calibrating Counter-clockwise Position

Press DN to select the counter-clockwise setpoint

parameter PoCC

Press SEL + UP to begin calibrating the parameter.

1) Use either the UP or DN switches to manually rotate

the actuator to its full counter-clockwise (CCW)

position.

2) With the actuator in the full CCW position, the voltage

reading on the display should be greater than 3.000

volts. If not, recheck PoC. If it is correct and the PoCC

reading is still not correct, contact factory.

Press SEL to accept the value shown and return to

the calibration menu.

4.2.6 Key Sequences for Calibrating Analog Process #1 Lower

Input Signal

This procedure is followed only if an analog process

module is used.

Press DN to select the lower input parameter PrlL

Press SEL + UP to begin calibrating the parameter.

Attach an accurate current source to the process input

and set a current of 4.0 mA. The voltage reading on the

display should be less than 1 volt.

Press SEL to accept the value shown and return to the

calibration menu.

4.2.7 Key Sequences for Calibrating Analog Process #1 Upper

Input Signal

This procedure is followed only if an analog process

module is used.

Press DN to select the upper input parameter PrlU

Press SEL + UP to begin calibrating the parameter.

Attach an accurate current source to the process input

and set a current of 20 mA. The voltage reading on the

display should be greater than 3.000 volts

Press SEL to accept the value shown and return to the

calibration menu.

4.2.8 Key Sequences for Calibrating Single Channel RTD Process

Module

This procedure is followed only if a single channel RTD

process module is used. With this type of process

module, an attached 100 ohm platinum RTD develops a

voltage representing the temperature of the process.

RTDs can cover a very wide temperature range. The RTD

module however allows a narrower temperature range to

be used. This is useful for applications that need higher

resolution and do not need a wide range.

The purpose of this procedure is to specify the

temperature units, temperature range, and to record the

actual voltage values at the lower and upper process

limits. This procedure involves adjusting components on

the RTD module. This procedure is entered by selecting

either the Pr1L or Pr1U parameter for calibration. When

either of those parameters is selected for calibration, the

controller starts the following calibration sequence. At any

time in the menu, the user can press the SEL key to

return to the calibration menu.

Any one step in the calibration procedure can be

performed without performing the others. However, it is

recommended to perform all the calibration steps if any

one item is changed.

Calibrating the RTD module circuitry involves adjusting

the span and zero potentiometers on the module to

achieve a good voltage swing for the temperature range

selected. When adjustments have been properly

completed, the calibration routine will use the calibrated

analog voltages to create a linearization table.

Flow Control Division

Worcester Actuation Systems

Table 4.2.1 Calibration Mode Menu

Display Description Acceptable Range

SEtL Setpoint lower limit signal value. Less than 1 volt.

SEtU Setpoint upper limit signal value. Between 3.800 volts

and 5.000 volts.

PoC Shaft position feedback value at full clockwise position. Between .200 volts and .400 volts.

PoCC Shaft position feedback value at full counter-clockwise position. Greater than 3.0 volts.

PrlL Process #1 signal lower limit value. Unique to process.

PrlU Process #1 signal upper limit value. Unique to process.

Pr2L Process #2 signal lower limit value. Unique to process.

Pr2U Process #2 signal upper limit value. Unique to process.

CYt Cycle time measurement. Dependent on actuator.

Page 15

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 15

The table above shows a calibration step and the

procedure required to complete the step. It is

recommended to perform all the calibration steps if any

one item is changed. Any time a potentiometer is adjusted,

both the AdcL and AdcU procedures must be performed.

Press the DN key until the PrlL parameter appears. On

that display, press the SEL and UP keys simultaneously to

enter the RTD calibration menus.

On the menus, use the DN key to move from one

parameter to the next one in sequence. When calibration

is completed, press and hold the SEL key for three

seconds to return to the main Calibration Mode menu (the

PrlL parameter). Release and then press the SEL key

again for three seconds to return to the RunMode.

Note: When the RTD temperature units are changed, the

upper range limit will be changed to the default maximum

range shown below.

Default (maximum)

Temperature Units temperature range

°C -200 to +800

°F -300 to +999

Note: Maximum allowable span is 800°C, e.g., -200°C to

+600°C or 0°C to 800°C. Minimum span is 50°C. Span

must be set in 50°C increments.

The procedure for calibrating the module will involve

adjusting the span and zero potentiometers on the RTD

module. Since there can be some interaction between the

two pots, the lower and upper limits are adjusted in the

step for the upper limit. The lower limit procedure is used

only to record the lower limit voltage and no adjustments

should be made in that step.

When adjusting the potentiometers for the upper and

lower limit, the voltage range should be as great as

possible for the best resolution. However, some

guard band area should be left for the possibility of

temperatures slightly outside the specified range. For

example, if the lower limit voltage was 0.100 volts and the

upper limit voltage was 4.900 volts, that would give very

good resolution, but would not allow much room for

temperatures outside of the specified limits. A span of

0.500 and 4.500 might be better.

Flow Control Division

Worcester Actuation Systems

Step Display Procedure

Press SEL and UP to change the temperature units. When SEL and UP are pressed, the units will begin flashing.

Unit Pressing the UP or DOWN keys will change the units between degrees Fahrenheit and Celsius. When the correct

units are flashing, press SEL to lock in the selection.

Press SEL and UP to change the temperature range upper limit. When SEL and UP are pressed, the upper limit will

begin flashing. Pressing the UP or DOWN keys will change the upper limit to another value. When the correct

rn9U range value is flashing, press SEL to lock in the selection. The upper limit of the range will not be able to be

set to a value that is less than 50°C (100°F) above the lower limit (i.e., there must be at least 50°C or 100°F

between limits).

Press SEL and UP to enter the voltage display mode. Be sure a resistance type RTD simulator is attached in place

of the RTD. Simulate the upper limit temperature and adjust the span potentiometer on the module such that the

voltage is between 4.200 and 4.700 volts on the display. Change the RTD simulator to simulate the lower limit

RdcU temperature and adjust the zero potentiometer on the module such that the voltage is between 0.200 and 0.800

volts. Repeat the above process until the upper and lower voltages are within the stated limits. When completed,

be sure the simulator is simulating the upper limit temperature. Press the SEL key to lock in the upper limit voltage.

Press SEL and UP to change the temperature range lower limit. When SEL and UP are pressed, the lower limit will

rn9L begin flashing. Pressing the UP or DOWN keys will change the lower limit to another value. When the correct range

value is flashing, press SEL to lock in the selection. The lower limit of the range will not be able to be set to a value

that is greater than 50°C (100°F) below the upper limit (i.e., there must be at least 50°C or 100°F between limits).

Press SEL and UP to enter the voltage display mode. Be sure a resistance type RTD simulator is attached in place

Rdcl of the RTD. Enter the lower limit temperature (either 0°C or 32°F) in the simulator. The resulting voltage reading

will be displayed.

Do NOT adjust either the zero or span potentiometers in this step.

Press the SEL key to lock in

the lower limit voltage. Note that zero adjustments are made in the procedure for the upper limit. This step is just

used to record the lower limit voltage.

Page 16

16

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

4.2.9 Key Sequences for Calibration of Optional Two-Channel

RTD Process Module

A. Key Sequences for Calibrating Two-Channel RTD

Process #1 Input Signal

This procedure is followed only if a two channel RTD

process module is used. This step calibrates both the

lower and upper process signals for input #1.

Press DN to select the lower input parameter PrlL

Press SEL + UP to begin calibrating the parameter.

1) Attach a calibrated RTD simulator to process

input #1.

2) Select an RTD resistance that corresponds to

-100°C. The voltage corresponding to the

resistance is shown on the display as “X.XX”.

3) Press the UP switch to record the lower

temperature value.

4) Select an RTD resistance that corresponds to

+350°C. The display will show a differential

voltage as “dX.XX”. The d indicates that the

displayed value is the difference between the

actual current voltage and the recorded lower

temperature voltage.

5) Adjust the span potentiometer for a differential

voltage reading of “d4.60” volts.

6) Repeat steps 2) through 5) until the voltage

difference reads “d4.60” without further

adjustments.

Press SEL to accept the value shown and return

to the calibration menu.

B. Key Sequences for Calibrating Two-Channel RTD

Process #2 Input Signal

This procedure is followed only if a two channel RTD

process module is used. This step calibrates both the

lower and upper process signals for input #2. Follow

this step only if an RTD is connected to the process

#2 input.

Press DN to select the lower input parameter Pr2L.

Press SEL + UP to begin calibrating the parameter.

1) Attach a calibrated RTD simulator to process

input #2.

2) Select an RTD resistance that corresponds to

-100°C. The voltage corresponding to the

resistance is shown on the display as “X.XX”.

3) Press the UP switch to record the lower

temperature value.

4) Select an RTD resistance that corresponds to

+350°C. The display will show a differential

voltage as “dX.XX”. The d indicates that the

displayed value is the difference between the

actual current voltage and the recorded lower

temperature voltage.

5) Adjust the span potentiometer for a differential

voltage reading of “d4.60” volts.

6) Repeat steps 2) through 5) until the voltage

difference reads “d4.60” without further

adjustments.

Press SEL to accept the value shown and return

to the calibration menu.

4.2.10 Key Sequence for Calibrating Thermocouple Process

Module

With this type of process module, an attached

thermocouple develops a voltage representing the

temperature of the process. Thermocouples can cover a

very wide temperature range. The thermocouple module

however allows a narrower temperature range to be used.

This is useful for applications that need higher resolution

and do not need a wide range.

The purpose of this procedure is to specify the

thermocouple type, temperature units, temperature range,

and to record the actual voltage values at the lower and

upper process limits. This procedure involves adjusting

components on the thermocouple module. This procedure

is entered by selecting either the Pr1L or Pr1U parameter

for calibration. When either of those parameters is

selected for calibration, the controller starts the following

calibration sequence. At any time in the menu, the user

can press the SEL

key to return to the calibration menu.

Note: For greatest accuracy, the thermocouple simulator

should be connected to the controller input module, and

the simulator and the controller board should be turned

on and allowed to temperature stabilize for at least 15

minutes prior to calibrating. The minimum allowable

temperature span is 100°C (212°F).

Any one step in the calibration procedure can be

performed without performing the others. However, it is

recommended to perform all the calibration steps if any

one item is changed.

Calibrating the thermocouple module circuitry involves

adjusting the gain potentiometer on the module to

achieve the desired temperature range. When

adjustments have been properly completed, the

calibration routine will use the calibrated analog voltages

to create a linearization table.

The table below shows a calibration step and the

procedure required to complete the step. It is

recommended to perform all the calibration steps if any

one item is changed.

Press the DN key until the Pr1L parameter appears. On

that display, press the SEL and UP keys simultaneously to

enter the thermocouple calibration menus.

Flow Control Division

Worcester Actuation Systems

Page 17

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 17

On the menus below, use the DN key to move from one

parameter to the next one in sequence. When calibration

is completed, press and hold the SEL key for three

seconds to return to the main Calibration Mode menu (the

Pr1L parameter). Release and then press the SEL key

again for three seconds to return to the Run Mode.

Note: When either the thermocouple type or units is

changed, the upper range limit will be changed to the

maximum upper limit as described earlier. The lower

range limit is always fixed at 0°C or 32°F.

Thermocouple Types and Temperature Ranges

For a controller with a thermocouple module, different

types of thermocouples can be used to measure process

temperature. Some types have wider available

temperature ranges than others. The maximum range

available for the type used is shown in the table at right.

A narrower range can be specified in the Calibration

Mode. Narrowing the range will increase the resolution of

the process temperature measurement and will allow for

better setpoint control.

Thermocouple Range Range

Type Lower Limit Upper Limit

E 0°C 350°C

32°F 650°F

J 0°C 500°C

32°F 900°F

K 0°C 550°C

32°F 999°F

T 0°C 400°C

32°F 750°F

4.2.11 Key Sequences for Calibrating the Cycle Time

Press DN to select the cycle time parameter Cyt.

Press SEL + UP to perform the cycle time measurement.

Flow Control Division

Worcester Actuation Systems

Step Display Procedure

tyPE Press SEL and UP to change the thermocouple type. When SEL and UP are pressed, the type will begin

flashing. Pressing the UP or DOWN keys will change the display to another type. When the correct value

is flashing, press SEL to lock in the selection.

Unit Press SEL and UP to change the temperature units. When SEL and UP are pressed, the units will begin

flashing. Pressing the UP or DOWN keys will change the units between degrees Fahrenheit and Celsius.

When the correct units are flashing, press SEL to lock in the selection.

rn9U Press SEL and UP to change the temperature range upper limit. When SEL and UP are pressed, the

upper limit will begin flashing. Pressing the UP or DOWN keys will change the upper limit to another

value. When the correct range value is flashing, press SEL to lock in the selection. The upper limit of the

range will not be able to be set below 100°C or 212°F.

RdcU Press SEL and UP to enter the voltage display mode. Be sure a thermocouple simulator is attached in

place of the thermocouple. Simulate the upper limit temperature and adjust the gain potentiometer on the

module such that the voltage is between 4.200 and 4.700 volts on the display. Press the SEL key to lock

in the upper limit voltage.

rn9L The value given with this display is the lower temperature limit and is shown to remind the technician of

the temperature to use for the simulator. This value is fixed and not programmable.

RdcL Press SEL and UP to enter the voltage display mode. Be sure a thermocouple simulator is attached in

place of the thermocouple. Enter the lower limit temperature (either 0°C or 32°F) in the simulator.

The

resulting voltage reading will be displayed. Do NOT adjust the gain potentiometer in this step.

Press the

SEL key to lock in the lower limit voltage.

Page 18

18

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

4.3 Program Mode

Press SEL key for three seconds to enter Program Mode Prog

from Run Mode. A security code may be required for entry to the

Program Mode. If one is required, it is checked and entered

using the instructions below and for editing a numeric value as

described in paragraph 4.3.2.

“Prog” will be displayed for two seconds and the security code

will be checked. If the required security code is not zero

(“0000”), the display will begin alternating between “CodE” and

“0000”. If the required security code is zero, it will not need to

be entered, i.e., it will be bypassed and display will

automatically flash “Addr”. You can now select functions as

found in table below.

Enter the security code, if necessary, as follows. (If the code is

forgotten, the special number 4800 can be used to gain entry).

Quick tap SEL key once. First 0 will flash. Quick tap UP key until

you reach code number. Quick tap the DN key once. The

second 0 will flash. Quick tap the UP key until the next code

number is reached. Continue this procedure as needed for the

remaining code numbers. Quick tap SEL to accept code.

Press SEL for two seconds to return to the Run Mode.

4.3.1 Program Mode Menu

See table on page 19.

4.3.2 Instructions for Editing Parameters

Press UP or DN to select the desired parameter.

Press SEL to begin editing.

A. Numeric Parameters

1) Press DN to select the digit to be edited. The

selected digit will blink.

2) Press UP to increment the digit value as many

times as necessary.

3) Press SEL to store the parameter value and return

to menu.

B. Selection List Parameters

1) Press UP or DN to select the desired choice. The

choice will blink.

2) Press SEL to store the parameter value and return

to menu.

C. Combination Parameters

Some parameters may have both numeric and

selection list possibilities for their values. If the

present value of the parameter is numeric, the

leftmost digit of the display will be blinking; if the

present value is a selection list choice, the entire

choice name will be blinking.

1) Pressing DN will advance through the digits or

will enter and leave selection list editing.

2) Pressing UP will increment a digit or will advance

to the next available choice in the selection list.

3) Press SEL to store the parameter value and return

to menu.

D. Cycle Count Parameter

The cycle count parameter may only be cleared. The

cycle count will begin flashing.

Press DN for four seconds to clear the cycle count

and return to menu.

4.3.3 Default Values for Process Control (factory installed)

When parameters are defaulted in the Program Mode,

they are set as described below. The table below shows

values for the 4–20 mA (analog) process module. If

another process module is used, the other columns show

exceptions to the default values (if any). Use the PrSt

function to set default values.

See table on page 20.

4.4 Manual Setpoint Mode

Press

SEL + UP keys for three seconds to enter Manual Setpoint

Mode from Run Mode. LSEt

A security code may be required for entry to the Manual Setpoint

Mode. If one is required, it is entered using the instructions for

editing a numeric value as described in Program Mode.

Press SEL key for two seconds to return to the Run Mode.

Changing the Manual Setpoint Value

Press SEL to enter the edit mode. Edit the value of the setpoint

as a Combination Parameter as described in the Program Mode.

Disabling Manual Setpoint

Press UP + DN while the display is alternating to turn off the

manual setpoint feature. The display will show OFF.

4.5 Manual Position Mode

Press SEL + UP + DN keys for three seconds to enter Manual

Position Mode from Run Mode. LP0S

A security code may be required for entry to the Manual Position

Mode. If one is required, it is entered using the instructions for

editing a numeric value as described in Program Mode.

Press SEL key for two seconds to return to the Run Mode.

Flow Control Division

Worcester Actuation Systems

Page 19

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 19

Program Mode Menu

Display Description Mininum Value Maximum Value

CodE Security code for access to Program, Calibration 0000 9999

and Manual Setpoint modes.

Addr Communications unit address 1 255

PtEr Proportional Control Term 0000 9999

itEr Integral Control Term 000 999

dtEr Derivative Control Term 0000 8000

onH Motor Cycle Interval 1.0 sec 999.9 sec

FiLT Process Signal Filter Time 0.8 sec 60.0 sec

bLt Gearbox Backlash Time 0 ms 9999 ms

tort Gear Torque Time 0 ms 9999 ms

dEbA Controller Dead Band 0.1 20.0

ACt Controller Action – RISE or FALL

CyCr Cycle Interval Reset – ON or OFF

FPOS Process or Setpoint invalid reading action – 0.0% 100.0%

HOLD, NONE, or a position value.

SAct Invalid feedback pot reading action – GOC (go clockwise),

GOCC (go counter-clockwise), HOLD, or NONE.

yA Lower shaft position limit 0.0% 100.0%

yE Upper shaft position limit 0.0% 100.0%

br Brake ON time. 0.10 sec 0.99 sec

CyCn Run Time Cycle Count (reading represents thousands of cycles).

AHi Over-travel Alarm 0.0% 100.0%

ALo Under-travel Alarm 0.0% 100.0%

PrLo Process Low Alarm Value PENL PENU

PrHi Process High Alarm Value PENL PENU

bAUD Communications Baud Rate 1200 bps 38.4 Kbps

PrS9 Process Signal Selection – PR1, PR2, or BOTH

PEnL Process Engineering Units Range (Lower) -999 999

PEnU Process Engineering Units Range (Upper) -999 999

SEnL Setpoint Engineering Units Range (Lower) -999 999

SEnU Setpoint Engineering Units Range (Upper) -999 999

PrSt Restore Default Parameters (YES or NO)

Note: A decimal point may be entered when entering PEnL and PEnU values, if the controlled range falls between -99.9 and 99.9. This has the

effect of improving resolution for small process ranges (i.e., 0.0 to 10.0 GPM). See Controller Specification on floppy disk for more detail.

Flow Control Division

Worcester Actuation Systems

Page 20

20

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

Flow Control Division

Worcester Actuation Systems

Default Values for Process Control

Parameter Analog Module Thermocouple Module RTD Module

Communications Addr 1

Proportional Term 1,000

Integral Term 60

Derivative Term 0

Motor Cycle Interval 1.5 seconds

0Filter Time 0.8 seconds

Backlash Time 600 ms

Gear Torque Time 0 ms

Dead Band 0.5 units

Controller Action RISE

Cycle Interval Reset ON

Process Low Alarm 0 (see note 1) -100°C

Process High Alarm 100 (see note 1) +350°C

Invalid Process Reading Action NONE (ignore)

Invalid Shaft Reading Action NONE (ignore)

Lower (Ya) Limit 0%

Upper (Ye) Limit 100%

Brake Time 0.25 seconds

Lower Travel Alarm 0%

Upper Travel Alarm 100%

Communications Baud Rate 38,400 bps

Process Signal Selection Pr1

Process Lower Engineering Units 0 (see note 1) -100°C

Process Upper Engineering Units 100 (see note 1) +350°C

Setpoint Lower Engineering Units 0 (see note 1) -100°C

Setpoint Upper Engineering Units 100 (see note 1) +350°C

Note 1: For the thermocouple module, default values depend on the type of thermocouple used. The maximum range will be used for the

thermocouple type selected. See Temperature Range Table for a list of maximum range values.

Page 21

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 21

Flow Control Division

Worcester Actuation Systems

Setting Position

Press UP or DN to rotate the controller shaft either counterclockwise or clockwise respectively. The shaft will continue to

move as long as the key is held down and a limit switch has not

tripped.

During the Manual Position Mode, a host controller connected

on the serial data link has no control of either the setpoint or the

actuator/valve position. Also in this mode, the setpoint input is

ignored.

Auto-Tuning

Press SEL + DN to enter the Auto Tune mode. The display will

show Atun for three seconds. At this and at any point in the autotuning procedure, the user can press the SEL key for three

seconds to exit auto-tuning and return to the Manual Position

Mode.

4.6 Positioner Mode

The controller has a unique feature, which allows the application

of a 24 VDC signal to the controller board to switch it to a basic

positioner mode. The board then uses the analog 4–20 mA

setpoint signal as the positioning signal. When the 24 VDC signal

is removed, the board switches back to the controller mode. The

24 VDC signal connects to circuit board terminals TB2–5

(positive) and TB2–6 (negative).

4.7 Auto-Tuning Safety Considerations

4.7.1 Things to Know Before Tuning

Know how fast and how much the process value

changes with a valve position change. The relationship

should be graphed.

Determine the valve safe operating range. This can be

determined from the step above. This range should

provide an adequate change to the process, but should

also not allow dangerous situations to occur. The safe

operating range should be considered when setting the

percentage offset term in Auto-Tuning.

The names for the lower and upper position limits

respectively are: yA and yE

If necessary, to ensure safe operation of the controller, set

shaft position limits using yA and yE.

4.7.2 Safety Concerns During Operation

Determine what should happen in the event of a loss of

either the process signal or the setpoint signal.

Program the Invalid Reading Action parameter

correspondingly. That parameter defaults to an action of

NONE which means that if it is not changed, no action will

be taken (control will attempt to be maintained) if an

invalid setpoint or process signal is received.

The name for the Invalid Reading Action parameter is:

FPOS

Auto Tune Menu

Display Description Min Value Max Value

StEP The amount of valve position step change desired when running Auto-Tune. 1% 40%

Flct The amount of fluctuation in the signal value while it is monitored

for 60 seconds.

StP 1 The elapsed time since StP1 was started. 30 minutes

StP2 The elapsed time since StP2 was started. 30 minutes

StP3 The elapsed time since StP3 was started. 30 minutes

PtEr The value of the suggested Proportional Term calculated by the

Auto-Tune Algorithm. 0000 9999

ltEr The value of the suggested Integral Term calculated by the

Auto-Tune Algorithm. 000 999

dtEr The value of the suggested Derivative Term calculated by the

Auto-Tune Algorithm. 0000 8000

CyCt The value of the suggested Cycle Interval calculated by the

Auto-Tune Algorithm. 1.0 second 999.9 seconds

ALr Any alarm except the setpoint alarm will cause Auto-Tune to halt and

the actuator shaft will return to its original position.

Erto A 30 minute timeout error will cause Auto-Tune to abort and the

actuator shaft to return to original position.

Page 22

22

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

4.8 Controller Setup

4.8.1 General Setup

Read the Safety Considerations section to determine what

steps might be necessary to insure a safe control system.

Determine the Engineering Units for the setpoint and

process inputs. Program the lower and upper process

limits and lower and upper setpoint limits using

Program Mode.

Program alarm limits if they are used.

4.8.2 Tuning the Controller Automatically (open-loop tuning)

Be sure the controller is properly set up as described

above. Be sure to know the safe operating range of the

valve.

Enter the Manual Position Mode and set a starting valve

position.

Enter the Auto-Tune Mode and establish the offset

percentage for valve movement.

Run the Auto-Tune procedure. If an alarm occurs, note

the alarm condition, exit the Auto-Tune Mode and take

appropriate action to insure a safe condition. If Auto-Tune

completes, view the computed control terms and decide

whether to install them or reject them.

If there are no alarm conditions, return to the Run Mode

and observe controller operation. If more tuning is

desired, consider the closed-loop tuning described below.

Alternately, individual control parameters can be modified

in the Program Mode.

4.8.3 Tuning the Controller Manually

Manual tuning involves making changes to the setpoint

and observing the behavior of the process. Observations

should be recorded and some type of recording device

(e.g., a strip chart recorder) is highly recommended.

Be sure the controller is operating in a safe and relatively

stable manner at or near a typical setpoint.

Enter the Manual Setpoint Mode and make a step change

to the setpoint value. The suggested amount of setpoint

step change is in the range of 5% to 10%, but should

not cause an unsafe condition to occur. Return to the

Run Mode.

Measure the lag time. This is the time it takes after the step

is made before any change in the process is observable.

Measure the response of the process. Did it overshoot? If

so, by how much? Does it tend to oscillate after a step

change? If so, what is the frequency of oscillation? How

long does it take the process to reach the new setpoint?

Analyze the results. Based on the requirements for control,

determine what control parameters might need changing.

4.8.4 Some Guidelines for Control Parameters

The maximum gain possible occurs where the process

begins to oscillate about the setpoint.

The recommended proportional gain (the P-term) for

stability is one-half or even one-third the maximum gain

determined. So, for example, if oscillation begins at a

P-term setting of 6000, good stability will be achieved by

reducing the setting to 2000 or 3000.

Leave the Integral (I-term) value at 60 unless very high

performance operation is required. Refer to the Appendix

on floppy disk for fine tuning guidelines.

Leave the Derivative (D-term) value at 10 unless faster

response time for high performance systems with short

lag times and high proportional gain is required.

Set the Cycle Time to a value greater than or equal to the

measured process system lag time. If the cycle time is set

to less than the lag time, the valve position might change

before the effect of a previous change is detected.

Flow Control Division

Worcester Actuation Systems

Page 23

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 23

5.0 TECHNICAL DATA

5.1 Allowable Supply Voltage Range

All voltages +/- 10%

Power Consumption (Circuit board only) – 2.5 Watts

5.2 Analog Input Circuit Specifications

Maximum Tolerated Noise Level at Maximum Controller

Resolution/ Sensitivity – Approx. 3.5 mV (16 microamps).

Resistance Input

DFC-1K – Nom. 1000 ohms

DFC-13 – Nom. 135 ohms

Current Input

DFC-1 – 1 to 5 milliamps

DFC-4 – 4 to 20 milliamps

DFC-10 – 10 to 50 milliamps

Voltage Input

DFC-5V – 0 to 5 VDC

DFC-XV – 0 to 10 VDC

5.3 Output Circuit Specifications

All Models

Maximum Surge Current 100 amps for 1 cycle

Maximum Normal Starting or

In-rush Current 10 amps for 1 second

Maximum Stall Current 8 amps for 1 minute

Maximum Running Current – Resistive Load 5 amps

90% Duty Cycle

Maximum Running Current – Inductive Load 3 amps

90% Duty Cycle

Maximum Peak Voltage at Load Circuit 800 VAC

(All 120 & 240 VAC Models)

Maximum Driver Circuit Current 3 amps Continuous

(All 12 & 24 VDC Models)

Alarm Output 100 mA maximum current

at 50 volts DC maximum

5.4 Input Circuit Load Resistances

1 to 5 milliamp Models Approx. 1000 ohms

4 to 20 milliamp Models Approx. 220 ohms

10 to 50 milliamp Models Approx. 100 ohms

0 to 5 VDC Models Approx. 800 ohms

0 to 10 VDC Models Approx. 1100 ohms

Flow Control Division

Worcester Actuation Systems

Page 24

24

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

Flow Control Division

Worcester Actuation Systems

6.0 TROUBLESHOOTING

6.1 General

The following paragraphs and charts are a troubleshooting guide

for servicing the Controller, should a malfunction occur. If the

problem cannot be solved, the unit should be returned to the

factory for service.

The first thing to be checked, before proceeding to the

troubleshooting guide, is to determine if the malfunction is in the

Controller, or in the actuator. To do this for AC boards, remove

the red and black Controller leads from terminals 3 and 4 of the

actuator, and the AC line connections from terminals 1 and 2.

Tape these leads. Using a test cable, apply power to actuator

terminals 1 and 3. The actuator should rotate CCW until stopped

by the CCW limit switch. Then apply power to terminals 1 and 4

to check CW actuation and the CW limit switch.

For 240 VAC Digital Controller only, switches do not directly limit

travel. Exercise caution not to override limit switches. Operate

the unit to its limits in each direction, to assure that the basic

actuator is functional.

If the AC actuator does not operate, check wiring from the

terminal strip, through the limit switches to the motor and

capacitor. For 240 VAC actuator with Digital Controller, check

wiring from the terminal strip to the capacitor and to the motor.

Check switch continuity. Check for an open motor winding, and

check for a shorted capacitor.

If the problem in the actuator still cannot be determined, return

the unit for service. If the actuator functions properly, then

proceed to the troubleshooting guide.

For DC boards, remove red and black leads coming from

motor(s) at terminals 3 and 4. Connect these leads to power

supply to check motor(s) operation. If motor(s) run properly, then

proceed to the troubleshooting guide or return unit for service.

To facilitate troubleshooting a Controller, it would be

advantageous on resistive input units to connect a

potentiometer directly to the Process signal input terminals in

place of the standard process input. Use a 150 ohm or 1000

ohm potentiometer depending on which model is used. Figure 6

shows a schematic of a simple test unit that can be connected

to the input terminals to stimulate the process signal for a

milliamp rating.

6.1.1 Cam Adjustment

The actuator cams should actuate the limit switches 1° to

3° after the actuator stops at either the fully open or fully

closed position.

If the actuator is closed at 0 degrees, the limit switch

must actuate by the time the actuator is at the minus 1 to

3 degree position. Similarly, at the open or 90 degree

position, the limit switch must actuate by the time the

actuator is at the 91 to 93 degree position.

NOTE: See NOTE in paragraph 6.1.3.

6.1.2 Check Fuse F1

Check fuse F1 to see if it is blown. If it is, replace it with

Littlefuse PICO II very fast-acting fuse rated at 62 mA.

(Newark part number 94F2146).

For DC boards, also check fuse F2 to see if it is blown. If

it is, replace it with a 1

1

/

4", 250 volt, 3 amp fuse, available

through any electrical supplier.

IMPORTANT: To check fuse F1 - remove it from circuit

and test with ohmmeter. Resistance should be about

6 ohms.

NOTE: If fuse F1 is blown, excessive voltage (possibly

120 VAC) was applied to the signal input circuit. If so,

correct this condition before changing fuse. See

paragraph A of Part 1.1.

6.1.3 Check Basic Actuator for Proper Operation

For AC boards, check basic actuator for proper operation

using the correct AC Voltage.

A. Remove red and black leads coming from AC circuit

board at terminals 3 and 4 (if already installed). Tape

stripped ends of these wires.

B. For AC boards, alternately energize, with the

appropriate AC voltage, terminals 1 and 3 and 1 and

4. The actuator should move clockwise when

energizing terminals 1 and 4, stopping only at the

clockwise limit switch. The actuator should move

counter-clockwise when energizing terminals 1 and 3,

stopping only at the counter-clockwise limit switch.

NOTE: For 240 VAC Digital Controller only, limit

switches do not directly control motor. Therefore, the

actuator will not stop when the limit switches trip.

Use care not to drive the actuator past its normal

limits. Run the actuator to its limits in each direction,

to assure proper operation of the actuator.

6.1.4 Check for Noise Problems

If the circuit board’s light emitting diodes (LEDs) blink or

seem to continuously glow, electrical noise is interfering

with the Controller’s Process input signal or the setpoint

input signal. (Always use shielded cable for both the

process signal and the setpoint signal coming to the

Digital Controller board. Ground the shield at only one

end.) Adjust Digital Controller as necessary. See Part 4.2.

6.1.5 Replace Circuit Board

The following information is provided if it becomes

necessary to replace the circuit board.

A. Turn off the power supply and disconnect the circuit

board wires from the terminal strip. Disconnect the

pot wires at TB1 and any wires at TB2.

B. Remove circuit board mounting screws, nylon

washers, circuit board and insulator board with

rubber grommets from the brackets.

Page 25

WCAIM2026

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions 25

Flow Control Division

Worcester Actuation Systems

6.2 Symptom Table

SYMPTOM GUIDELINES TO FOLLOW

6.2.1 Actuator will not operate in either direction (no sound from motor(s)). 6.3.1, 6.3.2, 6.3.3, 6.3.4, 6.3.5,

6.3.6, 6.3.7, 6.3.10

6.2.2 Actuator will not operate in either direction 6.3.2, 6.3.3, 6.3.4, 6.3.5, 6.3.6,

(humming or buzzing sound from motor(s)). 6.3.9, 6.3.10, 6.3.11, 6.3.12

6.2.3 Actuator slowly moves in one direction on its own. 6.3.4

6.2.4 Actuator runs normally for 7-8° while coming off limit switch, 6.3.4, 6.3.15

then slows down or stops (motor(s) hum or buzz).

6.2.5 Actuator oscillates intermittently or upon reaching a new position. 6.3.2, 6.3.8, 6.3.13

6.2.6 Actuator runs slowly in one or both directions, 6.3.2, 6.3.4, 6.3.9, 6.3.10,

but otherwise operates normally. 6.3.11, 6.3.12

6.2.7 Actuator works intermittently. 6.3.2, 6.3.10, 6.3.12

6.2.8 Actuator runs normally in one direction but will 6.3.2, 6.3.4, 6.3.7

not operate in the other direction (no hum or buzz from motor(s)).

6.2.9 Actuator will not move valve after a stop when signaled to travel in 6.3.14

same direction as previous command.

Test Unit for Milliamp Setpoint Input Controller – Set R1 all the way toward the plus end. Adjust R2 for a 20 mA reading. Varying R1 will now

provide input signals between 4 and 20 milliamps.

Figure 6 Simple 4–20 mA Supply Circuit

C. Install new circuit board onto the brackets using the

procedure in paragraph B above in reverse order.

Tighten the mounting screws so that the grommets

are about half compressed. Note that 23 size 75

actuators use a spacer in place of a grommet at the

transformer support bracket.

D. Make electrical connections per the appropriate wiring

diagrams (see section 3.0). Feed the 3 feedback pot

wires up through the hole in the board near TB1 (see

figure 1 on either page 6 or 7).

E. Calibrate the new circuit board per Part 4.2

Page 26

26

DataFlo

Digital Electronic Controller DFC17 Installation, Operation and Maintenance Instructions WCAIM2026

Flow Control Division

Worcester Actuation Systems

6.3 Troubleshooting Guidelines

Use the following troubleshooting guidelines to isolate

problems/bad components.

Prior to beginning any procedure, read all of Check, Action, and

Notes and Cautions sections.

CHECK ACTION NOTES AND CAUTIONS

6.3.1 Check for proper AC/DC power to actuator and Correct as necessary.

circuit board. See Figures 2, 3 or 4.

6.3.2 With power off, check for broken wires and/or Repair broken wires and

loose connections. tighten loose connections.

6.3.3 With power off, check to see if fuse F1 is blown. Remove F1 from socket Before restoring power, try to

(For DC boards, see paragraph 6.1.2 also.) pins and check for determine what caused F1 to blow

continuity through fuse with and correct problem. See part 3.2

an ohm meter. If F1 is bad, Note and Paragraph A of Part 1.1, and

replace it with a new fuse. also paragraph 6.1.2.

6.3.4 Check operation of basic See Part 6.1. This check will isolate the problem to

Setpoint actuator per Part 6.1. either the actuator or the circuit board.

6.3.5 Check for proper range of setpoint and Use ammeter, voltmeter or See models listed at beginning of IOM

process input signals. ohmmeter to verify input for ranges. 4–20 mA is most common.

signal range.

6.3.6 Check calibration of feedback potentiometer. With shaft in full CW position, When trying to move the valve

adjust pot for a reading between manually with the clutch disengaged,

.200 and .400 volts. Recalibrate be certain that the wrench fits

per part 4.2 if necessary. properly on the flats of the actuator

shaft. Improper fit can cause shaft

damage with consequent damage to

cover bearing surface. Stay within the

preset quadrant of operation. See

Paragraph C of Part 1.1.

6.3.7 Check to see that varying the process If LEDs do not turn on and off, The turning on and off of the LEDs

signal above and below the Setpoint value replace board. is indicative that the input side of the

causes the light emitting diodes (LEDs) to circuit board is OK.

turn on and off individually.

6.3.8 Check the operation of the Controller with a If intermittent or jittery operation Increasing the deadband may help to

portable, battery-operated Process signal stops, it is indicative of a noisy alleviate the problem.

source if possible or some other appropriate online signal input. To avoid

process signal simulator. damaging the actuator, it is

necessary to “clean up” the signal.

Also, follow the shielding guidelines

of Paragraphs 1.2 and 1.2.3.

6.3.9 Check the motor run capacitor for a short, Replace as necessary. Disconnect all leads from capacitor

excessively high leakage and low terminals (power off) prior to testing.

capacitance. Use a capacitance meter to Do not exceed rated voltage of

check. (AC boards only) capacitor. Make certain that

capacitor is discharged before

reconnecting.

continued on next page

Page 27

WCAIM2026

DataFlo