Page 1

Installation, Operation, Maintenance Instructions

Pneumatic and

Electropneumatic Actuators

Series 4, Types 37, 38, 39, 3D and 47, 48, 49, 4D

Flow Control Division

Kammer Control Valves

Index

1 Using Kämmer valves and actuators correctly.

2Unpacking

3 Installation

4 Quick check / Maintenance

5 Methode of operation

6 Remove and install actuator

7 Disassemble and assemble actuator

8 Calibration / Technical data

1 USING KÄMMER VALVES AND ACTUATORS

CORRECTLY

1.1 General

The following instructions are designed to assist in

unpacking, installing and performing maintenance as

required on Kämmer products. Product users and

maintenance personnel should thoroughly review this

bulletin prior to installing, operating or performing

any maintenance.

DANGER:

are designed for specific applications (e.g. with regard

to medium, pressure, temperature). For this reason

they should not be used in other applications without

first contacting the manufacturer.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAUTION and

NOTE are used in these instructions to highlight

particular dangers and/or to provide additional

information on aspects that may not be readily

apparent.

DANGER:

and/or substantial property damage will occur if

proper precautions are not taken.

STOP!

WARNING:

and/or substantial property damage can occur if

proper precautions are not taken.

CAUTION:

In most cases Kämmer valves and actuators

indicates that death, severe personal injury

indicates that death, severe personal injury

indicates that minor personal injury and/

or property damage can occur if proper precautions

are not taken.

NOTE:

information, which may not be very obvious even to

qualified personnel.

Compliance with other, not particularly emphasised

notes, with regard to transport, assembly, operation

and maintenance and with regard to technical

documentation (e.g. in the operating instruction,

product documentation or on the product itself) is

essential, in order to avoid faults, which in themselves

might directly or indirectly cause severe personal

injury or property damage.

1.3 Protective clothing

Kämmer products are often used in problematic

applications (e.g. extremely high pressures, dangerous, toxic or corrosive mediums). In particular

valves with bellows seals point to such applications.

When performing service, inspection or repair

operations always ensure, that the valve and actuator

are depressurised and that the valve has been cleaned

and is free from harmful substances. In such cases

pay particular attention to personal protection

(protective clothing, gloves, glasses etc.).

1.4 Qualified personnel

Qualified personnel are people who, on account of

their training, experience and instruction and their

knowledge of relevant standards, specifications,

accident prevention regulations and operating

conditions, have been authorised by those responsible

for the safety of the plant to perform the necessary

work and who can recognise and avoid possible

dangers.

1.5 Installation

DANGER:

serial-no. and/or the tag-no. to ensure that the valve/

actuator is correct for the intended application.

Do not insulate extensions that are provided for hot

or cold services.

Pipelines must be correctly aligned to ensure that the

valve is not fitted under tension.

indicates and provides additional technical

Before installation check the order-no,

KMEIM0006-00 - 08.03

1

Page 2

Flow Control Division

Kammer Control Valves

1.6 Spare parts

Use only Kämmer original spare parts. Kämmer

cannot accept responsibility for any damages that

occur from using spare parts or fastening materials

from other manufactures. If Kämmer products

(especially sealing materials) have been on store for

longer periods check these for corrosion or deterioration before using these products. Fire protection for

Kämmer products must be provided by the end user.

1.7 Service / repair

To avoid possible injury to personnel or damage to

products, safety terms must be strictly adhered to.

Modifying this product, substituting nonfactory parts,

or using maintenance procedures other than outlined

in this instruction could drastically affect performance

and be hazardous to personnel and equipment, and

may void existing warranties. Between actuator and

valve there are moving parts. To avoid injury

Flowserve provides pinch-point-protection in the form

of cover plates, especially where side-mounted

positioners are fitted. If these plates are removed for

inspection, service or repair special attention is

required. After completing work the cover plates must

be refitted.

Apart from the operating instructions and the

obligatory accident prevention directives valid in the

country of use, all recognised regulations for safety

and good engineering practices must be followed.

WARNING:

for repair or service Kämmer must be provided with

STOP!

Before products are returned to Kämmer

a certificate which confirms that the product has been

decontaminated and is clean. Kämmer will not accept

deliveries if a certificate has not been provided (a form

can be obtained from Kämmer).

1.8 Storage

In most cases Kämmer Products are manufactured

from stainless steel. Products not manufactured from

stainless steel are provided with an epoxy resin

coating. This means that Kämmer products are well

protected from corrosion. Nevertheless, Kämmer

products must be stored adequately in a clean, dry

environment. Plastic caps are fitted to protect the

flange faces and to prevent the ingress of foreign

materials. These caps should not be removed until

the valve is actually mounted into the system.

1.9 Valve and actuator variations

These instructions cannot claim to cover all details

of all possible product variations, nor in particular

can they provide information for every possible

example of installation, operation or maintenance.

This means that the instructions normally include only

the directions to be followed by qualified personal

where the product is being used for is defined

purpose. If there are any uncertainties in this respect

particularly in the event of missing product-related

information, clarification must be obtained via the

appropriate FLOWSERVE sales office.

2 UNPACKING

2.1 Each delivery includes a packing slip. When unpacking, check all delivered valves and accessories using

this packing slip.

2.2 Larger valves can be lifted using slings on the yoke

rods or, if present, on the lugs provided for this

purpose. If slings are used, attach them so that the

outer tubing or attaching parts are not damaged.

WARNING:

If slings are used, be aware that the cen-

tre of gravity of the valve may be above the lifting

STOP!

point. In this case, secure or support the valve against

rotating, to prevent damage or personnel injury.

2.3 Report transport damage to the carrier immediately.

2.4 In case of discrepancies, contact your nearest

FLOWSERVE sales office.

3 INSTALLATION

3.1 Clean tubing prior to installing.

3.2 If possible, install the valve in an upright position

(actuator on top), to ease maintenance. An upright

installation position is important with low-temperature applications, in order to keep the distance between the packing material and the medium as large

as possible. The packing material then retains the

ambient temperature as much as possible.

NOTE:

Do not insulate extension bonnets that are pro-

vided for hot or cold services

3.3 Make sure that sufficient overhead clearance above

the actuator is maintained, to allow for disassembly

of plug from the valve body (see following table).

Actuator Clearance Actuator Clearance

size (mm) size (mm)

37/47 95 P2 140

38/48 140 P3 140

39/49 140 P4 140

39D/49D 140 P5 140

3.4 After installing, check direction of flow again. The

direction of flow is shown by the arrow on the

housing.

3.5 If the valve is to be welded into the line, make sure that

the valve is shielded from excessive heat.

3.6 Connect supply pressure and signal lines. Control

valves are supplied with a positioner. The end connections for supply pressure and signal are clearly

marked. Series 4 actuators and positioners are suitable for max. 4.2 bar (60 psi) supply pressure. If the

supply pressure exceeds the pressure specified on

the nameplate, a pressure reducing station is required. If instrument air is not available, install an oil

separator/air filter in the air inlet line. All connections

must be leak free.

2

Page 3

Flow Control Division

Kammer Control Valves

4 QUICK CHECK / MAINTENANCE

4.1 QUICK CHECK

Before operating, check the valve as follows:

4.1.1 Open and close the valve, and observe the movement

of the actuator stem. The movement must be smooth

and linear.

4.1.2 Check for maximum stroke through change of signal

(for pneumatic positioners, 0.2 - 1.0 bar or corresponding split-range values; for IP positioners, 4-20

or 0-20 mA).

4.1.3 Check all air connections for leaks.

4.1.4 Tighten packing nut (see table 1).

Torque

Thread PTFE Grafoil

M20 x 1,5 1 3

M30 x 1,5 6 15

M38 x 1,5 15 35

M45 x 1,5 17 40

Table 1

NOTE:

An excessively tightened gland nut can cause

excessive packing wear and can hinder the free movement of the plug stem.

4.1.5 Check fail-safe position. To do this, close supply

pressure and observe whether the valve opens or

closes as defined.

4.1.6 After use at fluctuating temperatures, re-tighten all

bolt connections and check for leaks.

4.2 Maintenance

Check valves for correct functioning at regular intervals (at least once every 6 months) as follows. This

check can be made when installed and in many

cases without interrupting production. If internal defects are suspected, see section „Disassembly and

Assembly of Valve“.

4.2.1 Examine gaskets for leaks and if necessary re-tighten

bolts (see Fig. 1).

4.2.2 Check bellows gasket and test connection - if present

- for external leaks.

4.2.3 Check valve for damage caused by corrosive residues

or corrosive vapours.

4.2.4 Clean valves and repaint as necessary.

STOP!

Warning:

clean the actuator/valve with a damp cloth only.

To prevent a buildup of electrostatic charge

4.2.5 Check gland nut for correct torque (see table 1).

NOTE:

An excessively tightened gland nut can cause

excessive packing wear and can hinder the free movement of the plug stem.

4.2.6 If possible, open and close valve and check for

maximum stroke and smooth movement of the plug

stem. Irregular movement of the plug stem may

indicate internal defects.

NOTE: With graphite packing, irregular movement of

the plug stem is normal.

STOP!

WARNING:

all moving parts. Failure to do so can lead to serious

Keep hands, hair, clothing, etc. away from

injury.

4.2.7 Check all accessories for firm seating.

4.2.8 If possible, close supply pressure and check the failsafe position.

4.2.9 Check stem boot for wear.

4.2.10 Check actuator for leaks. To do this, spray housing,

air connections and plug stem guide with leak spray

and check for any bubble formation.

4.2.11 Clean plug stem.

4.2.12 Check air filter, if present, and if necessary replace

insert.

Note:

For further information regarding service and

maintenance please contact your nearest FLOWSERVE

office.

DANGER:

On actuators with aluminium cases the

actuator springs must be renewed with original spare

parts every 10 years or after 50.000 operating hours

which ever occurs first.

3

Page 4

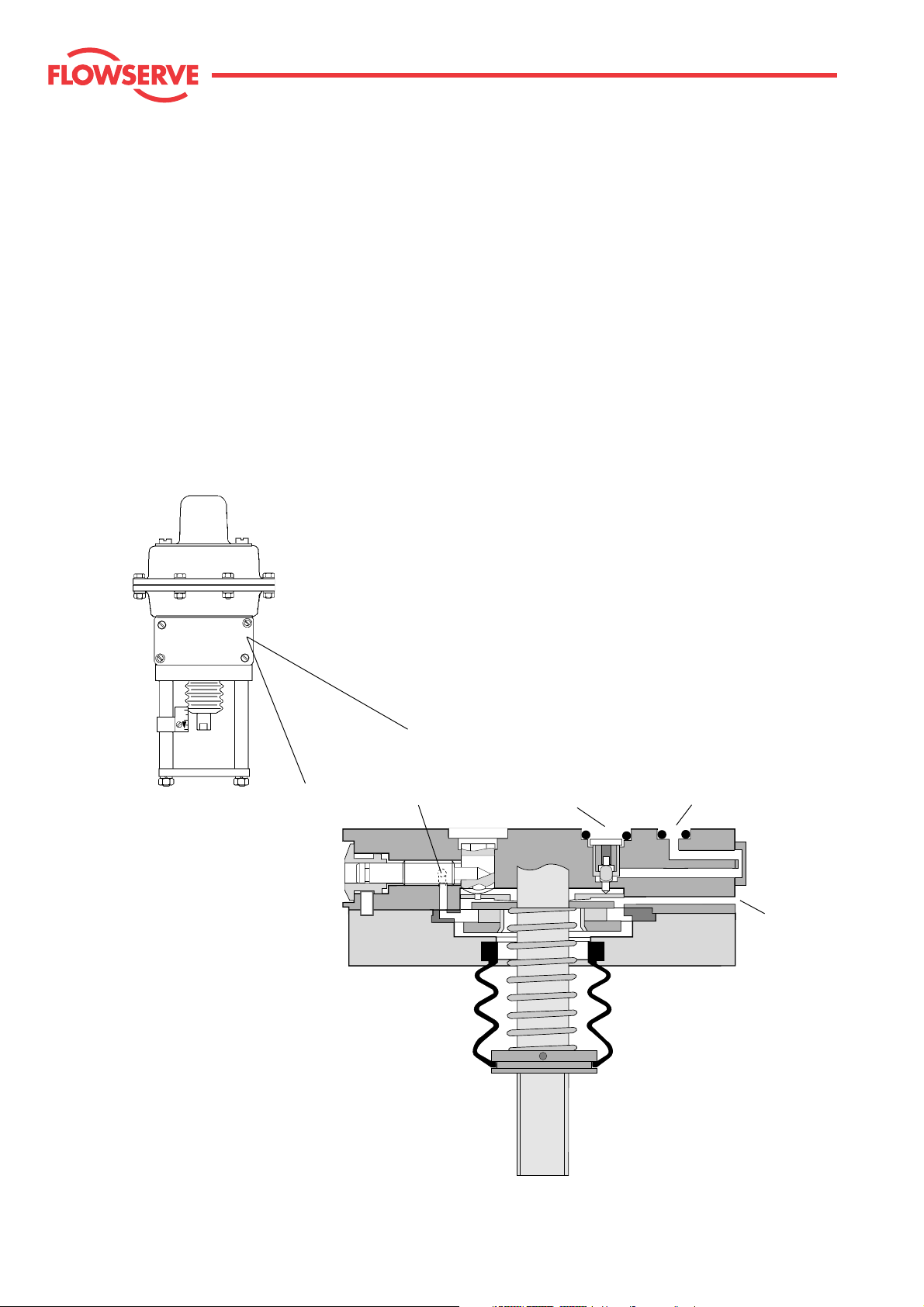

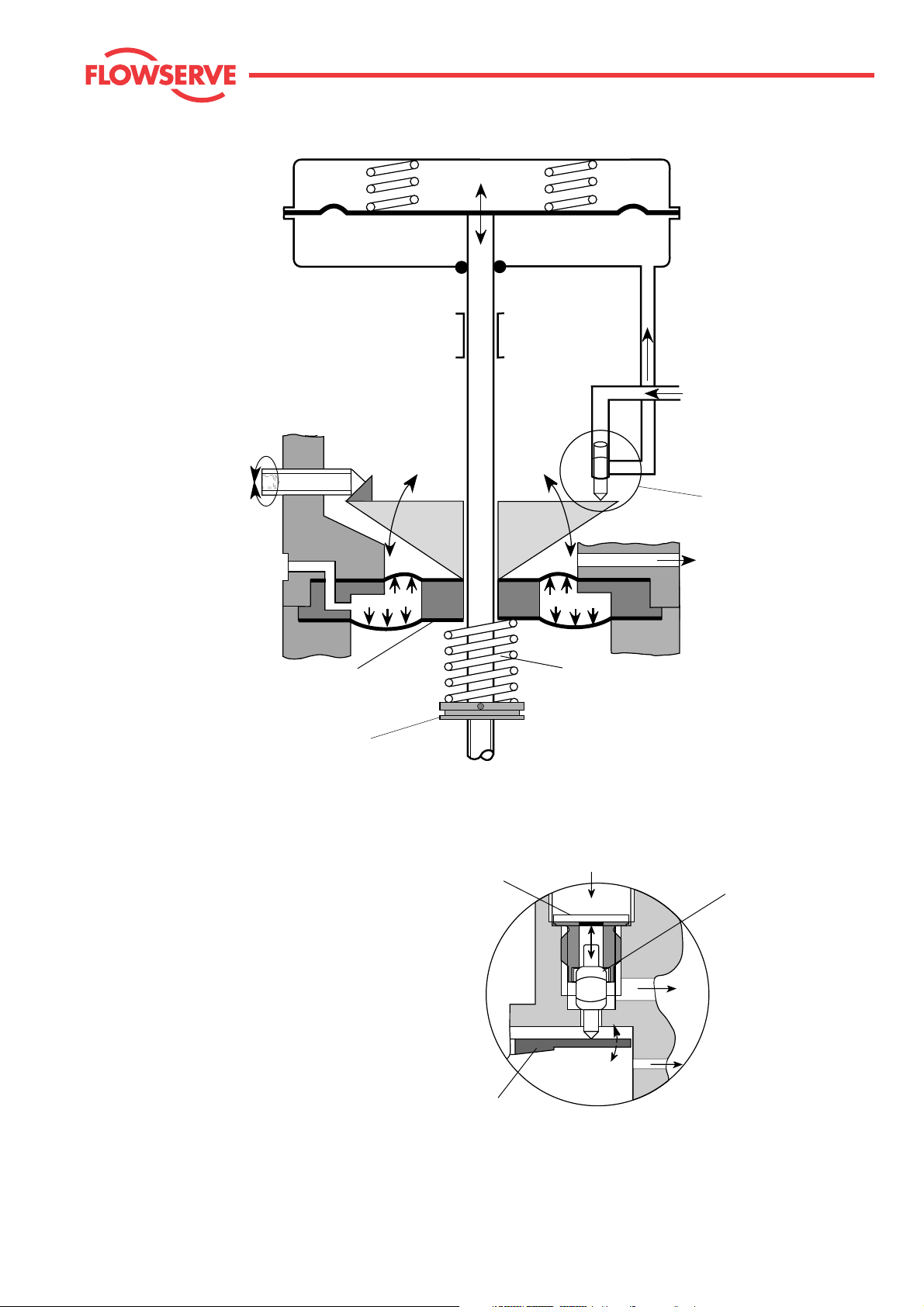

5 Method of operation (actuators with integral Kämmer positioner)

5.1 P/P Actuator

The actuator with integrated pneumatic positioner works on the force balance principal, which ensures that the

position of the actuator stem is proportional to the value of the input signal (see figs. 1 and 2).

An increased signal to the double diaphragm assembly creates an unbalanced condition. The pilot valve then

moves to cover the vent, increasing the positioner output pressure to the actuator diaphragm until the forces of

the positioner spring and the double diaphragm are equal. The positioner output is then stabilized at an amount

necessary to maintain the desired valve position.

Flow Control Division

Kammer Control Valves

Signal input

Fig. 1: P/P - Positioner

Supply

To actuator

Vent

4

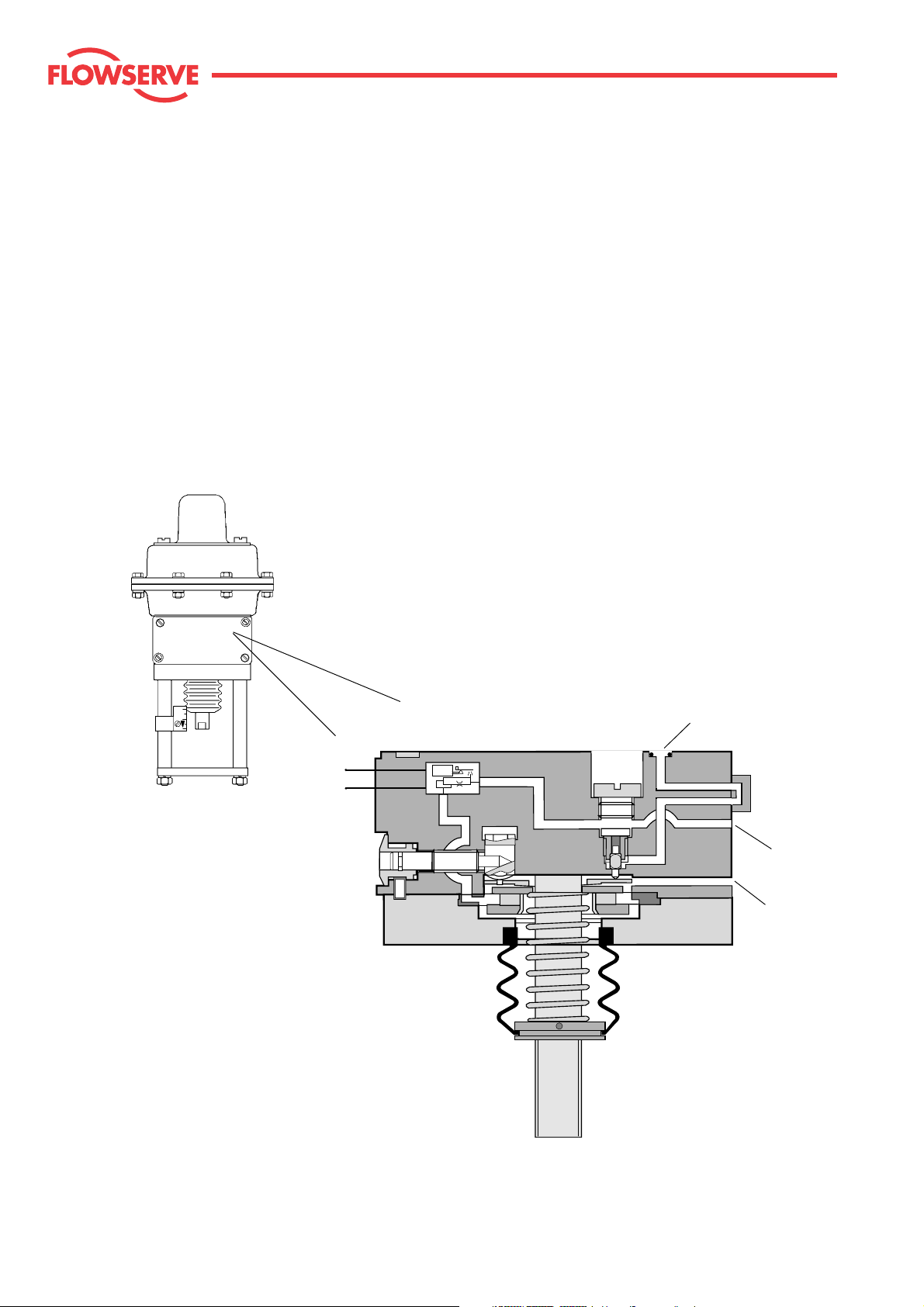

Page 5

Range adjustment screw

(max. 3 turns)

Flow Control Division

Kammer Control Valves

Supply output to

actuator diaphragm

Supply input

1.4–4.2 bar (20–60 psi)

Pilot plug

(see detail below)

Signal input

0.2–1.0 bar

(3–15 psi)

Double diaphragm

Adjusting nut

Seat ring

Vent

Positioner spring

Supply input

1.4 – 4.2 bar

(20 – 60 psi)

Pilot valve

Supply to

actuator diaphragm

Balancing plate

Pilot plug

Fig. 2: P/P - Positioner

Vent

5

Page 6

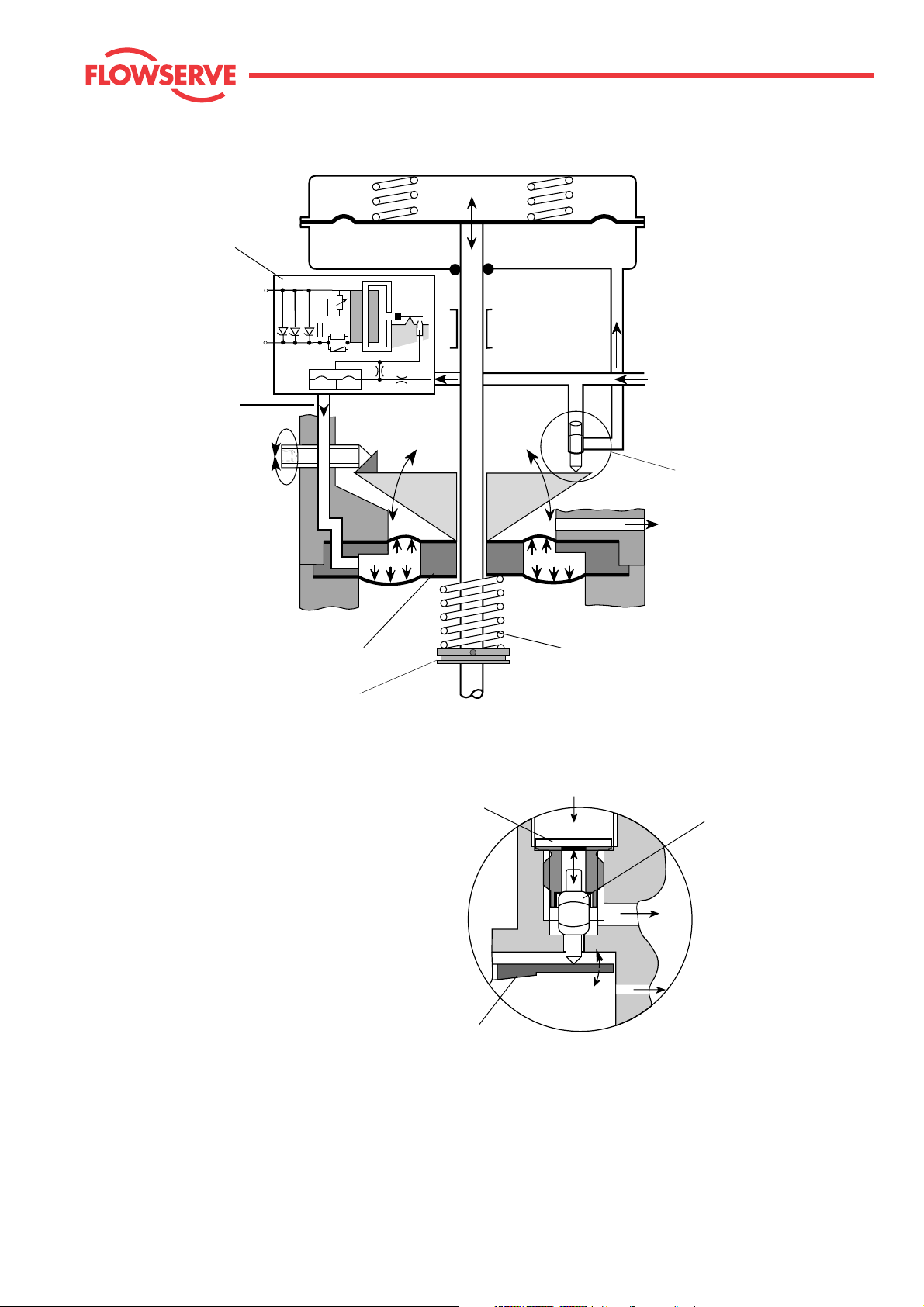

5.2 I/P Actuator

The I/P transducer, which is an integral part of the actuator, converts the standard electric signal

(0/4 – 20 mA) into a standard pneumatic signal (0.2 – 1.0 bar) by means of a system of light weight moving

parts. This form of signal conversion is extremely insensitive to shocks. The pneumatic signal is supplied to the

integrated pneumatic positioner.

The pneumatic positioner works on the force balance principal, which ensures that the position of the actuator

diaphragm is always directly proportional to the value of the instrument input signal pressure (see figs. 3 and 4).

An increased signal to the double diaphragm assembly creates an unbalanced condition. The pilot valve then

moves to cover the vent, increasing the positioner output pressure to the actuator diaphragm until the forces

of the positioner spring and the double diaphragm are equal. The positioner output is then stabilized at an amount

necessary to maintain the desired valve position.

Flow Control Division

Kammer Control Valves

Signal

To actuator

Supply

Vent

Fig 3: I/P Positioner

6

Page 7

Transducer

Flow Control Division

Kammer Control Valves

Signal

0/4 – 20 mA

Signal input

0.2–1.0 bar (3–15 psi)

Range adjustment screw

(max. 3 turns)

Double diaphragm

Adjusting nut

Seat ring

Supply output to

actuator diaphragm

Supply input

1.4–4.2 bar (20–60 psi)

Pilot plug

(see detail below)

Vent

Positioner spring

Supply input

1.4 – 4.2 bar

(20 – 60 psi)

Pilot valve

Balancing plate

Fig. 4: I/P Positioner

Supply to

actuator diaphragm

Vent

Pilot plug

7

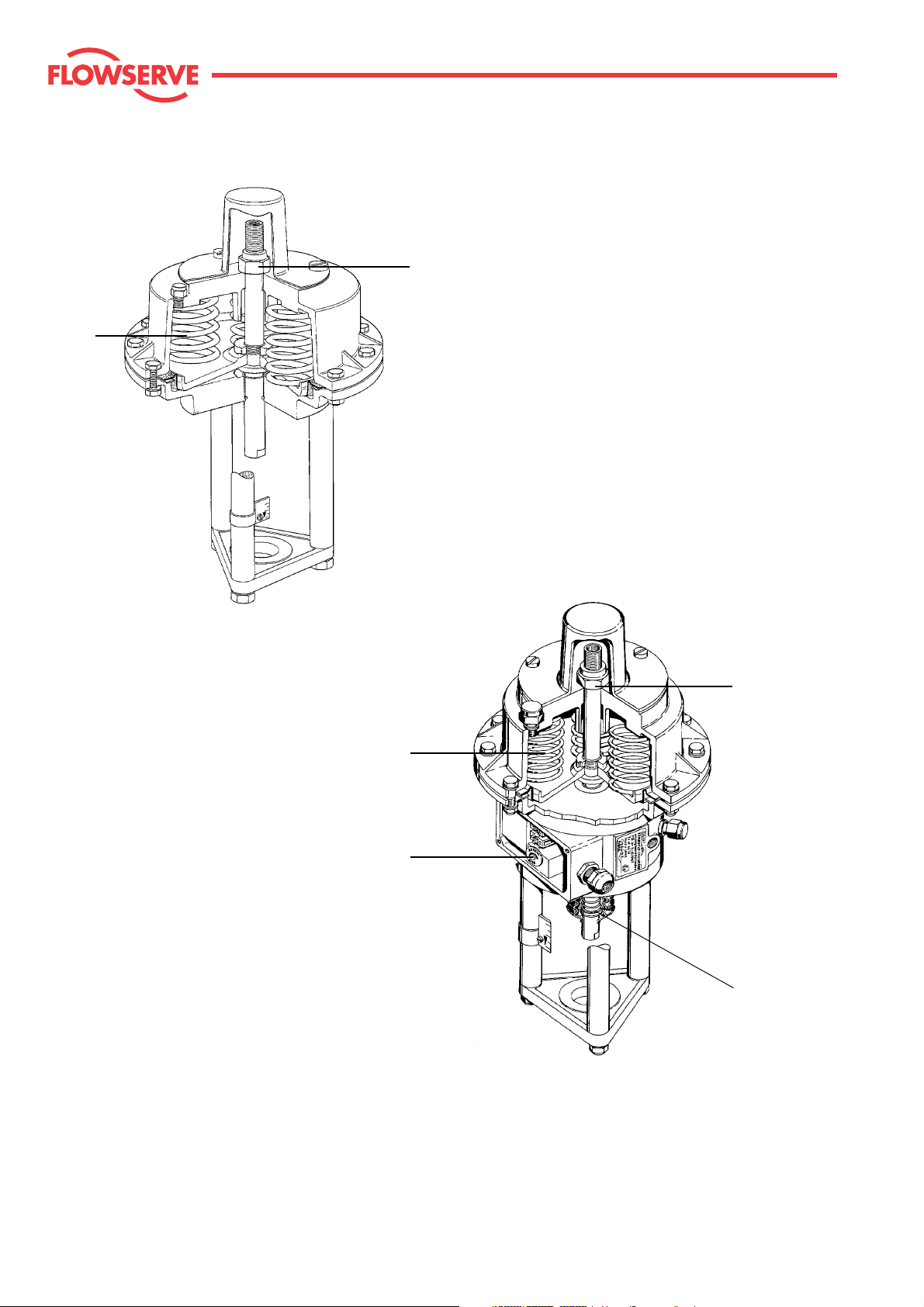

Page 8

Flow Control Division

Kammer Control Valves

2

1

Series 47 / 48 / 49

(without positioner)

2

1

3

4

Series 37 / 38 / 39

(with positioner)

Fig. 5

8

Page 9

5.3 Actuator Springs - (fig. 5 pos. 1)

Different actuator spring sets are available depending on the actuator thrust requirements and the fail

position of the actuator. The appropriate spring set can be chosen from the spare parts list.

5.4 Zero Adjustment Locknut - (fig. 5 pos. 2)

The zero adjustment locknut is used as a mechanical stop so that the actuator just begins to travel when

the desired signal is applied to the positioner.

5.5 Range Adjustment - (fig. 5 pos.3)

(Actuator with positioner only)

The actuator travel is adjusted by means of the range adjustment screw. Turn the range adjustment screw

so that the actuator stem travels the required distance in response to the positioner input signal.

5.6 Positioner Spring - (fig. 5 pos. 4)

(Actuator with positioner only)

To change the signal range from full to split range the positioner spring must be changed.

Flow Control Division

Kammer Control Valves

Examples:

from 3-15 psi to 3-9 psi or 9-15 psi

from 4-20 mA to 4-12 mA or 12-20 mA

Notice that split ranging on electro-pneumatic actuator is also done by means of the positioner spring.

After removal of the spring boot and retaining ring on older actuators or by removing the boot, positioner

spring adjustment nut on newer actuators, the spring can be replaced.

9

Page 10

Flow Control Division

Kammer Control Valves

Air-to-open Air-to-close

5.7 Changing the Actuator Action

To change the actuator action from fail-open to fail-closed, or vice versa, the complete actuator

must be reversed. Remove the yoke assembly and actuator cap, invert the actuator and replace all

parts. If necessary, use other spring sets (see spare parts list) according to the actuator thrust

requirements.

Fig. 6

10

Page 11

Flow Control Division

Kammer Control Valves

Gasket

O - Ring

Connection "EXT"

For positioner without "EXT" cover

on the reverse side exchange

position of gasket and O-ring.

Fig. 7a

Special O - Ring

5.8 External Piping

When using solenoid valves (not NAMUR), lock-up valves, volume boosters, etc.; external piping is possible

without the need of additional parts. Solenoid valves to NAMUR-standard (modified) can be bolted directly onto

the positioner body.

Positioner without "EXT" cover on the reverse side:

Exchange position of gasket and O - ring (Fig. 7a).

Remove the plugs marked "EXT" from the positioner body and diaphragm case.

Accessories can now be piped between the positioner and diaphragm case.

Positioner with "EXT" cover on the reverse side:

Exchange the position of the O - ring and special O - ring in the "EXT" cover. (Fig. 7b)

Remove the plugs marked "EXT" from the positioner body and diaphragm case.

Accessories can now be piped between the positioner and diaphragm case.

Connection "EXT"

"EXT" cover

O - Ring

For positioner with "EXT" cover on the

reverse side exchange position of

O - ring and special O-ring.

Fig. 7b

11

Page 12

Flow Control Division

Kammer Control Valves

Cap

Zero adjustment locknut

Upper coupling half

Lip serves as travel

indicator

Actuator stem

Screw

Travel indicator

Plug stem locknut

Packing gland nut

Actuator clamp nut

Valve plug stem

Coupling insert

Lower coupling half

Locknut

Plug stem

Valve/actuator with coupling

(see page 23)

12

Fig. 8: Typical actuator and valve configuration

Page 13

Kammer Control Valves

6 GENERAL SERVICE INFORMATION

Service to the actuator is best performed when the actuator is removed from the valve body.

For the purpose of these instructions, consider the actuator as a separate subassembly with the procedures

described in these instructions being performed on a bench. However, many service repairs and adjustments

can be accomplished in the field while the actuator and valve body are still connected to each other.

Flow Control Division

6.1 REMOVING ACTUATOR FROM VALVE BODY

DANGER:

Depressurise the line to atmospheric pressure

and drain all fluids from the valve before working on the

actuator. Failure to do so can cause serious injury.

For air-to-open actuators start with 6.1.1

For air-to-close actuators start with 6.1.2.1

6.1.1 Remove the valve cap and nameplate. Turn the zero adjustment locknut until it just makes contact with the actuator

spring case (this removes the spring force from the valve

plug).

6.1.2 Valve/actuator without coupling

6.1.2.1 With a wrench, hold the actuator stem to prevent it from

rotating while using a second wrench to loosen the plug

stem locknuts.

If the actuator stem is rotated the diaphragm will be

NOTE:

twisted and this may cause irreparable damage.

6.1.2.2 Loosen the packing gland nut and the actuator clamp nut.

6.1.2.3 Being sure not to turn the plug stem, rotate the actuator

assembly counterclockwise to disengage the actuator stem

from the valve plug stem.

NOTE:

Ensure that the plug assembly is not rotated with the

plug seated. This may cause irreparable damage to the

seating faces.

6.1.2.4 Lift the actuator assembly from the valve body subassembly.

At the same time, remove the plug stem locknuts, the travel

indicator disc, packing gland nut, and clamping nut.

6.1.3 Valve/actuator with coupling

6.1.3.1 With a wrench, hold the actuator stem to prevent it from

rotating while using a second wrench to loosen and remove

coupling screws.

6.1.3.2 Remove the yoke rod nuts and lift actuator assembly

from the valve.

6.2 CONNECTING ACTUATOR TO VALVE BODY

General Notes:

• The actuator must be calibrated before connecting it to the

valve body. See section 3 "Calibration" of these instructions.

6.2.1 Valve/actuator without coupling

6.2.1.1 Place the actuator assembly onto the valve body

subassembly. At the same time, install the clamping nut,

packing gland nut, plug stem locknuts, and the travel indicator disc.

6.2.1.2 "Air-to-open/fail-to-close" actuators only:

Rotate the actuator assembly clockwise, threading the actuator stem onto the plug stem until the yoke plate just

makes contact with the bonnet flange, and the actuator is

properly aligned for installation.

NOTE:

Ensure that the plug assembly is not rotated with the

plug seated. This may cause irreparable damage to the

seating faces.

"Air-to-close/fail-to-open" actuators only:

Lift the plug stem to the actuator stem. Thread the plug stem

into the actuator stem so that the distance "plug in seat", to

"plug raised", is approximately the distance of the specified

stroke.

6.2.1.3 Tighten the clamping nut and the packing gland nut (see

valve service instructions for torque values).

6.2.1.4 Adjust the valve plug for seat off by threading the plug stem

further into or out of the actuator stem.

rotate the plug stem while the valve is in the closed

NOTE:

position. Open the valve first, make the adjustment while the

valve is open, and then close the valve to check for seat-off.

6.2.1.5 After final adjustments are made, lock the two stem nuts

against the actuator stem and set the position of the travel

indicator on the yoke rod.

6.2.2 Valve/actuator with coupling

6.2.2.1 Place actuator onto valve.

6.2.2.2 Screw on and tighten yoke rod nuts.

6.2.2.3 Fit the coupling screws finger tight.

6.2.2.4 Adjust the valve plug for seat off by threading the plug stem

further into or out of the coupling insert.

rotate the plug stem while the valve is in the closed

NOTE:

position. Open the valve first, make the adjustment while the

valve is open, and then close the valve to check for seat-off

• All worn or damaged parts must be replaced. All parts to be

reused should be cleaned for ease of reassembly.

6.2.2.5 After final adjustment tighten the coupling screws and set

the position of the travel indicator on the yoke rod.

13

Page 14

13

Flow Control Division

Kammer Control Valves

12

15

14

17

16

11

10

9

8

6

5

2

1

7

3

1

4

2

14

Series 47 / 48 / 49

(without positioner)

Series 37 / 38 / 39

(with positioner)

Fig. 9

Page 15

Flow Control Division

Kammer Control Valves

7 ACTUATOR DISASSEMBLY and ASSEMBLY

7.1 ACTUATOR DISASSEMBLY

(refer to figs. 9 and 11)

NOTE:

To help reassembly note or mark the rela-

tionship between the parts to be disassembled.

7.1.1 Remove yoke plate (1) and yoke rods (2).

For actuators without positioner continue with

7.1.5.

7.1.2 Actuators without adjustable positioner spring

(see Fig. 9)

Remove the positioner spring boot (3), retaining

ring (4), seating washer (5), and positioner spring

(6).

Actuators with adjustable positioner spring

(see Fig. 15)

Loosen the set screw in the positioner spring

adjusting nut and remove the nut. Remove boot

and positioner spring.

7.1.3 Loosen and remove the positioner cover screws

(7), positioner cover (8), double diaphgram (9)

and balancing plate (10).

7.1.4 Remove the positioner (11). All inner positioner

parts are now accessible for replacement or maintenance (

11

for positioner details see figs. 10 and

).

7.2 ACTUATOR ASSEMBLY

(refer to figs. 9 to 13)

7.2.1 Install the diaphragm and diaphragm plate on the

actuator stem. Use Loctite® #242 on the threaded

portion of the actuator stem where the clamping

nut (14) is to be installed. Install and tighten the

clamping nut, being sure not to kink the diaphragm.

7.2.2 Place the spring set into the spring case so that

they sit in the recessed area of the case (15).

Smaller diameter springs are placed inside of

larger diameter springs.

7.2.3 Insert the actuator stem through the hole in the

spring case (15).

7.2.4 Install the zero adjustment locknut (13) on the

actuator stem and tighten it down fully to compressing the springs.

DANGER:

A press must be used to compress the

springs when high thrust spring sets are installed

or when actuator stroke is 40 mm.

7.2.5 Before inserting a new O-ring (16) in the diaphragm case, pack the O-ring groove with a multitemperature assembly paste

7.2.6 Replace the diaphragm gasket (17) and install the

diaphragm case onto the spring case assembly.

7.2.7 Install and tighten all case screws (12), washers

and nuts using a crisscross pattern.

7.1.5 Loosen and remove all case screws (12).

DANGER:

Actuators with high thrust spring sets

and/or actuators with 40 mm (1.5") stroke must be

held in a press to prevent possible injury when

removing the case screws.

7.1.6 Unscrew the zero adjustment lock nut (13).

7.1.7 The spring case and diaphragm case can now be

separated, and the springs removed.

7.1.8 Holding the actuator stem, unscrew and remove

the clamping nut (14) to service the actuator

diaphragm and diaphragm plate.

Continued....

15

Page 16

19

Flow Control Division

Kammer Control Valves

18

Range adjustment pin

10

9

Positioner

Fig. 11

Signal orifice

16

Balancing plate

Balancing plate assembly

Fig. 12

Double diaphragm

Fig. 13

Page 17

(7.4 Actuator assembly continued)

Flow Control Division

Kammer Control Valves

7.4.8 to 7.4.11 for actuator with positioner only.

7.2.8 Assemble the positioner using new O-rings, gas-

kets and filters and install the positioner body (see

figs. 11).

7.2.9 Install the balancing plate (10) so that the small

hole fits over the plastic range adjustment pin (see

fig.12), and the bevelled side faces the double

diaphragm (flat side to positioner).

7.2.10 Install the double diaphragm assembly (9) aligning the small hole in the diaphragm with the hole

in the diaphragm ring and the signal orifice in the

positioner body (see fig. 13).

7.2.11 Actuator without adjustable positioner spring

(see Fig 9)

Install the positioner cover (8), positioner cover

screws (7), positioner spring (6), seating ring (5),

retaining ring (4), and positioner spring boot (3).

Actuator with adjustable positioner spring

(see Fig 15)

Install the positioner cover, positioner cover

screws, positioner spring and positioner spring

boot. Thread adjusting nut onto actuator stem and

adjust roughly using the gauge (lower edge of

adjusting nut the underside of positioner cover).

7.2.12 Refit yoke rods (2) and yoke plate (1).

The actuator is now ready to be calibrated.

7.3 POSITIONER SERVICE

The KÄMMER integral positioner is designed to be a

maintenance free unit. However; moisture, oil and dirt

entering the positioner can dampen its performance,

which will cause the need for maintenance and repair.

When this happens, remove all internal parts and clean

them thoroughly. Replace all O-rings, filters and damaged parts, and reassemble the positioner body according to fig. 11.

Positioners with integral I/P transducers are more

sensitive to contaminants than those without. Therefore, it is very important that all parts to be reused are

extremely clean and dry.

I/P transducer

To remove the I/P transducer, disconnect the wires

from the terminal block and loosen the set screw (19)

on the side of the positioner housing. The I/P transducer can then be pulled from the front of the positioner housing. The main cause of transducer malfunction is a polluted air supply. Filters are situated in

the input and output orifices of the transducer and are

readily accessible after removing the O-rings. Apart

from the O-rings and filters the transducer contains no

user serviceable parts. The transducer is factory adjusted to exactly 4 – 20 mA or 0 – 20 mA (documented

by a sticker on the transducer cover) and an attempt to

field calibrate is not recommended. For repair and/or

calibration the transducer assembly should be returned to Kämmer.

17

Page 18

Zero adjustment locknut

Dim. "A"

Flow Control Division

Kammer Control Valves

Range adjustment screw

(max. 3 turns)

Positioner spring

Adjusting nut

Fig. 14: Dial gauge

Actuator stem

KÄMMER

Type

H

10

39D>

37/38/39

10

39D<

10

39D>

20

20

37/38/39

20

39D<

10

38-2

40

39D>

38-2

20

39

40

39D<

40

Gauge

Set screw

Adjust positioner spring with gauge

Fig. 15

KÄMMER

Type

39D>

37/38/39

39D<

39D>

37/38/39

39D<

38-2

39D>

38-2

39

39D<

Gauge (scale 1:1)

H

10

10

10

20

20

20

10

40

20

40

40

63 mm

8 Calibration

Calibrate actuator

(actuator without adjustable positioner spring)

8.1 Range adjustment

See nameplate for signal range, supply pressure

and stroke.

8.1.1 Connect air supply to the "SUPPLY" port of the

actuator and an adjustable signal source to the

18

"SIGNAL" connection. Attach a dial gauge to the

actuator (see Fig 14).

8.1.2 Undo the zero adjustment locknut until it is a few

threads free of the actuator housing. Set the

signal to the low end value (e.g. 0,2 bar or 4 mA).

Adjust the dial gauge to zero.

8.1.3 Set the signal to the high end value (e.g. 1,0 bar or

20 mA).

Page 19

Flow Control Division

Kammer Control Valves

8.1.4 Using the range adjusting screw set the actuator to full

stroke + 1.5 mm (e.g. stroke 20 + 1.5 mm = 21.5 mm).

8.1.5 Make adjustment with the range adjusting screw as

required until desired stroke is obtained

8.2 Zero adjustment

3.2.1 The zero adjustment can only be set after the final

range adjustment has been made.

8.2.2 Maintain the low end signal (e.g. 0.2 bar or 4 mA) and

turn the zero adjustment locknut until it just makes

contact with the actuator housing.

8.3 Calibrate actuator

(actuator with adjustable positioner spring)

See nameplate for signal range, supply pressure and

stroke.

8.3.1 Connect air supply to the "SUPPLY" port of the actuator and an adjustable signal source to the "SIGNAL"

connection. Attach a dial gauge to the actuator (see Fig

14).

8.3.2 Undo the zero adjustment locknut until it is a few

threads free of the actuator housing.

Loosen the set screw and thread the adjusting nut on

the actuator stem until it's lower face is in alignment

with the appropriate type designation on the gauge.

8.3.3 Set the signal to the low end value (e.g. 0.2 bar or 4

mA). Adjust the dial gauge to zero.

8.3.4 Set the signal to the high end value (e.g. 1.0 bar or 20

mA).

8.3.5 Using the range adjusting screw set the actuator to full

stroke + 1.5 mm (e.g. stroke 20 + 1.5 mm = 21.5 mm).

8.3.6 Set signal and dial gauge to zero.

8.3.7 Set the signal to the low end value. Adjust the posi-

tioner spring adjusting nut to compress/decompress

the positioner spring until the actuator stem rises 1.5

mm.

8.3.8 Set the signal to the high end value (e.g. 1.0 bar or 20

mA). Using the range adjusting screw set the actuator

to full stroke + 1.5 mm (e.g. stroke 20 + 1.5 mm = 21.5

mm).

8.3.11 Check all adjustments for correctness.

8.4 Calibrate actuator/valve

8.4.1 Connect air supply to the "SUPPLY" port of the actua-

tor and an adjustable signal source to the "SIGNAL"

connection. Undo the zero adjustment locknut until it

is a few threads free of the actuator housing. Attach a

dial gauge to the actuator and set it to zero.

8.4.2 Determine the instrument signal at which the plug

should begin moving off the seat and apply that signal

to the valve. If the plug stem does not begin to move

at the predetermined signal, adjust the signal to

midrange until the plug is off the seat, loosen the plug

stem locknut and turn the plug stem in or out of the

actuator stem.

For example, if the plug begins to move at a lower

signal than the predetermined one, turn the plug stem

out of the actuator stem. If the plug begins to move at

a higher signal than the predetermined one, turn the

plug into the actuator stem. Repeat this process until

the actuator is calibrated as required and re-tighten

the plug stem locknut. Adjust the zero adjustment

locknut until it is 2 mm off the actuator and replace the

actuator cap.

NOTE:

Do not turn the plug stem when the plug is

seated; otherwise, the plug and seat ring may be

damaged.

8.5 Calibrate actuators without a positioner

8.5.1 With no air supply to the actuator, adjust the zero

adjustment locknut until dimension "A" as shown in

the table below is achieved.

Actuator Stroke Dimension “A”

size (mm)

47

47

48 / 49

48 / 49

Inch mm

3

/8 10 35

3

/4 20 25

3

/8 10 55

3

/4 20 45

48 / 49 11/2 40 25

49D 11/2 40 55

8.3.9 Repeat adjustments 8.3.3 to 8.3.8 until both adjust-

ments are correct.

8.3.10 Set signal to zero and tighten the set screw in the

adjusting nut. Set the signal to the low end value. Set

the dial gauge to zero and tighten zero adjustment

locknut, until the dial gauge pointer just moves (nut

contacts the actuator housing) and then a further 1/4

turn ( around 3/10 mm pretension).

19

Page 20

8.6 TECHNICAL DATA

Flow Control Division

Kammer Control Valves

Actuator without positioner Actuator with P/P positioner Actuator with I/P positioner

47 48 49 49D 37 38 39 39D IP-37 IP-38 IP-39 IP-39D

Diaphragm area cm

2

80 200 500 2 x 500 80 200 500 2 x 500 80 200 500 2 x 500

Thrust max. kg 160 400 1000 2000 160 400 1000 2000 160 400 1000 2000

Stroke mm 10/20 10/20 10/20/4010/20/40 10/20 10/20 10/20/4010/20/40 10/20 10/20 10/20/40 10/20/40

Time at stroke10 mm s* 0.1 0.25 0.5 1 0.5 1 2.5 5 0.5 1 2.5 5

20 mm s* 0.2 0.5 1 2 1 2 5 10 1 2 5 10

40 mm s* – – 2 4 – – 10 20 – – 10 20

Signal range 3 – 15 psi 3 – 15 / 3 – 9 / 9 – 15 psi 0/4 – 20, 4 – 12, 12 – 20 mA or rev.

0.2 – 1.0 bar 0.2 – 1.0 / 0.2 – 0.6 / 0.6 – 1.0 bar –

20 – 60 kPa 20 – 100 / 20 – 60 / 60 – 100 kPa –

Input resistance – – 260/170 Ohm**

Inductivity / Capacitance – – negligible (≈0)

Spring range see appropriate spare parts list see appropriate spare parts list see appropriate spare parts list

Supply pressure 20 – 60 psi 20 – 60 psi 20 – 60 psi

1.4 – 4.2 bar 1.4 – 4.2 bar 1.4 – 4.2 bar

140 – 420 kPa 140 – 420 kPa 140 – 420 kPa

Accuracy – ±1% = 1%

Hysteresis – < 1% = 1%

Operating sensitivity – – = 0.1%

<

<

<

Amplification factor – 50 50

Supply pressure influence – 0.4% / 0.1 bar 0.4% / 0.1 bar

Air consumption at 1,4 bar – 0.6 Nm3 / h 0.6 Nm3 / h

Electrical protection – – EEx ia C T6, PTB No. Ex-93.C. 2104X

Suitable for connection to intrinsical

safe circuits with I max.

<

= 60 mA (T6) thru 150 mA (T4)

Housing protection – – IP 54

Allowable ambient temp. – 30 to + 80 °C (-22 to +176° F)

Actuator action air-to-open / air-to-close, reversible

Installation position optional

Air supply dry and oil-free (instrument air)

* Stroking time with 1.4 bar supply pressure.

** Transducer adjustable = 260 Ohm, not adjustable = 170 Ohm

20

Page 21

Flow Control Division

Kammer Control Valves

Spring

set

No.

710

711

712

713

714

715

716

717

722

723

724

725

726

727

810

811

812

813

814

815

816

817

820

821

822

823

824

825

826

827

921

922

923

924

925

926

927

941

942

943

944

945

946

947

Spring range

(bar)

0,2 - 1,0

0,3 - 0,9

0,5 - 1,1

1,0 - 1,9

1,0 - 2,2

1,5 - 2,7

1,5 - 3,0

2,0 - 3,8

0,5 - 1,1

0,9 - 1,9

1,0 - 2,2

1,3 - 2,7

1,4 - 3,0

1,8 - 3,8

0,2 - 1,0

0,3 - 0,9

0,5 - 1,1

1,0 - 1,9

1,0 - 2,2

1,5 - 2,7

1,5 - 3,0

2,0 - 3,8

0,2 - 1,0

0,3 - 0,9

0,5 - 1,1

0,9 - 1,9

1,0 - 2,2

1,3 - 2,7

1,4 - 3,0

1,8 - 3,8

0,3 - 0,9

0,5 - 1,1

1,0 - 1,9

1,0 - 2,2

1,5 - 2,7

1,5 - 3,0

2,0 - 3,8

0,3 - 0,9

0,5 - 1,0

0,8 - 1,6

0,9 - 1,9

1,2 - 2,3

1,3 - 2,6

1,7 - 3,3

Spring set consists of:

Qty.

3

3

3

3

6

3

6

6

3

3

6

3

6

6

3

3

3

3

6

3

6

6

3

3

3

3

6

3

6

6

3

3

3

6

3

6

6

3

3

3

6

3

6

6

Part No.

37 10 10

37 10 40

37 10 20

37 10 20

37 10 20

37 10 20

37 10 20

37 10 20

37 20 20

37 20 20

37 20 20

37 20 20

37 20 20

37 20 20

38 10 10

38 10 40

38 10 20

38 10 20

38 10 20

38 10 20

38 10 20

38 10 20

38 20 10

38 20 40

38 20 20

38 20 20

38 20 20

38 20 20

38 20 20

38 20 20

39 20 40

39 20 20

39 20 20

39 20 20

39 20 20

39 20 20

39 20 20

39 40 40

39 40 20

39 40 20

39 40 20

39 40 20

39 40 20

39 40 20

Colour

code

W

S

B

B

B

B

B

B

B

B

B

B

B

B

W

S

B

B

B

B

B

B

W

S

B

B

B

B

B

B

S

B

B

B

B

B

B

S

B

B

B

B

B

B

Dimensions *

Ø Dm / Ø d / L o

20,5 / 3,20 x 42,5

23,0 / 3,20 x 45,0

22,0 / 3,20 x 48,3

22,0 / 3,20 x 48,3

22,0 / 3,20 x 48,3

22,0 / 3,20 x 48,3

22,0 / 3,20 x 48,3

22,0 / 3,20 x 48,3

26,0 / 2,75 x 56,7

26,0 / 2,75 x 56,7

26,0 / 2,75 x 56,7

26,0 / 2,75 x 56,7

26,0 / 2,75 x 56,7

26,0 / 2,75 x 56,7

35,5 / 5,60 x 62,5

32,0 / 5,00 x 65,0

39,0 / 5,60 x 68,3

39,0 / 5,60 x 68,3

39,0 / 5,60 x 68,3

39,0 / 5,60 x 68,3

39,0 / 5,60 x 68,3

39,0 / 5,60 x 68,3

40,0 / 5,00 x 65,0

36,5 / 4,50 x 70,0

42,5 / 5,30 x 76,7

42,5 / 5,30 x 76,7

42,5 / 5,30 x 76,7

42,5 / 5,30 x 76,7

42,5 / 5,30 x 76,7

42,5 / 5,30 x 76,7

55,0 / 8,00 x 110

66,0 / 9,00 x 116,7

66,0 / 9,00 x 116,7

66,0 / 9,00 x 116,7

66,0 / 9,00 x 116,7

66,0 / 9,00 x 116,7

66,0 / 9,00 x 116,7

57,0 / 7,00 x 120

67,0 / 7,20 x 138

67,0 / 7,20 x 138

67,0 / 7,20 x 138

67,0 / 7,20 x 138

67,0 / 7,2 0x 138

67,0 / 7,20 x 138

Qty.

-

-

-

3

6

3

6

3

6

3

6

-

-

3

6

3

6

-

-

3

6

3

6

-

3

6

3

6

-

3

6

3

6

Part No.

-

-

-

37 10 30

37 10 30

37 10 30

37 10 30

37 20 30

37 20 30

37 20 30

37 20 30

-

-

38 10 30

38 10 30

38 10 30

38 10 30

-

-

38 20 30

38 20 30

38 20 30

38 20 30

-

39 20 30

39 20 30

39 20 30

39 20 30

-

39 40 30

39 40 30

39 40 30

39 40 30

Colour

code

Ø Dm / Ø d / L o

-

-

-

R

14,0 / 2,2 x 56,7

-

R

14,0 / 2,2 x 56,7

R

14,0 / 2,2 x 56,7

R

14,0 / 2,2 x 56,7

-

R

19,7 / 2,2 x 60,0

-

R

19,7 / 2,2 x 60,0

R

19,7 / 2,2 x 60,0

R

19,7 / 2,2 x 60,0

-

-

-

R

26,5 / 4,0 x 76,7

-

R

26,5 / 4,0 x 76,7

R

26,5 / 4,0 x 76,7

R

26,5 / 4,0 x 76,7

-

-

-

R

26,5 / 3,6 x 80

-

R

26,5 / 3,6 x 80

R

26,5 / 3,6 x 80

R

26,5 / 3,6 x 80

-

-

R

43 / 6,3 x 133,3

-

R

43 / 6,3 x 133,3

R

43 / 6,3 x 133,3

R

43 / 6,3 x 133,3

-

-

R

45,7 / 5,25 x 148

-

R

45,7 / 5,25 x 148

R

45,7 / 5,25 x 148

R

45,7 / 5,25 x 148

Dimensions *

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

* All dimensions in mm

Colour code: W = White

(Each spring is

marked with a

spot of paint)

B = Blue

R = Red

S = Black

∅ d

∅ Dm

Lo

21

Page 22

Positioner spring

Flow Control Division

Kammer Control Valves

∅ Dm

∅ d

Lo

Part - No. Spring range Spring range Stroke Lo ø Dm ød

[bar] [mA] [mm] [mm] [mm] [mm]

0 36 00 10 00 0.2 - 1.0 0/4 - 20 10 39.75 20.0 2.0

0 36 00 20 00 0.2 - 0.6 0/4 - 10/12 10 42.5 20.0 1.6

0 36 00 30 00 0.2- 1.0 0.6 - 1.0

0 36 00 40 00 0.2 - 0.6 0/4 - 10/12 20 60.0 22.5 1.5

0 36 00 50 00 0.2- 1.0 0.6 - 1.0

0 36 00 60 00 0.2 - 0.6 0/4 - 10/12 40 100 21.0 1.4

0 36 00 70 00 0.6 - 1.0 10/12 - 20 40 140.0 18.7 1.4

0/4 - 20 10/12 - 20

0/4 - 20 10/12 - 20

20 10 55.5 19.5 1.7

40 20 85.0 20.5 1.6

22

Page 23

Flow Control Division

Kammer Control Valves

Coupling for actuators with 2 yoke rods Coupling for actuators with 3 yoke rods

Upper coupling half M6

Part-No. 0 37 01 06 00

Coupling insert M 4 Part-No. 0 37 01 08 00

Coupling insert M 6 Part-No. 0 37 01 09 00

Coupling insert M 10 Part-No. 0 37 01 10 00

Screw, M 4 x 12 (2x)

Part-No. 0 10 02 05 00

Lower coupling half

Part-No. 0 37 01 07 00

Coupling assy. M 6 / M 4 Part-No. 0 37 01 03 00

Coupling assy. M 6 / M 6 Part-No. 0 37 01 01 00

Coupling assy. M 6 / M 10 Part-No. 0 37 01 02 00

Upper coupling half M10

Part-No. 0 36 01 06 00

Coupling insert M 6 Part-No. 0 36 01 09 00

Coupling insert M 10 Part-No. 0 36 01 08 00

Screw, M 6 x 20 (2x)

Part-No. 0 10 02 22 00

Lower coupling half

Part-No. 0 36 01 07 00

Coupling assy. M 10 / M 6 Part-No. 0 36 01 01 00

Coupling assy. M 10 / M 10 Part-No. 0 36 01 02 00

23

Page 24

Flow Control Division

Kammer Control Valves

Regional Headquarters

Flowserve Flowserve Flowserve

Manderscheidtstr. 19 1350 N. Mt. Springs Prkwy. 12 Tuas Avenue 20

45141 Essen Springville, UT 84663

Germany USA Singapore 638824

Telephone: +49 (0) 201 8919 5 Telephone: +1 801 489 8611 Telephone: +65 862 3332

Facsimile: +49 (0) 201 8919 662 Facsimile: +1 801 489 3719 Facsimile: +65 862 4940

Main Sales Offices (Europa, Middle east, Africa)

Flowserve Flowserve Flowserve Flowserve

von-Braun-Straße 19a 12, av. du Québec Station Road Allee du Quartz 1

48681 Ahaus 91965, Courtaboeuf Cedex Pershore, Worcestershire CH-2300 La-Chaux-de Fonds

Germany France England WR102BZ Switzerland

Telephone: +49 (0) 2561 6860 Telephone: +33 (0) 1 60 923 251 Telephone: +44 (0) 1386 55 45 51 Telephone: +41 (0) 32 925 9700

Facsimile: +49 (0) 2561 68648 Facsimile: +33 (0) 1 60 923 299 Facsimile: +44 (0) 1386 55 49 68 Facsimile: +41 (0) 32 926 5422

Flowserve Flowserve

Cnr. Bismit and Granier Str. C/O Saleh & Abdulaziz Abahsain

Jet Park Ext 3 P.O. Box 209

Boksburg

1459 Gauteng Al Khobar 31952

South Africa Saudi Arabia

Telephone: +27 397-3150 Telephone: 9663 857 3442

Facsimile: +27 397-5300/01/02 Facsimile: 9663 859 5284

©03.2002 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

24

All data subject to change without notice

Loading...

Loading...