Page 1

3400IQ Digital Positioner

FCD LGENIM3401-00 – 06/06

USER INSTRUCTIONS

Installation

Operation

Maintenance

Experience In Motion

Page 2

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Contents

1 Terms Concerning Safety 4

2 General Information

3 Unpacking and Storage

3.1 Unpacking 5

3.2 Storage 5

3.3 Pre-installation Inspection

4 Logix 3400

4.1 Specifications 10

4.2 Positioner Operation 1

4.3 Detailed Sequence of Positioner Operations 1

5 Mounting and Installation 1

5.1 Mounting to Valtek Linear Mark One Valves 1

5.2 Mounting to Standard Valtek Rotary Valves (See Figure 4) 1

5.3 Optional Valtek Rotary Mounting Procedure (See Figure 5) 1

5.4 NAMUR Mounting Option 1

5.5 Tubing Positioner to Actuator 1

6 Wiring and Grounding Guidelines (See Figure 6) 1

6.1 FF Command Input Wiring 1

6.2 Grounding Screw 1

6.3 Segment Compliance Voltage (See Figure 7) 2

6.4 Cable Requirements 2

6.5 Intrinsically Safe Barriers 2

6.6 DD Support 2

7 Startup 22

7.1 Logix 3400

7.2 Initial DIP Switch Settings 2

7.3 Description of Configuration DIP Switch Settings 2

7.4 Description of Cal DIP Switch Settings 2

7.5 RE-CAL Operation 2

7.6 Manual Jog Calibration Operation 2

7.7 Local Control of Valve Position 2

7.8 Factory Reset 2

7.9 Logix 3400

7.10 Version Number Checking 3

7.11 375 Handheld Communicator 3

7.12 Device Description (DD) Files 3

7.13 Calibration 31

2

IQ Positioner Overview 7

IQ Local Interface Operation 22

IQ Status Condition 27

7.13.1 CALIBRATE_FLAGS 31

7.13.2 Control and Tuning 3

4

5

7

1

2

4

4

5

7

8

8

9

9

9

0

1

1

1

2

3

6

6

7

7

7

0

1

1

2

Page 3

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

7.14 Alerts 35

7.14.1 FINAL_VALUE_CUTOFF 35

7.14.2 Effects of FINAL_VALUE_CUTOFF on Operation 3

7.14.3 Soft Limits 3

7.14.4 Travel Accumulator 3

7.14.5 Cycle Counter 3

7.14.6 Position Deviation 3

7.14.7 Advanced Features 3

7.14.8 Standard vs. Advanced Diagnostics 3

7.14.9 Temperature and Pressure Units 3

7.14.10 Stroke Length 3

7.15 Characterization Retention 3

7.15.1 Initiating a Valve Signature 3

7.15.2 System Preparation 3

7.15.3 Signature Procedure 3

7.16 Step Signature 3

7.16.1 Collection of Stored Signature 3

7.17 Glossary 39

7.18 Transducer Block Parameters 4

8 Maintenance and Repair 5

8.1 Driver Module Assembly 5

8.2 Regulator 54

8.3 Checking or Setting Internal Regulator Pressure 5

8.4 Spool Valve 5

8.5 Spool Valve Cover 5

8.6 Stem Position Sensor 5

8.7 Main PCB Assembly 6

8.8 Pressure Sensor Board 6

8.9 User Interface Board 6

9 Optional Vented Design 6

10 Parts List 6

11 Logix 3400

12 Logix 3400

12.1 Valtek Mounting Kits 7

12.2 Logix O.E.M. Mounting Kits 7

12.3 NAMUR Accessory Mounting Kit Part Numbers 7

13 Frequently Asked Questions 7

14 How to Order 7

15 Troubleshooting 76

IQ Spare Parts Kits (See Figure 22 for item numbers) 68

IQ Mounting Kits 70

5

5

5

6

6

6

6

6

7

8

8

8

8

9

9

1

0

0

5

7

8

9

0

1

3

4

7

0

1

3

4

3

5

flowserve.com

Page 4

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

1 Terms Concerning Safety

The safety terms DANGER, WARNING, CAUTION and NOTE are used in these instructions to

highlight particular dangers and/or to provide additional information on aspects that may not be

readily apparent.

DANGER: Indicates that death, severe personal injury and/or substantial property damage

b

will occur if proper precautions are not taken.

WARNING: Indicates that death, severe personal injury and/or substantial property

c

damage can occur if proper precautions are not taken.

CAUTION: Indicates that minor personal injury and/or property damage can occur if proper

a

precautions are not taken.

NOTE: indicates and provides additional technical information, which may not be very obvious even

to qualified personnel. Compliance with other, not particularly emphasized notes, with regard to

transport, assembly, operation and maintenance and with regard to technical documentation (e.g.,

in the operating instruction, product documentation or on the product itself) is essential, in order to

avoid faults, which in themselves might directly or indirectly cause severe personal injury or property

damage.

2 General Information

The following instructions are designed to assist in unpacking, installing and performing maintenance as required on Flowserve Valtek Logix

used for all the positioners herein; however, specific numbers indicate features specific to model

(i.e., Logix 3400 indicates that the positioner has F

Model Number table in this manual for a breakdown of specific model numbers. Product users

and maintenance personnel should thoroughly review this bulletin prior to installing, operating, or

performing any maintenance on the valve.

Separate Valtek Flow Control Products Installation, Operation, Maintenance instructions cover the

valve (such as IOM 1 or IOM 27) and actuator (such as IOM 2 or IOM 31) portions of the system and

other accessories. Refer to the appropriate instructions when this information is needed.

To avoid possible injury to personnel or damage to valve parts, WARNING and CAUTION notes must

be strictly followed. Modifying this product, substituting non-factory parts or using maintenance

procedures other than outlined could drastically affect performance and be hazardous to personnel

and equipment, and may void existing warranties.

4

WARNING: Standard industry safety practices must be adhered to when working on this

c

or any process control product. Specifically, personal protective and lifting devices must be

used as warranted.

®

3400IQ digital positioners. Series 3000 is the term

oundation Fieldbus protocol). See Logix 3400IQ

Page 5

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

3 Unpacking and Storage

3.1 Unpacking

1. While unpacking the Logix 3400IQ positioner, check the packing list against the materials

received. Lists describing the system and accessories are included in each shipping

container.

2. When lifting the system from the shipping container, position lifting straps to avoid damage to

mounted accessories. Systems with valves up to six inches may be lifted by actuator lifting ring.

On larger systems, lift unit using lifting straps or hooks through the yoke legs and outer end of

body.

WARNING: When lifting a valve/actuator assembly with lifting straps, be aware the

c

center of gravity may be above the lifting point. Therefore, support must be given to

prevent the valve/actuator from rotating. Failure to do so can cause serious injury to

personnel or damage to nearby equipment.

3. In the event of shipping damage, contact the shipper immediately.

4. Should any problems arise, contact a Flowserve Flow Control representative.

3.2 Storage

Control valve packages (a control valve and its instrumentation) can be safely stored in an enclosed

building that affords environmental protection; heating is not required. Control valve packages must

be stored on suitable skids, not directly on the floor. The storage location must also be free from

flooding, dust, dirt, etc.

Long Term Storage of Logix 3000 series Positioners in Humid Locations

The Logix 3000 series positioners are designed to operate in humid environments when connected

to a proper instrument air supply. There are some occasions when valves and positioners are stored

at job sites or installed and commissioned and then left without instrument air for months. To make

startup easier for units that are left without instrument air and insure that the positioners will be

ready to operate, it is recommended that the vent assembly of the positioner be sealed preferably

with a desiccant pouch sealed with the vent assembly.

flowserve.com

5

Page 6

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

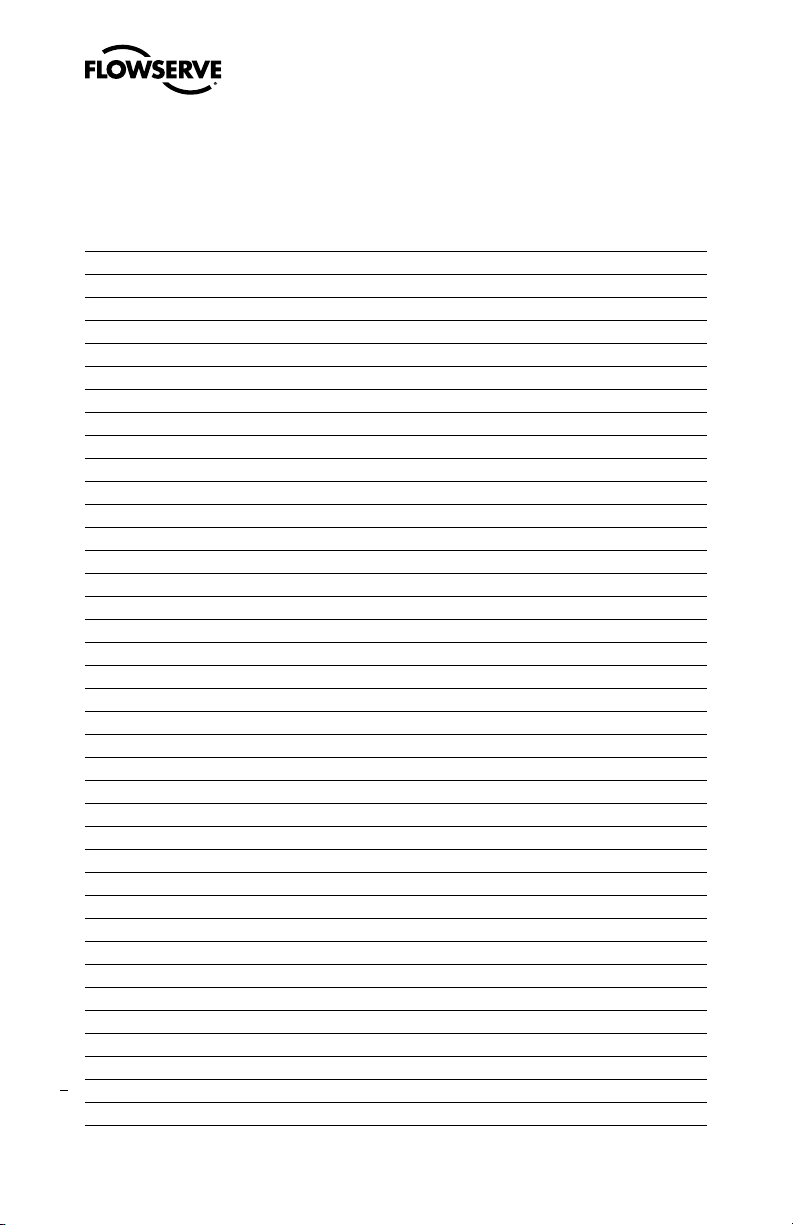

The vent assembly is located in the upper left side of the positioner. The gaps around the assembly

as noted by the arrows should be sealed for long term storage.

Joints to be sealed

Vent assembly

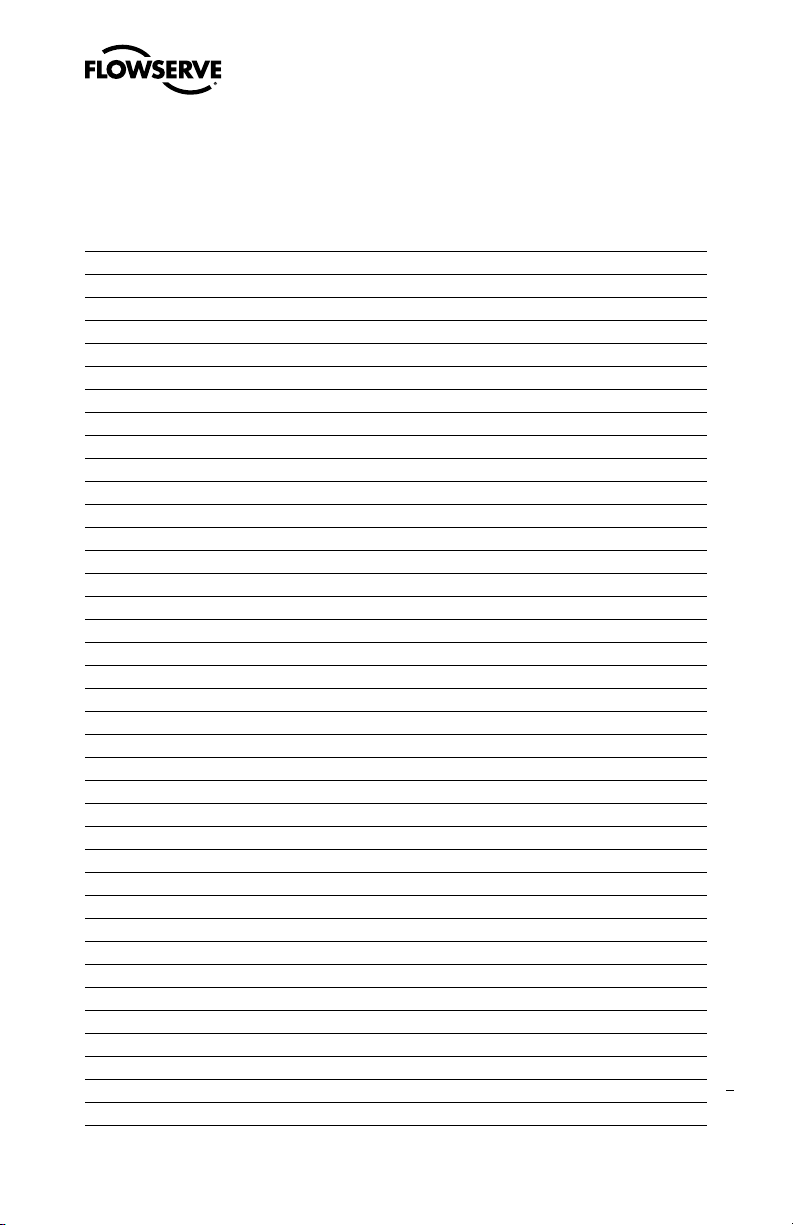

A small desiccant package as shown can be included under the sealing tape to insure proper

protection.

Desiccant packet

6

Page 7

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

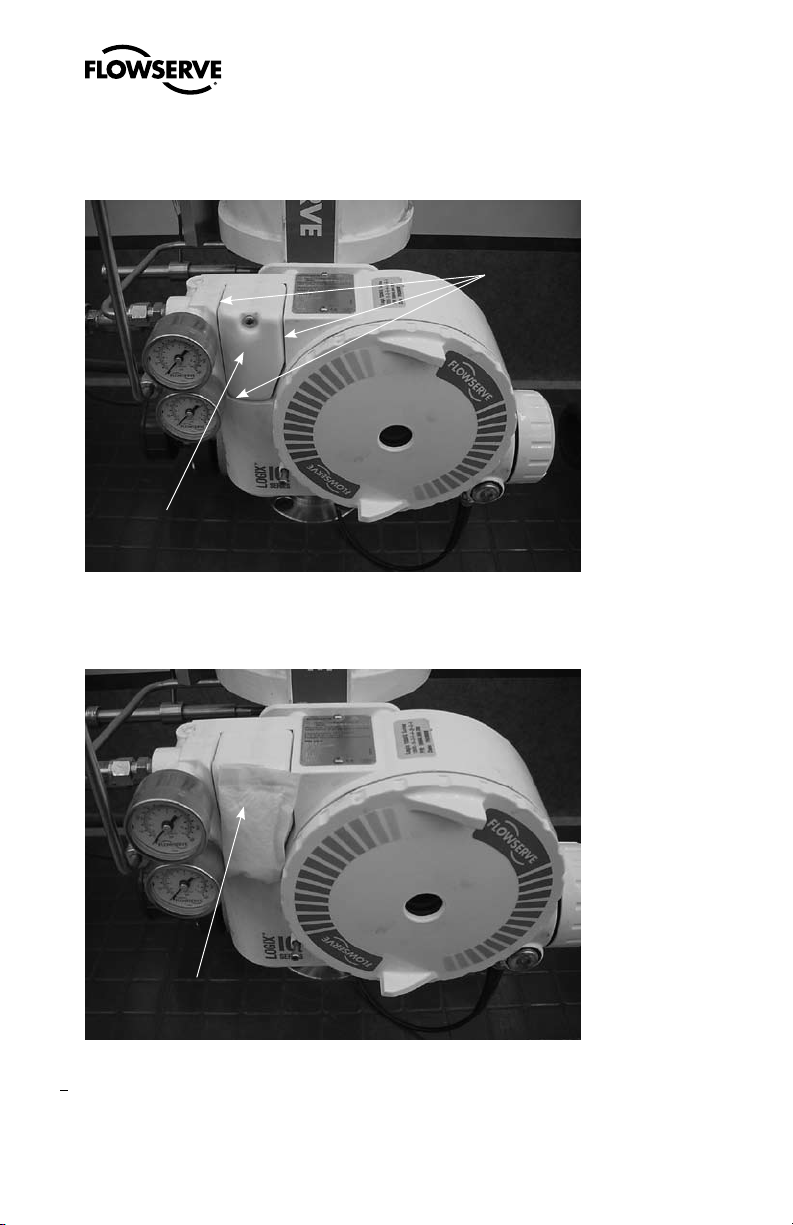

All of the edges around the vend assembly should be sealed similar to the picture below.

Removeable

sealing tape

The sealing tape and desiccant should be removed when instrument air is permanently applied to the

positioner.

3.3 Pre-installation Inspection

If a valve control package has been stored for more than one year, inspect one actuator by disassembling it per the appropriate Installation, Operation, and Maintenance Instructions (IOM) prior to

valve installation. If O-rings are out-of-round, deteriorated, or both, they must be replaced and the

actuator rebuilt. All actuators must then be disassembled and inspected. If the actuator O-rings are

replaced, complete the following steps:

1. Replace the pressure-balance plug O-rings.

2. Inspect the solenoid and positioner soft goods and replace as necessary.

4 Logix 3400IQ Positioner Overview

The Logix 3400IQ digital positioner is a two-wire Foundation Fieldbus compliant digital valve

positioner. The positioner is configurable through the local user interface. The Logix 3400IQ

the FF protocol to allow two-way remote communications with the positioner. The Logix 3400IQ

positioner can control both double- and single-acting actuators with linear or rotary mountings. The

positioner is completely powered by the FF signal. Start up voltage must be from a FF power supply

source.

utilizes

flowserve.com

7

Page 8

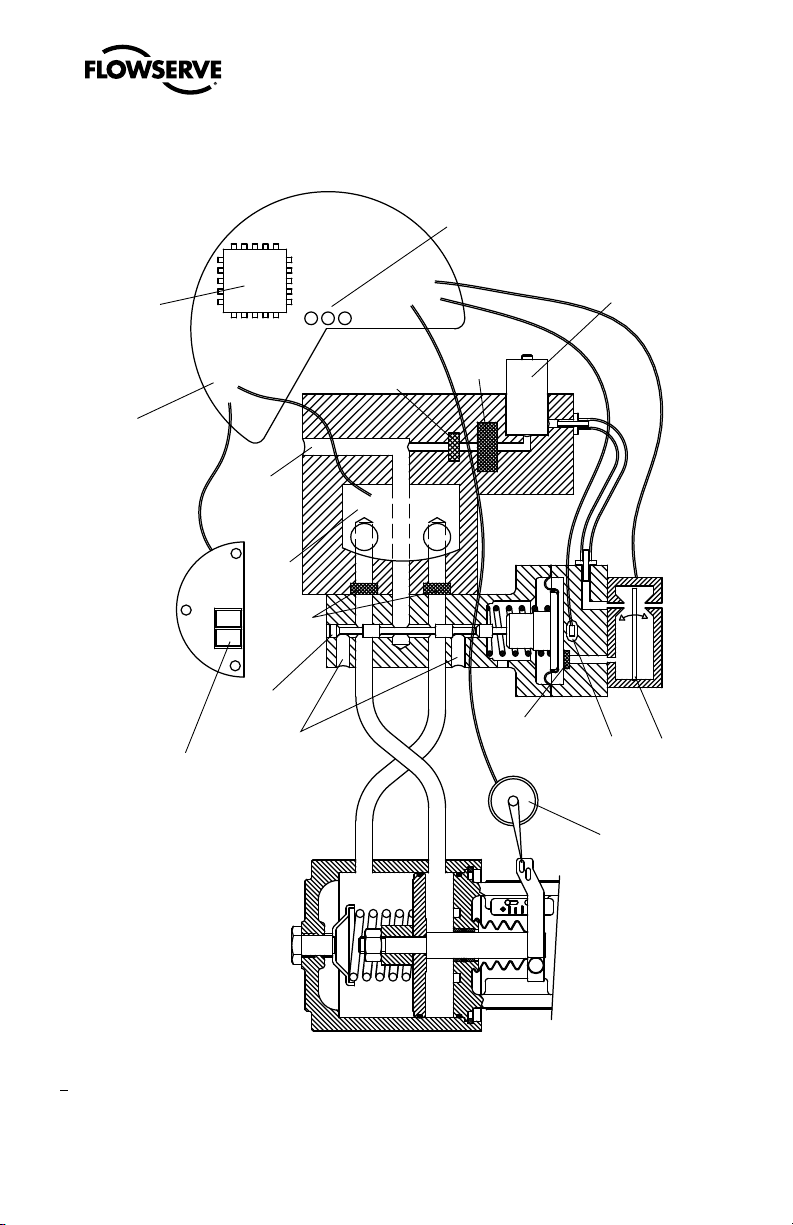

OO

Stem

Position

Sensor

Piezo Valve

Output 2

Output 1

Hall Effect

Sensor

Flame

Arrestor

Exhaust

Spool Valve

Flame

Arrestor

Pressure

Sensor Board

Air Supply

Main PCB

Regulator

Filter

Flame

Arrestor

Digital Position Algorithm

LED

Display

FF Input Signal

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Figure 1: Logix 3400IQ Digital Positioner Schematic (air-to-open configuration)

8

Page 9

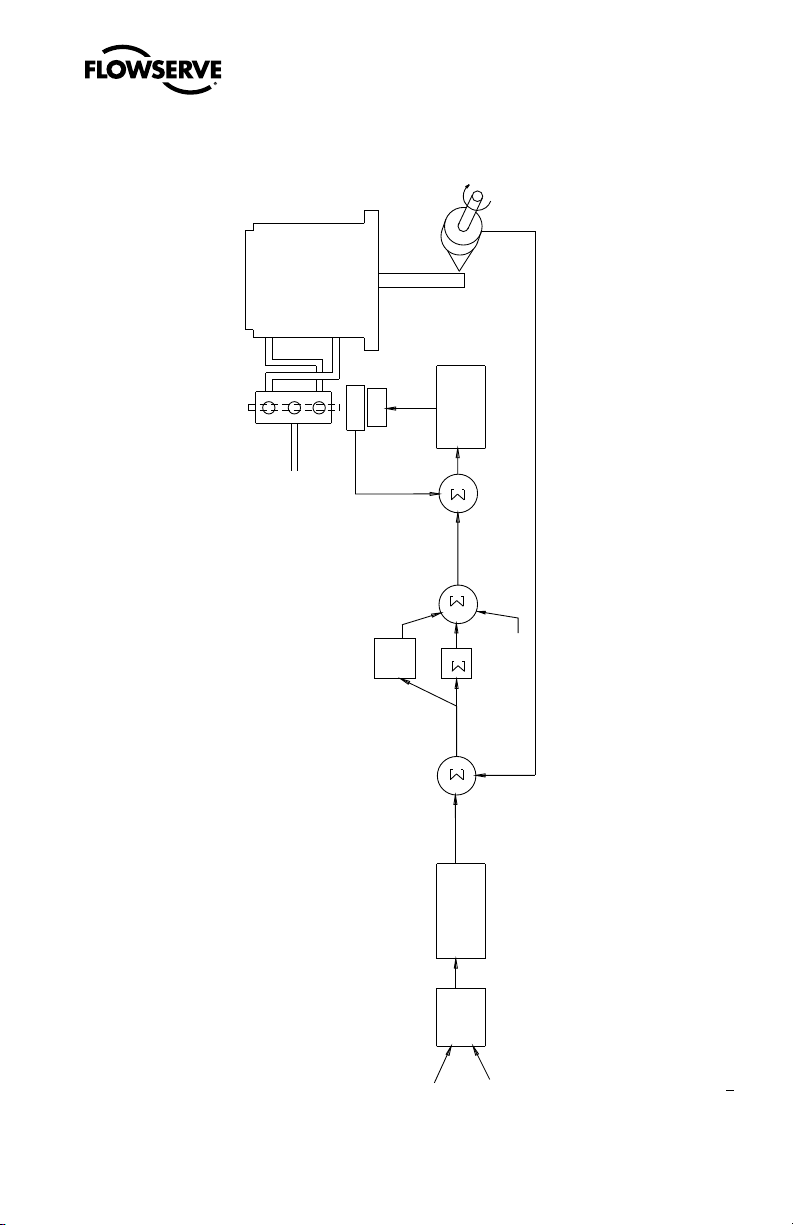

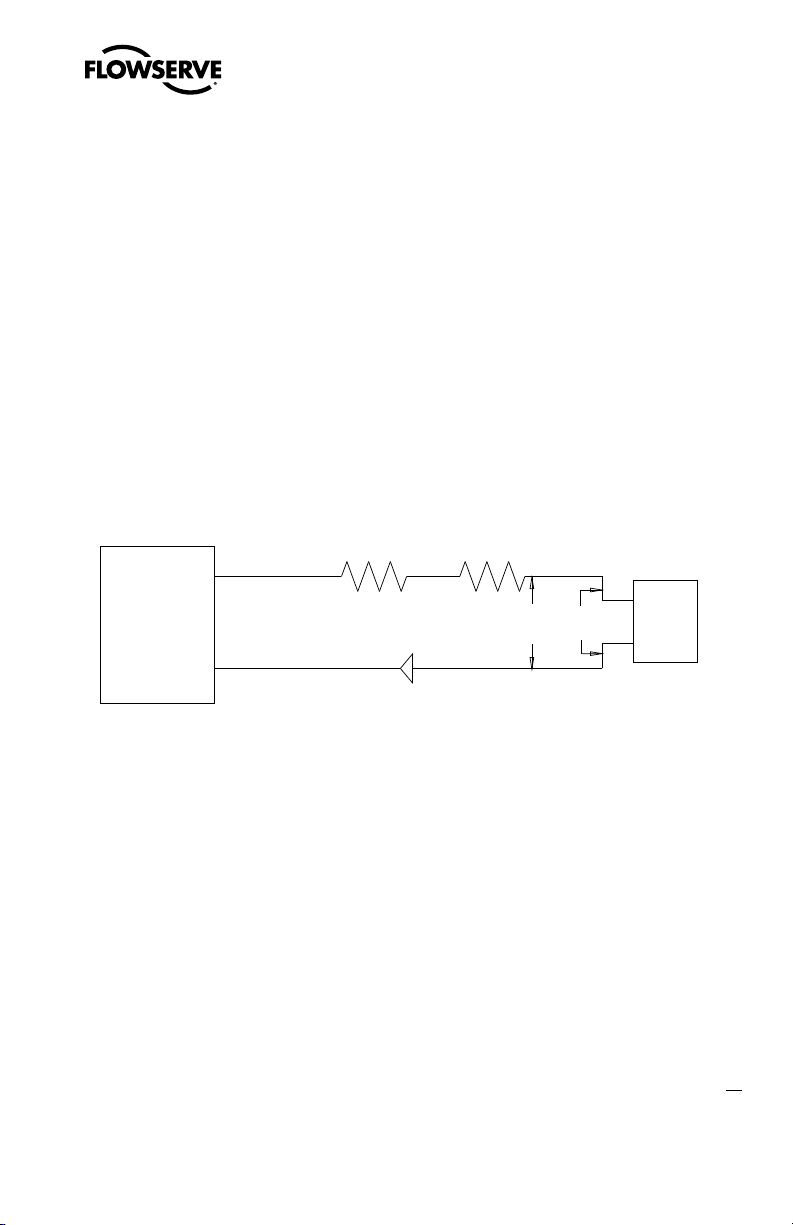

Figure 2: System Positioning Algorithm

Sensor

-

+

+

+

+

Summer

Integration

I

Offset

Loop

Inner

+

-

Gmult

Pmin

Pmax

Deviation

FOUNDATION

Fieldbus

Signal

Command In

(AO Block)

FOUNDATION

Fieldbus

Transducer

Block

CONTROL

COMMAND

Output

D/A

Percentage

Algorithm

Control

Supply

Air

Control

Spool

Loop

Inner

ATO

Tubed

Sensor

Position

Stem

Voltage

Valve

Piezo

MPC

Soft Limits

Characterization

Linear Mode

Output

Inner-Loop

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

9

flowserve.com

Page 10

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

4.1 Specifications

Table I: Electrical Specifications

Power Supply

IS Fisco compliant

Communications FF Protocol ITK 4.6x

Operating Current 23 mA

Maximum Voltage 36.0 VDC

Table II: Environmental Conditions

Operating Temperature Range Standard

Transport and Storage

Temperature Range

Operating Humidity 0 - 100% non-condensing

Note: The air supply must conform to ISA Standard ISA 7.0.01 (a dew point at least 18

degrees Fahrenheit below ambient temperature, particle size below five microns—one

micron recommended—and oil content not to exceed one part per million).

Two-wire, 9-32 VDC

FF compatible

-40° to 176°F

(-40° to 80°C)

-40° to 176°F (-40° to 80°C)

Table III: Physical Specifications

Housing Material Cast, powder-painted aluminum, stainless steel

Soft Goods Buna-N / Florosilicone

Weight

8.3 pounds (3.9 kg) aluminum

20.5 pounds (9.3 kg) stainless steel

Table IV: Positioner Specifications

Deadband <0.1% full scale

Repeatability <0.05% full scale

Linearity <0.5% (rotary), <0.8%, (sliding stem) full scale

3

Air Consumption <0.3 SCFM (0.5 Nm

Air Supply 30-150 psig (ISA 7.0.0.1 compliant)

/hr) @ 60 psi (4 bar)

10

Page 11

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

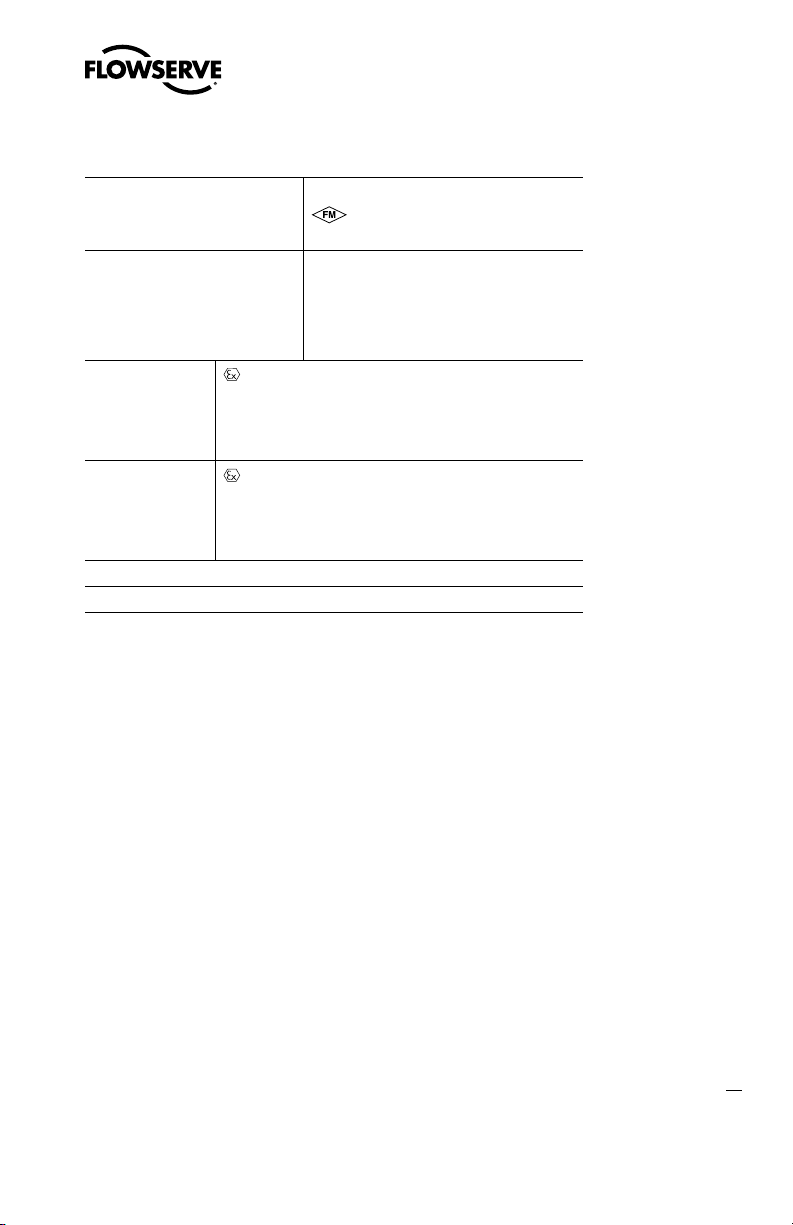

Table V: Hazardous Area Certifications

Intrinsically Safe

(PENDING)

Explosion Proof

Approved

Class I, Div 1, Groups A, B, C, D

Class II, III, Div 1, Groups E, F, G

(See Figure 1 for installation

requirements.)

Intrinsically Safe

(PENDING)

Flameproof

(PENDING)

CE Compliant

FISCO Compliant

II 1G EEx ia IIC T4, T5

T4 Ta = -40°C to 80°C

T5 Ta = -40°C to 35°C

IP 65

II 2 GD EEx d IIB + H2

T5, Ta = -40°C to 80°C

IP65

Class I, Div 1, Groups B, C, D

Class II, III, Div 1, Groups E, F, G

T6 Ta = 60°C

NEMA/TYPE 4X

4.2 Positioner Operation

The Logix 3400IQ positioner is an electric feedback instrument. Figure 1 shows a Logix 3400IQ

positioner installed on a double-acting linear actuator for air-to-open action.

The Logix 3400IQ receives power from the two-wire, FF input signal. This positioner utilizes

FF communications for the command signal. The command source can be accessed with the

Rosemount 375 communicator or other host software.

0% is always defined as the valve closed position and 100% is always defined as the valve open

position. During stroke calibration, the signals corresponding to 0% and 100% are defined.

The input signal in percent passes through a characterization/limits modifier block. The positioner

no longer uses CAMs or other mechanical means to characterize the output of the positioner. This

function is done in software, which allows for in-the-field customer adjustment. The positioner has

four basic modes:

Linear, Equal Percent (=%), Quick Open (QO) and Custom characterization. In

Linear mode, the input signal is passed straight through to the control algorithm in a 1:1 transfer. In

Equal Percent (=%) mode, the input signal is mapped to a standard 30:1 rangeability =% curve. In

Quick Open the input signal is mapped to an industry standard quick-open curve. If Custom char-

acterization is enabled, the input signal is mapped to either a default =% output curve or a custom,

user-defined 21-point output curve. The custom user-defined 21-point output curve is defined using

a handheld or the Host configuration tool software. In addition, two user-defined features,

Soft

Limits and Final Value Cutoff, may affect the final input signal. The actual command being used to

flowserve.com

11

Page 12

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

position the stem, after any characterization or user limits have been evaluated, is called the Control

Command.

The Logix 3400IQ

inner-loop, spool control and an outer-loop, stem position control. Referring again to Figure 1, a

stem position sensor provides a measurement of the stem movement. The

compared against the

the inner-loop control to move the spool up or down, depending upon the deviation. The inner-loop

then quickly adjusts the spool position. The actuator pressures change and the stem begins to

move. The stem movement reduces the deviation between

This process continues until the deviation goes to zero.

The inner-loop controls the position of the spool valve by means of a driver module. The driver

module consists of a temperature-compensated hall effect sensor and a piezo valve pressure

modulator. The piezo valve pressure modulator controls the air pressure under a diaphragm by

means of a piezo beam bender. The piezo beam deflects in response to an applied voltage from the

inner-loop electronics. As the voltage to the piezo valve increases, the piezo beam bends, closing off

against a nozzle causing the pressure under the diaphragm to increase. As the pressure under the

diaphragm increases or decreases, the spool valve moves up or down respectively. The hall effect

sensor transmits the position of the spool back to the inner-loop electronics for control purposes.

uses a two-stage, stem-positioning algorithm. The two stages consist of an

Control Command is

Stem Position. If any deviation exists, the control algorithm sends a signal to

Control Command and Stem Position.

4.3 Detailed Sequence of Positioner Operations

A more detailed example explains the control function. Assume the unit is configured as follows:

• Unit is in

• Custom characterization is disabled (therefore characterization is Linear).

• No soft limits enabled. No Final Value Cutoff set.

• Valve has zero deviation with a present input command of 50.

• Write to Final_Value to change command.

• Actuator is tubed and positioner is configured air-to-open.

Given these conditions, 50 represents a

is disabled so the

exists, the Stem Position is also at 50 percent. With the stem at the desired position, the spool valve

will be at a middle position that balances the pressures above and below the piston in the actuator.

This is commonly called the

OOS.

Command source of 50 percent. Custom characterization

Command source is passed 1:1 to the Control Command. Since zero deviation

null or balanced spool position.

Assume the input signal changes from 50 to 75. The positioner sees this as a

of 75 percent. With

is the difference between

where 50 percent is the present stem position. With this positive deviation, the control algorithm

12

sends a signal to move the spool up from its present position. As the spool moves up, the supply air

is applied to the bottom of the actuator and air is exhausted from the top of the actuator. This new

pressure differential causes the stem to start moving towards the desired position of 75 percent. As

Linear characterization, the Control Command becomes 75 percent. Deviation

Control Command and Stem Position: Deviation = 75% - 50% = +25%,

Command source

Page 13

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Logix 3400IQ

Positioner

Positioner

Bolts

Nut

Lock Washer

Nut

Follower Pin

Take-off Arm

Bolts

Stem Clamp

Bracket

Bolts

Bracket

Locknut

Washer

Follower

Arm

Nut

Metal Washers

the stem moves, the Deviation begins to decrease. The control algorithm begins to reduce the spool

opening. This process continues until the

Deviation goes to zero. At this point, the spool will be

back in its null or balanced position. Stem movement will stop and the desired stem position is now

achieved.

One important parameter has not been discussed to this point: Inner loop offset. Referring to Figure

2, a number called Inner loop offset is added to the output of the control algorithm. In order for the

spool to remain in its null or balanced position, the control algorithm must output a non-zero spool

command. This is the purpose of the

Inner loop offset. The value of this number is equivalent to the

signal that must be sent to the spool position control to bring it to a null position with zero deviation.

This parameter is important for proper control and is optimized and set automatically during stroke

calibration.

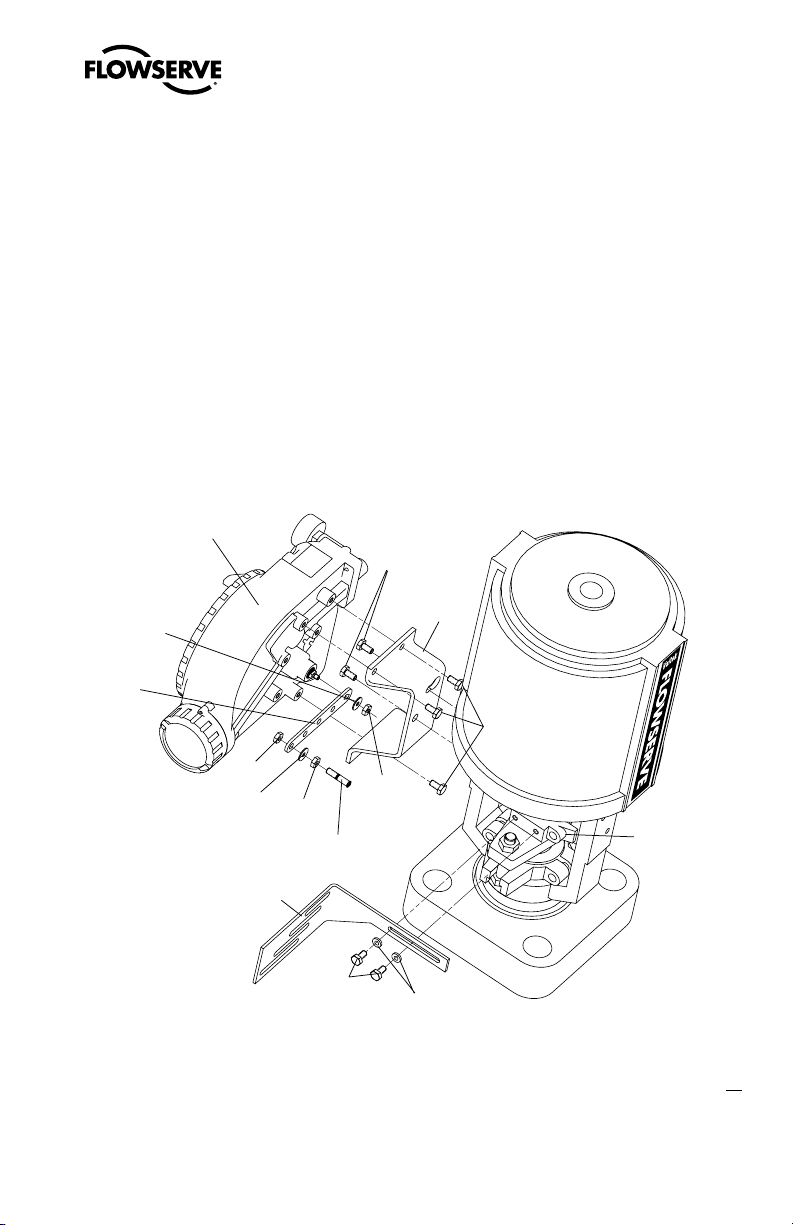

Figure 3: Linear Mark One Control Valve Mounting

13

flowserve.com

Page 14

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

5 Mounting and Installation

5.1 Mounting to Valtek Linear Mark One Valves

To mount a Logix 3400IQ positioner to a Valtek linear Mark One valve, refer to Figure 3 and proceed

as outlined below. The following tools are required:

• 9⁄16" open-end wrench (or ½" for spud sizes 2.88 and smaller)

• 7⁄16" box wrench

• 3⁄8" open-end wrench

1. Remove washer and nut from follower pin assembly. Insert pin into the appropriate hole in

follower arm, based on stroke length. The stroke lengths are stamped next to their corre

sponding holes in the follower arms. Make sure the unthreaded end of the pin is on the stamped

side of the arm. Reinstall lock washer and tighten nut to complete follower arm assembly.

2. Slide the double-D slot in the follower arm assembly over the flats on the position feedback shaft

in the back of the positioner. Make sure the arm is pointing toward the customer interface side

of the positioner. Slide lock washer over the threads on the shaft and tighten down the nut.

3. Align the bracket with the three outer mounting holes on the positioner. Fasten with ¼" bolts.

-

4. Screw one mounting bolt into the hole on the yoke mounting pad nearest the cylinder. Stop

when the bolt is approximately

5. Slip the large end of the teardrop shaped mounting hole in the back of the positioner/bracket

assembly over the mounting bolt. Slide the small end of the teardrop under the mounting bolt

and align the lower mounting hole.

6. Insert the lower mounting bolt and tighten the bolting.

7. Position the take-off arm mounting slot against the stem clamp mounting pad. Apply Loctite 222

to the take-off arm bolting and insert through washers into stem clamp. Leave bolts loose.

8. Slide the appropriate pin slot of the take-off arm, based on stroke length, over the follower arm

pin. The appropriate stroke lengths are stamped by each pin slot.

9. Center the take-off arm on the rolling sleeve of the follower pin.

10. Align the take-off arm with the top plane of the stem clamp and tighten bolting. Torque to 120

in-lb.

NOTE: If mounted properly, the follower arm should be horizontal when the valve is at 50%

stroke and should move approximately ±30° from horizontal over the full stroke of the valve.

14

If mounted incorrectly, a stroke calibration error will occur and the indicator lights will blink a

YRYR or YRRY code indicating the position sensor has gone out of range on one end of travel.

Reposition the feedback linkage or rotate the position sensor to correct the error.

3

⁄16" from being flush with mounting pad.

Page 15

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Positioner Bolts ¼-20 (4)*

* Located in ap propriate

hole pattern as indicated on

bracket. (25, 5 0, 100/200)

Take-off Arm, Rotary

Lock Washer (2)

10-32 Bolt

10-32 Nut

Self-tapping Screws (2)

Spline Lever Adapter

10-32 Nut

Lock Washer

Follower Arm

Logix 3400IQ

Digital Positioner

Bracket Bolts

-18 (2, not shown)

5

/

16

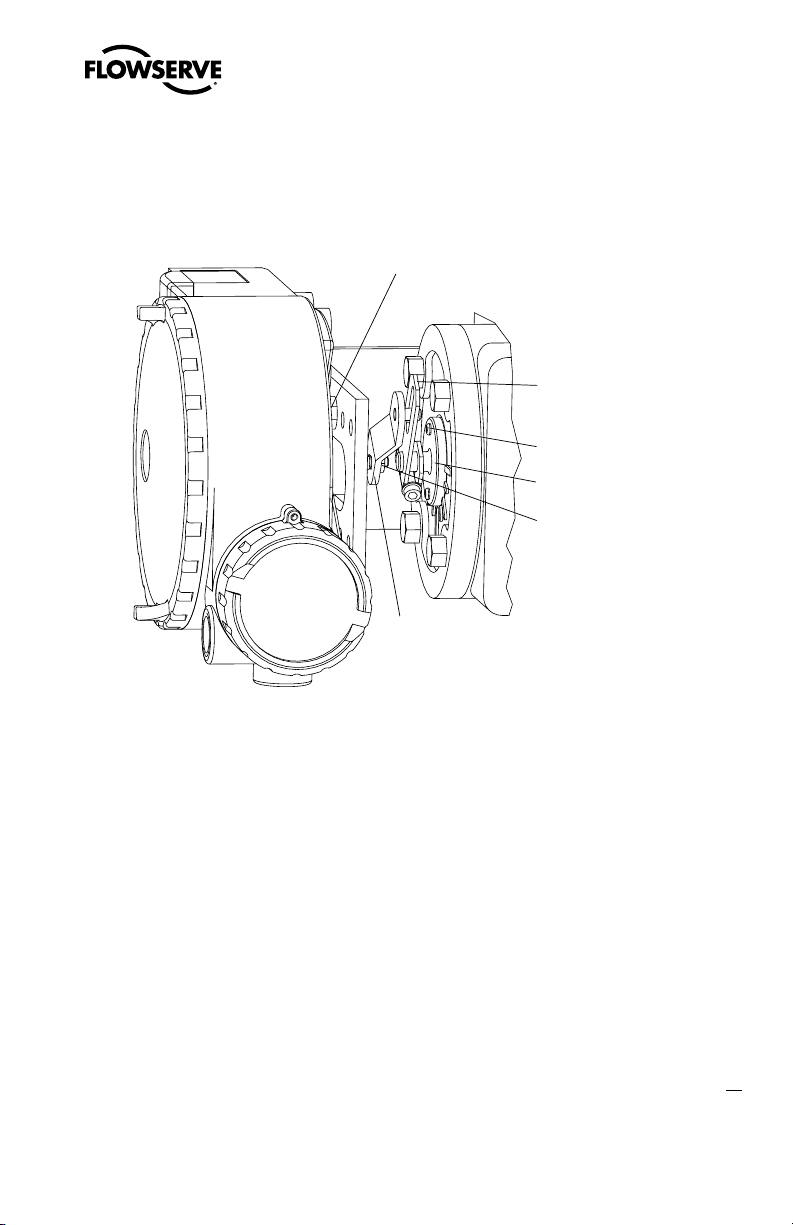

5.2 Mounting to Standard Valtek Rotary Valves (See Figure 4)

Figure 4: Standard Rotary Mounting

The standard rotary mounting applies to Valtek valve/actuator assemblies that do not have mounted

volume tanks or handwheels. The standard mounting uses a linkage directly coupled to the valve

shaft. This linkage has been designed to allow for minimal misalignment between the positioner and

the actuator. The tools required for the following procedure are:

• 5⁄32" Allen wrench

• ½" open-end wrench

• 7⁄16" open-end wrench

• 3⁄8" socket with extension

• 3⁄16" nutdriver

1. Fasten the spline lever adapter to the splined lever using two 6 x ½" self-tapping screws.

2. Slide the take-off arm assembly onto the spline lever adapter shaft. Insert the screw with star

washer through the take-off arm and add the second star washer and nut. Tighten nut with

socket so arm is lightly snug on the shaft but still able to rotate. This will be tightened after

linkage is correctly oriented.

3. Attach follower arm to positioner feedback shaft using the star washer and 10-32 nut.

flowserve.com

15

Page 16

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

NOTE: The arm will point up when feedback shaft is in the free position.

4. Using four ¼-20 x ½" bolts, fasten positioner to universal bracket using appropriate hole pattern

(stamped on bracket).

5

5. Using a ½" end wrench and two

⁄16-18 x ½" bolts, attach bracket to actuator transfer case pad.

Leave these bolts slightly loose until final adjustments are made.

6. Rotate take-off arm so the follower pin will slide into the slot on the take-off arm. Adjust the

bracket position as needed noting the engagement of the follower pin and the take-off arm

slot. The pin should extend approximately

1

⁄16" past the take-off arm. When properly adjusted,

securely tighten the bracketing bolts.

Orienting the Take-off Arm for Final Lock Down

1. Tube the Logix 3400IQ

positioner to the actuator according to the instructions given in Section

5.5, “Tubing Positioner to Actuator.”

2. With supply pressure off, rotate the follower arm in the same direction the shaft would rotate

upon a loss of supply pressure. When the mechanical stop of the follower arm (positioner) is

reached, rotate back approximately 15 degrees.

3. Hold the take-off arm in place; tighten the screw of the take-off arm.

NOTE: The take-off arm should be snug enough to hold the follower arm in place but allow

movement when pushed.

4. Connect regulated air supply to appropriate port in manifold.

5. Remove main cover and locate DIP switches and RE-CAL button.

6. Refer to sticker on main board cover and set DIP switches accordingly. (A more detailed

explanation of the DIP switch settings is given in Section 7, “Startup.”)

7. Press the RE-CAL button for three to four seconds or until the positioner begins to move. The

positioner will now perform a stroke calibration.

8. If the calibration was successful the green LED will blink GGGG or GGGY and the valve will be in

control mode. Continue with step 9. If calibration failed, as indicated by a YRYR or YRRY blink

code, the A/D feedback values were exceeded and the arm must be adjusted away from the

positioners limits. Return to step 2 and rotate the arm back approximately 10 degrees.

NOTE: Remember to remove the air supply before re-adjusting take-off arm.

9. Tighten the nut on the take-off arm. The socket head screw of the take-off arm must be tight,

about 40 in-lb.

16

NOTE: If the take-off arm slips, the positioner must be recalibrated.

Page 17

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

5SJQQFS

5SJQQFS$MBNQ

#PMUT

-PDLOVUT

5JF3PE

/VU

-PDL8BTIFS

#SBDLFU#PMUT

#BMM+PJOU&OET

'PMMPXFS"SN

3PUBUF1PTJUJPOFS¡

.PVOUJOH#PMUT

5JF3PENVTU CFDVUUPEFTJS FEMFOHUI

7BMUFL

WARNING: Failure to follow this procedure will result in positioner and/or linkage

c

damage. Check air-action and stroke carefully before lockdown of take-off arm to

spline lever adapter.

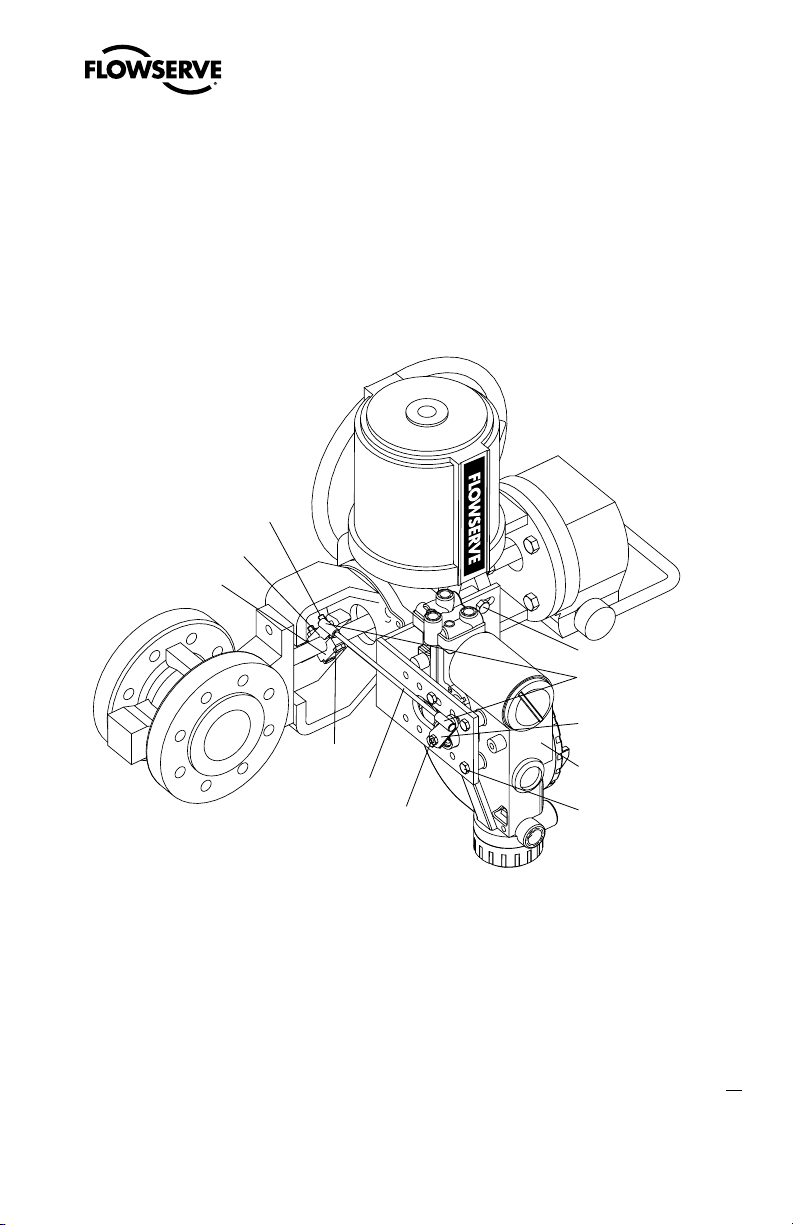

5.3 Optional Valtek Rotary Mounting Procedure (See Figure 5)

Figure 5: Optional Rotary Mounting

The optional rotary mounting applies to Valtek valve/actuator assemblies that are equipped with

mounted volume tanks or handwheels. The optional mounting uses a four-bar linkage coupled to the

valve shaft. The following tools are required:

• 3⁄8" open-end wrench

• 7⁄16" open-end wrench

• ½" open-end wrench

1. Using a ½" open-end wrench and two 5⁄16-18 x ½" bolts, attach bracket to actuator transfer case

pads. Leave bracket loose to allow for adjustment.

17

flowserve.com

Page 18

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

2. Using four ¼-20 x ½" bolts and a 7⁄16" open-end wrench, fasten positioner to universal bracket,

using the four-hole pattern that locates the positioner the farthest from the valve. Rotate

positioner 90 degrees from normal so gauges are facing upward.

3. Attach follower arm to positioner feedback shaft, using the star washer and 10-32 nut.

4. Attach tripper and tripper clamp to valve shaft using two ¼-20 bolts and two ¼-20 locknuts.

Leave tripper loose on shaft until final adjustment.

5. Thread ball joint linkage end to tripper and tighten (thread locking compound such as Loctite

is recommended to prevent back threading). Adjust the length of tie rod so follower arm and

tripper rotate parallel to each other (the rod must be cut to the desired length). Connect the

other ball joint end to follower arm using a star washer and a 10-32 nut.

6. Tighten bracket and tripper bolting.

7. Check for proper operation, note direction of rotation.

WARNING: If rotating in wrong direction, serious damage will occur to the positioner

c

and/or linkage. Check air action and stroke direction carefully before initiating

operation.

5.4 NAMUR Mounting Option

Logix 3200IQ is available with a NAMUR output shaft and mounts on an actuator using the ISO F05

holes. Proper alignment of the positioner shaft to the actuator shaft is very important since improper

alignment can cause excess wear and friction to the positioner.

5.5 Tubing Positioner to Actuator

The Logix 3400IQ digital positioner is insensitive to supply pressure changes and can handle supply

pressures from 30 to 150 psig. A supply regulator is recommended if the customer will be using

the diagnostic features of the Logix 3400IQ

pressure is higher than the maximum actuator pressure rating a supply regulator is required to lower

the pressure to the actuator’s maximum rating (not to be confused with operating range). An air filter

is highly recommended for all applications where dirty air is a possibility.

NOTE: The air supply must conform to ISA Standard ISA 7.0.01 (a dew point at least 18°F below

ambient temperature, particle size below five microns—one micron recommended—and oil content

not to exceed one part per million).

Air-to-open and air-to-close are determined by the actuator tubing, not the software. When air action

selection is made during configuration, that selection tells the control which way the actuator has

18

been tubed. The top output port is called

must receive air to begin the correct action on increasing signal. Verify that tubing is correct prior to

a stroke calibration. Proper tubing orientation is critical for the positioner to function correctly and

have the proper failure mode. Refer to Figure 1 and follow the instructions below:

but is not required. In applications where the supply

Output 1. It should be tubed to the side of the actuator that

Page 19

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Linear Double-acting Actuators

For a linear air-to-open actuator, the Output 1 port of the positioner manifold is tubed to the bottom

side of the actuator. The Output 2 port of the positioner manifold is tubed to the top side of the

actuator. For a linear air-to-close actuator the above configuration is reversed.

Rotary Double-acting Actuators

For a rotary actuator, the Output 1 port of the positioner manifold is tubed to the bottom side of the

actuator. The Output 2 port of the positioner manifold is tubed to the top side of the actuator. This

tubing convention is followed regardless of air action. On rotary actuators, the transfer case orienta

tion determines the air action.

Single-acting Actuators

For single-acting actuators, the Output 1 port is always tubed to the pneumatic side of the actuator

regardless of air action. The Output 2 port must be plugged.

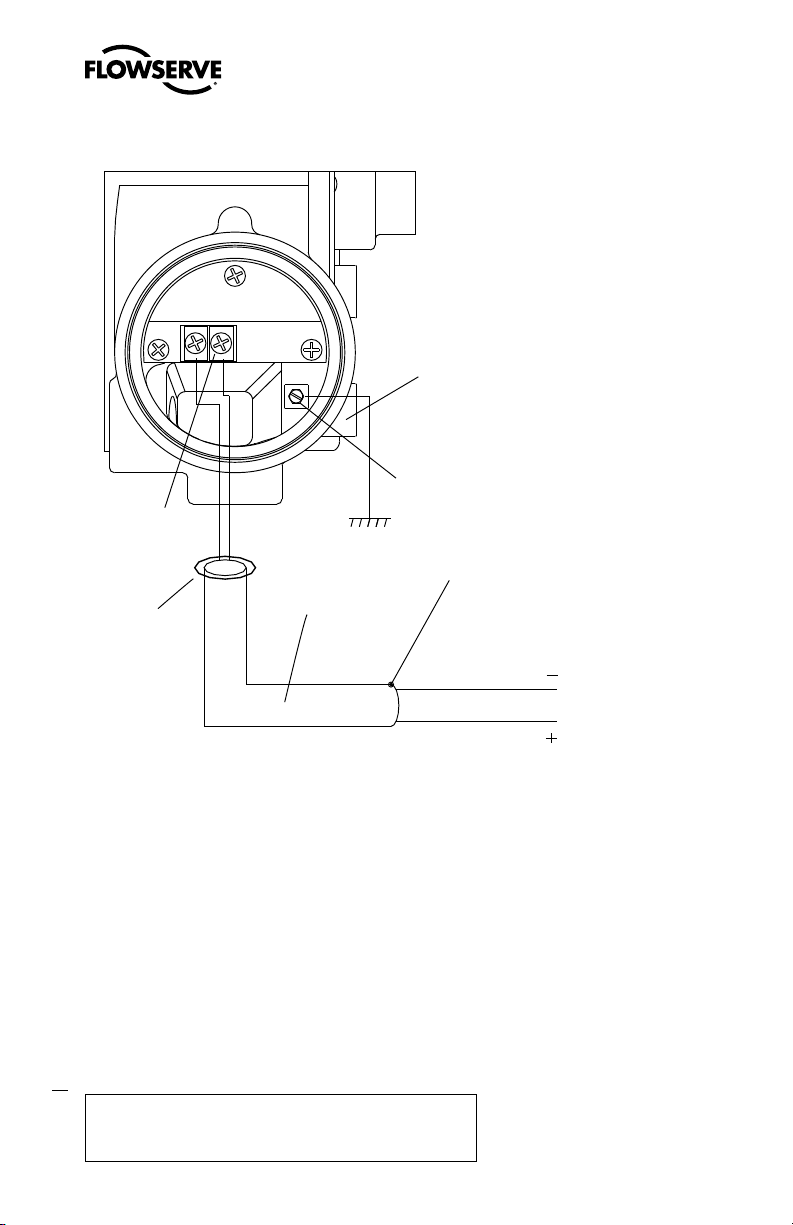

6 Wiring and Grounding Guidelines (See Figure 6)

WARNING: This product has electrical conduit connections in either thread sizes ½" NPT

c

or M20 which appear identical but are not interchangeable. Housings with M20 threads

are stamped with the letters M20 above the conduit opening. Forcing dissimilar threads

together will damage equipment, cause personal injury and void hazardous location

certifications. Conduit fittings must match equipment housing threads before installation. If

threads do not match, obtain suitable adapters or contact a Flowserve representative.

-

6.1 FF Command Input Wiring

The Logix 3400IQ is non-polarity sensitive. Wire FF source to the input terminals (see Figure 6).

Minimum operating voltage is 9 VDC.

The FF signal to the Logix 3400IQ digital positioner should be in shielded cable. Shields must be

tied to a ground at only one end of the cable to provide a place for environmental electrical noise

to be removed from the cable. In general, shield wire should be connected at the source. Refer to

guidelines in FF AG-181 for proper wiring methods.

NOTE: The Logix 3400IQ positioner carries an intrinsically safe barrier rating of 250 mA. Input

currents should not exceed 250 mA, 5 watts.

6.2 Grounding Screw

The green grounding screw, located inside the termination cap, should be used to provide the unit

with an adequate and reliable earth ground reference. This ground should be tied to the same ground

as the electrical conduit. Additionally, the electrical conduit should be earth grounded at both ends of

its run.

flowserve.com

19

Page 20

Figure 6: Field Termination

Shielded Cable

FF Signal

Connect Shield at Source

Housing EARTH

Terminal

External

Bonding

Location

FF Field

Terminators

Environmental

Seal

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

20

WARNING: The green grounding screw must not be used to terminate signal shield wires.

c

6.3 Segment Compliance Voltage (See Figure 7)

Output compliance voltage refers to the voltage limit that can be provided by the FF source. A FF

system consists of the FF source, wiring resistance, barrier resistance (if present), and the Logix

3400IQ positioner voltage. The Logix 3400IQ digital positioner requires that the system allows for a

9.0 VDC drop across the positioner at minimum segment voltage. The actual voltage at the terminals

varies from 9.0 to 32.0 VDC depending on the FF signal and ambient temperature.

Determine if the segment will support the Logix 3400IQ

digital positioner by performing the following

calculation.

Voltage = Compliance Voltage (@ 23 mA) –

23 mA • (R

barrier

+ R

)

wire

Equation 1

Page 21

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

+

-

R

barrier

(if present)

R

wire

FF

Signal

Source

Compliance

Voltage

Logix

3400IQ

Current

23 mA

9 VDC min

The calculated voltage must be greater than 9 VDC in order to safely support the Logix 3400IQ digital

positioner.

Example:

DCS Compliance Voltage = 19 VDC

R

= 300 Ω

barrier

R

= 25 Ω

wire

Current

= 23 mA

max

Voltage = 19 VDC – 0.023 A • (300 Ω + 25 Ω) = 11.5 VDC

The voltage 11.5 VDC is greater than the required 9.0 VDC; therefore, this system will support the

Logix 3400IQ

digital positioner.

Figure 7: Compliance Voltage

6.4 Cable Requirements

The Logix 3400IQ digital positioner utilizes the FF protocol. This communication signal is superimposed on the supply voltage.

FF rated cable should be used. Refer to H1 wiring specification.

6.5 Intrinsically Safe Barriers

When selecting an intrinsically safe barrier, make sure the barrier is FF compatible. Although the

barrier will pass the segment voltage and allow normal positioner operation, if not compatible, it may

prevent FF communication.

6.6 DD Support

The DD for the Logix 3400IQ can be downloaded from either the flowserve website: www.flowserve.

com or the F

oundation Fieldbus website: www.Fieldbus.org.

21

flowserve.com

Page 22

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

LEDs

DIP Switch Block

Jog Buttons

Rotary

Selector

Switch

RE-CAL Button

7 Startup

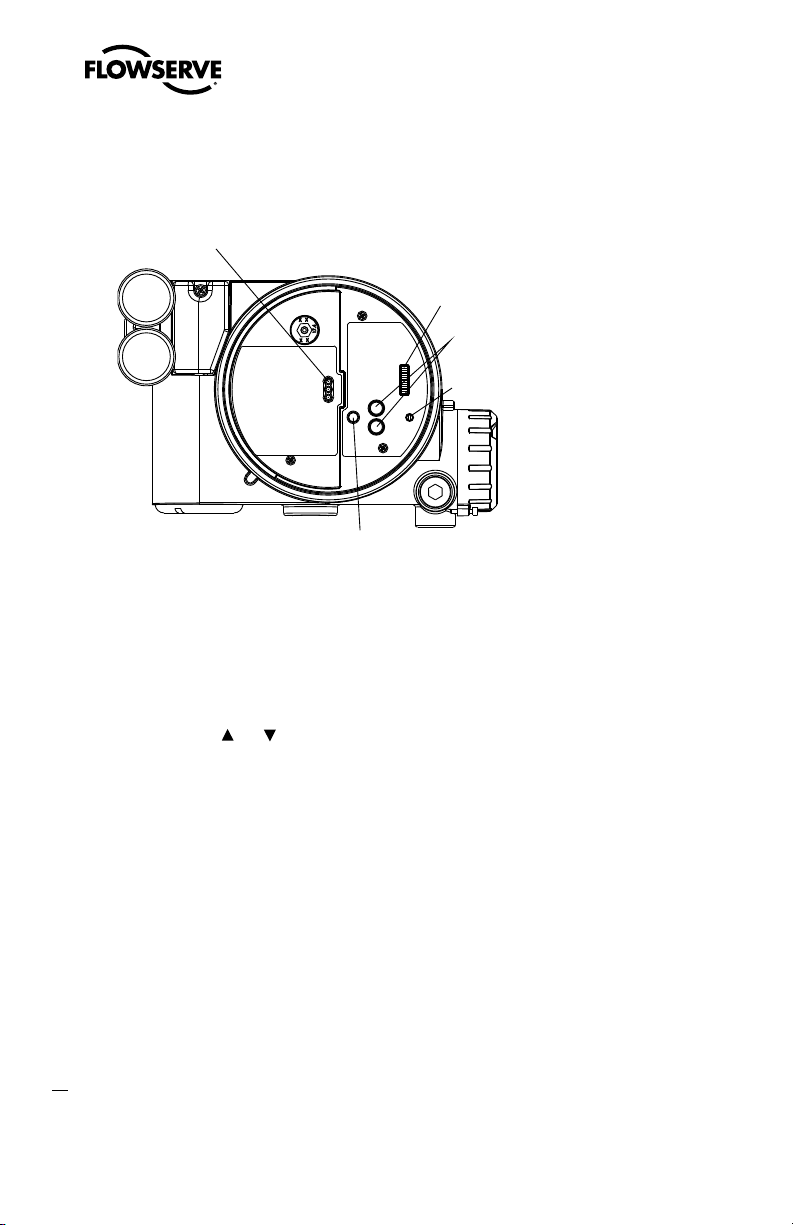

Figure 8: Local User Interface

7.1 Logix 3400IQ Local Interface Operation

The Logix 3400IQ local user interface (Figure 8) allows the user to configure the basic operation of

the positioner, tune the response, and calibrate the positioner without additional tools or configura

tors. The local interface consists of a RE-CAL button for automatic zero and span setting, along

with two jog buttons (

position. There is also a DIP switch block containing eight switches. Six of the switches are for basic

configuration settings and two are for FF options. There is also a rotary selector switch for adjusting

the positioner gain settings. For indication of the operational status or alarm conditions there are

three LEDs on the local user interface.

and ) for spanning valve/actuators with no fixed internal stop in the open

-

7.2 Initial DIP Switch Settings

Before placing the unit in service, set the DIP switches in the Configuration boxes to the desired

control options. A detailed description of each DIP switch setting follows.

NOTE: The Logix 3400IQ positioner reads the DIP switch settings each time the RE-CAL button is

pressed. If a FF handheld or Host software is used to configure and then calibrate the positioner, the

DIP switches are not read. The auto-tune adjustment switch labeled “GAIN” is always live and can be

adjusted at any time.

22

Transducer block settings will always override the DIP switch settings until the RE-CAL button is

pressed.

Page 23

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

7.3 Description of Configuration DIP Switch Settings

The first six DIP switches are for basic configuration. The function of each switch is described below.

Air Action

This must be set to match the configuration of the valve/actuator mechanical tubing connection and

spring location since these determine the air action of the system.

ATO (air-to-open)

Selecting ATO if increasing output pressure from the positioner is tubed so it will cause the valve to

open.

ATC (air-to-close)

Selecting ATC if increasing output pressure from the positioner is tubed so it will cause the valve to

close.

Pos. Characterization

Linear Select

Linear if the actuator position should be directly proportional to the input signal.

Other Select

Flags parameter in the transducer block.

Optional Pos. Characterization

If the Pos. Characterization switch is set to Other then this parameter is active with the following

options:

=% The =% option will characterize the actuator response to the input signal based on a standard 30:1

equal percent rangeability curve.

QO Quick open is based on a standard industry quick-open curve.

Custom If

set-up using a properly configured 375 handheld or other host software.

can be thought of as a “soft CAM.” The user can define a characterization curve using 21 points. The

control will linearly interpolate between points. Points do not have to be equally spaced in order to

allow more definition at critical curve areas. The default values will linearize the output of a valve with

an inherent =% characteristic (e.g. ball valves.)

Other if another characteristic is desired, which is set in conjunction with the Control_

Custom is selected, the positioner will be characterized to a custom table that must be

Custom characterization

23

flowserve.com

Page 24

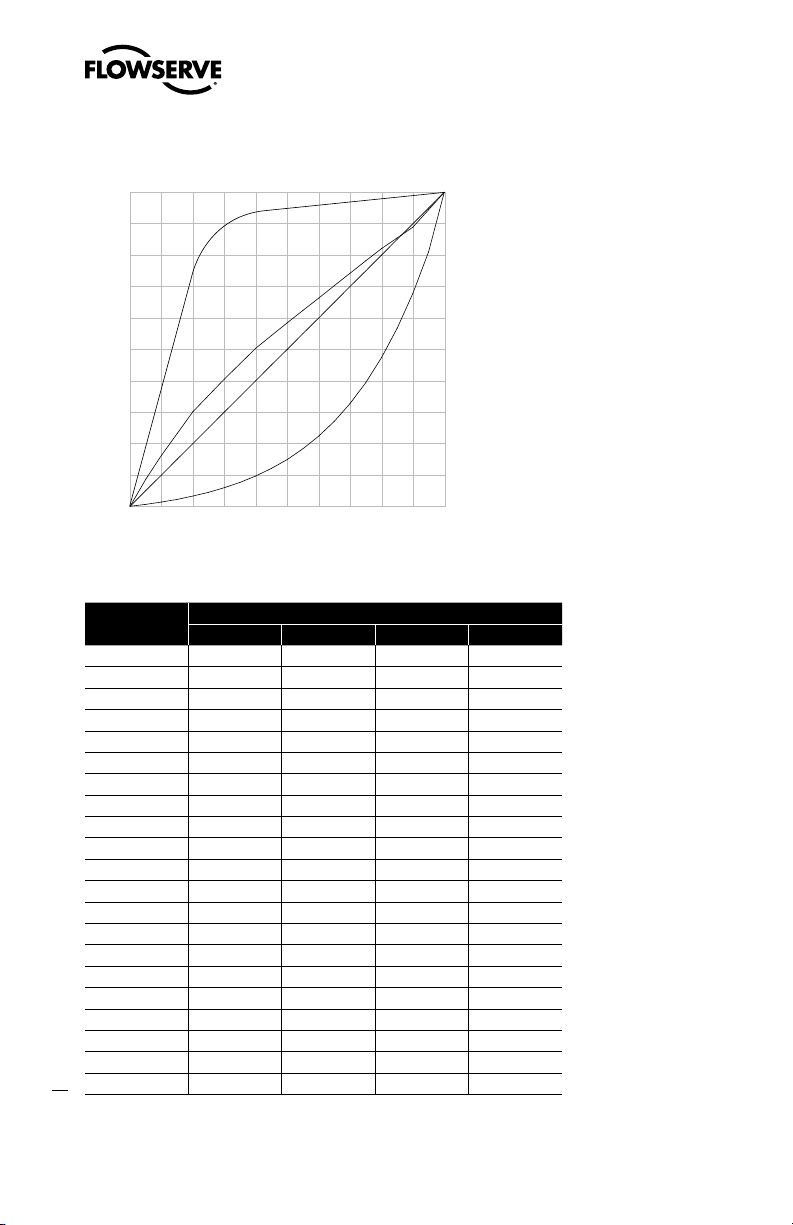

Figure 9: Default Custom Characterization

% Command

% Control Command

0 10 20 30 40 50 60 70 80 90 100

0

10

20

30

40

50

60

70

80

90

100

=%

Linear

Custom

Quick Open

Table VI : Characteristic Curve Data

% Command

0 0 0 0 0

5 0.62 5 8.66 18.8

10 1.35 10 16.24 37.6

15 2.22 15 23.17 56.4

20 3.25 20 30.11 74.0

25 4.47 25 35.31 84.3

30 5.91 30 40.51 90.0

35 7.63 35 45.42 92.0

40 9.66 40 50.34 93.4

45 12.07 45 54.40 94.2

24

50 14.92 50 58.47 94.8

55 18.31 55 62.39 95.5

60 22.32 60 66.31 96.0

65 27.08 65 70.27 96.5

70 32.71 70 74.23 97.0

75 39.40 75 78.17 97.5

80 47.32 80 82.11 98.0

85 56.71 85 85.50 98.5

90 67.84 90 88.89 99.0

95 81.03 95 94.45 99.5

100 100.00 100 100.00 100.0

=% Linear Custom QO

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

% Control Command

Page 25

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

A

GAIN

B

C

D

E

F

G

H

Auto Tune

This switch controls whether the positioner will auto tune itself every time the RE-CAL button is

pressed or use preset tuning parameters.

On

On enables an auto tune feature that will automatically determine the positioner gain settings

based on the current position of the adjustable GAIN switch setting and response parameters

measured during the last RE-CAL. The GAIN switch is live, meaning the settings can be adjusted at

any time by changing the rotary switch position. (Note that there is a small black arrow indicating the

selection. The slot in the switch is NOT the indicator.)

Figure 10: Adjustable GAIN Switch

If the adjustable GAIN selector switch is set to “E” with the auto tune switch on, a Flowserve standard

response tuning set will be calculated and used based on response parameters measured during the

last RE-CAL.

If the adjustable GAIN selector switch is set to “D”, “C”, “B”, or “A” with the auto tune switch on,

progressively lower gain settings will be used based on response parameters measured during the

last RE-CAL.

If the adjustable GAIN selector switch is set to “F”, “G”, or “H” with the auto tune switch on, progres

sively higher gain settings will be calculated and used based on response parameters measured

during the last RE-CAL.

Off Off forces the positioner to use one of the factory preset tuning sets determined by the

adjustable GAIN selector switch. Settings “A” through “H” are progressively higher gain predefined

tuning sets. The GAIN selector switch is live and can be adjusted at any time to modify the tuning

parameters.

NOTE: “E” is the default adjustable GAIN selector switch setting for all actuator sizes. Raising or

lowering the gain setting is a function of the positioner/valve response to the control signal, and

is not actuator size dependent.

Stability Switch

This switch adjusts the position control algorithm of the positioner for use with low-friction control

valves or high-friction automated valves.

Low-Friction Valves Placing the switch to the left optimizes the response for low-friction, highperformance control valves. This setting provides for optimum response times when used with most

low-friction control valves.

flowserve.com

25

Page 26

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

High-Friction Valves Placing the switch to the right optimizes the response for valves and actuators with high friction levels. This setting slightly slows the response and will normally stop limit

cycling that can occur on high-friction valves.

7.4 Description of Cal DIP Switch Settings

The sixth DIP switch selects between two calibration options. The function of the Cal DIP switch is

described below.

NOTE: The unit must be in OOS mode before a calibration sequence can begin.

Auto Select

mode the positioner will fully

the stop to register the 100% position when performing a self-calibration. See detailed instructions in

the next section on how to perform an auto positioner calibration.

Jog Select

In the

to set the open position using the Jog buttons labeled with the up and down arrows. See the detailed

instructions in Section 7.6 on how to perform a manual calibration using the Jog buttons.

Auto if the valve/actuator assembly has an internal stop in the open position. In Auto

close the valve and register the 0% position and then open the valve to

Jog if the valve/actuator assembly has no physical calibration stop in the open position.

Jog mode the positioner will fully close the valve for the 0% position and then wait for the user

WARNING: During the RE-CAL operation the valve may stroke unexpectedly. Notify

c

proper personnel that the valve will stroke, and make sure the valve is properly

isolated.

7.5 RE-CAL Operation

NOTE: The unit must be in OOS mode before a calibration sequence can begin.

The RE-CAL button is used to locally initiate a calibration of the positioner. Pressing and holding the

RE-CAL button for approximately three seconds will initiate the calibration. If the Config-Switches

option is enabled, the settings of all the configuration switches are read and the operation of the

positioner adjusted accordingly. A RE-CAL can be aborted at any time by briefly pressing the RE-CAL

button and the previous settings will be retained.

If the Quick Calibration switch (be careful not to confuse this with the RE-CAL button) is set to

Auto and the valve/actuator assembly has the necessary internal stops the calibration will complete

automatically. While the calibration is in progress you will notice a series of different lights flashing

indicating the calibration progress. When the lights return to a sequence that starts with a green light

the calibration is complete. An explanation of the various light sequences follows. The initial calibra

tion of extremely large or small actuators may require several calibration attempts. The positioner

adapts to the actuator performance and begins each calibration where the last attempt ended. On an

initial installation it is recommended that after the first successful calibration that one more calibra

26

tion be completed for optimum performance.

-

-

Page 27

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

WARNING: When operating using RE-CAL or local control, the valve will not respond to

c

external commands. Notify proper personnel that the valve will not respond to remote

command changes, and make sure the valve is properly isolated.

7.6 Manual Jog Calibration Operation

If the Quick Calibration switch is set to Jog, the calibration will initially close the valve then cause

a small jump in the valve position. The jog calibration process will only allow the user to manually

set the span; zero position is automatically always set at the seat. If an elevated zero is needed a

handheld or other PC-based configuration software is required. When performing a jog calibration,

the LEDs will flash in a sequence of Y-R-R-G (yellow-red-red-green) which indicates that the user

must use the Jog buttons (

stem is properly positioned press both the Jog buttons (

the 100% position and proceed. No more user actions are required while the calibration process

is completed. When the lights return to a sequence that starts with a green light the calibration is

complete. An explanation of the various light sequences follows.

and ) to manually position the valve to the 100% position. When the

and ) simultaneously again to register

7.7 Local Control of Valve Position

Local control of valve position can be achieved from the user interface by holding down both Jog

buttons and the RE-CAL button simultaneously for three seconds. While in this mode the LEDs will

flash a YGRR (yellow-green-red-red) sequence. Use the two Jog buttons (

control the position of the valve. To exit the local control mode and return to normal operation, briefly

press the RE-CAL button.

and ) to manually

7.8 Factory Reset

To perform a factory reset, disconnect power, hold the RE-CAL button down, and reconnect power.

Performing a factory reset will cause all of the internal variables, including calibration, to be reset

to factory defaults. The positioner must be recalibrated after a factory reset. User configured limits,

alarm settings, and valve information will also need to be restored.

WARNING: Performing a factory reset may result in the inability to operate the valve until

c

reconfigured properly. Notify proper personnel that the valve may stroke, and make sure the

valve is properly isolated.

7.9 Logix 3400IQ Status Condition

The blink codes used to convey the status of the Logix 3400IQ digital positioner are described in the

table below. In general, any sequence starting with a green light flashing first is a normal operating

mode and indicates that there are no internal problems. Any sequence starting with a yellow light

flashing indicates that the unit is in a special calibration or test mode, or that there was a calibra

-

flowserve.com

27

Page 28

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

tion problem. Any sequence starting with a red light flashing indicates that there is an operational

problem with the unit.

Table VII: Status and Conditions

Indication and Resolution

Colors

Identifier

G - - - Any sequence starting with a green light flashing first is a normal operating mode and

GGGG 1 Normal operation No errors, alerts, or warnings.

GGGY 2 Final Value cutoff active The command is below or above the user-set limits for tight

GGYR 4 Initializing This sequence should only be visible for three sequences when powering up

GGRG 5 Cycle limit exceeded (user-set) The cycle limit set by the user has been exceeded. To clear

GGRY 6 Travel limit exceeded (user-set) The total accumulated travel limit set by the user has been

GYYR 7 Soft Stop Low (user-set) The unit is being commanded to exceed a user-defined lower

GYRY 8 Soft Stop High (user-set) The unit is being commanded to exceed a user-defined upper

GRYR 9 Posalert Low (user-set) The position has reached or is exceeding a user-defined lower

GRRY 10 Posalert High (user-set) The position has reached or is exceeding a user-defined upper

Y - - -

YGYG 11 Signature test in progress This is a test initiated by Host software that can only be

YRGG 13 Stroke calibration in progress Calibration sequence started either using the local RE-CAL

28

Continued on page 29

indicates that there are no internal problems.

shutoff feature. This is a normal condition for a closed valve. The factory default setting is 1%

and 110% command. To clear the condition use handheld or Host software to reset the tight

shutoff if the range is incorrect or adjust the command signal above the specified Final Value

cutoff.

the unit.

use handheld or Host software to reset.

exceeded. To clear use handheld or Host software to reset.

position limit and the internal software is holding the position at the limit. The function is

similar to a mechanical limit stop except it is not active if the unit is un-powered. To clear the

condition use handheld or Host software to reset the limit if more travel is needed or adjust

the command signal back in the specified range.

position limit and the internal software is holding the position at the limit. The function is

similar to a mechanical limit stop except it is not active if the unit is un-powered. To clear the

condition use handheld or Host software to reset the limit if more travel is needed or adjust

the command signal back in the specified range.

position indicator similar to a limit switch indicator. To clear the condition use handheld or

Host software to reset the indicator if more travel is needed or adjust the command signal

back in the specified range.

position indicator similar to a limit switch indicator. To clear the condition use handheld or

Host software to reset the indicator if more travel is needed or adjust the command signal

back in the specified range.

Any sequence starting with a yellow light indicates that the unit is in a special calibration

or test mode, or that there was a calibration problem.

cancelled by that software.

button or by a handheld or Host software. It may be cancelled by briefly pushing the RE-CAL

button.

Page 29

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Table VII: Status and Conditions (continued)

Indication and Resolution

Colors

Identifier

YGRR 14 Local jog control mode The unit has been placed in a local override mode where the valve

YYGR 15 Pressure calibration in progress Calibration sequence controlled by a handheld or Host

YYYY 16 Local user interface disabled Host software has been used to disable the local interface. If

YRRG 17 Waiting Adjust to full open position setting from User—only used during Jog calibration

YRYG 18 Setting IL offset while calibrating An automatic step in the calibration process that is done

YRYY 19 No feedback motion while calibrating Indicates that there was no motion of the actuator

YRYR 20 Feedback 0% out of range Calibration error indicating that the position sensor was out

YRRY 21 Feedback 100% out of range Calibration error indicating that the position sensor was

YRRR 22 Feedback span too small The range of motion of the position feedback arm was too small

YRGR 23 Feedback unstable while calibrating Check for loose linkages or loose positioner sensor.

R - - -

RGRR 24 Position deviation (user-set) The position has exceeded user-defined error band between

RGYY 25 Pressure reading out of range The internal pressure sensors are either saturated with a

Continued on page 30

can only be stroked using the two local jog buttons. It may be cancelled by briefly pushing the

RE-CAL button.

software that can only be cancelled by that software.

local control is desired then the local interface must be re-enabled from the remote software.

This code is only present for a short time when the RE-CAL button is pressed.

see explanation in Section 7.5, “RE-CAL,” for operation.

with the valve at 50% position. This must be completed for proper calibration.

based on the current stroke time configuration. Check linkages and air supply to make sure

the system is properly connected. If the time out occurred because the actuator is very large

then simply retry the RE-CAL and the positioner will automatically adjust for a larger actuator

by doubling the time allowed for movement. This error may be cleared by briefly pushing

the RE-CAL button, which will force the positioner to use the parameters from the last good

calibration.

of range during the calibration of the closed position. To correct the condition, adjust the

positioner mounting, linkage or feedback potentiometer to move the position sensor back into

range then restart the calibration. This error may be cleared by briefly pushing the RE-CAL

button, which will force the positioner to use the parameters from the last good calibration.

out of range during the calibration of the open position. To correct the condition, adjust the

positioner mounting, linkage or feedback potentiometer to move the position sensor back into

range then restart the calibration. This error may be cleared by briefly pushing the RE-CAL

button, which will force the positioner to use the parameters from the last good calibration.

for optimum performance. Check for loose linkages and/or adjust the feedback pin to a position closer to the follower arm pivot to create a larger angle of rotation and recalibrate. Briefly

pushing the RE-CAL button acknowledges this condition and the positioner will operate using

the current short stroke calibration if otherwise a good calibration.

This error may be cleared by briefly pushing the RE-CAL button, which will force the

positioner to use the parameters from the last good calibration. This error may appear on

some very small actuators during the initial calibration. Redoing the calibration may clear the

problem.

Any sequence starting with a red light indicates that there is an operational problem with

the unit.

command and position.

pressure over 150 psi or the sensor has failed. Check supply pressure and if OK check the

pressure sensor board connections and replace pressure sensor board if necessary.

29

flowserve.com

Page 30

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Table VII: Status and Conditions (continued)

Indication and Resolution

Colors

Identifier

RGYR 26 Loss of supply pressure The Positioner has determined that the supply pressure is below

RYGG Factory reset condition Recalibrate.

RYYY 27 Pilot relay non-motion alert Check to make sure the air supply is connected. Also check

15 psi. Check the supply pressure and if OK check the pressure sensor board connections

and replace pressure sensor board if necessary. Minimum recommended supply pressure is

30 psi for proper operation.

the internal wiring harnesses for good connections. This error may be cleared by briefly

pushing the RE-CAL button, which will force the positioner to use the parameters from the

last good calibration. If the positioner still does not operate replace the pneumatic relay

assembly.

RRGG 30 Watchdog timer timeout (also listed as internal voltage reference) This is often caused

RRYG 31 Internal temperature alert The internal positioner temperature is currently exceeding

RRYY 32 Piezo voltage error Bad electronic assembly, replace.

RRYR 33 Internal voltage reference error Indicates that the circuit board is drawing too much

RRRG Loss of Inter-PCB Communications Cycle power to restart.

RRRY 34 NV RAM checksum error The checksum of the internal data was not updated correctly.

when intermittent operation occurs when connecting power. Remove power and then reconnect to clear. If problem persists it is a bad electronic assembly, replace.

operational limits of -40ºF (-40ºC) or 185ºF (85ºC).

power. Check internal wiring and connectors for electrical shorts—if no shorts are present,

replace the electronic assembly.

Cycle power and complete a RE-CAL if error persists. Check internal data to verify correct

settings. If the error still occurs, replace the electronic assembly.

7.10 Version Number Checking

The version number of the embedded code may be checked at any time except during a calibration

by holding down the up arrow Jog button (

to change the blink sequence to three blinks indicating the major version number. Holding the down

arrow Jog button (

) will give the minor version number without affecting operation. The version

codes are interpreted by adding up the numbers assigned according to the following table:

Color First blink value Second blink value Third blink value

Green 0 0 0

Yellow 9 3 1

Red 18 6 2

30

). This will not alter the operation of the unit other than

Page 31

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

For example if holding the up arrow Jog button ( ) gave a G-G-R code, and holding the down arrow

Jog button (

version 2.12.

) gave a Y-Y-G code then the resulting version number would be (0+0+2).(9+3+0) or

7.11 375 Handheld Communicator

The Logix 3400IQ Quick Start Guide is available from a Flowserve representative.

The Logix 3400IQ

The Device Description (DD) files and the manuals listed below can be obtained from the FF

Foundation or from your Flowserve representative. For more information please see the following

guides:

• Product Manual for the 375 Communicator.

• Logix 3400IQ

Diagnostic features such as the signature tests and ramp tests are performed internally. Certain

calibration features such as actuator pressure sensor calibrations are performed using the 375

Handheld Communicator or using the Host software.

digital positioner supports and is supported by the 375 Handheld Communicator.

Digital Positioner Reference Manual.

7.12 Device Description (DD) Files

The DD files for the Logix 3400 can be downloaded from the Flowserve website, http://fcd.flowserve.

com/valves/softwareDownload.jsp, or the Foundation Fieldbus website, www.fieldbus.org.

7.13 Calibration

7.13.1 CALIBRATE_FLAGS

Position 0% Calibration Flag in CALIBRATE_FLAGS

During stroke calibration, the Logix 3400 digital positioner checks to see if the linkage is placing the

stem position sensor in range. If the valve stroke causes stem position measurement to go out of

range in the closed position, a Position 0% Flag will be generated. The valve stem will stop in the

closed position and the red LED will blink. Linkage must be adjusted to bring the sensor in range.

Special LED indication: If the linkage is out of range, the LEDs can be used as an adjustment guide.

The LED will change from a red to yellow when the linkage is brought into range.

Position 100% Calibration Flag in CALIBRATE_FLAGS

During stroke calibration, the Logix 3400IQ digital positioner checks to see if the linkage is placing

the stem position sensor in range. If the valve stroke causes stem position measurement to go out

of range in the open position, a Position 100% Flag will be generated. The valve stem will stop in

the open position and the red LED will blink. Linkage must be adjusted to bring the sensor in range.

Special LED indication: If the linkage is out of range, the LEDs can be used as an adjustment guide.

The LED will change from a red to yellow when the linkage is brought into range.

flowserve.com

31

Page 32

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Position Span Flag in CALIBRATE_FLAGS

Position span is a check during stroke calibration to verify that the valve stem moved. The algorithm

waits to see if no movement is detected when the valve is automatically stroked open. Anything

that could prevent the valve from stroking will generate a Position Span error (no supply pressure,

malfunctioning spool valve).

7.13.2 Control and Tuning

Setting P + I Parameters

Using the Host configurator, you can set individual tuning parameters. A few key points are

mentioned below. (See Figure 11

GAIN_UPPER, GAIN_LOWER, and GAIN_MULT: These three parameters are related by the following

formula.

Proportional Gain =

Maximum Gain - | deviation | x Gain Multiplier

If Proportional Gain < Minimum Gain, then Proportional Gain = Minimum Gain

This algorithm allows for quicker response to smaller steps yet stable control for large steps. Setting

the gain multiplier to zero and max gain = min gain results in a typical fixed proportional gain.

The higher the gain multiplier, the larger the required deviation before the gain increases. Default

values upon initiating a RESET to factory defaults (under LOAD_EE_DEFAULTS) are maximum gain =

2.0, minimum gain= 1.0, and gain multiplier= 0.05. These values will allow stable control on all Valtek

control product actuator sizes.

.)

Integral Gain (IGAIN): The integral gain is primarily for deviations due to temperature drift within

the inner loop spool control. The factory default value is 10. Although higher numbers can speed

the time it takes to reach zero deviation, it can add overshoot if too large. It is recommended that

maximum and minimum gains be adjusted while leaving integral gain fixed at 10. Integration is

disabled below a stem position of 3 percent and above a stem position of 97 percent. This is to

prevent integration windup from calibration shifts due to lower pressure or a damaged seat that may

prevent fully closing the valve.

Integration Summer: The integral summer within the Logix 3400IQ digital positioner is clamped

at +20 percent and -20 percent. If the integration summer is fixed at +20 percent or -20 percent,

it usually indicates a control problem. Some reasons for a clamped integration summer are listed

below:

• Stroke calibration incorrect.

• Any failure which prevents stem position movement: stuck spool, handwheel override, low

pressure.

32

• Incorrect inner loop offset.

• Loss of air supply on a fail in place actuator.

Page 33

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Writing a zero to integral gain (IGAIN) will clear the integral summer. The integral gain can then be

returned to its original value.

Inner loop offset (IL_OFFSET): Three control numbers are summed to drive the inner loop spool

position control: proportional gain, integral summer, and inner-loop offset.

Inner-loop offset is the parameter that holds the spool in the ‘null’ or ‘balance’ position with a control

deviation of zero. This value is written by the positioner during stroke calibration and is a function of

the mechanical and electrical spool sensing tolerances. However, if it becomes necessary to replace

the driver module assembly or the software RESET calibration constants has been performed, it may

be necessary to adjust this value. The method below should be used to adjust inner-loop offset.

Or simply perform a new stroke calibration.

From the fieldbus configurator:

• Set transducer block to OOS

• Enable Diagnostic Variable access in TEST_MODE

• Send a 50 percent command.

• Set integral to zero.

• Locate the DAC_PERCENT

• Write this percentage value to IL_OFFSET

• Write original value to Integral

These tuning sets can be used to obtain initial values for Flowserve products and comparable

actuator sizes. The user may need to adjust this tuning to achieve optimal performance for a

particular application.

Table VIII: Factory Tuning Sets

Mfg. Tuning Set

VFactory_A 1.0 2.0 0.05 10 25

VFactory_B 1.0 2.5 0.05 10 50

VFactory_C 2.0 3.0 0.05 10 100

Valtek

Kammer

Automax

VFactory_D 4.0 5.0 0.05 10 200

VFactory_E 4.0 7.0 0.05 10 300

Trooper 48 0.4 0.5 0.05 25 31

Trooper 49 3.0 4.0 0.05 10 77.5

Trooper 48 0.4 0.5 0.05 25 31

Trooper 49 3.0 4.0 0.05 10 77.5

GAIN_

LOWER

R1 0.3 0.5 0.05 10 3 to 5

R2 1.0 1.5 0.05 10 9 to 12

R3 1.3 2.0 0.05 10 16 to 19

R4 2.0 2.5 0.05 10 27 to 37

R5 2.5 3.6 0.05 10 48 to 75

R6 4.0 5.0 0.05 10 109

GAIN_

UPPER

GAIN_

MULT

lgain

Comparable

Size (in2)

33

flowserve.com

Page 34

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

Sensor

-

+

+

+

+

Summer

Integration

I

Offset

Loop

Inner

+

-

Gmult

Pmin

Pmax

Deviation

FOUNDATION

Fieldbus

Signal

Command In

(AO Block)

FOUNDATION

Fieldbus

Transducer

Block

CONTROL

COMMAND

Output

D/A

Percentage

Algorithm

Control

Supply

Air

Control

Spool

Loop

Inner

ATO

Tubed

Sensor

Position

Stem

Voltage

Valve

Piezo

MPC

Soft Limits

Characterization

Linear Mode

Output

Inner-Loop

Figure 11: Logix 3400 Block Diagram

34

Page 35

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

7.14 Alerts

7.14.1 FINAL_VALUE_CUTOFF

The FINAL_VALUE_CUTOFF or tight shutoff feature of the Logix 3400IQ digital positioner allows the

user to control the level at which the command signal causes full actuator saturation in the closed or

open position.

This feature can be used to guarantee actuator saturation in the closed or open position or prevent

throttling around the seat at small command signal levels. To enable, use configuration to apply the

desired FINAL_VALUE_CUTOFF threshold.

NOTE: The positioner automatically adds a 1 percent hysteresis value to the FINAL_VALUE_CUTOFF_

LO setting to prevent jumping in and out of saturation when the command is close to the setting.

7.14.2 Effects of FINAL_VALUE_CUTOFF on Operation

With the FINAL_VALUE_CUTOFF_LO set at 5 percent the positioner will operate as follows: Assume

that the present command signal is at 50 percent. If the command signal is decreased, the positioner

will follow the command until it reaches 5 percent.

At 5 percent, full actuator saturation will occur. The actuator will maintain full saturation below 5

percent command signal. Now, as the command increases, the positioner will remain saturated until

the command reaches 6 percent (remember the 1 percent hysteresis value added by the positioner).

At this point, the stem position will follow the command signal.

If the FINAL_VALUE_CUTOFF_LO is set to 3 percent but the valve will not go below 10 percent,

SOFTSTOP_LOW may be enabled. The lower soft limit must be less than or equal to 0 percent in

order for the FINAL_VALUE_CUTOFF_LO to become active.

If soft stops are active (ie: SOFTSTOP_LOW = 0 or SOFTSTOP_HIGH = 100) FINAL_VALUE_CUTOFF

is disabled.

7.14.3 Soft Limits

Unlike position alerts, soft limits prevent the stem position from going below or above the configured

limits. If the command signal is trying to drive the position past one of the limits, the yellow LED will

blink but the stem position will remain at the set limit.

7.14.4 Travel Accumulator

The travel accumulator is equivalent to a car odometer and sums the total valve movement. Using the

user defined stroke length and travel dead-band, the Logix 3400IQ digital positioner keeps a running

total of valve movement. When the positioner first powers up, high and low dead-band limits are

calculated around the present position. When the stem position exceeds the travel dead-band, the

movement from the center of the deadband region to the new position is calculated and added to the

travel accumulator. From this new position, deadband high and low limits are again calculated.

flowserve.com

35

Page 36

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

EXAMPLE: The Logix 3400IQ digital positioner has a default dead-band configuration of 20 percent.

The valve has a 4 inch linear stroke. When the valve first powers up, the command signal is 50

percent. The unit will calculate a high travel threshold of 70 percent (50 percent present position plus

20 percent dead-band) and a low travel threshold of 30 percent (50 percent present position minus

20 percent dead-band). As long as the stem position remains greater than 30 percent and less than

70 percent, no additions are made to the travel accumulator. Now, assume the stem position moves

to 80 percent that is outside the present dead-band. The Logix 3400IQ digital positioner calculates

the stem movement and adds this number to the travel accumulator.

80 percent (present position) - 50 percent (previous) =

30 percent movement x 4-inch stroke = 1.2 inches

So, 1.2 inches is added to the travel accumulator. New dead-band thresholds of 100 percent (80

percent present position plus 20 percent dead-band) and 60 percent (80 percent present position

minus 20 percent dead-band) are calculated. This process continues as the stem position moves

throughout its stroke range.

7.14.5 Cycle Counter

The cycle counter is another means of monitoring valve travel. Unlike the travel accumulator, the

stem position must do two things to count as a cycle: exceed the cycle counter dead-band and

change direction. A cycle counter limit can also be written into the positioner. If this limit is exceeded,

the yellow LED will blink.

7.14.6 Position Deviation

If the stem position differs from the control command by a certain amount for a given length of time,

the yellow LED will blink to signify excess deviation. The trip point and settling times are set from the

transducer function block.

7.14.7 Advanced Features

NOTE: These features are contained in the transducer function block. Refer to the Reference Manual

for a more detailed explanation.

7.14.8 Standard vs. Advanced Diagnostics

Advanced diagnostics models add top, bottom, and supply pressure sensors. This allows for more

diagnostic calculations such as loss of pressure, advanced signatures, and troubleshooting.

7.14.9 Temperature and Pressure Units

The desired temperature and pressure units can be set during configuration. Once set, all readings

will be displayed in the desired units.

36

Page 37

Logix 3400IQ Digital Positioner FCD LGENIM3401-00 – 06/06

7.14.10 Stroke Length

Stroke length is used by the travel accumulator. When the stroke length and units are set, the length

is used to determine the total travel accumulated. The travel accumulator will have the units associ

ated with stroke.

EXAMPLE: Stroke length is set to four inches. If the valve is moved from 0 percent to 100 percent,

four inches will be added to the travel accumulator. The travel accumulator units will be inches. If

Stroke length is 90 degrees for a rotary, the travel accumulator will now have units of degree. A 0

percent to 100 percent stroke will add 90 to the travel accumulator.

NOTE: Stroke length is for information only and is not used during calibration.

Table IX: Transducer Block Characterization Parameters

Parameter Description Value - Meaning Comments

MODE_BLK The operating mode

CONTROL_

FLAGS

CURVEX Numeric X value

CURVEY Numeric Y value

of the transducer

block

Byte values which

select positioner

operation features

array for custom

point. (1 x 21 array

points)

array for custom

point. (1 x 21 array

points)

Auto - Auto (target mode) The transducer

OOS - Out of Service

1 - Quick Opening Curve* Loads factory-

2 - Equal Percent Curve* Loads factory-

3 - Actuator Type

4 - Advanced Model

5 - Rotary Actuator Gain

6 - Custom

Characterization Active

7 - Fail Position TBD

8 - Air Action

X-axis value for custom

stroke characterization

point. Range –10 to 110

Y-axis value for custom

stroke characterization

point. Range –10 to 110

block must be out

of service before

characterization

can be edited or

changed

defined QO curve as

custom curve.

defined equal

percent curve as

custom curve.

Activates custom

curve. If Off,

response is Linear.

Pair each X-value

with corresponding

Y-value to define

the desired point.

Values must be

in ascending (or

equal) order.

-

*NOTE: Must not be selected if a custom curve is to be created or edited.

37

flowserve.com

Page 38