Page 1

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 1

Date: 12.1995

Revision: 08.2009

Register 13

CONTENTS - AKH2A

Contents Page

Technical Data AKH2A ...................................................................................................... 2

Material Specication AKH2A ............................................................................................3

Dimensions AKH2A ........................................................................................................... 4

Spare Parts AKH2A Standard ..........................................................................................5

Assembly Instructions AKH2A ........................................................................................... 6

Disassembly Instructions AKH2A ...................................................................................... 7

AKH2A - Recommended Tightening Torques ....................................................................8

Manual Actuator ................................................................................................................9

Material specication ......................................................................................................... 9

Material Specication - AKH2A with manual actuator .....................................................10

Technical Data - AKH2A with manual actuator ................................................................ 11

AKH2A with actuator mounting (drawing) ........................................................................13

Material Specication- AKH2A with actuator mounting ..................................................14

AKH2A - Dimension Sheet for actuator mounting acc. to NAMUR-recommendation .....15

AKH2A/DA - Vented Seatrings ........................................................................................ 16

Material Specication AKH2A/DA ....................................................................................17

Assembly Instructions - AKH2A/DA .................................................................................18

AKH2A with stem extension (drawing) ............................................................................19

Material Specication - AKH2A with stem extension ....................................................... 20

Technical Data - AKH2A with stem extension..................................................................21

Technical Data/Material Specication- AKH2A with lockable hand lever ........................22

AKH2A - K

and Cv - Data ................................................................................................23

v

Optional C-ball in ball valves ..........................................................................................24

Optional V-ball in ball valves ...........................................................................................25

AKH2A - atomac ball valve

Page 2

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

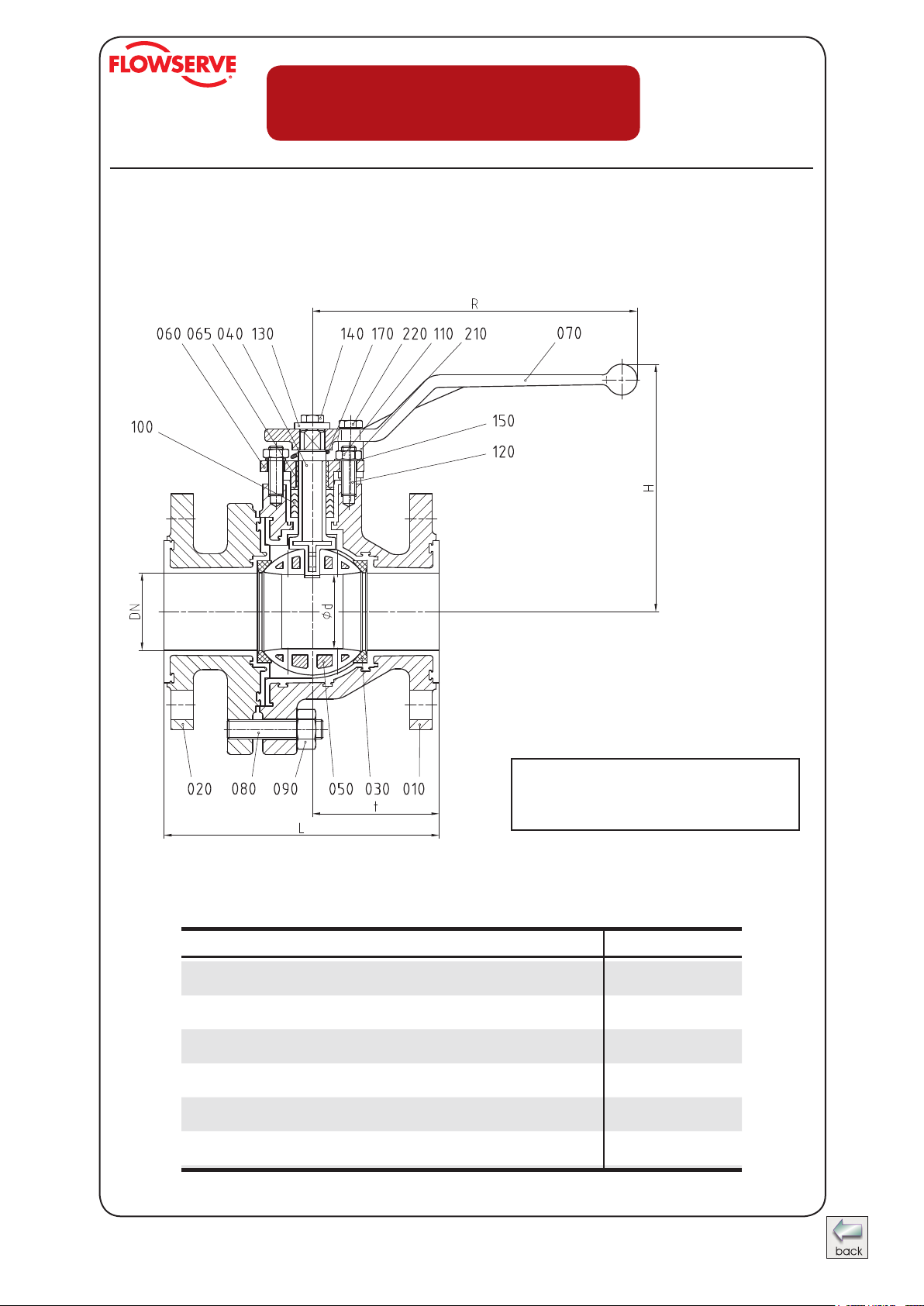

Technical Data AKH2A

Register: 13

Page: 2

Date: 12.1995

Revision: 08.2009

Face-to-Face Dimensions ISO 5752 Tab. 6, short

ANSI B 16.10, short

Flange Connections ANSI B 16.5 - 150lbs

DN / ANSI L H R t Ød

inch 5 4,72 6,3 2,26 0,94 lbs 9,1

1“

mm 127 120 160 57,5 24 kg 4,2

inch 6,5 5,71 8,27 2,95 1,5 lbs 17,2

1½“

mm 165 145 210 75 38 kg 7,8

inch 7 6,3 8,27 3,23 1,89 lbs 25,4

2“

mm 178 160 210 82 48 kg 11,6

inch 8 8,07 12,32 3,96 2,83 lbs 56,5

3“

mm 203 205 313 100,5 72 kg 25,7

inch 9 8,66 12,32 4,37 3,74 lbs 81,2

4“

mm 229 220 313 111 95 kg 36,9

inch 10,5 11,77 13,27* 5,28 5,12 lbs 171,6

6“

mm 267 299 337* 134 130 kg 78,0

* pass-through handlever ø 26,54 inch standard

weight

AKH2A - atomac ball valve

Page 3

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 3

Date: 12.1995

Revision: 08.2009

Material specication AKH2A

No. Designation Pieces Material Material-No. / DIN ASTM / AISI

010 body 1 ductile iron / FEP ° EN-JS1049 (GGG-40.3) / A 395

020 side piece 1 ductile iron / FEP ° EN-JS1049 (GGG-40.3) / A 395

030 seat ring 2 PTFE pure - PTFE

040 stem 1 stainless steel / PFA 1.4470 /DIN EN 10283 A 890 CD3MN

050 ball

060 gland follower 1 stainless steel 1.4308 / DIN EN 10283 A 743 CF-8

065 gland insert 1 PTFE-graphite

070 hand lever

080 stud bolt 1 set stainless steel 1.4301-K70 / DIN EN 10088-3 A 193 B8

090 hexagon nut 1 set stainless steel 1.4301-K70 / DIN EN 10088-3 A 194 8

100 packing material 1 set PTFE °

110 hexagon nut 2 stainless steel 1.4301 / DIN EN 10088-3 A 194 8

120 stud bolt 2 stainless steel 1.4301 / DIN EN 10088-3 A 193 B8

130 lock washer 1 stainless steel 1.4301 / DIN EN 10088-3 AISI 304

140 hexagon bolt 1 stainless steel 1.4301 / DIN EN 10088-3 A 193 B8

150 serrated lock washer 1 stainless steel 1.4301 / DIN EN 10088-3 AISI 304

170 grounding device 1 stainless steel 1.4310 / DIN EN 10270-3 AISI 301

210 stop

220 hexagon bolt** 1 stainless steel 1.4301 / DIN EN 10088-3 A 193 B8

DN 1“ - 2“ 1 tool steel, alloyed / PFA° 1.2343 / DIN EN ISO 4957 A 646-95 (Gr. 10)

DN 3“ - 6“ 1 ductile iron / FEP ° EN-JS1049 (GGG-40.3) / A 395

DN 1“ - 2“ 1 die cast metall ZP0410 / DIN EN 12844

DN 3“ - 4“ 1 malleable cast iron (galvanizing) EN-GJS-50-7 (GGG-50)

DN 6“: adapter;

level

(chevron) PTFE-graphite °

DN 1“ - 4“ 1 steel (galvanizing) 1.0037 / DIN EN 10025-2 A 283 B

DN 6“ 1 stainless steel 1.4104 / DIN EN 10088-3 AISI 430 F

1

ductile iron / PFA ° DIN EN 1563

ductile iron / PFA ° DIN EN 1563

Hastelloy C4 / PFA °° 2.4610 / DIN 17744

tool steel, alloyed / FEP°

ductile iron / PFA ° DIN EN 1563

ceramic Al

stainless steel;

steel (chromated)

2O3

*

1.4308 / DIN EN 10283;

1.0037 / DIN EN 10025-2

A 743 CF-8

A283 B

* ceramic ball on request

°° Hastelloy stem on request

° optional

** DN 6“ 2 hexagon bolts

AKH2A - atomac ball valve

Page 4

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

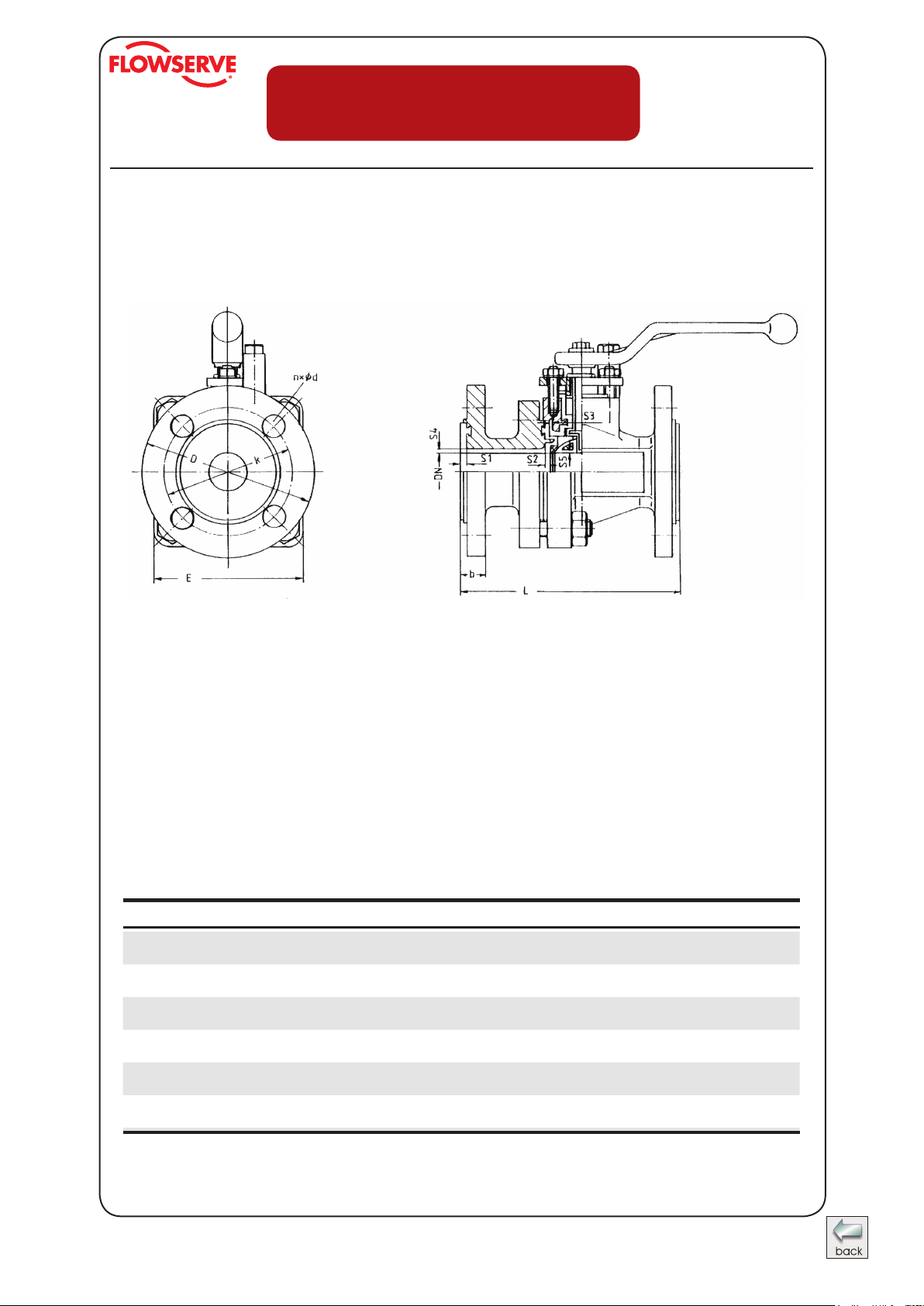

Dimensions AKH2A

Register: 13

Page: 4

Date: 12.1995

Revision: 08.2009

DN / ANSI L E ° b D k nxØd S1 S2 S3 S4 S5

inch 5 3,82 0,57 4,25 3,13 4x0,63 0,16 0,1 0,13 0,13 0,1

1“

mm 127 97 14,5 107,9 79,2 4x16 4,0 2,5 3 3 2,5

inch 6,5 4,65 0,71 5 3,88 4x0,63 0,16 0,13 0,13 0,13 0,13

1½“

mm 165 118 18 127 98,5 4x16 4 3 3 3 3

inch 7 5,51 0,75 6 4,75 4x0,75 0,16 0,13 0,13 0,13 0,13

2“

mm 178 140 19 152,4 120,5 4x19 4 3 3,0 3 3

inch 8 8,66 0,85 7,5 6 4x0,75 0,16 0,14 0,16 0,14 0,16

3“

mm 203 220 21,5 190,5 152,5 4x19 4 3,5 4 3,5 4

inch 9 9,65 1,02 9 7,5 8x0,75 0,16 0,14 0,16 0,14 0,16

4“

mm 229 245 26 228,6 190,5 8x19 4 3,5 4 3,5 4

inch 10,5 12,32 1,14 11 9,5 8x0,87 0,16 0,2 0,16 0,2 0,12

6“

mm 267 313 29 279,4 241,5 8x22 4 5 4 5 4,5

stem lining DN 1“ 0,059 inch

all other sizes at least 0,098 inch

° DN 3“ and 4“ hexagonal

° DN 6“ octagonal

AKH2A - atomac ball valve

Page 5

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 5

Date: 12.1995

Revision: 08.2009

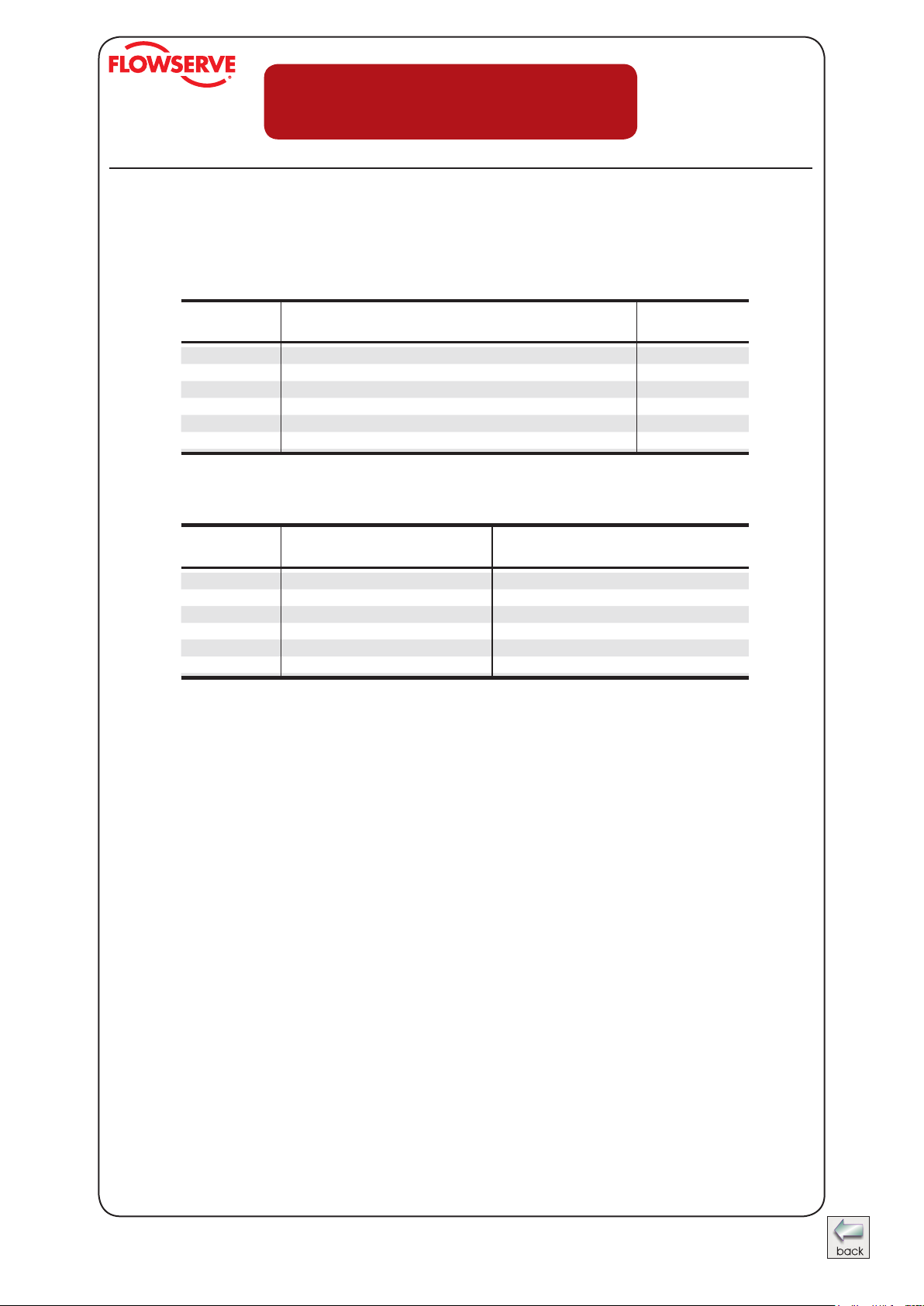

Spare Parts (item n°) - AKH2A Standard Version

ANSI

1“ 0000268 0000323 0002317 0000159

1½“ 0000270 0000325 0002319 0000160

2“ 0000271 0000326 0002320 0000161

3“ 0009170 0009172 -- 0009425

4“ 0009171 0009173 -- 0009426

6“ 0009340 0009341 -- 0009427

ANSI

1“ 0000115 0000116 0000167 0000174

1½“ 0000117 0000118 0000168 0000175

2“ 0000119 0000120 0000169 0000176

3“ 0000121 0000122 0000170 0000177

4“ 0000121 0000122 0000170 0000177

6“ 0000123 0000124 0000172 0000179

° Al

2O3

FEP PFA PTFE

Stem

Stainless Steel / PFA

Hastelloy / PFA PTFE

Ball

Ceramic°

Packing (set)

Seat Rings

PTFE / Graphite

AKH2A - atomac ball valve

Page 6

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 6

Date: 12.1995

Revision: 08.2009

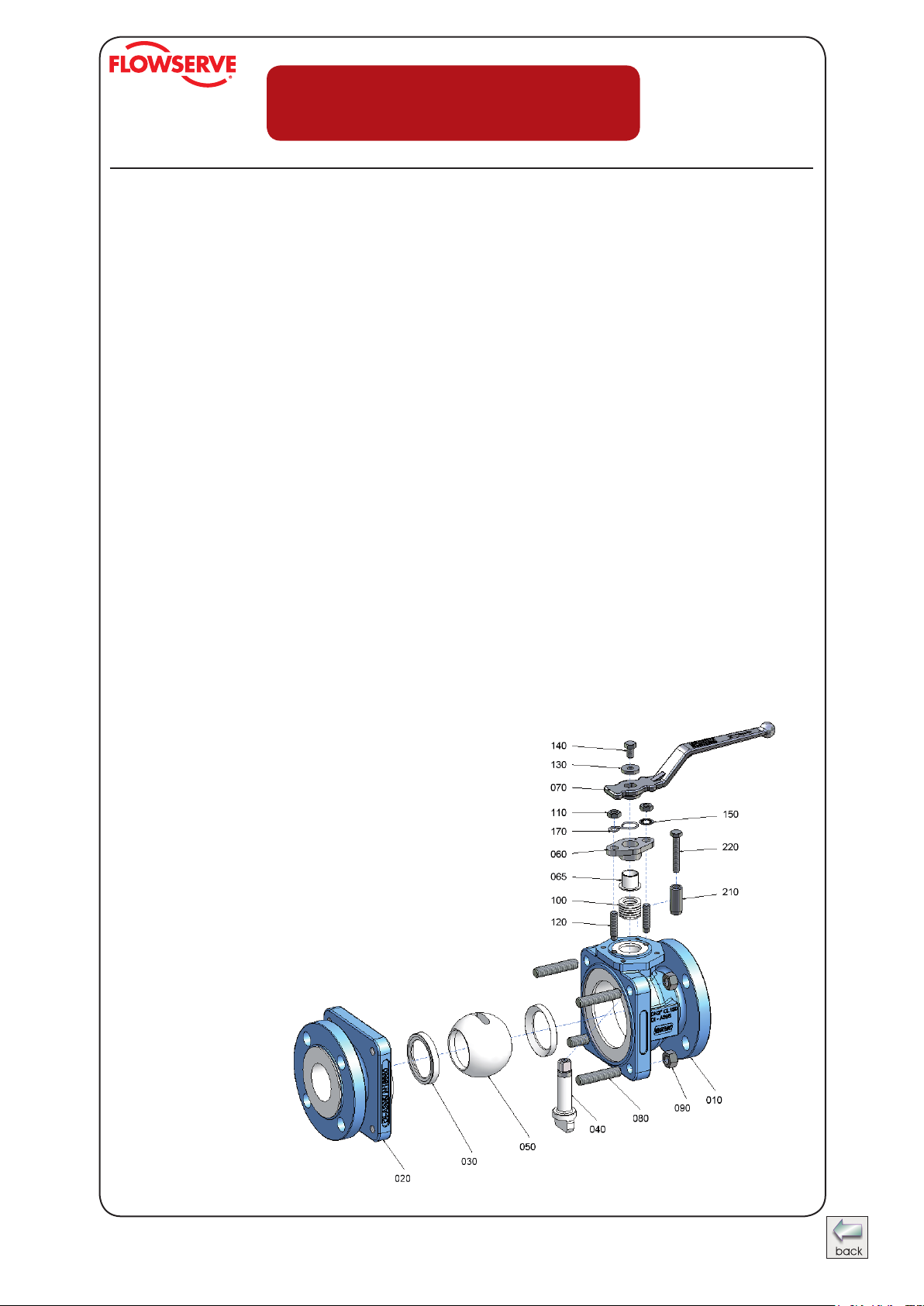

Assembly Instructions AKH2A

The general installation and maintenance instructions must be observed.

1. Screw stud bolts (120) into body (010).

2. Insert stem (040) from inside of body in such a way that the at side is parallel to

body longitudinal axis.

3. Insert chevron packing (100).

4. Install gland insert (065), gland follower (060), safety washers (150), hexagon nuts

(110) and grounding strap (170) also on valves with actuator.

5. Install hand lever (070) on to stem (040) and tighten it using lock washer (130) and

hexagon bolt (140).

6. Insert rst ball seat ring (030) into body (010).

7. Insert ball (050) to valve stem by pushing the ball in a downward motion through

valve body.

8. Turn hand lever 90° of longitudinal axis of body.

9. Install second ball seat ring (030) on to ball (050).

10. Install side piece (020) on to body (010).

11. Install body bolts (080) and hexagon nuts (090) and tighten by crisscross method to

recommended torques.

12. Assemble stop (210) with hexagon bolt (220).

AKH2A - atomac ball valve

DN 1“ to 2“ = quadrangular Flange

DN 3“ and 4“ = sexangular Flange

Page 7

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 7

Date: 12.1995

Revision: 08.2009

Disassembly Instructions for AKH2A

For all jobs which are to be carried out on an installed valve, the works safety requirements and the general accident prevention instructions must be observed. Moreover,

the general installation and maintenance instructions for atomac uorcarbon resin lined

valves must be considered.

1. Prior to disassembly, the valve must be cleared of all uid according to the above-

mentioned instructions. Particular care must be taken that during rinsing and draining of the piping, the valve is opened and closed repeatedly. These cycles (opening

and closing) are to be repeated during draining of the piping. Only when following

this procedure, is it ensured that all remaining pressure inside the body (stem guide

and ball seats) is eliminated.

2. For disassembly of the valve, put body on a work bench with a soft cover (rubber

mat). Remove hexagon bolt (110) and serrated lock washer (150).

3. Open valve completely. Remove hand lever (070).

4. Disassemble grounding device (170).

5. Disassemble gland follower (060) and gland insert (065). If necessary, stud bolts

(120) can also be removed now.

6. Remove body bolts (080) and separate side piece from body.

7. Remove rst ball seat ring (030).

8. Put ball in closed position and push ball out of the body.

9. Remove stem (040) by pushing it down through

the body (010). Care must be taken not to

damage body liner.

10. Chevron packing (100) can easily be removed.

11. If necessary, remove hand lever stop

(210) by releasing bolt (220).

DN 1“ to 2“ = quadrangular Flange

DN 3“ and 4“ = sexangular Flange

AKH2A - atomac ball valve

Page 8

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

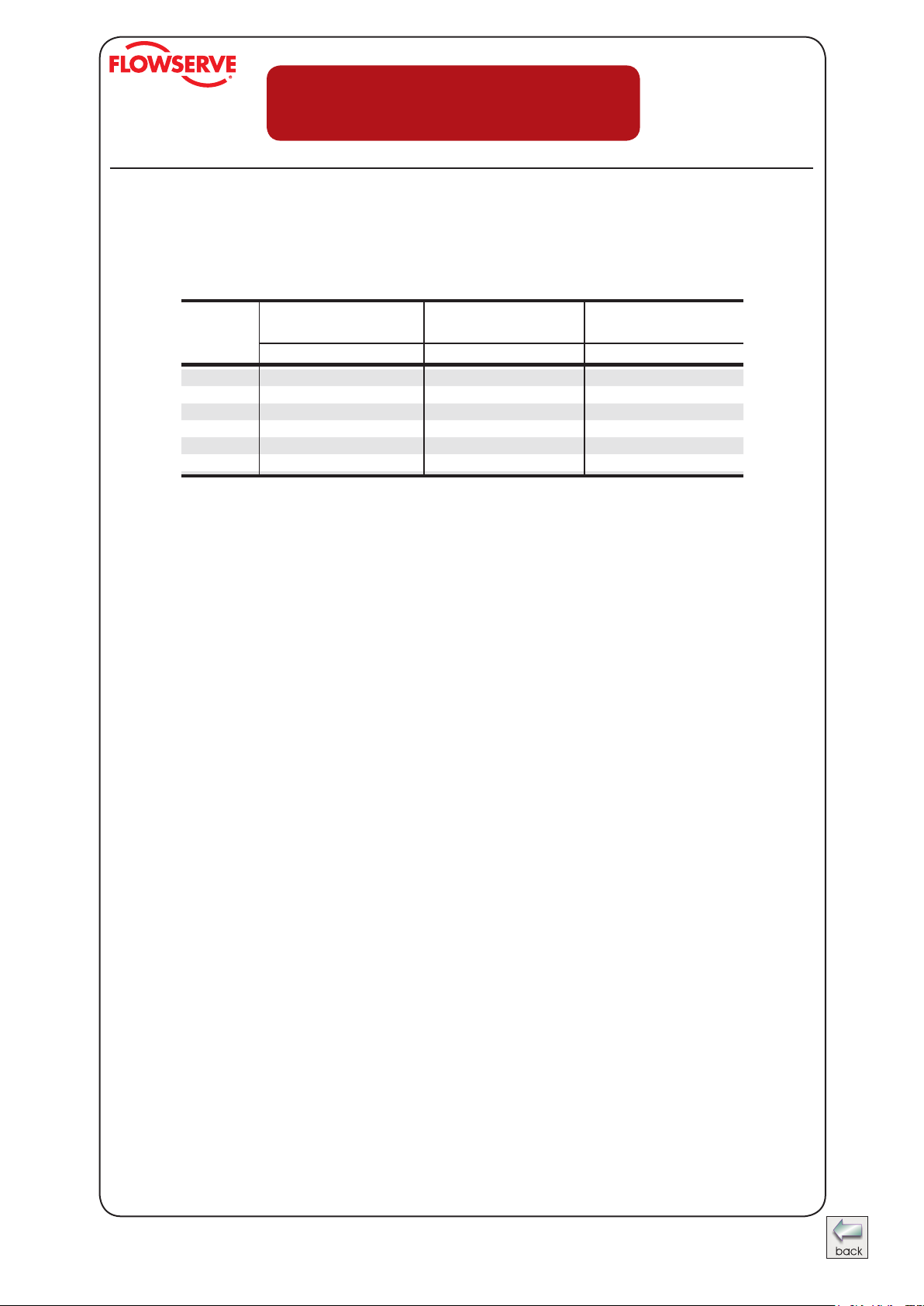

AKH2A - recommended tightening torques*

Technical Manual

Register: 13

Page: 8

Date: 12.1995

Revision: 08.2009

tie rods gland bolts

DN

1“ 19 168 15 133 4 35

1½“ 38 336 26 230 7 62

2“ 66 584 60 531 7 62

3“ 116 1027 100 885 8 71

4“ 140 1239 76 673 8 71

6“ 161 1425 129 1142 12 106

* maximum value

(080/090) (110/120/150)

Nm in.lbs Nm in.lbs Nm in.lbs

connection ange

AKH2A - atomac ball valve

Page 9

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 9

Date: 12.1995

Revision: 08.2009

Manual Actuator

(worm gear)

The fully closed, waterproof actuator consists of a body with lid, worm gear, input

shaft and hand wheel. For the correct adjustment of the ball position, there are two

adjustable stops mounted in the body.

The gear is fully greased and does not need any further lubrication.

The actuator with hand wheel is mounted on a bracket with four stainless steel bolts.

The on/off position is indicated through a pointer. The actuator is self-locked.

Material specication

Designation Material Material-No. DIN

body GG-25 0.6025 DIN EN 1561

worm EN-HJS-400-15U EN-JS1072 DIN 18299

(GGG-40) (0.7040)

gear EN-HJS-400-15U EN-JS1072 DIN 18299

(GGG-40) (0.7040)

grease special high temp. grease (up to 120°C)

input shaft AISI 303 1.4305

hand wheel malleable cast iron

AKH2A - atomac ball valve

Page 10

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Register: 13

Page: 10

Technical Manual

Date: 12.1995

Revision: 08.2009

Material specication - AKH2A with

manual actuator

No. Designation Pieces Material Material-No. DIN ASTM / AISI

010 actuator 1 steel 1.0037 DIN EN 10025-2 A 283 B

020 hexagon bolt 4 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

030 serrated lock washer 4 stainless steel 1.4301 DIN EN 10088-3 AISI 304

040 adapter 1 stainless steel 1.4104 DIN EN 10088-3 AISI 430 F

050 actuator 1

060 hexagon bolt 4 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

070 key 1 steel 1.0050 DIN EN 10277-1 A 572 GR 50

AKH2A - atomac ball valve

Page 11

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Data - AKH2A with manual actuator

Technical Manual

Register: 13

Page: 11

Date: 12.1995

Revision: 08.2009

Dimensions acc. to DIN EN ISO 5211

ANSI TYP* A B C D ØE F ØG K

4“

6“

* with standard hand wheel

Q 400 S 44 : 1 400 3540 3,87

Q 800 S 40 : 1 800 7081 7,68

mm

Q 400 S

inch 11,53 5,43 3,15 1,34 7,87 8,39 0,47 2,07

mm

Q 800 S

inch 14,23 7,52 3,15 1,67 11,81 11,14 0,59 2,71

Typ gear transmission ratio touque in Nm touque in lbs weight in kg

293 138 80 34 200 213 12 52,5

362 191 80 42,5 300 283 15 68,8

AKH2A - atomac ball valve

Page 12

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

AKH2A with actuator mounting

Register: 13

Page: 13

Date: 12.1995

Revision: 08.2009

AKH2A - atomac ball valve

Page 13

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 14

Date: 12.1995

Revision: 08.2009

Material specication - AKH2A with

actuator mounting

No. Designation Pieces Material Material-No. DIN ASTM / AISI

010 threaded pin 1 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

020 actuator bracket 1 steel (yellow chromated) 1.0037 DIN EN 10025-2 A 283-B

030 serrated lock washer 4 stainless steel 1.4301 DIN EN 10088-3 AISI 304

040 hexagon bolt 4 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

050 adapter 1 stainless steel 1.4304 DIN EN 10088-3 AISI 304F

Item-No. 010 „threaded pin“ is used with sizes DN 1“.

AKH2A - atomac ball valve

Page 14

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 15

Date: 12.1995

Revision: 08.2009

AKH2A - Dimension sheet for actuator mounting

acc. to NAMUR - recommendation

Dimensions acc. to DIN EN ISO 5211

with metric ISO-Threads DIN 13-1

+0,1 0

ANSI

mm 109 75 60 100 8 10 - 30,5 9,3

1“

inch 4,29 2,95 2,36 3,94 0,315 0,393 - 1,2 0,37

mm 129 100 60 100 12 16 - 25,5 12,5

1½“

inch 5,08 3,94 2,36 3,94 0,472 0,63 - 1 0,49

mm 142 100 60 100 12 16 - 23 12,5

2“

inch 5,59 3,94 2,36 3,94 0,472 0,63 - 0,91 0,49

mm 203 135 80 140 16 22 13 34 15,5

3“

inch 8 5,31 3,15 5,51 0,63 0,866 0,51 1,34 0,61

mm 218 135 80 140 16 22 13 34 15,5

4“

inch 8,58 5,31 3,15 5,51 0,63 0,866 0,51 1,34 0,61

mm 271 135 80 140 20 30 14 23 19,5

6“

inch 10,67 5,31 3,15 5,51 0,787 1,181 0,55 0,91 0,77

H a b c SW d S L1 L2

AKH2A - atomac ball valve

-0,1 -0,1

DIN EN ISO

5211

ISO 5211

F05

F07

F07

F10

F10

F12

Page 15

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 16

Date: 12.1995

Revision: 08.2009

AKH2A/DA

Seat ring with pressure compensation grooves

Nut a < DN 1“ = 1,5 mm

Nut a < DN 3“ = 2,0 mm

Nut a > DN 3“ = 3,0 mm

Special Recleaning and Packing Procedures

1. R e c l e a n i n g

The ball valve should be thouroughly cleaned with a clean, dry, lint-free towel and

blown off with dry nitrogen gas. This will assure that the valve is free from moisture,

grease and other media before packing.

2. P a c k i n g

Prior to packing, the ball valve should be jig welded in a PE-foil (0,2 mm thick). The

bag contains desiccants acc. to DIN 55473, quantity acc. to DIN 555474 and a

moisture indicator.

AKH2A - atomac ball valve

Page 16

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 17

Date: 12.1995

Revision: 08.2009

Material specication AKH2A/DA

No. Designation Pieces Material Material-No. / DIN ASTM / AISI

010 body 1 ductile iron / FEP ° EN-JS1049 (GGG-40.3) / A 395

020 side piese 1 ductile iron / FEP ° EN-JS1049 (GGG-40.3) / A 395

030 seat ring 1 PTFE pure - PTFE

035 seat ring with pressure

compensation grooves

040 stem 1 stainless steel / PFA 1.4470 /DIN EN 10283 A 890 CD3MN

050 ball

060 gland follower 1 stainless steel 1.4308 / DIN EN 10283 A 743 CF-8

065 gland insert 1 PTFE-graphite

070 hand lever

080 stud bolt 1 set stainless steel 1.4301-K70 / DIN EN 10088-3 A 193 B7

090 hexagon nut 1 set stainless steel 1.4301-K70 / DIN EN 10088-3 A 194 2H

100 packing material 1 set PTFE °

110 hexagon nut 2 stainless steel 1.4301 / DIN EN 10088-3 A 194 8

120 stud bolt 2 stainless steel 1.4301 / DIN EN 10088-3 A 193 B8

130 lock washer 1 stainless steel 1.4301 / DIN EN 10088-3 AISI 304

140 hexagon bolt 1 stainless steel 1.4301 / DIN EN 10088-3 A 193 B8

150 serrated lock washer 2 stainless steel 1.4301 / DIN EN 10088-3 AISI 304

170 grounding device 1 stainless steel 1.4310 / DIN EN 10270-3 AISI 301

210 stop

220 hexagon bolt** 1 stainless steel 1.4301 / DIN EN 10088-3 A 193 B8

DN 1“ - 2“ 1 tool steel, alloyed / PFA° 1.2343 / DIN EN ISO 4957 A 646-95 (Gr. 10)

DN 3“ - 6“ 1 ductile iron / FEP ° EN-JS1049 (GGG-40.3) / A 395

DN 1“ - 2“ 1 die cast metall ZP0410 / DIN EN 12844

DN 3“ - 4“ 1 malleable cast iron (galvanizing) EN-GJS-50-7 (GGG-50)

DN 6“: adapter;

level

(chevron) PTFE-graphite °

DN 1“ - 4“ 1 steel (galvanizing) 1.0037 / DIN EN 10025-2 A 283 B

DN 6“ 1 stainless steel 1.4104 / DIN EN 10088-3 AISI 430 F

ductile iron / PFA ° DIN EN 1563

ductile iron / PFA ° DIN EN 1563

1 PTFE pure - PTFE

Hastelloy C4 / PFA °° 2.4610 / DIN 17744

tool steel, alloyed / FEP°

ductile iron / PFA ° DIN EN 1563

ceramic Al

stainless steel;

1

steel (chromated)

2O3

*

1.4308 / DIN EN 10283; 1.0037 /

DIN EN 10025-2

A 743 CF-8

A283 B

* ceramic ball on request

°° Hastelloy stem on request

° optional

** DN 6“ 2 hexagon bolts

AKH2A - atomac ball valve

Page 17

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 18

Date: 12.1995

Revision: 08.2009

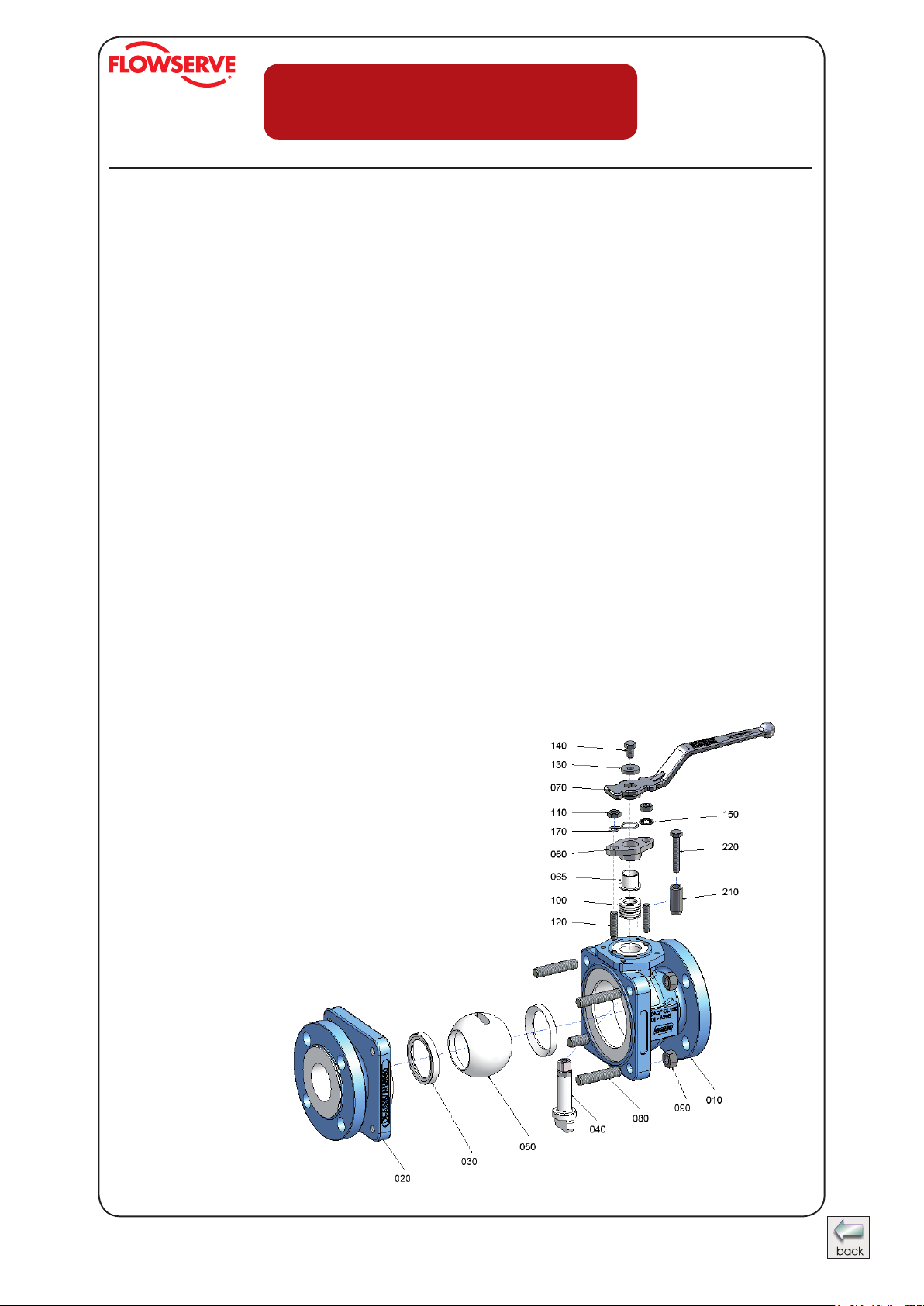

Assembly Instructions AKH2A/DA

The general installation and maintenance instructions must be observed.

Attention, please take care of the right direction of the indicator while assembly.

1. Screw stud bolts (120) into body (010).

2. Insert stem (040) from inside of body in such a way that the at side is paral-

lel to body longitudinal axis.

3. Insert chevron packing (100).

4. Install gland insert (065), gland follower (060), safety washers (150),

hexagon nuts (110) and grounding strap (170) also on valves with actuator.

5. Install hand lever (070) on to stem (040) and tighten it using lock washer

(130) and hexagon bolt (140).

6. Insert rst ball seat ring (030) into body (010).

7. Insert ball (050) to valve stem by pushing the ball in a downward motion

through valve body.

8. Turn hand lever 90° of longitudinal axis of body.

9. Install ball seat ring with pressure compensation grooves (035) on to ball (050).

10. Install side piece (020) on to body (010).

11. Install body bolts (080) and hexagon nuts

(090) and tighten by crisscross

method to recommended torques.

12. Assemble stop (210) with

hexagon bolt (220).

Disassembly instruction see register 13,

page 7

AKH2A - atomac ball valve

Page 18

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

AKH2A with stem extension

Register: 13

Page: 19

Date: 12.1995

Revision: 08.2009

AKH2A - atomac ball valve

Page 19

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 20

Date: 12.1995

Revision: 08.2009

Material specication - AKH2A with stem extension

No. Designation Pieces Material Material-No. DIN ASTM / AISI

010 threaded pin 1 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

020 stud bolt 2 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

030 gland follower 1 stainless steel / PTFE-graphite 1.4308 DIN EN 10283 A 351 CF 8

040 distance pipe 1 steel 1.0305 DIN EN 10216-2 A 192

050 gland 1 stainless steel 1.4308 DIN EN 10283 A 743 CF 8

060 serrated lock washer 2 stainless steel 1.4301 DIN EN 10088-3 AISI 304

070 hexagon nut 2 stainless steel 1.4301 DIN EN 10088-3 A 194 8

080 extended stem 1 stainless steel 1.4104 DIN EN 10088-3 AISI 430 F

090 mounting 1 steel 1.0037 DIN EN 10025-2 A 283 B

100 serrated lock washer 4 stainless steel 1.4301 DIN EN 10088-3 AISI 304

110 hexagon bolt 4 stainless steel 1.4301 DIN EN 10088-3 A 193 B8

Item - No. 010 „threaded pin“ is used with sized DN 1“ only.

AKH2A - atomac ball valve

Page 20

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Data - AKH2A with stem extension

Technical Manual

Register: 13

Page: 21

Date: 12.1995

Revision: 08.2009

ANSI L H h

1“

1½“

2“

3“

4“

6“

mm 100 149 126

inch 3,94 5,87 4,96

mm 100 169 138

inch 3,94 6,65 5,43

mm 100 182 151

inch 3,94 7,17 5,94

mm 130 252 216

inch 5,12 9,92 8,5

mm 130 267 231

inch 5,12 10,51 9,09

mm 160 351 307

inch 6,3 13,82 12,09

AKH2A - atomac ball valve

Page 21

Register: 13

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Page: 22

Date: 12.1995

Revision: 08.2009

Technical Data - AKH2A with lockable hand lever

A

A ( 1 : 2 )A ( 1 : 2 )

Material specication - AKH2A with lockable hand lever

Designation Pieces Material Material-No. DIN ASTM / AISI

lockable hand lever 1 stainless steel 1.4301 DIN EN 10088-3 AISI 304

stop bolt 1 Stainles steel / duroplastic 1.4301 DIN EN 10088-3 AISI 304

AKH2A - atomac ball valve

Page 22

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

AKH2A - Kv DATA and Cv Data

(DIN EN 60534-2-3)

Register: 13

Page: 23

Date: 12.1995

Revision: 08.2009

K

ANSI

1“ 46,6 54,1

1 ½“ 126,9 147,5

2“ 202,5 235,4

3“ 507,8 590,2

4“ 953,4 1108,1

6“ 1577,7 1833,8

V

m³/h gal/min

C

V

AKH2A - atomac ball valve

Page 23

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Optional C-ball in ball valves

Register: 13

Page: 24

Date: 12.1995

Revision: 08.2009

For details please contact ouer Sales ofce at Ahaus, Germany

AKH2A - atomac ball valve

Page 24

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Technical Manual

Optional V-ball in ball valves

Register: 13

Page: 25

Date: 12.1995

Revision: 08.2009

For details please contact ouer Sales ofce at Ahaus, Germany

AKH2A - atomac ball valve

Loading...

Loading...