Page 1

Installation

Automax Valve Automation Systems

APEX 7000 Pneumatic Positioner

FCD AXENIOM0125-00

Principles of Operation:

The Apex 7000 positioner causes rotation (or linear movement) of valve actuator in proportion to an input signal. This

signal may take the form of pneumatic pressure (Model 7000 and 7600) or electric current (Models 7100,7200 7400

7500). Supply pressure is directed to the actuator through a precision spool valve. As input pressure is varied, the

balance beam shifts away from its neutral position. The spool also shifts and a differential pressure is created across

the actuator causing rotation (or linear movement). Actuator motion is fed back through the positioner shaft and cam.

Cam rotation causes movement of the feedback arm, changing compression in the feedback spring, forcing the

balance beam and spool back to their neutral position. This shuts off the flow of air to the actuator and rotation stops

Installation:

The Apex 7000 positioner can be installed on rotary and linear actuators. Actuators can be either double a cting or

spring return. Positioners can be set up for rotation in either direction ( direct or reverse acting).

Supply Air Requirements:

Air pressure must be limited to 150 psi for supply and 30 psi for instrument signal to avoid damage to the positioner.

Supply air must be clean, dry and oil free instrument quality air in accordance with ISA S7.3 specifications ( dew point

>18 degrees below ambient temperature, particle size <5 microns, oil content <1ppm.

Mounting:

The following instructions apply to rotary actuators only. Linear applications require special mounting and coupling

(consult factory).

1. Mount bracket to actuator. Tighten bolts finger tight only at this time. A standard bracket is available for

mounting to NAMUR compliant actuators.

2. Install coupler (not required if installing to a NAMUR compliant actuator) on actuator shaft making sure it is

centered.

3. Verify that orientation of actuator ( and coupler ) flats match positioner shaft flats. If necessary, rotate the cam

before installing positioner ( see “Cam Installation”). NOTE: Actuator should be in orientation corresponding to

zero input signal.

4. Install positioner onto bracket. Make sure positioner shaft and coupler are engaged and centered. Tighten bolts

finger tight only at this time.

Pneumatic Connections: All pneumatic connections, the supply, both output ports, and instrument ports are

female ¼” NPT. All connections require user-supplied tubing fittings. Caution: Do not use Teflon tape as a pipe

thread sealant. Use only a liquid or paste non-hardening pipe sealant on the threads.

5. Connect positioner ports C1 and C2 to actuator. Port C2 is always connected to the actuator port used to drive

actuator away from its start or fail position ( the factor cam setting is full clockwise at minimum input ). Port C1 is

connected to the opposite port or may be plugged for spring return actuators. Note: For fail counterclockwise

applications, the cam must be flipped over so the “R” side is facing upwards (see “Cam Installation”).

Operation

Maintenance

.

Page 2

6. Connect supply air to port marked “S”.

7. Connect instrument signal air to the port marked “I” for model 7000 and 7600. For models 7100, 7200, or 7500,

connect 4-20 mA and ground (-). For intrinsically-safe applications (Model 7400 only), see separate intrinsically-safe

I/P IOM for barrier requirements and schematics. The I-P is factory calibrated and cannot be adjusted.

8. Stroke actuator/valve t wo or three times to align positioner, coupler and actuator. With 50% input (actuator at 45

degrees), tighten all mounting bolts. Stroke actuator/valve again to verify there is no misalignment throughout stroke.

Calibration:

The unit is shipped from the factory pre-calibrated for 90 degree travel (±0.5 degrees rotation – can also be 30/45/60

degrees, see installed cam). For most applications, the valve closed position is much more critical than the valve open

position. Most attention should be made to the valve closed position. Always start calibration procedure by applying

0% input signal, then adjusting zero position.

Caution: Cam pinch points may injure fingers. Be sure to avoid placing fingers and other object s in cam pinch points.

Also avoid touching balance bean and spool while making adjustments as an unpredictable cam rotation may result.

Finally, maintain control of input signal while making adjustments.

After mounting the positioner on the actuator, check cam setting and if needed, perform a cam adjustment:

After mounting the position on the actuator, check cam setting and if needed, perform a cam adjustment:

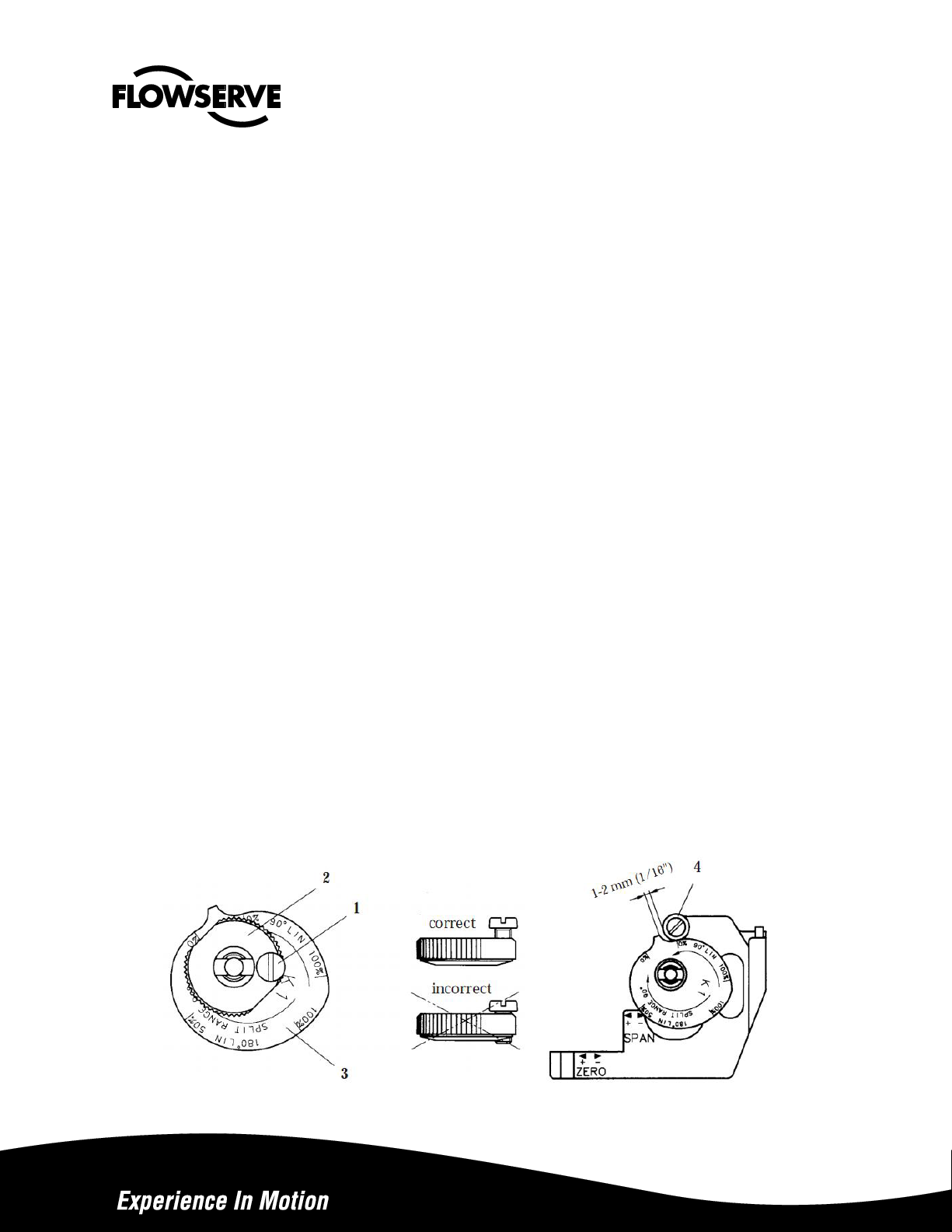

Cam Adjustment:

1. Remove cove and indicator.

2. Loosen the screw (1) and turn the cam locking nut (2) counter-clockwise until the cam loose ns.

3. Adjust the cam (3) as desired making sure that the ball bearing (4) is riding on an active lobe on the cam.

4. To secure the cam, make sure that the screw (1) is backed out form the locking nut (2) then finger tighten the

locking nut and tighten screw (1).

5. Install and adjust the indicator and re-install cover.

Page 3

Calibration Procedure:

1. Apply 0% input signal (0% = 20 kPa, 3 psi, or 4 mA).

2. Wait for steady state. It is important to wait for steady state. On very large actuators, it can take minutes to

establish.

3. Loosen locking screw A about 1 turn, if it is looser, you risk introducing unwanted movement.

4. Adjust “ZERO” position using thumbwheel B

5. Apply 100% input signal (100% = 100 kPa, 15 psi, or 20 mA).

6. Wait for steady state.

7. With a screw drive, adjust the “SPAN” setting by turning screw C, while doing so, keep the zero screw B in

position by applying pressure with your thumb.

8. Lock the calibration mechanism in place by tightening locking screw A

9. Apply 0% signal and verify zero position.

Cam Installation:

Introduction: The standard cam (labeled “K1” features linear, 90 degree operation for full 3-15 psi input, 3-9 and 9-15 psi

split ranges, and 3-15 psi 180 degree operation. The factory setting is 3-15 psi, 90 degrees, with “D: (direct) side up for full

clockwise position at 3 psi for 90 degree operation.

Caution: Be sure supply air pressure is removed and no pressure exists in the actuator before adjusting cam.

Page 4

Cam Adjustment/Replacement:

1. Remove cover and indicator.

2. Loosen the cam lock screw (1) and turn the cam locking nut (2) counter-clockwise until the cam is loose. It may

be necessary to brace the output shaft while loosening the cam locking nut.

3. Adjust the cam (3) as desired, making sure that the cam follower (4) always rides on an active lobe on the cam.

4. Secure the cam by finger tightening the cam locking nut (2) and then tighten the camlock screw (1) see bel ow

Figure below shows cam setting for Direct Action increasing signal 0-1005 (20 – 100 kPa, 3-15 psi) to open. Cam

follower to ride on lobe D, 0-100%

Figure below shows cam setting for reverse action, decreasing signal 100 – 0% (100 – 20 kPa, 15-3 psi) to open. Flip

cam over, cam follower to ride on lobe R, 0-100%

Split Range lobe is used to achieve high resolution in split range applications, where only a portion of the signal is

used to obtain 90 degrees valve travel. For example, to operate 0 to 90 degrees rotation with 0-50% input signal (20 –

60 kPa, 3-9 psi), adjust cam follower to ride on Split Range 0-50% lobe D. Note: to obtain reverse action, flip cam

over and use lobe R.

Page 5

Spool Valve Installation:

To change out or inspect spool valve, air supply to the positioner must be removed.

To remove spool valve:

1. Remove screw (1).

2. Carefully lift out entire spool valve assembly (2), disengaging spool (3) from balance arm (5).

To maintain highest performance, do not mix spool and block. Do not lubricate valve.

To Install new spool valve:

1. Ceck that O-rings are in place.

2. Insert spool valve assembly (2), making sure that the leaf spring (4) and balance arm (5) engage the slot in spo ol

(6).

3. Tighten screw (1).

4. Check for smooth operation of assembly.

I-P Installation:

All I-O modules are factory calibrated an cannot be adjusted. Kits are available to allow easy field installation of

various input options. Kits include modules, mounting hardware, fasteners, and O-rings.

1. disconnect signal and supply air from positioner.

2. Remove screw (1) from positioner housing.

3. Make sure O-rings (2) are seated correctly in I-P housing.

4. For weatherproof or intrinsically-safe I-P module, remove cover (4) to allow access to third mounting screw (5).

5. Attach I-P module (3) to positioner housing with three mounting screws (5) provided.

Page 6

Electrical Specifications

Model Agency Approvals Hazardous Location

Rating

1

Max Voltage

(vdc)

Min. Voltage

(vdc)

Max. Current

(mA)

7000 None None N/A N/A N/A

7100 None None 30 vdc 6 vdc 150 mA

7200

7400

7500

FM

CSA

ATEX/IECEx

2

FM

CSA

ATEX/IECEx

(EX) Cl. I Div 1, Gr. B-D

(EX) Cl. I Div. 1 Gr. B-D

(EX) Ex d IIC T4-T6

3

(IS) Cl. I Div. 1 Gr. A-D

(IS) Cl. I Div. 1 Gr. A-D

(IS) Ex ia IIC T6

3

30 vdc

30 vdc

30 vdc

28 vdc

28 vdc

30 vdc

4

4

4

4

6 vdc

6 vdc

6 vdc

6 vdc

6 vdc

6 vdc

150 mA

150 mA

50 mA

50 mA

50 mA

110 mA

4

4

4

4

7600 None None N/A N/A N/A

Warning: These instruments must be installed in accordance with local national electrical codes, especially for hazardous

locations. Consult unit label to determine specific unit certifications.

Notes:

1 See hazardous location certificate for detailed temperature ratings. All

Apex 7000 units comply with ATEX

directive for non-electric equipment intended for use in hazardous locations to Ex II 2 G.

2 Additional information regarding entity parameters and instructions for wiring to intrinsically-safe I-P may be found

in separate IOM, as well as in the hazardous location certificate.

3 See hazardous location certificate for special conditions for safe use.

4 Maximum voltage and current considerations may be affected by application specifics, such as choice of barrier,

ambient temperatures, etc. See hazardous location certificate for additional information.

Filter Plug Replacement:

Caution: Do not operate the unit without filter and filter plug installed. Do not attempt to unscrew filter plug while

positioner is pressurized

Note: This filter is not designed to act as a permanent source of clean, dry air.

.

Page 7

1. Remove air supply pressure from positioner.

2. Unscrew filter plug (1) and O-ring.

3. Remove filter (3) and inspect filter and filter compartment. If moisture is found, check upstream filters and oil-

water separators. Moisture can cause I-P failure.

4. Replace filter if necessary and reinstall.

Maintenance:

The Apex 7000 positioner is designed for long life and trouble-free operation. The following steps should b e followe d

every six months to assure proper operation.

1. Check air supply and associated filtration equipment. See “Supply Air Requirements.”

2. Make sure arms, bearings, and adjustment screws move freely. Caution: Moving parts to check freedom with

supply pressure connected will cause rotation of cam. Be sure to keep fingers away from cam pinch points. If

parts do not move freely disassemble and lubricate with a light, instrument grade grease (Lubriplate MAG 1 or

equivalent).

3. Check for smooth operation of the spool valve. If it sticks or feels “gummy”, remove and clean both spool and

valve bore with solvent. Make sure both parts are clean and dry before reinstalling. Do NOT apply grease to

these parts.

4. Check for air leaks in air supply.

5. Refer to “Troubleshooting” sections if maintenance dows not cure problem.

Page 8

Spare Parts APEX 7000, 7600

No. Part No Qty Description Remarks

1 1 Housing 1 N/A

2 1 Front Cover

3 1 Diaphragm cover incl. O-ring

4 1 Diaphragm

5 2 Diaphragm washer

6 1 Balance Arm

7 1 Feedback spring 3-15 psi assembly

7 1 Feedback spring 6-30 psi assembly Green

8 1 Lower arm assembly

9 1 Rod

10 1 Spring

11 1 Twist Stop

12 1 Pilot valve incl. O-rings

13 1 Cam locking nut incl. screw

15 1 Mounting adapter incl. screws

16 1 Ball bearing

17 1 Cam K1 90°/180° Linear 0-100%, split range 0-50-100% 1

17 1 Cam special, K2-K10 (Consult Factory)

18 1 Spindle

19 1 Indicator Arrow

20 1 Set Screw set

21 1 Seal and O-ring set NBR, Nitrile rubber (4,21)

Page 9

Spare Parts APEX 7100,7200,7300, 7400

No Part No. Qty Description Remarks

1

2

3

3

4

6

6

7

8

9

10

13

13

18

1 Housing

1 Front Cove incl. O-ring

1 Connecting block NPT ¼” assembly

1 Connecting block G ¼” assembly

1 Relief valve spring

1 Gasket for Apex 7000

1 Gasket for Apex 7100

1 Diaphragm cover incl. O-ring

1 Diaphragm

2 Diaphragm washer

1 Balance Arm

1 Feedback Spring 3-15 psi assembly

1 Feedback Spring 6-30 psi assembly

1 Lower arm assembly

Page 10

No Part No. Qty Description Remarks

19

20

21

21

21

22

22

22

24

25

26

27

29

30

31

32

35

36

36

37

38-45,75-80

6,46-53,67,70,75-80

6,46-53,67,70,75-80

54

61

62

63

63

64

65

66

67

71

73

74

74

74

84

4

4

1

1

1

1

1 Rod

1 Spring

1 Indicator Arrow

1 Indicator Flag

1 Indicator Pointer

1 Indicator cover transparent incl. O-ring

1 Indicator cover flag incl. O-ring

1 Indicator cover blind incl. O-ring

1 Twist stop

1 Pilot valve incl. O-ring

1 Shaft incl. O-rings, scres

1 Cam locking nut incl. screw

1 Zero Cover

1 Cover

1 Mounting adapter incl. screw

1 Ball bearing

1 Identification cover

Plug NPT 1/8”

Plug 1/8” G

Cam

Screw set Apex 7000/7100

O-ring set Apex 7000/7100, Nitrile NBR

O-ring set Apex 7000/7100, Silicone, Q

1 Spindle adapter

1 I/P box

1 I/P cover incl. screws

1 I/P nose NPT ¼” assembly

1 I/P nose G ¼” assembly

1 Relief valve spring

1 Filter plug incl. filter (66), O-ring (81)

1 Filters (5 per package)

1 Gasket I/P

1 I/P converter

1 Mounting bracket round I/P

1 Enclosure incl. I/P converter std.

1 Enclosure incl. I/P converter, flameproof (Cenelec)

1 Enclosure incl. I/P converter, Explosionproof (FM,CSA)

1 I/P converter fail in last position incl. bracker

Page 11

Representative:

Flowserve Corporation

1978 Foreman Drive

Cookeville, Tennessee, USA, 38501

931 432-4021

Flowserve Flow Control UK Ltd

Haywards Heath, West Sussex, Uk

44 (0)1444 314400

Flowserve Corporation

12 Tuas Avenue 20

Singapore

68798900

Flowserve Corporation

Rua Tocantins, 128

São Caetano do Sul, SP, Brazil

55 11 2169-630

0

Bulletin FCD AXENIOM0125-00

To find your local Flowserve representative please

use the Sales Support Locator System found at

www.flowserve.com

Or call toll free: 1-931-432-4021

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this

Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products

should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although

Flowserve can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must

therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve pr oducts .

The purchaser/user should read and understand the (INSERT OFFICIAL USER INSTRUCTION TITLE) instructions included with the product,

and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only

and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed

as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is continually improving

and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should

any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations

or offices.

For more information about Flowserve Corporation, contact

www.flowserve.com or call USA 1-800-225-6989.

Loading...

Loading...