Page 1

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606-6160 Facsimile: 801 489 2228

Automation Business Unit www.flowserve.com Email: actuators@flowserve.com

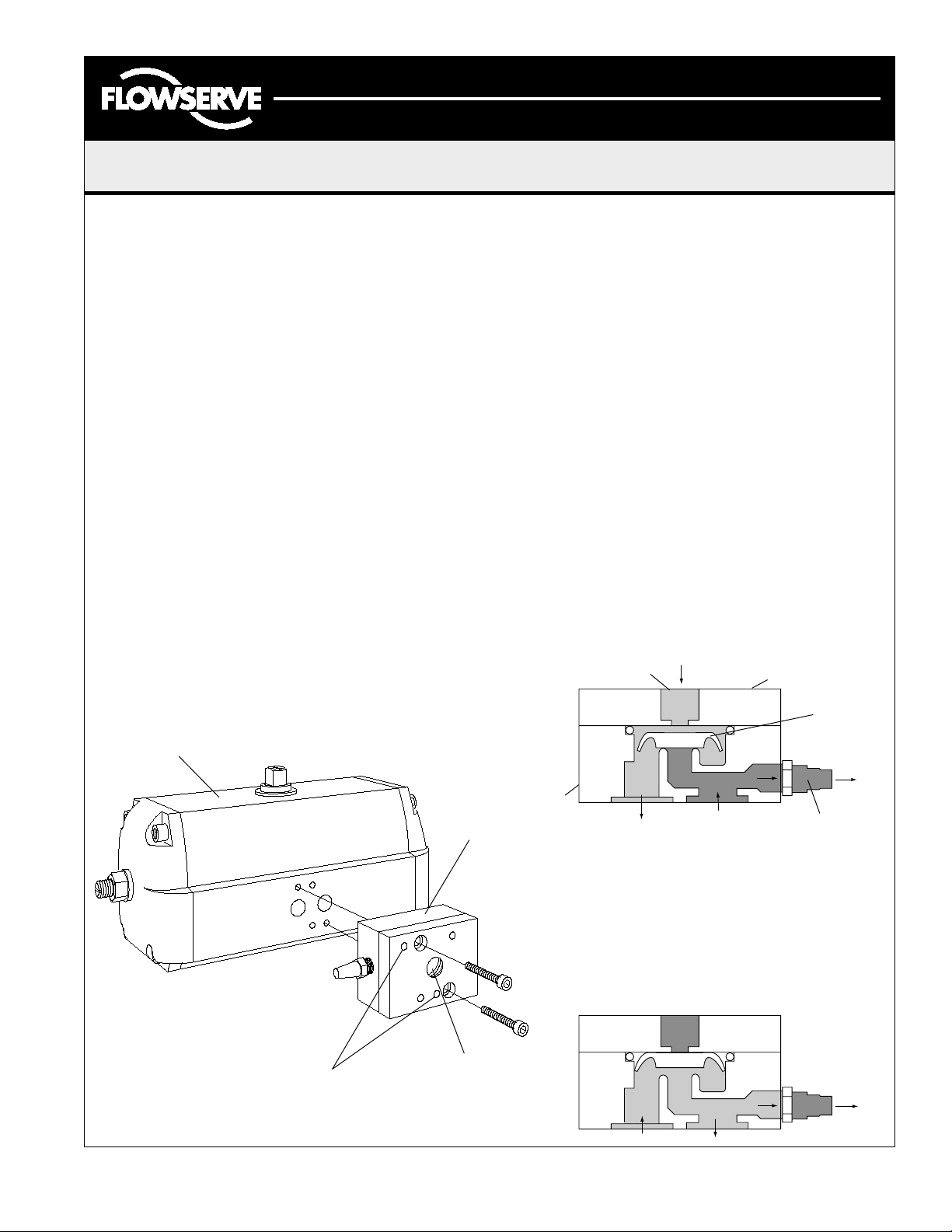

APS2 Module

Installation Instructions

The Automax APS2 may be installed very easily to any

SuperNova series spring return actuator, with the

hardware supplied with the module.

1. Place each o-ring provided into the o-ring bore on

the rear of the module (the side with two large

ports.) Each o-ring should be completely seated

in the bore.

2. Place the actuator with the two ports facing you,

and the stem pointing up. Orient the APS2

module with the o-rings toward the actuator, and

the breather vent facing left.

3. The module will be mounted to the actuator, using

the two diagonal tapped holes next to the ports.

Align these holes with C-bored through holes of

the module, and mount with screws provided.

Directional valves may be line mounted to the APS2

by connecting the appropriate valve port to the 1/4"

NPT supply port on the front of the APS2. In addition,

the module supports the NAMUR mounting standard.

In this case, the directional valve should be positioned

such that the correct port is covering the APS2 supply.

Tapped holes are provided for NAMUR mounting.

Two o-rings are required for this arrangement

(2mm x 16mm o-ring size).

Operation

The Automax APS2 module works with remote line

mounted solenoid valves and diverts exhaust air from

between the pistons into the spring chamber. This

prevents corrosive atmosphere from being pulled into the

spring chamber.

Note: The APS2 can not be used in conjunction with

a positioner.

Temperature: -20°F to 180°F

Pressure: 20psig to 100psig

Media: Dry or lubricated non-corrosive gas

compatible with nitrile and silicone seals.

Exhaust: C∨ = 0.8 (Spring Return Stroke)

Inlet: C∨ = 1.2 (Pressure Stroke)

Actuator Pressurized

Pressure at supply port presses edge of diaphragm to

ring, allowing air flow around and under ring. Air flows

into piston port of actuator, compressing springs. Spring

side air exhausts out vent to atmosphere.

1/4" NPT

Supply Port

Upper Housing

with NAMUR Mounting

Diaphragm

SuperNova

NAMUR Mounting Pattern

LMR0016-0 (AUTO-16) 11/01

© 2001, Flowserve Corporation, Provo, Utah

APS2

1/4" NPT

Supply

Lower

Housing

Piston

Port

Spring

Port

Breather

Vent

Actuator Exhausted

Supply pressure is released and springs push on piston

to force air out piston port. Pressure forces diaphragm

up, covering supply port and revealing spring port. Air

flows into spring port, allowing clean air in instead of

contaminated air from the environment.

Page 1 of 2

Page 2

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606-6160 Facsimile: 801 489 2228

Automation Business Unit www.flowserve.com Email: actuators@flowserve.com

Maintenance Instructions

Trouble Shooting the APS2

Actuator will not cycle.

1. Check for proper orientation of APS2.

2. Check for pinched diaphragm.

3. Check for plugged exhaust port.

Air leaks through breather exhaust when actuator

is held open.

1. Check for pinched diaphragm.

2. Check for diaphragm wear. Diaphragm should be

flexible with no tears.

3. Increase supply air pressure.

7

1

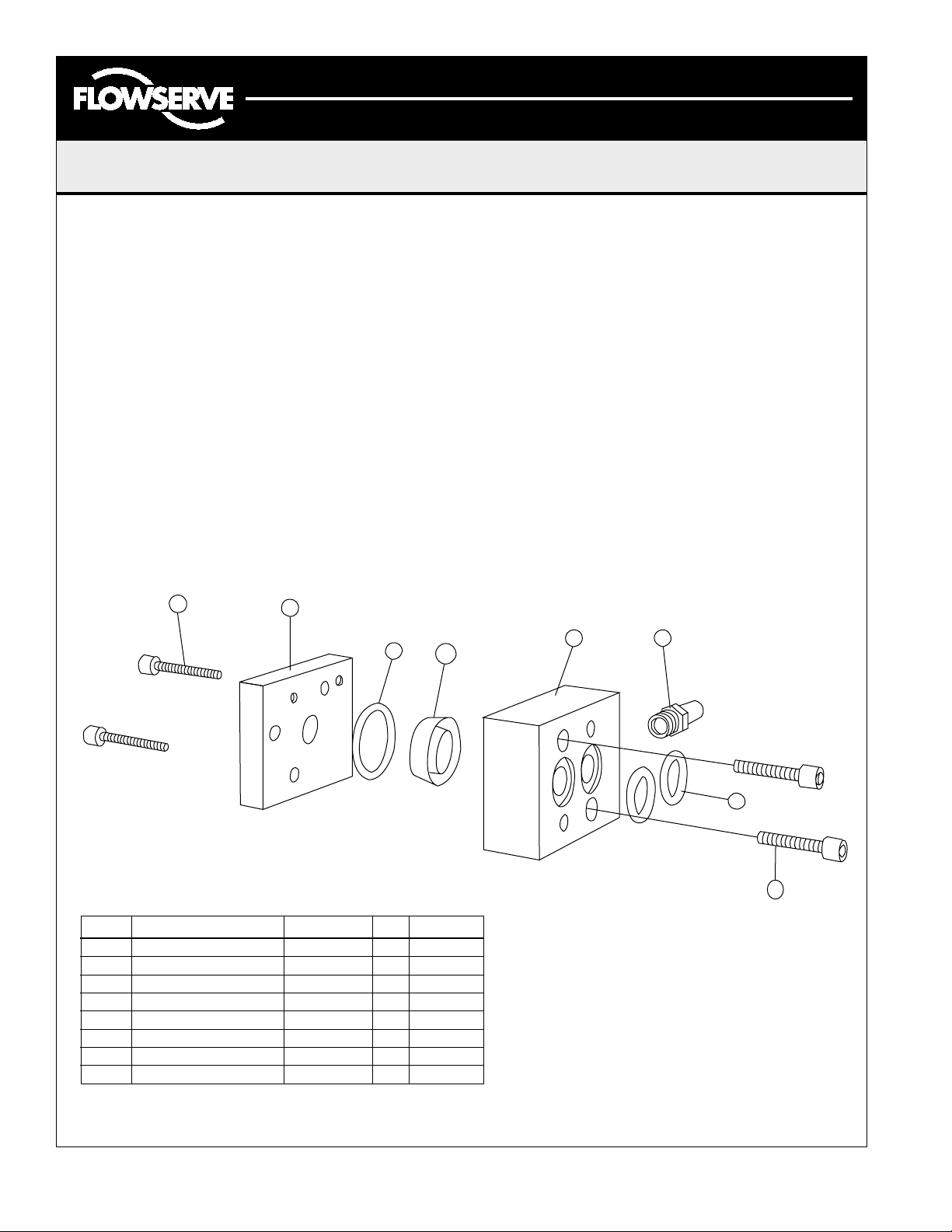

Assembly

1. Hold upper housing (2) with actuator ports side

down. Place large o-ring (4) into o-ring groove of

lower housing.

2. Place diaphragm (3) into center of bore of lower

housing. (See exploded view for diaphragm

orientation.)

3. Aligning pin in upper housing (1), place upper

housing on lower housing.

4. Fasten housing together with M5–.8 x 25 mm

SHCS (6) from lower housing side.

5. Attach breather vent (8) to lower housing, using a

sealant.

6. Place small o-rings (5) into o-ring grooves of

lower housing.

7. Mount to actuator with M5–.8 x 35mm SHCS (7).

Disassembly

Disassembly is reverse of assembly.

4

3

2

8

5

Standard Components

6

Part # Description Materials Qty. P/N

1 Upper Housing Aluminum 1 M610064

2 Lower Housing Aluminum 1 M610063

3 Diaphragm Polyurethane 1

4 O-Ring Nitrile 1 106073

5 O-Ring Nitrile 2 105775

6 M5––.8 x 25mm SHCS Steel 2

7 M5—.8 x 35mm SHCS Steel 2 106075

8 Breather Vent Bronze 1 106200

LMR0016-0 (AUTO-16) 11/01 Page 2 of 2

© 2001, Flowserve Corporation, Provo, Utah

Loading...

Loading...