Page 1

Issue Date: 10/06

GESTRA Steam Systems

Instructions for Installation and Maintenance

Cooling-Water Control Valves Gestramat

CW 41, CW 41/4

PN 16, DN 25 – 100 mm (1 – 4")

Description

The cooling-water control valves type CW are direct-acting

proportional controllers for installation in cooling water or

brine return lines. They ensure that the cooling-water outlet

temperature is maintained at a preset value, calculated for

the process requirements.

When using cooling-water control valves, higher temperatures are possible than with an uncontrolled process.

As a result of the larger heat absorption by the coolingwater or brine, cooling-agent and energy consumption

are reduced.

The regulator of the CW 41 consists of one, two or three

thermostats 3 (depending on the valve size) mounted in series

within a double-seat valve cone 2. The upper cone closes

tight whilst the lower one is designed with a tolerance

to form a leak passage (“s” cone), or the leak passage is

formed by a borehole in the cone (“r” cone).

The thermostats 3 contain an elastomer thermal expansion

material (“n” and “k” thermostats) or wax (“w” thermostat).

Under the influence of heat the volume of the thermostats

increases, projecting a pin which is included in the

thermostat body.

The lift of the thermostats is transmitted to the valve cone

via the pin of setting device 6, supporting the thermostats.

With rising cooling-water outlet temperature, the valve

cone is moved in the opening direction against the force

of the spring. When the temperature drops again the valve

cone is moved by the spring 7.1 in the closing direction.

With the aid of setting key 11 that can be removed and fits

all valve sizes, the position of the setting pin can be varied

to obtain higher or lower cooling-water outlet temperatures

(see “Temperature Adjustment”).

Even if the valve is closed, a continuous bleed flow ensures

a sensitive response. The bleed flow can be increased by

screwing setting screw 7.6 to the right (e.g. in the case of

a long line between heat exchanger and CW).

Installation

1. Screw pressure gauge (item 15) into the inlet (point A

in figure opposite) and thermometer (item 16) into the

outlet (point B in figure opposite). To avoid damaging

these instruments tighten them only at the hexagon

using a spanner (A.F. 14 and 19 mm).

2. Always install CW 41 in the cooling-water return line as

close as possible to the heat exchanger. Flow is in the

direction of arrow. Recommended position: in horizontal

lines, setting device 6 pointing downwards.

With free drainage the CW should be installed so that

it will not run empty, so as to prevent the formation of

deposits. If there is the danger of freezing it might be

useful to provide a drain valve in the water pocket (see

schematic diagram below). If necessary, the valve can

be emptied by unscrewing setting device 6.

Note: When the CW valve is closed, the cooling zone is

under full pump pressure.

Pressure / Temperature Rating

Max. service pressure 16 barg (230 psig)

Max. differential pressure 6 bar (85 psi)

Temperature ratings see “Adjustment Table”, page 4.

Differential pressure = inlet pressure minus outlet

pressure.

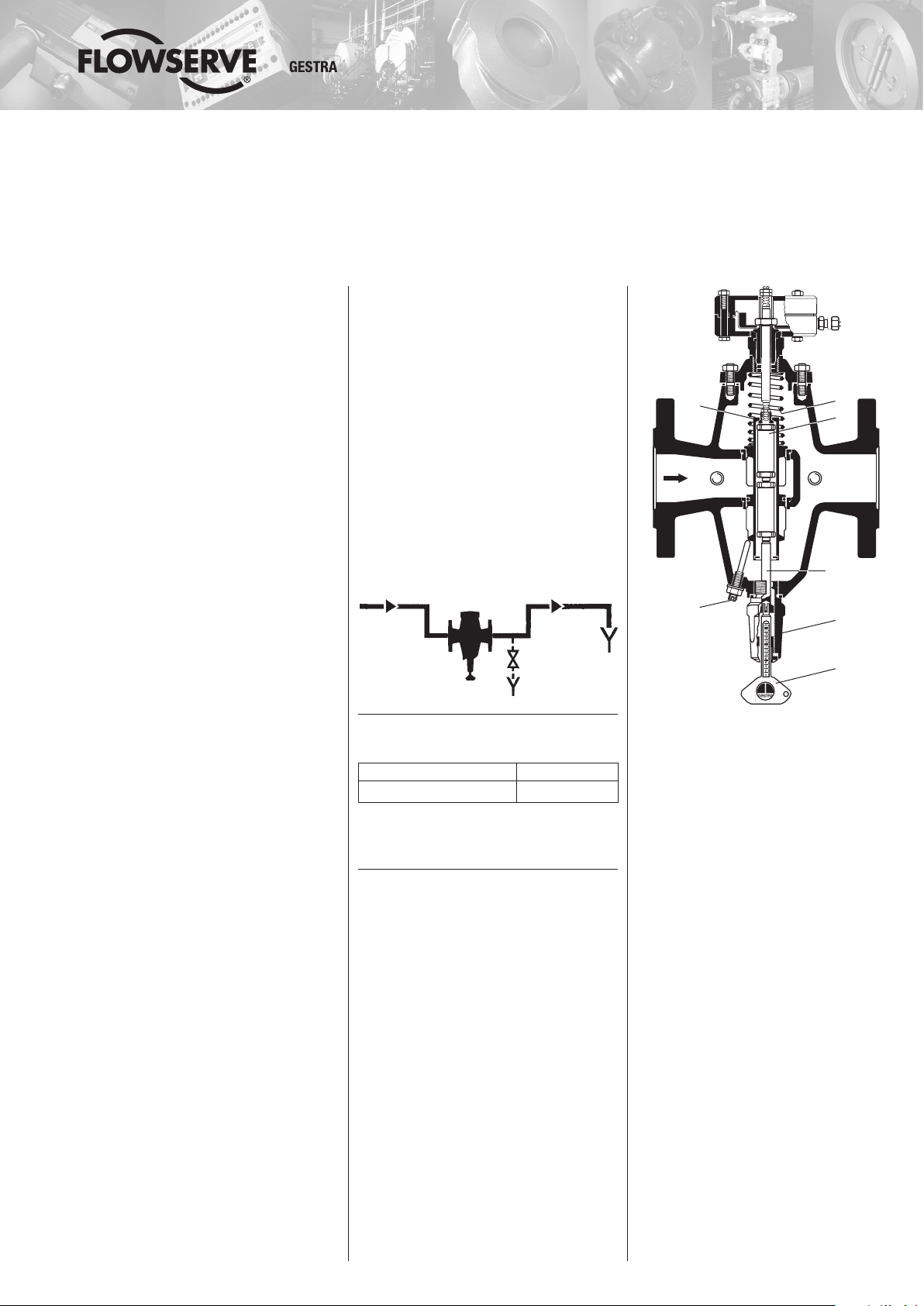

Product Range A4

CW 41

CW 41/4

2

R ¼"

A

7.6

A = Connection for pressure gauge

B = Connection for thermometer

CW 41 DN 40, 50

7.1

3

R ¼"

B

Setting pin

6

11

Maintenance

The CW 41 does not require any particular maintenance.

If there is the danger of freezing, the valve should be

emptied.

Page 2

Parts List CW 41

Item No. Description Stock code Number Material Hints

1

1.1

2 Valve cone:

2.1 O-ring

3 Thermostat complete:

4 Retaining ring 010332 1 S.S. (1.4034) DIN 472 21.1 x 1

5 Gasket 010333 1 DIN 7603 Steel A 26 x 31 mm

6

7.1 Spring

7.2 *) Gasket

7.3 Cover – 1 S.G. iron (0.7043) no spare part

7.4 Stud bolt

7.5 Nut

7.6 Setting screw 004965 1 S.S. (1.4122)

7.8 “Seal-lock” nut 004800 1 8.8 M 8

7.9 *) Gasket 000992 4 DIN 7603 – S.S. (1.4301 N) A 14 x 18

7.10 Plug 085289 4 Steel (1.0501) ¼" BSP

11 Adjusting key 004962 1 Brass (2.0401)

15 Pressure gauge 1) 004704 1

16 Thermometer 1) 184596 1 Measuring range: –30 °C to 100 °C

1

) With “k” thermostat use:

– Setting device complete with extension (stock code 031135)

– Pressure gauge with extension (stock code 031154) and

– Thermometer with extension (stock code 184598)

*) Parts subject to wear (stock keeping recommended)

Body

Seat

“r” cone complete

“s” cone

“w” thermostat

“n” thermostat

“k” thermostat

Setting device complete 1)

Threaded bush

Gasket

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25-50 mm (1-2")

DN 80, 100 mm (3, 4")

DN 25-50 mm (1-2")

DN 80, 100 mm (3, 4")

–

–

184283

184288

184292

004940

004980

030000

030092

030093

031787

004941

030040

030042

004953

031837

010501

004950

004981

030001

184372

184373

184374

010135

010140

010514

013123

1

2

S.G. iron GGG-40.3 (0.7043)

S.S. (1.4122 / 1.4401)

no spare part

no spare part, inerference-fit

1 Cast brass (2.0290)

1 Cast brass (2.0290)

1 EPDM for “r” cone only

1

2

3

1

2

3

1

Body:

Brass (2.0380)

Pin:

Austenitic satinless steel

(1.4571)

2

3

1

1

1

Brass (2.0380) / S.S.

Steel (1.0356)

DIN 7603 Steel

A 40 x 47

{ 100 mm (3, 4")

only for DN 80,

1

1

Austenitic stainless steel (1.4571)

1

1

1

Graphite/CrNi

1

4

6

4

6

DIN 939 – 5.6

DIN 939 – 5.8

DIN 934 – 5

DIN 934 – Steel (1.7258)

45.5 x 75 x 1.0

55.5 x 90 x 1.0

92.5 x 136 x 1.0

M 8 x 22

M 10 x 25

M 8

M 10

Measuring range:

0 – 6 barg (0 – 85 psig)

Note: CW 41 for usual industrial cooling water.

CW 41/4 for salt water, ammoniacal water and chlorinated hydrocarbons.

Page 3

7.5

7.4

7.9 + 7.10

2.1

7.8

7.6

Dismantling

Exchange of Valve Cone / Thermostat

1. Isolate the valve from pressure. Shut off feed line and

7.3

7.2

2

1

A B

7.1

3

7.9 + 7.10

1.1

4

5

6

in the case of back pressure also return line.

2. Remove nuts

Attention: Spring 7.1 is under tension!

Reduce tension by turning adjusting key

Be careful when loosening nuts. Remove cover 7.3,

and take out spring 7.1.

3. Turn adjusting key

felt to push valve cone 2 upwards.

4. Take out valve cone

To exchange thermostats 3 remove retaining ring 4.

(Number of thermostats:

DN 25 mm (1") = 1 off;

DN 40, 50 mm (1½, 2") = 2 off;

DN 80, 100 mm (3, 4") = 3 off.)

The setting device 6 is provided with a righthand thread.

Normally, the setting device need not be dismantled.

Reassembly in reverse order.

Take care that sealing surfaces are clean, replace gasket

7.2. Valves with “r” cone: Ensure that O-ring 2.1 is un-

damaged, replace if necessary.

Torques required for tightening nuts 7.5 at room temperature

DN 25, 40, 50 mm (1, 1½, 2") 15 Nm

DN 80, 100 mm (3, 4") 25 Nm

7.5.

11 to the left.

11 to the right until a resistance is

2 from above.

Tools Required

Spanners for items

7.5 DN 25, 40, 50 mm (1, 1½, 2") A.F. 13 mm

DN 80, 100 mm (3, 4") A.F. 17 mm

6 A.F. 32 mm

15 A.F. 14 mm

16 A.F. 19 mm

Shown

11

CW 41 DN 40, 50 mm (1½, 2")

A = Connection for pressure gauge

(item 15), ¼" BSP

B = Connection for thermometer

(item 16), ¼" BSP

Parts List CW 41/4 (for parts differing from those of CW 41)

Item No. Description Stock code Number Material Hints

2 Valve cone:

For “r” cone only:

O-ring of FKM (Item No. 2.1)

DN 25 mm (1") No. 031151

DN 40, 50 mm (1½, 2") No. 031152

DN 80, 100 mm (3, 4") No. 031788

Measuring range:

0 – 6 barg (0 – 85 psig)

“r” cone complete

“s” cone

3 Thermostat complete:

“w” thermostat

“n” thermostat

“k” thermostat

6

15

15.1

16

16.1

Setting device complete

with extension

Pressure gauge with extension

Pressure gauge, water-proof

Thermometer with extension

Thermometer 105 mm long

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

DN 25 mm (1")

DN 40, 50 mm (1½, 2")

DN 80, 100 mm (3, 4")

184348

184351

184352

030984

030987

030990

184427

184428

184429

031135 1 S.S. (1.4305 / 1.4104)

031154

033779

184598

184597

1 Satinless steel (1.4312)

1 Satinless steel (1.4312)

1

2

3

1

2

3

1

2

3

1

1

1

1

Body and Pin:

Austenitic satinless steel

(1.4571)

Extension: S.S. (1.4104)

Extension: S.S. (1.4104) Measuring range: –30 °C to 100 °C

Page 4

Cooling-Water Control Valves

Gestramat

CW 41, CW 41/4

PN 16, DN 25 – 100 mm (1 – 4")

Temperature Adjustment

GESTRA cooling-water control valves CW 41...– exact

designation see name plate – can be preset with the

adjusting key to the desired cooling-water outlet tem

perature. The graduations on the key correspond to the

temperatures indicated in the adjustment table.

The required outlet temperature is adjusted after start-up.

Turn adjusting key ¼ to ½ turn at a time. (Remember that

one key can be used for all CWs).

The outlet temperature is indicated by the thermometer.

Note that the reaction period of the plant to an adjusted

temperature might be 10 to 50 minutes.

Setting device of CW 41

Read graduation at this edge

Insert key into setting device

until it engages

Increase in Bleed Flow

When supplied, setting screw 7.6 is set so that it does not

touch valve cone 2. To adjust an additional bleed flow with

screw 6 proceed as follows:

1. Turn adjusting key

into closed position. The pressure gauge 15 will then

indicate the full service pressure.

2. Turn setting screw

gauge indicates a pressure drop which signifies that

the opening point of the valve is reached.

3. Adjust additional bleed flow. Normally, ¼ to ½ turn will

suffice. One complete turn to the right corresponds to

a valve lift of approx. 1.2 mm.

11 to the left to bring valve cone 2

7.6 to the right until the pressure

Adjustment table for CW 41 wr, ws, nr, ns, kr, ks

Desired outlet temperature in °C

DN 25 mm (1") DN 40, 50 mm (1½, 2") DN 80, 100 mm (3, 4")

wr

ws

-

68 114 79 41 72 37 36 58 23 –––– 12 –––

54 100 65 38 65 30 34 53 18 ––––––––––

47 82 51 36 58 23 33 49 14 –––– 10 –––

41 72 37 33 51 16 31 44 09 ––––––––––

36 58 23 31 44 09 30 39 04 –––– 8 –––

31 44 09 28 37 02 27 35 00 ––––––––––

25 30 –05 25 30 –05 25 30 –05 –––– 6 –––

18 16 –19 20 23 –12 20 25 –10 ––––––––––

Malfunction

Reasons and Remedies

1. Discontinuous operation, intermittent opening and

closing of valve cone, unstable control position

The reason may be that the cooling-water control

valve is installed at quite a long distance from the heat

exchanger.

Remedy: Install the CW directly downstream of the heat

exchanger or, if this is not possible, increase the bleed

flow.

2. Setting device hard to turn or blocked

This may be caused by foreign bodies, dirt or calcium

deposits in the valve body.

Remedy: Clean cooling-water control valve and mount

a strainer upstream of valve. Calcium deposits can

only be avoided by water softening or possibly a lower

discharge temperature adjustment might help.

nr

ns

03 –32 16 –19 21 –14 –––– 4 –––

kr

ks

wr

ws

68 114 79 47 86 51 –––– 18 –––

60 107 72 45 81 48 ––––––––––

54 100 65 43 77 42 –––– 16 –––

50 93 58 41 72 37 ––––––––––

47 86 51 39 67 32 –––– 14 –––

44 79 44 37 63 27 ––––––––––

nr

ns

09 –26 16 –19 ––––––––––

03 –32 11 –24 –––– 2 –––

kr

ks

wr

ws

63 109 74

57 104 69 –––– 22 –––

54 100 65 ––––––––––

51 95 60 –––– 20 –––

49 90 55 ––––––––––

3. Cooling-water outlet temperature too high

Possible reasons may be wrong temperature adjust

ment, deposits in valve body which affect valve lift or

water admission.

Remedy: Check water supply. Check whether valve

cone moves freely by operating setting device of

cooling-water control valve (see also point 2). Check

correct temperature adjustment in accordance with

adjustment table above.

4. Coolling-water outlet temperature too low

This may be caused by wrong temperature adjustment,

deposits in valve body which impair valve lift or too

large a bleed flow.

Remedy: Check whether valve cone moves freely

by operating setting device several times (see also

point 2).

Readjust cooling-water outlet temperature in accord-

ance with adjustment table above.

Check whether bleed flow is not too large. If necessary,

turn setting screw back to reduce bleed flow.

nr

ns

07 –28 ––––––––––

03 –32

kr

ks

Corresponding

graduations on

adjusting key

––––––––––

–––– 0 –––

-

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03- 0, Fax +49 (0) 421 35 03-393

E-Mail gestra.ag@flowserve.com, Internet www.gestra.de

812993-01/1006cm · 1991 GESTRA AG · Bremen · Printed in Germany

Loading...

Loading...