Page 1

Valtek StarPac II

Intelligent Control System

Valtek Logix Series 2000

Digital Positioner

GENERAL INFORMATION

The following instructions are designed to assist in

unpacking, installing and performing maintenance as

required on Valtek® StarPac® II Intelligent Control

Systems and LogixTM 2000 Digital Positioners. Product

users and maintenance personnel should thoroughly

review this bulletin prior to installing, operating, or

performing any maintenance on the valve.

More detailed operation instructions are included

in the StarPac II / Logix 2000 Manual; refer to them

when more information is needed.

Separate Valtek Installation, Operation, Maintenance

instructions cover the valve (IOM 1 or IOM 27) and

actuator (IOM 2 or IOM 31) portions of the system and

other accessories. Refer to the appropriate instructions

when this information is needed.

To avoid possible injury to personnel or damage to valve parts, users must strictly adhere

to WARNING and CAUTION notes. Modifying

this product, substituting non-factory parts,

or inferior parts, or using maintenance procedures other than outlined could drastically

affect performance and be hazardous to personnel and equipment, and may void existing

warranties.

WARNING: Standard industry safety practices must

be adhered to when working on this, or any, process

control product. Specifically, personal protective

and lifting devices must be used as warranted.

Unpacking

1. While unpacking the StarPac II / Logix 2000 unit,

check the packing list against the materials received. Lists describing the system and accessories are included in each shipping container.

2. When lifting the system from the shipping container,

position lifting straps to avoid damage to tubing and

mounted accessories. Systems with valves up to

eight inches may be lifted by actuator lifting ring. On

larger systems, lift unit using lifting straps or hooks

through the yoke legs and outer end of body.

WARNING: When lifting a valve/actuator assembly with lifting straps, be aware the center

of gravity may be above the lifting point. Therefore, support must be given to prevent the

valve/actuator from rotating. Failure to do so

can cause serious injury to personnel or damage to nearby equipment.

3. In the event of shipping damage, contact your

shipper immediately.

4. Should any problem arise, contact your Valtek

Control Valve representative.

Valtek No. 133389

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-1

Page 2

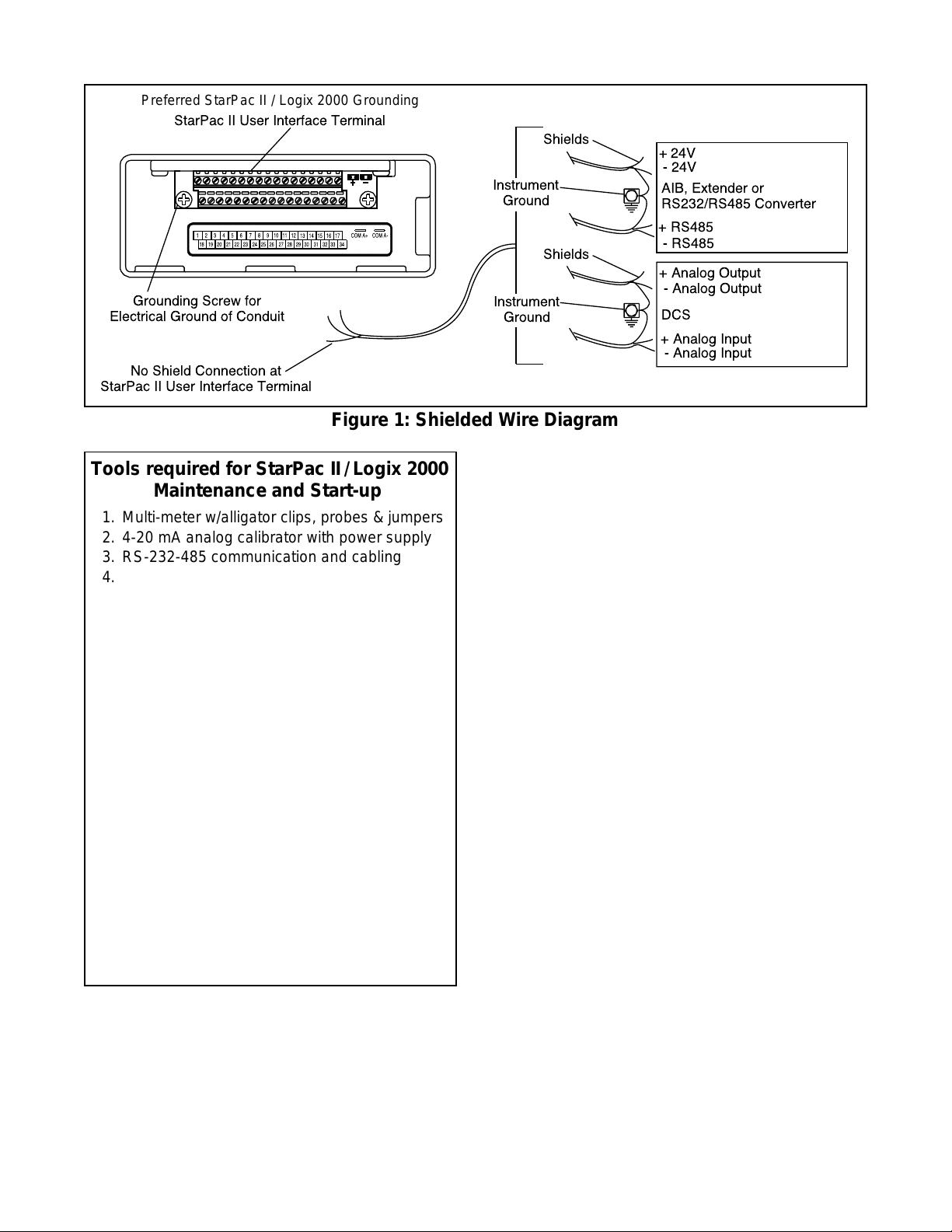

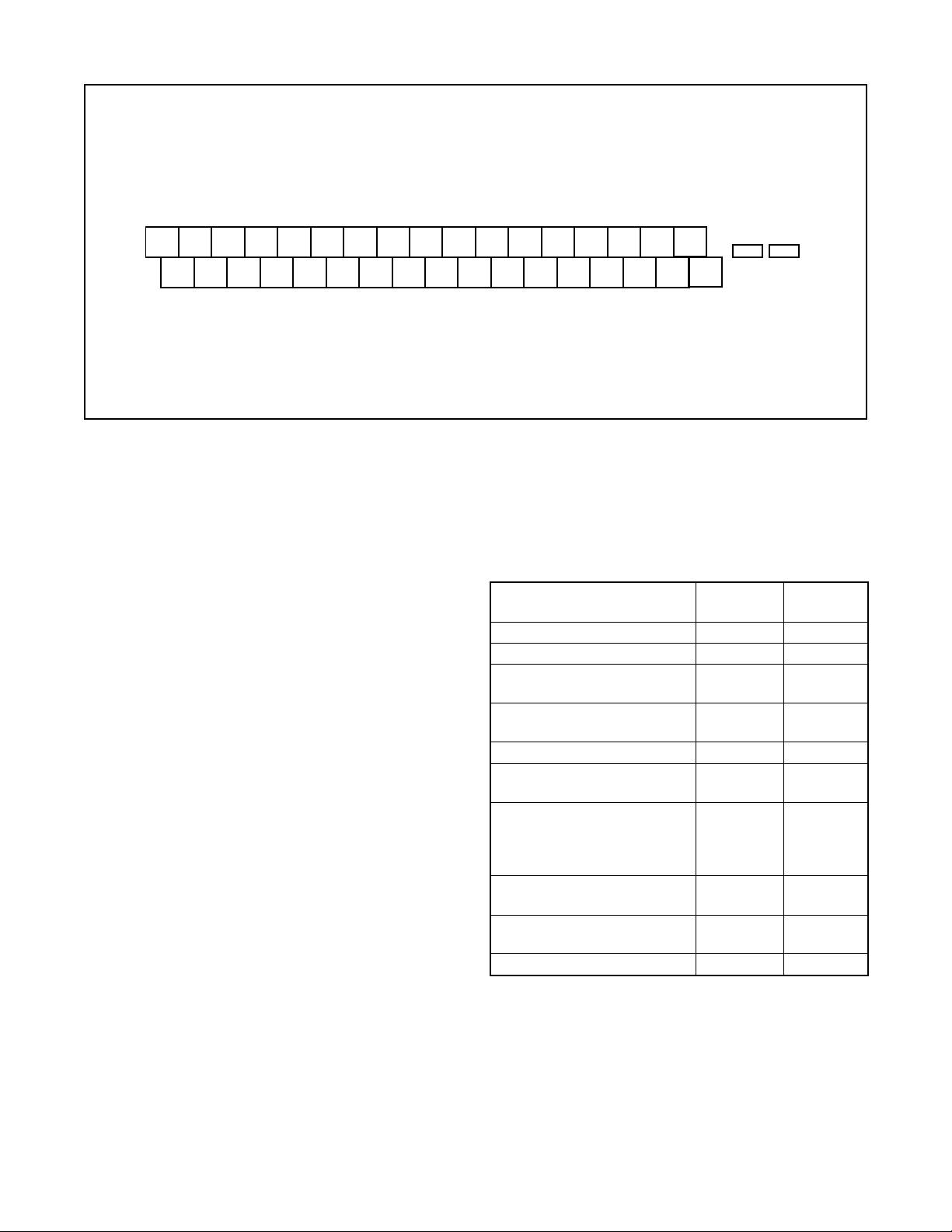

Preferred StarPac II / Logix 2000 Grounding

StarPac II User Interface Terminal

Grounding Screw for

Electrical Ground of Conduit

No Shield Connection at

StarPac II User Interface Terminal

Shields

Instrument

Ground

Shields

Instrument

Ground

Figure 1: Shielded Wire Diagram

+ 24V

- 24V

AIB, Extender or

RS232/RS485 Converter

+ RS485

- RS485

+ Analog Output

- Analog Output

DCS

+ Analog Input

- Analog Input

Tools required for StarPac II / Logix 2000

Maintenance and Start-up

1. Multi-meter w/alligator clips, probes & jumpers

2. 4-20 mA analog calibrator with power supply

3. RS-232-485 communication and cabling

4. Windows

TM

compatible PC

5. Standard 6-inch flat screwdriver

6. Standard phillips screwdriver

7.1/4-inch flat screwdriver

8. Small wire cutter (flush cut) & wire strippers

9. Needle-nose pliers

10.1/16-inch allen wrench

11. Vise grips

12. Small vise grips

13.1/2-inch nut driver

14.5/32-inch allen wrench

15. Large crescent wrench (minimum 15-inch)

16. 8-inch channel lock pliers

17.3/32-inch screwdriver

18. Wrist grounding strap

19. Antistatic bag or packaging

20. EPROM remover (PLCC type)

21. Electrical tape

22. Feedback shaft tool and drive module

pressure calibration connectors (supplied

with feedback module kit)

INSTALLATION

Valve Installation

The StarPac II / Logix 2000 Intelligent Control System

valve is installed in the same manner as a conventional

control valve and according to industry standards. Refer

to the appropriate valve installation, operation, maintenance instructions for proper installation procedures.

If the StarPac II is being installed in an insulated process

line, do not place more than four inches of insulation

around the pressure or temperature sensors; otherwise

the sensors may not operate properly. In addition,

NEVER

insulate the unit electronics assembly or

remote-mounted temperature/pressure sensors (when

used).

CAUTION: Do not insulate the StarPac II / Logix

2000 electronics housing or remote-mounted pressure or temperature sensors; otherwise excessive

heat may build up and affect operation.

Wiring and Grounding Guidelines

This section will help you achieve a maximum “noise -free”

environment and performance with a StarPac II / Logix

2000 unit.

Shielding Versus Grounding

All signals to the StarPac II / Logix 2000 unit should be

in shielded cables. Shields must be tied to a ground at

only one end of the cable to provide a place for environmental electrical noise to be removed from the cable. A

ground wire (unlike a shield) is attached at both ends to

provide a continuous path for electrical conductivity.

Grounding Screw

The green grounding screw by the user interface terminal block should be used to provide the unit with an

adequate and reliable earth ground reference. This

ground should be tied to the same ground as the

electrical conduit. Additionally, the electrical conduit

connecting to the unit should be earth grounded at both

ends of its run.

used to terminate signal shield wires.

24VDC Power

The 24 VDC connection points will work best with

shielded twisted pair wire with the shield wire connected

The green grounding screw must not be

42-2

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

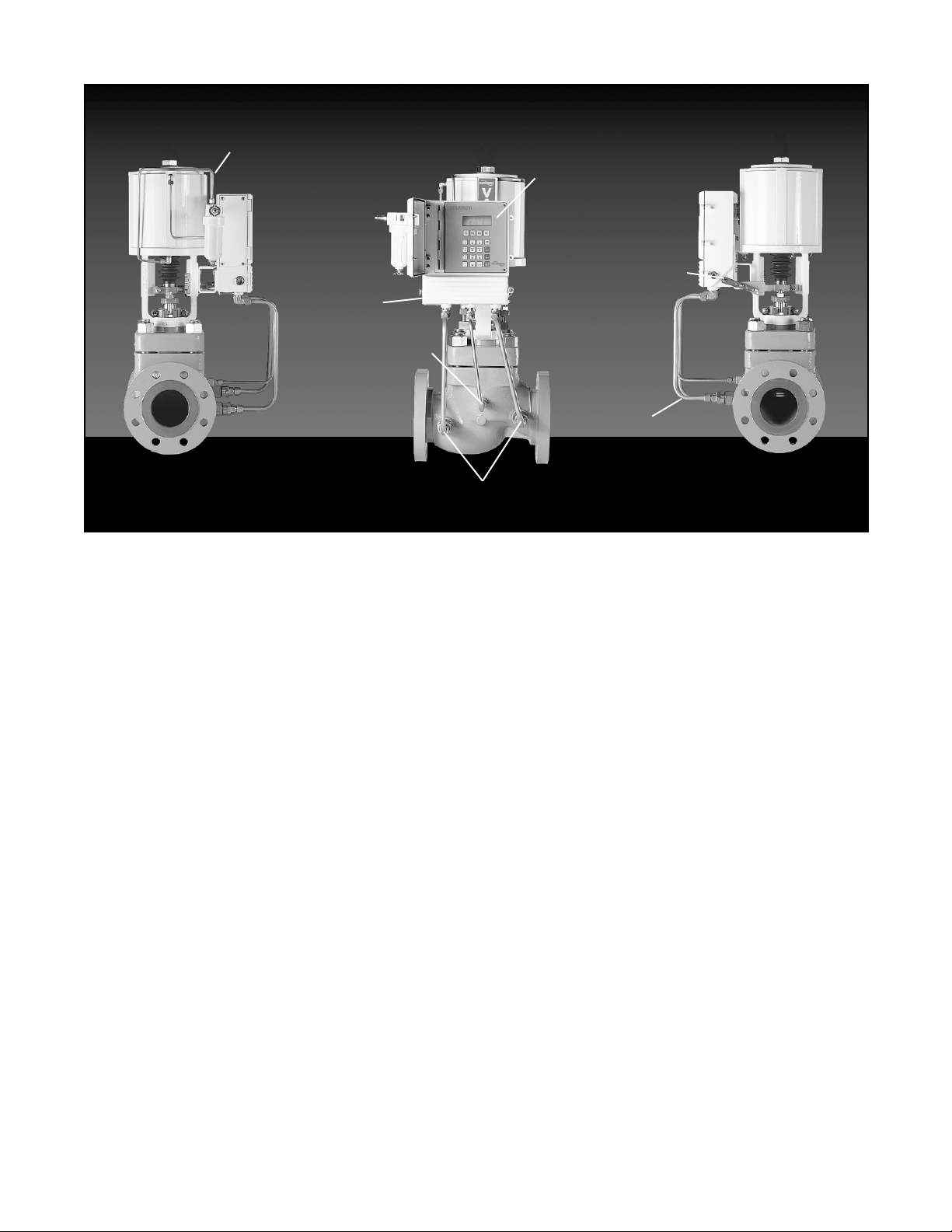

Air Lines to

Cylinder Actuator

Electronics Module

with Keypad and

Local Display

User Access

Terminal

Behind

Lower Door

Temperature

Sensor

Process Pressure Sensors

Figure 2: StarPac II / Logix 2000 Intelligent Control System Components

only at the source. The input power is isolated within the

unit and may be referenced to whatever level is necessary.

connected to earth ground.

RS-485 Communication

RS-485 wiring requires the use of a shielded twisted

pair cable, which is grounded only at the source and not

in the unit. (For maximum performance, wire should

have a characteristic impedance of 120 ohms.) The

RS-485 input is fully isolated, using opto-isolators.

The RS-485 allows only a 7 to 12 V common mode

voltage differential between stations. Valtek's RS-232

to RS-485 converter is not a grounded connection.

PC's with internal RS-485 cards, on the other hand, are

often grounded. If another ground communication

device is on the network, a fault condition will almost

certainly exist due to transient and steady state differences in ground potential.

4 - 20 mA Command Input, Auxiliary Input, and

Feedback Output

These signals are isolated but shielded twisted pair wire

should be used to reduce crosstalk from other signals.

The shield should be connected only at the source.

Discrete Inputs and Outputs

These signals are isolated, but because they are frequently used to switch high voltage (120 VAC), they

should be run in separate shielded wire paths away

from the other StarPac II / Logix 2000 signals.

The 24 VDC power supply should not be

Position

Feedback

Arm

Electronics

Conduit

AIB and RS-232 to RS-485 Converter Connection

When connecting a StarPac II / Logix 2000 unit to a

communication device, no shield or ground connections exist. Hence, the 24 VDC power and RS-485

communication shield drain wires must be connected to

a convenient ground near the AIB or converter.

Wiring The StarPac II / Logix 2000 System

All electrical connections must be done according to

local and industry electrical codes. Valtek recommends

a shielded cable be used for the RS-485 command

signal wire (e.g., Belden 9841 or equivalent).

When connecting multiple StarPac II / Logix 2000 units,

a parallel daisy-chain wiring pattern is used. Connect

unit's branch lines to main line, keeping branch lines as

short as possible. The total length of wiring should not

exceed 4,000 feet (1,200 meters) without use of repeaters.

Avoid devices producing electrical 'noise' while installing the cable.

CAUTION: The following procedure should be performed on the bench or with the unit isolated so that

unexpected valve stroking will not adversely affect

the process.

WARNING: The following procedures may cause

the valve to stroke, causing pressures and temperatures to vary from their norms. Notify appropriate personnel that the valve may stroke unexpectedly. Valtek suggests that the system be isolated

from the process, if installed in line.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-3

Page 4

1

2

3

52

48

46

44

45

11

50

49

47

59

60

62

55

53

51

83

61

58

57

56

54

42

43

29

31

80

81

30

32

33

35

82

8

7

36

37

34

38

40

41

64

68

12

69

72

71

70

73

76

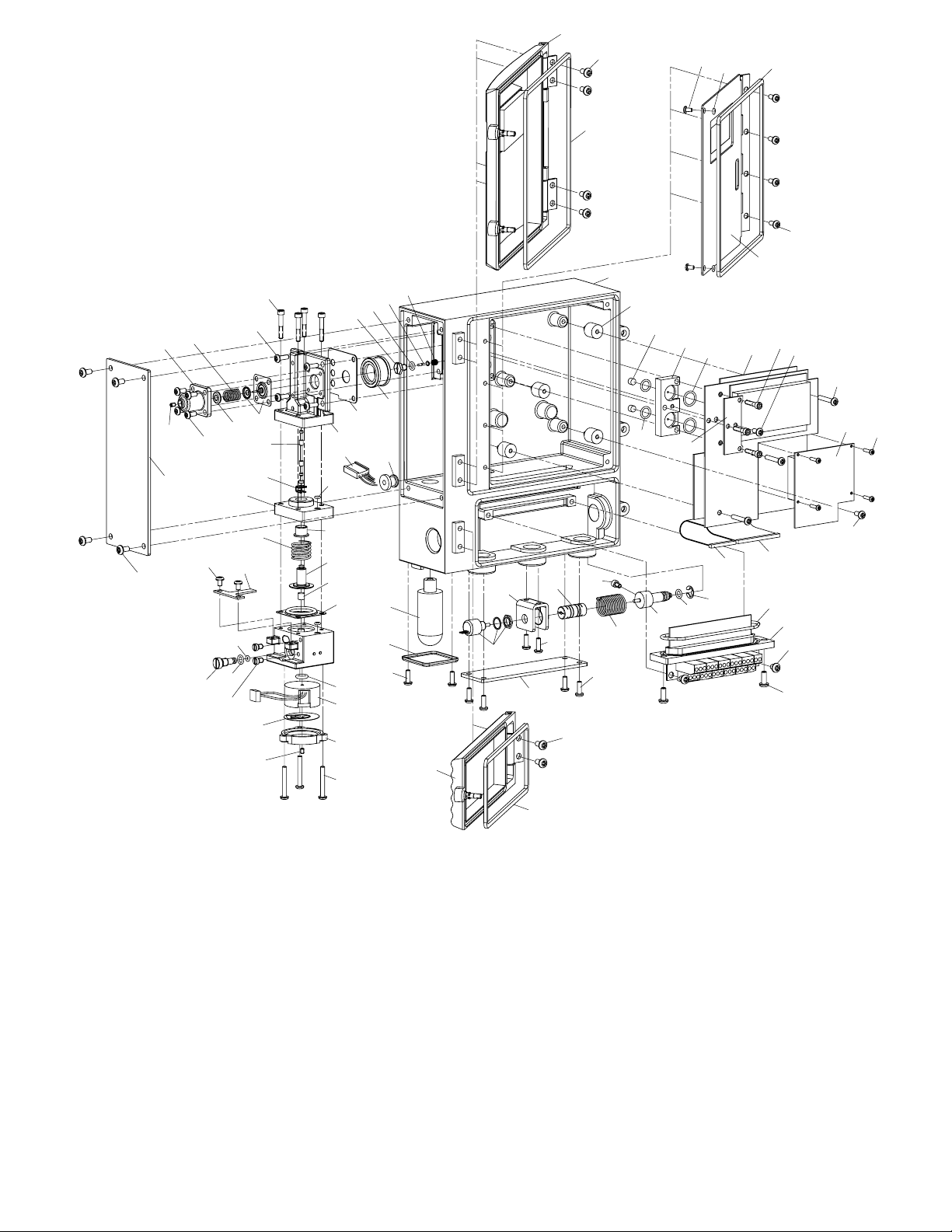

1. Upper door assembly

2. Door screw (4)

3. Upper door gasket

4. Lower door assembly

5. Door screw (2)

6. Lower door gasket

7. Inner door/keypad assembly

8. Inner door screw (4)

9. Feedback cover assembly

10. Cover screw (4)

11.Driver cover assembly

12. Cover screw (4)

13. Hydrophobic filter cover

14. Cover screw (2)

15. Hydrophobic filter

16. Hall potentiometer assembly

17. Potentiometer bracket

18. Flex couple

19. Bracket screws (2)

20. Torsional spring

21. Feedback shaft

22. Shaft O-ring

23. Retaining ring

24. Screw, hard stop

25. Feedthrough assembly

26. Feedthrough O-ring

27. Board screw (2)

28. Block screw (2)

63

65

66

67

74

75

77

78

79

29. Isolator (4)

30. Filter (2)

31. Adapter O-ring, lower (2)

32. Pressure sensor adapter

33. Adapter O-ring, upper (2)

34. StarPac II / Logix 2000

board assembly

35. Board stiffener

36. Board assembly screw (3)

37. Board stiffener screw

38. Board assembly screw (3)

39. Board assembly screw

40. Personality card

41. Personality card screw (4)

42. Rubber grommet (2)

43. Housing assembly

15

13

14

4

17

16

18

19

9

5

6

Figure 3: Exploded View

44. Regulator set screw

45. Regulator housing screw (4)

46. Regulator housing

47. Spring button

48. Regulator spring

49. Regulator diaphragm

assembly

50. Driver module mounting

screw (4)

51. Pilot valve

52. Pilot valve screw (4)

53. Pilot valve gasket

54. Regulator filter

55. Poppet guide

56. Poppet O-ring

57. Poppet

39

85

24

23

22

21

20

10

84

26

25

27

28

58. Poppet spring

59. Spool

60. Spool clip

61. Driver manifold O-ring

62. Driver spacer

63. Driver bearing

64. Spool return spring

65. Driver piston

66. Magnet

67. Driver manifold diaphragm

68. T-board screw (2)

69. T-board

70. Orifice screw

71. Orifice screw O-ring

72. Orifice O-ring

73. Testing plug (2)

74. Coil O-ring

75. Pressure modulator

assembly

76. Spring diaphragm

77. Modulator cover

78. Modulator set screw

79. Modulator screw (3)

80. Inner door screw (2)

81. Inner door screw O-ring (2)

82. Keypad gasket

83. Wire harness

84. 24-pin ribbon cable

85. 14-pin ribbon cable

42-4

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

out -

out +

out -

1

1

Analog

out +

Analog

Spare

Com B -

Com B +

Com A -

Com A +

24 VDC -

24 VDC +

Grnd (Blk)

out - (Wht)

1

P

out + (Grn)

1

P

P

+5 VDC (Red)

1

1

P

Thrm Coup (Yel)

2

2

Thrm Coup (Red)

Analog

Analog

1 2 3 4 5 6 7 8 9 10 1112 131415 1617

18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

Com A +

Com A -

Grnd (Blk)

out - (Wht)

2

P

out + (Grn)

2

P

P

in -

2

2

Analog

+5 VDC (Red)

2

P

in +

1

2

Analog

in -

in +

1

Analog

Analog

Spare

Figure 4: User Interface Terminal Pinouts

To connect the wiring to the StarPac II / Logix 2000 unit,

refer to Figures 1 and 4, and Table I, then proceed as

follows.

1. Open the lower door on the front of the housing.

WARNING: Do not open the electronic housing

covers in flammable atmospheres; otherwise,

possible injury to personnel or equipment may

occur.

2. Connect the required wires to the terminal interface

block and computer as described in Figure 4 and

Table I. (The system must have 24 VDC power for

operation.)

NOTE: The StarPac II / Logix 2000 unit remembers

the operating mode setting (automatic or manual)

from the last time the unit had power. When power

to the system is turned on again, the unit will resume

operation in the previous mode.

Normally the unit arrives from the factory set in the

manual analog operating mode. This means a

command signal will position the valve the same as

a traditional control valve, providing a plug position

proportional to the 4 - 20 mA signal.

To avoid upsetting the process because of improper

operating mode selection:

• Ensure that the system arrived from factory with

the proper operating mode setting in the shop prior

to installation by connecting air supply and command signal, then turning on the power and looking

at the mode value on the local display, or;

• Set the proper operating mode for the particular

application in the shop prior to installation by

selecting the desired operating mode from the

local interface or in the Tuning/Tune screen of the

StarTalk software, or;

Pulse Out

Pulse Out

Discrete 2 in

Discrete 2 in

Discrete 1 in

Alarm Contact

Alarm Contact

Discrete 1 in

• Ensure that the block valves in the process line

around the unit are closed and the process is

diverted around the unit.

Table I:

User Interface Terminal Connections

Signal Negative Positive

Term. No. Term. No.

24 VDC power 16 17

Valve command signal 24 25

Primary RS-485 14 15

communication link

Secondary RS-485 12 13

communication link

Auxiliary input (4-20 mA) 22 23

Analog output (4-20 mA) 1 9 10

Analog output (4-20 mA) 2 7 8

Discrete input 1 – switch/ 33 34

solenoid monitoring

(discrete mode source

input)

Discrete input 2 – switch/ 31 32

solenoid monitoring

Discrete output 1 (malfunc- 29 30

tion alarm contact)

Discrete output 2 (pulse) 27 28

3. Turn on the 24 VDC power to the unit, and verify that

it has been correctly wired by checking the following:

• 24 VDC power is at least 300 mA and between 18.0

and 64.0 VDC

• Polarity is correct

• Local display is on; if not, check the power supply.

4. Close the front cover on the housing of the unit.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-5

Page 6

System Communication Default

Configuration

StarPac II / Logix 2000 units are shipped from the factory

ready for installation and operation. Rarely do the units

need to be re-configured prior to operation. Table II lists

the factory default communication settings. If these

settings are not correct for the equipment being used,

proceed to the following sections.

Table II: Factory Default Mode Settings

Description Setting

Address 1

Parity odd

Baud Rate 19,200

Modbus Communication Mode RTU

RS-485 Termination Resistors Installed

Termination

Jumpers

Selecting Correct Address Setting

If the StarPac II / Logix 2000 unit is the only one on the

communication network, the default address (1) is fine.

If multiple units will be operating on the same communication network, each unit must have a unique address.

Before changing the address, the StarTalk software can

be used to determine what devices are on the line.

(Remember to include devices that may be temporarily

off line.)

If the default address setting needs to be changed, use

the 'Comm' option in the configuration menu of the local

interface to change the settings.

Selecting Correct Baud Rate Setting

StarPac II / Logix 2000 units support baud rates of up to

57,600 baud. However, both the StarPac II / Logix 2000

system and StarTalk software are shipped from the

factory set to 19,200 baud.

If the default baud rate setting needs to be changed, use

the 'Comm' option in the configuration menu of the local

interface to change the settings.

Selecting Correct Modbus Transmission

Mode

Two transmission modes exist in a Modbus system,

ASCII and RTU (default). Use the ASCII mode when

transmitting information through a device that uses

ASCII control codes; for example, a modem. Use the

RTU mode when connecting directly to both devices; for

example, an RS-485 interface card wired directly to a

StarPac II / Logix 2000 system.

If the default Modbus transmission mode setting needs

to be changed, use the 'Comm' option in the configuration menu of the local interface to change the settings.

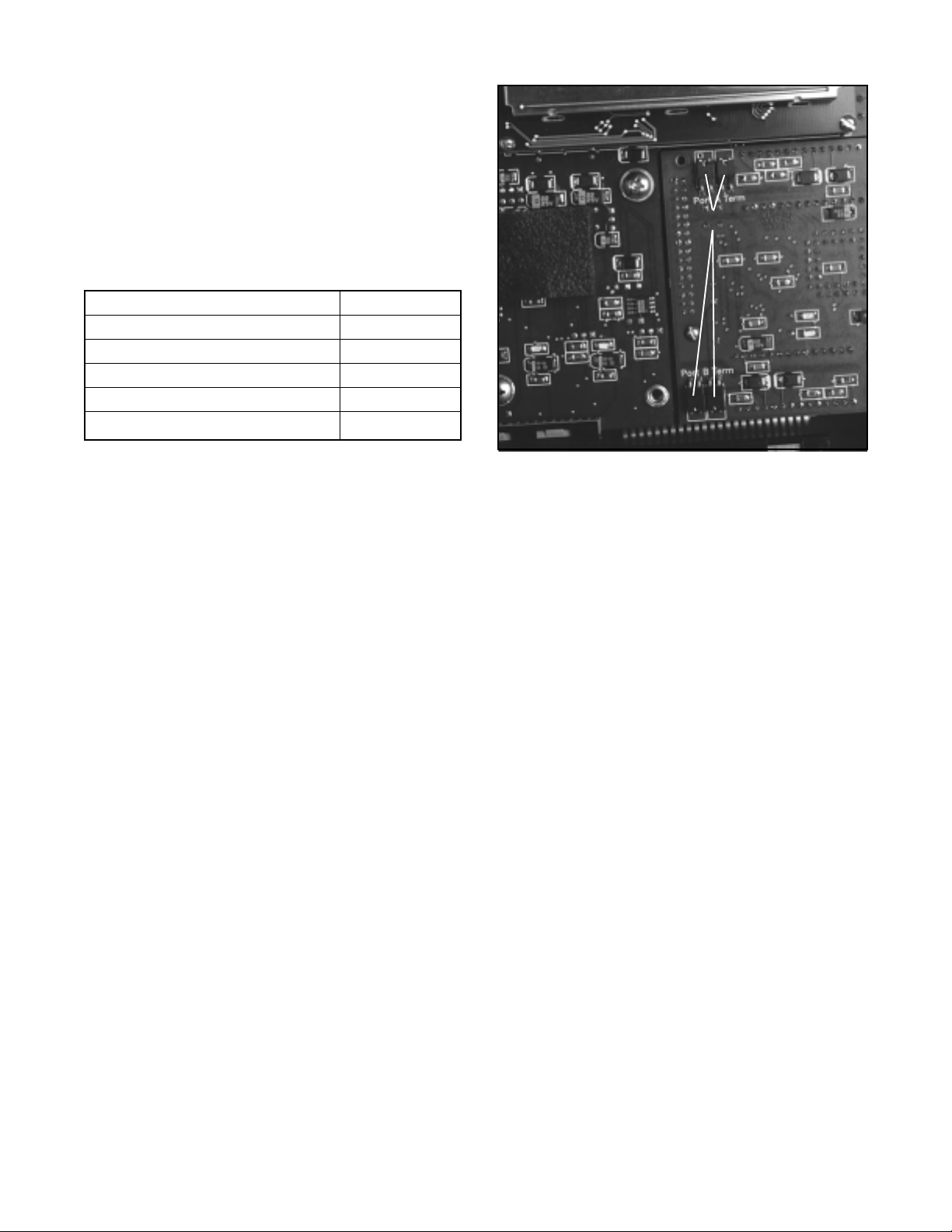

Figure 5: Termination Jumpers and

Personality Module

Selecting Proper RS-485 Termination

Resistor Setting

A termination resistor must be installed on the two most

remote devices on the network, counting the host

computer as any other device.

(For example, a single StarPac II / Logix 2000 unit and

the RS-485 driver in the host computer would each

require the termination resistor to be installed. If four

units were on the network with a host computer, decide

which of the two devices have the most combined cable

length between them. These two devices should have

the termination resistors installed. The termination

resistors should be disabled in the devices not considered to be the most remote using the instructions in the

next section. Using more than two termination resistors

in a network can cause the RS-485 communications to

operate erratically or fail.)

To enable 120 ohms termination, insert both jumpers

for A and B channels. To disable termination, remove

both jumpers from each channel as shown in

Figure 5.

SYSTEM MAINTENANCE

Valtek recommends that the StarPac II / Logix 2000

system calibration be checked every six months. If,

after checking the unit, a component is determined to

be defective, the following section will help with the

component replacement.

The following items may be needed to install, start up

and calibrate the unit's electronics.

42-6

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 7

• Power supply: 24 VDC, 300 mA

• Digital volt meter with 4 - 20 mA range

• Air supply: 50 psig minimum, 80-100 psig preferred

• Gauges or the ability to accurately determine pro-

cess pressures and valve air supply pressures

• 4 - 20 mA command source

• Thermocouple calibrator or simulator with 0 to 500°

Celsius range

8. Turn on the air supply to the valve and check for

leaks in the reattached actuator tubing lines.

9. Turn on power to the unit. Check the system

calibration and perform a Valve Stroke Calibration

to reset the position feedback. Refer to the Calibration section of the StarPac II / Logix 2000 manual.

StarPac II / Logix 2000 Positioner

Overview

Mechanical Subsystem Maintenance

Refer to the appropriate Valtek Installation, Operation &

Maintenance (IOM) instructions for details on repair and

maintenance of the control valve actuator components.

Please refer to the manufacturers’ manuals for maintenance and operation instructions for non-pneumatic

actuators, e.g., electric or electro-hydraulic actuators.

WARNING: The process line must be depressurized

and drained of process fluid and decontaminated

prior to working on internal valve components. Failure to do so may cause serious injury to personnel.

1. Depressurize the line, decontaminate the valve (if

needed) and shut off the air supply to the valve

positioner.

2. Disconnect the actuator air tubes from the unit.

3. Disconnect the two mounting bolts that attach the

StarPac II / Logix 2000 system bracket.

4. Disconnect the follower arm from the unit base.

This is done by removing the follower arm nut and

washer and pulling the arm off the shaft. Notice that

this shaft connection is keyed and that the shafts

are slightly spring loaded.

5. The actuator subassembly is now isolated and is

removed by loosening the bonnet bolts and lifting

the actuator away from the body.

The tubing holds the StarPac II / Logix 2000 base in

place, eliminating the need to disconnect wiring or

air connections.

6. Standard valve maintenance may now be done on

the actuator or valve body components. Refer to

the Valtek IOM instructions for details on such

things as trim or packing replacement. If you have

to replace the trim, use the same trim number and

characteristic as the original trim so the flow calculations are not affected. If a trim size change is

needed, contact your Valtek representative to find

out about flow characterization options.

7. Reassemble the system by reversing the above

steps. Be sure to follow the procedures outlined in

the Valtek IOM instructions for valve reassembly.

When reconnecting the follower arm, make sure

that the arm fits correctly on the keyed shaft and has

a positive spring action.

The StarPac II / Logix 2000 is double-acting, capable of

supplying air to either side of the actuator piston while

exhausting the other side to the atmosphere. Also, the

positioner can be mounted on either Valtek linear or

rotary actuators without modification to the actuator.

The positioner is pending non-incendive for class I,

division II, groups A, B, C, and D; class II, groups E,

F, and G. Since the positioner is insensitive to supply

pressure changes and can handle supply pressures

from 30 to 150 psig, a supply regulator is usually not

required; however, an air filter is required due to the

close tolerances of the spool assembly.

NOTE: The air supply should conform to ISA

Standard S7.3 (a dew point at least 18° F below

ambient temperature, particle size below 5 microns,

oil content not to exceed 1 part per million).

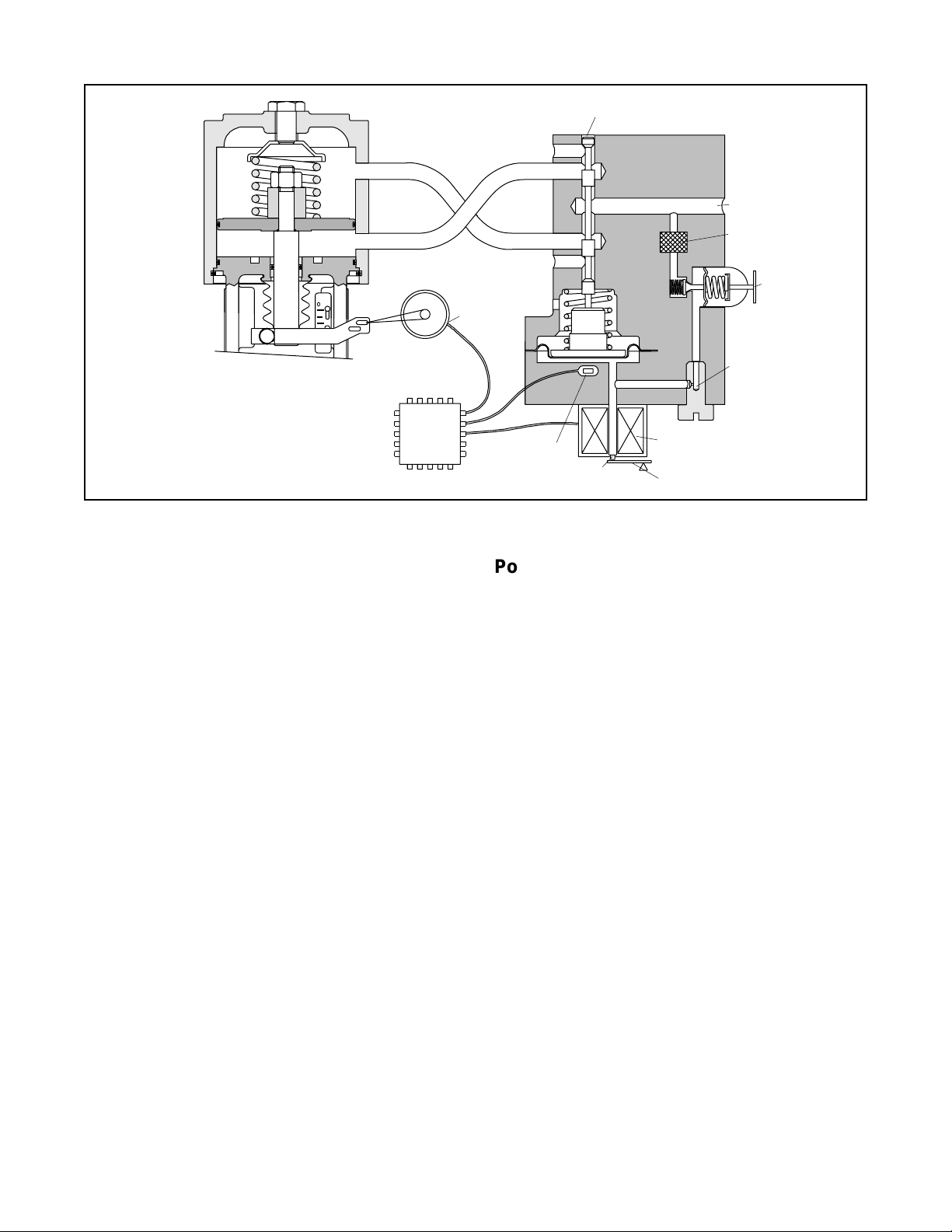

Positioner Operation

The StarPac II / Logix 2000 Positioner is an electric

feedback instrument. Figure 6 shows a StarPac II

installed on a double-acting actuator for air-to-open

action. Positioning is based on a balance of two signals:

one proportional to the modulator input signal and the

other proportional to the stem position.

The supply pressure for the positioner modulator is

tapped off the main supply and is filtered as it passes

through a field-replaceable, coalescing filter element in

the module. Next it passes through an internal pressure

regulator that regulates it to approximately 22 psig. The

air then goes through an orifice that restricts the flow

and air consumption (refer to Figure 6).

The air is further controlled to 6-12 psig using a springdiaphragm flapper that is attracted by an electromagnet

to a nozzle. A temperature compensated hall effect

sensor mounted on a circuit board senses the spool

valve position. The hall effect sensor and circuitry

create a feedback loop, which determines how much

current to send to the electromagnet for a desired spool

valve position. The electromagnet in the feedback loop

varies the nozzle-flapper spacing, which regulates the

output pressure to 6-12 psig proportional to the command input signal.

When these opposing signals are equal, the system will

be in equilibrium and the stem will be in the position

called for by the command signal. If these opposing

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-7

Page 8

Exhaust

Output 1

Pilot Valve Spool

Air Supply

OO

Air-to-open

Configuration

Digital

Position

Algorithm

Figure 6: Positioner Diagram

signals are not equal, the spool valve will move up (or

down) and, by means of the modulator, will change the

output pressures and flow rate. This will cause the

piston to move until the signal of the feedback sensor

equalizes with the command signal.

The detailed sequence of positioner operations are as

follows: An increase in the command signal forces the

modulator signal capsule and spool valve upward. This

motion of the modulator also pushes the pilot valve

spool upward from its equilibrium position. This opens

the pilot valve ports, supplying air to port one and

exhausting air from port two. This causes the actuator

piston to move upward.

This upward motion of the piston is transmitted back to

the positioner through the feedback linkage and hallpot

sensor signal changing proportionally to the valve position. The piston continues to stroke upward until the

signal of the feedback sensor increases sufficiently to

counter the signal being sent to the modulator. At this

point, the spool is at its equilibrium position as the

pressures in the cylinder stabilize and the air flow to the

actuator decreases.

After the piston has reached the required position, the

feedback signal will equal the spool position generated

in the modulator capsule. The computer will then make

small null adjustments to fine-tune the desired position

and compensate for changes in dynamic loading.

A decrease in the command signal reverses the described actions causing a proportional downward movement of the actuator piston and stem.

Output 2

Exhaust

Stem Position

Sensor

Spool Position

Sensor

Nozzle

Electromagnetic Coil

Flapper

Filter

Regulator

Orifice

Position Feedback System

The position feedback linkage of the StarPac II / Logix

2000 system is a critical part of the system. This linkage

is also used in the StarPac II to calculate the valve’s C

for a given stroke for flow measurement. This linkage

should be lubricated and checked periodically for tight,

smooth operation. The follower arm should operate

smoothly with no binding and have a positive spring

loading on the arm. Inspect the follower arm pin for

excess wear and replace if needed. The take-off arm

attached to the stem clamp must be firmly secured to

the stem clamp and perpendicular to the actuator stem.

If this takeoff arm is canted or misaligned, problems

may occur with positioner calibration and the position

reading on the unit may go out of range.

On rotary actuators, make sure the adjustment linkage

locknut is tight and has no excessive play in the ball

joints. The rotary shaft clamp must be tight and should

not freely rotate on the shaft.

Pressure Sensor Replacement

Standard StarPac II pressure sensors are typically installed directly into the control valve body. Before they

can be removed, the process line must be depressurized

and drained of all fluids and the valve decontaminated.

To replace a pressure sensor, refer to Figure 7 then

proceed as follows.

WARNING: The process line must be depressurized

and drained of process fluid, and decontaminated

prior to working on internal valve components. Failure

to do so may cause serious injury to personnel.

V

42-8

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 9

Figure 7: Disconnecting Lemo Connector

WARNING: If the pressure sensors are remotemounted, the sensor will be located in a sensor

housing in the tubing line and not in the sensor

housing located on the valve body. This section

of the tubing contains process fluid and must be

drained and decontaminated before the sensor is

removed. The procedure for sensor removal and

replacement will be similar to that outlined below.

(Refer to alternate sensor information when this type of

sensor is included with system.)

1. Depressurize and decontaminate the line and valve.

Loosen the tubing nuts on the conduit leading to the

pressure sensor, if applicable.

2. Loosen the sensor nut.

3. Gently pull the conduit and sensor nut approximately 1/2 to 0.75-inch from the sensor. Use needle

nose pliers to release the locking sleeve of the

Lemo™ connector by moving the collar away from

the sensor and disconnect the connector from the

sensor. Swing the sensor conduit out of the way

(refer to Figure 7).

4. Unscrew the sensor from the sensor boss.

5. Remove the sensor O-ring or gasket and replace

with a new one. Make sure the environmental

O-ring seal is in good condition and in place on the

new sensor.

6. Install the new sensor into the sensor port making

sure the O-ring or gasket remains properly in place

while tightening the sensor. Tighten the sensor

until it seats metal-to-metal at the gasket section of

the sensor port, ensuring the proper compression

of the process O-ring or gasket seal.

7. Align the red dots on the sensor and connector,

and reconnect the Lemo connector. Fully seat the

connector until the locking sleeve latches. Replace

the sensor nut and tighten.

8. Pressurize the valve body to make sure the sensors

are properly seated before attaching the sensor

conduit and tightening.

9. Reattach the conduit lines and securely tighten the

fittings.

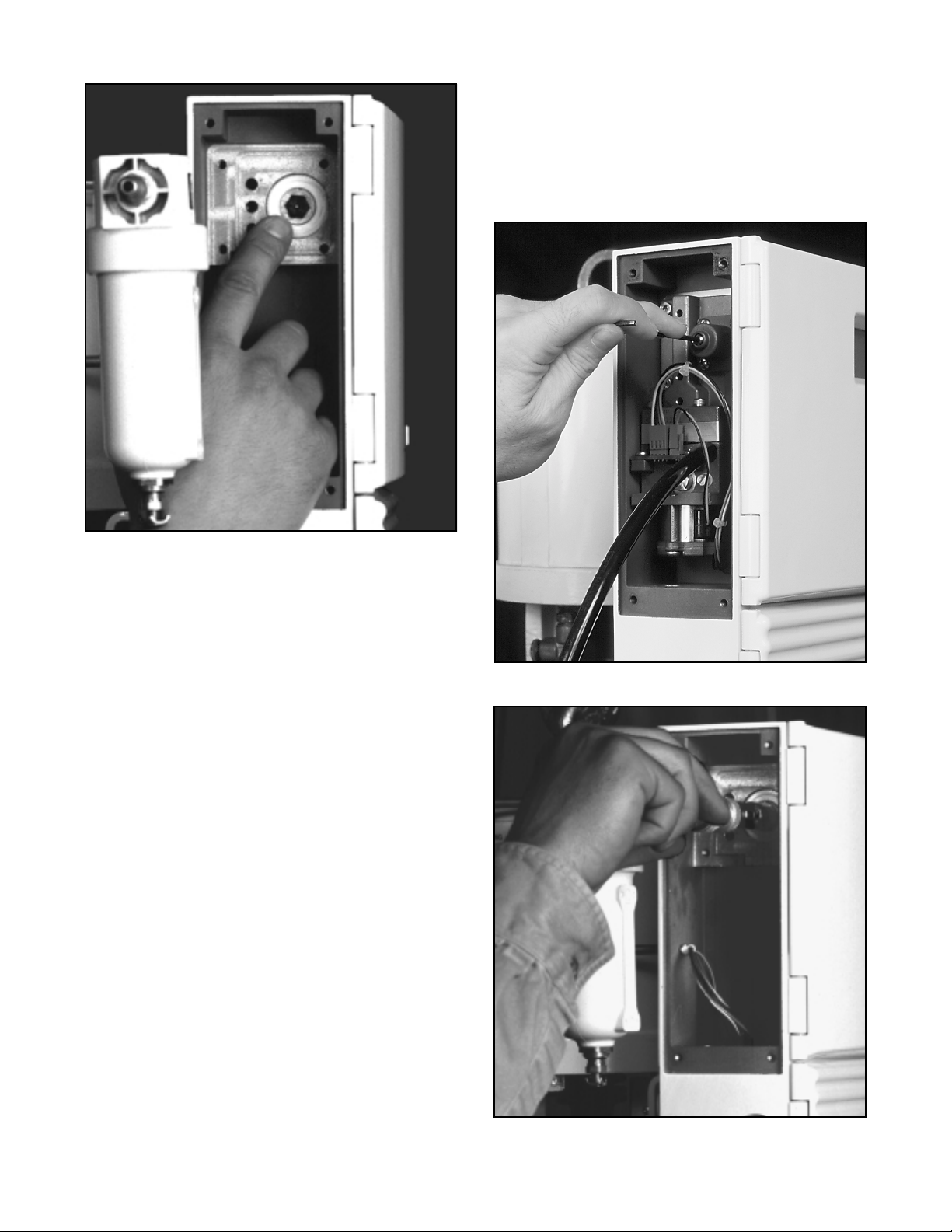

Figure 8: Thermocouple Replacement

Thermocouple Replacement

In normal configuration, the thermocouple does not

penetrate the valve body wall. Depressurizing the body

is not necessary

NOTE: If the StarPac II was ordered with a special

thermocouple option, verify the need to depressurize

the body before proceeding.

1. Disconnect power and air supply to the unit.

2. Open the lower terminal block cover and disconnect the red and yellow thermocouple wire.

3. Loosen the tubing nuts on both ends of the thermocouple assembly (refer to Figure 8).

4. Pull the wires out of the StarPac base and slip the

tubing off the wires.

5. Unscrew the old thermocouple from the body.

6. Install the new thermocouple.

7. Feed the wires back through the tubing and into the

StarPac housing.

8. Tighten the tubing nuts.

9. Cut the thermocouple wires to length. Strip and

reattach wires to the terminal block, noting color

polarity. (The red wire is the negative signal.)

10.Check that all the fittings are tight.

when replacing the thermocouple.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-9

Page 10

Keypad Assembly Replacement

If, after consulting with the local Valtek or factory representative, the StarPac II / Logix 2000's keypad is found

to be defective and needs replacement, refer to Figure

3 and proceed as follows.

1. Make sure valve is by-passed and in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Undo the two captive screws securing the upper

door to the housing and open the upper door.

4. Undo the two screws securing the inner door to the

housing and swing the inner door completely open.

5. Carefully disconnect the keypad connector from the

board stack.

6. Remove the four hinge mounting screws and remove the inner door.

7. Install the new keypad assembly in reverse order.

Note: When installing a new keypad assembly,

check for proper door alignment before final lockdown of hinge-mounting screws.

Feedback Assembly Replacement

If it is determined that the Feedback Assembly needs

replacement, refer to Figures 3 and 9 then proceed as

follows: (New feedback assembly is preset at the factory.)

1. Make sure valve is by-passed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Disconnect the positioner pin and follower arm from

the feedback shaft.

4. Remove the four feedback cover screws and

remove the cover.

5. Disconnect the three-pin connector from the hallpot

while observing the connector orientation.

6. Remove the two potentiometer bracket screws.

7. Remove the retaining ring from the feedback shaft.

8. Thread the feedback shaft tool (provided in the

replacement kit) onto feedback shaft and push

shaft out of bushing (refer to Figure 9).

9. Remove feedback shaft tool and feedback assembly.

10. To install the new feedback assembly, lightly grease

the feedback shaft and apply thread locking compound to the two potentiometer bracket mounting

holes. Slide the feedback assembly into the feedback bushing.

11. Thread on the feedback shaft tool and push while

turning clockwise, aligning the stroke-stop screw

and stop boss. Next, pull back to the seat stop on

the housing (refer to Figure 9).

12. Remove the feedback shaft tool and install the

retaining ring in the feedback shaft.

13. Using two mounting screws, fasten the potentiometer

bracket to the housing, making sure the feedback

assembly is aligned and the flex couple is engaged.

14. Reconnect the three-pin connector to the hallpot (in

orientation as noted above).

15. Replace the feedback cover and four cover screws.

Then perform a stroke calibration.

Figure 9: Feedback Shaft Tool

Regulator Filter Replacement

To replace the regulator filter, refer to Figures 3 and 10

then proceed as follows:

1. Make sure valve is by-passed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the four driver module cover screws and

set the cover aside.

4. Disconnect the four-pin connector from the T-board,

observing the connector orientation.

5. Remove the four driver module mounting screws

and remove the driver module.

6. Carefully remove the pilot valve gasket by peeling

or scraping.

7. Remove the old regulator filter and insert the new

filter (refer to Figure 10).

8. Remove the backing on the pilot valve gasket to

expose the adhesive and apply the pilot valve

gasket to the housing, making sure that the holes

are aligned.

9. Apply thread locking compound to the four mounting holes and fasten the driver module to the housing with the four mounting screws.

10. Reconnect the four-pin connector to the T-board in

the orientation as noted above.

11. Replace the driver module cover with the four cover

screws.

42-10

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 11

13. Apply thread locking compound to the four mount-

ing holes and fasten the driver module to the housing using the four mounting screws.

14. Reconnect the four-pin connector to the T-board in

the same orientation as noted above.

15. Replace the driver module cover and cover screws.

Figure 10: Regulator Filter Replacement

Driver Module Assembly Replacement

To replace the driver module assembly, refer to Figures

3, 10, 11, and 12 then proceed as follows:

1. Make sure valve is by-passed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the four driver module cover screws and

set the cover aside.

4. Disconnect the four-pin connector from the T-board,

observing the connector orientation.

5. Remove the four driver module mounting screws

and remove the driver module. (Check the pilot

valve and poppet assemblies for wear or deterioration. If needed, continue with steps 6-12. If cleaning only, refer to Spool Valve Assembly Replacement then proceed to step 13 after cleaning.)

6. Carefully remove the pilot valve gasket by peeling

or scraping.

7. Remove the poppet guide, poppet O-ring, poppet,

and poppet spring.

8. Remove and replace the regulator filter.

9. Insert the new poppet spring into the housing poppet hole.

10. Place the O-ring on the poppet seat.

11. Thread the poppet guide and poppet into the housing and tighten to 6-inch/lbs. maximum (refer to

Figure 12).

12. Remove the backing from the pilot valve gasket to

expose the adhesive and apply the gasket to the

housing, making sure the holes are aligned.

Figure 11: Setting Regulator Pressure

Figure 12: Poppet Guide Installation

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-11

Page 12

Driver Module Calibration

1. Hook power supply (24 VDC) leads to StarPac II /

Logix 2000 connector numbers 16 and 17.

2. Hook up supply pressure to the unit, using the port

marked S.

3. Remove the upper port plug from the Driver Manifold and screw the pressure test fitting into the port.

4. Set the regulator pressure to 22 psig, plus or minus

0.5 psig by adjusting the set screw on the regulator

(refer to Figure 11).

5. Remove the test fitting and replace it with the port

plug ensuring that the seal washer is present.

6. Remove the lower port plug from the Driver Manifold and screw the pressure test fitting into the port.

7. Set the Modulator pressure to 2 psig, plus or minus

0.25 psig by adjusting the set screw on the bottom

of the modulator cap (refer to Figure 13).

8. Remove the test fitting and replace it with the port

plug, making sure the seal washer is present.

9. Proceed with the positioner calibration routine. First,

edit register 40157 to put in a value of 2750 for the

null adjust. The valve should be set to be 50 percent

open during these calibrations and adjustments.

This typically takes several minutes to complete.

Replacing the Electronic Boards

The StarPac II / Logix 2000 has two main electronic

boards, one personality module, and one terminal strip

mounted inside the housing. The two boards are

located behind the keypad door of the housing, mounted

one atop the other in a stacked fashion. The personality

module is plugged into the lower right hand corner of the

boards.

If, after consulting with a local Valtek or factory representative, and determination is made that the electronic

boards need replacement, proceed as follows.

1. Make sure the valve is by-passed or in a safe position.

Follow handling procedures that protect the boards

from the static electricity and ground currents.

2. To access the board stack, open the housing door.

Undo the two screws that fasten the keypad door to

the housing and swing out the keypad door (the

stacks will be visible). Because the factory places

a serial number on each stack, the board stack

should be kept together as one unit. Mixing boards

with other stacks is not recommended.

3. The top board consists of a main section and a

smaller, removable personality card on the lower

right corner. The size of this card is about two

square inches. The card contains the programming

logic and is sometimes removed for software customizing. Remove the card by undoing the four

small screws holding it to the top board. Carefully

lift it out, as it is also held in place by a board-toboard connector. Transport this card in a static

resistant pouch.

4. To install the personality card, align the board-toboard connector and press straight in. Reinstall the

four screws. (Any time the version of the personality module is changed, re-initialize the system by

holding down the zero (0) button while turning the

24V power on – then releasing once the display is

legible. The unit will be in test mode and must be

reconfigured for proper operation.)

Figure 13: Setting Modulator Pressure

42-12

The Board Stack

1. Disconnect the power and air supply to the unit

before removing the electronic board stack. The

two pressurized pneumatic ports connect directly

with two board mounted pressure sensors. A total

of eight screws hold down the boards. The screw

with an allen head should not be removed. The

other seven are phillips head-type and can be

removed. Note that one of the seven phillips screws

is located on the lower right portion of lower board.

2. Undo the seven phillips screws and the board stack

will lift away from the housing. Disconnect the

connectors from the boards. Carefully undo the

integral clips as you pull the connector away from

the board (refer to Figure 14).

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 13

A

Discrete Jumpers

Figure 15: Discrete Jumpers Under

Personality Module

Figure 14: Replacing the Board Stack

3. Transport the board stack in a static resistant pouch.

4. To reinstall the new stack, reverse the above procedure. (Be careful to align the pins on the interconnection connector as you install the connectors.)

CAUTION: When sliding the new board stack in

place, push gently on the connector strip to slip

it behind the screw boss before installing the

lower left-hand screw of the board stack. Failure to do this will cause the strip (A, Figure 15)

to be pinched between the boss and board,

leading to damage of the connector strip.

Table III: MaxFlo Rotary Actuator

Mounting Kits

Actuator Shaft Size Air To Mounting

Size Kit

25 0.4375 Open 10059457

25 0.4375 Close 10059457

25 0.625 Open 10059458

25 0.625 Close 10059458

25 0.875 Open 10059460

25 0.875 Close 10059460

50 0.875 Open 10059473

50 0.875 Close 10059472

50 1.125 Open 10059477

50 1.125 Close 10059476

100 1.5 Open 10059481

100 1.5 Close 10059480

200 1.5 Open 10094609

200 1.5 Close 10094608

Mounting kit includes bracket, linkage assembly , follower

arm,and all necessary nuts, bolts and washers.

Discrete Jumpers

Three sets of jumpers (Figure 15) are located on the

main circuit board underneath the personality module.

These jumpers are used to configure the operation of

discrete inputs and outputs. These are labeled Relay,

DI 1, and DI 2.

The relay jumper allows selection of normally open

(N.O.) and normally closed (N.C.) forms of the alarm

contacts (A-B=N.O. and B-C=N.C.). DI 1 and DI 2

allows selection of the input voltage range for the two

discrete input channels. (A-B=60-120V input range,

B-C=20-48V input range.)

Note: Both jumpers on each of these blocks must be

moved to the desired position for proper operation.

Caution: Do not apply high voltage when low

voltage sensing is selected. Damage will occur.

Table IV: Linear Actuator Mounting Kits

Actuator Stroke Spud Mounting

Size (inches) (inches) Kit

25 0.5 - 1.5 2.00 10007189

50 0.5 - 3 2.00 10062174

50 0.5 - 3 2.62 10007191

100 3 2.62 - 2.88 10007192

100 4 3.38 - 4.75 10007193

200 1 - 4 2.88 10054278

200 1.5 - 4 3.38 - 4.75 1005428

300 1 - 4 3.38 - 4.75 10054284

Mounting kit includes bracket, stem clamp, follower arm,

follower pin, and all necessary nuts, bolts and washers.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-13

Page 14

Figure 16: Sensor Troubleshooting Chart

42-14

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 15

Troubleshooting StarPac II / Logix 2000 Systems

Failure Probable Cause Corrective Action

Local display not on 1. 24 VDC not on or set correctly 1. Verify power supply is outputting 24 VDC

(terminals 16 and 17)

2. Incorrect wiring polarity 2. Check wiring for correct polarity

3. Interface connections on bottom 3. Make sure connections are correctly

are not correct aligned and fully plugged in

Erratic communications 1. Multiple units have same address 1. Change each unit to a unique, sequential

on network line address (refer to Address Setting in

Maintenance section)

2. Proper polarity not maintained 2. Check all network connections for cor-

rect positive and negative connections

3. Individual units not properly wired 3. Begin with shortest RS-485 run, check-

ing polarity and communication; continue

checking units throughout network

4. Termination jumpers not installed 4. Install termination jumper on two most

distant devices

The unit does not 1. Unit still in initialize mode 1. Put unit in operation mode

respond to analog 2. Select analog input

commands

StarPac II / Logix 2000 1. Improper configuration file was 1. Find the correct file for this system and

data is not correct loaded onto system load onto the unit

Valve position reading 1. Hallpot connection not tight 1. Tighten hallpot connection set screw

is not correct 2. Stroke not calibrated 2. Calibrate valve stroke

3. Hallpot shaft is not at correct 3. Readjust hallpot shaft connection,

part of rotation making sure that as the shaft rotates

the output signal is always increasing

as valve opens

Stem position decreas- 1. Hallpot wiring harness is installed 1. Reverse three-wire harness

es when valve opens backwards

2. Hallpot shaft is not on correct arc 2. Readjust hallpot shaft connection,

making sure that as the shaft rotates,

the output signal is always increasing

as valve opens

Sticking or hunting 1. Contamination of the spool valve 1. Check air supply for proper filtering and

operation of the assembly meeting ISA Specification S7.3.

positioner 2. Clean spool valve assembly with a non-

residue cleaner.

StarPac II/Logix 2000 Electronics Initialization Procedure

To re-initialize the electronics:

1. Turn OFF the 24V power.

2. Press and hold down the ZERO (0) key on the keypad while turning the 24V power ON

3. Release the key after the display has booted and is active (approx. 5 seconds)

The following conditions are set upon re-initialization. Those items that have been previously configured by

the user may need to be reconfigured when the unit is put back into operation:

• Mode source is set to Digital

• Data Logger is disabled

• Test mode is set

• Process variable = Liquid Flow

• Command source = Analog

• Positioner Source = Normal

• Positioner Gain is reset to 25 in˝ actuator

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

• Analog Feedback = Position

• PID action = Normal

• Air Action = Air-To-Open

• Totalizer is reset

• Modbus address is set to 1

• Communications is set to 19200 baud, Odd parity, RTU mode

42-15

Page 16

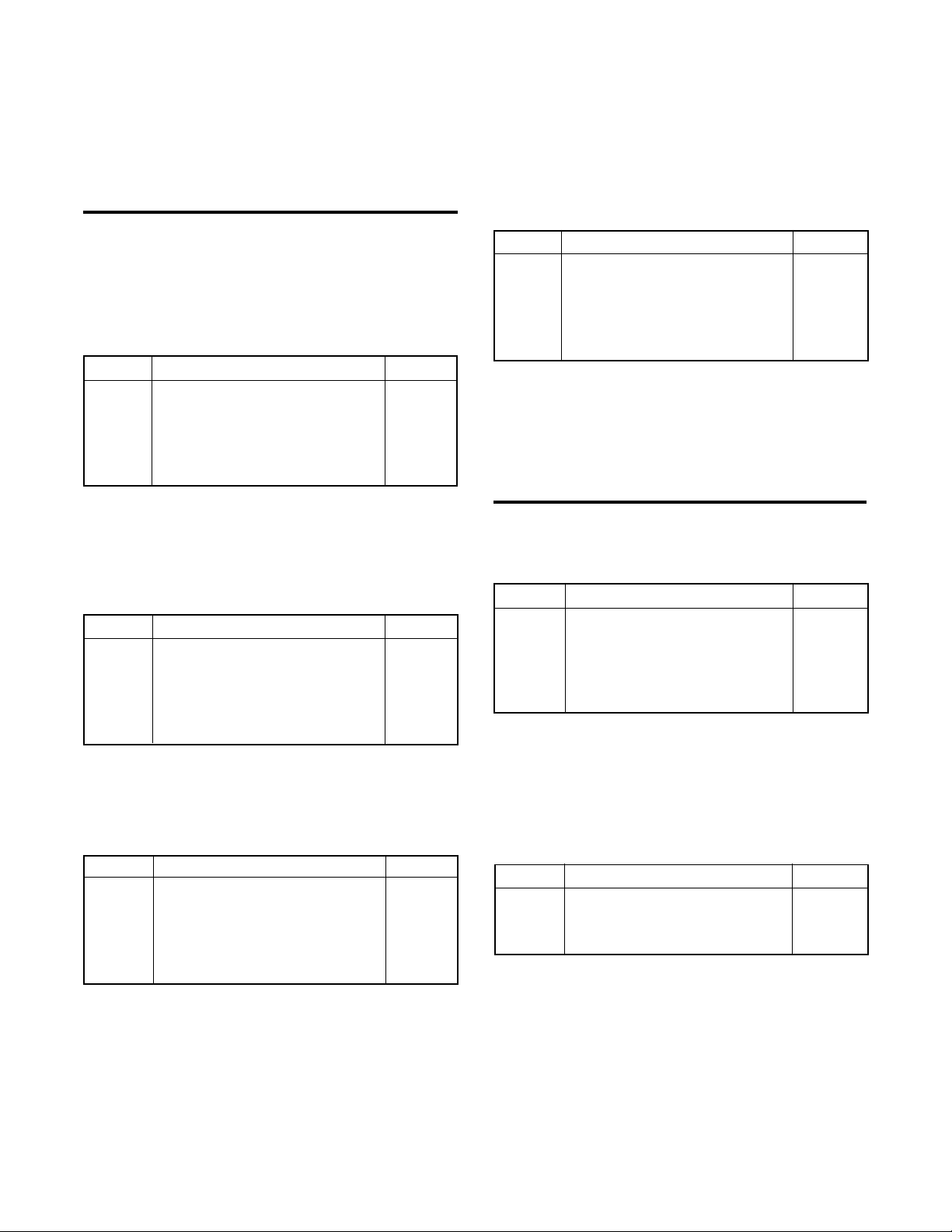

StarPac II and Logix Series 2000 Spare Parts Kits

See Figure 3: StarPac II / Logix 2000 Exploded View for item numbers.

Kit 1 - Upper Door Assembly

Part No. 10060956

Item No. Description Quantity

1 Upper door assembly 1

2 Door screw 4

3 Upper door gasket 1

Kit 2 - Lower Door Assembly

Part No. 10060958

Item No. Description Quantity

4 Lower door assembly 1

5 Door screw 2

6 Lower door gasket 1

Kit 3 - Key Pad Assembly

Part No. 10060978

Item No. Description Quantity

7 Inner door / keypad assembly 1

8 Inner door hinge screws 4

80 Inner door screw 2

81 Inner door screw O-ring 2

Kit 4 - Feedback Assembly*

Part No. 10060981

Item No. Description Quantity

16 Hall potentiometer assembly 1

17 Potentiometer bracket 1

18 Flex coupler 1

19 Bracket screw 2

20 Torsional spring 1

21 Feedback shaft 1

22 Shaft O-ring 1

23 Retaining ring 1

24 Hard stop screw 1

*NOTE: Feedback shaft tool included in kit. Assembly

comes pre-set from factory.

Kit 5 - Regulator Filter Replacement Kit

Part No. 10060988

Item No. Description Quantity

50 Driver module mounting screw 4

53 Pilot valve gasket 1

54 Regulator filter 1

Kit 6 - Driver Module Assembly*

Part No. 10060991

Item No. Description Quantity

44 Regulator set screw 1

45 Regulator housing screw 4

46 Regulator housing 1

47 Spring button 1

48 Regulator spring 1

49 Regulator diaphragm assembly 1

50 Driver module mounting screw 4

51 Pilot valve 1

52 Pilot valve screw 4

53 Pilot valve gasket 1

54 Regulator filter 1

55 Poppet guide 1

56 Poppet O-ring 1

57 Poppet 1

58 Poppet spring 1

59 Spool 1

60 Spool clip 1

61 Driver manifold O-ring 1

62 Driver spacer 1

63 Driver bearing 1

64 Spool return spring 1

65 Driver piston 1

66 Driver magnet 1

67 Driver manifold diaphragm 1

68 T-board screw 2

69 T-board 1

70 Orifice screw 1

71 Orifice screw O-ring 1

72 Orifice O-ring 1

73 Testing plug 2

74 Coil O-ring 1

75 Pressure modulator assembly 1

76 Spring diaphragm 1

77 Modulator cover 1

78 Modulator set screw 1

79 Modulator screw 3

*NOTE: Regulator and modulator are shipped factory

calibrated.

42-16

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 17

Kit 7 - StarPac II/Logix 2000 Electronics Board

Assembly

Part No. 10055130

Item No. Description Quantity

31 Adapter O-ring, lower 2

32 Pressure Sensor adapter 1

33 Adapter O-ring, upper 2

34 StarPac II board assembly 1

35 Board stiffener 1

36 Board assembly screw 3

37 Board stiffener screw 1

38 Board assembly screw 3

39 Board assembly screw 1

40 Personality card with EPROM 1

41 Personality card screw 4

84 24-pin ribbon cable 1

85 14-pin ribbon cable 1

Kit 8 - Personality Card, Modbus Communications

Part No. 10061003

Kit 13 - Soft Goods Kit

Part No. 10061007

Item No. Description Quantity

3 Upper door gasket 1

6 Lower door gasket 1

22 Shaft O-ring 1

29 Isolator 4

31 Adapter O-ring, lower 2

33 Adapter O-ring, upper 2

42 Rubber grommet 2

49 Regulator diaphragm assembly 1

53 Pilot valve gasket 1

56 Poppet O-ring 1

61 Driver manifold O-ring 1

67 Driver manifold diaphragm 1

71 Orifice screw O-ring 1

72 Orifice O-ring 1

73 Test plug 2

74 Coil O-ring 1

81 Inner door screw O-ring 2

Item No. Description Quantity

40 Personality card with EPROM 1

41 Personality card screw 4

Kit 9 - 24-pin Ribbon Cable

Part No. 10202746

Item No. Description Quantity

84 24-pin ribbon cable 1

Kit 10 - 14-pin Ribbon Cable

Part No. 10010221

Item No. Description Quantity

85 14-pin ribbon cable 1

Kit 11 - Standard Wire Harness Assembly

Part No. 10061008

Item No. Description Quantity

42 Rubber grommet 2

83 Wire harness assembly 1

Kit 12 - Wire Harness Assembly, Sealed

(Natural Gas Service)

Not shown in Figure 3

Part No. 10061012

Item No. Description Quantity

83 Wire harness assembly 1

Kit 14 - Driver Cover Assembly

Part No. 10061018

Item No. Description Quantity

11 Driver cover assembly 1

12 Cover screw 4

Kit 15 - Feedback Cover Assembly

Part No. 10061019

Item No. Description Quantity

9 Feedback cover assembly 1

10 Cover screw 4

Kit 16 - Door Gasket Replacement Kit

Part No. 10061384

Item No. Description Quantity

3 Upper door gasket 1

6 Lower door gasket 1

82 Keypad gasket 1

Kit 17 - External Air Filter Replacement

Part No. 10053002

Description Quantity

Coalescing air filter 1

Kit 18 - Follower Arm Pin for Linear Actuators

Part No. 10036685

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Description Quantity

Follower pin for linear actuators 1

42-17

Page 18

Table V: Valdisk Rotary Actuator

Mounting Kits

Actuator Shaft Size Air To Mounting

Size Kit

25 0.625 Open 10059458

25 0.625 Close 10059458

25 0.75 Open 10059459

25 0.75 Close 10059459

25 0.875 Open 10059460

25 0.875 Close 10059460

50 0.625 Open 10059461

50 0.625 Close 10059462

50 0.75 Open 10059463

50 0.75 Close 10059471

50 0.875 Open 10059472

50 0.875 Close 10059473

50 1.125 Open 10059476

50 1.125 Close 10059477

100 0.875 Open 10059474

100 0.875 Close 10059475

100 1.125 Open 10059478

100 1.125 Close 10059479

100 1.5 Open 10059480

100 1.5 Close 10059481

100 1 0.75 Open 10059482

100 1 0.75 Close 10059483

200 1.125 Open 10094606

200 1.125 Close 10094607

200 1.5 Open 10094608

200 1.5 Close 10094609

200 1 0.75 Open 10094610

200 1 0.75 Close 10094611

Mounting kit includes bracket, linkage assembly ,

follower arm, and all necessary nuts, bolts and

washers.

T able VI: StarPac Accessories

Description Number

Converter, RS232/RS485, 110/220 VAC 10055963

StarPac Analog Interface (8 Channel),

24 VDC 10069207

Power supply, DIN rail mounted,

110 VAC to 24 VDC 10079519

Table VII: Valdisk 150 Rotary Actuator

Mounting Kits

Actuator Shaft Size Air To Mounting

Size Kit

25 0.625 Open 10059458

25 0.625 Close 10059458

25 0.875 Open 10059460

25 0.875 Close 10059460

50 0.625 Open 10059461

50 0.625 Close 10059462

50 0.875 Open 10059472

50 0.875 Close 10059473

50 1.0625 Open 10059484

50 1.0625 Close 10059486

50 1.34375 Open 10059489

50 1.34375 Close 10059490

100 0.875 Open 10059474

100 0.875 Close 10059475

100 1.0625 Open 10059487

100 1.0625 Close 10059488

100 1.34375 Open 10059492

100 1.34375 Close 10059495

100 1.375 Open 10059496

100 1.375 Close 10059504

100 1.5 Open 10059480

100 1.5 Close 10059481

100 1 0.75 Open 10059482

100 1 0.75 Close 10059483

200 1.0625 Open 10094612

200 1.0625 Close 10094613

200 1.34375 Open 10094614

200 1.34375 Close 10094615

200 1.375 Open 10094616

200 1.375 Close 10094617

200 1.5 Open 10094608

200 1.5 Close 10094609

200 1 0.75 Open 10094610

200 1 0.75 Close 10094611

Mounting kit includes bracket, linkage assembly ,

follower arm, and all necessary nuts, bolts and

washers.

T able VIII: Completed Assemblies

Description Number

StarPac II assembly 10007028

Logix 2000 assembly 10053635

42-18

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 19

Table IX: ShearStream Rotary Actuator Mounting Kits

Shaft Size Air To / Shaft Mounting 25 Actuator 50 Actuator 100 Actuator 200 Actuator

Open / Up Right (Std) 10059457

Left 10059457

Close / Up Right (Std) 10059457

0.4375

0.625

0.75

0.875

1.125

1.5

10.75

Close / Down Right (Std) 10059457

Open / Down Right (Std) 10059457

Open / Up Right (Std) 10059458 10059461

Close / Up Right (Std) 10059458 10059462

Close / Down Right (Std) 10059458 10059461

Open / Down Right (Std) 10059458 10059462

Open / Up Right (Std) 10059459 10059463

Close / Up Right (Std) 10059459 10059471

Close / Down Right (Std) 10059459 10059463

Open / Down Right (Std) 10059459 10059471

Open / Up Right (Std) 10059460 10059472 10059474

Close / Up Right (Std) 10059460 10059473 10059475

Close / Down Right (Std) 10059460 10059472 10059474

Open / Down Right (Std) 10059460 10059473 10059475

Open / Up Right (Std) 10059476 10059478 10094606

Close / Up Right (Std) 10059477 10059479 10094607

Close / Down Right (Std) 10059476 10059478 10094606

Open / Down Right (Std) 10059477 10059479 10094607

Open / Up Right (Std) 10059480 10094608

Close / Up Right (Std) 10059481 10094609

Close / Down Right (Std) 10059480 10094608

Open / Down Right (Std) 10059481 10094609

Open / Up Right (Std) 10059482 10094610

Close / Up Right (Std) 13359483 10094611

Close / Down Right (Std) 10059482 10094610

Open / Down Right (Std) 13359483 10094611

Mounting kit includes bracket, linkage assembly, follower arm, and all necessary nuts, bolts and washers.

Left 10059457

Left 10059457

Left 10059457

Left 10059458 10059462

Left 10059458 10059461

Left 10059458 10059462

Left 10059458 10059461

Left 10059459 10059471

Left 10059459 10059463

Left 10059459 10059471

Left 10059459 10059463

Left 10059460 10059473 10059475

Left 10059460 10059472 10059474

Left 10059460 10059473 10059475

Left 10059460 10059472 10059474

Left 10059477 10059479 10094607

Left 10059476 10059478 10094606

Left 10059477 10059479 10094607

Left 10059476 10059478 10094606

Left 10059481 10094609

Left 10059480 10094608

Left 10059481 10094609

Left 10059480 10094608

Left 13359483 10094611

Left 10059482 10094610

Left 13359483 10094611

Left 10059482 10094610

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-19

Page 20

Pressure and Temperature Sensor Spare Part Kits

See Body Mount Sensor Configurations Drawing and Remote Mount Sensor

Configuration Drawing for item numbers.

Pressure Sensor Gasket Kits

NOTE: Kits 1 thru 4 will service two body or two remote-

mount pressure sensors from any one of the pressure

sensor configuration drawing numbers listed below

each table.

Kit 1 - Viton O-ring Replacement Kit

Part No. 10061027

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 O-ring seal, Viton 2

20 Environmental O-ring, Viton 2

21 O-ring seal, Viton 2

Configuration Drawing Numbers: 83883, 83891,

83904, 83884, 83892, 101565, 83887 83900,

127586, 83888, 83901

Kit 2 - Spiral Wound Gasket Replacement Kit

Part No. 10061028

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 O-ring seal, Viton 2

20 Environmental O-ring, Viton 2

21 Spiral wound gasket seal 2

Configuration Drawing Numbers: 83938, 83890,

122670, 83886, 83903, 127563, 83899, 127632

Kit 4 - Kalrez O-ring Replacement Kit

Part No. 10061113

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 O-ring seal, Kalrez

20 Environmental O-ring, Kalrez 2

21 O-ring seal, Kalrez 2

Configuration Drawing Numbers: 83885, 83889,

127665, 83893, 83902

™

2

Pressure Sensor Hardware Kits

Kit 5 - Pressure Sensor Connection Kit, Div II

Non-incendive Configuration

Part No. 10061022

Item No. Description Quantity

3 Swagelok nut 2

4 Swagelok ferrules 2

5 Sensor nut 2

6 Environmental O-ring, Viton

7 Division II sensor fitting 2

NOTE: Kit will service two pressure sensors.

For class I, Division II, Group A, B, C, & D.

See Table XIII for Tubing.

®

2

Kit 3 - PTFE Gasket Replacement Kit

Part No. 10061029

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 PTFE gasket seal 2

20 Environmental O-ring, Viton 2

21 PTFE gasket seal 2

Configuration Drawing Numbers: 122513, 127565

42-20

Kit 6 - Pressure Sensor Connection Kit, Div I

Configuration

Part No. 10061023

Item No. Description Quantity

13 Division I sensor fitting 2

5 Sensor nut 2

6 Environmental O-ring, Viton 2

NOTE: Kit will service two pressure sensors.

For class I, Division I, Groups B, C, & D.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 21

Kit 7 - Remote Mount Pressure Sensor Hardware Kit

Part No. 10061025

Item No. Description Quantity

3 Swagelok nut 4

4 Swagelok ferrules 4

15 Temperature extended fitting 2

19 Adapter fitting 2

NOTE: Kit will service two remote-mount pressure

sensors. See Table XIII for tubing. (Wet-leg tubing

wall thickness must be 0.065-inch).

Kit 8 - Remote Mount Pressure Sensor Hardware

Kit with Purge and Isolation Valves

Part No. 10061026

Item No. Description Quantity

3 Swagelok nut 4

4 Swagelok ferrules 4

15 Temperature extended fitting 2

16 Purge valve 2

17 Isolation valve 2

19 Adapter fitting 2

NOTE: Kit will service two remote-mount pressure

sensors. See Table XIII for tubing. (Wet-leg tubing

wall thickness must be 0.065-inch).

Kit 12 - Pressure Sensor Calibration Kit

Part No. 10061118

Description Quantity

Pressure sensor calibration fixture 1

Electrical connector extension cable 2

O-ring seal, Viton 2

NOTE: Two sensors can be calibrated simultaneously with this kit.

Kit 13 - DP Cell Manifold Replacement

Part No. 10203723

Description Quantity

Valve manifold 1

Temperature Probe Kits

See temperature sensor configurations drawing for

item numbers.

Kit 14 - Standard Temperature Probe

Replacement, Div II Configuration

Part No. 10055955

Item No. Description Quantity

2 Standard temperature probe 1

Kit 9 - Explosion Proof Union Fitting

Part No. 10007238

Item No. Description Quantity

14 Explosion proof union 1

Kit 10 - Pressure Sensor Electrical Cable

Replacement Kit

Part No. 10061117

Item No. Description Quantity

1 Electrical connector cable 2

22 Four-pin connector 2

23 Wire crimp terminal 16

NOTE: Kit will service two pressure sensors.

Kit 11 - Pressure Sensor Electrical Extension Cable

Part No. 10054518

Description Quantity

Electrical connector extension cable 1

Kit 15 - Standard Temperature Probe

Replacement, Div I Configuration

Part No. 10070891

Item No. Description Quantity

2 Standard temperature probe 1

6 Adapter fitting 1

7 Adapter fitting 1

Kit 16 - Through Hole Temperature Probe

Replacement

Part No. 10065272

Item No. Description Quantity

2 Through hole temperature probe 1

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-21

Page 22

12

11

10

Boss on

valve body

8

13

6

5

14

1

9

8

1. Electrical connection cable

2. Tubing, 0.035 wall thickness (see Table XIII)

3. Swagelock nut

4. Swagelock ferrule set

5. Sensor nut

6. Environmental O-ring

7. Division II sensor fitting

8. Environmental O-ring

9. Pressure sensor

10. O-ring seal

11. Length adapter fitting

Figure 17: Body-mount Sensor Configurations

This table is a combination of Kit 17 and Table XI.

Table X: Pressure Sensor Accessories

Description Number

PTFE cap for flush-mount sensors 10203061

Pressure sensor length adapters

w/Viton O-rings, 10070892

Pressure sensor length adapters

w/spiral-wound gaskets 10070893

NOTE: On July 1993, the sensor manufacturer

shortened the process end of the pressure sensors.

If the StarPac uses the longer style sensors, order

one of the above adapter kits with the new sensor

purchase. Each kit will service two pressure sensors.

4

3

7

2

6

5

12. O-ring seal

13. Division I sensor fitting

14. Explosion-proof union

15. Wire crimp terminals

16. Four-pin connector

15

16

Table XI: Flush Mount Pressure Sensor

Diaphragm

Description

Hastelloy C

Pressure sensor, 0-25 PSIA, flush 10103511

Pressure sensor, 0-50 PSIA, flush 10103512

Pressure sensor, 0-100 PSIA, flush 10103514

Pressure sensor, 0-150 PSIA, flush 10103516

Pressure sensor, 0-300 PSIA, flush 10103519

Pressure sensor, 0-500 PSIA, flush 10103521

Pressure sensor, 0-1000 PSIA, flush 10103522

NOTE: Flush mount sensors are not rated for Division I applications.

Material

42-22

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 23

Boss on

valve body

12

11

21

20

22

23

4

5

2

3

6

7

8

13

6

9

5

14

16

15

4

3

19

1

4

3

8

10

18

17

4

3

18

1. Electrical connector cable

2. Tubing 0.035-inch wall, (see T able XIII)

3. Swagelock nut

4. Swagelock ferrule set

5. Sensor nut

6. Environmental O-ring

7. Division II sensor fitting

8. Environmental O-ring

9. Pressure sensor

10. O-ring seal

11. Length adapter fitting

12. O-ring seal

13. Division I sensor fitting

14. Explosion-proof union

3

4

15. Temperature extended fitting

16. Purge valve

17. Isolation valve

18. Wet-leg tubing, 0.065-inch wall, (see T able XIII)

19. Adapter fitting

20. Environmental O-ring

21. O-ring seal

22. Four-pin connector

23. Wire crimp terminals

Figure 18: Remote-mount Sensor Configurations

Table XII: Standard Pressure Sensor

Description

Pressure sensor, 0-25 PSIA 10062971

Pressure sensor, 0-50 PSIA 10062972

Pressure sensor, 0-100 PSIA 10062957

Pressure sensor, 0-150 PSIA 10062963

Pressure sensor, 0-300 PSIA 10062974

Pressure sensor, 0-500 PSIA 10062965

Pressure sensor, 0-1000 PSIA 10062960

Pressure sensor, 0-1500 PSIA 10062975

Pressure sensor, 0-3000 PSIA 10062977

Pressure sensor, 0-5000 PSIA 10062978

Pressure sensor, 0-7500 PSIA 10091198

NOTE: Hastelloy C sensors are not rated for Division I applications.

Diaphragm Material

316 Stainless steel

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

42-23

Page 24

4

Temperature probe boss

3

Div II Configuration

2

1

7

2

146

5

Div I Configuration

1. T wo-pin connector

2. Temperature probe

3. T ubing, 0.035 wall, (see Table XIII)

4. Swagelock tube fitting

5. Stainless steel pipe

6. Adapter fitting

7. Adapter fitting

14. Explosion-proof union

Figure 19: StarPac Temperature Sensor, Flush-mount Version

Table XIII: 316 Stainless Steel Tubing

Description Number

Pressure sensor wire tubing (0.50-inch diameter 0.035-inch thick) 10045503

Temperature extended wet leg tubing (0.50-inch diameter 0.065-inch thick) 10055784

I/P wire and thermocouple tubing (3/8-inch diameter, 0.035-inch thick) 10013367

1

On remote mount pressure sensor configurations, the wet-leg tubing must have a wall thickness of 0.065-inch.

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its

intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications

under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation and maintenance of Flowserve products.

The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe

use of Flowserve products in connection with the specific application.

While the information and specifications presented in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or

as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect

to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change

without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any of its worldwide operations or offices.

For more information, contact:

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

FCD VLAIM042-03 © 2000 Flowserve Corporation. Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

For more information about Flowserve, contact www.flowserve.com or call USA 972 443 6500

Regional Headquarters

1350 N. Mt. Springs Prkwy.

Springville, UT 84663

Phone 801 489 8611

Facsimile 801 489 3719

12 Tuas Avenue 20

Republic of Signapore 638824

Phone (65) 862 3332

Facsimile (65) 862 4940

12, av. du Québec, B.P. 645

91965, Courtaboeuf Cedex,

France

Phone (33 1) 60 92 32 51

Facsimile (33 1) 60 92 32 99

Quick Response Centers

5114 Railroad Street

Deer Park, TX 77536 USA

Phone 281 479 9500

Facsimile 281 479 8511

104 Chelsea Parkway

Boothwyn, PA 19061 USA

Phone 610 497 8600

Facsimile 610 497 6680

1300 Parkway View Drive

Pittsburgh, PA 15205 USA

Phone 412 787 8803

Facsimile 412 787 1944

Loading...

Loading...