Page 1

4-75 Position

Indicator

FCD WCAIM2070-00 (Part 06525)

1. Description

The 4-75 position indicator is designed to be used with and mounted

in the Series 75, 120 VAC actuator with many of its standard options

including the I-75 Interface Kit and the DFC17 controller. Its output

is suited for 4-20 mA DC meter with 0-100% scale (such as General

Electric Type GE185), which is not part of the package. If properly

calibrated, it indicates actuator shaft position from closed (0°, 0%)

to open (90°, 100%). It is combined with standard Potentiometer

Kit, which supplies information on shaft position. If feedback potentiometer is required for other functions such as remote resistance

indication, or with a DFC17 controller, a dual Potentiometer Kit

must be used. Each potentiometer can serve only one function. For

installation procedures and wiring of potentiometer, see Potentiometer Kit Instructions (WCAIM2067) or 75 Actuator instructions

(WCAIM2013) or DFC17 instructions (WCAIM2026). These instructions can be obtained from your local distributor/supplier or online

at www.flowserve.com.

Parts included in kit:

Installation, Operation and Maintenance

2. Installation

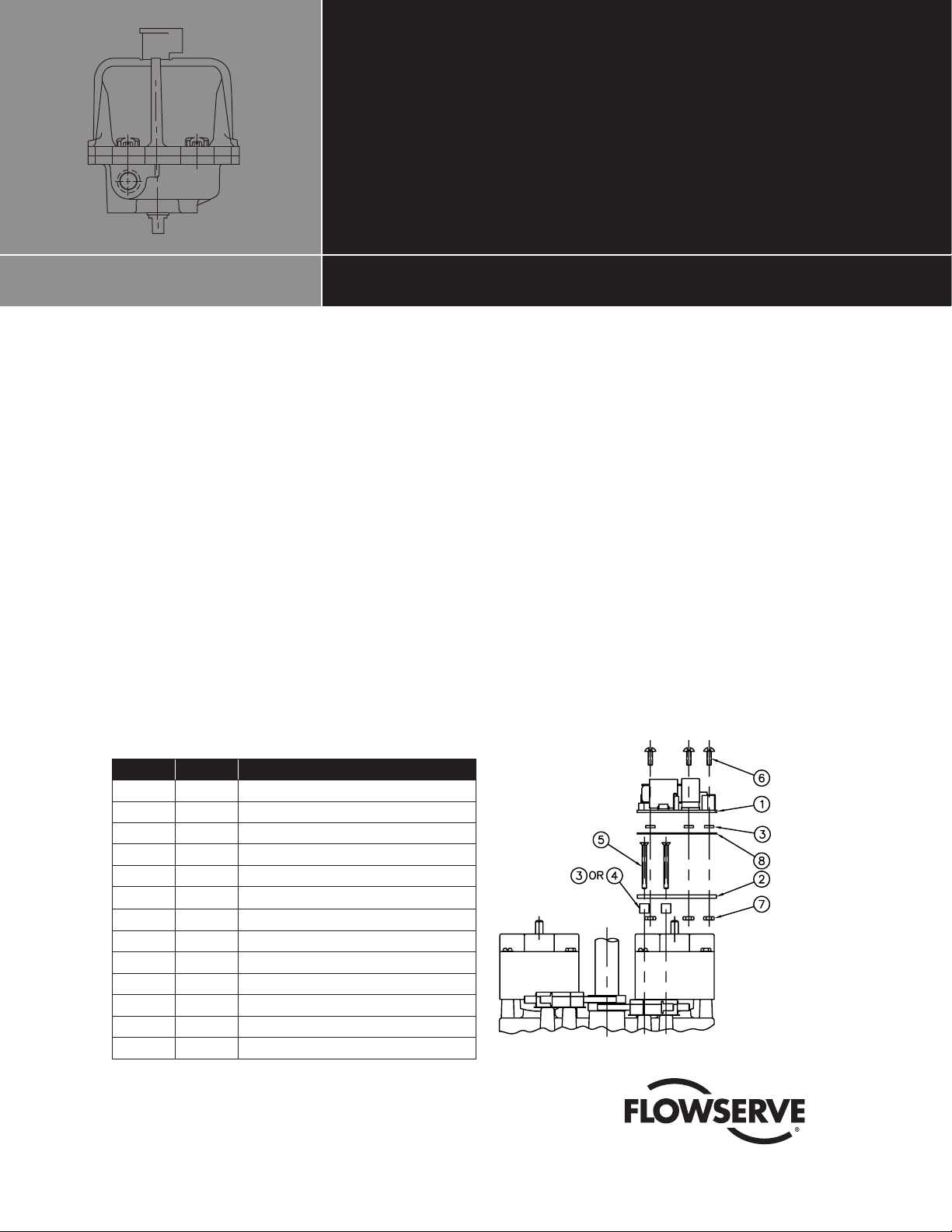

(See Figure 1.)

NOTE: This instruction sheet shows standard installation and wiring

of a 4-75 Position Indicator only. For 25/30 75 actuator, mount

4-75 assembly on top of limit switch(es) using same procedure as

shown below.

Remove the two mounting screws from right limit switch(es), as

viewed from terminal strip. Place two spacers (4) (use two spacers

(3) for M1 or M2 option) between limit switch and mounting plate

(2), and fasten mounting plate in place with two longer flat head

screws (5). Locate insulator (8) on top of mounting plate. Using

three spacers (3) to separate circuit board (1) from mounting plate

(2) and insulator (8), mount circuit board using #4-40 x 3⁄8 round

head screws (6) and nuts (7). Check entire assembly and firmly

secure all screws.

Figure 1—10-23 75 Installation

Item Qty. Description

1 1 Circuit Board

2 1 Mounting Plate

3 5 Spacers (.06")

4 2 Spacers (.25")

5 2 #4-40 x 1¼" F.H. Screws

6 3

7 3 #4-40 Nuts

8 1 Insulator

9 3 Cable Ties (Not Shown)

10 1 Potentiometer Kit (Not Shown)

11 1 Wiring Label (Figure 2)

12 1 Wire—White (Not Shown)

13 1 Closed End Splice (Not Shown)

#4-40 x

3

⁄8" R.H. Screws

Page 2

Flow Control

1211987 10

EXTERNAL INTERNAL

BOAR

D

6

POSITIVE

NEGA

TIV

E

54321

NEUT.

HOT

4-20 mA—OUTPUT

FROM EXT. SWITCH

FROM EXT. SWITCH

CLOSE—CW WIRE

4-20 mA—OUTPUT

VAC POWER

TO BOARD

OPEN—CCW WIRE

RED—MOTOR

BLACK—MOTO

R

BLACK—CIRCUI

T

BROWN—CIRCUIT BOAR

D

HO

T

WHITE—CIRCUIT BOARD

COMMON

WHITE MOT.

COMMON(S

)

CCW LIMIT SW

CW LIMIT

S

W

RED—CIRCUI

T

BOA

RD

Worcester Actuation Systems

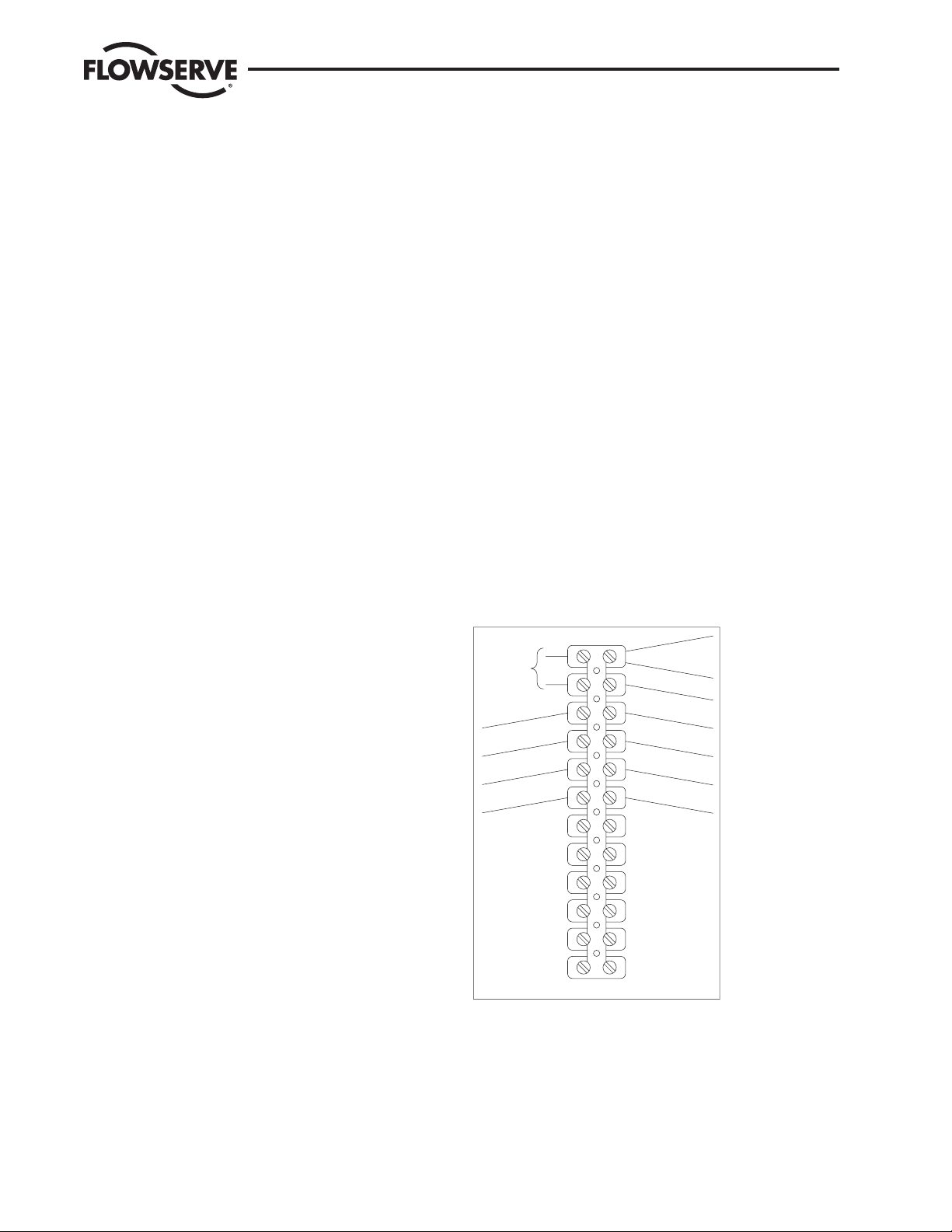

3. Wiring

(See Figure 2.)

NOTES: All wiring to terminal strip should be inserted only to midpoint of terminal strip.

When there are multiple wires going to terminal 1, use the short

white wire included in kit. Connect it to terminal 1 and then

splice it to the other white wires (common) using the closed end

splice provided.

Internal Wiring

There is internal wiring between the actuator terminal strip, feedback

potentiometer, and position indicator PC board. The white wire

(common) from PC board is wired to terminal 1 on internal side; the

brown wire (hot) from PC board is wired to terminal 2 on internal

side. Connect feedback potentiometer wires to the 4-75 position

indicator board terminal block (green to terminal 3, white/black to

terminal 2, and purple to terminal 1).

Remove yellow wire from terminal 5 and brown wire from terminal

6, disconnect them from N.O. contacts of switches 1 and 2 and

discard them. Output signal from PC board red wire (+) is wired to

terminal 5 and black wire (-) is wired to terminal 6 on internal strip

of terminal strip.

External Wiring

External wiring is between actuator terminal strip and outside power

supply and various controls. Common wire of the power supply is

wired to terminal 1 and hot wire of the power supply to terminal 2.

The actuator motor windings are electrically powered through its

own individual external single pole, double throw switch (supplied

by customer); counterclockwise and/or “to open” wire is wired to

terminal 3; clockwise and/or “to close” wire is wired to terminal

4, as shown in wiring diagram for actuator. An outside position

indicator meter is wired with positive connection to terminal 5 and

negative connection to terminal 6.

NOTE: External switch not needed when position indicator is

used with DFC17 controller, as controller board will power

motor windings.

Securely tighten all terminal screws. Secure all wires neatly with the

cable ties (9). Keep wiring away from all rotating parts and ensure

wiring is not pinched when actuator cover is installed.

Grounding wires should be connected to green-colored grounding

screw (if present) on actuator base or to any base plate mounting

screw in actuator.

Figure 2—Wiring of 4-75 120 VAC Position Indicator

NOTE: Attach wiring diagram label, included with kit, on inside of

cover, or modify existing label for the 4-75 option by marking terminal 5 “+”, terminal 6 “-”, and adding “4-20 mA output.”

For actuator using a 4-75 Position Indicator with a DFC17 Controller, the red and black wires from the indicator board will have to be

spliced directly to the external positive and negative output (Meter)

wires, respectively.

NOTE: Prior to wiring, follow Position Indicator board output calibration instructions in Section 4.

2 4-75 Position Indicator FCD WCAIM2070-00

Page 3

Flow Control

Worcester Actuation Systems

4. Adjustment and Calibration

The feedback potentiometer has to be adjusted to obtain the proper

resistance range. With the actuator either in the OPEN (full counterclockwise) or CLOSED (full clockwise) position, and power off,

rotate the face gear, thus turning the potentiometer shaft, until the

resistance between the white/black lead and the green lead (actuator

full counterclockwise), or the white/black lead and the purple lead

(actuator full clockwise), respectively, as measured by ohmmeter, is

between 80 ohms and 90 ohms.

NOTE: It is not necessary to loosen or remove face gear snap ring(s)

to rotate gear; it is a friction fit. If for any reason any snap ring is to

be removed, do not overstretch it; use the minimum opening needed

to allow it to slip over the gear.

Power the actuator to the opposite position from where resistance

was measured. At this position, with power off, measure the resis-

tance at the same terminals as stated above. The resistance reading

should be greater than 700 ohms. If not, then power actuator back to

original position and adjust pot again, as stated in paragraph above.

If unsuccessful in getting proper resistance readings, pot is defective

and should be replaced.

NOTE: For units with a DFC17 controller, do not use above instructions, as adjustment and calibration are accomplished through

controller circuit board only. See DFC17 IOM (WCAIM2026).

To obtain proper 4-20 mA output, the indicator board output has to

be calibrated. Using an ammeter connected to actuator terminals

5 (positive) and 6 (negative)—or for DFC17 controller, connected

directly to red and black wires of indicator board—adjust the two

potentiometers R4 and R5 on the board. With the actuator in the

closed position (0%), adjust R5 potentiometer (adjacent to the number “4” etched on the circuit board and closest to terminal block) to

obtain 4 mA on the ammeter. Move the actuator to the open position

(100%) and adjust R4 potentiometer (adjacent to the number “20”

etched on the circuit board) to obtain 20 mA. Because adjustment

of one potentiometer affects the other, repeat the procedure several

times to obtain proper values.

IMPORTANT: The feedback potentiometer is calibrated for only one

90° quadrant of valve operation. If the output shaft is repositioned to

another 90° quadrant—or if the output shaft is rotated a multiple of

360° from its original position, or if the position indicator is removed

from the actuator—the feedback potentiometer will no longer be in

calibration and must be recalibrated.

5. Repair

Schematic diagram in Figure 3 may be used for customer troubleshooting. If factory repair is necessary, contact factory and request

an RMA (Return Material Authorization) number. After receiving

a new circuit board, replace defective board (per instructions in

section 2) and return it to factory with description of problem and

application.

Figure 3—Wiring Schematic

FCD WCAIM2070-00 4-75 Position Indicator 3

Page 4

Flowserve Corporation has established industry leadership in the design and manu-

facture of its products. When properly selected, this Flowserve product is designed to

perform its intended function safely during its useful life. However, the purchaser or

user of Flowserve products should be aware that Flowserve products might be used in

numerous applications under a wide variety of industrial service conditions. Although

Flowserve can (and often does) provide general guidelines, it cannot provide specific

data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and

understand the Installation Operation Maintenance (IOM) instructions included with the

product, and train its employees and contractors in the safe use of Flowserve products

in connection with the specific application.

While the information and specifications contained in this literature are believed to be

accurate, they are supplied for informative purposes only and should not be considered

certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained

herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and

upgrading its product design, the specifications, dimensions and information contained

herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one

of its worldwide operations or offices.

For more information about Flowserve Corporation, visit www.flowserve.com or call

USA 1-800-225-6989.

FLOWSERVE FLOW CONTROL

Worcester Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434-528-4400

Fax: 434-845-9736

© 2004 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. FCD WCAIM2070-00 Printed in USA.

(Part IOM 06525)

Loading...

Loading...