Page 1

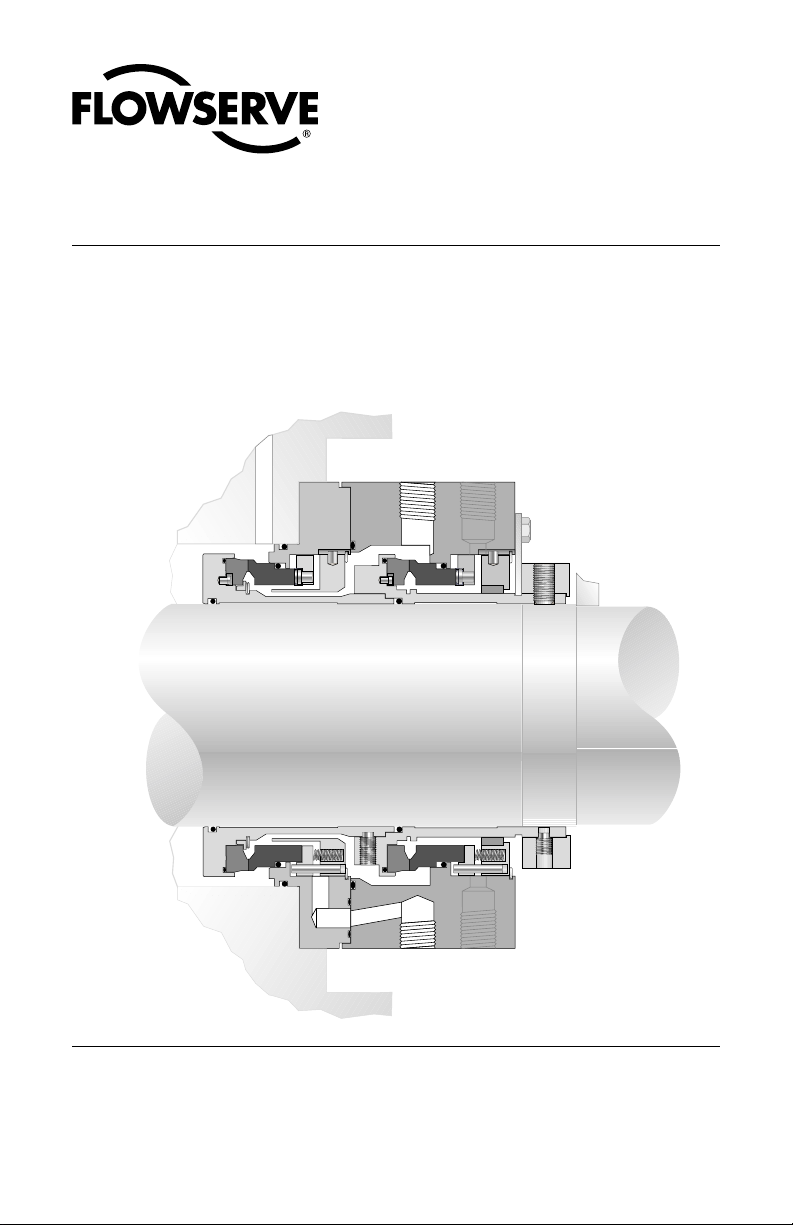

Allpac MP

Flow Solutions Division

BW Seals

Durametallic Seals

Pacific Wietz Seals

Pac-Seal

Dual-inline, cartridge seal

for multiphase applications

Installation Instructions

Page 2

Introduction

The Allpac MP is a dual-inline, cartridge seal specifically designed for multiphase twinscrew pumps. Four mechanical seal assemblies are installed on one pump. Each seal is

identical; they are designed to fit in any location on the pump.

1 Equipment Check

1.1 Follow site safety regulations prior to equipment disassembly.

• Lock out motor and valves

• Wear designated personal safety equipment

• Relieve any pressure in the system

• Consult site MSDS files for hazardous material regulations

1.2 Disassemble equipment to allow access to seal installation area.

1.3 Remove all burrs and sharp edges from the shaft or sleeve including sharp edges

of keyways and threads. Replace shaft or sleeve if worn in the sleeve gasket

area. Make sure the seal housing bore and face are clean and free of burrs.

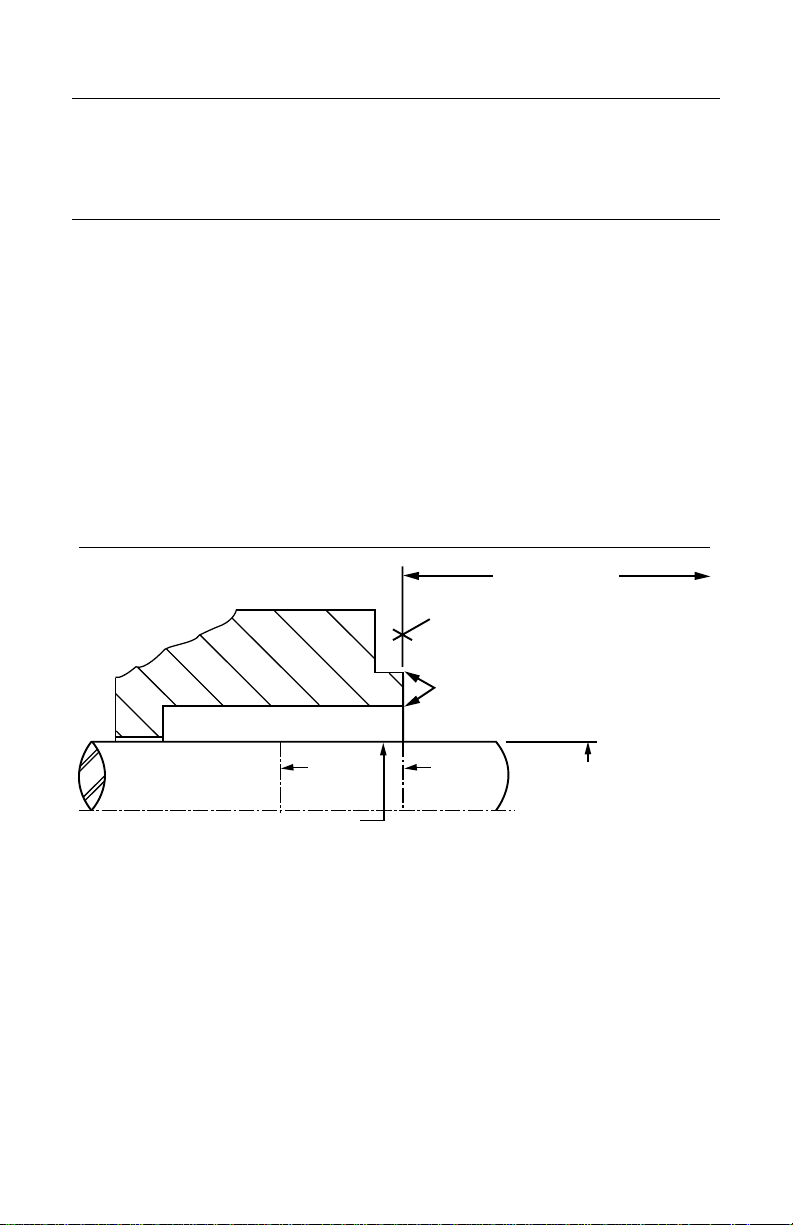

1.4 Check requirements for shaft, sleeve, and seal housing, see Figure 1.

Seal Chamber Requirements

To first obstruction

Face of seal housing to be square to the axis

of the shaft to within .005 inch (0.13 mm) FIM

and have a √63 µ inch (1.6 µm) R

better

Concentric to within .005 inch (0.13mm) FIM

Seal housing bore to have a √125 µ inch

(3.2 µm) Ra finish or better

Scribe

Mark B

Sleeve or shaft finish to be

√32 µ inch (0.8 µm) Ra or better

• Bearings must be in good condition.

• Maximum lateral or axial movement of shaft (end play) = .010 inch (0.25mm) FIM

• Maximum shaft runout at face of seal housing = .003 inch (0.07mm) FIM

• Maximum dynamic shaft deflection at seal housing = .002 inch (0.05mm) FIM

of shaft or sleeve O.D.

Scribe

Mark A

+.000 inch (+.000mm) API 610

Figure 1

finish or

a

1.5 Check assembly drawing included with the cartridge seal for materials of construc-

tion, dimensions, and piping connections.

1.6 Check shaft or sleeve O.D., box bore, and distance to the first obstruction to

ensure that they are dimensionally the same as shown on the seal assembly

drawing.

1.7 Check gland pilot and bolt holes to ensure they are adaptable to the equipment

and are the same as shown on the assembly drawing.

2

© Copyright 2002 Flowserve Corporation

Page 3

1.8 Handle all seal parts with care, they are manufactured to precise tolerances. The

contacting surfaces of the rotating and stationary seal faces must be treated with

particular care. These two surfaces are lapped flat to within three helium light bands

(34.8 millionths of an inch). Keep the seal faces perfectly clean at all times.

2 Allpac MP Seal Installation

2.1 Lubricate the shaft or sleeve lightly with silicone lubricant before installing any seal

parts.

2.2 Lubricate the two sleeve gaskets before installing them in their grooves in the sleeves.

2.3 Lubricate the flange gasket before installing onto the pilot diameter on the seal

cartridge.

2.4 Back out the drive collar set screws slightly so that no portion of them extends

inward past the sleeve ID.

2.5 Install the complete cartridge seal assembly on the shaft and position it with the

seal oriented toward the pump. If at any time the seal requires a significant amount of

force to position correctly, STOP, BACK UP, and assess the situation.

2.6 Position the cartridge flange against the seal chamber face and tighten the gland

stud nuts evenly in a star pattern. The nuts can be torqued using ordinary wrenching

techniques.

2.7 Adjust the bearings, coupling and pump rotating assembly so that the shaft is in

its operating axial position. Any subsequent axial adjustment of the shaft requires

resetting of the seal.

2.8 Tighten the drive collar set screws to the value specified on the assembly drawing.

Improper installation torque can damage the screws or shaft or result in lower axial

thrust retention of the drive collar.

2.9 Loosen the setting plate fasteners and slide the setting plates away from the drive

collar and sleeve as far as possible. Tighten the setting plate fasteners so that the

setting plates do not come loose during operation.

3 Barrier System Piping

3.1 Each dual cartridge seal has pipe ports labeled as shown in the assembly drawing.

3.2 The Allpac MP seal is designed to be operated with the seal flush and support systems

as defined on the assembly drawing.

4 Operation

4.1 During the first hour of operation, seal performance should be monitoredvery

closely:

• The temperature rise of the barrier fluid should be steady and should level out

after an hour of operation. A quickly rising temperature or a temperature that does

not seem to be leveling off signals a problem and should be thoroughly investigated.

• A sudden rise or decrease in barrier fluid, or a significant color change of barrier

fluid signals off-design leakage and should be thoroughly investigated.

3

Page 4

• A leakage rate of more than 30 drops per minute of the outboard seal signals off-

design leakage and should be thoroughly investigated.

• Excessive vibration of the pump should be investigated immediately.

5 Repairs

This product is a precision sealing device. The design and dimension tolerances are critical

to seal performance. Only parts supplied by Flowserve shall be used to repair the seal.

These are available from numerous Flowserve stocking locations. To order replacement

parts, refer to the part number, material code and description listed on the assembly

drawing.

Decontaminate the seal assembly and return it to Flowserve with an order marked

“Repair or Replace.” A signed certificate of decontamination must be attached.

A Material Safety Data Sheet (MSDS) must be enclosed for any product that came in

contact with the seal. The seal assembly will be inspected and, if repairable, it will be rebuilt,

tested and returned in its original condition.

All Flowserve Corporation, Flow Solutions Division, products must be installed in accordance with Flowserve

installation instructions. Failing to do so or attempting to change or modify Flowserve products will void

Flowserve’s limited warranty. Flowserve’s limited warranty is described fully in Flowserve’s Standard Terms and

Conditions of Sale. Flowserve makes no warranty of merchantability or fitness for a particular purpose and in

no event shall Flowserve be liable for consequential or incidental damages.

Flowserve Corporation Flow Solutions Division

Primary Worldwide Flow Solutions Division Locations Licensees, authorized agents, and affiliated companies located worldwide

United States

Kalamazoo, MI

Phone 269-381-2650

Fax 269-381-8368

Edmonton, Alberta

Phone 780-463-7958

Fax 780-450-1241

Canada

Scarborough, Ontario

Phone 416-292-2877

Fax 416-292-5190

Singapore Japan

Phone 65-746-4318

Fax 65-747-1963

Printed in U.S.A.

Tlaxcala

Phone 52-2-461-6791

Fax 52-2-461-6847

Sao Paulo

Phone 55-11-4066-8600

Fax 55-11-4066-7014

Netherlands

Roosendaal

Phone 31-165-581400

Fax 31-165-552622

Osaka

Phone 81-720-85-5571

Fax 81-720-85-5575

www.flowserve.com

ISO 9000

Certified

Argentina

Villa Martelli

Phone 54-11-4709-6800

Fax 54-11-4709-7072

GermanyBrazilMexico

Dortmund

Phone 49-231-6964-0

Fax 49-231-6964-248

Australia

Marayong NSW

Phone 61-2-8822-7100

Fax 61-2-9679-7511

FIS156

ORG 07/02 USA

Loading...

Loading...