Page 1

400-D HYDRAULIC HAND GUN

Assembly, Operation and

Maintenance Manual

Page 2

Contents

Flowserve Nordstrom Valve Sealants ............................................ 2

Flow Control

Nordstrom Valves

Functions of Nordstrom Valve Sealants ........................................ 2

400-D Hydraulic Hand Gun ........................................................... 3

Operation ...................................................................................... 4

Kits and Accessories .................................................................... 5

Parts List ...................................................................................... 6

Illustrations ................................................................................... 6

Care and Maintenance .................................................................. 8

Troubleshooting Guide ................................................................ 11

Authorized Distributors ............................................................... 12

Flowserve Nordstrom Valve Sealants

At Flowserve our primary goal is to serve lubricated valve

users with the highest quality sealant and sealant injection

equipment.

We offer:

• A broad variety of valve sealants

• A flexible, service-oriented manufacturing

facility providing outstanding quality

• An experienced, dedicated staff ready to

serve your needs

The success of Flowserve comes from customer service.

Competent, experienced personnel handle your orders from

development, to order entry, to manufacturing, to shipping.

We supply the most advanced formulations. Our highquality sealants range from -85°F to 700°F (-65°C to 371°C)

and from air and water applications to the most aggressive

line fluids.

Functions of Flowserve Nordstrom Valve Sealants

1. Drop-Tight Seal: To secure an absolutely tight seal, the film of

the sealant works to form a seal between the sealing surfaces

of the valve. The seal is formed by sealant transmitted through

a system of passageways around the valve ports. With proper

selection of sealant for your particular service, a seal can be

retained over a wide range of

temperatures and pressures.

2. Lubrication: Prevents metal-to-metal contact of the valve

sealing surfaces by filming over irregularities. No matter how

finely ground a metal surface may be, the metal is a series of

tiny peaks and valleys. As one metal surface slides against

another, friction is set up and adhesion, shearing or plowing

may result. A protective film of sealant between the bearing

surfaces prevents metal-to-metal rubbing.

3. Renewable Seat: There is no need to disassemble a

lubricated valve or to remove it from service to replace mildly

damaged seats. Sealant, as a structural part of lubricated

valves, provides a flexible and renewable seat, eliminating

the necessity of force-fit contact to effect a seal. For this

purpose, the sealant not only must have proper plasticity, but

also resistance to line fluids such as solvents and chemicals.

Sealant forms a seal between the sealing surfaces of the valve

even under pressure.

4. Plug Jacking: The fundamental operating principle of the

traditional lubricated plug valve design lies in the application

of Pascal’s Law. The law states that a unit of pressure applied

to the liquid contained in a sealed vessel is transmitted

to every part of the liquid with undiminished force, thus

multiplying the force many times, depending on the area of the

interior of the vessel. The sealant, under pressure developed

by sealant injection, supplies the hydraulic means for lifting

the plug from its tapered seat when and if that force is needed

to free the plug for easier operation.

2

400-D HYDRAULIC HAND GUN

Page 3

Flow Control

Nordstrom Valves

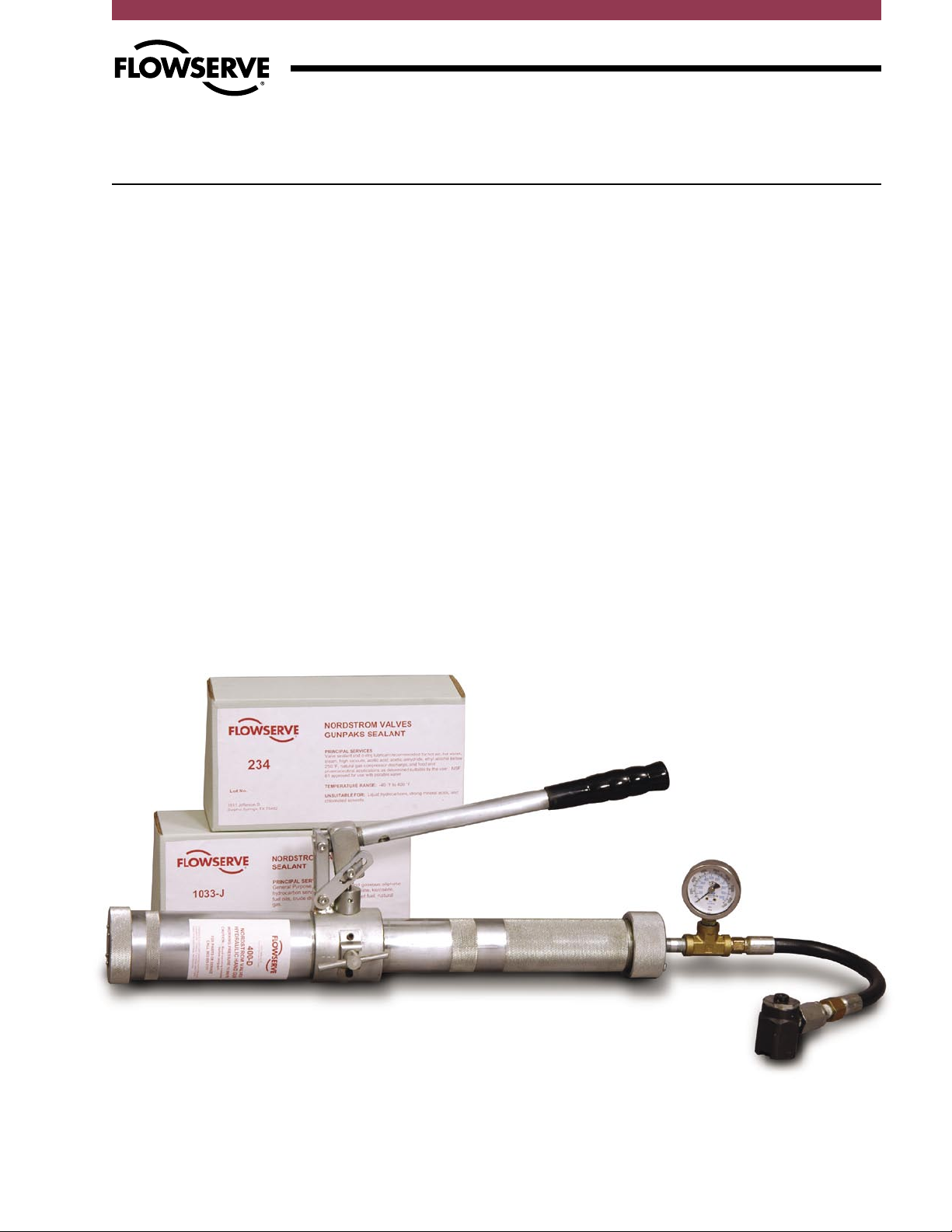

400-D Hydraulic Hand Gun

The Flowserve Nordstrom 400-D High-Pressure Hand Gun

is rated at 10,000–11,000 psi (690–759 bar) and includes many

features for meeting the exact demands of replacing sealant in

lubricated valves.

One of the most outstanding features of the 400-D Hand Gun

is the large fluid capacity, which permits long periods of operation

between recharging.

In the 400-D Hand Gun, any air entrapment is eliminated by

adding fluid when recharging, automatically purging the system of

air. The gun operates effectively in all positions.

The floating piston in the gun is solid. There is no cap screw

to cause fluid leakage and eventual operation failure.

By using a special-formula hydraulic fluid in the pumping

mechanism, the gun pumps smoothly and with minimum effort.

Its powerful hydraulic floating piston principle forces sealant out

of the gun with ease, regardless of the sealant viscosity.

The 400-D Hand Gun is equipped with a Giant Button Head

Coupler for connection to the button head sealant fitting of the

valve. This coupler has a design feature that locks it to the sealant

fitting when the gun is under positive pressure. The coupler

cannot be connected to or separated from the fitting with the gun

under pressure.

Due to the “built-in” safety features, the 400-D Hand Gun

provides maximum safety both to the user and the gun itself. The

hydraulic system of the gun is equipped with an internal relief

valve to protect the operator if pumping continues after the gun is

depleted of sealant.

The internal relief valve is tamperproof and is relatively

unaffected by temperature change and relieves approximately the

same pressure at temperatures between 0°F (-18°C) and 80°F

(27°C), assuring maximum pump output throughout the variation.

A pressure gauge indicates the point at which sufficient

sealant pressure has been developed within the valve.

In designing the 400-D Hand Gun, engineers concentrated on

greatly simplifying maintenance and repair procedures. In most

cases, the gun can be easily maintained and repaired by valve

service personnel, without requiring factory service.

400-D HYDRAULIC HAND GUN

3

Page 4

Operation

Flow Control

Nordstrom Valves

Preparing the

400-D Hand Gun for Use

The 400-D Hand Gun is packaged with the Sealant Barrel Cap and

hose assembly separate from the gun. To make the 400-D Hand

Gun operational, all you need to do is load the gun with sealant

and attach the cap and hose assembly. Refer to the

Sealant Brochure

specific valve application.

for information on the sealant required for your

Nordstrom

Loading the 400-D

Hand Gun with Sealant

The 400-D Hand Gun is capable of pumping all viscosities

of valve sealants. The barrel is designed to accept a size “J” sealant

stick (1.50" diameter x 8.75" length). Bulk grade sealants can be

loaded into the gun manually or by using Nordstrom Gun Pak. For

the Gun Pak, insert the heat-sealed end of the bag first.

CAUTION: The 400-D Hand Gun is a hydraulic hand gun

capable of developing high pressures. The following

operating instructions should be read and followed

closely to assure the safe and proper use of the

equipment.

Note: Numbers in parentheses refer to gun parts, as illustrated on

pages 6 and 7.

1. “Crack” open the By-Pass Valve (12) by turning counter clockwise less than one full turn. It should not be

tightened against the By-Pass Stop (14). Backing

out the By-Pass Valve too far will allow air to enter

the hydraulic system of the gun.

2. Remove the Sealant Barrel Cap (26), complete with

hose assembly, using the Handle with Grip (1). The

Handle is detachable and has a hole drilled near one

end. By unscrewing the Handle and placing the hole

over the protruding pin on the Sealant Barrel Cap,

the cap may be easily removed and replaced.

3. Using the Handle as a push rod, return the Floating

Piston (41) to the bottom of the Sealant Barrel (24).

4. Clean and replace the Handle.

5. Close the By-Pass Valve. Do not jam the By-Pass

Valve into the seat, as this may damage the sealing

member.

6. Insert the J-Stick or Gun Pak (heat-sealed end first)

into the Sealant Barrel.

7. Operate the gun until the J-Stick or Gun Pak

protrudes approximately ¼" (6 mm) from the end

of the Sealant Barrel.

8. Replace the Sealant Barrel Cap and tighten snugly

using the Handle.

9. Before attaching the Giant Button Head Coupler

(44) to the valve sealant fitting, operate the gun until

resistance is felt or the gun begins to build pressure

(the hose will stiffen). Continue to pump until the

internal relief valve releases and note the pressure at

which this occurs.

10. Crack open the By-Pass Valve again to relieve pressure

and then close. The 400-D Hand Gun is now ready for

servicing lubricated valves.

Lubricating Valves

with the 400-D Hand Gun

1. Slide the Giant Button Head Coupler (44) over

the button head fitting on the valve to be injected

with sealant.

2. Tighten the By-Pass Valve (12).

3. Begin sealant injection by pumping the Handle

(1). It may take a number of strokes for the gun to

prime itself and inject sealant into the valve.

4. As the valve sealant system becomes full, the gun

should become harder to operate and a drop in pressure

should be visible on the gauge. When the valve is full of

sealant, open the By-Pass Valve and disengage the Giant

Button Head Coupler. (Hydraulic pressure must be removed

from the gun before the coupler can be removed.)

Note: To retain most of the hydraulic pressure in the gun when

removing from a valve, quickly crack open and close the By-Pass

Valve. This will relieve enough hydraulic pressure to allow for easy

removal of the coupler but maintain enough pressure to keep from

repriming the gun between valves.

CAUTION: Do not continue pumping the gun after the

sealant barrel has been emptied of sealant, as the

Floating Piston Assembly may be damaged or the Gun

Pak bag may be pumped into the hose.

4

400-D HYDRAULIC HAND GUN

Page 5

Flow Control

Nordstrom Valves

Kits and Accessories

Major Repair Kit #1900028

Part Part

Qty. Number Description

1 47524 Button Head Coupler Repair Kit

1 60040 Hydraulic Pump Cylinder with

Piston 60041 & O-Ring 934005

1 60048 By-Pass Valve

1 60059 Check Valve Assembly

1 70960M Hydraulic Fluid Bag

1 71251 Hydraulic Fluid (1 pint can)

2 1900011 Nylon Cup

1 1900027 Minor Repair Kit

1 934006 O-Ring

1 908705 Screw

Minor Repair Kit #1900027*

Part Part

Qty. Number Description

1 934005 O-Ring

1 934006 O-Ring*

1 934007 O-Ring

1 934015 O-Ring

2 934029 O-Ring

1 943102 O-Ring

1 1900013 O-Ring

Button Head Coupler

Repair Kit #47524*

Consists of 1 each: Spring, Washer, O-Ring, Valve

Check Valve Assembly #60059*

Part Part

Qty. Number Description

1 60045 Screw

1 60046 Washer

1 60083 Screen

1 905151 Spring

1 930206 Ball

Linkage Assembly #60058

Part Part

Qty. Number Description

2 60039 Link

3 1619604 Washer

3 908683 Shoulder Screw

3 1618357 Lock Nut

1 1900065 Stop Link

Floating Piston Assembly

#1900009

Part Part

Qty. Number Description

1 1900010 Sealant Side Nut

2 1900011 Nylon Cup*

1 1900012 Body

1 1900013 O-Ring

1 1900014 Oil Side Nut

Body Assembly #60065

Part Part

Qty. Number Description

1 60040 Hydraulic Pump Cylinder*

1 60045 Screw

1 60046 Washer

1 60047 By-Pass Stop Valve

1 60048 By-Pass Valve*

1 60051 Body

1 60083 Screen

1 905151 Spring

2 908685 By-Pass Stop Screw

1 930206 Ball

1 934007 By-Pass Valve O-Ring

1 934015 Pump Cylinder Top O-Ring

1 934029 O-Ring

1 943102 Pump Cylinder Bottom O-Ring

1 1900149 Internal Relief Valve

400-D Hoses by Length

(¼" NPT Male and ½–27 Female)

Hose Part Hose Part

Length Number Length Number

1 ft. 60076 3 ft. 1900109

1.5 ft. 47501 4 ft. 47503

2 ft. 47502 6 ft. 47504

400-D HYDRAULIC HAND GUN

Repair Tools

Part Part

Number Description

47517 Piston Pulling Tool

47518 Spanner Wrench for Pump Cylinder

47519 Spanner Wrench for Floating Piston

47520 Floating Piston Guide

47521 Gun Assembly Wrench

*Component of Major Repair Kit

5

Page 6

1

12

13

15

14

3

2

5

30

7

25

9

23

22

32

21

16

10

25

6

27

19

20

29

18

4

8

11

31

43

42

41

35

33

46

NORDSTROM 400-D Hand Gun Parts

Flow Control

Nordstrom Valves

Part Qty.

Ref. Part Name Number Reqd.

1 Handle with Grip 60033 1

2 Fulcrum 60036 1

3 Link

4 Screw, Check Valve

5 Stop Link

6 Body, Hand Gun

7 Hydraulic Pump Cylinder with Piston

8 Washer, Check Valve

9 O-Ring, Pump Cylinder (top)

10 O-Ring, Pump Cylinder (bottom)

11 Screen, Check Valve

12 By-Pass Valve

13 O-Ring, By-Pass Valve

14 By-Pass Stop

15 By-Pass Stop Screw

16 Internal Relief Valve

(3)

60039 2

(4)(6)

(3)

1900065 1

60045 1

(4)

60051 1

(4)(6)

60046 1

(4)(6)

60083 1

(1)(4)

60048 1

(2)(4)

(4)

60047 1

(4)

908685 2

(4)

1900149 1

(1)(4)

60040 1

(2)(4)

934015 1

(2)(4)

943102 1

934007 1

Part Qty.

Ref. Part Name Number Reqd.

18 Spring, Check Valve

19 Washer, Linkage

20 Shoulder Screw, Linkage

21 Sealing Ring 60060 1

22 Fluid Bag Barrel 60054 1

23 Fluid Bag Barrel Cap 60055 1

24 Sealant Barrel 60028 1

25 O-Ring, Sealant Barrel

26 Sealant Barrel Cap 60026 1

27 Lock Nut

29 Ball, Check Valve

30 O-Ring, Pump Cylinder Piston

31 O-Ring, Fluid Bag

32 Hydraulic Fluid Bag

33 Nut, Sealant Side

(3)

(4)(6)

905151 1

(3)

1619604 3

(3)

908683 3

(2)(4)

934029 1

914980 3

(4)(6)

930206 1

(1)(2)

(1)(2)

934006 1

(1)

70960M 1

(5)

1900010 1

934005 1

6

400-D HYDRAULIC HAND GUN

Page 7

1

34

24

39

25

40

38

37

36

44

26

45

Optional

Flow Control

Nordstrom Valves

Part Qty.

Ref. Part Name Number Reqd.

34 Carry Strap 60070 1

35 Nylon Cup

36 Straight Swivel 927437 1

37 One Foot Hose 60076 1

38 Tee 1900074 1

39 Nipple 1900073 1

40 15,000 psi Gauge 1900052 1

41 Body, Floating Piston

42 O-Ring, Floating Piston

43 Nut, Oil Side

44 Giant Button Head Coupler 64584 1

45 Shutoff & Relief Valve (optional) 60010 1

46 Screw, Fluid Bag

Gauge Cover 60090 1

Hydraulic Fluid (1 pint can)

Z-Type Swivel (optional equipment) 927436

(1)(5)

(5)

1900011 2

(5)

1900012 1

(2)(5)

1900013 1

1900014 1

(1)

908705 1

(1)

71251

(1) Component of Major Repair Kit

(2) Component of Minor Repair Kit

(3) Component of Linkage Assembly

(4) Component of Body Assembly

(5) Component of Floating Piston Assembly

(6) Component of Check Valve Assembly

400-D HYDRAULIC HAND GUN

7

Page 8

Care and Maintenance

Flow Control

Nordstrom Valves

Suggested Care

The following suggestions will ensure efficient

and continued operation of the 400-D Hand Gun.

1. Do not carry the gun by the Handle unless

secured with the Carry Strap. Carrying the gun

with an unsecured handle can damage the Piston.

2. Keep the Piston area of the gun free of debris.

3. Do not unscrew the By-Pass Valve more than one

complete turn. Doing so may allow air to enter the

hydraulic system of the gun.

4. Protect the Gauge from damage.

Maintenance

If the operating instructions are carefully followed and hydraulic

fluid is added at regular intervals, the 400-D Hand gun will operate

indefinitely without further maintenance. It is recommended a

maintenance program be established where the number of hours

the gun is used determines when maintenance is required.

Note: Numbers in parentheses refer to parts as illustrated

on pages 6 and 7 of this brochure.

Recharging and Bleeding

the Hydraulic System of Air

1. Open the By-Pass Valve (12) and remove the Handle (1).

2. Remove the Sealant Barrel Cap (26) and stand

the gun with the Sealant Barrel (24) up.

3. With the Handle, press the Floating Piston (41)

to the bottom of the Sealant Barrel. Make sure the

Floating Piston bottoms out in the Sealant Barrel.

4. Leave the Handle inside the Sealant Barrel and turn

the gun so the sealant barrel is pointing downward

and remove the Fluid Bag Barrel Cap (23).

5. Slowly remove the Screw (46) and O-Ring (31) from

the Fluid Bag (32).

6. Allow the weight of the gun to rest against the Handle

and slowly fill the Fluid Bag with Nordstrom

Hydraulic Fluid 71251. Allow the gun to stand 15 minutes to

permit the air suspended in the fluid to escape. (It is

recommended to allow the gun to sit for 2 to 3 hours after

recharging the hydraulic system with fluid to allow the

Fluid Bag to regain its original shape.)

7. Replace the Screw and O-Ring, being careful not to

entrap air.

8. Remove the Handle and replace the Fluid Bag Barrel Cap.

9. Reload the Gun with Sealant and replace the Sealant

Barrel Cap.

Replacing the Hydraulic Fluid Bag

1. Remove the Handle (1), open the By-Pass Valve (12)

and push the Floating Piston (41) to the bottom of the

Sealant Barrel (24). Clean the Handle and replace.

2. Place the Fluid Bag Barrel (22) end of the gun in a vise.

3. Place a suitable size container below the vise to catch

hydraulic fluid.

4. Using Gun Assembly Wrench 47521, remove the Body

(6) and attached parts from the Fluid Bag Barrel.

Hydraulic fluid will spill from the Fluid Bag.

5. If the Floating Piston could not be returned to the bottom of

the Sealant Barrel, return it now. See Step 1.

6. Remove the damaged Fluid Bag (32) from the Fluid Bag Barrel

and clean the barrel.

7. Remove the Sealing Ring (21).

8. Place the Sealing Ring onto the new Fluid Bag, loosen the

Fluid Bag Screw (46) and tighten snug.

9. Place the Fluid Bag into the Fluid Bag Barrel.

10. Fill the Fluid Bag to within ¾" of the top with Nordstrom

Hydraulic Fluid 71251.

CAUTION: Take care to keep foreign matter

from entering the hydraulic fluid. Debris in

the hydraulic system can prevent the gun

from operating properly.

11. Replace the gun assembly removed in Step 4 and tighten

by hand.

12. Tighten the assembly to approximately 50 ft-lb using the

Gun Assembly Wrench.

CAUTION: Overtightening the Fluid Bag Barrel to the

Body may damage the Fluid Bag Assembly.

13. After equipping the gun with a new Fluid Bag, recharge the

gun with hydraulic fluid as described in this brochure.

Sealant Barrel Replacement

1. Open the By-Pass Valve (12) and push the Floating

Piston (41) to the bottom of the Sealant Barrel (24).

2. Close the By-Pass Valve.

3. Place the Sealant Barrel end of the gun in a vise and,

with Gun Assembly Wrench 47521, remove the Body

(6) and attached parts from the Sealant Barrel.

4. Remove the Sealant Barrel from the vise and push

the Floating Piston from the Sealant Barrel. Note

the position of the assembly when removing.

8

8

400-D HYDRAULIC HAND GUN

Page 9

Flow Control

Nordstrom Valves

Care and Maintenance (cont.)

5. Using Floating Piston Guide 47520, place the Floating

Piston into the non-knurled end of the new Sealant

Barrel. The Floating Piston should be flush with the

bottom of the Sealant Barrel.

CAUTION: Make sure the Sealant Barrel

and Floating Piston Assembly are free of

contaminates prior to assembly.

6. Replace the Sealant Barrel O-Ring (25).

7. Place the Sealant Barrel onto the Body, with

the knurled end furthest away from the Body,

and tighten hand-tight.

8. Place the Sealant Barrel end of the gun into the

vise and tighten the Body using Gun Assembly

Wrench.

9. After equipping the gun with a new Sealant Barrel,

recharge the gun with hydraulic fluid as described

in this brochure.

Pump Cylinder Replacement

1. Remove the Handle (1), open the By-Pass Valve (12)

and push the Floating Piston (41) to the bottom of the

Sealant Barrel (24). Clean the Handle and replace.

2. With the gun in the horizontal position, Handle up,

remove the Shoulder Screw (20) from the Pump Piston.

3. Tip the linkage back.

4. Unscrew the Hydraulic Pump Cylinder (7) with

Spanner Wrench 47518. (The cylinder cavity will

probably fill with hydraulic fluid. Do not disturb

this condition.)

5. Replace the O-Ring (10) in the bottom of the cylinder

cavity of the Body.

6. Install O-Ring (9) on the new Hydraulic Pump

Cylinder. It is recommended that the cylinder be

replaced as assembly 60040.

7. Install the new Hydraulic Pump Cylinder into the

Body (6) and tighten with Spanner Wrench 47518.

8. Reconnect the Linkage.

9. After equipping the gun with a new Hydraulic Pump

Cylinder, recharge the gun with hydraulic fluid as

described in this brochure.

Pump Cylinder

Piston O-Ring Replacement

Remove the defective Pump Cylinder Piston O-Ring (30) using

a sharp object. Pinch the O-Ring between the forefinger and

thumb. Push the O-Ring into the top of the Hydraulic Pump

Cylinder (7) so that it partially enters the O-Ring groove. Use a

blunt instrument to work the O-Ring completely into the groove.

Check Valve Repair

Symptoms of Check Valve failure are easily recognizable.

When the Handle develops a spring-like action where,

under pressure, the Handle will spring back each time it

is pushed down, the Check Valve is not seating

properly. This is usually indicative of a foreign particle

on the valve seat.

1. Open the By-Pass Valve (12) and push the Floating

Piston (41) to the bottom of the Sealant Barrel (24).

2. Close the By-Pass Valve.

3. Place the gun in a vise on a workbench and loosen the

Check Valve Screw (4).

4. Remove the Check Valve Screw and Washer (8) and

turn the gun Check Valve down so the Spring (18),

Ball (29) and Screen (11) fall out.

5. If it did not fall out, use a pointed instrument to remove

the cylindrical Screen (11) from the Check Valve cavity.

6. Thoroughly clean the Check Valve seat and cavity with

a lint-free paper towel. The cleaning must be thorough

or the Check Valve may not seat.

7. Position the gun on the workbench with the Check

Valve cavity up.

8. Insert the Ball.

9. With the Ball in position on the seat, place a short

length of ¼" brass or cold-rolled rod on the Ball and,

with a firm blow from a hammer, seat the Ball.

10. Turn the Body (6) over and remove the Ball by tapping

the unit against your hand.

11. Clean the cavity and seat the Ball again.

12. Turn the Body upside down. If the Ball falls out,

repeat the seating procedure until the Ball does not

fall out without assistance.

13. Insert the Screen and Spring.

14. Replace the Washer and Check Valve Screw and

tighten the screw snugly, being careful to not

overtighten.

15. After equipping the gun with a new Check Valve

Assembly, recharge the gun with hydraulic fluid

as described in this brochure.

By-Pass Valve

Replacement

1. Remove the Handle (1), open the By-Pass Valve (12)

and push the Floating Piston (41) to the bottom of the

Sealant Barrel (24). Clean the Handle and replace.

2. Remove the By-Pass Stop Screw (15) and the By-Pass

Valve Stop (14).

3. Remove the damaged By-Pass Valve.

4. Lubricate the By-Pass Valve O-Ring (13) on the new

By-Pass Valve.

400-D HYDRAULIC HAND GUN

9

Page 10

Care and Maintenance (cont.)

Flow Control

Nordstrom Valves

5. To avoid damage to the O-Ring, carefully screw the

By-Pass Valve into the Body until the O-Ring engages

the Body. Screw the valve in ½ turn, and unscrew ¼

turn. Repeat this procedure until the O-Ring has

entered the Body and the By-Pass Valve has seated.

CAUTION: If hydraulic fluid is present in

the By-Pass Valve cavity of the Body, fluid

back pressure may shear the O-Ring and the

O-Ring will have to be replaced.

6. After installing a new By-Pass Valve, recharge the

gun with hydraulic fluid as described in this brochure.

Floating Piston Replacement

1. Remove the Sealant Barrel Cap (26) and open the

By-Pass Valve (12).

2. Push Piston Assembly to bottom of Sealant Barrel (24)

with Handle (1). Clean the Handle and replace.

3. Remove the Sealant Barrel from the gun (see

instructions listed in Sealant Barrel Replacement).

4. Remove the Floating Piston (41) from the Sealant

Barrel using Piston Pulling Tool 47517.

5. Place the Floating Piston into a vise and disassemble

using Spanner Wrench 47518.

6. Replace the O-Ring (42) and Nylon Cups (35).

7. Tighten the assembly using two spanner wrenches.

8. Replace the Floating Piston using Floating Piston Guide

Tool 47520. The assembly should be positioned flush

with the bottom of the Sealant Barrel.

9. After installing the Floating Piston, recharge the

gun with hydraulic fluid as described on page 8 of

this brochure.

Sealant Change-out

1. Remove the Sealant Barrel Cap (26), complete with

hose assembly.

2. Force Piston Pulling Tool 47517 into the center of

the sealant in the Sealant Barrel (24) and push until

the tool is in contact with the Floating Piston (41).

3. Screw the tool into the Floating Piston, open the

By-Pass Valve (12), and pull the piston out of the barrel

until the assembly is flush with the end of the barrel.

4. Remove the Piston Pulling Tool and scrape the

existing sealant from the end of the Floating Piston.

5. Follow instructions for Loading the 400-D Hand Gun

with Sealant as listed in this brochure.

6. Attach a sealant fitting to the Giant Button Head

Coupler (44) and purge old sealant from the hose by

operating the gun until new sealant is pumped through

the fitting.

Factory Repair Service

Factory Repair Service is available from Flowserve Nordstrom

Valves. Consult your Authorized Distributor or Nordstrom

Customer Service for more details.

1010

400-D HYDRAULIC HAND GUN

Page 11

Flow Control

Nordstrom Valves

Troubleshooting Guide

These troubleshooting tips are provided as a means of assisting the consumer in recognizing operational difficulties sometimes

associated with the 400-D Hand Gun. Part numbers in parentheses denote illustration numbers as listed on pages 6 & 7 of this brochure.

WARNING: Never attempt to repair a 400-D Hand Gun without relieving the hydraulic pressure.

■ Problem: The gun will not pump.

Cause 1: Air has entered the hydraulic system.

Solution 1: Bleed the hydraulic system. See page 8 of this

brochure. Tip!: With the Fluid Bag end of the Gun

positioned vertically in a vice, the Fluid Bag full of

oil, the Floating Piston pushed all the way into the

Sealant Barrel, and the By-Pass Valve open two

full turns, pump the handle 10 to 15 times. This

will ensure air entrapped in the hydraulic system

passages has been pumped into the Fluid Bag and

allowed to escape to the atmosphere.

Cause 2: The Piston is broken.

Solution 2: Replace the Pump Cylinder/Piston assembly.

See page 9 of this brochure.

Cause 3: The gun is void of sealant.

Solution 3: Refill the gun with sealant. See page 4 of this

brochure.

Cause 4: A Gun Pak bag has been forced into the hose by

attempting to inject sealant after the gun is void

of sealant.

Solution 4: Remove the Hose Assembly from the gun and

remove the bag from the Hose. You may attempt

this by flipping the hose and pumping out the bag.

Replace the Hose if the bag cannot be removed.

Cause 5: The Giant Button Head Coupler is damaged.

Solution 5: Replace the Giant Button Head Coupler or repair

the coupler using repair kit 47524.

Cause 6: Ambient temperature is low enough to cause the

sealant to become more viscous.

Solution 6: Place the gun and sealant in a warm place and only

expose them to cold temperature only during valve

injection.

■ Problem: The gun is difficult to pump.

Cause 1: The supply of sealant is depleted.

Solution 1: Reload the gun with sealant. See page 4 of this

brochure.

Cause 2: The injection pressure of the sealant has not lifted

the plug from the seat of the valve.

Solution 2: Continue to inject sealant until the plug has been

lifted from the seat of the valve or until the Internal

Relief Valve relieves.

■ Problem: Hydraulic fluid leakage around the Body and

Fluid Barrel threads.

Cause 1: Hydraulic Fluid is leaking past the Screw and

O-Ring in the end of the Hydraulic Fluid Bag.

Solution 1: Carefully tighten the Screw.

Cause 2: The Hydraulic Fluid Bag is damaged.

Solution 2: Replace the Hydraulic Fluid Bag.

See page 8 of this brochure.

■ Problem: Floating Piston Assembly will not return to the

bottom of the Sealant Barrel.

Cause 1: Air in hydraulic system.

Solution 1: Bleed the hydraulic system. See page 8 of this

brochure. See tip for problem “The gun will

not pump.”

Cause 2: Excessive hydraulic fluid in gun.

Solution 2: Note: This procedure should be performed over

a basin to catch the excess hydraulic fluid.

Remove the Sealant Barrel Cap and insert the

Handle into Sealant Barrel against the Floating

Piston. Turn gun upside down and let the weight

of the gun rest on the Handle. Remove the

hydraulic Fluid Barrel Cap. Slowly remove the

Screw and O-Ring, located in the end of the

Hydraulic Fluid Bag, while lightly pressing the

gun down against the Handle. This will force out

excessive hydraulic fluid. Once the Piston is all the

way to the bottom of the Sealant Barrel, insert the

Screw and O-Ring into the Fluid Bag and replace

the Fluid Barrel Cap.

■ Problem: Hydraulic fluid leakage at the Sealant Barrel

to Body threads.

Cause 1: The hydraulic fluid side Nylon Cup or O-Ring has

been damaged, allowing hydraulic fluid to enter the

sealant side of the Hydraulic Piston.

Solution 1: Clean and check the Nylon Cups for damage.

Replace parts if required. See page 10 of

this brochure.

Cause 2: The cylinder wall of the Sealant Barrel has been

scored, allowing hydraulic fluid to enter the sealant

side of the Hydraulic Piston.

Solution 2: Clean and check the Sealant Barrel for damage.

Replace the part if required. See page 8 of

this brochure.

■ Problem: The gun will not develop pressure when pumping.

Cause 1: Air is present in the hydraulic system.

Solution 1: Bleed the hydraulic system. See page 8 of

this brochure.

Cause 2: The Check Valve Assembly is faulty.

Solution 2: Repair or replace the Check Valve Assembly.

See page 9 of this brochure.

Cause 3: The By-Pass Valve (12) is not sealing.

Solution 3: Tighten the By-Pass Valve while lightly tapping with

small hammer.

Cause 4: The Internal Relief Valve (16) has failed.

Solution 4: Replace the Internal Relief Valve.

400-D HYDRAULIC HAND GUN

11

Page 12

Flow Control

Nordstrom Valves

Authorized Distributors

For detailed information on these and other Nordstrom

products, call your customer service representative

for the name and number of the nearest authorized

1511 Jefferson Street

Sulphur Springs, Texas 75482

USA

Nordstrom distributor.

1-800-225-6989

Email: nmkt@flowserve.com

or visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function safely

during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service

conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume

the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation Operation

Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is

continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning these

provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, visit www.flowserve.com or call USA 1 800 225 6989.

United States

Telephone: 903-885-4691 or 4693

FAX: 903-439-3411

Latin America

Telephone: 903-439-3407

Fax: 903-439-3411

Other Countries

Telephone: 903-885-4692

Fax: 903-439-3404

© 2004 Flowserve Corporation, Irving, Texas, USA. Flowserve and Nordstrom Valves are registered trademarks of Flowserve Corporation. FCD NVAIM2002-01 Printed in USA.

(Replaces SIE-201)

Loading...

Loading...