Page 1

GAS/ELECTRIC

for residential use only

Fisher Paykel

GE

Modol,:OR30S PWGX

iNSTALLATiON iNSTRUCTiONS C

®

US

iMPORTANT - PLEASE READ AND FOLLOW

. Before beginning, please read these instructions completely and carefully.

. Do not remove permanently affixed labels, warnings, or plates from the product. This may

void the warranty.

. Please observe all local and national codes and ordinances.

. Please ensure that this product is properly grounded.

. The electrical plug should always be accessible.

• The installer should leave these instructions with the consumer who should retain

for local inspector's use and for future reference.

Installation must conform with local codes or in the absence of codes, the National Fuel Gas

Code ANSI Z223.1/NFPA 54 - latest edition. Electrical installation must be in accordance with

the National Electrical Code, ANSI/NFPA70 - latest edition and/or local codes.

IN CANADA: installation must be in accordance with the current CAN/CGA-B149.1 National

Gas installation Code or CAN/CGA-B149.2, Propane installation Code and/or local codes.

Electrical installation must be in accordance with the current CSA C22.1 Canadian Electrical

Codes Part 1 and/or local codes.

INSTALLATION IN MANUFACTURED (MOBILE) HOME: The installation must conform with

the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly

the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD (Part 280)]

or, when such standard is not applicable, the Standard for Manufactured Home Installations,

ANSI/NCSBCS A225.1, or with local codes where applicable.

INSTALLATION IN RECREATIONAL PARK TRAILERS: The installation must conform with

state or other codes or, in the absence of such codes, with the Standard for Recreational

Park Trailers, ANSI Al19.5.

installation of any gas-fired equipment should be made by a licensed plumber. A manual

shut-off valve must be installed in an accessible location in the gas line external to the ap-

pliance for the purpose of turning on or shutting off gas to the appliance (In Massachusetts

such shutoff devices should be approved by the Board of State Examiners of Plumbers &

Gas Fitters).

If an external electrical source is utilized, the appliance, when installed, must be electrically

grounded in accordance with local codes or, in the absence of local codes, with the national

Electrical Code, ANSI/NFPA 70.

somemoae

parts; This film must be removed before installing!using the appliance:

i

FOR INSTALLER ONLY

THIS RANGE IS FOR RESIDENTIAL USE ONLY

co

o

_L

O

%-

O

<

co

03

L_

O

O_

L_

Page 2

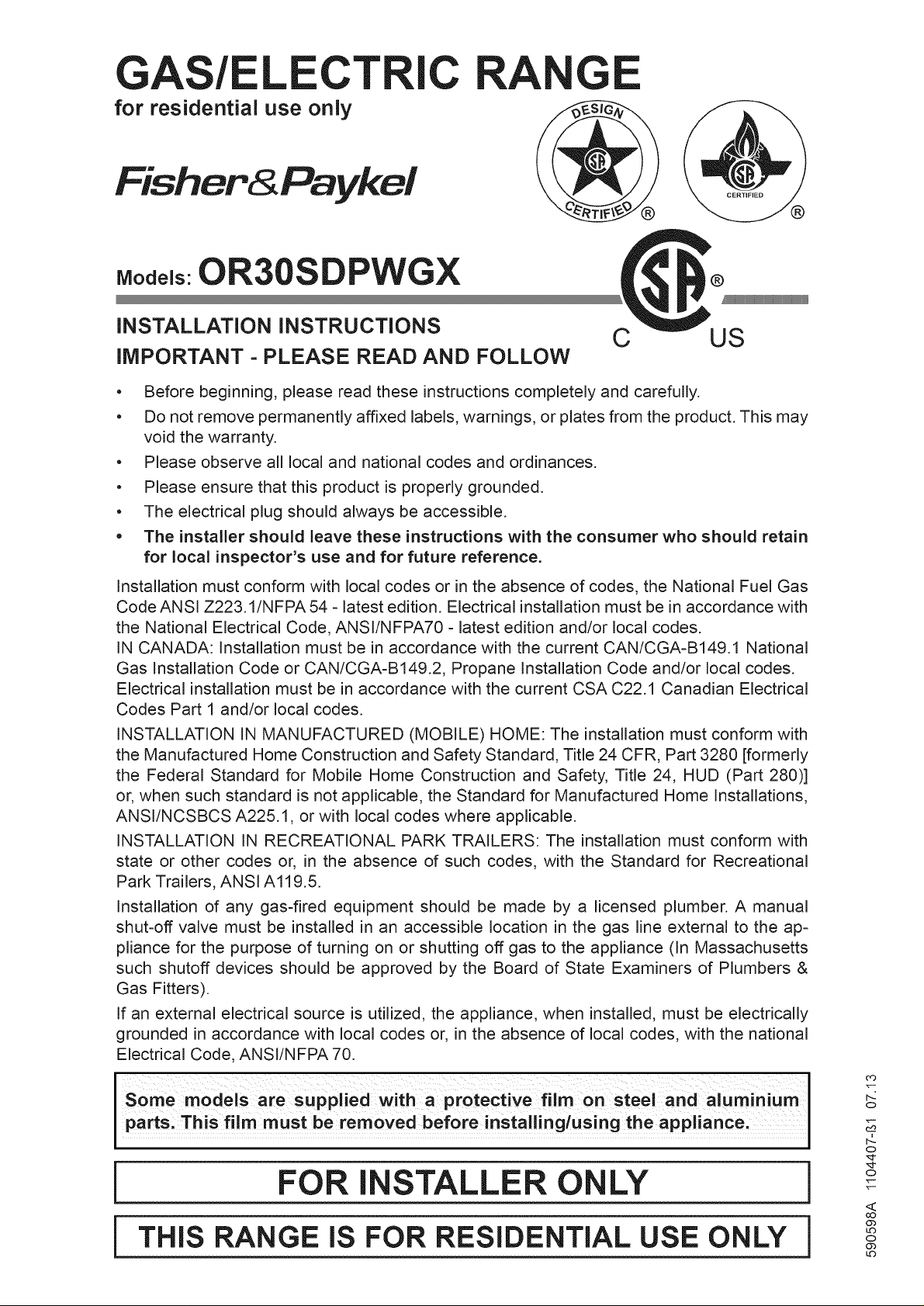

To reduce the risk of tipping the appliance,

the appliance must be secured by properly

installed anti-tip device packed with the

appliance.

• ALL RANGES CAN TiP

• iNJURY TO PERSONS COULD RESULT

• iNSTALL ANTI-TIP DEVICE PACKED

WiTH RANGE

• SEE iNSTALLATiON iNSTRUCTiONS

if the information in this manual is not followed exactly,

a fire or explosion may result causing property damage,

personal injury,or death.

Donot store or usegasoline or otherflammable vapors and

liquids inthe vicinity ofthis orany otherappliance.

NEVER use this appliance as a space heater to heat or warm

the room. Doing so may result in carbon monoxide poiso-

ning and overheating of the appliance.

WHATTO DOIFYOUSMELLGAS:

• Do not try to lightany appliance.

• Do not touch any electricalswitch.

• Donot use any phoneinyour building.

• Immediately call your gas supplier from a neighbor's

phone.Followthe gassupplier'sinstructions.

• if you cannot reach your gas supplier,call the fire de-

partment.

installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

Page 3

DATA PLATE

CONVERSION LABEL

The product data plate is

attached below the bottom

drawer, To check the label,

it is necessary to remove

the drawer (operating as

indicated in this manual),

The Governor of California is required to publish a list of substances known to the state of Califor-

nia to cause cancer or reproductive harm and requires businesses to warn customers of potential

exposures to such substances.

WARNING!: Gas appliances contain or produce substances which can cause death or serious

illness and which are known to the State of California to cause cancer, birth defects or other repro-

ductive harm. To reduce the risk from substances in fuel or from fuel combustion, make sure this

appliance is installed, operated, and maintained according to the manufacturer's instructions.

This appliance is designed and manufactured solely for the cooking of domestic (household) food

and in not suitable for any non-domestic application and therefore should not be used in a commer-

cial environmement.

The appliance warranty will be void if the appliance is used within a non-domestic environment i.e.

a semi commercial, commercial or communal environment.

Page 4

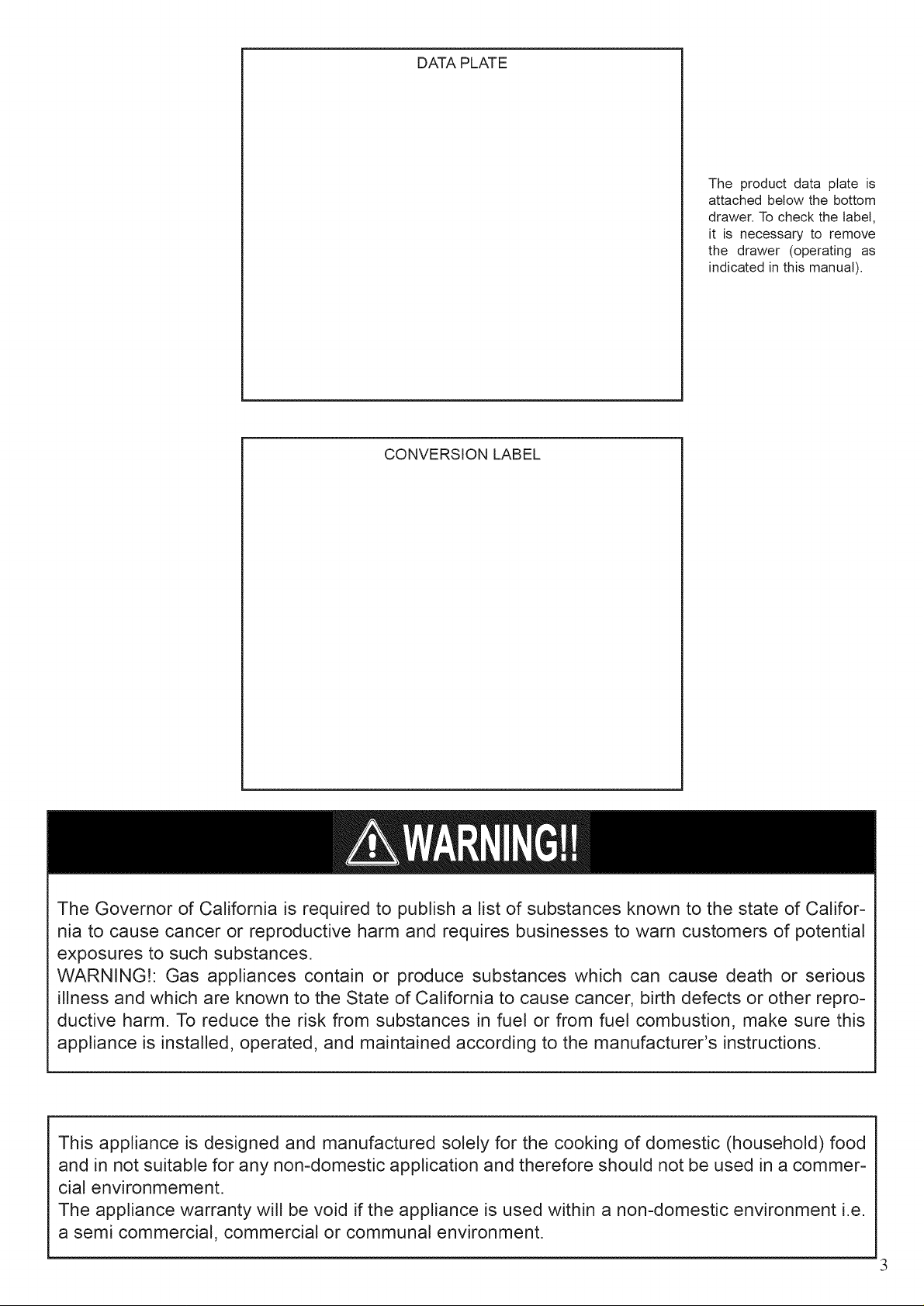

WARNING!

THIS APPLIANCE MUST BE INSTALLED BY A QUALIFIED INSTALLER.

Improper installation, adjustment, alteration, services, or maintenance can cause injury or property damage. Consult a quali-

fied installer, service agent, or the gas supplier.

iMPORTANT: The use of suitable protective clothing/gloves is

recommended when handling or installing this appliance.

TOOLS NEEDED FOR iNSTALLATiON (NOT SUPPLIED WiTH THE APPLIANCE)

Suitable protective

gloves

T-handle

wrench Pencil

Adjustable

Adjustable

wrench

pliers

Tape

measure

_i:iii_iiiiiiiiiiiiiiiii_i;_;_ii:;i_ii_ii_i_iiiii1_iii!_ii!iiii_ii1iii_:ii]i!!ii;_i;i_i__ii

_ ;ii:;iiiiiii!ii/;iii;;i!iiii !]i_

Drill

Page 5

GENERAL INFORMATION

1,

Installation must conform with local codes or, in the absen-

ce of local codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 - Latest Edition, CAN/CGA-B149.1 or CAN/

CGA-B149.2.

2,

Installation in manufactured (mobile) home: installation must

conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 [formerly the

Federal Standard for Mobile Home Construction and Sa-

fety, Title 24, HUD (Part 280)] or, when such standard is

not applicable, the Standard for Manufactured Home Instal-

lations, ANSI/NCSBCS A225.1, or with local codes where

applicable.

3,

Installation in Recreational Park Trailers: installation must

conform with state or other codes or, in the absence of such

codes, with the Standard for Recreational Park Trailers,

ANSI Al19.5.

4. To eliminate risk of burns or fire by reaching over heated sur-

face units, cabinet storage located above the surface units

should be avoided.

5. Air curtain or other overhead range hoods, which operate by

blowing a downward air flow on to a range, shall not be used

in conjunction with gas ranges other than when the hood and

range have been designed, tested and listed by an indepen-

dent test laboratory for use in combination.

16.

When installing or removing the range for service, a rolling lift

jack should be used. Do not push against any of the edges of

the range in an attempt to slide it into or out of the installation.

Pushing or pulling a range (rather than using a lift jack) also

increases the possibility of bending the leg spindles or the

internal coupling connectors.

WARNING!!

ELECTRICAL GROUNDING INSTRUCTIONS

The range must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the Natio=

nal Electrical Code, ANSI/NFPA No. 70-latest edition, in Cana-

da Canadian Electrical Code.

Installation should be made by a licensed electrician.

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PRO-

PERLY GROUNDED.

If an external electrical source is utilized, the installation must be

electrically grounded in accordance with local codes or, in the

absence of local codes, with the national Electrical Code, ANSI/

NFPA 70.

o. WARNING!!

This appliance shall not be used for space heating. This

information is based on safety considerations.

7,

All openings in the watt behind the appliance and in the floor

under the appliance shall be sealed.

8,

Keep appliance area clear and free from combustible mate-

rials, gasoline, and other flammable vapors.

9. Do not obstruct the flow of combustion and ventilation air.

10.

Disconnect the electrical supply to the appliance before ser-

vicing.

11.

When removing appliance for cleaning and/or service;

A. Shut off gas at main supply.

B. DisconnectAC power supply.

C. Disconnect gas line to the inlet pipe.

D. Carefully remove the range by pulling outward.

CAUTION: Range is heavy; use care in handling.

12. Electrical Requirement

Electrical installation should comply with national and local

codes.

13. Air Supply and Ventilation

The installer must refers to local/national codes.

This appliance is equipped with a four-prong grounding plug

(NEMA 14-50P) for your protection against shock hazard and

should be plugged directly into a properly grounded socket.

Do not under any circumstances cut or remove the fourth

(ground) prong from the power plug.

REPLACEMENT PARTS

Only authorized replacement parts may be used in performing ser-

vice on the range. Replacement parts are available from factory

authorized parts distributors. Contact the nearest parts distributor

in your area.

14. Gas Manifold Pressure

Natural gas - 4.0" W.C.R

LP/Propane - 11.0" W.C.R

15. The misuse of oven door (e.g. stepping, sitting, or leaning on

them) can result in potential hazards and/or injuries.

Page 6

Fig.l.1

installation

PROXiMiTY TO SIDE CABINETS

1,

This range may be installed directly adjacent to existing 36" (914 mm)

high base cabinets.

Range dimensions:

• width: 29" 7/8 (759 mm)

• depth: 24" 3/16 (615 mm)

• height (without backguard): MIN 35" 21/32 (906 mm)- MAX 36" 11/32

• backguard (height): 3" (76 mm)

Gas line opening: Watt - 37/64" (14.5 mm) from the right side to centre

of range; from 5" 7/16 (138 mm) to 6" 1/8 (155.5 mm) [depending on feet

regulation] from the floor.

Grounded outlet: should be located 37/64" (14.5 mm) from the left side

to centre of range; from 5" 7/16 (138 mm) to 6" 1/8 (155.5 mm) [depen-

ding on feet regulation] from the floor.

The electric cord with 4-prong ground plug (NEMA 14-50P) shall have

a minimum length of 48" (1220 mm) beyond the back of the appliance.

2,

The range CANNOT be installed directly adjacent to sidewalls, tall cabi-

nets, tall appliances, or other side vertical surfaces above 36" (914 mm)

high.

There must be a minimum d 11" 13/16 (300 mm) side clearance from the

range to such combustible surfaces TO THE LEFT or TO THE RIGHT

above the 36" (914 mm) high countertop.

IMPORTANT: One side (left or right) above the 36" (914 ram) high

countertop must always be kept clear.

Island installation: There must be a minimum of 12" (305 mm) clearan-

ce from the rear of the backguard to such combustible surface on the

back of the range above the 36" (914 mm) high countertop.

3,

The maximum upper cabinet depth recommended is 13" (330 mm). Walt

cabinet above the range must be a minimum of 30" (762 mm) above the

countertop for a width of minimum 30" (762 mm): it has to be centered

with the range. Side wall cabinets above the range must be a minimum

of 18" (457 mm) above the countertop.

(923 mm)

Page 7

Dotted line showing the position

of the range when installed ......_\

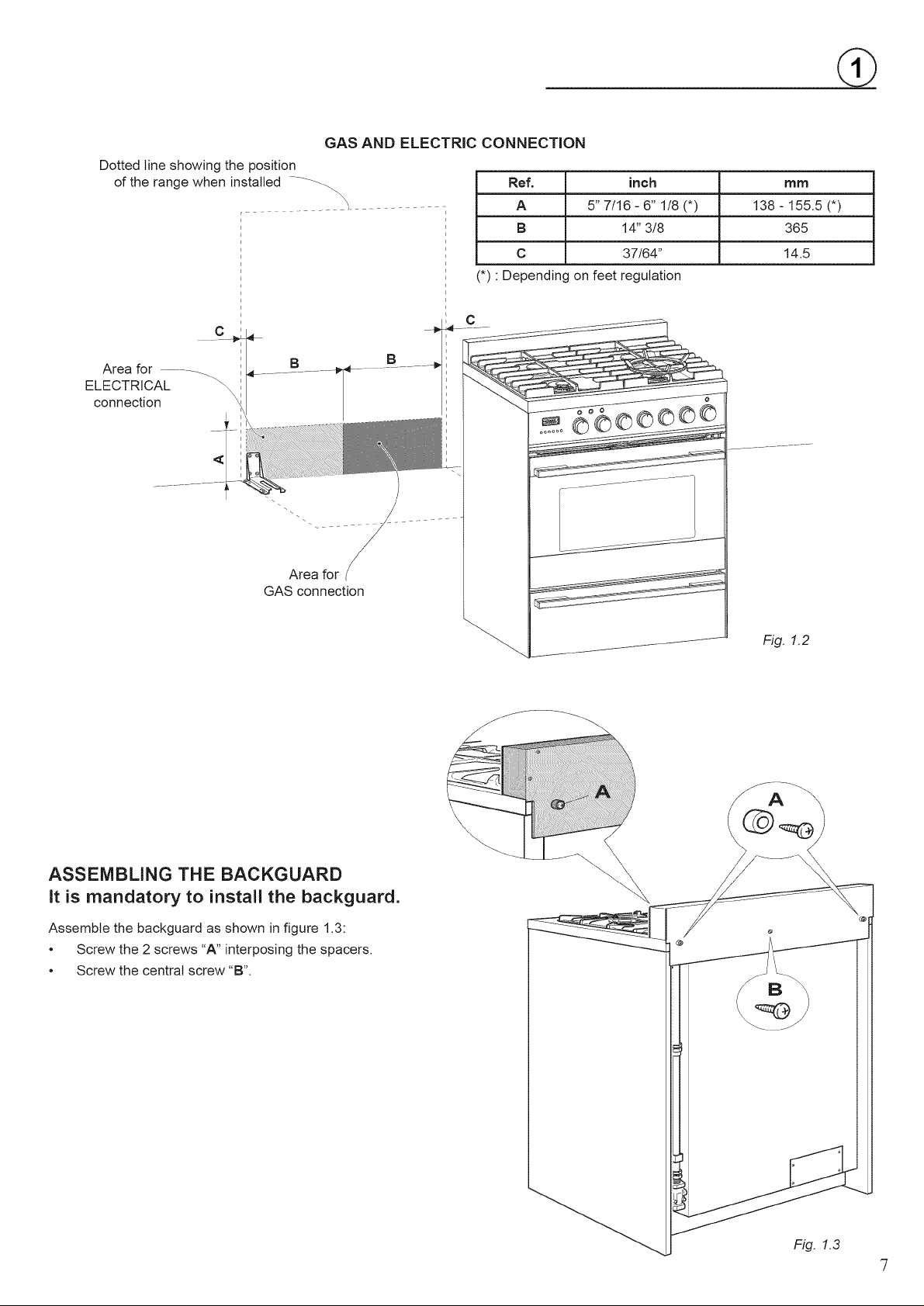

GAS AND ELECTRIC CONNECTION

\\

Ref. inch mm

A 5" 7/16- 6" 1/8 (*) 138- 155.5 (*)

B 14" 3/8 365

C 37/64" 14.5

(*) " Depending on feet regulation

Area for ...... --__

ELECTRICAL _,

connection \

B B

/

/

Area for (

GAS connection

Fig. 1.2

ASSEMBLING THE BACKGUARD

it is mandatory to install the backguard.

Assemble the backguard as shown in figure 1.3:

• Screw the 2 screws "A" interposing the spacers.

• Screw the central screw "B".

Fig. 1.3

Page 8

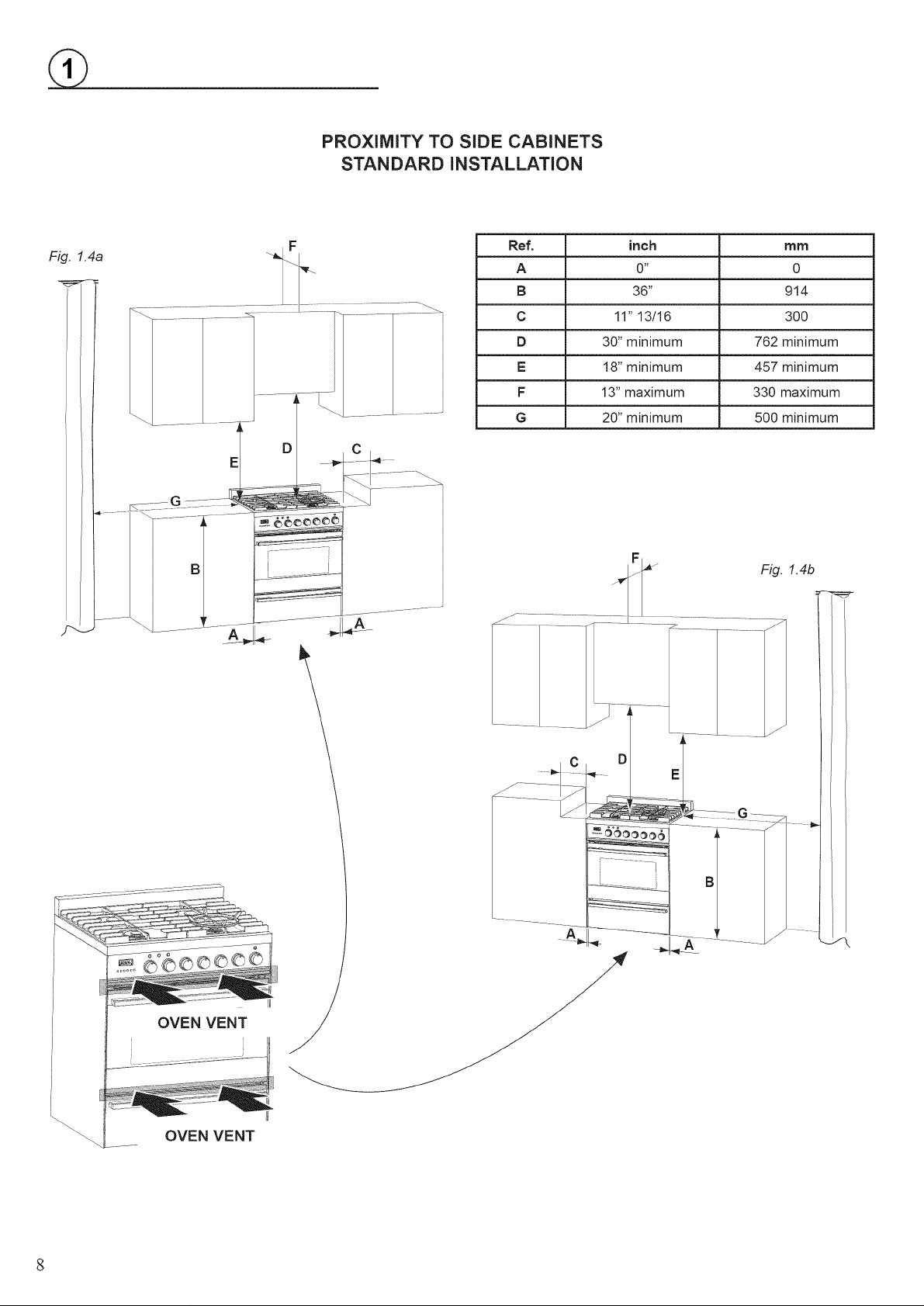

PROXiMiTY TO SIDE CABINETS

STAN DARD iNSTALLATiON

Fig. 1.4a

Ref. inch mm

A 0" 0

B 36" 914

C 11" 13/16 300

D 30" minimum 762 minimum

E 18" minimum 457 minimum

F 13" maximum 330 maximum

G 20" minimum 500 minimum

Fig. 1.4b

OVEN VENT

OVEN VENT

/

Page 9

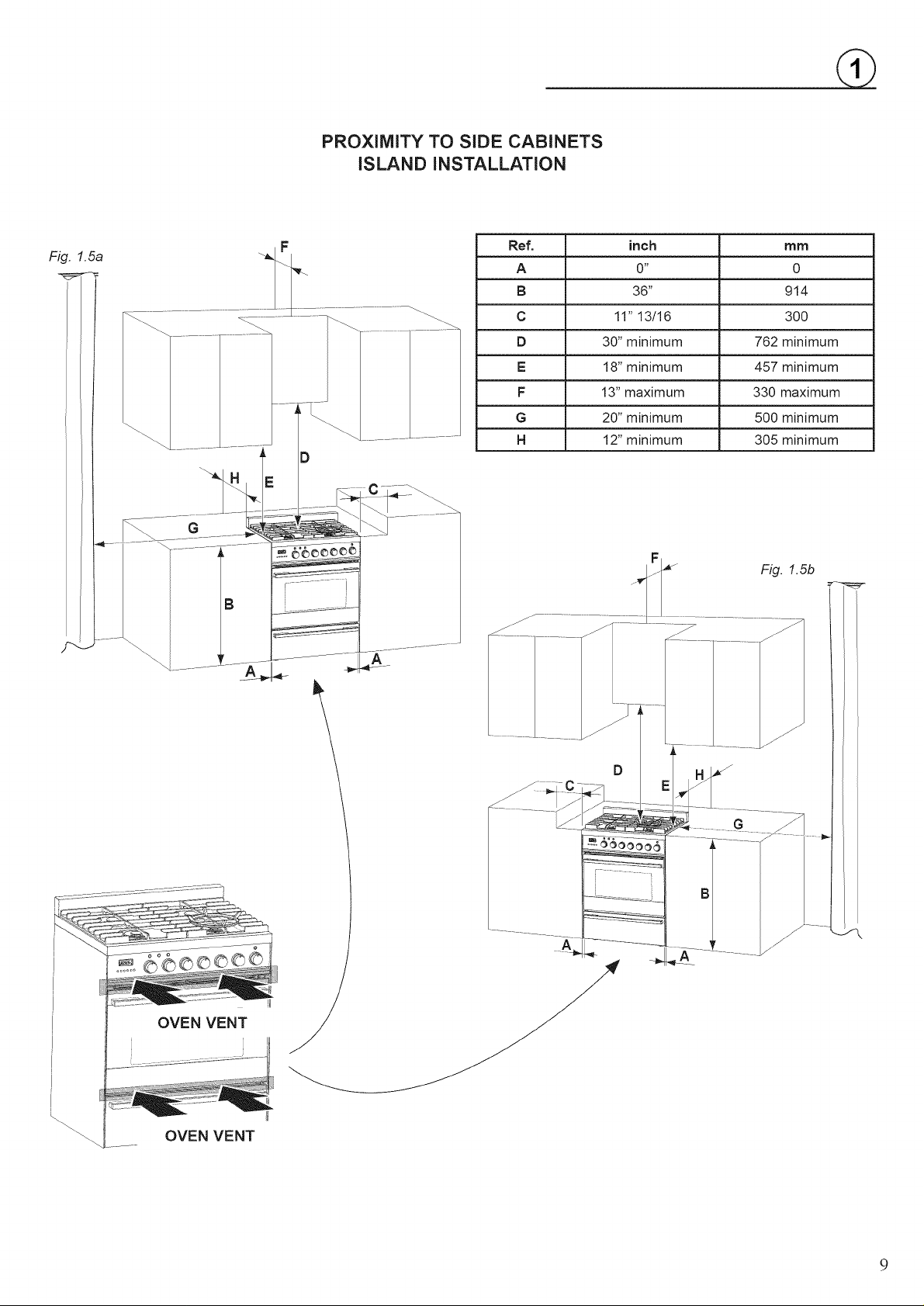

PROXiMiTY TO SIDE CABINETS

iSLAND iNSTALLATiON

Fig. 1.5a

¢"-,.

F

D

Ref. inch mm

A 0" 0

B 36" 914

C 11" 13/16 300

D 30" minimum 762 minimum

E 18" minimum 457 minimum

F 13" maximum 330 maximum

G 20" minimum 500 minimum

H 12" minimum 305 minimum

Fig. 1.5b

OVEN VENT

OVEN VENT

Page 10

& . &

Fig. 1.6

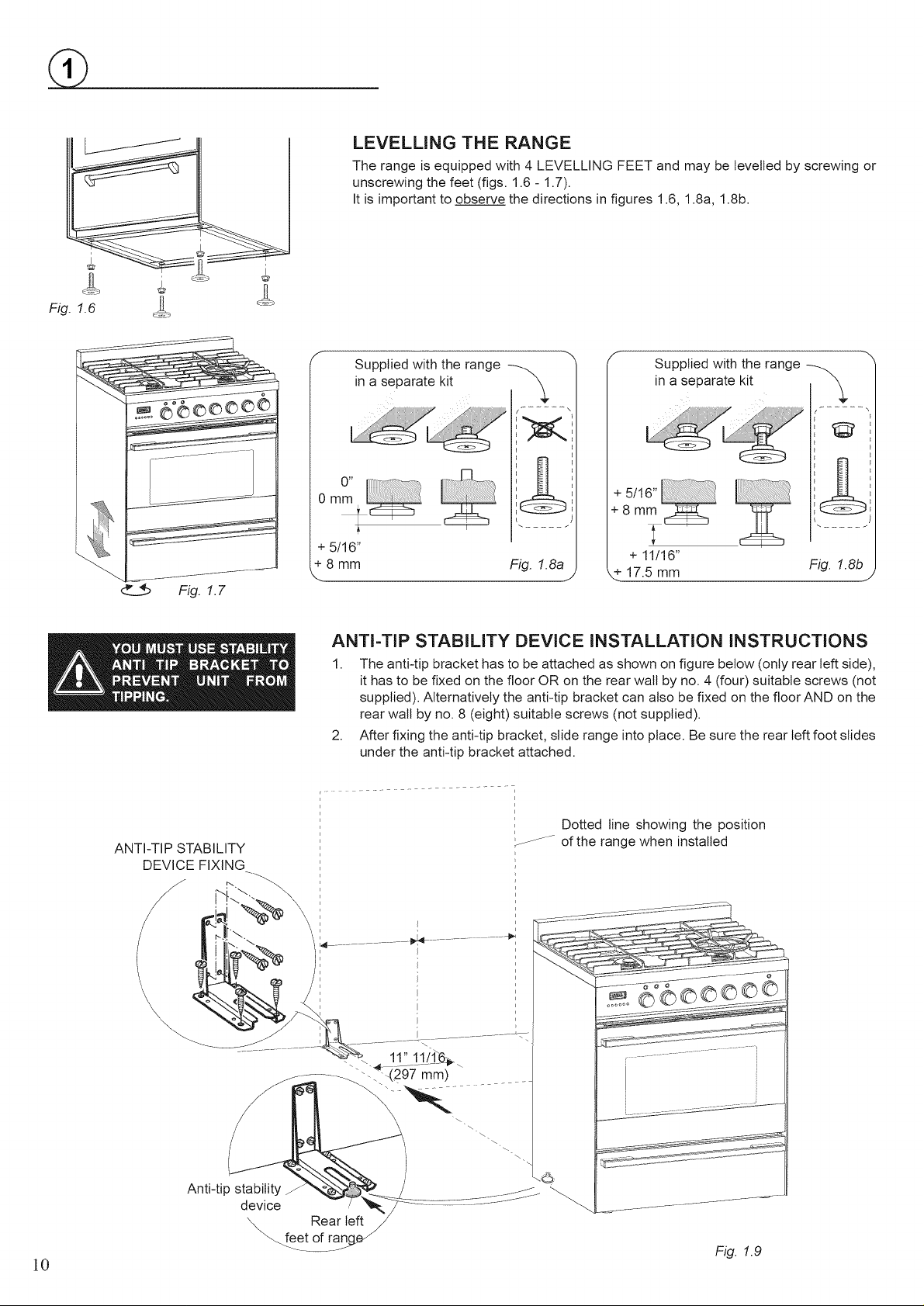

LEVELLING THE RANGE

The range is equipped with 4 LEVELLING FEET and may be levelled by screwing or

unscrewing the feet (figs. 1.6 - 1.7).

It is important to observe the directions in figures 1.6, 1.8a, 1.8b.

____ Fig. 1.7

Supplied with the range

in a separate kit

+ 5/16"

+8mm

\

i

Fig. 1.8a Fig. 1.8b

/ _ 17.5 mm 1,

Supplied with the range

in a separate kit

+ 11/16"

, _5' !

' i

F I

ANTi=TIP STABILITY DEVICE INSTALLATION INSTRUCTIONS

1. The anti-tip bracket has to be attached as shown on figure below (only rear left side),

it has to be fixed on the floor OR on the rear wall by no. 4 (four) suitable screws (not

supplied). Alternatively the anti-tip bracket can also be fixed on the floorAND on the

rear wall by no. 8 (eight) suitable screws (not supplied).

2. After fixing the anti-tip bracket, slide range into place. Be sure the rear left foot slides

under the anti-tip bracket attached.

r ..............

10

ANTI-TIP STABILITY

DEVICE FIXING

Anti-tip

device

"\ Rear left

feet of range/

Dotted line showing the position

J_ of the range when installed

k

Fig. l.9

Page 11

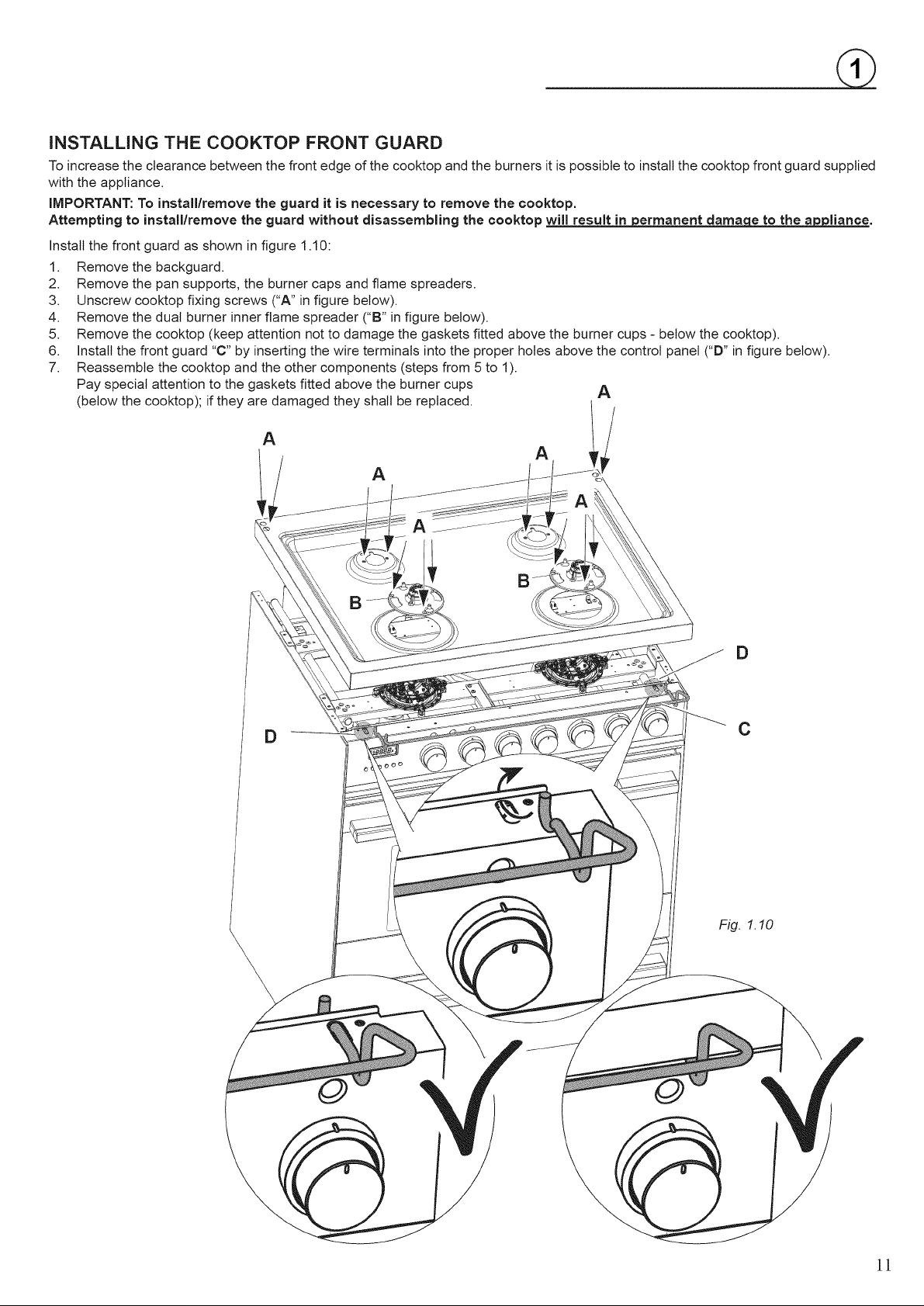

iNSTALLiNG THE COOKTOP FRONT GUARD

To increase the clearance between the front edge of the cooktop and the burners it is possible to install the cooktop front guard supplied

with the appliance.

IMPORTANT: To instalUremove the guard it is necessary to remove the cooktop.

Attempting to install/remove the guard without disassembling the cooktop will result in ermanent dama e to the a liance.

Install the front guard as shown in figure 1.10:

1. Remove the backguard.

2. Remove the pan supports, the burner caps and flame spreaders.

3. Unscrew cooktop fixing screws ("A" in figure below).

4. Remove the dual burner inner flame spreader ("B" in figure below).

5. Remove the cooktop (keep attention not to damage the gaskets fitted above the burner cups - below the cooktop).

6. Install the front guard "C" by inserting the wire terminals into the proper holes above the control panel ("D" in figure below).

7. Reassemble the cooktop and the other components (steps from 5 to 1).

Pay special attention to the gaskets fitted above the burner cups A

(below the cooktop); if they are damaged they shall be replaced.

A

A

A

A

D

D

C

Fig. 1.10

11

Page 12

All gas connections must be made according to national and local codes. This gas supply

(service) line must be the same size or greater than the inlet line of the appliance. Sea-

lant on all pipe joints must be resistant to the action of LP/Propane gas.

The range is equipped for the use with NATURAL gas. It is design-certified by CSA Inter-

national for NATURAL and L.R gases with appropriate conversion.

The model/serial rating plate, located below the bottom drawer, has information on the

type of gas that can be used. If this information does not agree with the type of gas avai-

lable, check with the local gas supplier. See page from 16 to 19 for L.P. gas conversion

instructions.

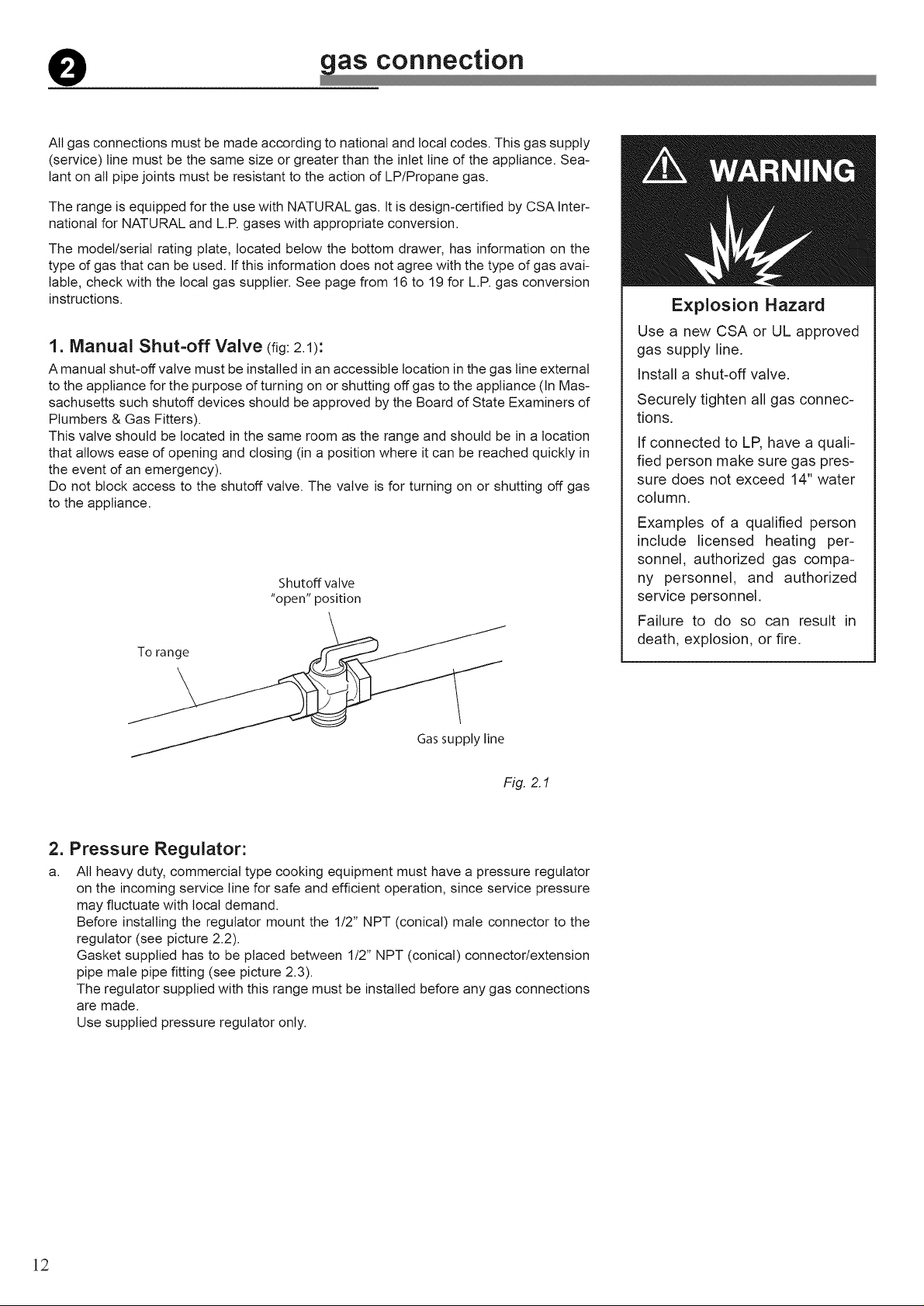

1. Manual Shut=off Valve (fig:2.1):

A manual shut-off valve must be installed in an accessible location in the gas line external

to the appliance for the purpose of turning on or shutting off gas to the appliance (In Mas-

sachusetts such shutoff devices should be approved by the Board of State Examiners of

Plumbers & Gas Fitters).

This valve should be located in the same room as the range and should be in a location

that allows ease of opening and closing (in a position where it can be reached quickly in

the event d an emergency).

Do not block access to the shutoff valve. The valve is for turning on or shutting off gas

to the appliance.

Shutoff valve

"open" position

Explosion Hazard

Use a new CSA or UL approved

gas supply line.

Install a shut-off valve.

Securely tighten all gas connec-

tions.

If connected to LP, have a quali-

fied person make sure gas pres-

sure does not exceed 14" water

column.

Examples of a qualified person

include licensed heating per-

sonnel, authorized gas compa-

ny personnel, and authorized

service personnel.

Failure to do so can result in

death, explosion, or fire.

To range J_

Gas supply line

Fig. 2.1

2. Pressure Regulator:

a. All heavy duty, commercial type cooking equipment must have a pressure regulator

on the incoming service line for safe and efficient operation, since service pressure

may fluctuate with local demand.

Before installing the regulator mount the 1/2" NPT (conical) male connector to the

regulator (see picture 2.2).

Gasket supplied has to be placed between 1/2" NPT (conical) connector/extension

pipe male pipe fitting (see picture 2.3).

The regulator supplied with this range must be installed before any gas connections

are made.

Use supplied pressure regulator only.

12

Page 13

PRESSURE REGULATOR iNSTALLATiON

STEP 1

Mount the 1/2" NPT (conical) male connector to the pressure regulator and

tighten by using a wrench.

Do not over tighten the connector.

Over tightening may crack the regulator.

®

LOCK

STEP 2

Assemble the 1/2" NPT connector + pressure regulator group to the extension pipe interposing the gasket supplied.

The regulator cover must be oriented toward the front side of the range.

IMPORTANT: use two wrenches to tighten the connection.

Fig. 2.2

Gasket

Regulator cover

Fig. 2.3

13

Page 14

GAS CONNECTION SPECiFiCATiON

manifold

malepipefitting

= 1/2" G cylindrical

(ISO 228-1) female

To range _-i

Fig. 2.4

---,I

1/2" G cylindrical

To mains

connection

1/2" NPT

female I

WARNING: check the correct positioning of the gas

regulator.

The arrow on the back of the gas regulator must be

oriented toward the connector.

Arrow

14

Page 15

TEST POINT ADAPTER

The Test Point adapter is available from the

After-Sales Service.

o'6o0000

®

b. Any conversion required must be performed by your dealer or a qualified licen-

sed technician or gas service company. Please provide the service person with

this manual before work is started on the range. (Gas conversions are the re-

sponsibility of the dealer or end user.)

c. This range can be used with NATURAL or LP/PROPANE gas. It is shipped from

the factory adjusted for use with NATURAL gas.

d. Manifold pressure should be checked with a manometer and by operating as

below detailed:

• Remove the orifice from the rear left (or rear right) burner and mount the

proper test point adapter which is available from the After-Sales Service

(see side figure and the "OPERATIONS TO BE PERFORMED WHEN SUB-

STITUTING THE ORIFICES" chapter).

• Turn the rear left (or rear right) burner control knob to the maximum position.

• Press the knob and keeping it pressed check the manifold pressure with a

manometer; NATURAL gas requires 4.0" W.C.R and LP/PROPANE requires

11.0" W.C.R

• Incoming line pressure upstream from the regulator must be 1" W.C.P. hi-

gher than the manifold pressure in order to check the regulator.

• The regulator used on this range can withstand a maximum input pressure

of 1/2 PSI (14.0" W.C.P). If the line pressure is in excess of that amount, a

stepdown regulator will be required.

e. The appliance, its individual shut-off valve, and pressure regulator must be di-

sconnected from the gas supply piping system during any pressure testing of

that system at pressures in excess of 1/2 PSI (3.5 kPa).

f. The appliance must be isolated from the gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the gas supply

piping system at test pressure equal to or less than 1/2 PSI (3.5 kPa).

Fig. 2.5

3. Fle×ible Connections"

If local codes permit, CSA or UL design-certified, flexible metal appliance connector

is recommended for connecting this range to the gas supply line. Do Not kink or da-

mage the flexible connector when moving the range. The pressure regulator has 1/2"

NPT female pipe threads.You will need to determine the fittings required, depending

on the size of your gas supply line, flexible metal connector and shutoff valve.

4. Rigid Pipe Connections:

If rigid pipe is used as agas supply line, a combination of pipe fittings must be used to

obtain an in-line connection to the range. All strains must be removed from the supply

and fuel lines so the range will be level and in line.

• Use joint compounds and gaskets that are resistant to action of natural or propa-

ne gas on all male pipe threads.

• Do not over tighten gas fitting when attaching to the pressure regulator. Over

tightening may crack the regulator.

5. Leak Testing:

IMPORTANT: Leak testing of the appliance shall be conducted as follows:

• After final gas connection is made, turn on manual gas valve and test alt con-

nections in gas supply piping and appliance for gas leaks with a soapy water

solution. During this test all appliance gas valves have to be closed.

• In order to avoid property damage or serious personal injury, never use a lighted

match. If a leak is present, tighten joint or unscrew, apply more joint compound,

tighten again and retest connection for leak.

15

Page 16

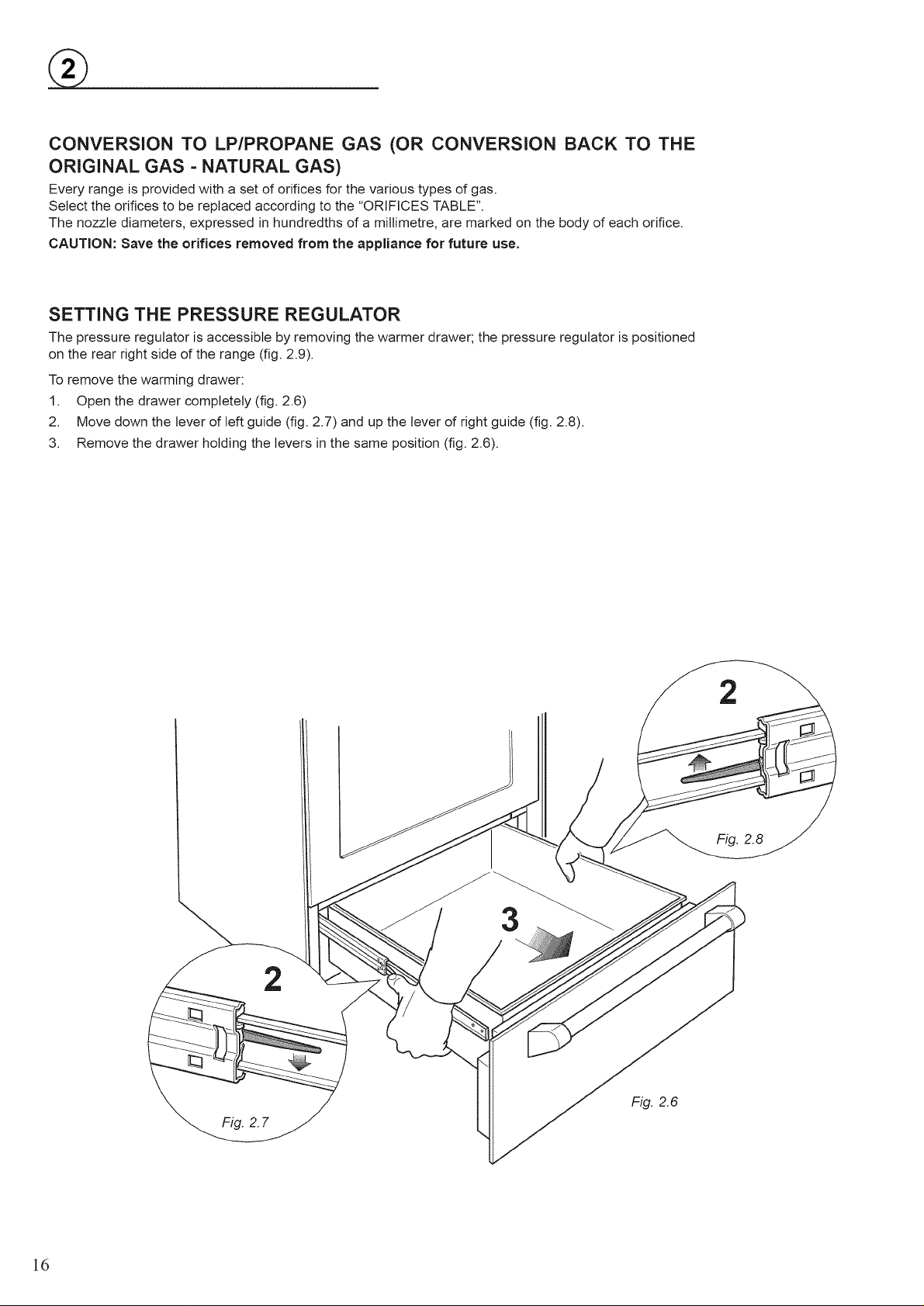

CONVERSION TO LP/PROPANE GAS (OR CONVERSION BACK TO THE

ORIGINAL GAS - NATURAL GAS)

Every range is provided with a set of orifices for the various types of gas.

Select the orifices to be replaced according to the "ORIFICES TABLE".

The nozzle diameters, expressed in hundredths of a mitlimetre, are marked on the body of each orifice.

CAUTION: Save the orifices removed from the appliance for future use.

SETTING THE PRESSURE REGULATOR

The pressure regulator is accessible by removing the warmer drawer; the pressure regulator is positioned

on the rear right side of the range (fig. 2.9).

To remove the warming drawer:

1. Open the drawer completely (fig. 2.6)

2. Move down the lever of left guide (fig. 2.7) and up the lever of right guide (fig. 2.8).

3. Remove the drawer holding the levers inthe same position (fig. 2.6).

Fig. 2.7

2

Fig. 2.8

3

2

Fig. 2.6

16

Page 17

Pressure

regulator --_

®

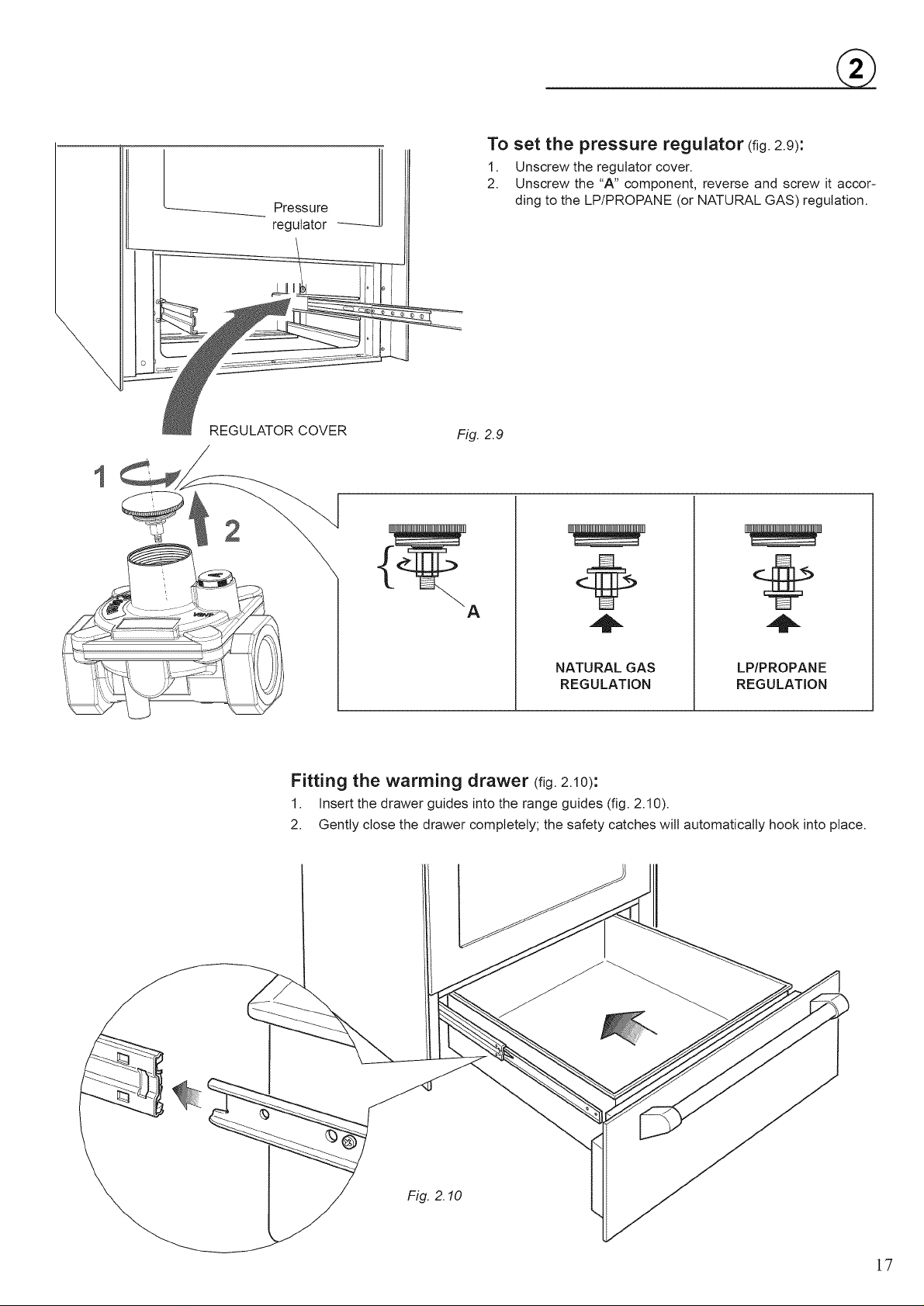

To set the pressure regulator (fig.2.9):

1. Unscrew the regulator cover.

2. Unscrew the "A" component, reverse and screw it accor-

ding to the LP/PROPANE (or NATURAL GAS) regulation.

1

REGULATOR COVER

2

Fitting the warming drawer (fig.2.10):

1. Insert the drawer guides into the range guides (fig. 2.10).

2. Gently close the drawer completely; the safety catches will automatically hook into place.

Fig. 2.9

A

NATURAL GAS

REGULATION

LP/PROPANE

REGULATION

Fig. 2.10

17

Page 18

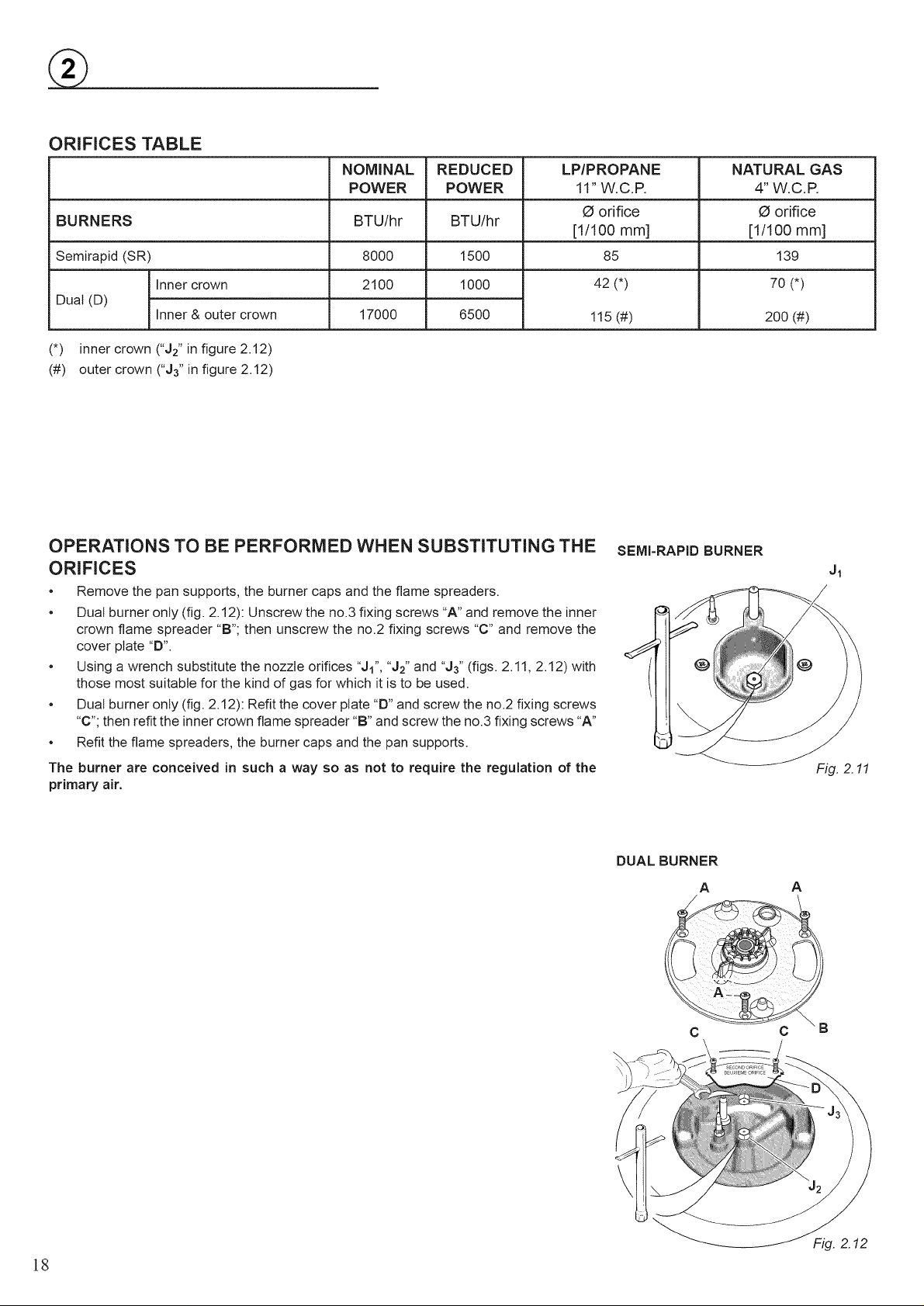

ORIFICES TABLE

BURNERS

Semirapid (SR)

NOMINAL REDUCED LP/PROPANE NATURAL GAS

POWER

BTU/hr

8000

POWER

BTU/hr

1500

11" W.C.P.

O orifice

[1/100 mm]

85

4" W.C.P.

O orifice

[1/100 mm]

139

Inner crown

Dual (D)

(*)

inner crown ("J2" in figure 2.12)

(#)

outer crown ("J3" in figure 2.12)

Inner & outer crown

2100

17000

1000

6500

OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING THE

ORIFICES

• Remove the pan supports, the burner caps and the flame spreaders.

• Dual burner only (fig. 2.12): Unscrew the no.3 fixing screws "A" and remove the inner

crown flame spreader "B"; then unscrew the no.2 fixing screws "C" and remove the

cover plate "D".

• Using a wrench substitute the nozzle orifices "Jl", "J2" and "J3" (figs. 2.11, 2.12) with

those most suitable for the kind of gas for which it is to be used.

• Dual burner only (fig. 2.12): Refit the cover plate "D" and screw the no.2 fixing screws

"C"; then refit the inner crown flame spreader "B" and screw the no.3 fixing screws "A"

Refit the flame spreaders, the burner caps and the pan supports.

The burner are conceived in such a way so as not to require the regulation of the

primary air.

42 (*)

115 (#)

SEMI-RAPID BURNER

70 (*)

200 (#)

J1

Fig. 2.11

18

DUAL BURNER

A A

C C

\

Fig. 2.12

Page 19

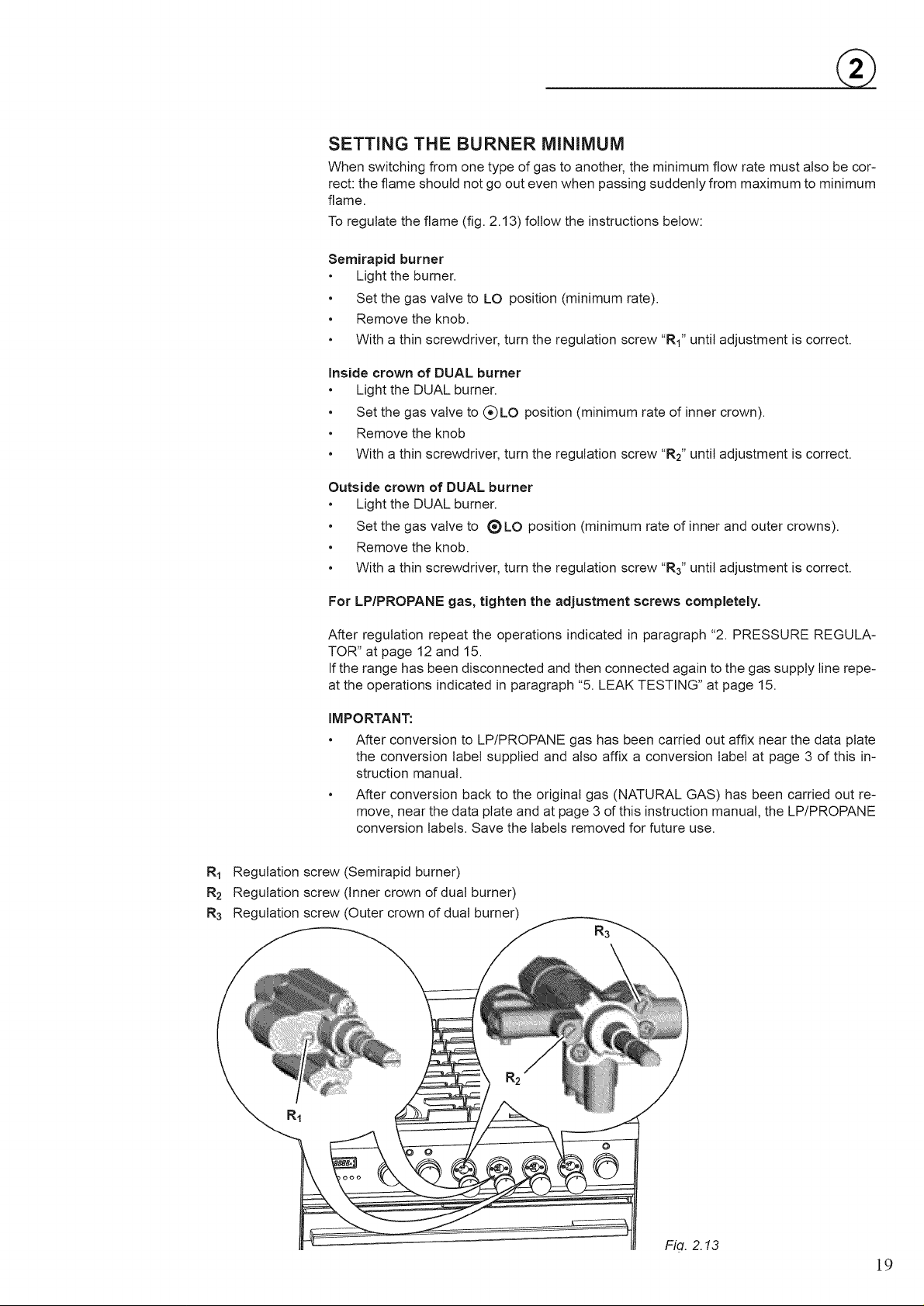

®

SETTING THE BURNER MiNiMUM

When switching from one type of gas to another, the minimum flow rate must also be cor-

rect: the flame should not go out even when passing suddenly from maximum to minimum

flame.

To regulate the flame (fig. 2.13) follow the instructions below:

Semirapid burner

• Light the burner.

• Set the gas valve to LO position (minimum rate).

• Remove the knob.

• With a thin screwdriver, turn the regulation screw "RI" until adjustment is correct.

Inside crown of DUAL burner

* Light the DUAL burner.

. Set the gas valve to (_ LO position (minimum rate of inner crown).

. Remove the knob

. With a thin screwdriver, turn the regulation screw "R2" until adjustment is correct.

Outside crown of DUAL burner

• Light the DUAL burner.

• Set the gas valve to _} LO position (minimum rate of inner and outer crowns).

• Remove the knob.

• With a thin screwdriver, turn the regulation screw "R3" until adjustment is correct.

For LP/PROPANE gas, tighten the adjustment screws completely.

After regulation repeat the operations indicated in paragraph "2. PRESSURE REGULA-

TOR" at page 12 and 15.

Ifthe range has been disconnected and then connected again to the gas supply Sinerepe-

at the operations indicated in paragraph "5. LEAK TESTING" at page 15.

IMPORTANT:

• After conversion to LP/PROPANE gas has been carried out affix near the data plate

the conversion label supplied and also affix a conversion label at page 3 of this in-

struction manual.

• After conversion back to the original gas (NATURAL GAS) has been carried out re-

move, near the data plate and at page 3 of this instruction manual, the LP/PROPANE

conversion labels. Save the labels removed for future use.

R1 Regulation screw (Semirapid burner)

R2 Regulation screw (Inner crown of dual burner)

R3 Regulation screw (Outer crown of dual burner)

Fla. 2.13

19

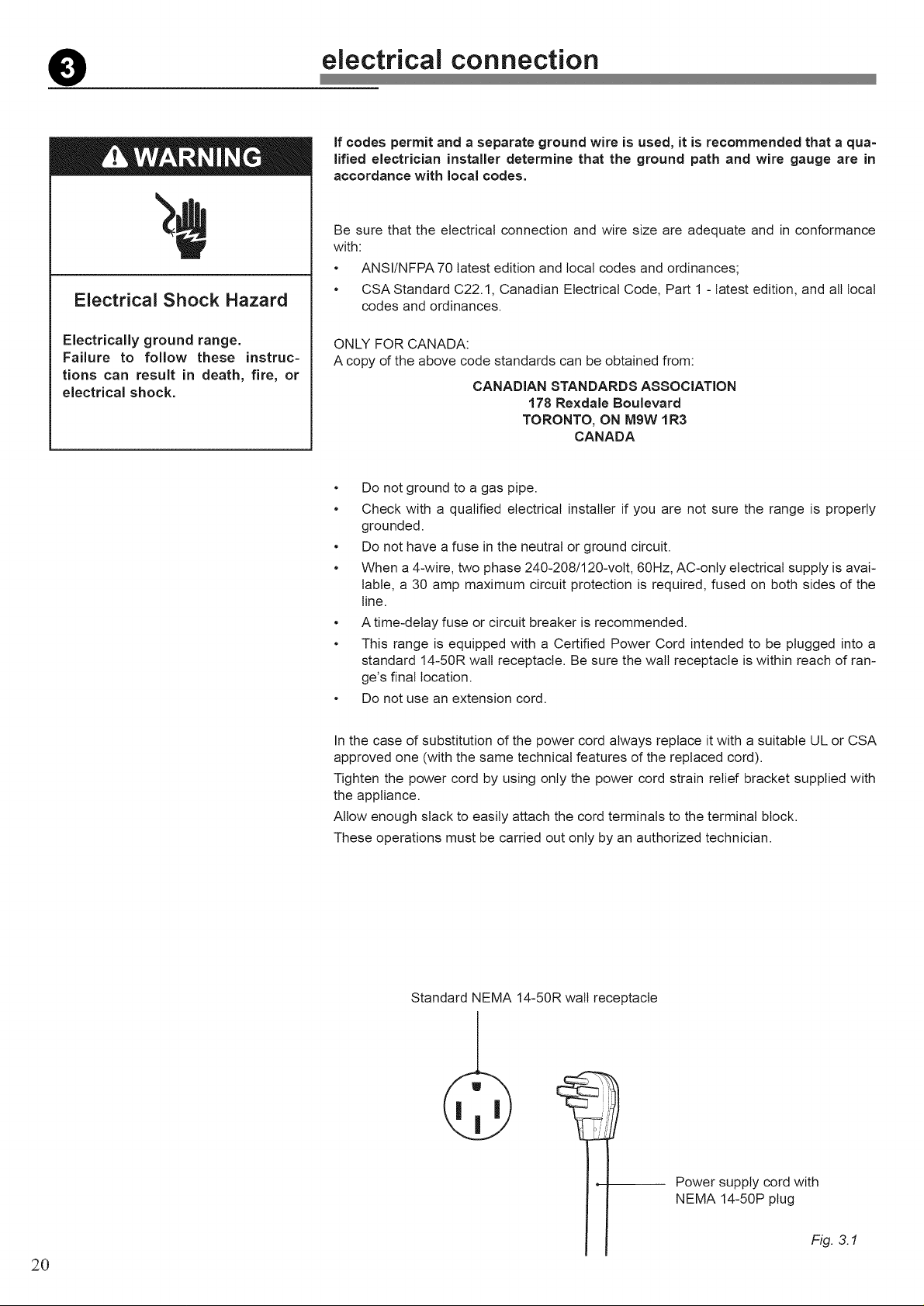

Page 20

Electrical Shock Hazard

electrical connection

if codes permit and a separate ground wire is used, it is recommended that a qua=

lified electrician installer determine that the ground path and wire gauge are in

accordance with local codes.

Be sure that the electrical connection and wire size are adequate and in conformance

with:

• ANSI/NFPA 70 latest edition and local codes and ordinances;

CSA Standard C22.1, Canadian Electrical Code, Part 1 - latest edition, and all local

codes and ordinances.

Electrically ground range.

Failure to follow these instruc=

tions can result in death, fire, or

electrical shock.

ONLY FOR CANADA:

A copy of the above code standards can be obtained from:

CANADIAN STANDARDS ASSOCIATION

178 Rexdale Boulevard

TORONTO, ON M9W 1R3

CANADA

• Do not ground to a gas pipe.

• Check with a qualified electrical installer if you are not sure the range is properly

grounded.

• Do not have a fuse in the neutral or ground circuit.

• When a 4-wire, two phase 240-208/120-volt, 60Hz, AC-only electrical supply is avai-

lable, a 30 amp maximum circuit protection is required, fused on both sides of the

line.

• A time-delay fuse or circuit breaker is recommended.

• This range is equipped with a Certified Power Cord intended to be plugged into a

standard 14-50R wall receptacle. Be sure the wall receptacle is within reach of ran-

ge's final location.

• Do not use an extension cord.

In the case of substitution of the power cord always replace it with a suitable UL or CSA

approved one (with the same technical features of the replaced cord).

Tighten the power cord by using only the power cord strain relief bracket supplied with

the appliance.

Allow enough slack to easily attach the cord terminals to the terminal block.

These operations must be carried out only by an authorized technician.

2O

Standard NEMA 14-50R wall receptacle

-- Power supply cord with

NEMA 14-50P plug

Fig. 3.1

Page 21

ELECTRIC DIAGRAM KEY

IC IGNITION COIL

ISG IGNITION SWITCHES GROUP

OL OVEN LAMP

E61 RELAY

CE CIRCULAR ELEMENT

GE BROIL ELEMENT

TE TOP ELEMENT

BE-INT BOTTOM ELEMENT INT,

BE-EXT BOTTOM ELEMENT EXT,

TPL THERMOSTAT PILOT LAMP

LI

DSPL

CF

OF

ER

DLM

SL/U

LPL

WD

ST

ELP

SD

ODL

DOOR SAFETY PILOT LAMP

COOLING FAN

OVEN FAN

ENERGY REGULATOR

DOOR LOCK MOTOR

STATUS LOCK/UNLOCK

LINE PILOT LAMP

WARMING DRAWER ELEMENT

SAFETY THERMOSTAT

ELECTRONIC PROGRAMMER

DOOR STATUS, OPEN/CLOSED

OVEN DOOR LATCH

AS AIR SWITCH

CONNECTIONS ON PROGRAMMER

PN/PL

K1

K2

K3

PHV

X0

X1

P4

P5B

SUPPLY

PROGRAM THERMOSTAT RELAY1

COOLING/OVEN FAN RELAY2

DOOR LOCK/UNLOCK RELAY3

FUNCTION STATE

THERMOSTAT ENCODER

FUNCTIONS ENCODER

PROBE (Sonde)

WIRES P5B(1 )+P5B(2)+P5B(3)

(3

L1 - L2 = 240-208V

[

L1 - N = 120V

L2- N= 120V

EARTH

Terre

lp6

JU

_AS + ......

_- p_

M

Z

m

m

=

PHV

B

9_

IRELAY2 K21

is T

)6

5a

4a

4 IC

ISG

-t EL.P....

"_FT-/\)'° I I J,._,,

PL

ODL

I

I 2

)la L _

I I

PT2 I

.)

p9

_9a

L2

Page 22

The manufacturer cannot be held responsible for possible inaccuracies due to printing or transcription errors

in the present booklet.

The manufacturer reserves the right to make all modifications to its products deemed necessary for manu-

facture or commercial reasons at any moment and without prior notice, without jeopardising the essential

functional and safety characteristics of the appliances.

22

Page 23

CUI I A GAZ/ELECTRIQUE

Cet appareil est reserve a I'usage residentiel uniquement.

Fisher Paykel

®

Mod io :OR30SDPWGX

®

iNSTRUCTiONS D'INSTALLATION

C US

iMPORTANT =VEUILLEZ LIRE ET SUIVRE

o

Avant de commencer, veuillez lire attentivement toutes les instructions.

o

N'enlevez pas les etiquettes, plaques ou avertissements permanents de I'appareil. Cela

pourrait annuler la garantie.

o

Veuillez respecter tous les codes et les reglements Iocaux et nationaux.

o

Veuillez vous assurer que cet appareil est bien mis a la terre.

o

La prise de courant devrait _tre toujours accessible.

®

L'installateur doit confier ces instructions au consommateur qui ies conservera

pour I'usage de I'inspecteur local et pour s'y reporter ult_rieurement.

L'installation doit _tre conforme aux codes Iocaux, ou en I'absence de ces codes, a la der=

niere edition du National Fuel Gas Code ANSI Z223.1/NFPA 54. L'installation electrique doit

_tre conforme a la derniere edition du Code national de I'electricit6, ANSI/NFPA70 et/ou aux

codes Iocaux.

AU CANADA: L'installation doit _tre conforme au CAN/CGA-B149.1, Code d'installation du

gaz naturel ou au CAN/CGA=B149.2, Code d'installation du propane en vigueur et/ou aux co-

des Iocaux. L'installation electrique doit _tre conforme au Code canadien de I'electricit6 CSA

C22.1, partie 1, en vigueur et/ou aux codes Iocaux.

INSTALLATION DANS UNE MAISON PRg:FABRIQUg:E (MOBILE) : L'installation doit _tre

conforme au Manufactured Home Construction and Safety Standard, Titre 24 CFR, Partie

3280 [anciennement le Federal Standard for Mobile Home Construction and Safety, Titre 24,

HUD (Partie 280)] ou, Iorsque cette norme n'est pas applicable, au Standard for Manufactu-

red Home Installations, ANSI/NCSBCS A225.1, ou aux codes Iocaux, la oQ il y a lieu.

INSTALLATION DANS UNE CARAVANE DE PARC : L'installation doit etre conforme aux

codes de I'l_tat ou aux autres codes ou, en I'absence de tels codes, au Standard for Recrea-

tional Park Trailers, ANSI Al19.5.

L'installation de tout appareil au gaz doit etre effectuee par un technicien qualifie. Par mesure

de s6curite et pour faciliter le service, un robinet d'arret de gaz manuel doit etre installe dans

le tuyau d'alimentation en gaz, juste avant I'appareil.

Si vous utilisez une source d'alimentation electrique exterieure, cet appareil doit etre, au

moment de son installation, mis a la terre conformement aux codes Iocaux en vigueur ou,

en I'absence de tels codes, conformement au Code national de I'electricit6, ANSI/NFPA 70.

Certains mod61es sont livres avec une pellicule protectdce recouvrant les pieces

en acier et en aluminium:

Cette pe I!ic ule d o it 6tre e n!ev6e ava nt I'i nstall at ion ou I' ut ilisat io n de I'a ppa re il.

A L'INTENTION DE L'INSTALLATEUR SEULEMENT

CETTE CUISINIi RE EST RI SERVI E A L'USAGE

RI SIDENTIEL UNIQUEMENT.

Page 24

Pour reduire le risque de basculer I'appareil, il dolt _tre

fi×e correctement par le dispositif antibasculement

fourni avec I'appareil.

- TOUS LES TYPES DE CUISINIERE PEUVENT

BASCULER

. CELA PEUT PROVOQUER DES BLESSURES

. INSTALLEZ LE DISPOSITIF ANTIBASCULEMENT

FOURNI AVEC LA CUISINll_RE

. CONSULTEZ LES iNSTRUCTiONS D'INSTALLATION

Le fait de ne pas suivre toutes les instructions de ce

manuel peut provoquer un feu ou une e×plosioncausant

des dommagesmateriels, des blessures ou ia mort.

Nerangezet n'utilisez pasde I'essenceou d'autresliquidesetvapeurs

inflammables_ pro×imit_de cet appareiiou detout autre appareii.

N'utilisezJAlVlAIScetappareii pourchaufferune piece. Lenon-respect

de cette consigne peut causer un empoisonnementau mono×ydede

carboneet une surchauffede I'appareil.

QUE FAIRESI VOUS DECELEZ UNE ODEUR DE GAZ:

• Ne tentez d'allumer aucun appareil.

• Ne touchez _ aucun interrupteur_iectrique.

• N'utilisez aucun t_l_phone dartsI'_difice.

• Appeiez imm_cliatementvotre fournisseur de gaz en utiiisant ie

t_l_phone d'un voisin.Suivezles consignesdufournisseur degaz.

24

• S'il vous est impossible de joindre votre fournisseur de gaz,

appelez ieservice d'incendie.

L'installation et I'entretien doivent _tre effectu_s par un installateur

ou un technicien qualifi_, ou par un employ_ de votre fournisseur de

gaz,

Page 25

PLAQUE SIGNALETIQUE

ETIQUETTE DE CONVERSION

La plaque signaletique

du produit est fixee dans

la surface en dessous du

tiroir. Pour contr61er l'eti-

quette, it est necessaire de

retirer le tiroir (en operant

comme indique dans ce

manuel).

Le Gouverneur de la Californie est tenu de publier une liste de substances dont I'Etat salt qu'ils

accroissent les risques de cancer ou d'infertilite; les entreprises sont tenues d'aviser leur clientele

des risques associes a de telles substances.

AVERTlSSEMENT! : Les appareils au gaz contiennent ou produisent des substances qui peuvent

entrafner la mort ou des maladies graves, et dont I'Fttat de la Californie reconnaft qu'ils augmentent

les dsques de cancer, d'anomalies congenitales ou autres risques au systeme reproductif. Pour

reduire les risques causes par les substances contenues dans le carburant ou par la combustion

du carburant, s'assurer d'installer, d'entretenir et d'utiliser cet appareil selon les consignes du fa-

bdcant.

Cet appareil a et6 con(_u et fabrique uniquement pour la cuisson domestique des aliments et ne

convient pas a I'usage non menager. Cet appareil ne devrait donc pas _tre utilise dans un environ-

nement commercial.

La garantie de I'appareil sera annutee s'il est utilise dans un environnement non domestique, c'est-

a-dire un environnement semi-commercial, commercial ou communautaire.

Page 26

AVERTISSEMENT!

CET APPAREIL DOlT ETRE INSTALL¢: PAR UN INSTALLATEUR QUALIFIE.

Une mauvaise installation, modification, reparation ou un mauvais reglage ou entretien peuvent causer des blessures ou des

dommages materiels. Consultez un installateur qualifie, un agent autorise ou le fournisseur de gaz.

iMPORTANT: L'utilisation de v_tements et de

gants de protection est recommandee Iors de la

manutention et I'installation de cet appareil.

OUTILS REQUIS POUR L'INSTALLATION (NON FOURNIS AVEC L'APPAREIL)

Tournevis

de protection

©

Clef

poign6e en T

Clef

molette

Crayon

Pince

multiprise

M_tre

ruban

26

Page 27

RENSEIGNEMENTS GENERAUX

1. L'instaltation dolt 6tre conforme aux codes tocaux ou, en

l'absence de ceux-ci, a ta derniere edition du National Fuel

Gas Code, ANSI Z223.1/NFPA 54, au CAN/CGA=B149.1 ou

au CAN/CGA=B149.2.

2. Installation dans une maison prefabriqu6e (mobile): L'in-

stallation dolt 6tre conforme au Manufactured Home Con-

struction and Safety Standard, TJtre 24 CFR, Pattie 3280

[anciennement le Federal Standard for Mobile Home

Construction and Safety, Titre 24, HUD (Pattie 280)] ou,

lorsque cette norme n'est pas applicable, au Standard for Ma-

nufactured Home Installations, ANSI/NCSBCS A 225.1, ou

aux codes tocaux, ta oe it y a lieu.

3. Installation dans une caravane de parc: L'instaltation dolt 6tre

conforme aux codes de l'E_tat ou aux autres codes ou, en

l'absence de tets codes, au Standard for Recreational Park

Trailers, ANSI A119.5.

4. Afin d'eliminer tes risques de br_lures ou d'incendie qui peu-

vent se produire lorsqu'on s'etire au-dessus d'appareits aux

surfaces chauffantes, evitez de placer des armoires de cuisi-

ne au-dessus de t'appareit.

5. Les rideaux d'air ou les hottes de cuisinieres en hauteur, qui

projettent de Fair vers ta cuisiniere en contrebas, ne doivent

pas 6tre utitises avec des cuisinieres a gaz, sauf si la hotte

et la cuisiniere ont 6te congues, testees et repertori6es par

un laboratoire d'essais independant pour pouvoir fonctionner

conjointment.

6 |AVERTISSEMENT!!

Cet appareil ne doJt pas _tre utilJse pour chauffer une

piece. Ces renseignements sont bases sur des facteurs

de securite.

7,

Toute ouverture dans lemur derriere t'appareit et dans le sol

au-dessous de l'appareit dolt 6tre obstruee.

8.

Gardez l'appareit loin des materiaux combustibles, de l'es-

sence ou de toute autre vapeur inflammable.

9.

N'obstruez pas le flux de Fair de combustion et de Fair de

ventilation,

marcher, s'asseoir ou s'appuyer dessus) peut presenter des

dangers possibles et/ou entraTner des blessures.

16.

Lors de t'installation ou du deplacement de la cuisiniere

pour une reparation, un timon rouleur devrait 6tre utitise. Ne

poussez pas en appuyant sur les rebords de ta cuisiniere en

tentant de la faire gtisser dans ou en dehors de l'installation.

Pousser ou tirer une cuisiniere (plut6t que d'utitiser un timon

rouleur) augmente egalement les risques de deformation des

tiges ou des connecteurs de couplage internes.

AVERTISSEMENT!!

iNSTRUCTiONS DE MISE A LA TERRE

La cuisiniere doit _tre raise a la torte conformement au× co=

des Iocau× ou, en I'absence de ceu×=ci, a la derniere edition

du Code national de I'electricit6, ANSJ/NFPA n° 70 ou au Code

canadien de I'electricite au Canada.

L'installatJon dolt _tre effectuee par un electricien qualifie.

POUR VOTRE St_CURITI_, CET APPAREIL DOlT IeTRE COR-

RECTEMENT MIS A LA TERRE.

Si vous utitisez une source d'alimentation electrique exterieure,

cet appareit dolt 6tre, au moment de son installation, mis a ta terre

conformement aux codes locaux en vigueur ou, en l'absence de

ces codes, conformement au Code national de l'€tectricit¢, ANSI/

NFPA 70.

Pour diminuer tes risques de choc etectrique, cet appareit est muni

d'une fiche de mise a ta terre a quatre broches (NEMA 14-50P)

et devrait _tre branche directement dans une prise correctement

mise a ta terre.

Ne coupez et ne retirez en aucun cas la quatrJeme broche

(raise a la terre) de la fiche du cordon d'alimentation.

10. Coupez t'alimentation etectrique de t'appareit avant de

proceder a t'entretien.

11.

Lots du deplacement de t'appareit pour le nettoyage et/ou une

reparation :

A. Fermez l'alimentation gen6rale en gaz.

B. Coupez l'alimentation c.a.

C. Debranchez le tuyau d'alimentation en gaz du

tuyau d'entree.

D. Deplacez la cuisiniere avec soin en la tirant en

dehors de t'installation.

ATTENTION : La cuisiniere est lourde. Faites attention

lorsque vous la manipulez.

12. Exigences electriques

L'installation electrique dolt 6tre conforme aux codes natio-

naux et locaux.

13. Alimentation d'air et ventilation

L'installateur dolt consulter les codes locaux et nationaux.

14.

Pression du collecteur d'alimentatJon en gaz

Gaz naturet - 4,0 po CE

Gaz propane/GPL - 11,0 po CE

15. L'utitisation inappropriee de la porte du four (par exemple,

PIECES DE RECHANGE

Seules les pieces de rechange autorisees peuvent 6tre utitisees

lots d'une reparation sur la cuisiniere. Des pieces de rechange

sont disponibtes chez tes concessionnaires de pieces d'origine.

Veuitlez communiquer avec le concessionnaire de pieces de votre

region.

27

Page 28

Fig. l.1

(759 ram)

installation

PROXlMITE DES ARIVIOIRES

1. Cette cuisiniere peut 6tre instaltee directement adjacente a des armoires

de base existantes de 36 po (914 mm) de hauteur.

Dimensions de ta cuisiniere :

• largeur : 29-7/8 po (759 mm)

• profondeur : 24-3/16 po (615 mm)

, hauteur (sans dosseret) : 35-21/32 po (906 mm) MtN. - 36-11/32 po (923

mm) MAX.

• dosseret (hauteur) : 3 po (76 mm)

Ouverture du tuyau de gaz: Mur - 37/64 po (14,5 mm) du c6te droit

vers le centre de la cuisiniere; de 5-7/16 po (138 mm) a 6-1/8 po (155,5

mm) du sol, selon te reglage des pieds.

Zone pour le raccordement electrique: 37/64 po (14,5 mm) du c6te

gauche vers le centre de ta cuisiniere; de 5-7/16 po (138 mm) a 6-1/8 po

(155,5 mm) du sol, seton le regtage des pieds.

Le cordon d'atimentation electrique avec fiche de mise a ta terre a quatre

broches (NEMA 14-50P) dolt avoir une longueur minimale de 48 po (1

220 mm) au-deta de l'arriere de l'appareit.

2. La cuisiniere NE PEUT PAS 6tre installee directement adjacente a un

mur, a une armoire haute, a un etectrom6nager haut ou a toute autre

surface laterate verticate de plus de 36 po (914 mm) de hauteur.

Un degagement tateral minimal de 11-13/16 po (300 mm) est necessaire

entre ta cuisiniere et toute surface combustible ,ik DROITE ou A GAU-

CHE, au-dessus du comptoir de 36 po (914 mm) de hauteur.

IMPORTANT : Un cbte (gauche ou droit) au=dessus du comptoir de

36 po (914 ram) de hauteur doit toujours _tre degage.

Installation en d'ilot: Un degagement minimal de 12 po (305 mm) est

necessaire entre l'arriere du dosseret et toute surface combustible derri-

ere ta cuisiniere, au-dessus du comptoir de 36 po (914 mm) de hauteur.

3. La profondeur maximale recommandee de l'armoire superieure est de

13 po (330 mm). L'armoire au-dessus de la cuisiniere dolt _tre situee au

moins 30 po (762 mm) au-dessus du comptoir, avec une targeur minima-

le de 30 po (762 mm); erie dolt 6tre centree avec ta cuisiniere. Les armoi-

res taterales au-dessus de ta cuisiniere doivent 6tre situees au moins 18

po (457 mm) au-dessus du comptoir.

28

Page 29

Ligne pointitlee itlustrant la position de la

cuisiniere au moment de l'installation ....._

C

Zone pour le.................

raccordement

¢:LECTRIQUE

B

Zone pour le /

raccordement au GAZ

RACCORDEMENTS I_LECTRIQUE ET AU GAZ

Ref. pouces

A 5-7/16 po - 6-1/8 po (*)

B 14"- 3/8 po

C 37/64 po

(*) : En fonction du regtage des pieds

B

/

/

mm

138- 155.5 (*)

365

14.5

MONTAGE DU DOSSERET

L'installation du dosseret est obligatoire.

Montez te dosseret tel qu'indique a ta figure 1.3 "

• Vissez les 2 vis "A" en interposant les butoirs.

• Vissez la vis centrale "B".

Fig. 1.2

@

Fig. 1.3

29

Page 30

PROXIMIT¢: DES ARMOIRES

iNSTALLATiON STAN DARD

Fig. 1.4a

Ref. pouces mrn

A 0 po 0

B 36 po 914

C 11-13/16 po 300

D 30 po minimum 762 minimum

E 18 po minimum 457 minimum

F 13 po maximum 330 maximum

G 20 po minimum 500 minimum

Fig. 1.4b

3O

EVENT DE FOUR

E_VENTDE FOUR

/

Page 31

PROXIMITE DES ARMOIRES

iNSTALLATiON EN/LOT

Fig. 1.5a

p..,,,

G

F

D

Ref. pouces rnrn

A 0 po 0

B 36 po 914

C 11-13/16 po 300

D 30 po minimum 762 minimum

E 18 po minimum 457 minimum

F 13 po maximum 330 maximum

G 20 po minimum 500 minimum

H 12 po minimum 305 minimum

Fig. 1.5b

EVENT DE FOUR

€:VENT DE FOUR

31

Page 32

_'____ Fig. 1.7

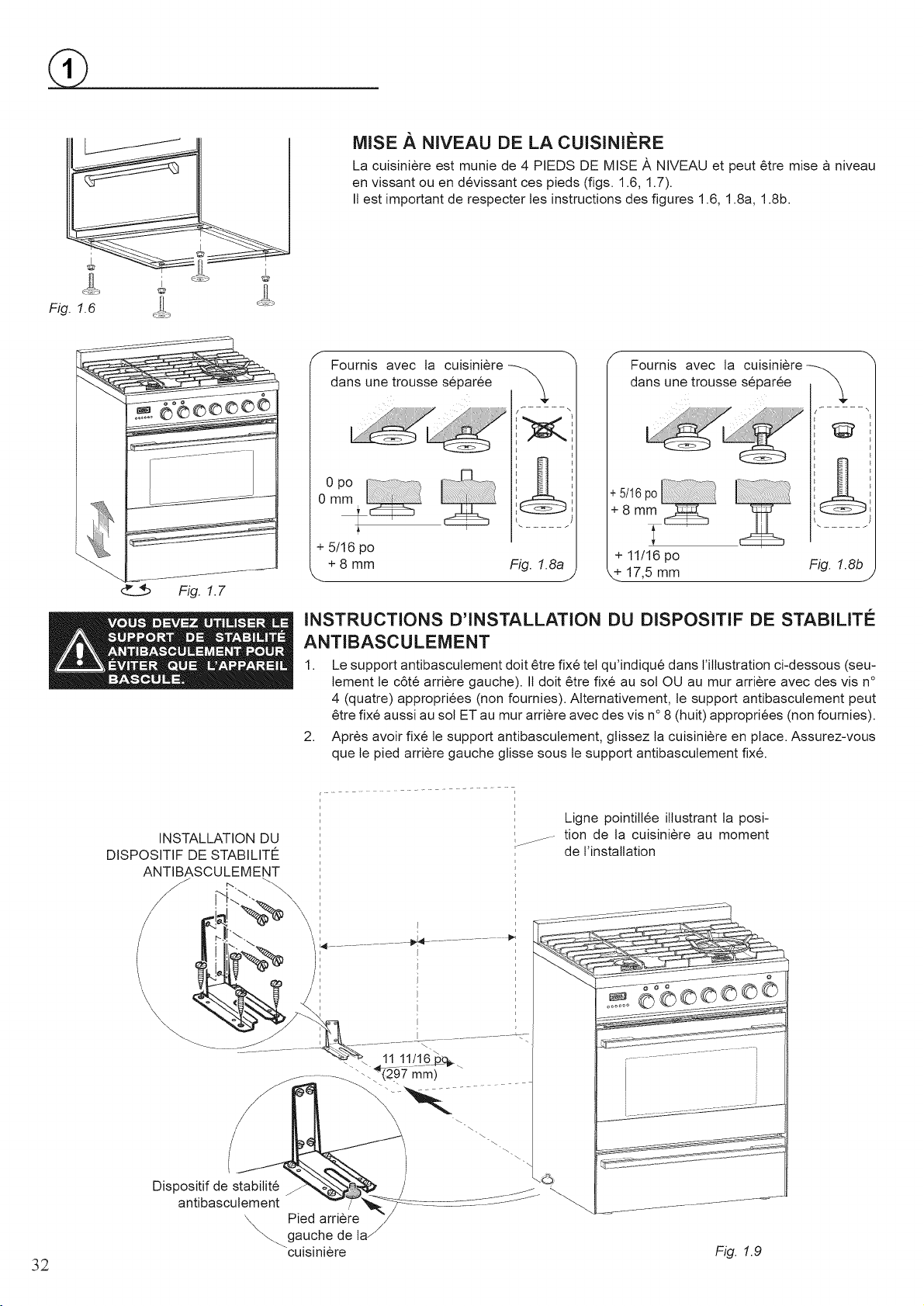

NllSE A NIVEAU DE LA CUISINIERE

La cuisiniere est munie de 4 PIEDS DE MISE A NIVEAU et peut 6tre mise a niveau

en vissant ou en devissant ces pieds (figs. 1.6, 1.7).

I1est important de respecter les instructions des figures 1.6, 1.Sa, 1.8b.

dans une trousse separ6e

Foumis avec la cuisini6re---_,,

+ 5/16 po

+ 8 mm Fig. 1.8a

\ J

17,5 mm

Fig. 1.8b

INSTALLATION DU

DISPOSITIF DE STABILITE

ANTIBASCULEMENT

/

INSTRUCTIONS D'INSTALLATION DU DISPOSITIF DE STABILITI_

ANTIBASCULEMENT

1. Le support antibasculement doit 6tre fixe tel qu'indique dans l'itlustration ci-dessous (seu-

lement le c6te arriere gauche). I1dolt 6tre fixe au sol OU au mur arriere avec des vis n°

4 (quatre) appropriees (non fournies). Alternativement, le support antibasculement peut

6tre fixe aussi au sol ET au mur arriere avec des vis n° 8 (huit) appropriees (non fournies).

2. Apres avoir fixe le support antibasculement, gtissez ta cuisiniere en place. Assurez-vous

que le pied arriere gauche gtisse sous le support antibasculement fixe.

Ligne pointittee itlustrant la posi-

tion de ta cuisiniere au moment

de l'installation

i

i

i

i

32

Dispositif de stabitite

antibasculement

_ ied arriere

/

gauche de la/

CUlSlntere

Fig. l.9

Page 33

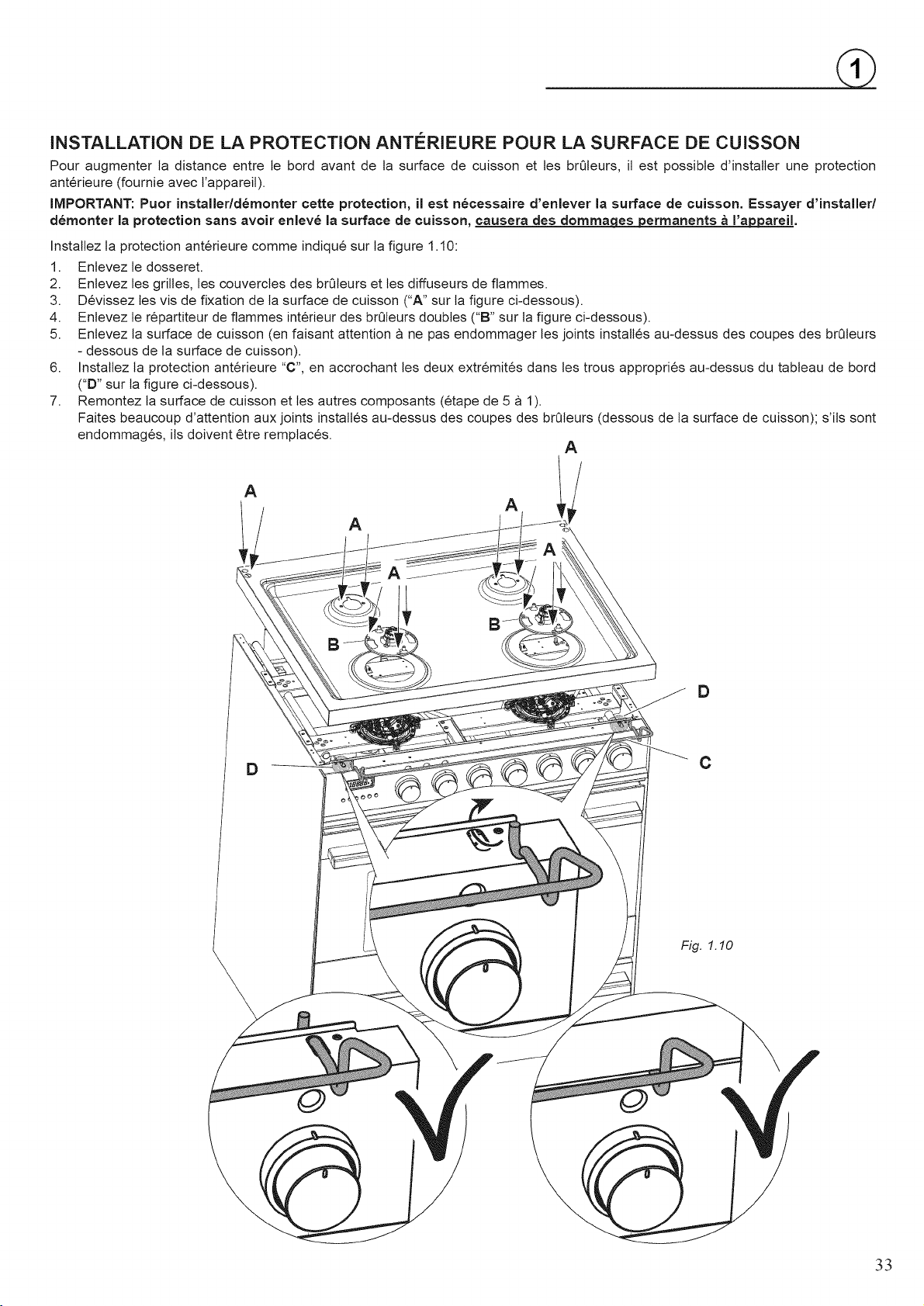

iNSTALLATiON DE LA PROTECTION ANTI_RIEURE POUR LA SURFACE DE CUISSON

Pour augmenter la distance entre te bord avant de la surface de cuisson et les br_leurs, it est possible d'installer une protection

anterieure (fournie avec l'appareit).

IMPORTANT: Puor installeddemonter cette protection, il est necessaire d'enlever la surface de cuisson. Essayer d'installed

demonter la protection sans avoir enleve la surface de cuisson, causera des domma e_qe_J_ermanentsa _pareil.

Installez la protection anterieure comme indique sur la figure 1.10:

1. Enlevez te dosseret.

2. Enlevez tes grilles, les couvercles des brQleurs et les diffuseurs de flammes.

3. Devissez tes vis de fixation de la surface de cuisson ("A" sur ta figure ci-dessous).

4. Enlevez le repartiteur de flammes int@ieur des brQleurs doubles ("B" sur ta figure ci-dessous).

5. Entevez ta surface de cuisson (en faisant attention a ne pas endommager les joints installes au-dessus des coupes des brQleurs

- dessous de la surface de cuisson).

6. Installez ta protection anterieure "C', en accrochant les deux extremit6s dans les trous appropries au-dessus du tableau de bord

("D" sur ta figure ci-dessous).

7. Remontez ta surface de cuisson et tes autres composants (etape de 5 a 1).

Faites beaucoup d'attention aux joints instaltes au-dessus des coupes des brQleurs (dessous de la surface de cuisson); s'its sont

endommages, its doivent 6tre remplaces.

A

A

A

A

A

D

D

C

Fig. 1.10

33

Page 34

raccordement au gaz

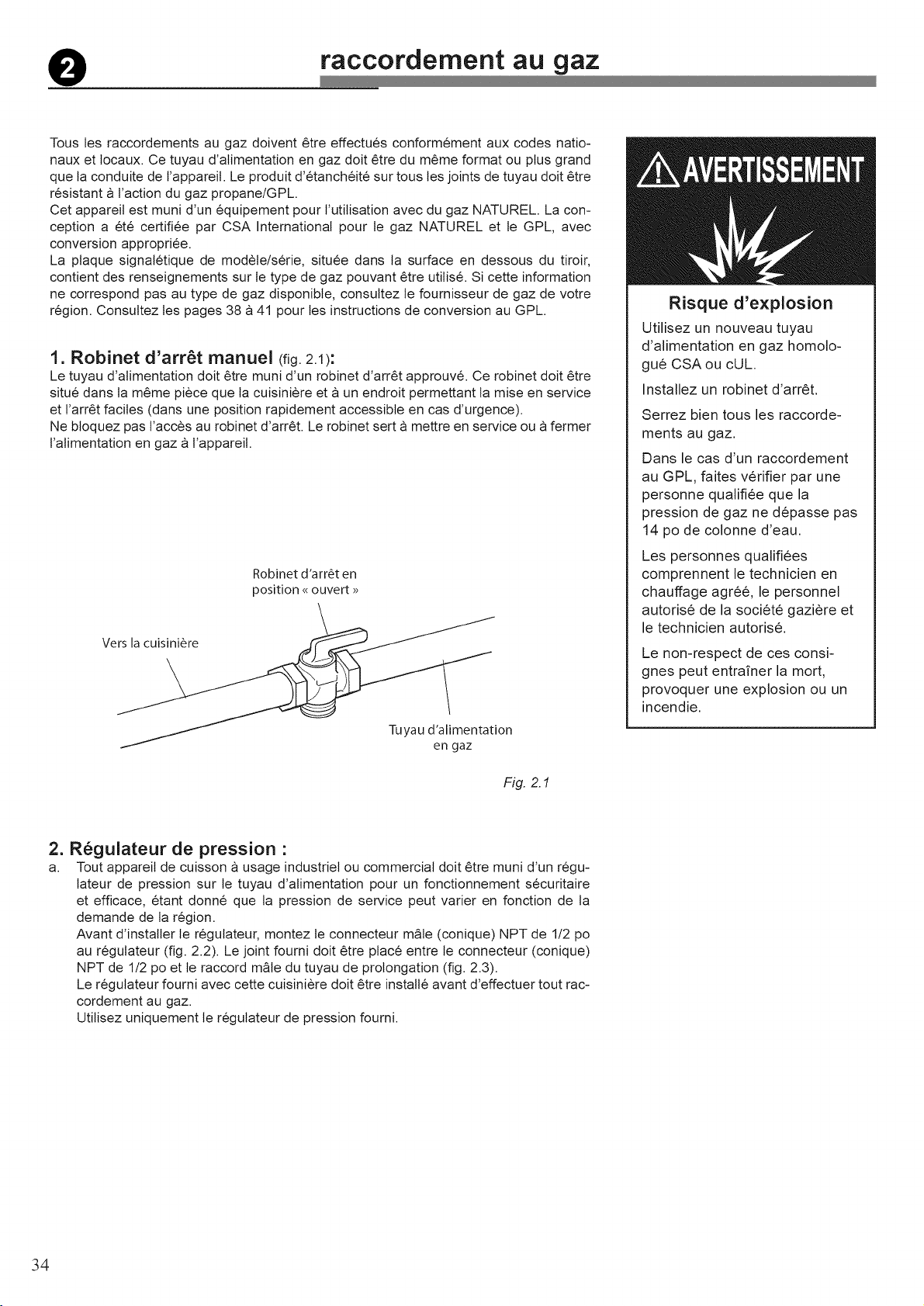

Tousles raccordements au gaz doivent 6tre effectues conformement aux codes natio-

naux et locaux. Ce tuyau d'alimentation en gaz dolt 6tre du m_me format ou plus grand

que la conduite de t'appareit. Le produit d'etanch6it6 sur tous les joints de tuyau dolt 6tre

resistant a Faction du gaz propane/GPL.

Cet appareit est muni d'un equipement pour l'utitisation avec du gaz NATUREL. La con-

ception a et6 certifiee par CSA International pour le gaz NATUREL et le GPL, avec

conversion appropriee.

La plaque signaletique de modete/serie, situee dans la surface en dessous du tiroir,

contient des renseignements sur le type de gaz pouvant 6tre utitis& Si cette information

ne correspond pas au type de gaz disponible, consultez le foumisseur de gaz de votre

region. Consultez les pages 38 a 41 pour les instructions de conversion au GPL.

1. Robinet d'arr6t manuel (fig.2.1):

Le tuyau d'alimentation dolt 6tre muni d'un robinet d'arr6t approuv& Ce robinet dolt 6tre

situe darts ta m_me piece que ta cuisiniere eta un endroit permettant la mise en service

et l'arr6t facites (dans une position rapidement accessible en cas d'urgence).

Ne btoquez pas l'acces au robinet d'arr6t. Le robinet sert a mettre en service ou a fermer

l'alimentation en gaz a t'appareit.

Robinet d'arr_t en

position <<ouvert >>

Vers la cuisini@e

Tuyau d'alimentation

en gaz

Risque d'e×plosion

Utilisez un nouveau tuyau

d'alimentation en gaz homolo-

gue CSA ou cUL.

Installez un robinet d'arr6t.

Serrez bien tousles raccorde-

ments au gaz.

Dans le cas d'un raccordement

au GPL, faites verifier par une

personne qualifiee que la

pression de gaz ne depasse pas

14 po de colonne d'eau.

Les personnes qualifiees

comprennent le technicien en

chauffage agre6, le personnel

autorise de la societ6 gaziere et

le technicien autorise.

Le non-respect de ces consi-

gnes peut entrafner la mort,

provoquer une explosion ou un

incendie.

Fig. 2.1

2. R6gulateur de pression •

a. Tout appareit de cuisson a usage industriet ou commercial dolt 6tre muni d'un regu-

lateur de pression sur te tuyau d'alimentation pour un fonctionnement securitaire

et efficace, etant donne que la pression de service peut varlet en fonction de la

demande de la region.

Avant d'instalter le regulateur, montez le connecteur mSle (conique) NPT de 1/2 po

au regulateur (fig. 2.2). Le joint foumi dolt 6tre place entre te connecteur (conique)

NPT de 1/2 poet te raccord mSle du tuyau de prolongation (fig. 2.3).

Le regulateur fourni avec cette cuisiniere dolt 6tre installe avant d'effectuer tout rac-

cordement au gaz.

Utitisez uniquement le regulateur de pression foumi.

34

Page 35

iNSTALLATiON DU REGULATEUR DE PRESSION

ETAPE 1

Montez le connecteur m_le (conique) NPT de 1/2 po sur le regulateur de

pression et serrez avec une clef.

Ne serrez paste connecteur outre mesure.

Trop serrer pourrait entraTner une fissure dans te regulateur.

®

FERMER

Fig. 2.2

ETAPE 2

Montez le connecteur NPT de 1/2 po et t'ensembte du regulateur de pression sur le tuyau de prolongation en interposant le joint

foumi. Le couvercle du regulateur dolt 6tre oriente vers l'avant de la cuisiniere.

IMPORTANT : Utitisez deux clefs pour serrer le raccord.

Joint @_

Couvercle du regulateur

Fig. 2.3

35

Page 36

SPI_CIFICATION DU RACCORDEMENT AU GAZ

I 0,,oo,oo',o

0rd,._edutwaud, o0,octeu,1

a cuisini_re_

M_le G cytindrique ,-L

(Iso 228-1) de 1/2 po

Femetle G cytindrique

--, ' ,, (ISO 228-1) de 1/2 po

IRaccord femelle"]_

i _proIongation_

M_le G cytindrique

(ISO 228-1) de 1/2 po

c::::= _

__ Femetle G

---'l I b(ISO228-1)de1/2p°

M_le NPT (conique) _c0nnecteurl

de 1/2 po ,IL-J_I, • •

--I , I

Femetle NPT

i _ de 1/2 po

Vers

la cuisiniere

cytindrique

Vers te raccord

principal

36

Fig.

2.4

Femetle NPT /

_,IL_!, de 1/2po /

Fleche

/

AVERTISSEMENT : Verifiez que le regulateur de gaz

est bien positionne.

La fleche situee a I'arriere du regulateur de gaz doit

_tre orientee vers le connecteur.

Page 37

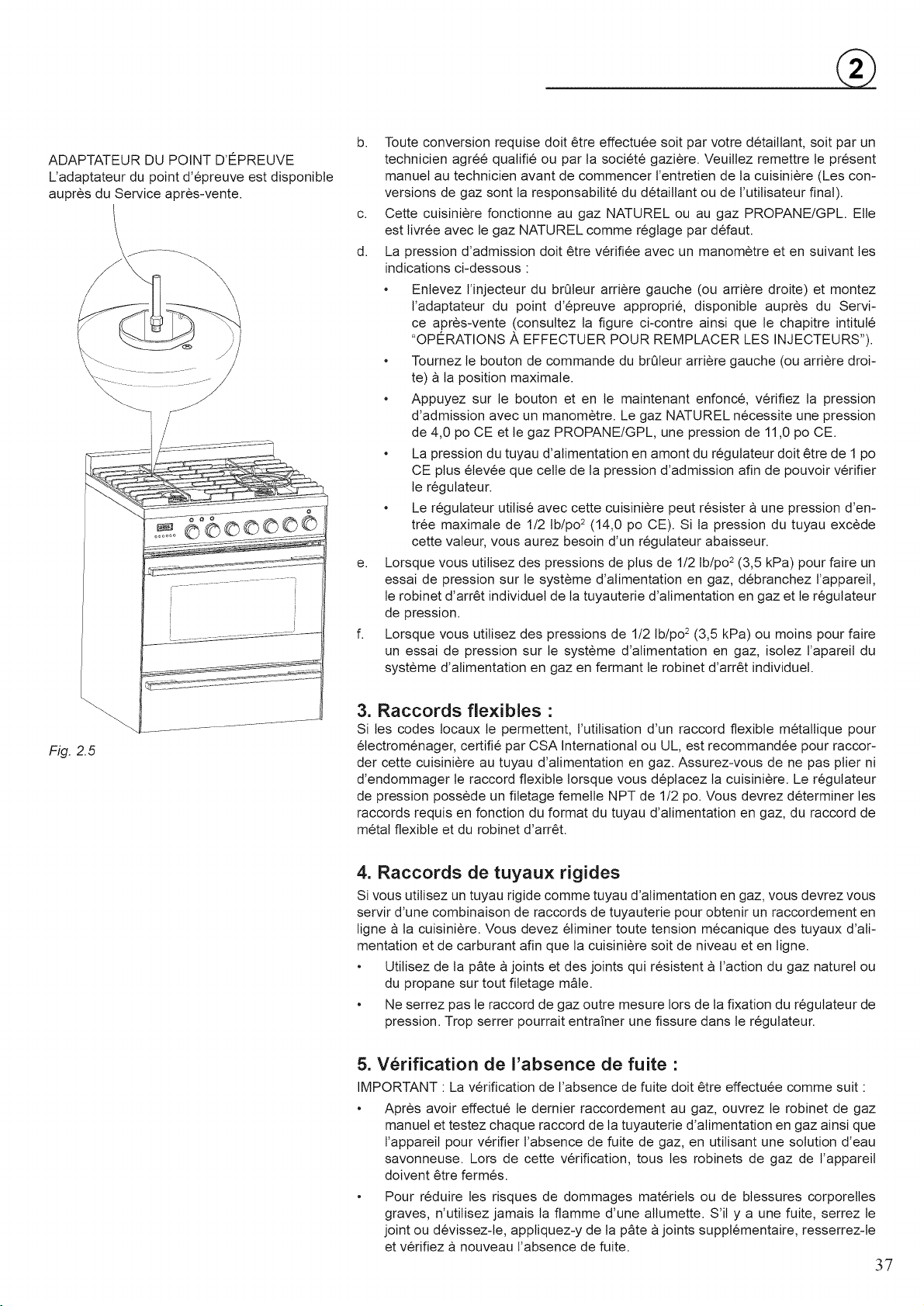

ADAPTATEUR DU POINT D'FI:PREUVE

L'adaptateur du point d'epreuve est disponible

aupres du Service apres-vente,

o°6ooooo

®

b. Toute conversion requise dolt etre effectuee soit par votre detaittant, soit par un

technicien agre6 qualifie ou par ta societ6 gaziere. Veuittez remettre te present

manuel au technicien avant de commencer t'entretien de la cuisiniere (Les con-

versions de gaz sont la responsabitite du detaitlant ou de l'utitisateur final).

c. Cette cuisiniere fonctionne au gaz NATUREL ou au gaz PROPANE/GPL. Etle

est livree avec te gaz NATUREL comme reglage par defaut.

d. La pression d'admission dolt 8tre verifi6e avec un manometre et en suivant les

indications ci-dessous :

• Enlevez l'injecteur du brQleur arriere gauche (ou arriere droite) et montez

l'adaptateur du point d'epreuve approprie, disponible aupres du Servi-

ce apres-vente (consultez ta figure ci-contre ainsi que te chapitre intitule

"OPt:RATIONS A EFFECTUER POUR REMPLACER LES INJECTEURS").

• Tournez le bouton de commande du brQleur arriere gauche (ou arriere droi-

te) a la position maximale.

• Appuyez sur le bouton et en le maintenant enfonce, verifiez la pression

d'admission avec un manometre. Le gaz NATUREL necessite une pression

de 4,0 po CE et te gaz PROPANE/GPL, une pression de 11,0 po CE.

La pression du tuyau d'alimentation en amont du regulateur dolt 6tre de 1 po

CE plus elev6e que cette de la pression d'admission afin de pouvoir verifier

le regulateur.

• Le regulateur utitise avec cette cuisiniere peut resister a une pression d'en-

tree maximale de 1/2 tb/po2 (14,0 po CE). Si ta pression du tuyau excede

cette valeur, vous aurez besoin d'un regulateur abaisseur.

e. Lorsque vous utitisez des pressions de plus de 1/2 tb/po 2(3,5 kPa) pour faire un

essai de pression sur le systeme d'atimentation en gaz, debranchez l'appareit,

le robinet d'arrSt individuet de la tuyauterie d'alimentation en gaz et le regulateur

de pression.

f. Lorsque vous utitisez des pressions de 1/2 lb/po 2 (3,5 kPa) ou moins pour faire

un essai de pression sur le systeme d'alimentation en gaz, isolez l'apareil du

systeme d'alimentation en gaz en fermant le robinet d'arret individuet.

Fig. 2.5

3. Raccords flexibles :

Si les codes locaux le permettent, t'utitisation d'un raccord flexible metallique pour

electrom6nager, certifie par CSA International ou UL, est recommandee pour raccor-

der cette cuisiniere au tuyau d'alimentation en gaz. Assurez-vous de ne pas plier ni

d'endommager le raccord flexible lorsque vous deplacez la cuisiniere. Le regulateur

de pression possede un filetage femelte NPT de 1/2 po. Vous devrez determiner les

raccords requis en fonction du format du tuyau d'alimentation en gaz, du raccord de

metal flexible et du robinet d'arrSt.

4. Raccords de tuyaux rigides

Si vous utitisez un tuyau rigide comme tuyau d'alimentation en gaz, vous devrez vous

servir d'une combinaison de raccords de tuyauterie pour obtenir un raccordement en

ligne a la cuisiniere. Vous devez etiminer toute tension mecanique des tuyaux d'ali-

mentation et de carburant afin que la cuisiniere soit de niveau et en ligne.

• Utitisez de la p_te a joints et des joints qui resistent a l'action du gaz naturet ou

du propane sur tout filetage m_le.

• Ne serrez paste raccord de gaz outre mesure tors de la fixation du regulateur de

pression. Trop setter pourrait entraYner une fissure dans le regulateur.

5. V6rification de I'absence de fuite :

IMPORTANT : La verification de t'absence de fuite dolt 8tre effectuee comme suit :

• Apres avoir effectue le dernier raccordement au gaz, ouvrez le robinet de gaz

manuel et testez chaque raccord de la tuyauterie d'alimentation en gaz ainsi que

l'appareit pour verifier t'absence de fuite de gaz, en utitisant une solution d'eau

savonneuse. Lots de cette verification, tous les robinets de gaz de l'appareit

doivent 8tre fermes.

• Pour reduire les risques de dommages materiels ou de blessures corporeltes

graves, n'utitisez jamais la flamme d'une allumette. S'it y a une fuite, serrez te

joint ou devissez-te, appliquez-y de la p_te a joints supplementaire, resserrez-te

et verifiez a nouveau l'absence de fuite.

37

Page 38

CONVERSION AU GAZ PROPANE/GPL (OU CONVERSION POUR RE=

TOURNER AU GAZ ORIGINEL =GAZ NATUREL)

Chaque cuisiniere est fournie avec un ensemble d'injecteurs pour les divers types de gaz.

Choisissez tes injecteurs a 6tre remplaces seton te "TABLEAU DES INJECTEURS".

Le diametre de la busette, exprime en centiemes de mittimetre, est indique sur te corps de chaque injecteur.

REMARQUE : Conservez les embouts que vous avez enleves de rappareil pour un usage ulterieur.

Ri=GLAGE DU RC:GULATEUR DE PRESSlON

Vous pouvez acceder au regulateur de pression en retirant te tiroir de maintien au chaud. Le regulateur de

pression est situe sur le c6te droit arriere de la cuisiniere (fig. 2.9).

Pour retirer te tiroir de maintien au chaud :

1. Ouvrez le tiroir completement (fig. 2.6).

2. Abaissez te levier de la gtissiere gauche (fig. 2.7) et levez te levier de la gtissiere droite (fig. 2.8).

3. Retirez le tiroir; les leviers ne doivent pas bouger (fig. 2.6).

Fig. 2.7

2

Fig. 2.8

3

2

Fig. 2.6

38

Page 39

®

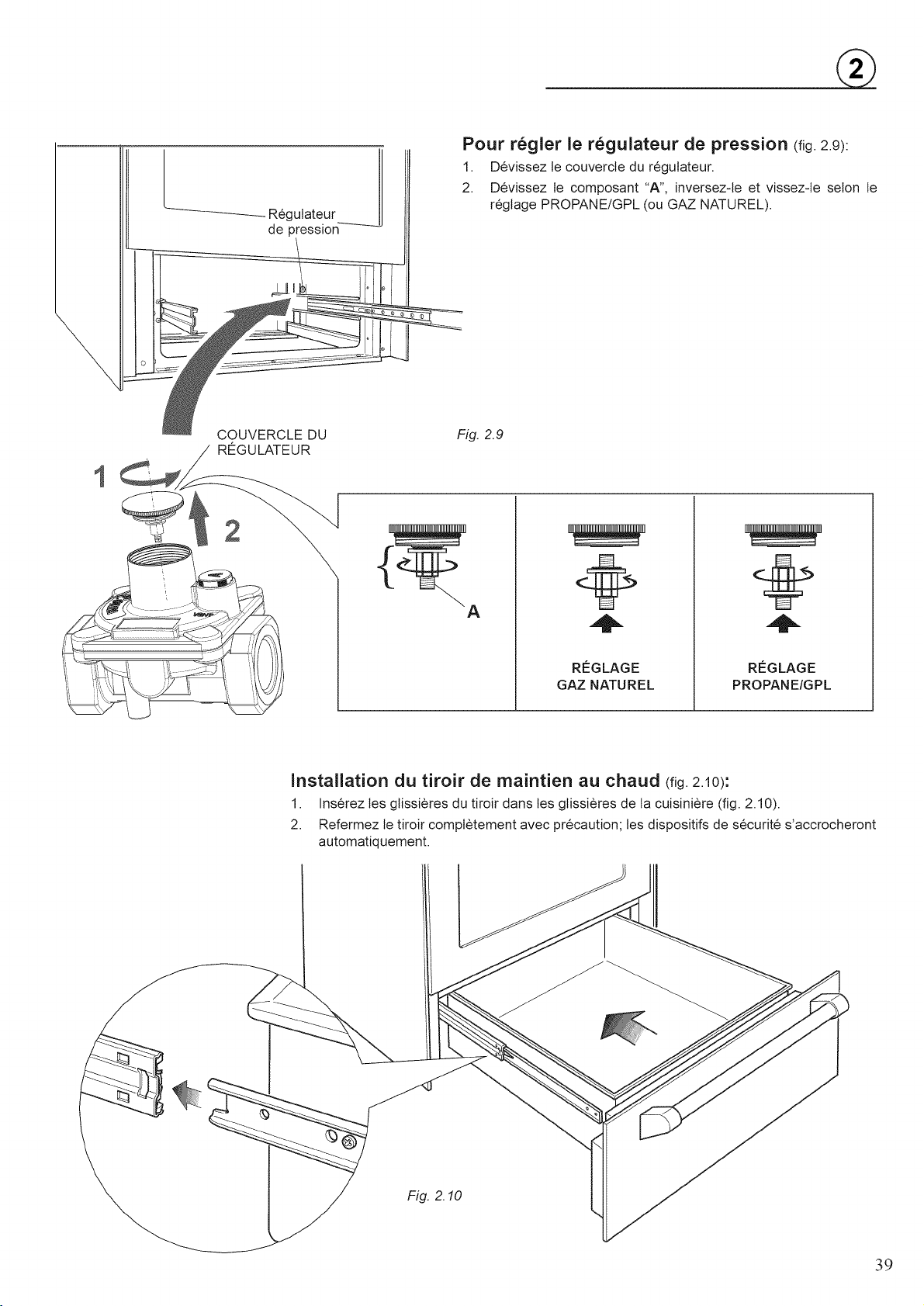

Pour r6gler le r6gulateur de pression (fig.2.9):

1. D@issez te couvercte du regulateur.

2. D@issez le composant "A", inversez-le et vissez-te selon le

Regulateur

de pression--_

o

regtage PROPANE/GPL (ou GAZ NATUREL).

1

COUVERCLE DU

RI_GULATEUR

2

Installation du tiroir de maJntJen au chaud (fig. 2.10):

1. Inserez tes gtissieres du tiroir dans les gtissieres de ta cuisiniere (fig. 2.10).

2. Refermez le tiroir completement avec precaution; les dispositifs de securit6 s'accrocheront

automatiquement.

Fig. 2.9

A

@

REGLAGE

GAZ NATUREL

REGLAGE

PROPANEIGPL

Fig. 2.10

39

Page 40

TABLEAU DES INJECTEURS

BROLEURS

Semi-rapide (SR)

PUISSANCE PUISSANCE PROPANE/GPL GAZ NATUREL

NOMINALE RC:DUITE Pression de 11po CE Pression de 4 po CE

BTU/hr

8000

BTU/hr

1500

Injecteur O Injecteur O

[1/100 ram] [1/100 ram]

85 139

Couronne interieure

Double (D)

Couronne exterieure

(*) couronne interieure ("J2" dans la figure 2.12)

(#) couronne exterieure ("J3" dans la figure 2.12)

2100

17000

1000

6500

OPERATIONS A EFFECTUER POUR REMPLACER LES

INJECTEURS

• Enlevez tes grilles, tes couverctes des br_leurs et les diffuseurs de flammes.

• Seulement pour te brQleur double (fig. 2.12): Devissez les trois vis "A" et enlevez le

diffuseur de flammes interieures "B"; ensuite devissez les deux vis "C" et enlevez la

plaquette de recouvrement "D".

• En vous servant d'une clef, remplacez tes busettes "Jl", "J2" et "J3" (fig. 2.11, 2.12)

avec cettes tes plus appropriees pour le type de gaz a utitiser.

• Seulement pour le brQleur double (fig. 2.12): Remontez la plaquette de recouvrement

"D" et vissez tes deux vis "C'; ensuite remontez le diffuseur de flammes interieures

"B" et vissez les trois vis "A".

• Remontez les diffuseurs de flammes, tes couverctes des brQleurs et tes grilles.

Les brQleurs ont _t_ con£us de fa£on telle qu'its ne n_cessitent pas de r_glage de

I'air primaire.

42 (*)

115 (#)

BROLEUR SEMI-RAPIDE

70 (*)

200 (#)

J1

Fig. 2.11

4O

BROLEUR DOUBLE

A A

\

Fig. 2.12

Page 41

®

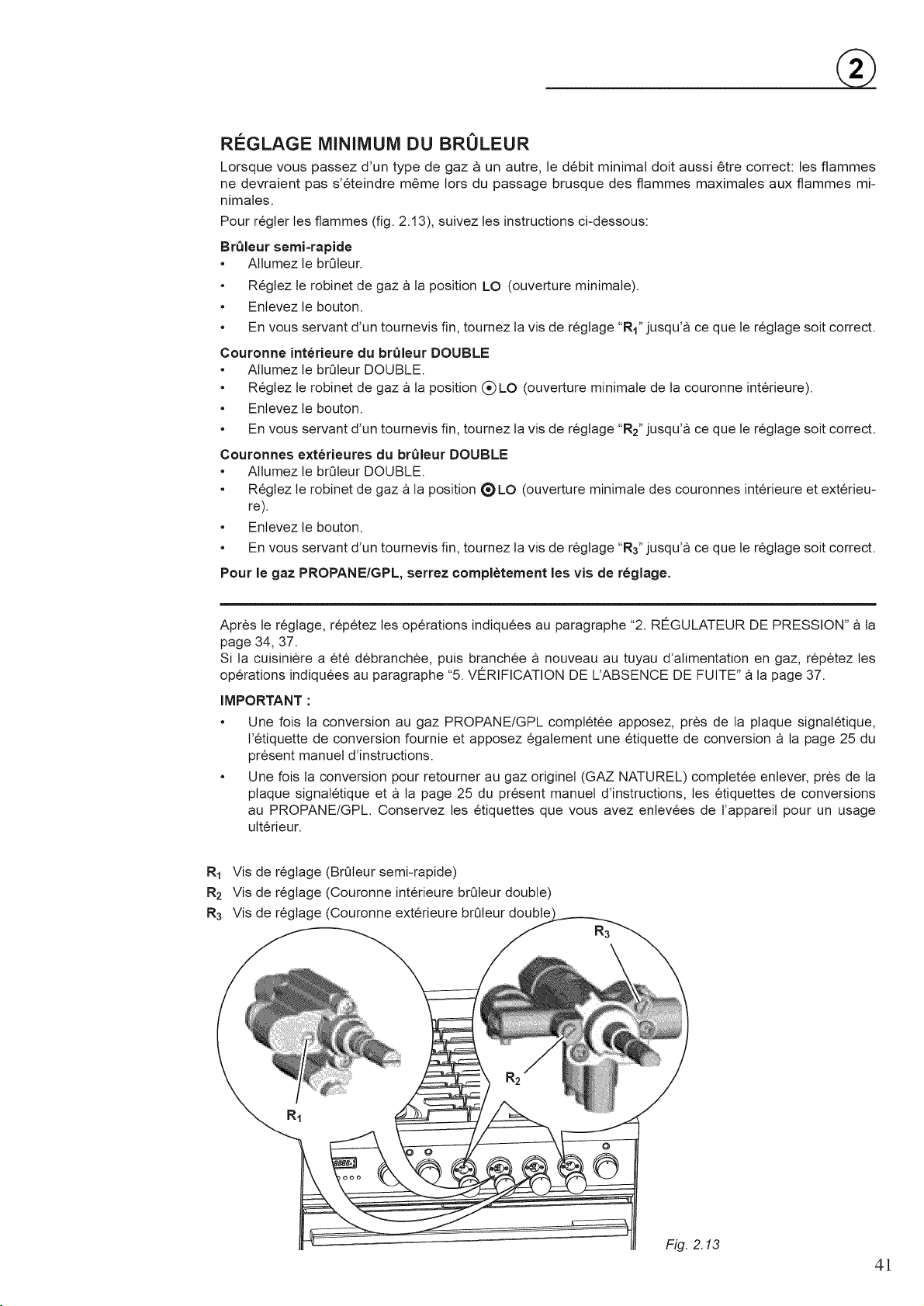

Ri_GLAGE MiNiMUM DU BRULEUR

Lorsque vous passez d'un type de gaz a un autre, le d6bit minimal dolt aussJ etre correct: les flammes

ne devraient pas s'6teindre meme Iors du passage brusque des flammes maximates aux flammes mi-

nimales.

Pour regter les flammes (fig. 2.13), suivez les instructions ci-dessous:

BrQleur semi-rapide

• Allumez le br_leur.

• Regtez te robinet de gaz a la position LO (ouverture minimale).

• Enlevez le bouton.

• En vous servant d'un tournevis fin, toumez la vis de regtage "Rt" jusqu'a ce que le regtage soit correct.

Couronne interieure du br_leur DOUBLE

• Altumez le brQleur DOUBLE.

• Regtez te robinet de gaz a la position (_)LO (ouverture minimale de la couronne interieure).

• Enlevez te bouton.

• En vous servant d'un tournevis fin, tournez la vis de regtage "R2" jusqu'a ce que le regtage soit correct.

Couronnes exterieures du brQleur DOUBLE

• Altumez te brQleur DOUBLE.

• Regtez le robinet de gaz a la position (_ LO (ouverture minimale des couronnes interieure et exterieu-

re).

• Enlevez le bouton.

• En vous servant d'un toumevis fin, tournez la vis de regtage "R3" jusqu'a ce que le regtage soit correct.

Pour le gaz PROPANE/GPL, serrez completement les vis de reglage.

Apres te regtage, repetez les operations indiquees au paragraphe "2. RItGULATEUR DE PRESSlON" a la

page 34, 37.

Si la cuisiniere a ¢t€ debranchee, puis branchee a nouveau au tuyau d'alimentation en gaz, repCtez les

operations indiquees au paragraphe "5. VITRIFICATION DE L'ABSENCE DE FUITE" a la page 37.

IMPORTANT :

• Une fois ta conversion au gaz PROPANE/GPL completee apposez, pres de la plaque signaletique,

l'etiquette de conversion fournie et apposez egalement une etiquette de conversion a la page 25 du

present manuel d'instructions.

• Une fois la conversion pour retourner au gaz originet (GAZ NATUREL) completee enlever, pres de la

plaque signaletique eta la page 25 du present manuel d'instructions, les etiquettes de conversions

au PROPANE/GPL. Conservez tes etiquettes que vous avez enlevees de t'appareit pour un usage

ulterieur.

R1 Vis de reglage (BrQleur semi-rapide)

R2 Vis de regtage (Couronne interieure brQleur double)

R3 Vis de regtage (Couronne exterieure brQleur double

Fig. 2.13

41

Page 42

Risque de choc _lectrique

Cuisiniere mise a la terre.

Le non-respect de ces instructions

peut entrafner la mort, provoquer un

incendie ou un choc etectrique.

Si les codes le permettent et qu'un fil de raise a la terre distinct est utilise, il est

recornmande qu'un electricien qualifie determine que le trajet de raise a la terre et

le calibre du fJi sont conformes au× codes Iocau×.

Assurez-vous que te raccordement electrique et que la taitle du fil sont adequats et con-

formes a:

• la derniere edition du Code national de l'etectricit6, ANSI/NFPA 70, et aux codes et

regtements tocaux;

la derniere edition du Code canadien de l'etectricit6 CSA C22.1, pattie 1, et aux

codes et regtements tocaux.

POUR LE CANADA SEULEMENT:

Vous pouvez obtenir une copie des normes ci-dessus en ecrivant a :

ASSOCIATION CANADIENNE DE NORMALISATION

178, boulevard Re×dale

TORONTO, ON Mgw 1R3

CANADA

• Ne mettez pas a la terre a un tuyau de gaz.

• Si vous n'6tes pas certain que ta cuisiniere est bien mise a ta terre, consultez un

electricien qualifie.

• N'installez pas de fusibtes dans te circuit de mise a ta terre ou te circuit neutre.

• Lorsqu'une alimentation electrique biphasee a 4 fJls, en c.a. uniquement, de 240-

208/120 volts, 60 Hz est disponible, une protection de circuit de 30 A maximum est

necessaire, avec fusible a chaque extremit6 du circuit.

• Un fusible temporise ou un disjoncteur est recommande.

• Cette cuisiniere est equip6e d'un cordon d'atimentation certifie par CSA International

ou UL, congu pour 6tre utitise avec une prise standard de type 14-50R. Assurez-

vous que la prise de courant est a portee de la cuisiniere, a son emplacement final.

• N'utitisez pas de cordon prolongateur.

Dans te cas de substitution du cordon d'alimentation remplacez-te avec un cordon con-

venabte certifie par UL ou CSA (avec les m6mes caracteristiques techniques du cordon

remplace).

Serrez le cordon d'alimentation en utitisant seulement la bride passe-fils fournie avec

l'appareit.

Laissez l'espace suffisant pour permettre de connecter facitement les terminaux du cor-

don aux terminaux du bornier.

Ces operations doivent 6tre execut6es seulement par un instaltateur qualifie.

Prise murale standard de type NEMA 14-50R

Cordon d'alimentation

muni d'une fiche

de type NEMA 14-50P

42

Fig. 3.1

Page 43

¢q

LI

%-

L1 - L2 = 240-208V

r

L1- N = t20V

L2- N = t20V

EARTH

_rre

_J== p_

PHV

W

EL.P

O

-J

PL

AS

4-

O

W

ODL

'W

B

Sl P'

,, I Ii

-'--_/ ' II y y L

,,_ _,16 II .dll.A12.,

I s_o[_

>

-i

ELAY1 K1

O

1PT2 I

4a

4

)9

)9a

IC

ISG

L2

N

LE_GENDE DU SCHI_MA E_LECTRIQUE

IC

ISG

OL

E61

CE

GE

TE

BE-INT

BE-EXT

TPL

GI_NI_RATEUR D'ALLUMAGE

GROUPE D'INTERRUPTEURS D'ALLUMAGE

LAMPE DU FOUR

RELAIS

I_LI_MENT CIRCULAIRE

I_LI_MENT CHAUFFANT DE GRIL

I_LI_MENT CHAUFFANT SUPI_RIEUR

I_LI_MENT INFI_RIEUR INT.

I_LI_MENT INFI_RIEUR EXT.

VOYANT DE THERMOSTAT

DSPL

CF

OF

ER

DLM

SL/U

LPL

WD

ST

ELP

SD

ODL

VOYANT DE SI_CURITI_ DE LA PORTE

VENTILATEUR DE REFROIDISSEMENT

VENTILATEUR DU FOUR

RI_GULATEUR D'ENERGIE

MOTEUR DE VERROUILLAGE PORTE DU FOUR

I_TAT VERROUILLAGE/DI_VERROUILLAGE

VOYANT DE FONCTIONNEMENT

I_LI_MENT DU TIROIR DE MAINTIEN AU CHAUD

THERMOSTAT DE SI_CURITI_

PROGRAMMATEUR I_LECTRONIQUE

I_TAT PORTE DU FOUR, OUVERTE/FERMI_E

LOQUET DE LAPORTE DU FOUR

AS INTERRUPTEUR D'AIR

CONNEXIONS SUR LE PROGRAMMATEUR

PN/PL

K1

K2

K3

PHV

X0

Xl

P4

P5B

ALIMENTATION

RELAISl DE THERMOSTAT DE PROGRAMMATEUR

RELAIS2 DE VENTILATEUR DE REFROIDISS./DU FOUR

RELAIS3 DE VERROUILLAGE/DI_VERROUILLAGE PORTE

I_TAT DE FONCTION

ENCODEUR DE THERMOSTAT

ENCODEUR DE FONCTIONS

SONDE

CABLES P5B(1 )+P5B(2)+P5B(3

Page 44

Lefabricantnepeut6tretenuresponsabledesinexactitudespossiblesduesadeserreursd'impressionou

detranscriptiondanslepresentlivret.

Lefabricantsereserveledroitd'effectuersursesproduitstoutemodificationqu'ilconsiderenecessaire,

pourlafabricationoupourdesraisonscommerciales,atoutmomentetsanspreavis,sanscompromettre

lescaracteristiquesindispensablesdefonctionnaliteetdesecurit6desappareils.

44

Loading...

Loading...