Page 1

TM

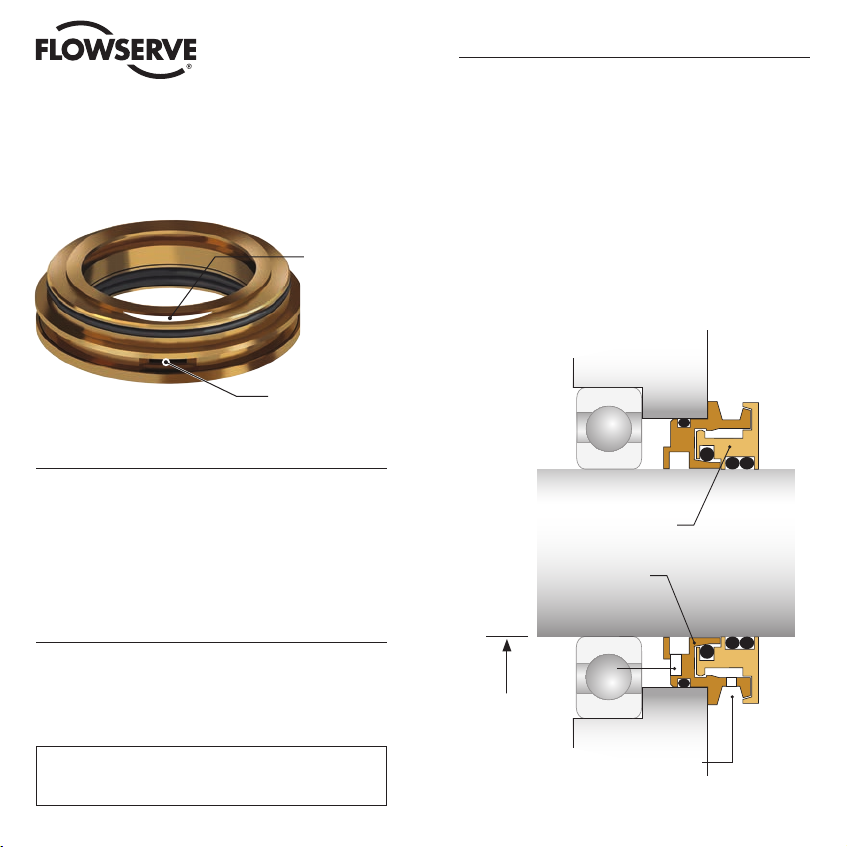

Bearing Gard

Installation, Operation

and Maintenance Instructions

Oil outlet

Section 3 - Preparations for Installation

3.1 Remove the oil seal from the housing.

3.2 Inspect for and remove sharp edges from the

housing bore, keyways, and shaft steps where

Bearing Gard O-rings must pass.

3.3 Thoroughly clean both the shaft and housing bore.

3.4 Ensure Bearing Gard shaft O-ring position is

located on an area of the shaft free from scratches,

nicks, or dings.

3.5 Shaft and housing surface nish must be

0.8 micrometer (32

3.6 Concentricity of the housing bore to the shaft must

to be maintained within 0.127 mm (0.005 inch) TIR.

min) or better.

Contaminant

outlet

Section 1 - Description of Use

The Bearing Gard is a permanent, non-wearing bearing

protection device used to replace lip seals and simple

labyrinth seals in bearing housings for pumps, motors,

gearboxes and other pieces of rotating equipment. It's

main purpose is to retain lubrication in the bearing

housing and prevent the ingress of contamination as this

can lead to premature failure of the lubrication and

bearings.

Section 2 - Hazzard Summary

To ensure safe and reliable operation of the Bearing

Gard follow all installation, operation, and maintenance

instructions. Failure to comply with these instructions

may result in frictional heating of the Bearing Gard

components and will result in loss in performance.

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

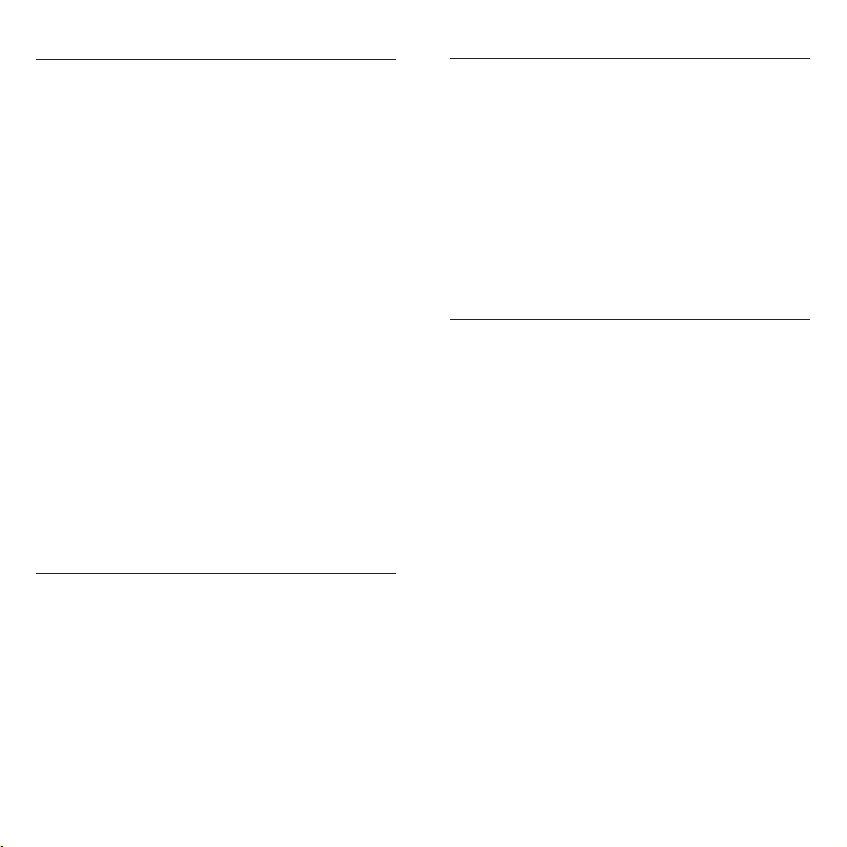

Top view

Maximum

oil level

Bottom view

Housing

Rotor

Shaft

Stator

Oil outlet

Contaminant outlet

Bearing Gard

cross section.

Features vary

by design.

Page 2

Section 4 - Installation

4.1 Do not disassemble the Bearing Gard.

It is designed to be installed as a unit.

4.2 Lightly lubricate O-rings, shaft, and housing bore

with the lubricant provided.

4.3 Align the Bearing Gard in housing so drain port

is located on the bottom.

4.4 Use an arbor press to push rotor into cover bore.

Tool should make contact with as much of rotor

surface as possible. Do not hammer or hit the

Bearing Gard.

4.5 Be sure the face is perpendicular to the shaft.

4.6 Once Bearing Gard is in place, remove and plug

the bearing housing vent. The Bearing Gard is

self-venting and will not allow pressure build up in

the housing. Plugging the bearing housing vent will

reduce contamination entry into the housing.

4.7 Rell bearing housing to proper oil level.

4.8 Spin shaft by hand. Listen and feel for any shaft

binding for rubbing. If binding or rubbing occurs,

verify equipment is within tolerances shown in

Operation section of this document.

4.9 Protect Bearing Gard from mechanical impact in

service by location or suitable guarding.

4.10 Properly align rotating equipment.

FIS223eng REV 12/14 Printed in USA

Flowserve Corporation has established industry leadership in the design and manufacture of its products.

When properly selected, this Flowserve product is designed to perform its intended function safely during its

useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products

might be used in numerous applications under a wide variety of industrial service conditions. Although

Flowserve can provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and

selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read

and understand the Installation Instructions included with the product, and train its employees and contractors

in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are

supplied for informative purposes only and should not be considered certified or as a guarantee of satisfactory

results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or

implied, regarding any matter with respect to this product. Because Flowserve is continually improving and

upgrading its product design, the specifications, dimensions and information contained herein are subject

to change without notice. Should any question arise concerning these provisions, the purchaser/user should

contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2014 Flowserve Corporation

Section 5 - Operation

5.1 Shaft tolerance ± 0.051 mm (0.002 inch)

5.2 Housing tolerance ± 0.025 mm (0.001 inch)

5.3 Maximum axial movement: 0.63 mm (0.025 inch) TIR

Maximum radial runout: 0.13 mm (0.005 inch) TIR

5.4 Speed: 30 m/s (6000 ft/min) maximum

5.5 Maximum temperature: 190°C (375°F)

5.6 Bearing Gard’s labyrinth is designed to contain oil

and repel water. It is not designed for use in either

horizontal or vertical applications that are ooded

with oil or other liquid.

Section 6 - Maintenance

6.1 Use an arbor press to push the Bearing Gard

from the bore. Do not hammer.

6.2 Contact your Flowserve seal representative

for technical support of the Bearing Gard.

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Roosendaal, the Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

Loading...

Loading...