Page 1

Worcester Actuation Systems

This manual includes instructions for extra limit switch and auto

sequence timer options.

DESCRIPTION

Flowserve Worcester Actuation Systems Series 36 Electric Actuators

are unidirectional rotary valve actuators. Standard units can provide

up to 550 in-lb of torque delivered at the output shaft. The AC

versions of these actuators use rugged shaded-pole motors with

integral thermal overload protection and automatic reset. An internal

adjustable limit switch is used for accurate control. One additional

limit switch (optional) can be mounted within the unit for remote

position indication or the control of an auxiliary piece of equipment.

IMPORTANT: The Series 36 Actuator is a unidirectional, 90° actuator,

and therefore cannot be used on butterfly valves, ball valves with an

upstream relief hole (cryogenic, chlorine, etc.), or on diverter/three-

way valves (the series 75 is required for these). The actuator must be

mounted above the valve, with the output shaft and valve stem

vertical. It will not function if mounted at an angle, or below the valve.

a WARNING: Series 36 Actuators are electromechanical devices

subject to normal wear and tear. Actuator life is dependent upon

application and environmental conditions. If used in hazardous

services, such as but not limited to, media temperature extremes,

toxins, flammables, or other services where improper or incomplete

operation could produce a safety hazard, it is incumbent upon the

system designer and the user to provide proper warning devices such

as temperature sensors, oxygen sensors and flow sensors. Flowserve

also recommends that the optional auxiliary limit switches be used for

monitoring and/or electrical interlock.

CAUTION: Flowserve recommends that all products which must be

stored prior to installation be stored indoors, in an environment

suitable for human occupancy. Do not store product in areas

where exposure to relative humidity above 85%, acid or alkali

fumes, radiation above normal background, ultraviolet light, or

temperatures above 120°F or below 40°F may occur. Do not store

within 50 feet of any source of ozone.

I. INSTALLATION

A. Attach mounting bracket to actuator using four (4) cap screws

and lockwashers, and tighten securely. For small size top-mount

style valves, attach bracket such that bracket nameplate will be to

side of valve.

B. Attach actuator/bracket assembly to valve as follows:

CAUTION: Ball valves can trap pressurized media in the internal

cavity. If it is necessary to remove any valve body bolts, stem

nuts, or remove valve from the line, and if the valve is or has

been in operation, make sure there is NO

pressure to or in the

valve and operate valve one full cycle.

1. Valve Models 51/52 (

1

/

2"–2" only), 59 (2" only), 45 (2

1

/

2" only),

82/83 (

1

/

2"–2" only) and Top Mount 44 (

1

/

4"–2") and

59 (

1

/

4"–1

1

/

2"):

Note: For above listed valves, it is not necessary to remove

any valve body bolts or remove valve from line in order to

mount actuator.

a. Close valve (valve is closed when flats on stem are

perpendicular to the line of flow). If any valve information

is marked on stop plate or handle, it will be necessary to

transfer this information to the bracket nameplate.

b. For

1

/

4"–2" 44,

1

/

4"–1

1

/

2" 59 series top-mount style valves

and

1

/

2"–2" 51/52,

1

/

2"–1

1

/

2" 82/83 series valves, with high

cycle stem packing as standard, remove handle nut,

lockwasher, handle, seperate stop plate (if any), retaining

nut and stop pin(s). Add the two additional Belleville

washers with their larger diameter sides touching each

FCD WCAIM2007-00

(Part 08522)

Series 36 Electric Actuator

Installation, Operation and Maintenance Instructions

Page 2

Flow Control

Worcester Actuation Systems

other. Add the self-locking nut to the stem and tighten

while holding the stem flats with a wrench. Tighten until

Belleville washers are flat, the nut will “bottom”, and then

back nut off

1

/

3 turn. The two additional Belleville washers

and the self-locking nut are included in the mounting kit.

CAUTION: The self-locking stem nut is difficult to

tighten, and must fully flatten the Belleville washers

before backing off.

For 2" 59, 2

1

/

2" 45, and 2" 82/83 valves only, remove

handle assembly, retaining nut, stop and stop screws.

Replace with valve stem spacer, or with two Belleville

washers (if valve has graphite stem packing), and replace

retaining nut. NOTE: Belleville washers are installed with

larger diameters touching each other. Using a wrench to

prevent stem from turning, tighten retaining nut until

stem packing is fully compressed or Bellevilles, if used,

are fully flattened, then back off nut

1

/

6 turn. Excessive

tightening causes higher torque and shorter seal life.

NOTE: Valves with V51 high cycle stem packing option

installed, identified by two Belleville washers installed and

handle assembly, stop and stop screws removed, do not

require stem area disassembly.

c. Center coupling on valve stem.

d. Lower actuator/mounting bracket assembly over coupling

and onto valve, making sure that the slot in the actuator

shaft will engage male tang on coupling.

e. Secure bracket to valve using cap screws and

lockwashers provided in mounting kit. Tighten securely.

For small size top-mount style valves, the bracket

nameplate will be to the side of the valve.

II.ELECTRICAL INSTALLATION AND

ADJUSTMENT

(Refer to Figures 1 and 2)

Make conduit connection to NPT fitting on actuator base (

1

/

2" NPT for

10-2036).

CAUTION: In cases where the conduit connected to the actuator may

be partially or completely run underground, or through which

moisture may contact energized live parts, or where the actuator

and/or conduit is exposed to temperature differences, the conduit

should be sealed within 18" of the actuator in accordance with the

National Electrical Code.

A. Wiring Termination

The 36 Actuator wiring is done using the wire terminations

provided. One “wire nut” is used to connect the actuator’s “free”

motor lead to incoming power. Two other incoming leads are

connected at the actuator limit switch by

3

/

16" “quick-connect”

crimp-type wiring connectors. These wiring connectors are fitted

to the NO (normally open) and NC (normally closed) terminals of

the actuator limit switch.

The actuator should be electrically grounded in accordance with

standard procedures.

See table for minimum fuse rating when overcurrent protection is

used in motor power circuit. NOTE: The table shows the minimum

rating to prevent inrush current from blowing the fuse.

TABLE 1: MINIMUM FUSE RATING FOR OVERCURRENT PROTECTION

Actuator Size AC Voltage Fuse Rating (A)

10 120 3

20 120 5

10 240 1.5

20 240 3

B. Actuator Rotation

Incoming power is alternately applied between the NO or NC

switch terminals and the “free” motor lead. When the proper

voltage is applied to the actuator its output shaft and bull gear

turn counterclockwise (CCW) when viewed from above.

C. Proper 90° Operation

The 36 Actuator is a unidirectional actuator which is designed to

stop at each 90° position of one complete rotation. This interval is

determined by the detents on the face of the actuator’s output

gear. The arm of a limit switch rides over these detents

controlling the point at which actuator motion will stop.

Mounting the actuator to the valve such that the actuator’s

conduit entry is in line with the piping will allow the following

operation:

Switch Arm Position* Valve Position

Up Open

Down Closed

*The switch arm has just hit the transition point on the gear face detent.

Rotating the entire actuator on the valve 90° (and rotating the ball

90°) so that the conduit opening is cross-line to the piping will

Figure 1

1

Page 3

Flow Control

Worcester Actuation Systems

change the above details. When the switch arm is up, the valve is

closed; when the switch arm is down, the valve is open.

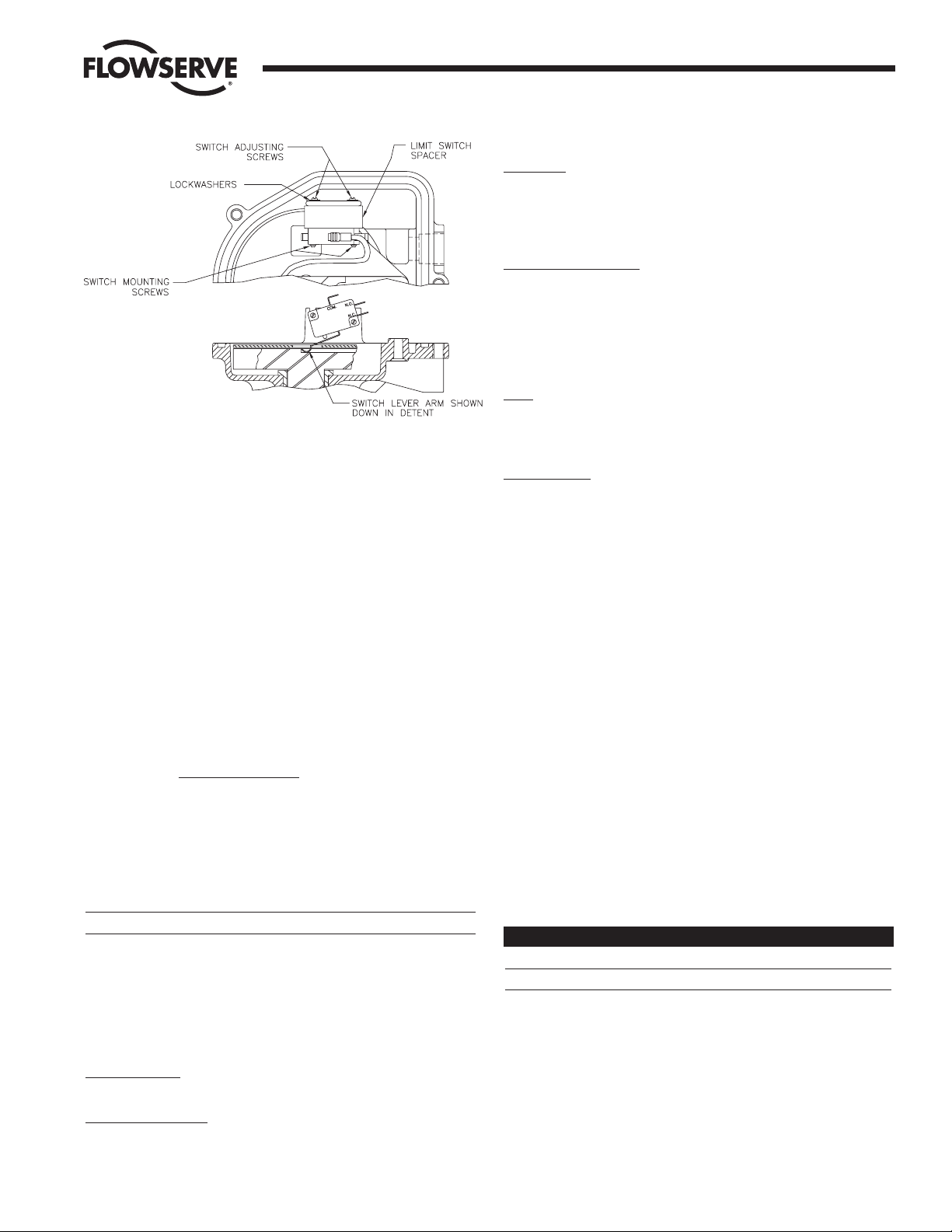

D. Proper Alignment of Switch:

The limit switch is adjusted and set at the factory for proper 90°

operation. Verify switch setting prior to operation. In the event

that the switch is not at the desired setting, adjust as follows:

The limit switch of the 36 Actuator can be adjusted in two

directions; up-and-down and side-to-side (refer to Fig. 2).

To adjust the limit switch, loosen the adjusting screws on the

casting’s switch support. Once these screws are loosened, the

limit switch can move up, down and sideways a total of

3

/

8 inches.

Moving the switch horizontally causes both stop points to shift.

Moving the switch vertically changes the 90°/90° rotation.

Adjust the switch vertically for uniform 90° cycles, then shift it

horizontally to set the stop points.

Secure the switch fastening screws when proper valve indexing is

verified thru one complete rotation

of the valve (360°).

The actuator is now ready for operation.

III. MAINTENANCE and

TROUBLESHOOTING

a WARNING: Disconnect power during cover removal.

The Series 36 Electric Actuator requires no regular maintenance. The

actuator utilizes a permanently lubricated gear train. No additional

lubrication is necessary.

Should the actuator fail to operate, the following are hints for troubleshooting.

Electrical Supply:

Be sure the actuator is supplied with the correct

voltage.

Electrical Connections:

Does the wiring conform to the wiring diagram?

Motor Module:

AC Motors: If the motor winding is short-circuited, or if the

thermostat has opened the winding, the unit will not operate. If the

motor is hot, allow it to cool down so that the stator is at room

temperature. Apply voltage to motor. If motor still fails to operate,

replace the entire motor module.

Motor Bearing Alignment

: The actuator motor uses self-aligning

bearings. During shipment, the bearing may become misaligned, so the

actuator will not operate. Tapping the motor stator (lamination around

top bearing bracket with a plastic hammer or screwdriver handle) while

it is energized will realign the bearings. The unit will then develop full

output. To perform this adjustment, reenergize unit with cover off. If

rotor hums, but does not turn, tap stator lightly as described.

V

alve: The problem may lie with the valve instead of with the actuator.

Check the operation of the valve by removing the actuator and

operating the valve manually. Measure valve torque and compare to

actuator torque.

Optional Switch

: If an extra switch is used, its contact arm must lead

(be shorter than) the contact arm of the actuator operating switch,

i.e., the auxilliary switch must trip before the positioning switch.

Check to ensure clearance between the extra limit switch lever arm

and the retaining shroud. If they are touching, loosen the motor

mounting screws and move retaining shroud enough to clear the

switch lever arm.

IV. SPARE PARTS

The following are recommended spare parts which should be kept on

hand for Series 36 Electric Actuators:

1 Spare Limit Switch (Used for Valve Control Only)

NOTE: This spare limit switch can be ordered by part number and

differs from the (optional) extra limit switch.

When ordering any spare parts, please specify actuator size and

voltage.

V. ELECTRICAL REQUIREMENTS

The following table represents current draw in amperes at the various

voltages and rated stall torque for each motor:

Voltage (AC) 1036 (5 sec.) 2036 (5 sec.)

120 2.3 3.8

240 1.0 1.7

The duty cycle for all motors used in the Series 36 Actuator is 20%

(at 70°F).

Figure 2

Page 4

Flow Control

Worcester Actuation Systems

ITEM QTY DESCRIPTION MATERIAL

1 1 Base Die Cast

Aluminum

2 1 Bearing Sintered Bronze

3 1 Seal (Base) Rubber

4 1 Spur Gear Steel (Black

Oxide Coating)

5 1 Retaining Shroud Steel (Black

Oxide Coating)

6 1 Motor

Module (AC)

7 3 Motor Mounting

Screw

8 3 O-Ring Buna

(Motor Screw)

(Watertight “W”

Actuator Only)

9 1 Cover Die Cast

Aluminum

10 3 Cover Screw Plated Steel

11 1 Flange Gasket Neoprene

(Cover Seal)

(Watertight “W”

Actuator Only)

12 1 Limit Switch Phenolic

13 2 Switch Mounting Plated Steel

Screw

14 1 Spacer Phenolic

(Limit Switch)

15 2 Spacer Mounting Plated Steel

Screw

16 4 Lockwasher Plated Steel

17 2 Nut Plated Steel

18 1 Conduit Plug Polyethylene

To order proper parts, please specify the actuator size, model, and

revision number. Use the standard nomenclature listed above.

Page 5

Flow Control

Worcester Actuation Systems

VI. OPTIONS

1. Extra Limit Switch Installation

A. The extra limit switch, M1, is different from the limit switch used

in the actuator for proper valve indexing. Tripping of the extra limit

switch is advanced due to a shorter lever arm on the switch.

B. Remove the actuator cover.

C. Remove the screws attaching the actuator’s limit switch to the

limit switch spacer.

D. Position the extra limit switch against the existing limit switch and

fix both switches to the spacer, use the longer screws provided

with the extra limit switch kit and reuse the existing lockwashers

(see Figure 2).

Check to make sure there is clearance between the extra limit

switch lever arm and the retaining shroud. If they are touching,

loosen the motor mounting screws and move retaining shroud

enough to clear the switch lever arm.

E. Three quick-connectors are provided for fixing external wiring to

this extra limit switch. Using the proper crimping tools, connect

field wiring to these connectors.

NOTE: The extra limit switch contact arm must lead (be shorter than)

the contact arm of the actuator operating switch, i.e., the auxilliary

switch must trip before the positioning switch.

F. Adjust the limit switches as necessary to obtain the necessary

switch actuation through the extra limit switch’s three terminals

Common (c) Normally-Open (NO) Normally-Closed (NC)

These terminal designations are shown on the switch body.

With the switch lever arm up, the NO terminal becomes closed;

with the switch lever arm down the NO terminal is open.

G. Test the actuator and check continuity of the M1 switch. It must

trip before limit switch does.

H. With the switch properly adjusted, tighten all screws, tuck all

wiring away from any rotating parts and replace actuator cover.

Tighten each actuator cover screw insuring that cover to base seal

remains properly in position.

2. Auto Sequence T

imer

A. GENERAL

The Worcester Actuation Systems Auto Sequence Timer is a solid

state electronic circuit board which is mounted inside the 36

actuator. It is available at 120 VAC standard. The timer allows the

actuator to periodically open and close a valve for various time

periods that are field-selectable. By simply opening or closing

switches on the timer’s circuit board, various open and closed

time periods can be selected.

B. TIME PERIODS

The following table shows the required switch position of the

several switches in a small switch package mounted on the board.

The first four switches, #1 through #4, control the open time,

while the second four switches, #5 through #8, control the closed

time.

Timer cycle operation is indicated by two board-mounted light

emitting diodes (LEDs). For current boards (identified by a label

containing the board part no. and revision letter), the lower LED

lights when the timer is in the short-time part of its cycle,

normally the open time period. The upper LED lights when the

timer is in the long-time part of its cycle, normally the closed time

period. The LEDs on older boards are reversed.

IMPORTANT - A minimum of one switch in the first four switches, #1

through #4, AND a minimum of one switch in the second four

switches, #5 through #8, MUST BE in the “ON” position for the auto

sequence timer to properly operate. (The “ON” position is marked on

the switch).

The open cycle selection is independent of the closed cycle selection;

“O” = Switch On, “X” = Switch Off.

OPEN CYCLE SWITCHES CLOSED CYCLE SWITCHES

1234TIME IN SECONDS 1234TIME IN HOURS

OXXX 6 OXXX .25

XOXX 12 XOXX .50

O O X X 18 O O X X .75

X X O X 24 X X O X 1.00

OXOX 30 OXOX 1.25

X O O X 36 X O O X 1.50

O O O X 42 O O O X 1.75

X X X O 48 X X X O 2.00

O X X O 54 O X X O 2.25

XOXO 60 XOXO 2.50

O O X O 66 O O X O 2.75

X X O O 72 X X O O 3.00

O X O O 78 O X O O 3.25

X O O O 84 X O O O 3.50

OOOO 90 OOOO 3.75

C. WIRING

The auto sequence timer is mounted into the actuator as shown

in Figure 4. Field wiring connects to the terminal block as shown

in the wiring diagram, Figure 3.

D. RESET SWITCH

Included with the auto sequence timer circuit board is a reset

switch that is mounted to the base of the actuator with a

waterproof boot. The switch, when pressed and held

, will allow

the timer circuit to open the valve. (Hold down until the valve is

open! Leaving the valve partly open will stall the actuator.)

Releasing the button will automatically restart the sequence that

is selected on the circuit board’s time period selection switch,

starting with “on” time.

Page 6

Flow Control

Worcester Actuation Systems

Figure 4

Figure 3

Page 7

Flow Control

Worcester Actuation Systems

E. INSTALLATION

Install the 36 actuator per Sections I and II of this manual. Verify that

the 36 actuator limit switch is properly secured.

Valve opening time (“on” time) is powered through the circuit board’s

red wire and is connected to the limit switch’s (NC) normally-closed

contact. Valve closed time is powered through the circuit board’s

black wire and is connected to the limit switch’s (NO) normally-open

contact. (See Figures 3 and 4.)

When the actuator, with its timer, is properly installed and wired,

simply apply power to the actuator to begin operation.

After power is turned on, the valve will open for the required short

time period and then close and stay closed for required long period.

F. TROUBLESHOOTING

Proper limit switch action in the 36 actuator is very important for

proper timer operation.

If erratic operation is noted, do the following:

1. Verify that valve operates easily and is not sticking. Verify that

proper AC voltage is available at terminals 1 and 2.

2. Verify that the timer board is cycling properly by observing the

operation of the LED cycle indicators and/or the operation of the

reset switch to force the timer board into the open cycle. (Note: If

timer is already in the open part of the cycle, lower LED is lighted for

current boards or upper LED for older boards. Operation of the reset

switch will have no effect.) It is suggested that, for checking

purposes, the shortest time periods be set into each cycle to

minimize testing time. (Only switches 1 and 5 should be in the ON

position.)

3. Verify proper actuator and actuator limit switch operation.

Remove supply power from the actuator. Disconnect the supply

power at the circuit board terminal strip and remove the circuit

board’s red and black wires at the limit switch. Tape these leads’

ends and fold them back away from the limit switch contacts.

Apply power between the motor common lead and the limit

switch’s NO and then NC switch contacts. The actuator should

open and then close as power is alternately applied between the

motor common lead and these switch contacts. If problems are

noted, either the limit switch or motor is defective.

4. If in Step 2 above, the motor operates properly but actuator

does not stop at correct position, check the limit switch for

proper adjustment. Adjust the limit switch as noted in Section II,

Parts C and D. If the limit switch is defective, remove and

replace the switch.

5. If the actuator motor and switch are properly operating, then

erratic problems are caused by the auto sequence timer circuit

board. Remove circuit board and replace with a new circuit board

from Flowserve.

Page 8

Flow Control

Worcester Actuation Systems

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, visit www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

Flow Control

Worcester Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone (434) 528-4400,

Fax (434) 845-9736

© 2004 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. FCD WCAIM2007-00 Printed in USA.

(Part 08522)

Loading...

Loading...