Page 1

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Logix ® 420

Digital Positioner

FCD LGENIM0106-0612/13

Installation

Operation

Maintenance

Safety Manual

USER INSTRUCTIONS

flowserve.com 1

Page 2

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Quick Start Instructions 15

CONTENTS

1 GENERAL INFORMATION ................................. 3

1.1 USING THIS DOCUMENT ............................................................3

1.2 TERMS CONCERNING SAFETY ......................................................3

1.3 PROTECTIVE CLOTHING .............................................................3

1.4 QUALIFIED PERSONNEL .............................................................3

1.5 VALVE AND ACTUATOR VARIATIONS .............................................3

1.6 SPARE PARTS .........................................................................3

1.7 SERVICE / REPAIR ....................................................................3

1.8 BASIC OPERATION ...................................................................4

1.9 HART ..................................................................................4

1.10 POSITION DEFINITION ...............................................................4

1.11 COMMAND INPUT AND FINAL COMMAND ......................................4

1.12 OUTER LOOP ..........................................................................5

1.13 INNER LOOP ...........................................................................5

1.14 DETAILED SEQUENCE OF POSITIONER OPERATIONS ...........................5

1.15 INNER LOOP OFFSET.................................................................5

2 SPECIFICATIONS ............................................... 6

2.1 INPUT SIGNAL ........................................................................6

2.2 AIR SUPPLY ...........................................................................6

2.3 PHYSICAL SPECIFICATIONS ..........................................................6

2.4 PNEUMATIC OUTPUT................................................................6

2.5 STROKE OUTPUT .....................................................................6

2.6 TEMPERATURE ........................................................................6

2.7 POSITIONER PERFORMANCE CHARACTERISTICS ................................6

2.8 VALVESIGHT DTM SOFTWARE SPECIFICATIONS ...............................6

3 HAZARDOUS AREA CERTIFICATIONS............ 7

4 STORAGE AND UNPACKING ............................ 8

4.1 STORAGE ..............................................................................8

4.2 UNPACKING ...........................................................................8

4.3 PRE-INSTALLATION INSPECTION ...................................................8

5 MOUNTING AND INSTALLATION ..................... 9

5.1 DIRECT MOUNTING TO VALTEK GS AND FLOWTOP ..........................9

5.2 MOUNTING TO NAMUR VALVES ............................................. 10

6 TUBING ............................................................. 11

6.1 DETERMINE AIR ACTION ......................................................... 11

6.2 CONNECT SUPPLY PORT .......................................................... 11

6.3 VENTED DESIGN .................................................................... 11

6.4 PURGING ............................................................................ 11

7 ELECTRICAL CONNECTIONS ......................... 12

7.1 ELECTRICAL TERMINALS ........................................................... 12

7.2 COMMAND INPUT (4-20 MA) CONNECTION ................................ 12

7.3 CONNECTIONS FOR INTRINSICALLY SAFE OPERATION ....................... 14

9 POSITIONER FUNCTIONS (NO DISPLAY

REQUIRED) ....................................................... 18

9.1 LIVE MANUAL TUNING (ADJUSTING THE GAIN) ............................. 18

9.2 LOCAL CONTROL OF VALVE POSITION ......................................... 18

9.3 COMMAND SOURCE RESET ...................................................... 18

9.4 FACTORY RESET .................................................................... 18

9.5 VIEWING VERSION NUMBERS ................................................... 19

10 POSITIONER FUNCTIONS (LCD DISPLAY) .... 19

10.1 MAIN DISPLAY VIEW .............................................................. 19

10.2 MENU OVERVIEW ................................................................. 21

10.3 MENU FEATURES .................................................................. 22

11 HART COMMUNICATION ................................. 27

11.1 VALVESIGHT DTM ................................................................ 27

11.2 HART 475 HANDHELD COMMUNICATOR .................................... 27

11.3 BURST MODE ....................................................................... 27

11.4 CHANGING HART VERSIONS .................................................... 27

12 REQUIREMENTS FOR SAFETY INTEGRITY .. 28

12.1 FAIL SAFE STATE ................................................................... 28

12.2 SAFETY FUNCTION ................................................................. 28

12.3 FAIL SAFE STATE RESPONSE TIME .............................................. 28

12.4 INSTALLATION ...................................................................... 28

12.5 REQUIRED CONFIGURATION SETTINGS......................................... 28

12.6 MAXIMUM ACHIEVABLE SIL..................................................... 28

12.7 RELIABILITY DATA .................................................................. 28

12.8 LIFETIME LIMITS .................................................................... 28

12.9 PROOF TESTING .................................................................... 29

12.10 MAINTENANCE ..................................................................... 29

12.11 REPAIR AND REPLACEMENT ...................................................... 29

12.12 TRAINING REQUIREMENTS ....................................................... 29

13 MAINTENANCE AND REPAIR ......................... 30

13.1 SCHEDULED MAINTAINANCE .................................................... 30

13.2 REQUIRED TOOLS AND EQUIPMENT ............................................ 30

13.3 REPLACING A MAIN BOARD ..................................................... 30

14 TROUBLESHOOTING ....................................... 31

14.1 TROUBLESHOOTING GUIDE ...................................................... 31

14.2 STATUS CODE INDEX .............................................................. 32

14.3 STATUS CODE DESCRIPTIONS .................................................... 33

14.4 HELP FROM FLOWSERVE ......................................................... 39

15 POSITIONER DIMENSIONS.............................. 40

15.1 POSITIONER DIMENSIONS ........................................................ 40

16 HOW TO ORDER ............................................... 41

16.1 POSITIONERS ........................................................................ 41

16.2 SPARE PARTS KITS ................................................................. 41

16.3 MOUNTING KITS ................................................................... 41

INDEX ........................................................................... 42

8 STARTUP .......................................................... 15

8.1 QUICK START INSTRUCTIONS .................................................... 15

8.2 LOCAL USER INTERFACE OVERVIEW ............................................ 15

8.3 CONFIGURATION SWITCH SETTINGS ............................................ 15

8.4 STROKE CALIBRATION ............................................................. 16

flowserve.com 2

Page 3

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

1 GENERAL INFORMATION

1.1 Using This Document

Product users and maintenance personnel should thoroughly

review this manual prior to installing, operating, or performing

any maintenance on the positioner.

The following instructions are designed to assist in unpacking,

installing and performing maintenance as required on Logix®

420 positioners. .

Separate Flow Control Products User Instructions cover the

valve, actuator, or portions of the system and other accessories.

Refer to the appropriate instructions when this information is

needed. In most cases FLOWSERVE valves, actuators and

accessories are designed for specific applications with regard to

medium, pressure and temperature. For this reason they

should not be used in other applications without first

contacting the manufacturer.

To avoid possible injury to personnel or damage to positioner

parts, DANGER and CAUTION notes must be strictly followed.

Modifying this product, substituting non-factory parts or using

maintenance procedures other than outlined could drastically

affect performance and be hazardous to personnel and

equipment, and may void existing warranties.

1.2 Terms Concerning Safety

The safety terms DANGER, CAUTION and NOTE are used in

these instructions to highlight particular dangers and/or to

provide additional information on aspects that may not be

readily apparent.

NOTE: Indicates and provides additional technical information,

which may not be very obvious even to qualified personnel.

CAUTION: Indicates that minor personal injury and/or

property damage can occur if proper precautions are not taken.

DANGER: Indicates that death, severe personal injury

and/or substantial property damage can occur if proper

precautions are not taken.

Compliance with other, not particularly emphasized notes, with

regard to assembly, operation and maintenance and technical

documentation (e.g., in the operating instruction, product

documentation or on the product itself) is essential in order to

avoid faults, which in themselves might directly or indirectly

cause severe personal injury or property damage.

1.3 Protective Clothing

FLOWSERVE positioners use high pressure gas to operate. Use

eye protection when working around pressurized equipment.

Follow proper procedures for working with natural gas if it is

used.

DANGER: Standard industry safety practices must be

adhered to when working on this or any process control product.

Specifically, personal protective equipment must be used as

warranted.

1.4 Qualified Personnel

Qualified personnel are people who, on account of their

training, experience, instruction and their knowledge of

relevant standards, specifications, accident prevention

regulations and operating conditions, have been authorized by

those responsible for the safety of the plant to perform the

necessary work and who can recognize and avoid possible

dangers.

In unpacking, installing and performing maintenance as

required on FLOWSERVE products, product users and

maintenance personnel should thoroughly review this manual

prior to installing, operating or performing any maintenance.

1.5 Valve and Actuator Variations

These instructions cannot claim to cover all details of all

possible product variations, nor can they provide information

for every possible example of installation, operation or

maintenance. This means that the instructions normally include

only the directions to be followed by qualified personal where

the product is being used for its defined purpose. If there are

any uncertainties in this respect particularly in the event of

missing product-related information, clarification must be

obtained via the appropriate Flowserve sales office.

1.6 Spare Parts

Use only FLOWSERVE original spare parts. FLOWSERVE

cannot accept responsibility for any damages that occur from

using spare parts or fastening materials from other

manufactures. If FLOWSERVE products (especially sealing

materials) have been in storage for longer periods check

these for corrosion or deterioration before using these

products. See section 4 STORAGE AND UNPACKING more

information.

1.7 Service / Repair

To avoid possible injury to personnel or damage to products,

safety terms must be strictly adhered to. Modifying this

product, substituting non-factory parts, or using maintenance

procedures other than outlined in this instruction could

drastically affect performance and be hazardous to personnel

and equipment, and may void existing warranties.

Between actuator and valve there are moving parts. To avoid

injury FLOWSERVE provides pinch-point-protection in the

flowserve.com 3

Page 4

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

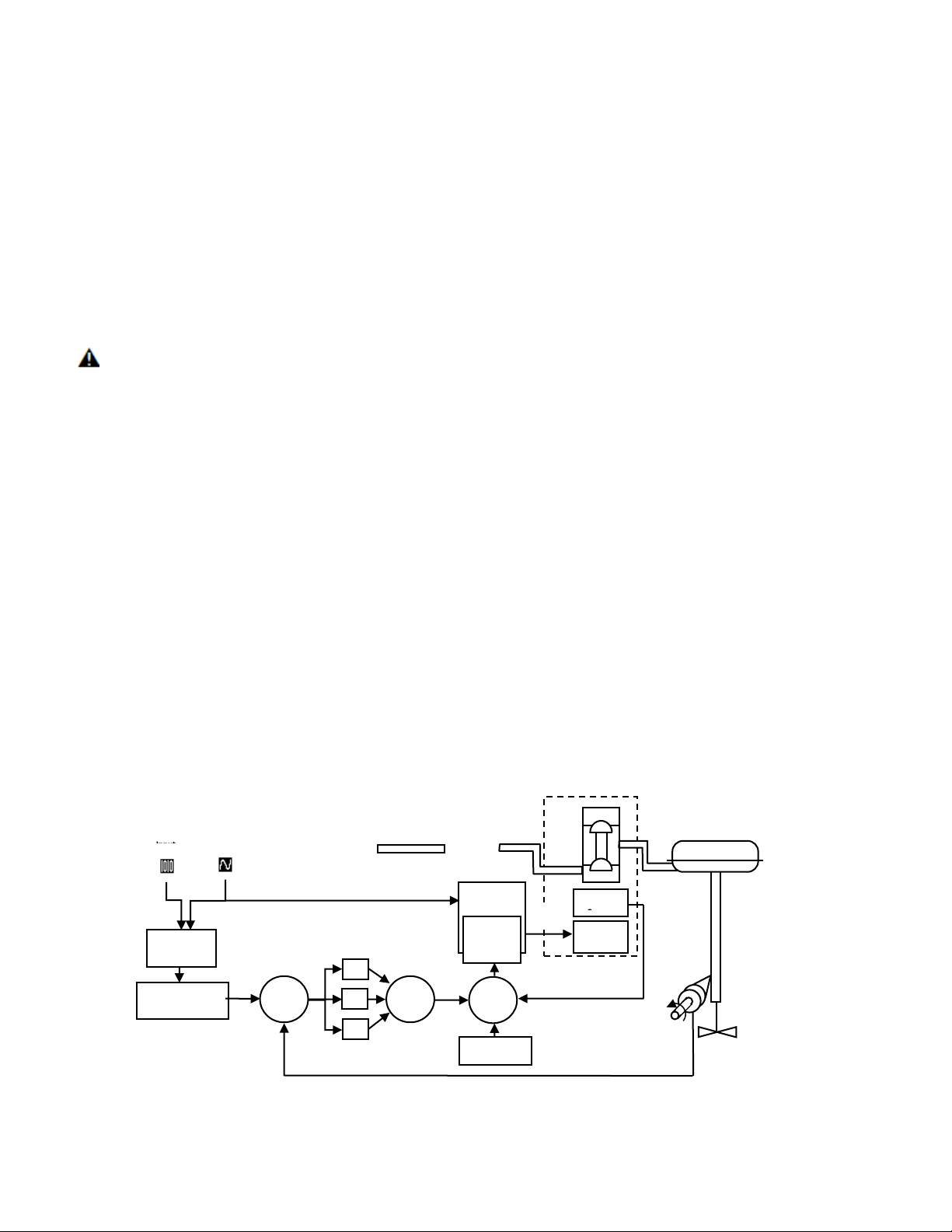

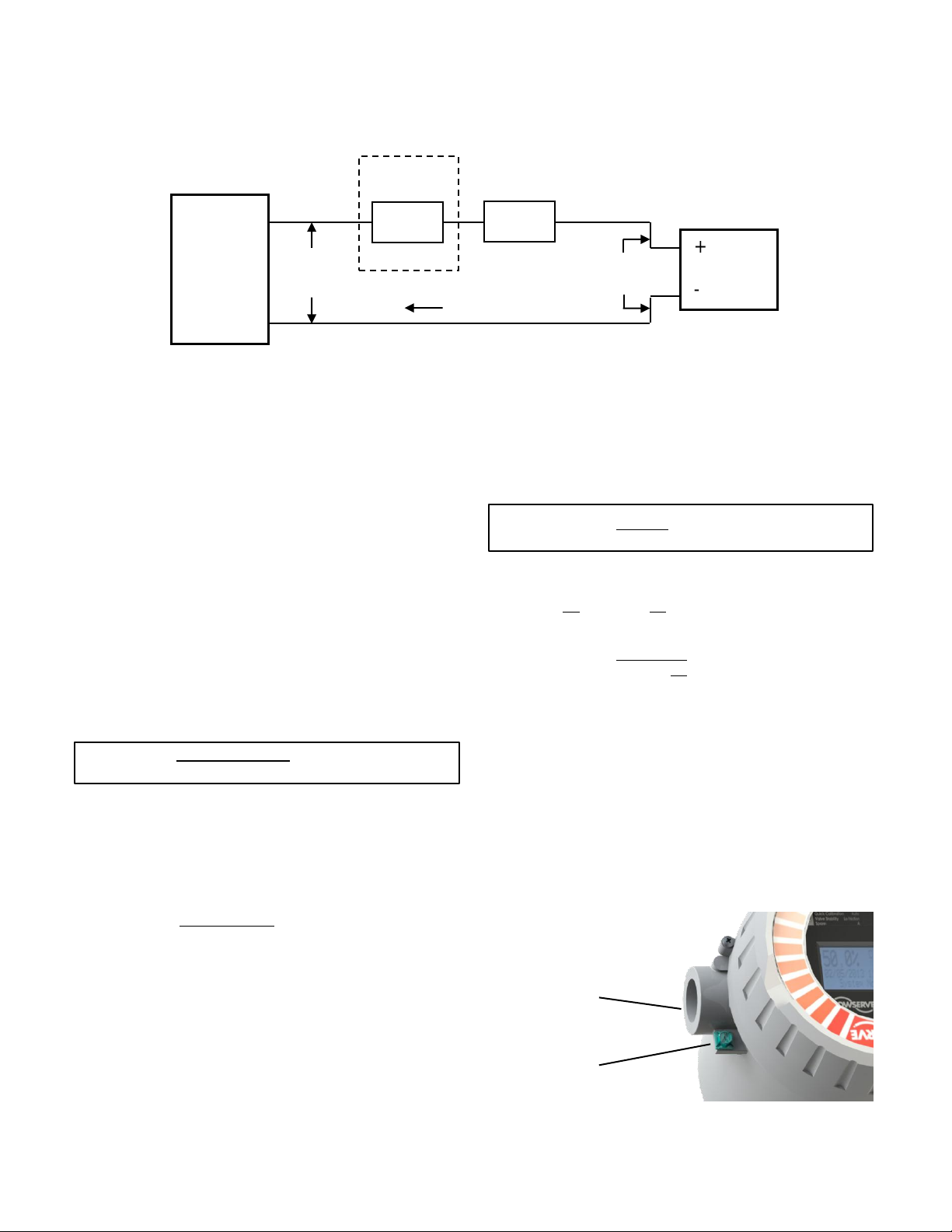

Figure 1: Principles of Operation of Logix 420

Piezo

Hall

Air Supply

Poppet

Single Acting

Piezo

Piezo Kill

Inner

Spool

Position

Control

Actuator

Final

Command

Input

Characterization,

Soft Limits,

Digital

Command

Analog

(4-20 mA)

Output

+

+

I

D

+

_

Inner-Loop

+

_

Inner-Loop

form of cover plates, especially where side-mounted

positioners are fitted. If these plates are removed for

inspection, service or repair special attention is required.

After completing work the cover plates must be refitted.

Logix 420 positioner repair is limited to the replacement of

sub-assemblies and circuit boards with FLOWSERVEmanufactured replacements as outlined in this manual.

DANGER: Substitution of with non-factory positioner

components may impair intrinsic safety.

CAUTION: Before products are returned to

FLOWSERVE for repair or service, FLOWSERVE must be

provided with a certificate which confirms that the product

has been decontaminated and is clean. FLOWSERVE will

not accept deliveries if a certificate has not been provided (a

form can be obtained from FLOWSERVE).

Apart from the operating instructions and the obligatory

accident prevention directives valid in the country of use, all

recognized regulations for safety and good engineering

practices must be followed.

PRINCIPLES OF OPERATION

1.8 Basic Operation

The Logix 420 digital positioner is a two-wire 4-20 mA input

digital valve positioner which uses the HART protocol to

allow two-way remote communications. The positioner is

completely powered by the 4-20 mA input signal. Start-up

current must be at least 3.8 mA. The positioner is

configurable through the local user interface, hand-held or

DTM. The Logix 420 positioner can control single-acting

pneumatic actuators with linear or rotary mountings.

The Logix 420 digital positioner is an electronic and

pneumatic closed-loop feedback instrument. Figure 1 shows

a schematic of a Logix 420 positioner installed on a singleacting linear actuator for air-to-open action.

1.9 HART

The Logix 420 receives power from the two-wire, 4-20 mA

input signal. However, since this positioner utilizes HART

communications, two sources can be used for the command

signal: Analog and Digital. In Analog source, the 4-20 mA

signal is used for the command source. In Digital source, the

level of the input 4-20 mA signal is ignored (used only for

power) and a digital signal, sent via the HART

communication protocol, is used as the command source.

The command source can be accessed with ValveSight

software, the HART 375 communicator, or other host

software. See section 11 HART COMMUNICATION

HART COMMUNICATION for more information.

1.10 Position Definition

Whether in Analog or Digital Source, The position at 0% is

always defined as the valve in a closed position and 100% is

always defined as the valve in an open position. In Analog

Source, the 4-20 mA signal is converted to a position (in

percent). During loop calibration, the signals corresponding

to 0% and 100% are defined.

1.11 Command Input and Final Command

The Command Input signal (in percent) passes through a

characterization/limits modifier block. This function is done in

software, which allows for in-the-field customer adjustment.

The characterization block can apply no adjustment (Linear),

Command

Input

Σ

flowserve.com 4

Circuit

Loop

Σ

Σ

one of several pre-defined characterization curve

Page 5

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Vent

adjustments (including several Equal Percent), or a 21-point

Custom Characterization curve adjustment. In Linear mode,

the input signal is passed straight through to the control

algorithm in a 1:1 transfer. In Equal Percent (=%) mode, the

input signal is mapped to a standard rangeability equal

percent curve. If Custom Characterization is enabled, the

input signal is mapped to a custom, user-defined 21-point

output curve. The custom user-defined 21-point output curve

is defined using a handheld or ValveSight software. In

addition, two user-defined features, Soft Limits and Tight

Shutoff may affect the position. The actual command being

used to position the stem after the evaluation of

characterization curves and user limits, is called the Final

Command.

1.12 Outer Loop

The Logix 420 uses a two-stage, stem-positioning algorithm.

The two stages consist of an inner-loop (pilot relay control)

and an outer-loop (stem position control). Referring again to

Figure 1, a stem position sensor provides a measurement of

the stem movement. The Final Command is compared

against the Stem Position. If any deviation exists, the control

algorithm sends a signal to the inner-loop control to move the

relay in a direction, depending upon the deviation. The innerloop then quickly adjusts the spool position. The actuator

pressures change and the stem begins to move. The stem

movement reduces the deviation between Final Command

and Stem Position. This process continues until the deviation

goes to zero.

1.13 Inner Loop

The inner-loop controls the position of the relay valve by

means of a driver module. The driver module consists of a

temperature-compensated hall-effect sensor and a Piezo

valve pressure modulator. The Piezo valve pressure

modulator controls the air pressure under a diaphragm by

means of a Piezo beam bender. The Piezo beam deflects in

response to an applied voltage from the inner-loop

electronics. As the voltage to the Piezo valve increases, the

Piezo beam bends, closing off against a nozzle causing the

pressure under the diaphragm to increase. As the pressure

under the diaphragm increases or decreases, the poppet

valve moves up or down respectively. The Hall effect sensor

transmits the position of the poppet back to the inner-loop

electronics for control purposes.

1.14 Detailed Sequence of Positioner Operations

A more detailed example explains the control function.

Assume the unit is configured as follows:

Unit is in Analog command source.

Custom characterization is disabled (therefore

characterization is Linear).

No soft limits enabled. No tight shutoff (MPC) set.

Valve has zero deviation with a present input signal of

12 mA.

Loop calibration: 4 mA = 0% command, 20 mA = 100%

command.

Actuator is tubed and positioner is configured air-to-

open.

Given these conditions, 12 mA represents a Command

source of 50 percent. Custom characterization is disabled so

the command source is passed 1:1 to the Final Command.

Since zero deviation exists, the stem position is also at 50

percent. With the stem at the desired position, the poppet

valve will be at a middle position that balances the pressures

and spring force in the actuator. This is commonly called the

null or balanced poppet position.

Assume the input signal changes from 12 mA to 16 mA. The

positioner sees this as a command source of 75 percent.

With Linear characterization, the Final Command becomes

75 percent. Deviation is the difference between Final

Command and Stem Position: Deviation = 75% - 50% =

+25%, where 50 percent is the present stem position. With

this positive deviation, the control algorithm sends a signal to

move the poppet up from its present position. As the poppet

moves, the supply air is applied to the bottom of the actuator.

This new pressure differential causes the stem to start

moving towards the desired position of 75 percent. As the

stem moves, the Deviation begins to decrease. The control

algorithm begins to reduce the poppet opening. This process

continues until the Deviation goes to zero. At this point, the

poppet will be back in its null or balanced position. Stem

movement will stop and the desired stem position is now

achieved.

1.15 Inner Loop Offset

The position of the poppet at which the pressure and springs

are balanced, holding the valve position in a steady state, is

called the Inner Loop Offset. The controlling algorithm uses

this value as a reference in determining the Piezo voltage.

This parameter is important for proper control and is

optimized and set automatically during stroke calibration.

flowserve.com 5

Page 6

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

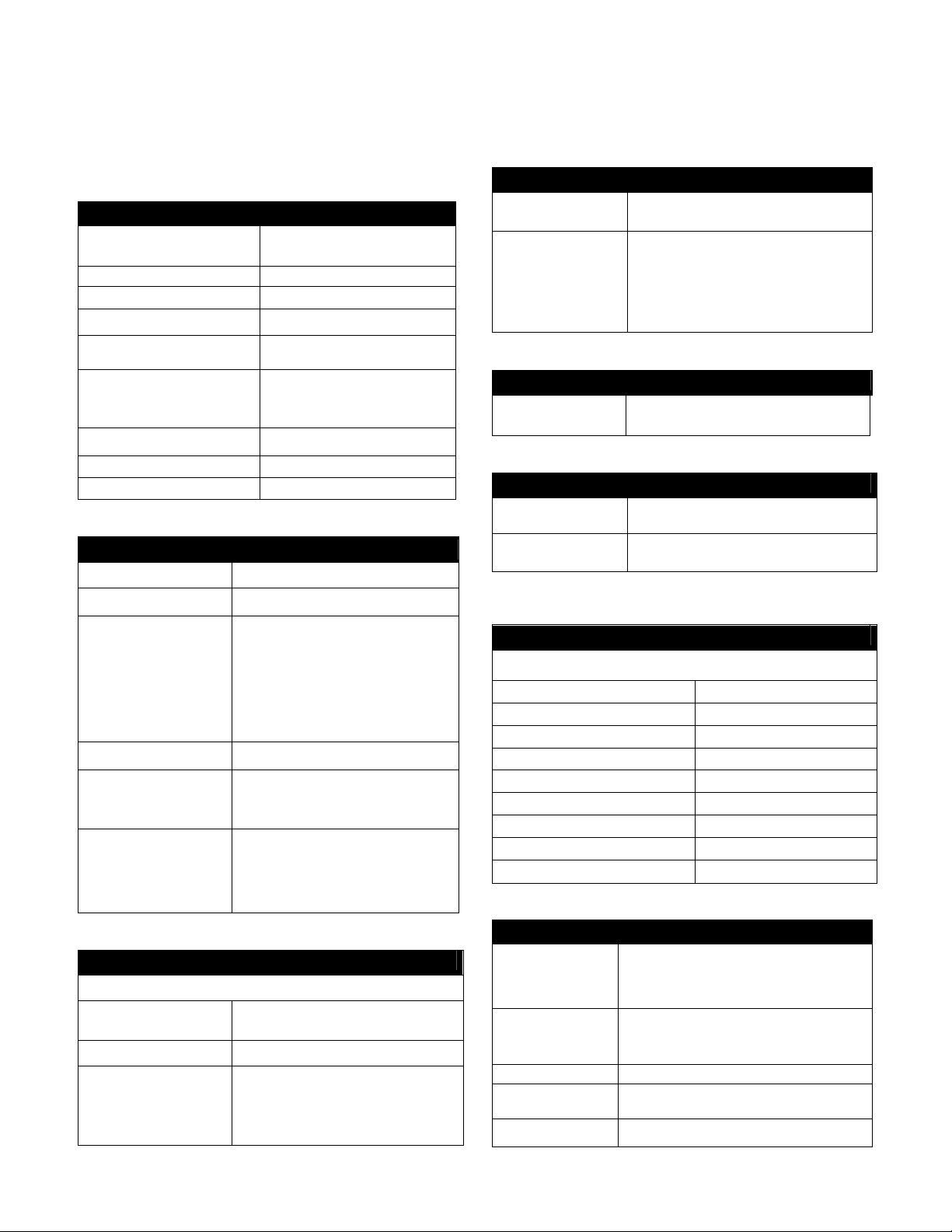

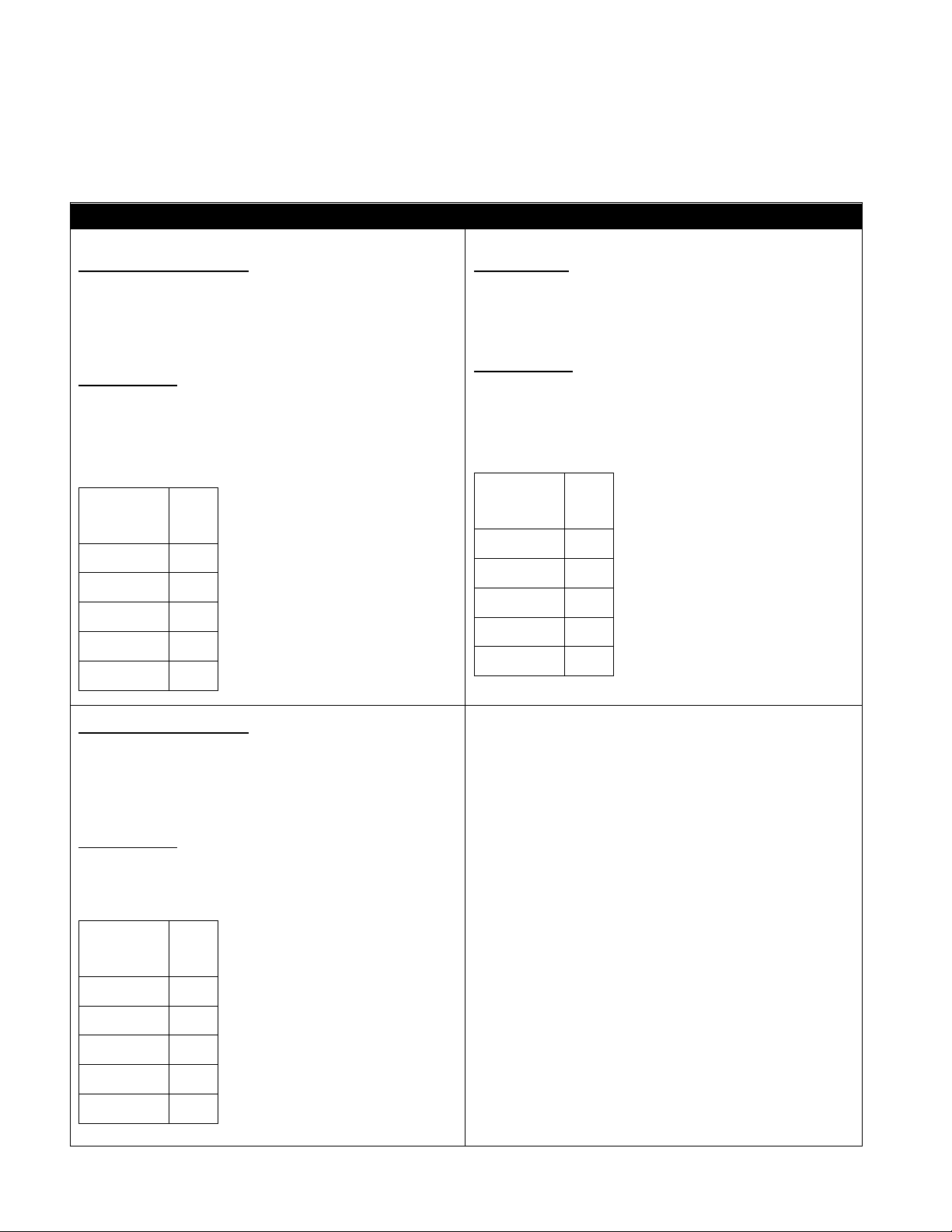

Table 1: Input Signal

Power Supply

Two-wire, 4-20 mA

10.0 VDC terminal voltage

Input Signal Range

4 - 20 mA (HART)

Compliance Voltage

10.0 VDC @ 20 mA

Effective Resistance

500 Ω @ 20 mA Typical

Minimum Required Operating

Current

3.8 mA

Signal Interrupt Without Restart

Time (after powering positioner

for at least one minute)

80 ms

Maximum Shut-down Current

3.6 mA

Communications

HART protocol

Table 2: Air Supply

Minimum Input Pressure

1.5 Bar (22 PSI)

Maximum Input Pressure

Single Acting Relay – 6 Bar (87 PSI)

Air Supply Quality

The air supply must be free from

moisture, oil and dust by conforming to

the ISA 7.0.01 standard. (A dew point

at least 18 degrees Fahrenheit below

ambient temperature, particle size

below five microns—one micron

recommended—and oil content not to

exceed one part per million).

Operating Humidity

0 - 100% non-condensing

Acceptable Supply

Gasses

Air, sweet natural gas, nitrogen and

CO2 are acceptable supply gasses.

Sour natural gas is not acceptable.

Air Consumption

0.069 Nm³/h @ 1.5 bar

(0.041 SCFM @ 22 PSI)

0.082 Nm³/h @ 4.1 bar

(0.050 SCFM @ 60 PSI)

Table 3: Physical Specifications

For dimensions, see section 15 POSITIONER .

Housing Material

Cast, powder-painted aluminum

EN AC-AlSi12(Fe)

Soft Goods

Fluorosilicone

Weight of Base Positioner

Without Accessories

With LCD and Glass Cover

2.70 kg (5.95 lb)

With Solid Cover

3.11 kg (6.85 lb)

Table 4: Pneumatic Output

Output Pressure

Range

0 to 100% of air supply pressure.

Output Air Capacity

Single Acting Relay –

9.06 Nm³/h @ 1.5 bar

(5.33 SCFM @ 22 PSI)

20.8 Nm³/h @ 4.1 bar

(12.2 SCFM @ 60 PSI)

Table 5: Stroke Output

Feedback shaft

Rotation

Min 15°, Max 90°

45° recommended for linear applications.

Table 6: Temperature

Operating

Temperature Range*

-52 to 85°C (-61.6 to 185°F)

Transport and Storage

Range

-52 to 85°C (-61.6 to 185°F)

Table 7: Performance Characteristics

Better than or equal to the following values on a 25 square inch

Mark I actuator per standard ISA 75.13.

Resolution

0.25%

Linearity

+/-1.25%

Repeatability

0.25%

Hysteresis

1.0%

Deadband

0.3%

Sensitivity

0.25%

Stability

0.4%

Long term drift

0.5%

Supply Pressure Effect

0.2%

Table 8: ValveSight DTM Software Specifications

Computer

Minimum Pentium processor running

Windows 95, 98, NT, 2000, XP, 32 MB total

memory (64 MB recommended), 30 MB

available hard disk space, CD-ROM drive

Ports

1 minimum available with 8 maximum

possible. (Can also communicate via serial,

PCMCIA and USB connections)

HART Modem

RS-232, PCMCIA card, or USB

HART Filter

May be required in conjunction with some

DCS hardware.

HART MUX

MTL 4840/ELCON 2700

2 SPECIFICATIONS

2.1 Input Signal

2.2 Air Supply

2.4 Pneumatic Output

2.5 Stroke Output

2.6 Temperature

*Reduced performance at low temperatures.

2.7 Positioner Performance Characteristics

2.3 Physical Specifications

flowserve.com 6

2.8 ValveSight DTM Software Specifications

Page 7

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Table 9: Logix 420 Hazardous Locations Information

ATEX

Explosion Proof/Flame Proof

FM13ATEX0097X

II 2 G

Ex d IIB+H2 Gb T4/T6

T4 Tamb = -52˚C ≤ Ta ≤ +85˚C

T6 Tamb = -52˚C ≤ Ta ≤ +45˚C

IP 66

Intrinsically Safe

FM12ATEX0009X

II 1 G

Ex ia IIC Ga T4/T6

T4 Tamb = -20˚C ≤ Ta ≤ +85˚C

T6 Tamb = -52˚C ≤ Ta ≤ +45˚C

IP 66

Entity

Parameters

4-20

Input

Ui (Vdc)=

30

Ii (mA)=

100

Pi (mW)=

800

Ci (nF)=

0

Li (µH)=

47

Note: Reference installation drawing # 291780

North America (cFMus)

Explosion Proof

Class I, Div 1, Groups B,C,D

Class I, Zone 1, AEx d IIB+H2 T4/T6 (US)

Class 1, Zone 1, Ex d IIB +H2 T4/T6 (Canada)

T4 Tamb = -52˚C ≤ Ta ≤ +85˚C

T6 Tamb = -52˚C ≤ Ta ≤ +45˚C

Intrinsically Safe

Class I, Div 1, Groups A,B,C,D

Class I, Zone 0, AExia IIC (US)

Class I, Zone 0, Ex ia IIC (Canada)

T4 Tamb = -20˚C ≤ Ta ≤ +85˚C

T6 Tamb = -52˚C ≤ Ta ≤ +45˚C

Type 4X

Entity

Parameters

4-20

Input

Ui (Vdc)=

30

Ii (mA)=

100

Pi (mW)=

800

Ci (nF)=

0

Li (µH)=

47

Note: Reference installation drawing # 291780

IECEx

Explosion Proof/Flame Proof

FMG 13.0038X

II 2 G

Ex d IIB+H2 Gb T4/T6

T4 Tamb = -52˚C ≤ Ta ≤ +85˚C

T6 Tamb = -52˚C ≤ Ta ≤ +45˚C

IP 66

Intrinsically Safe

FMG 12.0001X

Ex ia IIC Ga T4/T6

T4 Tamb = -20˚C ≤ Ta ≤ +85˚C

T6 Tamb = -52˚C ≤ Ta ≤ +45˚C

IP 66

Entity

Parameters

4-20

Input

Ui (Vdc)=

30

Ii (mA)=

100

Pi (mW)=

800

Ci (nF)=

0

Li (µH)=

47

Note: Reference installation drawing # 291780

Warning!

Covers must be properly installed in order to maintain

environmental ratings.

Special Conditions for Safe Use:

The equipment must be installed in such a manner as to

minimize the risk of impact or friction with other metal surfaces.

To avoid possibility of static discharge clean only with a damp

cloth.

For Intrinsically Safe installations the positioner must be

connected to suitably rated intrinsically safe equipment, and

must be installed in accordance with applicable intrinsically safe

installation standards.

Substitution of components may impair Intrinsic Safety.

Use appropriately rated cable insulation at higher temperatures.

Contact Flowserve for flame path information.

Conditions spéciales pour une utilisation en toute sécurité:

Le matériel doit être installé de sorte à réduire au minimum le

risque de choc ou de frottement avec d'autres surfaces

métalliques.

Pour éviter les risques de décharge d'électricité statique

Nettoyez uniquement avec un chiffon humide.

Pour les installations en sécurité intrinsèque, le positionneur

doit être connecté à un équipement sécurité intrinsèque

convenablement qualifié, et doit être installé conformément aux

normes d'installation sécurité intrinsèque applicables.

La substitution de composants peut compromettre la sécurité

intrinsèque.

Utiliser une isolation appropriée du câble à des températures

plus élevées.

Contactez Flowserve pour les informations de trajet de flamme.

3 HAZARDOUS AREA CERTIFICATIONS

flowserve.com 7

Page 8

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

4 STORAGE AND UNPACKING

4.1 Storage

FLOWSERVE Control valve packages (a control valve and

its instrumentation) are typically well protected from

corrosion. Nevertheless FLOWSERVE products must be

stored in a clean, dry environment such as an enclosed

building that affords environmental protection. Heating is not

required. Control valve packages must be stored on suitable

skids, not directly on the floor. The storage location must also

be free from flooding, dust, dirt, etc. Plastic caps are fitted to

protect the flange faces and positioner ports to prevent the

ingress of foreign materials. These caps should not be

removed until the valve or positioner is actually mounted into

the system.

If FLOWSERVE products (especially sealing materials) have

been in storage for longer periods check these for corrosion

or deterioration before using these products. Fire protection

for FLOWSERVE products must be provided by the end

user.

4.2 Unpacking

While unpacking the valve and/or Logix 500MD+ positioner,

check the packing list against the materials received. Lists

describing the system and accessories are included in each

shipping container.

In the event of shipping damage, contact the shipper

immediately. Should any problems arise, contact a Flowserve

Flow Control Division representative.

4.3 Pre-installation Inspection

When installing a positioner, verify the shaft has not been

damaged and that the plugs and cover are in place. The

plugs keep debris and moisture from damaging the internal

components of the positioner. If the positioner has been

contaminated, clean the positioner components gently with a

soft damp cloth. Some components may be removed for

better access. See section 13 MAINTENANCE AND

REPAIR. Check connectors to ensure that no debris is

present. Port screens can be removed with a flat screwdriver

for access to internal passages.

flowserve.com 8

Page 9

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Actuator

Take-Off Plate

Take-Off

Take-Off Plate

Actuator O-

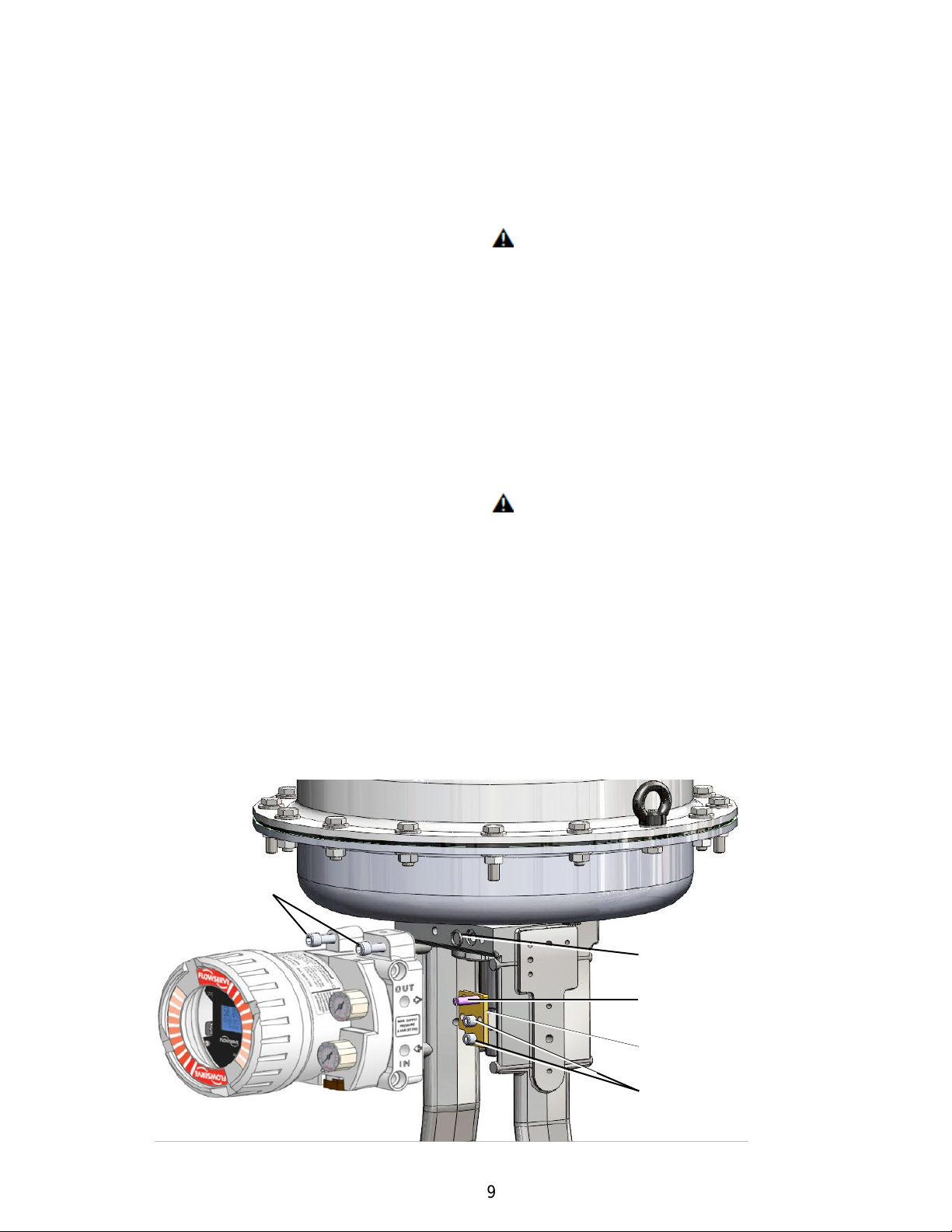

Figure 2: Valtek GS and FlowTop Mounting

5 MOUNTING AND INSTALLATION

5.1 Direct Mounting to Valtek GS and FlowTop

Refer to Figure 2: Valtek GS and FlowTop Mounting.

1 Assemble the take-off pin to the take-off plate and

mount the take-off plate to the valve stem using the two

screws. See Table 10: FlowTop and GS Take-Off

Plate and Pin Configuration for proper plate and pin

orientation.

2 Place the actuator O-ring.

3 Ensure the 1/16 NPT plug for the control port (if

present) has been removed.

4 Place the positioner on the actuator, ensuring the take-

off pin is inside the follower arm slot. Adjust the

follower arm as needed.

NOTE: The feedback shaft has a clutch mechanism that

allows for over-rotation of the shaft for easy adjustments.

Just move the follower arm to the desired location.

5 Use the actuator screws to secure the positioner in

place.

6 Connect regulated air supply to appropriate port in

manifold. See section 6 TUBING.

7 Connect the power to the 4-20 mA terminals. See

section 7 ELECTRICAL CONNECTIONS.

8 Remove main cover and locate DIP switches and

QUICK-CAL/ACCEPT button.

9 Refer to sticker on main board cover and set DIP

switches accordingly. See section 8 STARTUP.

10 Press the QUICK-CAL/ACCEPT button for three to four

seconds or until the positioner begins to move. The

positioner will now perform a stroke calibration.

CAUTION: Performing a Stroke Calibration will cause full

movement of the valve in both directions.

11 If the calibration was successful the green LED will blink

GGGG or GGGY and the valve will be in control mode.

12 If calibration fails, as indicated by a RGGY blink code,

retry the calibration. If it still fails, the feedback values

were exceeded and the arm must be adjusted away

from the positioner’s limits. Rotate the feedback shaft

so that the full free travel of the feedback shaft is in the

range of the actuator movement. Optionally, continue

to attempt the calibration. Each calibration attempt

adjusts the acceptable limits and it should pass

eventually.

CAUTION: Remember to remove the air supply before

re-adjusting follower arm.

NOTE: If mounted properly, the follower arm should be

horizontal when the valve is at 50% stroke and should move

approximately ±30° from horizontal over the full stroke of the

valve.

NOTE: To virtually eliminate any non-linearity due to linkage

geometry, use the Linearization feature on the Custom

Characterization page of the DTM.

flowserve.com 9

Page 10

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

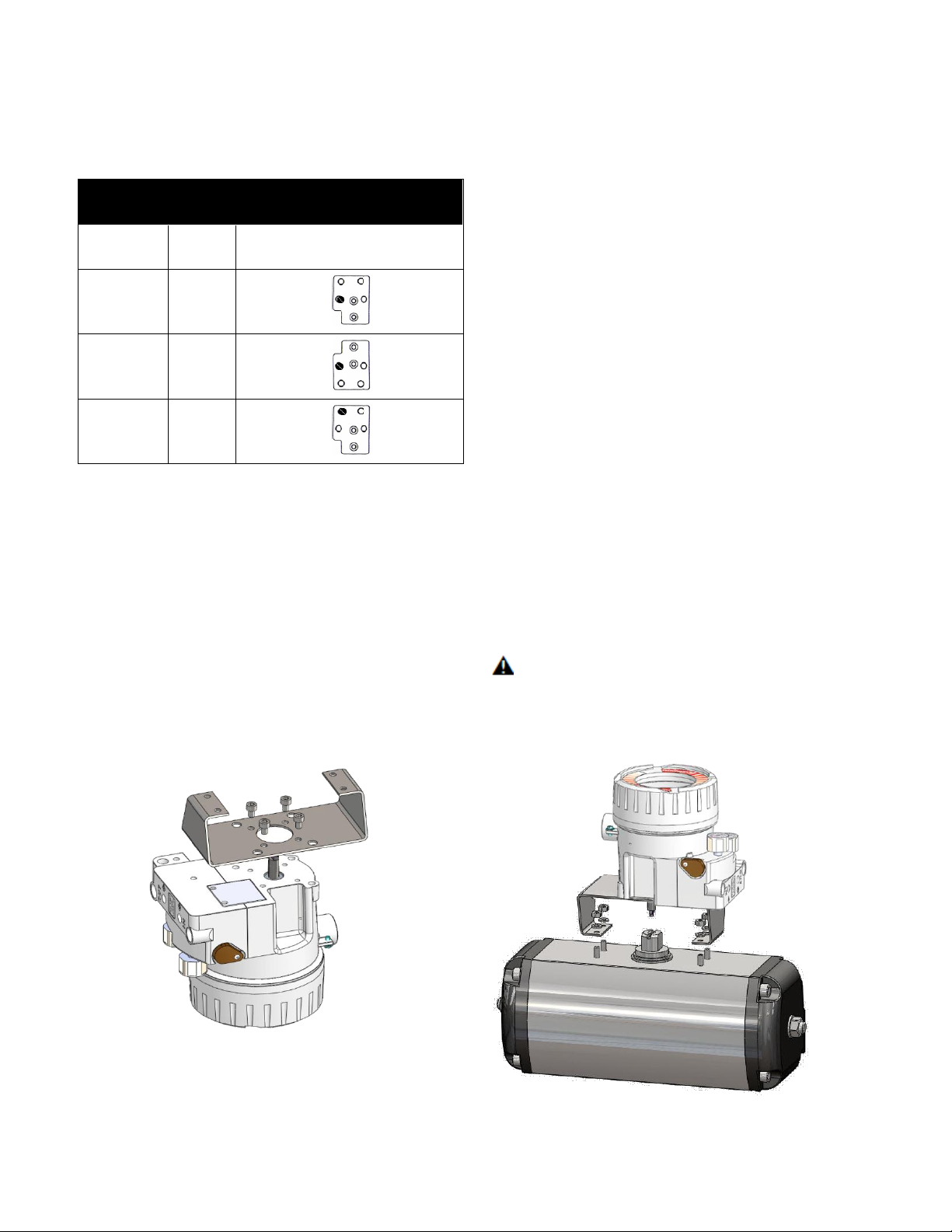

Table 10: FlowTop and GS Take-Off Plate and Pin

Configurations

Actuator

Stroke

(mm)

Plate and Pin Orientation

127 / 252

10

127 / 252

20

502

20 or 40

Figure 3: NAMUR Bracket

5.2 Mounting to NAMUR Valves

1 Attach the mounting plate to the positioner using 4

screws.

2 Rotate the feedback shaft to match the orientation of

the receiver on the actuator.

NOTE: The feedback shaft has a clutch mechanism that

allows for over-rotation of the shaft for easy adjustments.

3 Mount the positioner onto the actuator using the

washers and nuts.

4 Connect regulated air supply to appropriate port in

manifold. See section 6 TUBING.

5 Connect the power to the 4-20 mA terminals. See

section 7 ELECTRICAL CONNECTIONS.

6 Remove main cover and locate DIP switches and

QUICK-CAL/ACCEPT button.

7 Refer to sticker on main board cover and set DIP

switches accordingly. See section 8 STARTUP.

8 Press the QUICK-CAL/ACCEPT button for three to four

seconds or until the positioner begins to move. The

positioner will now perform a stroke calibration.

9 If the calibration was successful the green LED will blink

GGGG or GGGY and the valve will be in control mode.

10 If calibration fails, as indicated by a RGGY blink code,

retry the calibration. If it still fails, remove power from

the positioner, disconnect the air, and remove the

positioner from the actuator. Rotate the feedback shaft

so that the full free travel of the feedback shaft is in the

range of the actuator movement. Optionally, continue

to attempt the calibration. Each calibration attempt

adjusts the acceptable limits and it should pass

eventually.

CAUTION: Remember to remove the air supply before

re-adjusting take-off arm.

flowserve.com 10

Figure 4: AutoMax Assembly

Page 11

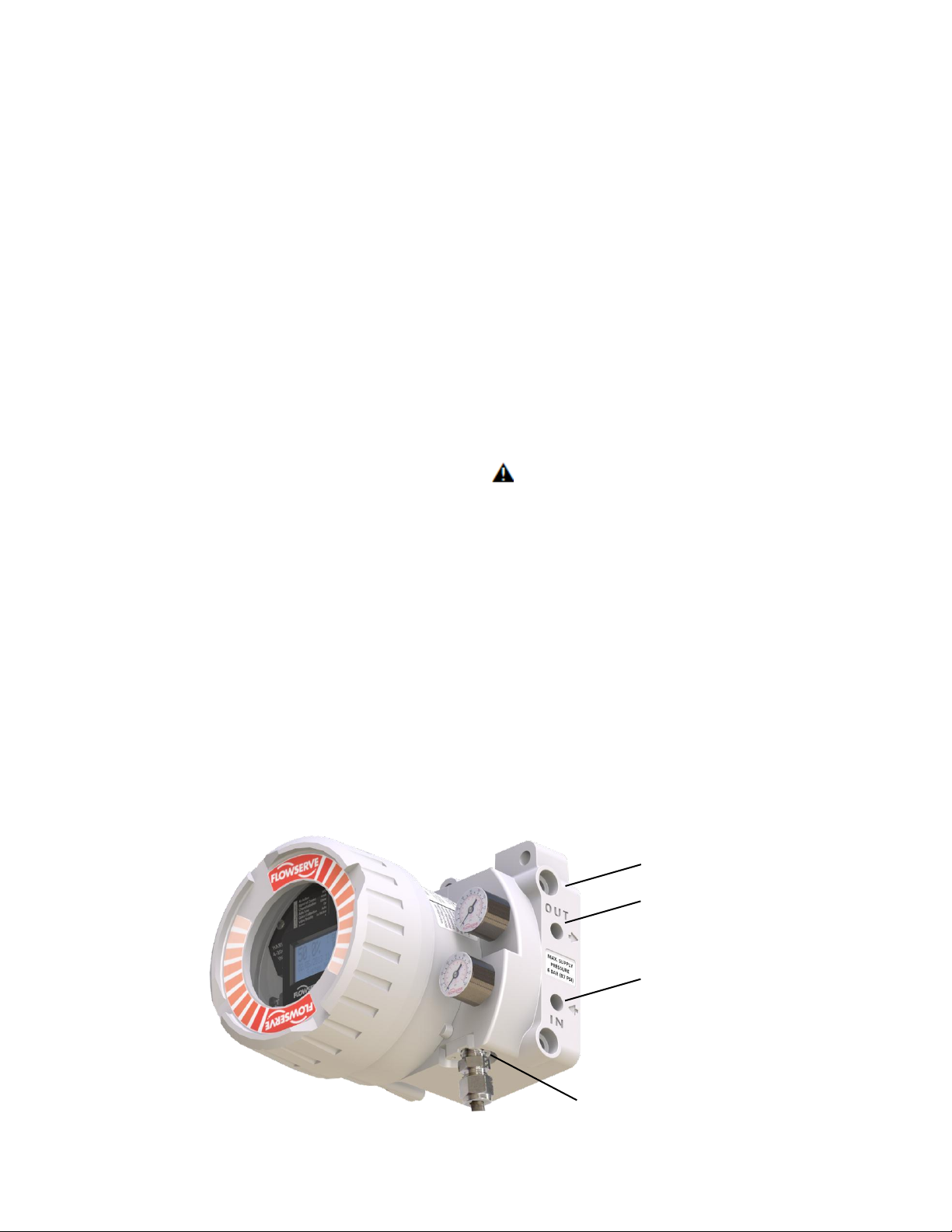

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Exhaust (Piezo and

Out

(Control)

6 TUBING

After mounting has been completed, tube the positioner to

the actuator using the appropriate compression fitting

connectors. For best performance, use 10 mm (3/8 inch)

tubing for 645 square cm (100 square inch) actuators or

larger.

6.1 Determine Air Action

The port labeled “Out” delivers air when an air supply is

present and the relay is energized. This port should be tubed

to the pneumatic side of the actuator (the side that would

result in the air compressing the actuator spring). When

tubed this way, the spring is designed to return the valve to

the fail safe state should supply air or power to the unit fail.

If air from the output should open the valve, set the Air Action

configuration switch on the positioner to Air-to-Open,

otherwise set it to Air-to-Close.

The Air-to-Open and Air-to-Close selection is determined by

the actuator assembly, not the software.

6.2 Connect Supply Port

The positioner ports are threaded with 1/4 NPTF. The direct

mount output is 1/16 NPTF.

In order to maintain the recommended air quality, a

coalescing filter should always be installed in the supply gas

line. An air filter is highly recommended for all applications

where dirty air is a possibility. The positioner passage ways

are equipped with small filters, which remove medium and

coarse size dirt from the pressurized air. If necessary, they

are easily accessible for cleaning.

In applications where the supply pressure is higher than the

maximum actuator pressure rating a supply regulator is

required to lower the pressure to the actuator’s maximum

rating.

6.3 Vented Design

A standard Logix 420 positioner is vented directly to the

atmosphere. When supply air is substituted with sweet

natural gas, piping must be used to route the exhausted

natural gas to a safe environment.

The exhaust port is located on the bottom of the positioner.

The port is tapped with either ¼ NPTF threads and covered

with a protective cap. To control vented gas, remove the cap

and connect the necessary tubing/piping to this port.

This piping system may cause some positioner back

pressure.

The maximum allowable back pressure from the exhaust port

is 0.14 barg (2.0 PSIG). For output flow rates, see section 2.4

Pneumatic Output.

CAUTION: The back pressure in the main housing must

never rise above 0.14 barg (2.0 PSIG). This could cause the

positioner to become unresponsive under some

circumstances.

6.4 Purging

Purging is intended to supply the non-pressurized side of a

single acting actuator with instrument air. This helps prevent

air from the environment (which may be salty, dirty or humid)

from corroding the springs and other actuator components.

Purging uses exhaust air from the positioner to flush the

spring side of the actuator.

Tubing Configuration - Tube the Exhaust port with a “T”

where one line goes to the non-pressurized side of the

positioner and the second line goes to the atmosphere.

Install an exhaust plug on the second line to prevent debris

from entering the tubing.

(Direct

Mount

Control)

Out

In

(Supply)

Actuator)

(0.14 barg (2 psi) Max)

flowserve.com 11

Page 12

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

HART 4-20

mA

Housing EARTH

Terminal

Internal

External

7 ELECTRICAL CONNECTIONS

7.1 Electrical Terminals

7.2 Command Input (4-20 mA) Connection

The Logix 420 is reverse polarity protected, however, verify

polarity when making field termination connection. Wire 4-20

mA current source to the input terminal labeled “HART 420mA INPUT”. See Figure 6: Terminal Diagram.

Depending on the current source, a HART filter may be

required. See 14.1 Troubleshooting Guide.

7.2.1 Compliance Voltage

Output compliance voltage refers to the voltage limit the

current source can provide. A current loop system consists of

the current source, wiring resistance, barrier resistance (if

present), and the Logix 420 impedance.

The Logix 420 requires that the current loop system allow for

a 10 VDC drop across the positioner at maximum loop

current. The operating current range is from 3.8 to 24 mA.

In order to determine if the loop will support the Logix 420,

perform the calculation in Equation 1. The Available Voltage

must be greater than 10VDC in order to support the Logix

420. Also, see Table 1: Input Signal.

Equation 1

Inp

Figure 6: Terminal Diagram

Example:

The available voltage (12.5 V) is greater than the required

voltage (10.0 V) therefore; this system will support the Logix

420. The Logix 420 has an input resistance equivalent to 500

Ω at a 20 mA input current.

CAUTION: The current must always be limited for 4-20

mA operation. Never connect a voltage source directly

across the Logix 420 terminals. This could cause permanent

circuit board damage.

flowserve.com 12

Page 13

Barrier

(If Present)

Wire

R

R

Compliance 10

Voltage VDC

Controller

+

-

Current

Grounding

Terminal

Conduit

Connection

7.2.2 Cable Requirements

The Logix 420 digital positioner utilizes the HART

Communication protocol. This communication signal is

superimposed on the 4-20 mA current signal. The two

frequencies used by the HART protocol are 1200 Hz and

2200 Hz. In order to prevent distortion of the HART

communication signal, cable capacitance and cable length

restrictions must be calculated. The cable length must be

limited if the capacitance is too high. Selecting a cable with

lower capacitance/foot rating will allow longer cable runs. In

addition to the cable capacitance, the network resistance

also affects the allowable cable length.

In order to calculate the maximum network capacitance, use

the following formula:

Equation 2

Example:

4-20 mA

Current

Source

(if present)

flowserve.com 13

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Logix

420

Voltage

= 0.08

Figure 7: Compliance Voltage

In order to calculate the maximum cable length, use the

following formula:

Equation 3

Example:

To control cable resistance, 24 AWG cable should be used

for runs less than 5000 feet. For cable runs longer than 5000

feet, 20 AWG cable should be used.

The input loop current signal to the Logix 420 digital

positioner should be in shielded cable. Shields must be tied

to a ground at only one end of the cable to provide a place

for environmental electrical noise to be removed from the

cable. In general, shield wire should be connected at the

source, not at the positioner.

Figure 8: Conduit and Grounding

Page 14

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Display

LED

QUICK-CAL/

Button

UP Button

DOWN Button

Selectable

Configuration

BACK

Left)

HART

Input

7.2.3 Intrinsically Safe Barriers

When selecting an intrinsically safe barrier, make sure the

barrier is HART compatible. Although the barrier will pass the

loop current and allow normal positioner control, if not

compatible, it may prevent HART communication.

7.2.4 Grounding and Conduit

The grounding terminal, located by the electrical conduit port

should be used to provide the unit with an adequate and

reliable earth ground reference. This ground should be tied to

the same ground as the electrical conduit. Additionally, the

electrical conduit should be earth grounded at both ends of

its run.

This product has electrical conduit connections in a thread

size of 1/2" NPTF. Conduit fittings must match equipment

housing threads for installation.

NOTE: The grounded screw must not be used to terminate

signal shield wires. Shield wires should be terminated only at

the signal source.

4-20

mA

Button

(Move

Figure 9: Local User Interface

7.2.5 Electromagnetic Compatibility

The Logix 420 digital positioner has been designed to

operate correctly in electromagnetic (EM) fields found in

typical industrial environments. Care should be taken to

prevent the positioner from being used in environments with

excessively high EM field strengths (greater than 10 V/m).

Portable EM devices such as hand-held two-way radios

should not be used within 30 cm of the device.

Ensure proper wiring and shielding techniques of the control

lines, and route control lines away from electromagnetic

sources that may cause unwanted electrical noise. An

electromagnetic line filter can be used to further eliminate

noise (FLOWSERVE Part Number 10156843).

In the event of a severe electrostatic discharge near the

positioner, the device should be inspected to ensure correct

operability. It may be necessary to recalibrate the Logix 420

positioner to restore operation.

7.3 Connections for Intrinsically Safe Operation

For intrinsically safe connections, see entity parameters in

section 3 HAZARDOUS AREA CERTIFICATIONS. If a

control drawing is required, ask your Flowserve

representative for drawing 314746 - CONTROL DRAWING,

LOGIX 420 DIGITAL POSITIONER.

GAIN

Switch

Status

ACCEPT

flowserve.com 14

Page 15

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

8 STARTUP

8.1 Quick Start Instructions

Once installed, the DIP switch settings and Quick-Cal

function listed below are typically all that are needed to

calibrate and tune the positioner for use. This simple

procedure takes only seconds for most valves.

1 Using the Configuration Switches, select the desired

configuration. See section 8.3 Configuration Switch

Settings for details.

2 Hold the Quick-Cal button for 3 seconds. This will

initiate a stroke calibration. (LCD Screen must show

the main menu before pressing Quick-Cal button. See

Figure 9.)

After the stroke calibration is complete, the positioner is

ready for control.

CAUTION: During the QUICK-CAL operation the valve

may stroke unexpectedly. Notify proper personnel that the

valve will stroke, and make sure the valve is properly

isolated.

8.2 Local User Interface Overview

The Logix 420 local user interface allows the user to

calibrate, configure the basic operation, and tune the

response of the positioner without additional tools or

configurators. The Local interface consists of:

Configuration Switches (7) – Used to set basic

configuration. See explanations in section 8.3

Configuration Switch Settings.

Interface Buttons – Used to calibrate the positioner,

perform special functions and navigate the display

menu.

o ►QUICK-CAL / ACCEPT(Move Right)

o ▲Up

o ▼Down

o ◄Back (Move Left)

Selectable GAIN Switch (Rotary) – Used to manually

fine-tune the performance.

LED Indicators (Red, Yellow, and Green) – Indicate

status, alarms and warnings.

Display (Optional) – Provides a full menu of detailed

information and configuration.

8.3 Configuration Switch Settings

Before placing the unit in service, set the Configuration

Switches to the desired control options.

NOTE: The Configuration Switch settings are activated only

by performing a Stroke calibration (pressing the “QUICKCAL” button for 3 seconds). However, the Configuration

Switch settings may be edited from the DTM or Handheld at

any time.

8.3.1 Air Action Switch

This must be set to match the configuration of the

valve/actuator mechanical tubing connection since the tubing

determines the air action of the system.

ATO - Increasing pressure from the output port causes the

valve to open.

ATC - Increasing pressure the output port causes the valve

to close.

8.3.2 Signal at Closed Switch

Normally this will be set to 4 mA for an Air-To-Open actuator

configuration, and 20 mA for Air-To-Close.

4 mA - Selecting 4 mA will make the valve close when the

signal is low (4 mA) and open when the signal is high (20

mA).

20 mA - Selecting 20 mA will make the valve close when the

signal is high (20 mA) and open when the signal is low (4

mA).

NOTE: When using an Analog Output (AO) function of the

Multi-Function Card, the AO signal corresponds with the

Signal At Closed selection. If the valve closes with a 4 mA

signal, the AO will show a 4 mA signal at closed. If the valve

closes with a 20 mA signal, the AO will show a 20 mA signal

at closed.

8.3.3 Characterization Switch

The Characterization Switch allows a better match between

the input command and the actual fluid flow through the

valve. This feature is typically used with valves that have

non-linear flow characteristics. The positioner makes a

correction by applying an adjustment to the input command

according to a characterization curve.

Linear - Select Linear if the actuator position should be

directly proportional to the command input signal. (For most

rotary valves, this setting gives an =% Cv characteristic due

to their inherent =% characteristics.)

Other - Select Other if one of the pre-set characterization

curves or a custom curve is desired. The default will be the

Custom curve which is populated with a standard 30:1 equal

percent rangeability curve which generally opens less than

the input command. To select one of the other curve options,

use the LCD menu, a Handheld or the ValveSight DTM. To

flowserve.com 15

Page 16

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

More

Stable

More

Responsive

modify the Custom curve, use the DTM. See section 10.3.6

Configuration (Characterization) for more information.

8.3.4 Auto Tune Switch

This switch controls whether the positioner will automatically

tune itself during the stroke calibration (Quick-Cal), or use

preset tuning parameters.

On - Selecting On enables an auto tune feature that will

automatically determine the positioner gain settings. The

automatic tuning will be based on response parameters

measured during the latest Quick-Cal. The valve response is

a combination of these response parameters and the current

position of the Selectable GAIN Switch.

Off - Selecting Off forces the positioner to use one of the

factory preset tuning sets determined by the Selectable GAIN

Switch. Settings “B” through “J” are progressively higher

predefined tuning sets. Selecting “A” on the Selectable Gain

Switch during a Quick-Cal allows the user to use and

preserve manually adjusted gains.

See section 8.4 Stroke Calibration for more details.

NOTE: The gain switch is live meaning that regardless of the

Auto Tune selection, the gain settings can be adjusted at any

time during operation by changing the selectable GAIN

switch position.

Figure 10: Selectable GAIN Switch

8.3.5 Quick Calibration Switch

This switch selects between Auto and Jog calibration modes.

Auto - Use the Auto setting if the fully opened position of the

valve has a mechanical stop. This is typical for most valves.

In Auto mode during a stroke calibration (Quick-Cal), the

positioner will fully close the valve and register the 0%

position, then fully open the valve to register the 100%

position.

Jog - Use the Jog setting if the fully opened position of the

valve has no hard stop, but needs to be set manually. In Jog

mode during a stroke calibration (Quick-Cal), the positioner

will fully close the valve and register the 0% position, then

wait for the user to move the valve to the 100% open position

using the ▲Up and ▼Down buttons. Press the

►ACCEPT/QUICK-CAL button to accept the 100% location.

See section 8.4 Stroke Calibration for more details.

8.3.6 Valve Stability Switch

This switch adjusts the position control algorithm of the

positioner for use with low-friction control valves or highfriction automated valves.

Lo Friction - Placing the switch to Lo Friction optimizes the

response for low friction, high performance control valves.

This setting provides for optimum response times when used

with most low friction control valves.

Hi Friction - Placing the switch to the right optimizes the

response for valves and actuators with high friction levels.

This setting slightly slows the response and will normally stop

limit cycling that can occur on high friction valves. See

section 10.3.7 Configuration (Pressure Control) for more

details.

8.3.7 Spare Switch

If special features have been purchased they may be

controlled by this switch. See associated documentation for

more details.

8.4 Stroke Calibration

The ►ACCEPT/QUICK-CAL button is used to initiate an

automatic stroke calibration. The stroke calibration

determines the closed (0%) and open (100%) positions of the

valve and gathers information about the response of the

valve (such as valve stroke time) in order to determine the

gains. The gains are then set automatically. After a stroke

calibration, the positioner is ready to control.

To perform a Quick-Cal, first ensure the Quick Calibration

Switch is set to Auto or Jog (to manually adjust the stroke

limits) as appropriate. Press and hold the

►ACCEPT/QUICK-CAL button for approximately 3 seconds.

This will initiate the automatic stroke calibration. While the

calibration is in progress, the LED lights will flash status

codes indicating the calibration progress. See section 14.3

Status Code Descriptions for an explanation of the status

code sequences.

The initial calibration of extremely large or very small

actuators may require several calibration attempts and will

perform these automatically. The positioner adapts to the

actuator performance and begins each calibration where the

last attempt ended. On an initial installation it is

recommended that after the first successful calibration that

one more calibration be completed for optimum performance.

flowserve.com 16

Page 17

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

8.4.1 Quick Calibration Switch – Jog

Set the Quick Calibration Switch to Jog if the valve/actuator

assembly has no internal mechanical stop at the fully open

position. In this case, follow these instructions:

1 Press and hold the ►ACCEPT/QUICK-CAL button for

approximately 3 seconds.

This will initiate the jog stroke calibration. The positioner will

then close the valve and set the zero position. The zero

position is automatically always set at the valve seat. At this

point the LED‘s will flash in a sequence of G-R-R-R (greenred-red-red) which indicates that the user must use the jog

keys to manually position the valve to approximately 100%.

2 Use the up and down keys to position the valve at

approximately 100% open.

3 Press the ►ACCEPT/QUICK-CAL button to proceed.

No more user actions are required while the calibration

process is completed. When the lights return to a sequence

that starts with a green light the calibration is complete. The

jog calibration process will only allow the user to set the

span. If an elevated zero is needed a handheld or

ValveSight DTM are required.

8.4.2 Tuning Options

Quick-Cal Custom Gains – This is typically the fastest way to

achieve ideal gains. Set the Auto Tune Configuration Switch

to On and the Selectable GAIN Switch to “E”. Then perform

a Quick-Cal. During the Quick-Cal, custom tuning

parameters will be determined based on measured response

parameters. The gains can then be fine-tuned by adjusting

the Selectable GAIN Switch. Selecting “D” “C” or “B” will

progressively provide a more stable response. Selecting “F”

through “J” will progressively provide a more active response.

In most cases selecting “E” will give the best results. This is

the default setting for all actuator sizes. Raising or lowering

the Selectable GAIN Switch setting is a function of the

positioner/valve response to the control signal, and is not

actuator size dependent.

Standard Preset Gains - If standard, preset gains are

desired, set the Auto Tune Configuration Switch to Off. After

performing a Quick-Cal, use the Selectable GAIN switch to

the desired level (“B” – “J”). The standard, preset gain

settings are not affected by Quick-Cal. It may be necessary

to set the gain switch before the Quick Cal. Very fast

stroking valves may need to be at lower gains and very slow

stroking valves may need to be at higher gains.

It may be necessary to set the gain switch BEFORE the

Quick Cal. Very fast stroking valves may need to be at lower

gains and very slow stroking valves may need to be at higher

gains.

Custom Manual Gains - To set gains manually, set the

selectable GAIN switch to “A”. Changing the switch from “B”

to “A” will write the standard “B” settings into the “A”

parameters, allowing a starting point for modification.

Similarly, changing the switch from “J” to “A” will write the

standard “J” settings into the “A” parameters. Custom tuning

values can then be entered using the Display Menu, a

Handheld or ValveSight DTM. With the Selectable GAIN

Switch set to “A”, the tuning will not be modified during a

Quick-Cal.

8.4.3 Aborting a Quick-Cal

The Quick-Cal can be aborted at any time by briefly pressing

the ►ACCEPT/QUICK-CAL button again. In this case, the

previous settings will be retained.

8.4.4 On Line Stroke Calibration Adjustments

At times an adjustment to the calibration is desired, but the

process cannot be interrupted. The stroke calibration can be

adjusted with minimal valve movement. Contact your local

Field Service Technician for more information.

flowserve.com 17

Page 18

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

9 POSITIONER FUNCTIONS (No

Display Required)

The following features can be performed using the local

interface. No display is required for these features.

Additional features are offered with the use of a display,

Handheld or DTM.

NOTE: In order to prevent unintentional adjustments of the

configuration, tuning, or control of the valve, the Tamper Lock

feature may be used. This is set in the DTM and disables the

buttons and menus except for the ability to view the status of

the positioner. When locked, the positioner may be

temporarily unlocked by entering a PIN. (An LCD is required

to enter the PIN.) Or, the positioner can be unlocked from

the DTM.

9.1 Live Manual Tuning (Adjusting the

Gain)

Use the Selectable GAIN Switch to adjust the gain at any

time during operation. This adjustment takes effect

immediately. For faster response select settings above “E”

(F-J). For more stable response, select settings below “E”

(B-D). See Figure 10: Selectable GAIN Switch on page 16.

9.2 Local Control Of Valve Position

To manually adjust the position of the valve regardless of the

input command (analog or digital), press and hold the ▲Up,

▼Down and ◄ BACK buttons for about 3 seconds. The

▲Up, ▼down buttons can then be used to position the valve.

While in this mode the LED‘s will flash a GRRY (green-red-

red-yellow) sequence. To exit the local control mode and

return to normal operation, briefly press the ►

ACCEPT/QUICK-CAL button.

CAUTION: When operating using local control of the

valve, the valve will not respond to external commands.

Notify proper personnel that the valve will not respond to

remote command changes, and make sure the valve is

properly isolated.

9.3 Command Source Reset

Performing a command source reset will reset the command

source to analog if it has been inadvertently left in digital

mode. This is done by holding down both the ▲Up and

▼Down buttons, then briefly pressing the

►ACCCEPT/QUICK-CAL button.

9.4 Factory Reset

To perform a factory reset, hold ► ACCEPT/QUICK-CAL

button while applying power. All of the internal variables

including calibration will be reset to factory defaults. The

positioner must be re-calibrated after a factory reset. Tag

names and other user configured limits, alarm settings, and

valve information will also be lost and need to be restored. A

factory reset will always reset the command source to analog

4-20 mA.

CAUTION: Performing a factory reset may result in the

inability to operate the valve until reconfigured properly.

Notify proper personnel that the valve may stroke, and make

sure the valve is properly isolated.

flowserve.com 18

Page 19

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Table 11: Viewing Version Numbers

First

Blink Color

Second

Blink Color

Third

Blink Color

Version

Number

G G G 0 G G Y 1 G G R 2 G Y G 3 G Y Y 4 G Y R 5 G R G

6

G R Y

7

G R R 8 Y G G 9 Y G Y

10 Y G R 11 Y Y G 12 Y Y Y 13

Y Y R

14

Y R G

15 Y R Y 16 Y R R 17 R G G 18

R G Y

19

R G R

20 R Y G 21 R Y Y 22 R Y R 23 R R G 24 R R Y 25 R R R 26

Figure 11: Main Display View

Final Command

Status Icon

Position

Scrolling Status

Message

Current Alarm Status

9.5 Viewing Version Numbers

The version number of the positioner software may be

checked at any time except during a calibration. To see the

major version number, hold the ▲Up button. This will not

alter the operation of the unit other than to change the blink

sequence to 3 blinks indicating the major version number.

Holding the ▼Down button will give the minor version

number without affecting operation. The version codes are

interpreted according to the following table:

For example, if holding the ▲Up button gave a G-G-R code,

and holding the ▼Down gave a Y-Y-G code then the

resulting version number would be 2.12.

10 POSITIONER FUNCTIONS (LCD

Display)

The optional LCD display provides a variety of useful

information and functions. The Main View shows important

information using icons and scrolling status lines. Using the

directional buttons (▼▲►◄) to navigate the menu, the user

can view detailed information perform commonly used

functions.

NOTE: The LCD backlight may change brightness during

use. This is normal. The backlight uses any residual power

not used by other functions of the circuitry. When current

supply is low (4mA) the light will appear darker. When

current supply is high (20mA) the light will appear brighter.

10.1 Main Display View

The main view provides an instant display of important status

parameters: Position, Final Command, Scrolling Status

Message, Current Alarm Status and Status Icons.

10.1.1 Position and Command

The current Position and Command are always shown. This

shows the Final Command which has been adjusted

according to a Characterization Curve, MPC, or Soft Limits

that have been applied and should match the Position.

flowserve.com 19

Page 20

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Table 12: Status Icons

Icon Location

Icon

Icon Meaning

Command

Source

Analog command mode

Digital command mode

Out of service

Pressure

Control

Pressure control locked

(blank)

Pressure control not locked

HART

Communicatio

ns

HART communication currently in

progress

Burst mode in progress

(blank)

No HART communication currently

in progress

10.1.2 Scrolling Status Messages

The Scrolling Status Message provides the following

information as applicable:

Ambient Temperature – This is the temperature inside the

positioner.

DIP Switch Override – This indicates that the Configuration

(DIP) Switches do not reflect the actual configuration of the

positioner. This can happen if a Configuration Switch is

changed after a Quick-Cal, or if the configuration is was

changed from the DTM. Performing a Quick-Cal will reset

the configuration to what the Configuration Switches show,

which may not be desirable. Ensure the Configuration

Switches are set properly before performing a Quick-Cal.

10.1.3 Current Alarm Status

The Current Alarm Status area shows the highest priority

alarm, warning, alert or status indication. This matches the

code indicated by the flashing LEDs.

10.1.4 Status Icons

Status icons continuously show the state of the features and

modes.

Pressure Control – When the position of the valve gets very

close to the commanded position, the positioning algorithm

will change to pressure control. This means the pressures

will be held constant (locked), improving the stability of the

valve position. The point at which the pressure control is

locked depends on the Valve Stability switch on the

positioner. When the switch is set to “Lo Friction”, the locking

point is self-adjusting to optimize accuracy. When the switch

is set to “Hi Friction” and the deviation is smaller than +/-

1.0%, the pressure “locks”. This value can be adjusted using

the Display Menu or DTM. See section 10.3.7 Configuration

(Pressure Control).

HART Communications Icons – When the positioner is

sending or receiving data via the HART communication

protocol, the icon will be displayed. During burst mode, a

pulsating heart icon will be displayed.

10.1.5 Adjusting the Display Contrast

To adjust the display contrast, hold the ◄ Back button for 3

seconds. Use the ▲Up and ▼ Down buttons to adjust the

contrast. Use the ►ACCEPT/QUICK-CAL to accept the

settings.

Command Source Icons – The positioner is in Analog

Command mode if it is using the 4-20 mA signal to control

the location of the valve. In Digital Command mode, the

positioner ignores the 4-20 command and responds to the

position command given through HART. In Out Of Service

mode, the positioner is performing a calibration, signature,

partial stroke test or is in a factory reset state.

flowserve.com 20

Page 21

10.2 Menu Overview

Status

Command (mA)

Command (%)

Position (%)

Temperature

Valve Cycles

Valve Travel (%)

Alerts and Alarms

Current Alarms (Prioritized)

Event History

Last Event

2nd Event

3rd Event

*

*

*

32nd Event

Partial Stroke Test

Start

Last Result

Calibration

Stroke/Quick Calibration

Command Input Calibration

Calibration Dates

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

Configuration

Positioner Tuning

Characterization

Pressure Control

Soft Limits & Cutoff

High Soft Limit

Low Soft Limit

Upper Position Cutoff

Lower Position Cutoff

User Preferences

All Units

Temperature Units

Actuator Area Units

Date Format

Number Format

LCD Orientation

Burst Mode

ON/OFF

Positioner Revs

EC Major Rev

EC Minor Rev

EC Build Date and Time

Universal Rev

Hardware Rev

Factory Reset

Language

English

German

French

Spanish

Portuguese

Russian

Turkish

Italian

flowserve.com 21

Page 22

►Status

►Command (mA)

►Command (%)

►Position (%)

►Temperature

►Valve Cycles

►Valve Travel (%)

►Alerts and Alarms

►Current Alarms (Prioritized)

►Event History

►Last Event

►2nd Event

►3rd Event

*

*

*

►32nd Event

►Partial Stroke Test

►Start

►Last Result

►Calibration

►Stroke/Quick Calibration

►Command Input Calibration

►Calibration Dates

10.3 Menu Features

10.3.1 Status

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

10.3.3 Partial Stroke Test

The Status menu is used to view information about the

configuration and operation of the system.

Command displays the final command in mA.

Command displays the final command in %.

Position displays the valve position in %.

Temperature displays the temperature inside the positioner.

Valve Cycles are counted each time the positioner changes

direction. The movement must be beyond a dead-band

window. This window is set to 0.5% as a default, but can be

changed using the DTM.

Valve Travel is counted in small increments every time the

valve moves beyond the dead-band window. The travel is

displayed in % of full stroke.

10.3.2 Alerts and Alarms

The Alerts and Alarms menu shows current and past alarms,

warnings, alerts, and calibrations.

Current Alarms displays all events that are actively sounding.

Event History displays past 32 events including alarms,

warnings, alerts, and calibrations. The event that occurred

most recently is displayed first (event 32) with later events

recorded below.

The Partial Stroke Test (PST) menu provides the user the

ability to start a PST and see the results of the latest PST.

CAUTION: Performing a Partial Stroke Test will result in

valve movement and the inability to operate the valve until

the test is complete. Notify proper personnel that the valve

may stroke, and make sure the valve is properly isolated if

required by plant procedures.

Start allows the user to initialize the (PST).

Last Result shows “Pass” or “Fail” from the last PST attempt.

10.3.4 Calibration

The Calibration menu allows the user to calibrate the

positioner’s sensors. The positioner can accurately control

with only a Quick-Cal. Typically this is all that is needed. A

friction calibration is recommended if the positioner has been

upgraded to Pro diagnostics. See section 8 STARTUP for

more details.

CAUTION: Performing a calibration may result in valve

movement and the inability to operate the valve until the

calibration is complete. Notify proper personnel that the valve

may stroke, and make sure the valve is properly isolated

before proceeding.

Stroke/Quick Calibration starts an automatic calibration of the

position feedback sensor. The stroke calibration determines

the closed (0%) and open (100%) positions of the valve and

gathers information about the response of the valve (such as

valve stroke time) in order to determine the gains. The gains

are then set automatically. After a stroke calibration, the

positioner is ready to control. See section 8.4 Stroke

Calibration for more information.

Command Input Calibration is used to adjust the input range.

Set the lowest current (Set 0%) and the highest current (Set

100%) that will be used. The default input range is 4 to 20

mA. The “Set 0%” value must be lower than the “Set 100%

value.

flowserve.com 22

Page 23

User Instructions - Logix® 420 Series Digital Positioners FCD LGENIM0106-06 12/13

►Configuration

►Positioner Tuning

►P-Gain Open

►I-Gain Open

►D-Gain Open

►P-Gain Close

►I-Gain Close

►D-Gain Close

►Open Stroke Time

►Close Stroke Time

►Minimum Open Time

►Minimum Close Time

►Configuration

►Characterization

►MaxFlo Linear

►MaxFlo Equal %

►Valdisk Linear

►Valdisk Equal %

►ShearStream Linear

►ShearStream Equal %

►Custom

Split Range Example:

A split range is easily configured. For example, a 4 to 12 mA

signal can be set to correspond to a 0 to 100% stroke. When

the display shows “Set 0%”, set the command input current

to 4 mA. (The display will show a low Analog to Digital Count

(ADC) that corresponds to 4 mA.) Then press the

►ACCEPT/QUICK-CAL button to set the value. Press the

▼Down button to move to “Set 100%”. Set the command

input current to 12 mA. (The display will show a high ADC to

correspond to 12 mA.) Again press the ►ACCEPT/QUICKCAL button to set the value. Select the ◄Back Button to

exit.

Signal At Closed = 20mA Example:

If the desired signal at closed is 20 mA, first set the Signal at

Closed DIP switch to 20 mA. Then perform a stroke

calibration by pressing the ►ACCEPT/QUICK-CAL button for

more than 3 seconds. This registers the DIP switch settings.

Then, in the Command Input Calibration menu, when the

display shows “Set 0%” it is expecting the lowest current

value. Set the input current to 4 mA. For “Set 100%”, it is

looking for the highest current value. Set the input current to

20 mA. After accepting theses values, the positioner will

interpret the 20 mA input as 0% valve position and the 4 mA

input as 100%.

Calibration Dates lists the most recent date of each

calibration. The date is available only if the calibration was

performed using the DTM.

10.3.5 Configuration (Positioner Tuning)

NOTE: Only those with specific training in PID tuning

algorithms should attempt to adjust the tuning by manually

changing the PID values.

Open Stroke Time is the fastest time it took the valve to

stroke from 0% to 100% during Quick-Cal. Increasing this

parameter will affect the responsiveness of the valve in the

opening direction.

Close Stroke Time is the fastest time it took the valve to

stroke from 100% to 0% during Quick-Cal. Increasing this

parameter will affect the responsiveness of the valve in the

closing direction.

Minimum Open Time and Minimum Close Time (Speed

Limits) are used to prevent the valve from moving too quickly.

This can be used when the process is sensitive to rapid flow

or pressure changes. This shows the time (in seconds) that

the positioner will allow the valve to travel a full stroke. This

speed limit applies to smaller movements of the valve too.

For example, if the Minimum Open Time were set to 20

seconds, and the command was changed from 40% to 50%,

the positioner would move the valve at a constant rate, taking

2 seconds to complete the move. If the Minimum Close Time

was set to 0, and the command was changed from 50% back

to 40%, the positioner would make the move as quickly as

possible.

The default values are 0 seconds, meaning the positioner will

move the valve as quickly as possible.

10.3.6 Configuration (Characterization)

The Configuration – Positioner Tuning menu allows the user

to manually adjust individual tuning parameters. All tuning

parameters are automatically set to optimal values during