Fisher & Paykel OR30SLDGX, OR30SNDGX User Guide

Installation instructions

and User guide

Freestanding range

OR30SLDGX & OR30SNDGX models

Instructions d’installation

et Guide d’utilisation

Cuisinière indépendante

Modèles OR30SLDGX et OR30SNDGX

US CA

WARNING!

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

NEVER use this appliance as a space heater

to heat or warm the room. Doing so may

result in carbon monoxide poisoning and

overheating of the appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Contents

Important installation information 2

Safety practices and precautions

Parts identi cation 7

Planning the installation

Unpacking and handling

Ventilation requirements

Installing anti-tip device

Cabinet preparation

Backguard installation

Electrical connections

Gas hook-up

Test and adjustments

Installer final checklist

22

Before using your appliance 23

Cooktop use 25

Oven use

Care and maintenance 36

Troubleshooting

How to obtain service

11

13

14

15

17

18

19

20

28

41

43

1

US CA

3

9

Warranty

Important!

SAVE THESE INSTRUCTIONS

The models shown in this user guide may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please go to our website www.fisherpaykel.com or

contact your local Fisher & Paykel dealer.

45

US CA

2

Important installation information

The range is tested in accordance with ANSI Z21.1 Standard for Household Cooking Gas

Appliances. The range must be installed in conjunction with a suitable overhead vent hood

(see ventilation requirements on page 13). Due to the professional high heat capacity of this

unit, particular attention should be paid to the hood and duct work installation to ensure it

meets local building codes. To eliminate risk of burns or fire by reaching over heated surface

units, cabinet storage located above the surface units should be avoided.

Check local building codes for the proper method of range installation. Local codes vary.

Installation, electrical connections, and grounding must comply with all applicable codes. In

the absence of local codes, the range should be installed accordance with the National Fuel

Gas Code ANSI Z223-1 and National Electrical Code ANSI/NFPA 70. Be sure that the unit being

installed is set up for the kind of gas being used. The gas ranges are shipped from the factory

set and adjusted for natural gas or LP (propane), depending on the specific model ordered.

Verify that the range is compatible with gas supply at the installation site before proceeding

further. Return range to dealer if unit is not set for site gas supply.

Important safety precautions!

To reduce the risk of injury to persons in the event of a rangetop grease fire, observe the following: Turn

burner off first. Smother flames with a close-fitting lid, cookie sheet, metal tray, baking soda or use a

dry chemical or foam-type fire extinguisher. Be careful to prevent burns. If the flames do not go out

immediately, evacuate and call the fire department. Never pick up a flaming pan - You may be burned.

DO NOT USE WATER ON GREASE FIRES, including wet dishcloths or towels - a violent steam explosion will

result. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

Safety practices and precautions

When properly cared for, your new Fisher & Paykel Appliance has been designed to be a safe,

reliable cooking appliance. When using this restaurant caliber appliance, use it with extreme

care, as this type appliance provides intense heat and can increase the accident potential. Basic

safety precautions must be followed when using kitchen appliances, including the following:

Read the Installation Instructions and User Guide which came with this appliance thoroughly before

using your new appliance. This will help to reduce the risk of fire, electric shock, or injury to persons.

Begin by insuring proper installation and servicing. Follow the installation instructions in this manual.

Be sure to have a qualified technician install and ground this appliance before using.

Have the installer show you where the gas supply shut-off valve is located so you will know how and

where to turn off the gas to the appliance.

If you smell gas, the installer has not done a proper job of checking for leaks. You can have a small

leak and therefore a faint gas smell if the connections are not completely tight. Finding a gas leak is

not a “do-it-yourself” procedure. Some leaks can only be found with the burner control in the “ON”

position and for your protection it must be done by a qualified service technician.

If by some chance a burner goes out and gas escapes, open a window or a door to let the room

air out. Do not attempt to use the appliance until the gas has had time to dissipate. Follow the

instructions on the inside front cover of this manual.

This appliance has been factory assembled for natural or LP gas. It should be correctly adjusted from

the factory for the type of gas that is used.

Do not repair or replace any part of this appliance unless it is specifically recommended in this

manual. All other servicing should be referred to a qualified technician.

Children should not be left alone or unattended in an area where appliances are in use. They should

never be allowed to turn knobs, push buttons, sit or stand on, and/or touch any part of an appliance

while in operation.

Children in walkers, or children crawling can be attracted to the oven door handle and may grab and

open the oven door. This can result in injury from the door being pulled open on a child, or severe

burns if the oven is in use and hot.

3

US CA

Important!

Do not store items of interest to children above or at the back of any appliance. Children could be seriously

injured if they should climb onto the appliance to reach these items.

Never store anything in the oven or on the cooktop. Flammable materials can catch fire, plastic items

may melt or ignite and other types of items could be ruined.

Do not hang articles from any part of the appliance or place anything against the oven. Some fabrics

are quite flammable and may catch on fire.

If the appliance is near a window be certain the curtains do not blow over or near the cooktop

burners; they could catch on fire.

Do not use water on grease fires. Turn all burners “OFF”, then smother fire with baking soda or use a

dry chemical or foam-type fire extinguisher.

Never let clothing, pot holders, or other flammable materials come in contact with, or too close to,

any burner or burner grate until it has cooled. Fabric may ignite and result in personal injury.

Be certain to use only dry pot holders: moist or damp pot holders on hot surfaces may cause burns

from steam. Do not use a towel or other bulky cloth in place of pot holders. Do not let pot holders

touch hot burners, or burner grates.

US CA

4

Safety practices and precautions

For personal safety, wear proper apparel. Loose fitting garments or hanging sleeves should never

be worn while using this appliance. Some synthetic fabrics are highly flammable and should not be

worn while cooking.

Do not use aluminum foil to line any part of the oven or cooktop. This will cause heat to be trapped

underneath it. This trapped heat can upset the cooking performance and can damage the finish of

the oven or the cooktop parts.

Important!

Never cover any slots, holes or passages in the oven bottom or cover an entire rack with materials such

as aluminum foil. Doing so blocks airflow through the oven and may cause carbon monoxide poisoning.

Aluminum foil linings may also trap heat, causing a fire hazard.

This appliance is for cooking. Never use the oven or cooktop to warm or heat a room. This could

damage the cooktop or oven parts.

Important!

Never use this appliance as a space heater to heat or warm the room. Doing so may result in carbon

monoxide poisoning and overheating of the oven.

When using the cooktop: Do not touch the burner grates or the immediate surrounding area. Areas

adjacent to the burners may become hot enough to cause burns.

When using the oven: Do not touch the interior surfaces of the oven, the exterior area immediately

surrounding the door or the back trim. The surfaces directly above the oven door may be hot if the

oven has been operated with the door open, or if something has prevented the door from sealing.

Never leave the cooktop unattended when using high flame settings. When cooking with high flame

settings, boil overs may cause smoking and greasy spill overs may ignite. More importantly, if the

burner flames are smothered by a severe boil over which effects the igniter, unburned gas will escape

into the room.

Only certain types of glass, heat-proof glass-ceramic, ceramic, earthen ware, or other glazes utensils

are suitable for cooktop use. This type of utensil may break with sudden temperature changes.

Use only on low or medium flames settings according to the manufacturer’s directions. The use of

professional utensils is recommended.

Do not heat unopened food containers; a build up of pressure may cause the container to burst.

During cooking, set the burner control so that the flame heats only the bottom of the pan and does

not extend beyond the bottom of the pan. This could heat and/or melt the handles, and may increase

cooking time.

Always use utensils that have flat bottoms large enough to cover the burner. The use of undersized

utensils will expose a portion of the flame to direct contact and may result in ignition of clothing.

To minimize burns, ignition of flammable materials and unintentional spill overs, position handles

of utensils inward so they do not extend over adjacent work areas, cooking areas, or the edge of the

cooktop.

Hold the handle of the pan to prevent movement of the utensil when stirring or turning food.

Grease is flammable. Let hot grease cool before attempting to handle it. Avoid letting grease deposits

collect around the cooktop burners. Clean after each use or boil over.

Safety practices and precautions

For proper lighting and performance of the cooktop burners, keep the burner ports clean. It may

be necessary to clean these when there is a boil over or when the burner does not light, even

though the electronic igniters click.

Clean the cooktop with caution. Avoid steam burns; do not use a wet sponge or cloth to clean the

cooktop while it is hot. Some cleaners produce noxious fumes if applied to a hot surface. Follow

directions provided by the cleaner manufacturer.

Be sure all the range and/or cooktop controls are turned off and the appliance is cool before using

any type of aerosol cleaner on or around the appliance. The chemical that produces the spraying

action could, in the presence of heat, ignite or cause metal parts to corrode.

Place oven racks in desired position while the oven is cool. If a rack must be moved while the oven

is hot, do not let the pot holders contact the hot interior of the oven.

Use care when opening the oven door; let hot air or steam escape before removing or replacing

foods.

Do not rub, damage, move or remove the door gasket. It is essential for a good seal during

baking. Wash the gasket with hot water only.

Clean the ventilator hood and filters above the range or cooktop frequently so grease from

cooking vapors does not accumulate on them. The filters can be cleaned in a dishwasher or

DishDrawer. Follow directions provided by ventilation manufacturer for cleaning.

Turn the ventilator “OFF” in case of fire or when intentionally “flaming” liquor or other spirits on

the cooktop. The blower, if in operation, could unsafely spread the flames.

DO NOT obstruct the flow of combustion or ventilation air to the appliance. Be sure a fresh air

supply is available.

For safety reasons and to avoid damage to the appliance never sit, stand, or lean on the oven

door or cooking surface.

Service should only be done by authorized technicians. Technicians must disconnect the power

supply before servicing this appliance.

5

US CA

Important!

The Governor of California is required to publish a list of substances known to the state of California to

cause cancer or reproductive harm and requires businesses to warn customers of potential exposures

to such substances.

WARNING!: Gas appliances contain or produce substances which can cause death or serious illness and

which are known to the State of California to cause cancer, birth defects or other reproductive harm. To

reduce the risk from substances in fuel or from fuel combustion, make sure this appliance is installed,

operated, and maintained according to the manufacturer’s instructions.

Recommendations on hook-up to gas supply:

A manual valve must be installed external to the appliance, in an accessible location from the

front for the purpose of shutting off the gas supply. The supply line must not protrude beyond the

back of the unit. Make sure the gas supply is turned off at the wall valve before connecting the

appliance.

US CA

6

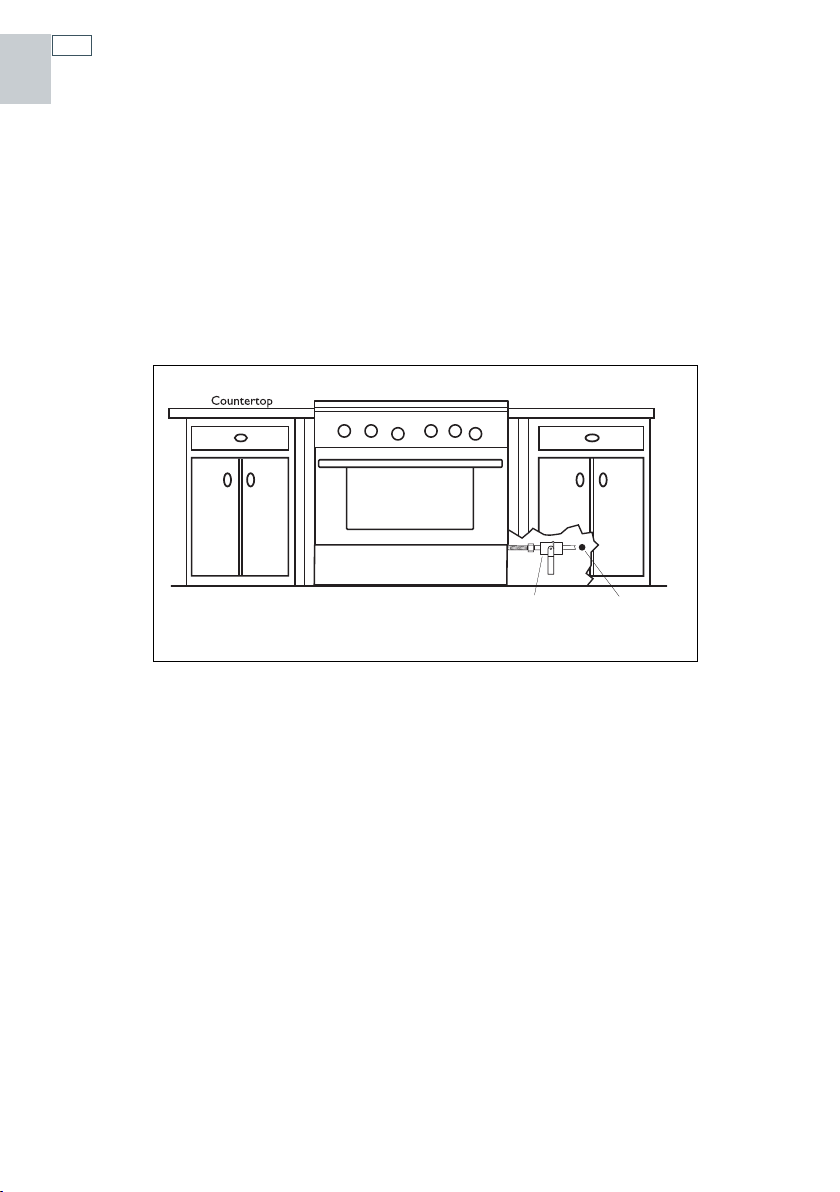

Safety practices and precautions

The gas supply connections should be made by a qualified technician and in accordance with

local codes or ordinances. In the absence of a local code, the installation must conform to the

latest edition of National Fuel Gas Code ANSI Z223.1.

Note: This product must be installed by a licensed plumber or gas fitter when installed within

the Commonwealth of Massachusetts.

Note: (mandatory for the State of Massachusetts)

Alternate method of supplying gas must be installed into the unit (see illustration below).

Installer supplied shut-o valve

must be easily accessible inside

cabinetry.

Gas Supply

Parts identi cation

1

2

7

US CA

3

7

4

5

6

8

1

Island Trim

2

Burner Grates

3

Cooktop Burners Control Knobs

4

Oven Control Knob

5

Oven Door Handle

6

Window

7

Convection Fan Control Knob

8

Kick Panel

US CA

8

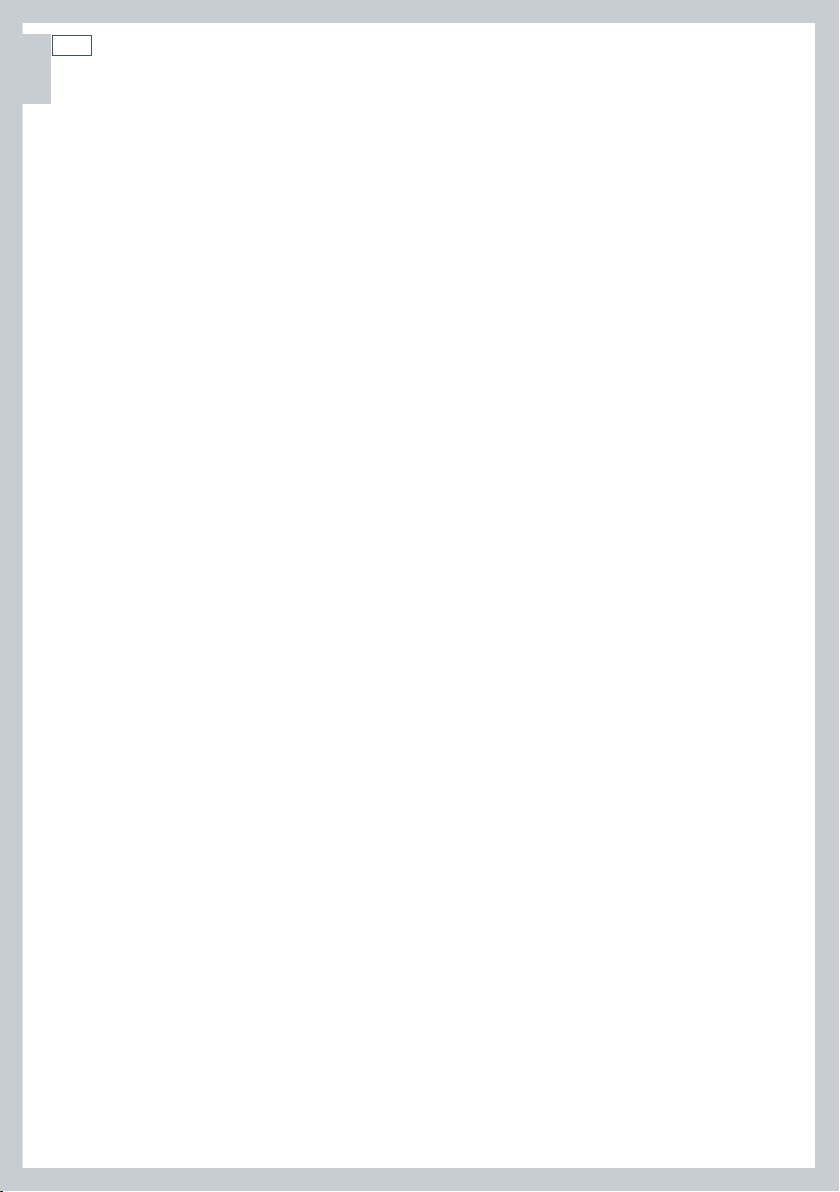

Parts identi cation

1

5

2

6

7

3

8

4

1

Broiler Burner

2

Convection Baffle

3

Oven Racks

4

Oven Door

5

Oven Light (not shown)

6

Oven Thermostat Sensing Bulb

7

Convection Fan (behind the baffle in the back wall of the oven)

8

Oven Door Gasket

Planning the installation

Important installation information

This gas range is tested in accordance with ANSI Z21.1 Standard for Household Cooking Gas

Appliances.

The range must be installed in conjunction with a suitable overhead vent hood. (See

ventilation requirements, page 13). Due to the professional high heat capacity of this unit,

particular attention should be paid to the hood and duct work installation to ensure it meets

local building codes. To eliminate risk of burns or fire by reaching over heated surface units,

cabinet storage located above the surface units should be avoided.

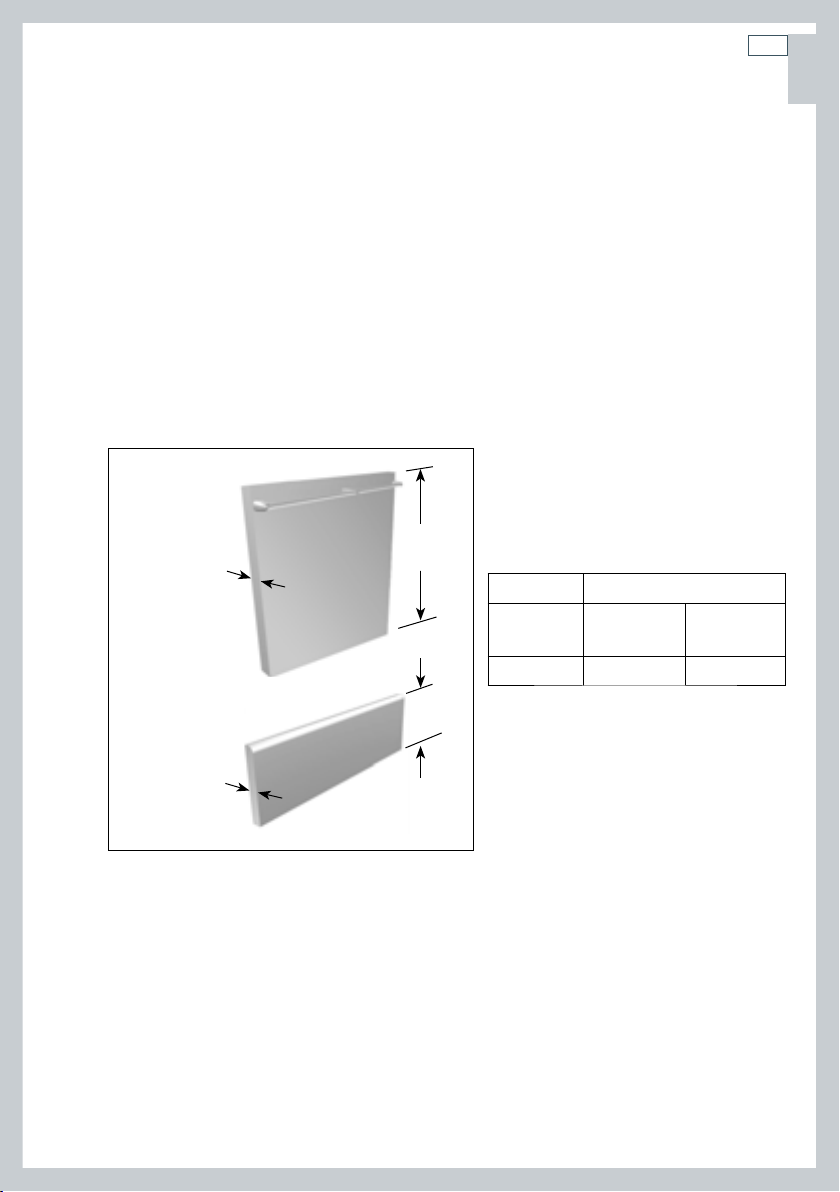

All range models with less than a 12” clearance between combustible material and the back

edge and sides of the range (above the cooking surface), require the installation of one of

the two offered Wall Mount Backguards (Fig.01) – see page 17.

Wall Mount

Full Backguard

9

US CA

1⁄”

Wall Mount

Low Backguard

1⁄”

Check local building codes for the proper method of range installation. Local codes vary.

Installation, electrical connections, and grounding must comply with all applicable codes.

In the absence of local codes, the range / cooktop should be installed in accordance with

the latest edition of National Fuel Gas Code ANSI Z223.1 and National Electrical Code ANSI /

NFPA 70.

Be sure that the unit being installed is set up for the kind of gas being used. The gas range

is shipped from the factory set and adjusted for Natural Gas or LP (propane), depending

on the specific model ordered. Verify that the range is compatible with the gas at the

installation site before proceeding further. Return range to dealer if the unit is not set for

site gas supply.

28⁄”

10⁄”

Model Number

Low

Backguard

30” Range BGS-1230 BGS-3030

All ranges are shipped with a

standard 2” integral island trim.

Fig. 01

Full

Backguard

US CA

10

Planning the installation

Recommended Installation Instruction

Install components in the following order:

A. Ventilation (see page 13)

B. Backguard System (sold separately, refer to page 17)

C. Range

1. Locate and level the range so that the top side panels are at the same height as the finished

countertop.

2. Measure distance from floor to top of island trim on range, adding ⁄” for backguard

clearance.

3. Transfer this measurement to the wall. This will mark the bottom of your backguard.

4. From this line measure 28” up wall to mark the top of a 30” backguard. This is the minimum

height that the bottom of your vent hood can be installed.

5. Follow vent hood manufacturer’s installation instructions to install vent hood.

6. Follow backguard installation instructions to install backguard.

7. Connect gas and electric connections and slide range into position.

Note: A manual gas supply valve must be installed. See page 19.

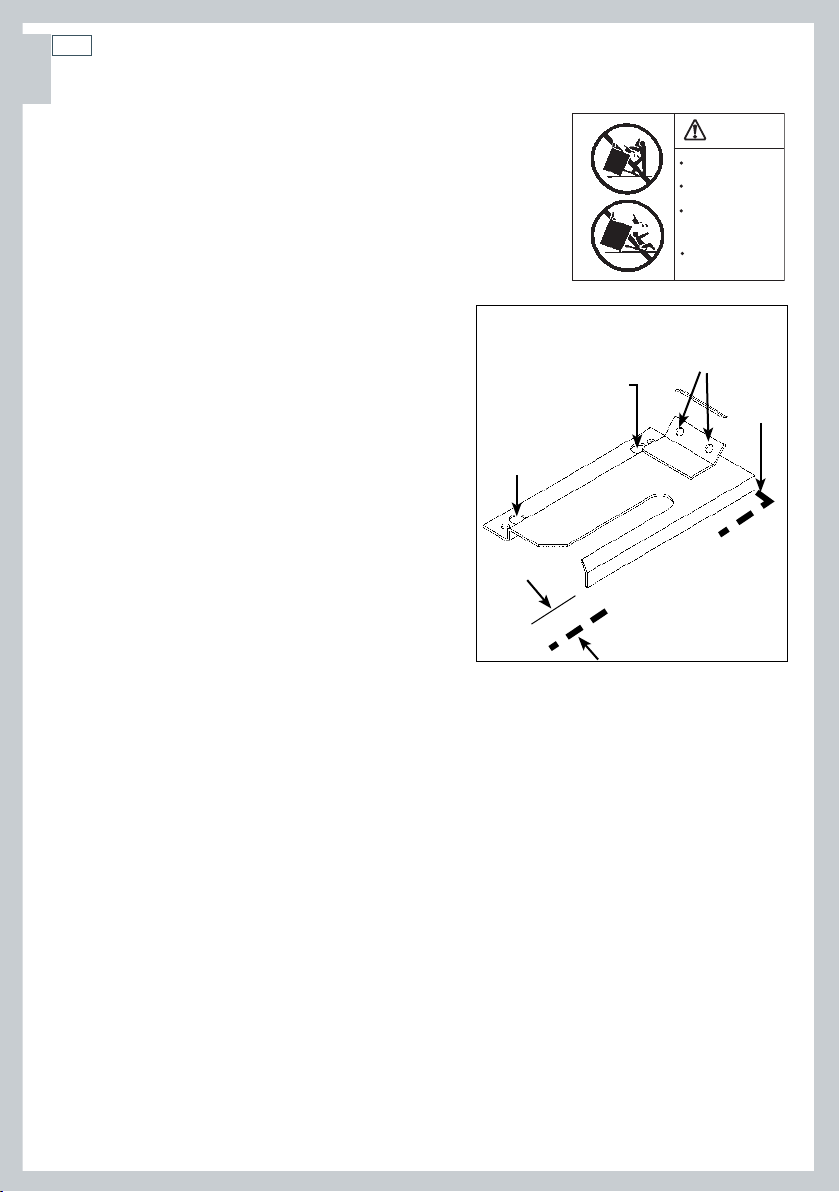

Unpacking and handling

Important!

Proper equipment and adequate manpower must be used in moving the range to avoid

damage to the unit or the floor. The unit is heavy and rests on adjustable steel legs.

DO NOT lift range by the oven door handle!!

Moving and placing the range

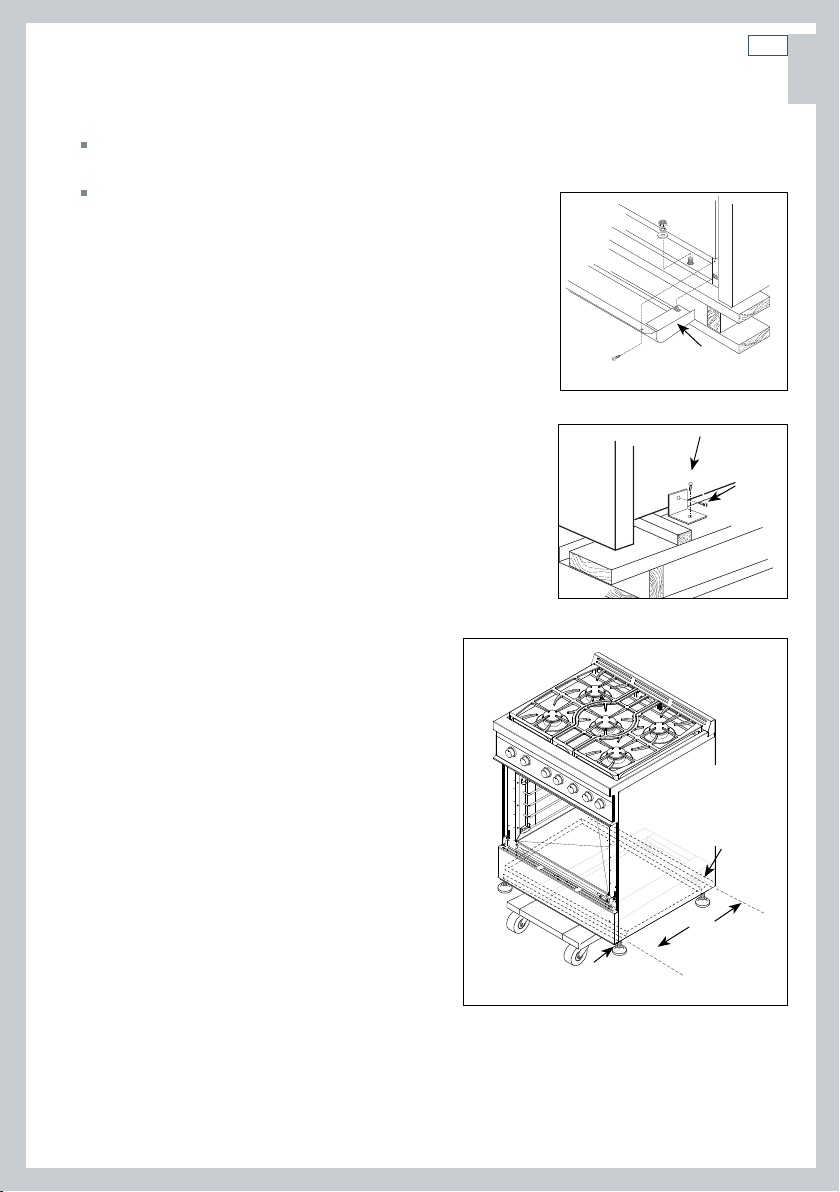

The range has a shipping weight of 380 lbs. less approx. 50

lbs. after removal of packing material. It is recommended

that the door, grates, and front kick panel be removed to

facilitate handling. This will reduce the weight for ease of

handling.

Remove the two screws at the top of the kick panel and

pull the panel forward. The range is held to the skid by two

bolts in the front, behind the kick panel (Fig. 02), and two

L-brackets located on the bottom flange of the range back

(Fig. 03). After removing the bolts and brackets, the range

must be lifted and removed from the skid.

It may be necessary to remove the oven door and knobs to

pass through some doorways. With the door

and knobs removed, a 29⁄” wide opening

is required. Without removing the door, a

30” wide opening is required. Remove the

outer carton and packing material from the

shipping base.

Kick panel

Fig. 02

Left rear

shipping

screws

Fig. 03

11

US CA

Due to the weight, a dolly with soft wheels

should be used to move this unit. The

weight must be supported uniformly across

the bottom (Fig. 04).

Electric and gas connections should be

made before the range is slid into the

cabinet opening (see pages 18-19). If

installing a full backguard with the range,

it should also be installed before the range

is placed in its final position (refer to pages

9 and 17). For proper performance, the

range should be level. To achieve a flush fit

of the range to adjoining countertops, it will

be necessary to have level cabinets (front to back, and left to right across opening of the

range). After checking the countertops for level and before sliding the range into place,

measure the distance from the floor to the top of the counter work surface in the rear left

and right corners. Adjust the corresponding rear corner of the range to an equal height of

Leveling legs

Range must

be uniformly

supported on

braces

22”

Fig. 04

US CA

Hinge tongue

Hinge slot

12

Unpacking and handling

the counter, as the rear leveling legs are not accessible once the range is pushed into place.

Once the range is in place, the front leg levelers can be accessed to level the front of the

range. Replace the kick panel and oven door by reversing the procedure described on this

page and page 11 . It is important that the two screws retaining the kick panel are secure to

prevent accidental access to live electrical components and wires (Fig. 02).

Anti-tip device should be installed (see page 14 for instructions). The range should be

transported by a dolly close to its final location. The range can be tipped back and

supported on the rear legs while the dolly is removed. The floor under the legs should be

protected (wood strips, carpet, paneling, etc.) before pushing the unit back into position.

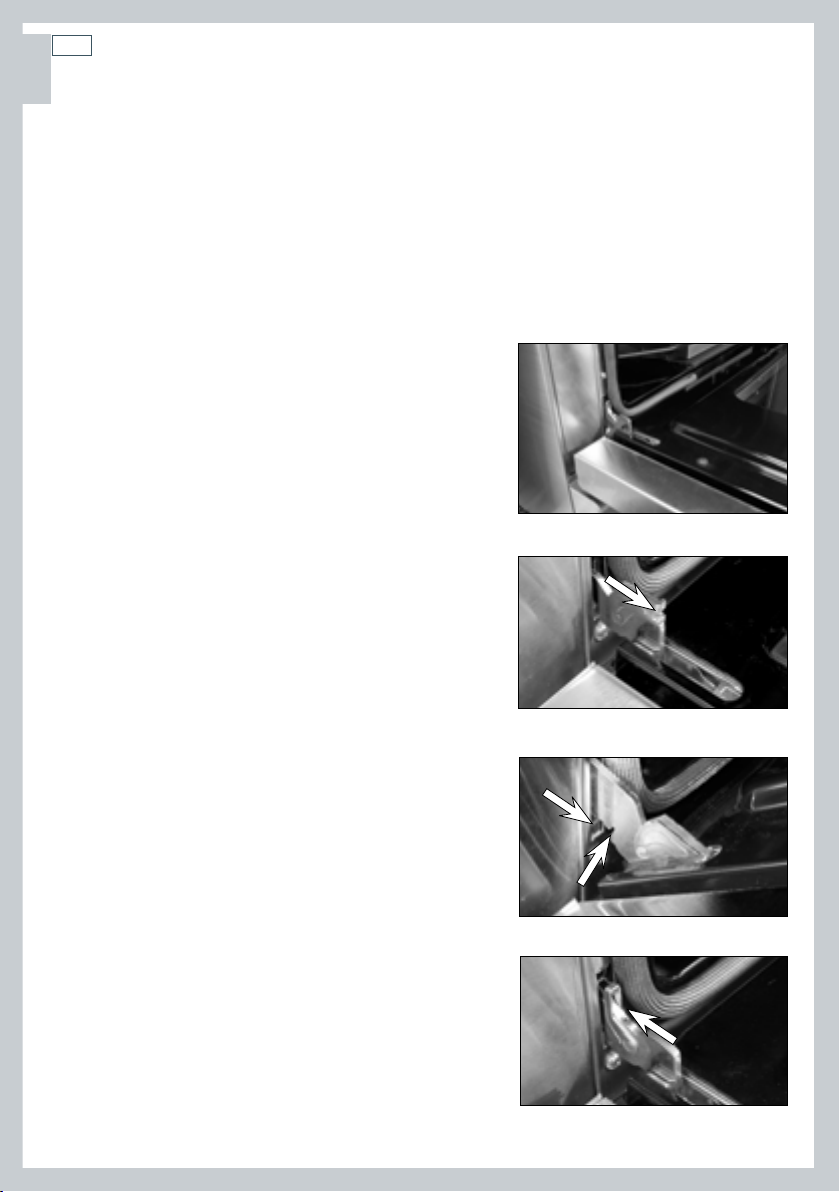

To remove door:

Important!

Do not lift oven door by the handle - this will cause

damage! Be sure the oven and door are cool before you

begin to remove the door!

1. Open the door all the way open (Fig. 05).

2. Unlock the door hinges by rotating the lock forward

(Fig. 06).

3. Once both hinges are unlocked, gently close the door

until approximately halfway closed. Grabbing the

sides of the door and gently lifting up and slightly

forward, the door will unlatch from the hinge.

4. Continue to lift and pull the door away from the

range.

Important!

The door is heavier than it looks.

To re-install door:

1. Position the door in approximately halfway open

position.

2. Simply place the hinge tongue into the hinge slots

(Fig. 07).

3. Push the door into the slots until you feel them fall

into the latches.

4. Open the door completely and rotate the locks into

the closed position (Fig. 08).

5. Close the oven door.

Fig. 05 Oven hinge assembly

Fig. 06 Hinge retainer clip in unlocked

Hinge tongue

Hinge slot

position

Fig. 07 Hinge assembly

Fig. 08 Hinge retainer clip in

locked position

Ventilation requirements

A suitable exhaust hood must be installed above the range. The following chart indicates

the minimum blower capacity recommended for hood ventilation.

13

US CA

Ventilation Unit Standard Counter Installation

Recommendations

HOOD 24” Deep x Unit Width 30” Deep x 36” at Bottom

BLOWER 600 CFM 600 CFM

Island Installation

Recommendations

Important!

Ventilation hoods and blowers are designed for use with single wall ducting. However, some local

building codes or inspectors may require double wall ducting and/or damper. Consult local building

codes and/or local agencies, before starting, to ensure that hood and duct installation will meet local

requirements.

Hood blower speeds should be variable to reduce noise and loss of heated or air conditioned

household air when maximum ventilation is not required.

For best smoke elimination, the lower edge of the hood should be installed a minimum of

30” to a maximum of 36” above the range cooking surface (page 15). If the hood contains

any combustible materials (i.e. a wood covering) it must be a minimum of 36” above the

cooking surface.

Due to a high volume of ventilation air, a source of make-up air (outside replacement air)

is recommended. This is particularly important for tightly sealed and insulated homes. A

reputable heating and ventilating contractor should be consulted.

US CA

14

Installing anti-tip device

All ranges must have an anti-tip device correctly installed as

per the following instructions. If you pull the range out from

the wall for any reason, make sure that the device is properly

engaged when you push the range back against the wall. If

it is not, there is a possible risk of the range tipping over and

causing injury if you or a child stand, sit or lean on an open

oven door.

Included Parts:

(4) #10 x 2” wood screws, (1) Anti-tip bracket, and

(1) Installation Instructions

Installing the Kit:

Instructions are provided for wood and cement

floors. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the

Anti-tip bracket to the floor and wall. The use

of this bracket does not preclude tipping of the

range when not properly installed.

(2) Small Holes for

Wood Installations

(2) Large Holes

for Concrete

Installations

Wood construction:

⁄”

WARNING

ALL RANGES CAN TIP

INJURY COULD RESULT

INSTALL ANTI-TIP

BR ACKE T PAC KED

INSIDE OVEN

SEE INSTRUCTIONS

(2) Wood Screws

into Back Wall

(ALL Installations)

RIGHT SIDE OF

WALL OR

RANGE

Back

Wall

Fig. 09

Place the bracket against the back wall, into the right rear corner where the range is to be

located. Leave a gap between the wall (or side of range) and the bracket (see Fig. 09). Drill

(2) ⁄” diameter pilot holes in the center of the small holes. A nail or awl may be used if a drill

is not available. Fasten the bracket securely to the floor and wall.

Concrete or cement construction:

Hardware Required:

(2) sleeve anchors, lag bolts, and washers (not provided).

Locate the bracket as described above. Drill the recommended size holes for the hardware.

Install the sleeve anchors into the holes and then install the lag bolts through the bracket.

The bolts must be properly tightened as recommended for the hardware. Fasten the bracket

securely to the floor and wall.

Once Installed:

Complete the range installation per the instructions provided with the product. Check for

proper installation of the range and Anti-tip device by grasping the back of the unit and

carefully attempt to tilt the range forward.

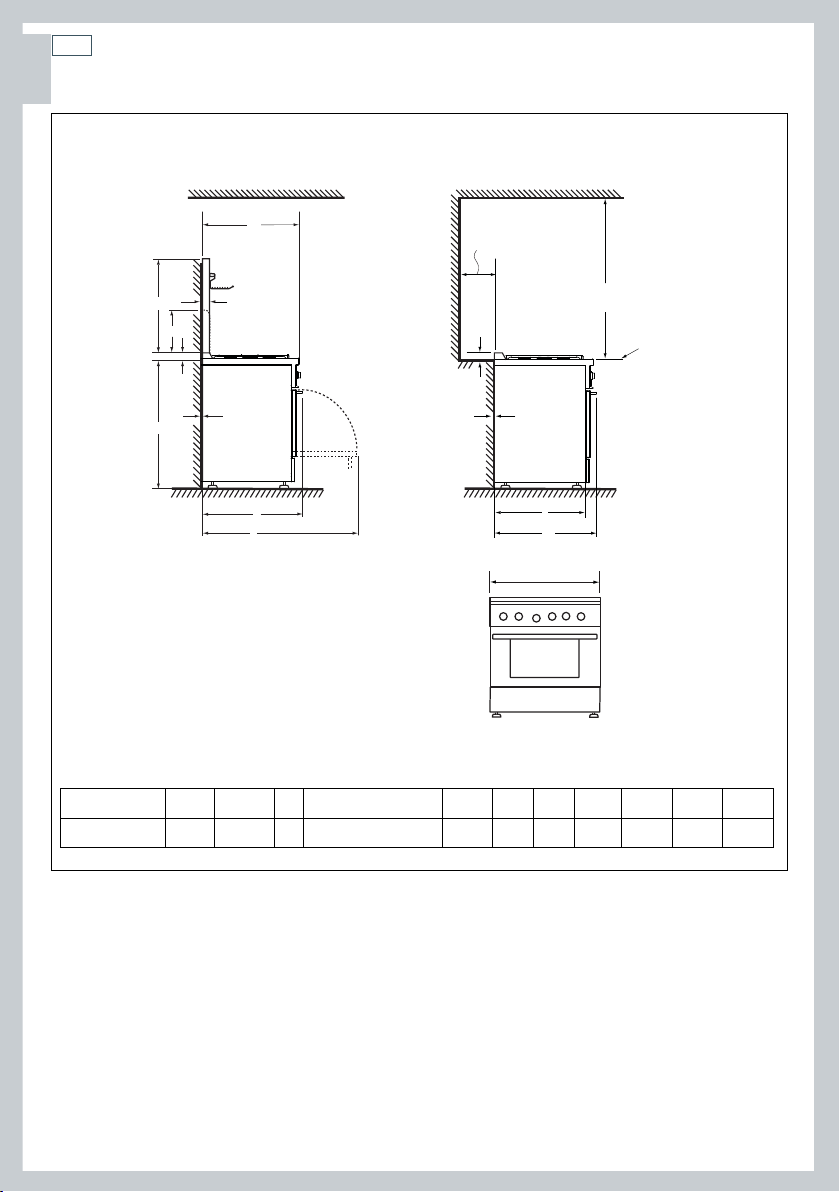

Cabinet preparation

15

1. The range is a free standing unit. If the unit is to be placed adjacent to cabinets, the

clearances shown in Fig. 10 are required. The same clearances apply to island installations.

2. The range can be placed in various positions with respect to the cabinet front, with the front

frame (not the door) either flush or projecting, depending on the countertop depth.

3. The gas and electrical supply should be within the zones shown in Fig. 10.

4. The maximum depth of overhead cabinets installed on either side of the hood is 13”.

5. Any openings in the wall behind the range and in the floor under the range must be sealed.

6. When there is less than a 12” clearance between combustible material and the back edge

and sides of the range, (above the cooking surface) a Low backguard or Full backguard must

be installed (Fig. 11, standard installation). When clearance to combustible material is over

12” no backguard is necessary (Fig. 11, island installation). The backguards must be ordered

separately (page 9). Fig. 11 indicates the space required for each type of backguard.

7. Always keep the appliance area clear and free from combustible materials, gasoline and

other flammable vapors and liquids.

8. Do not obstruct the flow of combustion and ventilation air to the unit.

min. 30"

wide hood

CAUTION:

36" min. to

combustible

material ,

from cooking

surface

18" Min.

12" min. to

combustible

material , each side

16"

cooking surface

13"

Max

2"

US CA

4"

gas and

electrical

supply

35⁄" max. for level counter,

36¾" max. with range

leveling legs fully extended

As def ined in the “National Fuel Gas Code”

(ANSI Z223.1, lastest edition).

The horizontal surfaces of the range top (cooktop) trim must

not be below countertop level.

Fig. 10

US CA

16

Cabinet preparation

Standard Installation Island Installation

G

A

D

The horizontal surfaces of the range top

H

B

C

0” Clearance

E

F

As def ined in the “National Fuel Gas Code”

(ANSI Z223.1, Latest Edition).

(cooktop) trim must not be below

countertop level.

12" Min. to

Combustibles

without backguard

C

0” Clearance

I

J

K

36" Min. to

Combustibles

Counter top level

Model ABC D EFGHIJK

OR30SG 28⁄” 10⁄” 2” 35¾ ” min–37” max 27⁄” 44” 27” 1⁄” 24¼ ” 26¾ ” 29⁄”

Fig. 11

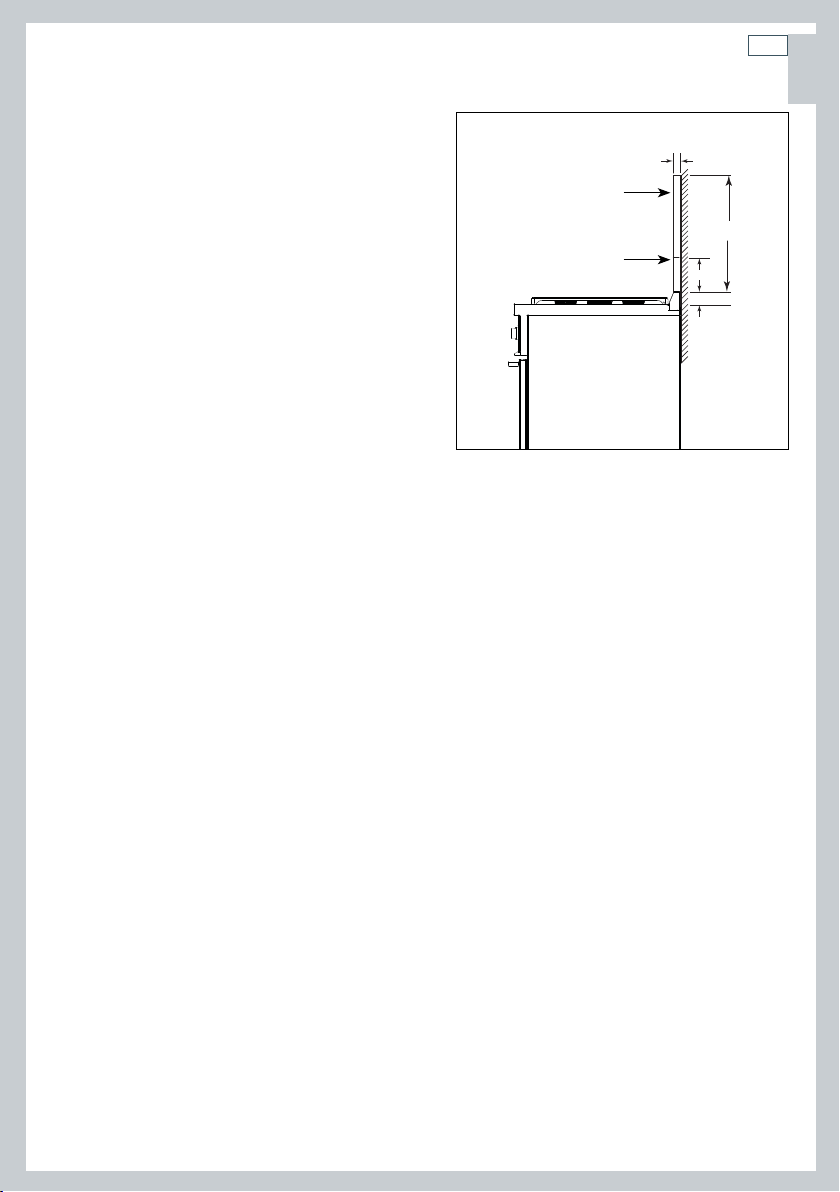

Backguard Installation

17

US CA

The backguard is located as shown in Fig. 12.

Secure the backguard to the wall behind the

range. Specific instructions for installation

of the full backguard or low backguard can

be found packaged with the backguard.

See also page 9, “Planning the installation”

section. A backguard must be installed when

there is less than a 12” clearance between

combustibles and the back of the range

(above the cooking surface). See

Fig. 11. Backguards are sold separately.

Wall Mount

Full Backguard

(Model # BGS-3030)

Wall Mount

Low Backguard

(Model # BGS-1230)

1⁄"

28⁄"

10⁄"

2"

Fig. 12

US CA

18

Electrical connections

Electrical connections

Power Requirements for the Range:

120 VAC, 60 Hz., single phase

OR30SG: 4 Amp. Max., 15 Amp. circuit

Always disconnect electric supply cord from the wall outlet or service disconnect before

servicing this appliance. Observe all governing codes and ordinances when grounding, in

absence of which, observe National Electrical Code ANSI / NFPA No. 70.

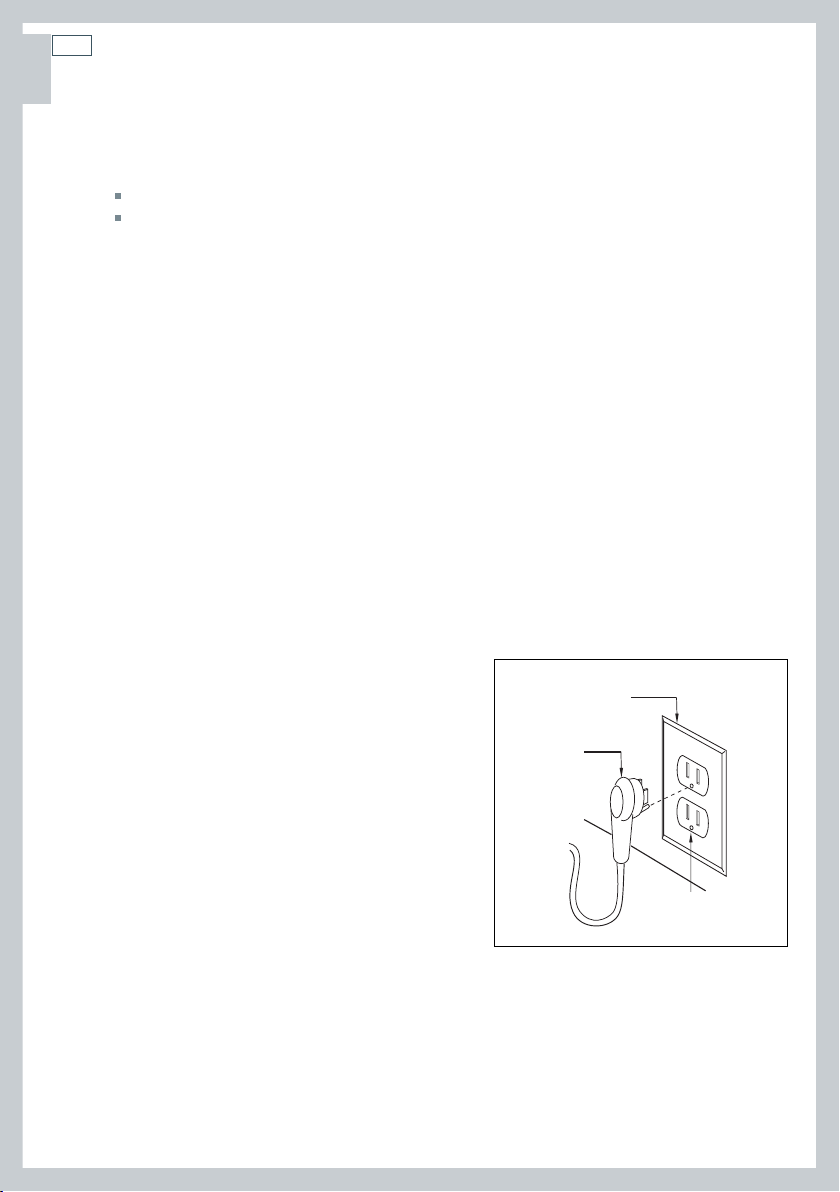

Recommended grounding method

This appliance is factory equipped with a power supply cord with a three-prong grounding

plug (with polarized parallel blades)(Fig. 13). It must be plugged into a mating grounding

type receptacle, connected to a correctly polarized 120 volt circuit. If the circuit does not

have a grounding type receptacle, it is the responsibility and obligation of the installer to

have the existing receptacle changed to a properly grounded and polarized receptacle in

accordance with all applicable local codes and ordinances by a qualified electrician. In the

absence of local codes and ordinances, the receptacle replacement shall be in accordance

with the National Electrical Code.

Note: The third prong should not, under ANY circumstances, be cut or removed.

Receptacle box

cover plate

Three

Three

Prong

prong

Plug

Receptacle Box

Cover Plate

plug

Three prong

Three Prong

Receptacle

receptacle

Fig. 13

Gas hook-up

19

Gas requirements

Verify the type of gas supplied to the location. The range is shipped from the factory set up

and adjusted for Natural gas or LP (propane), depending on the specific model ordered. Verify

that the range is compatible with gas supply at the installation site before proceeding

further. Return the range to the dealer if the unit is not set for the gas supplied at the site.

Natural gas

Connection: ½ ” NPT Minimum ⁄” dia. flex line. Supply Pressure: 6” to 9” W.C.

LP Gas

Connection: ½ ” NPT Minimum ⁄” dia. flex line. Supply Pressure: 11” to 14” W.C.

A regulator is required at the LP source to provide a maximum of 14” W.C. to the range regulator.

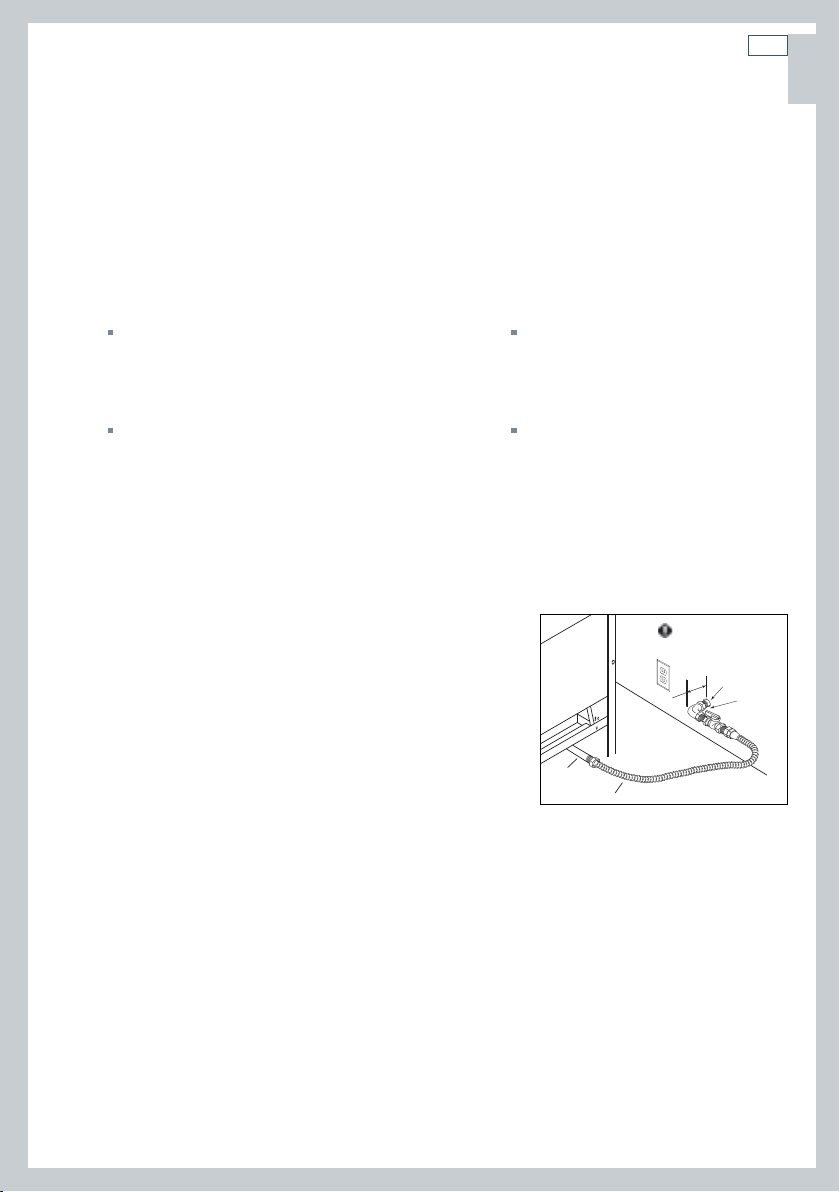

Hook-up to gas supply

A manual valve must be installed external to the appliance, in an accessible location from

the front for the purpose of shutting off the gas supply. The supply line must not protrude

beyond the back of the unit. Make sure the gas supply is turned off at the wall valve before

connecting the appliance.

The gas supply connections should be made by a

qualified technician and in accordance with local codes

or ordinances. In the absence of a local code, the

installation must conform to the National Fuel Gas Code

ANSI Z223.1, latest edition.

Manifold Inlet

½” NPT

Important!

Metal Flex Gas Line

The appliance must be isolated from the building’s gas supply

piping system by closing its individual manual shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less than ½ psig (3.5kPa.). The appliance and its

individual shut-off valve must be disconnected from the gas supply piping system during any pressure

testing of the system at the test pressures in excess of ½ psig (3.5kPa.). When checking the manifold gas

pressure, the inlet pressure to the regulator should be at least 7.0” W.C. for natural gas or 12.0” for LP.

Note: The flex line for the gas supply must be metal and be approved by an approved

certifying agency (AGA, CGA, or UL). Never use a hose made of rubber or other synthetic

material, as the heat may cause the hose to melt and develop leaks.

2” max.

protrusion

from wall

Manual Shut-Off

Valve must be

Easily Accessible

Gas supply

WALL

Hard Pipe

Connection

Fig. 14

US CA

When hooking up the gas supply from range rear hard pipe to wall hard pipe, installation

length of flex line between range/wall hard piping must accommodate range being pulled

from wall for cleaning or servicing purposes. When range is pulled from wall, no strain should

occur at range or wall hard pipe connections (Fig. 14).

"

US CA

20

Test and adjustments

Important!

For warranty coverage, Fisher & Paykel requires that burner adjustments be made by a qualified

technician at the time of installation. Extreme care should be used when adjustments are made after

installation. IMPROPER OR LACK OF ADJUSTMENT WILL VOID YOUR WARRANTY.

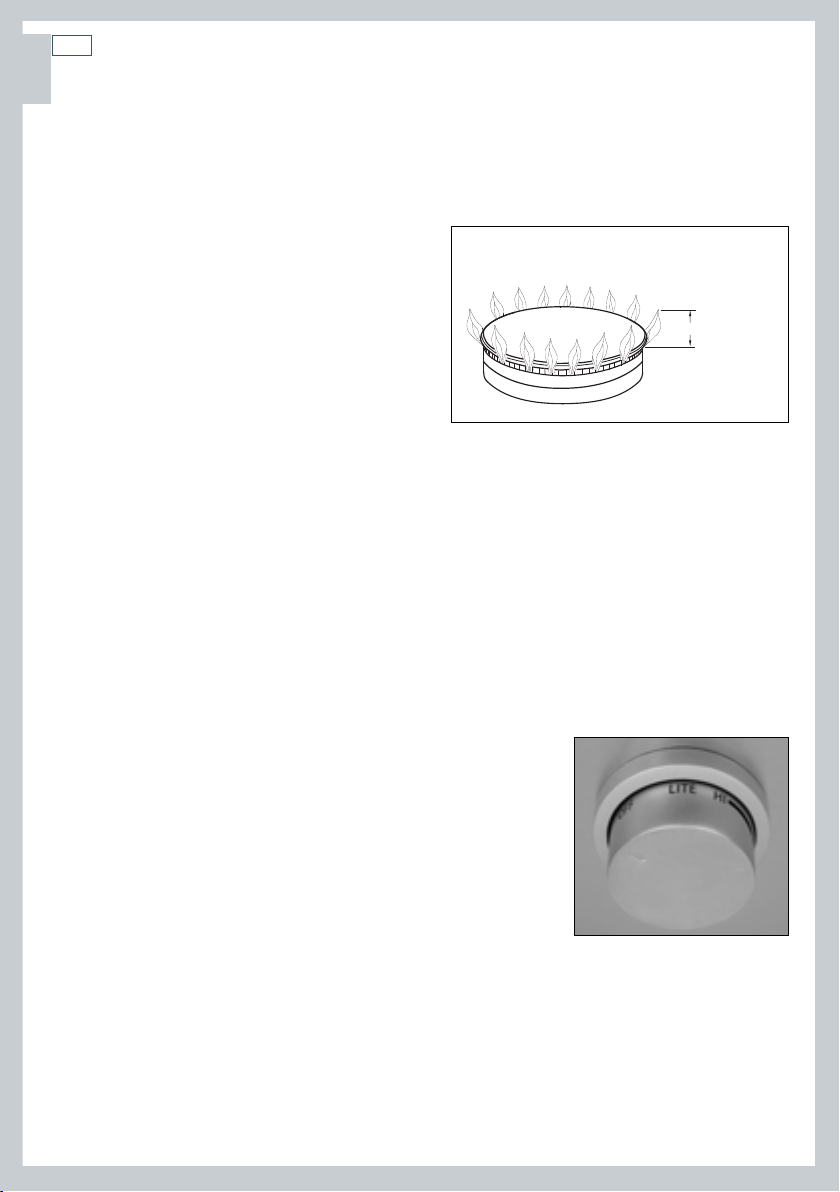

Cooktop burners

The cooktop burners are not adjustable.

Proper operation is achieved when the correct

orifices for gas supply are installed at the

factory, based on model ordered.

When installing the burner port ring, be sure

that the two locating pins in the bottom side

of the port ring are properly aligned with the

locating notch and center holes on the top side of the simmer ring. Incorrect alignment will

produce a potentially dangerous flame and poor burner performance.

Note: No air shutter adjustment is possible on the cooktop burners. Burner flames should

be blue and stable with no yellow-tipping (some yellow-tipping is normal with LP gas),

excessive noise, or lifting of flame from the burner (Fig. 15).

COOKTOP BURNER

1½

for “HI”

setting

Fig. 15

Cooktop burner lighting note

The cooktop burners have an infinite number of heat settings and there are no fixed

positions on the control knobs between HI and LO. To turn the cooktop burner on, push in

on the control knob and turn it counterclockwise to the “LITE” position. An audible clicking

sound will be heard. When the gas has been ignited by the

electronic spark igniter, turn the knob to the desired setting

(Fig. 16).

Note: The igniter will continue to click until a flame is

present. If the cooktop burner does not ignite, check the

spark igniter by listening for a clicking sound. If you do not

hear the igniter click, turn off the burner. Check for a tripped

circuit breaker, blown fuse, or poor wire connection to the

igniter.

Fig. 16

Important!

When turning on any cooktop burner, be sure to stop at the “LITE” position before turning the burner

to a flame setting for cooking. If the burner is not lit and it is turned beyond the “LITE” position, to HI,

medium, or LO, there will be a burst of flame when the burner does light. This could cause burns or

damage to the surrounding countertop.

Test and adjustments

21

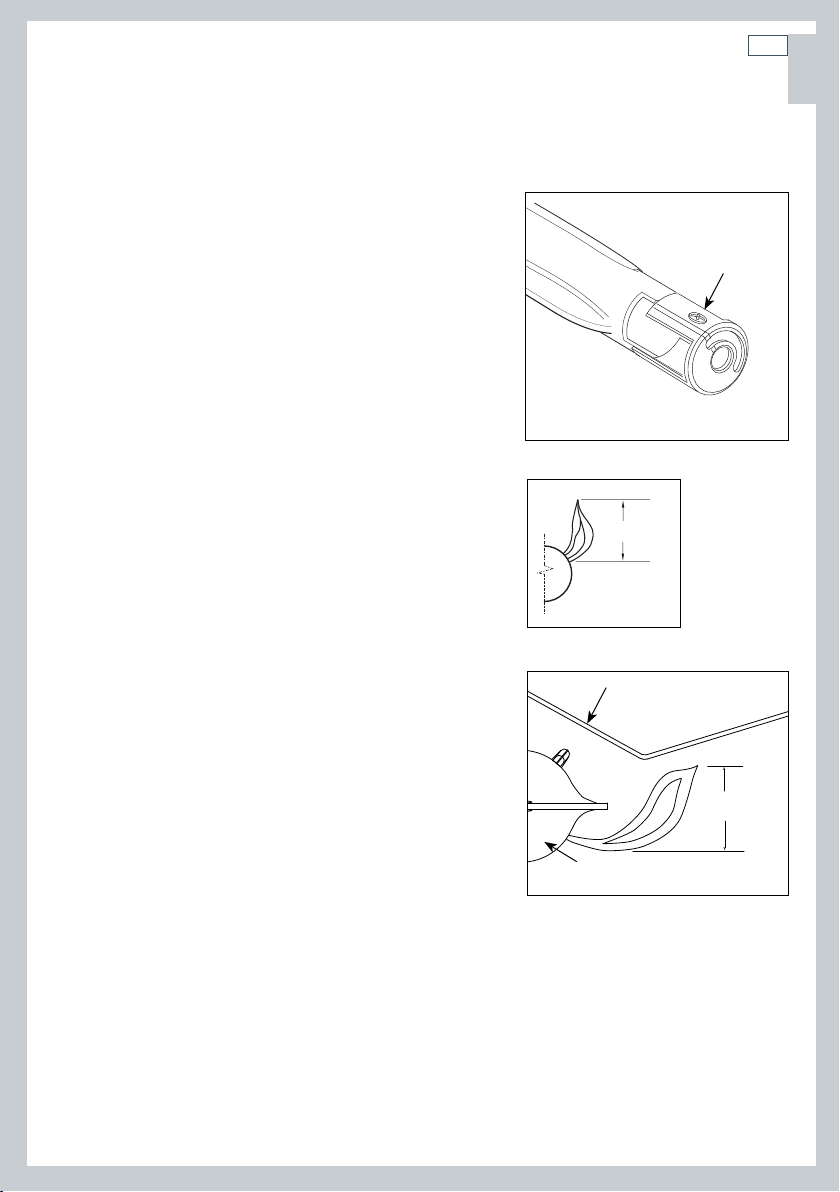

Bake and broil flame and oven burners

Check for the proper burner flame characteristics and adjust air shutter if necessary (Fig. 17).

Each valve and air shutter is individually tested and

adjusted prior to shipment. Normally adjustment

is not required, however, vibration during transit,

gas conversion or variations in the local gas supply

may make minor adjustments necessary. Burner

flames should be blue and stable with no yellow

tips, excessive noise or lifting of the flame from the

burner. If any of these conditions exist, check that

the air shutter or burner ports are not blocked. If this

condition persists, adjust the air shutter as required.

If the flame is too yellow, indicating insufficient air,

adjust the shutter counterclockwise to increase air

inlet. If the flame is noisy or tends to lift away from

the burner, indicating too much air, turn the shutter

clockwise to reduce air. The oven flames should be

1½ ” to 2” (Fig. 18). The broiler flames should be ¾ ” to 1”

(Fig. 19).

1½" - 2"

Air

shutter

Fig. 17

US CA

Important!

Before first use, the oven bake burner should be run for 20-30

minutes, then the broiler for 20-30 minutes to eliminate

any manufacturing oils, contaminates, and harsh

odors.

Oven

Fig. 18 Typical section of proper flame

Radiant

broiler burner

¾” to 1”

Broiler burner

Fig. 19 Typical section of proper flame

US CA

22

Installer nal checklist

General

❑ Placement of unit.

❑ Specified clearance maintained to cabinet surfaces.

❑ Unit Level - front to back, side to side.

❑ All packaging material and tie straps removed.

❑ Backguard attached if there is less than 12” clearance above the cooking surface to

combustibles behind unit.

Electrical

❑ Receptacle with 15 ampere over-current protection is provided for service cord connection.

❑ Adequate ground connection.

❑ Front kick panel in place and two (2) screws secure.

Gas supply

❑ Connection: ½ NPT with a minimum ⁄” diameter flex line. Site gas supply is compatible with

range model, and sufficient pressure is available (see gas requirements pg. 19).

❑ The pressure regulator which is connected to the manifold is set for 5.0” W.C. for Natural gas

or 10.0” W.C. for LP.

❑ Manual gas shut-off valve installed in an accessible location.

❑ Unit tested and free of gas leaks.

Operation

❑ All internal packing materials removed. Check below grate.

❑ If used on LP gas, verify that pressure regulator, orifice hoods, air shutters, and valve jets have

been set for use with LP gas.

❑ Bezels centered on burner knobs and knobs turn freely.

❑ Each burner lights satisfactorily, both individually and with other burners operating at the

same time.

❑ Flame adjustment for ⁄” soft blue cone made on ports of each top burner, low flame

adjustment verified.

❑ Flame adjustment made on air shutter of each oven and broiler.

❑ Oven door hinges seated and door opens and closes properly.

❑ Burner grates correctly positioned, level, and do not rock.

❑ Cooktop burner flame (see page 20).

❑ Oven and broiler flame (see page 21).

Before using your appliance

1. Remove all packaging materials from your appliance. If the installer has not set up your

appliance, do it now. Check that you have the following items:

23

Cooktop

5 burner head assemblies, burner caps and 3 grates.

Oven:

One two-piece broil pan

Three oven racks

Note: If any of the listed accompanying items are missing, contact Fisher & Paykel at

(888) 936-7872. Please be prepared with your Model #, Serial # and description of product

you have purchased.

Regarding use of aluminum foil in a Fisher & Paykel Range Oven: DO NOT use aluminum foil

to cover the oven racks or to line the oven. Heat can be trapped beneath the foil; this can

cause damage to the oven and cause food to not cook correctly.

2. Place the oven racks in the proper position before turning on the oven. For correct rack

position check your recipe. The most frequently used position is number 2 (the food product

must be in the center of the oven for airflow). The rack positions are numbered from the

bottom as in the floors of a building (Fig. 20).

US CA

RACK POSITIONS

4

3

2

1

4

3

2

1

Fig. 20

US CA

24

Before using your appliance

3. Before baking or broiling:

One at a time, turn the bake and broiler burners “ON” for 20 to 30 minutes each. This burns

off the manufacturing oils used by the factory. Turn the oven burner on to 450º F and the

broiler burner on to “BROIL”. TURN ON the ventilator above your range while these burners

are on, as there will be an odor.

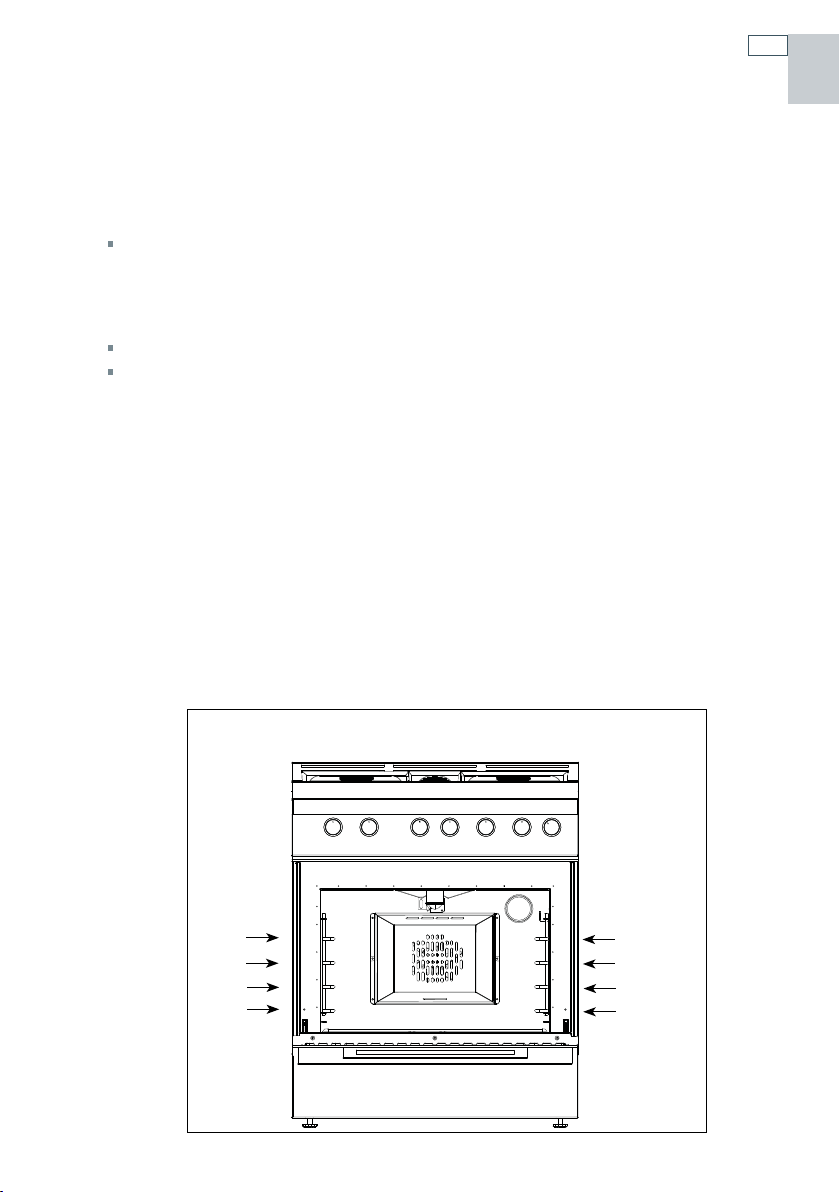

To insert the oven racks in oven:

1. Hold the rack with the back safety rail in the up

position and towards the rear of the oven. Slip it into

the oven so the rack slides are between the rack and

the rack guides.

2. As you slide the rack into the oven, tip the front of

the rack up slightly, so that the safety stops on the

back of the rack clear the rack slides (see Fig. 21).

The safety stops keep the rack from sliding out of the

oven when pulled forward.

RACK

GUIDE

RACK

SLIDE

To remove or reposition the racks:

1. Pull the rack forward.

2. Lift the front of the rack up so the safety stops clear

the rack slides.

3. Pull the rack forward.

SAFETY STOP

Fig. 21

Cooktop use

25

US CA

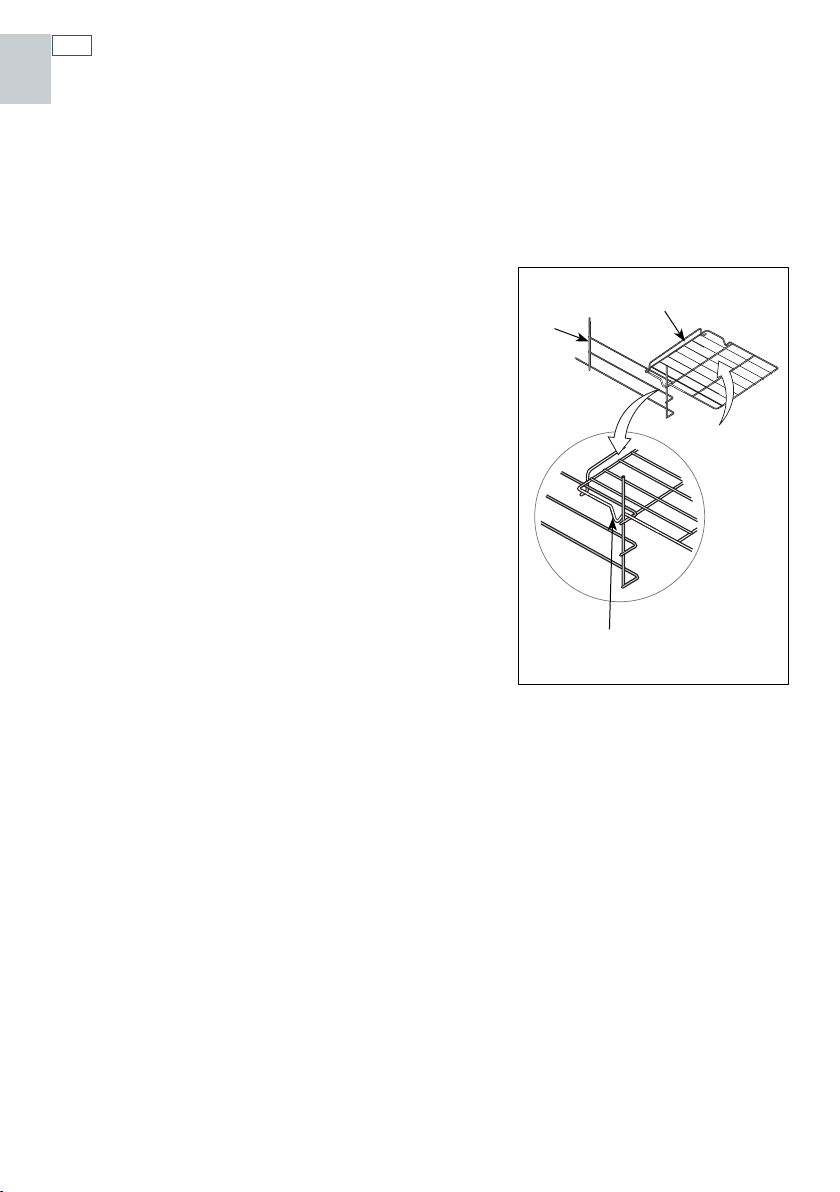

Burners

Your new gas range is equipped with one dual

flow burner (Fig. 22) and four single flow burners

( Fig. 23). These burners are typical of those used

in restaurants. These burners are designed for

maximum cleanability and controllability. The large

cap spreads the simmer heat out to avoid too much

heat being concentrated on the center of the pan.

The simmer flame on the center burner is always

“on” when the burner is in use. The burner should

never be operated if the cap is not in place. All

the cooktop burners have electronic spark ignition

to eliminate continuously burning pilots; when

the burner is on and the flame is blown out, it will

relight.

Simmering

Your new cooktop has exceptionally low simmering

capabilities. The large cap serves as a heat diffuser

to spread out the heat to avoid having a center

hotspot. Keep in mind that because of the high

heat capacity of the flame, and the mass of the

cast iron burner grates (they retain heat longer

than lighter, conventional grates) some foods may

continue to cook by retained heat after the burner

has been turned off. Should a strong draft or boil

over extinguish the simmer flame, it will relight

automatically as the main burner would.

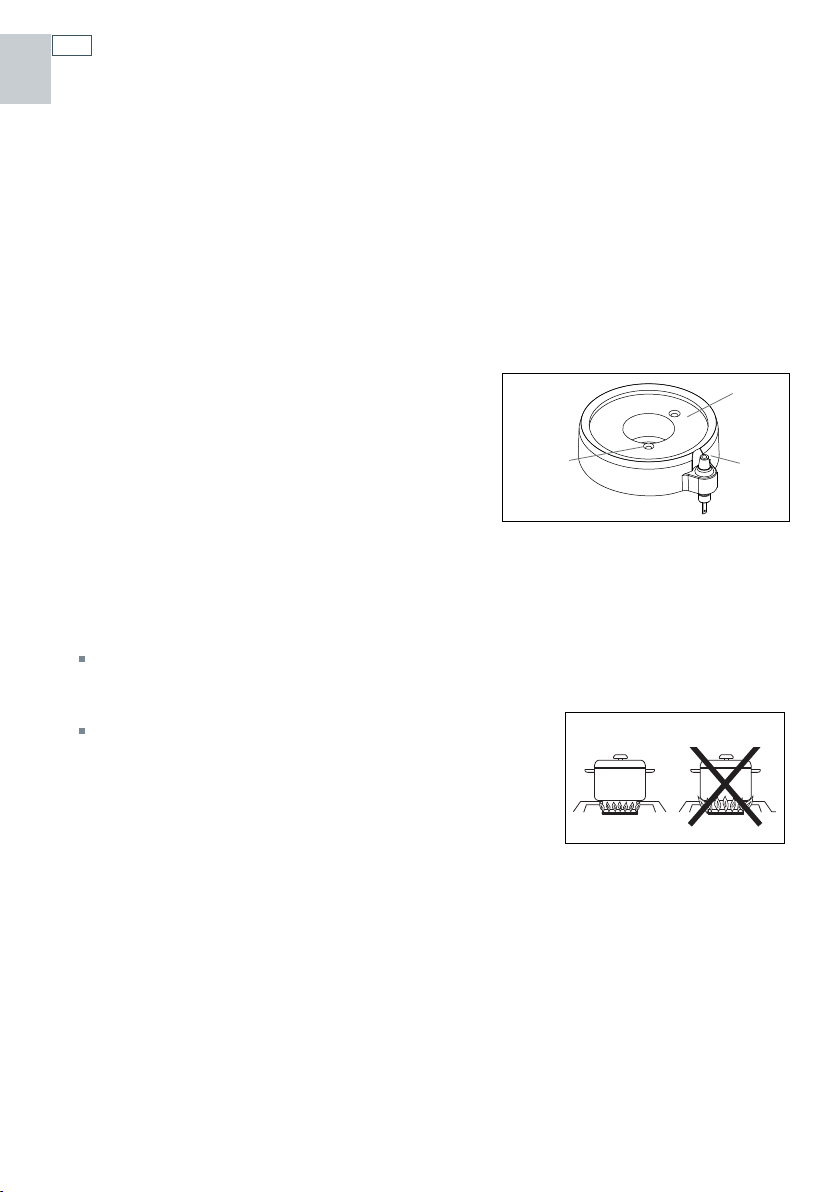

DUAL FLOW BURNER (Center)

Port

ring

SINGLE FLOW BURNER

Port

ring

2

Simmer

Flame

4

5

1

COOKTOP SECTION SHOWN

3

Cap

Fig. 22

Cap

Fig. 23

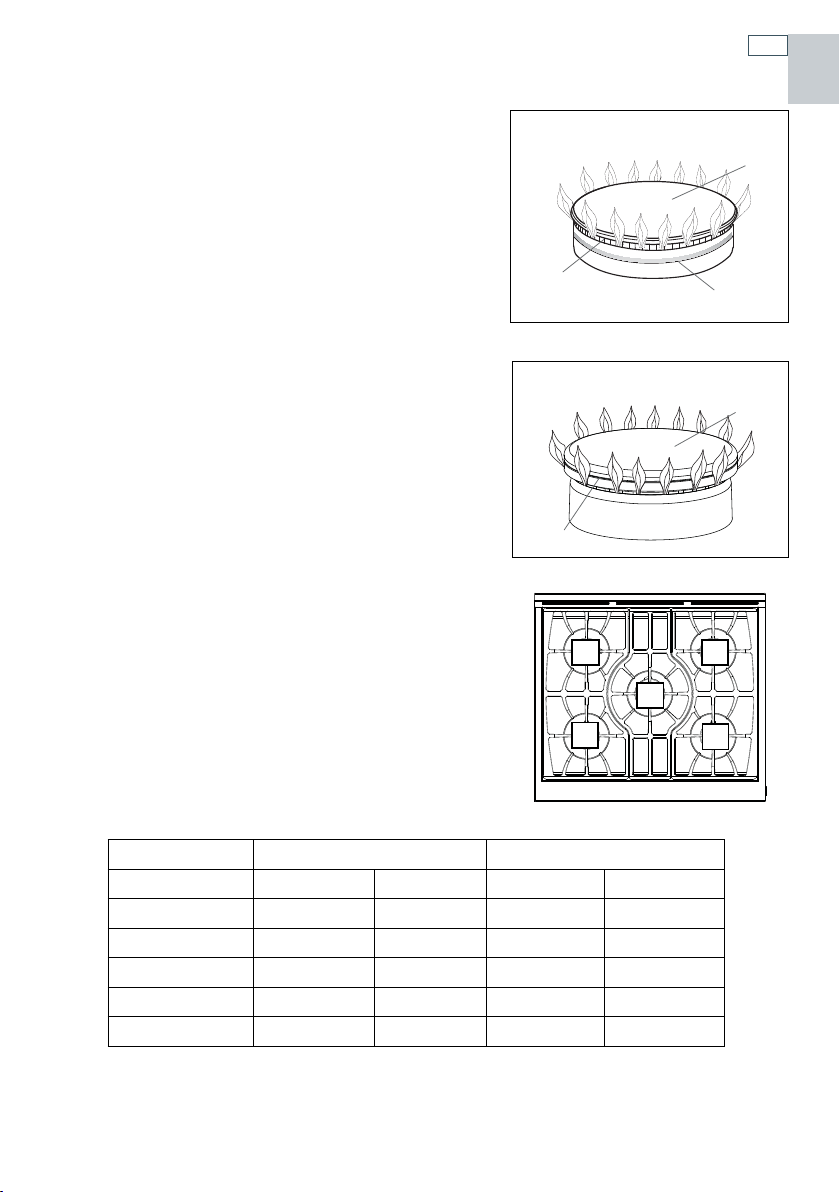

Burner Location Max. (Btu/hr) Simmer (Btu/hr)

Natural LP Natural LP

1 10,000 10,000 – –

2 10,000 10,000 – –

3 10,000 10,000 – –

4 10,000 10,000 – –

5 15,000 15,000 500-1,200 500-1,200

Electronic igniters

If a burner does not ignite, listen for the clicking sound. If the igniter is not clicking, TURN

OFF THE BURNER. Check the circuit breaker for a blown fuse or a tripped circuit breaker. If

US CA

26

Cooktop use

the igniter still fails to operate, see page 43 “Before You Call For Service”. To light the burner

manually, see page 40, “Power Failure”.

vNote: If you are using propane gas, a slight pop or flash may occur at the burner ports

a few seconds after the burner has been turned “off”. This “extinction pop” is normal for

propane gas.

Burner efficiency and flame characteristics

It is necessary to keep the burner ports and the igniters clean for proper lighting and

efficient performance of the cooktop burners (Fig. 24). The burner flame should burn

completely around the burner with no excessive noise or lifting. The flame should be blue in

color and stable with no yellow tips. An improper

air-gas mixture may cause either a burner flutter or

a yellow tipped flame. During initial use, foreign

particles in the gas line, or dust in the air around

the appliance may cause an orange flame. This will

disappear with use.

Flame height

The correct height of the flame mainly depends on the size of the bottom of the cooking

utensil, the material of the cooking utensil, the amount and type of food and the amount of

liquid in the utensil. Following are some basic rules for selecting flame height.

Locating

pin hole

inside

Burner

base

Igniter

Fig. 24

For safety reasons the flame must never extend beyond the bottom of the cooking utensil.

Never allow flames to curl up the side of the pan (see Fig. 25). This will discolor or damage

the utensil.

Utensils which conduct heat slowly (such as glass-ceramic)

PROPER FLAME HEIGHT

should be used with medium to low flame. If you are

cooking with a large amount of liquid, a slightly larger flame

can be used.

Cooktop burners

The cooktop burners must be kept clean. Cleaning of the cooktop burners should include

the igniter. The cooktop burners have an infinite number of heat settings and there are no

fixed positions on the control knobs between HI and LO. To turn the cooktop burner on,

push in on the control knob and turn it counterclockwise to the “LITE” position. An audible

clicking sound will be heard. When the gas has been ignited by the electronic spark igniter,

turn the knob to the desired setting. (The clicking sound should stop as soon as the burner

is lit).

Note: When adjusting the heat of the top burner, the main burner flame will not increase or

decrease visually until the lower setting on the dial is used. Even if the flame looks the same,

the heat output is changing according to the dial setting.

Fig. 25

Cooktop use

Important!

When turning on any cooktop burner, be sure to stop at the “LITE” position before turning the burner

to a flame setting for cooking. If the burner is not lit and it is turned beyond the “LITE” position, to HI,

medium, or LO, there could be a burst of flame when the burner does light.

Burner grates

The burner grates are heavy cast iron. They have a flat surface making it easy to move large

pans from one burner to another. They were designed in sections to make them easier to

remove and clean (see page 36).

Cookware

For best results we recommend using professional cookware.

This type of utensil can be found at your finer department

stores, specialty cooking shops, or restaurant supply stores. If

using regular cookware, be very careful if the pans have plastic

handles, as these large professional size burners can flame up

on the outside of the pan and melt or bubble the handles.

Control knobs

27

US CA

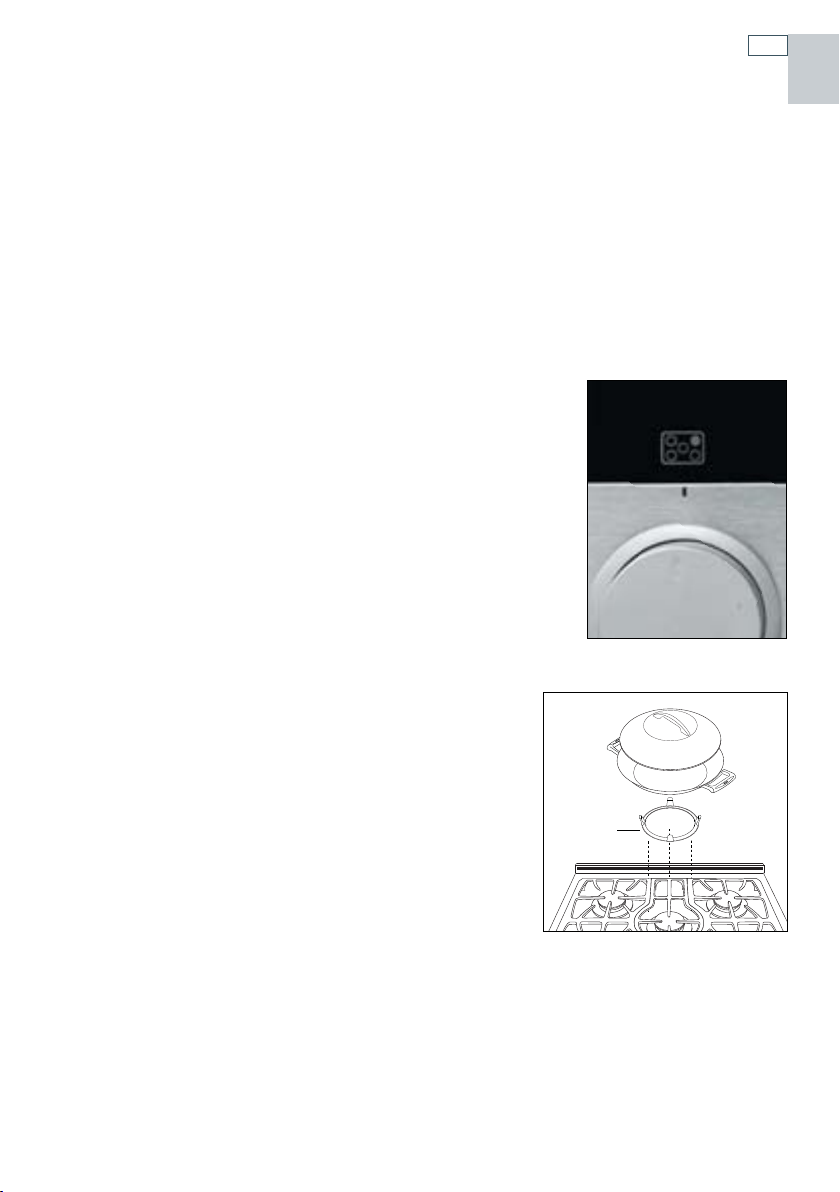

The control knobs are readily associated with the burners they

control. The cooktop control knobs are labeled and are in front

of the burners (see Fig. 26).

Fig. 26

Wok ring (purchase separately)

A Wok ring is available as an accessory for your new

Fisher & Paykel appliance. To purchase a wok ring

accessory (model # WRS) for use on your range or

cooktop please contact an authorized Fisher & Paykel

Dealer. The ring is cast iron, and has a porcelain enamel

finish. It can be used with the Fisher & Paykel model CW

wok and most commercially available woks. To use the

ring, place it on the grate over the desired burner. The

vertical tabs on the ring should be aligned with the main

fingers of the grate. The small protrusions on the bottom surface of the ring should straddle

the grate fingers to prevent the ring from rotating during cooking. See Fig. 27. The bottom

of the wok should be supported and retained by the vertical tabs of the ring.

For best performance on the range, the ring and wok should be used on the center burner

(position 5, see page 25) as it has the highest output on the top section. To clean the wok

ring, place it in the dishwasher after use. Stubborn food deposits may be removed by

soaking to loosen the soil, then washing as usual.

Wok

Ring

Fig. 27

US CA

28

Oven use

Oven burners

Your new gas range is equipped with bake and broil oven gas burners. The oven broil burner

is 14,000 Btu/hr. The oven baking burner is 30,000 Btu/hr.

Electric glow igniter

The oven bake and broil burners are equipped with an electric glow igniter and safety valve

system which lights the gas. There will be a delay of 30 to 90 seconds after the control knob

has been turned on before you actually hear the burner come on. The burner will ignite

within 4 seconds after the gas reaches the burner.

Oven

Your new oven can be used in three cooking modes: convection bake, traditional bake or

regular broil. To help you decide which way to cook your food, read this information first.

Remember, this is a new oven and the thermostat has been checked for accuracy. Your old

oven may have had a thermostat that over the years got a little hot or a little cold. Check

your recipes for the correct time and temperature and don’t use the old time or temperature

you were using to compensate for your old oven being off temperature.

Oven racks

The oven has 3 oven racks and 4 rack positions.

Preheating

Preheating takes about 10 to 15 minutes depending on the temperature set. Preheating

is usually necessary for foods baked at a high temperature for a short period of time, for

example drop cookies and cakes.

Condensation

During any cooking process there is a certain amount of moisture that evaporates from the

food. The amount of moisture that condenses on the oven depends on the moisture content

of the food. The moisture will condense on any surface that is cooler than the inside of the

oven, such as the control panel or the top of the door and door glass.

Important!

Aluminum foil should never be used to cover the oven racks or to line the oven bottom. The trapped

heat can damage the porcelain and the heated air cannot adequately reach the food being baked.

Loading...

Loading...