Page 1

Airfin Cooler

Flow Solutions Division

Durametallic Seals

Means of reducing

the temperatures

surrounding a

mechanical seal

Model 625 FC Air Motor

Code: WCA26748333

Installation Instructions

Model 625 FC Electric Motor

3 phase Code: WCA14020233

1 phase Code: WCA18856933

Model 625 NC

Code: WCA14640733

Page 2

Description

The Airfin Cooler provides a reliable means of reducing the temperature surrounding a mechanical seal, without the use of cooling water.

There are three models of Airfin Coolers. The Model 625 NC operates by means

of natural convection. Hot air rises up through the center of the coiled tubing,

drawing cool air in from the sides and bottom. The two Model 625 FC units are

identical to the above model, except they are equipped with motor driven squirrel

cage type blower wheels.

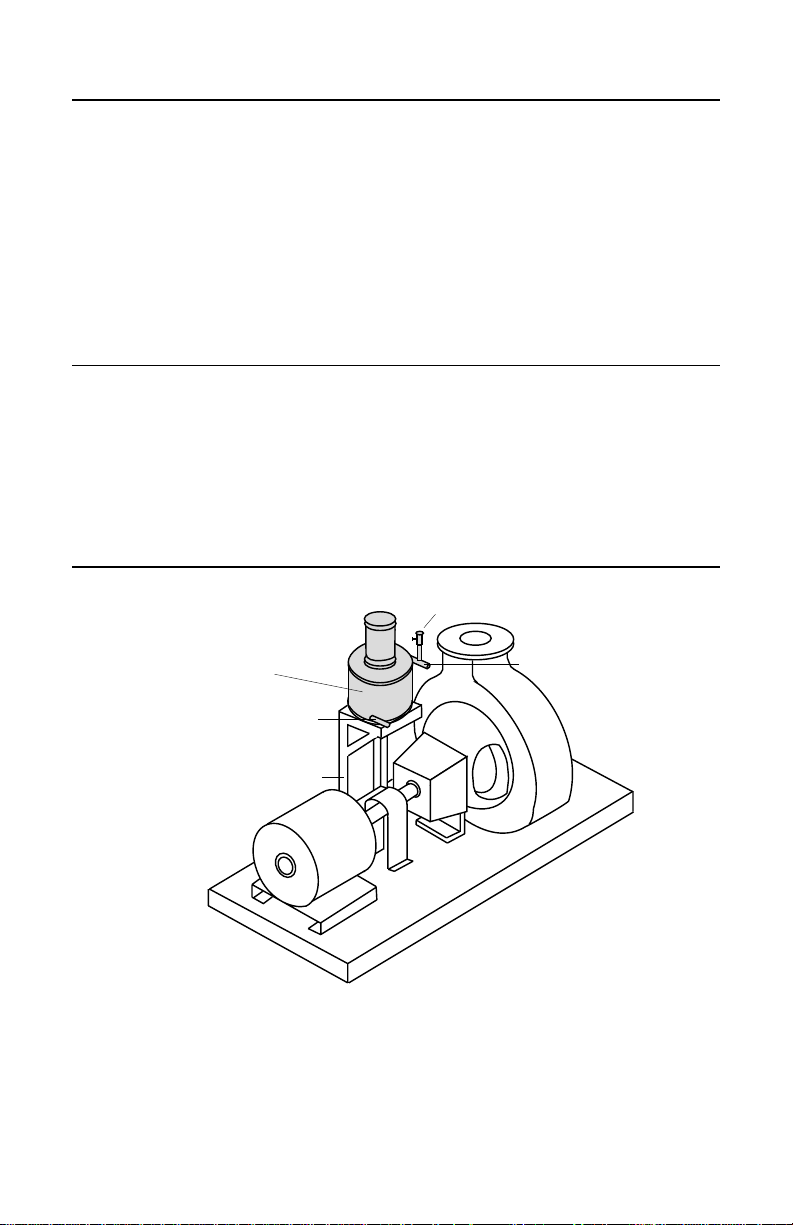

1 Installation

1.1 All models must be mounted in a vertical position, adjacent to and above

the seal chamber. The piping, or tubing, to and from the Airfin Cooler

should be as short as possible. See Figure 1.

Typical Installation of Airfin Cooler Figure 1

Airfin Cooler

• 6-12" Above

seal chamber

• No more than 4'

from seal chamber

Cooled Product Outlet

Mounting

Bracket

Vent Valve

Hot Product Inlet

1.2 The Airfin Cooler should be mounted in a location where it will be free from

all obstructions on the top, bottom, and sides. Failure to do so will result in

an appreciable reduction in heat transfer efficiency.

1.3 Please read the complete instructions before starting installation. Be sure

you have a copy of the proper Airfin Cooler assembly drawing.

© Copyright 2003 Flowserve Corporation

2

Page 3

1.4 Select the proper location. It will be necessary to fabricate or purchase a

mounting bracket to suit your particular installation. See Figure 2 for

recommended mounting bracket dimensions. The Airfin Cooler should be

located 6-12” above and no more than 4’ from the seal chamber.

Mounting Bracket Details Figure 2

9.00" Min.

9.00" Min.

10.50"

5.25"

5.25"

10.50"

4 - .437” Dia. holes

as shown

1.5 Carefully place the Airfin Cooler on the mounting bracket. The Airfin Cooler

should be positioned so that the least amount of elbows or tube bends are

needed for the inlet and outlet piping.

Note: If the inlet and outlet fittings are not in the desired positions, the coil

assembly can be rotated 360° to any desired position. Loosen the four hex

head bolts (Part No. 10 of Model 625 FC and Part No. 5 of Model 625 NC)

and rotate the cooling coil/shroud assembly to the desired position. Be sure

to tighten the four hex head bolts securely.

1.6 After the unit has been placed on the mounting bracket in the desired

position, secure it down with four hex nuts (3/8” - 16 UNC-2B) with lock

washers.

1.7 Consult your assembly drawing for the connections size and location. The

hot product line to the Airfin Cooler should be piped to the top of the unit

and the cooled product outlet line should be piped from the bottom of the

unit. Connect the inlet and outlet lines with suitable piping or tubing.

1.8 Be sure to install a vent value in the hot product inlet line. The vent valve

should be located at he highest point in the piping.

1.9 The Model 625 FC Airfin Cooler has a 1/3 HP motor. Consult the assembly

drawing for your motor specifications.

3

Page 4

TO REORDER REFER TO

B/M #

.

F.O

2 Operation

2.1 Inspect the Airfin Cooler to insure that the cooling coil has not been

painted, sprayed with oil, or covered with dirt or dust. Insure that there are

no obstructions on the top, bottom, and sides.

2.2 Apply power momentarily to the motor on the Model 625 FC to check for

rotation. If the rotation is in the wrong direction, rewire the motor.

2.3 Open the pump suction valve and fill the system with product. Crack the

vent valve in the hot product line and vent all air from the system.

2.4 Check all fittings for leaks and make required adjustments. Do not tighten

fittings excessively.

2.5 Apply power to the motor on the Model 625 FC and start the pump, for the

625 NC model start the pump.

Maintenance

The Airfin Cooler is relatively maintenance free. To insure maximum heat transfer

efficiency, keep the cooling coils dry and free of dirt and dust. Periodically, clean

the cooling coil by blowing air or steam through the protective shroud.

All Flowserve Corporation, Flow Solutions Division, products must be installed in accordance with Flowserve

installation instructions. Failing to do so or attempting to change or modify Flowserve products will void Flowserve’s

limited warranty. Flowserve’s limited warranty is described fully in Flowserve’ s Standard Terms and Conditions

of Sale. Flowserve makes no warranty of merchantability or fitness for a particular purpose and in no event shall

Flowserve be liable for consequential or incidental damages.

Flowserve Corporation Flow Solutions Division

Primary Worldwide Flow Solutions Division Locations Licensees, authorized agents, and affiliated companies located worldwide

United States

Kalamazoo, MI

Phone 269-381-2650

Fax 269-382-8726

Singapore Japan

Phone 65-6-8465100

Fax 65-6-747-1963

Printed in U.S.A.

Edmonton, Alberta

Phone 780-463-7958

Fax 780-450-1241

Tlaxcala

Phone 52-2-461-6791

Fax 52-2-461-6847

Canada

Scarborough, Ontario

Phone 416-292-2877

Fax 416-292-5190

Sao Paulo

Phone 55-11-4066-8600

Fax 55-11-4066-7014

Netherlands

Roosendaal

Phone 31-165-581400

Fax 31-165-552622

Osaka

Phone 81-720-85-5571

Fax 81-720-85-5575

ISO 9000

Certified

Argentina

Villa Martelli

Phone 54-11-4709-6800

Fax 54-11-4709-7072

GermanyBrazilMexico

Dortmund

Phone 49-231-6964-0

Fax 49-231-6964-248

Australia

Marayong NSW

Phone 61-2-8822-7100

Fax 61-2-9679-7511

FIS154

REV 02/03 USA

Loading...

Loading...