Page 1

SERVICE MANUAL Colour Television

FILE NO.

Model No.PC-R20R2

(USA)

Service Ref.No.PC-R20R2-00

SPECIFICATIONS

Receiving System

Colour System

Picture Tube

Ext. Antenna

Ext. In/Out

Speaker

Audio Output

Power Consumption

Dimension

Net Weight

REMOTE CONTROL

Transmitting System

Power Supply

Dimension

Net Weight

Design and specifications are subject to change without prior notice.

: M

NTSC

:

: 20 inch screen

: 75 Ohm Coaxial Cable

Audio/Video -In/Out

:

: (8 Ohm) x 2

: Maximum 3W

: AC 120V 60Hz, 84W

: 525(W) x 510(D) x 464(H)mm/

20.7(W)

: 22.8 kg/50.26lbs

: Infrared

: DC 3V (1.5 x 2)

: 60(W) x 200(L) x 24(D)mm/

2.4

: 100 g(approx)/0.22lbs

x20.1(D) x 18.3(H)inch

(W) x 7.9(L) x 0.9(D)inch

Product Code: 1 113 495 46

Original Version

Chassis Series: 3Y03

Give complete SERVICE REF.NO. for

parts order or servicing. It is shown on

the rating plate at the cabinet back of

the unit.

This T.V. Receiver will not work properly in

foreign countries where the television

transmission system and power source

differ from the design specifications.

Refer to the Specification table.

""

REFERENCE NO. SM 2300011

Page 2

Contents

Safety Notice..................................................................2

Chassis Block Diagram....................................................3

IC Block Diagram .........................................................4-7

PCB Top Layer .............................................................8-9

Service Adjustments .................................................10-16

Purity and Convergence Adjustment ...............................17

Control Location............................................................18

Input and Output Terminals.............................................19

Operation Instructions...............................................20-21

Mechanical Disassemblies .............................................22

Cabinet Parts List ..........................................................23

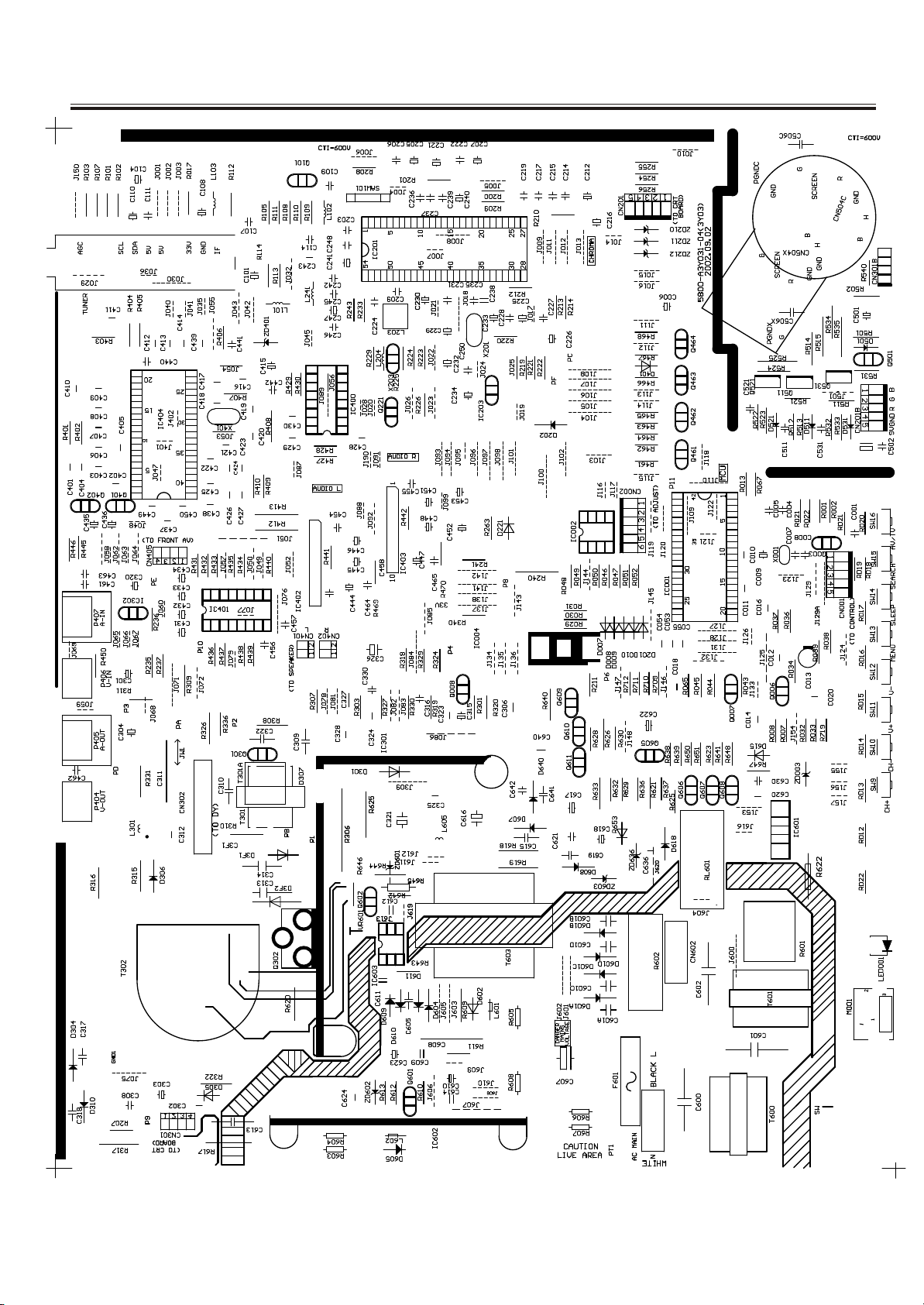

Circuit Diagram..............................................................24

Chassis Electrical Parts List.......................................25-33

Safety Notice

SAFETY PRECAUTIONS

1:An isolation transformer should be connected in the power line between the receiver and

the AC line when a service is performed on the primary of the converter transformer of the

set.

2:Comply with all caution and safety-related notes provided on the cabinet back, inside the

cabinet, on the chassis or the picture tube.

3:When replacing a chassis in the cabinet, always be certain that all the protective devices

are installed properly,such as,control knobs, adjustment covers or shields, barriers,isola tion resistor-capacitor networks etc.. Before returning any television to the customer,the

service technician must be sure that it is completely safe to operate without danger of

electrical shock.

X-RADIATION PRECAUTION

The primary source of X-RADIATION in television receiver is the picture tube. The picture

tube is specially constructed to limit X-RADIATION emissions. For continued X-RADIATION

protection, the replacement tube must be the same type as the original including suffix

letter. Excessive high voltage may produce potentially hazardous X-RADIATION. To avoid

such hazards, the high voltage must be maintained within specified limit. Refer to this

service manual, high voltage adjustment for specific high voltage limit. If high voltage exceeds specfied limits, take necessary corrective action. Carefully follow the instructions for

+B1 volt power supply adjustment, and high voltage check to maintain the high voltage

within the specified limits.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area

of a receiver. Components indicated by mark in the parts list and the schematic diagram

designate components in which safety can be of special significance. It is particularly

recommended that only parts designated on the parts list in this manual be used for component replacement designated by mark . No deviations fromresistance wattage or voltage ratings may be made for replacement items designated by mark .

-2-

!

!

!

Page 3

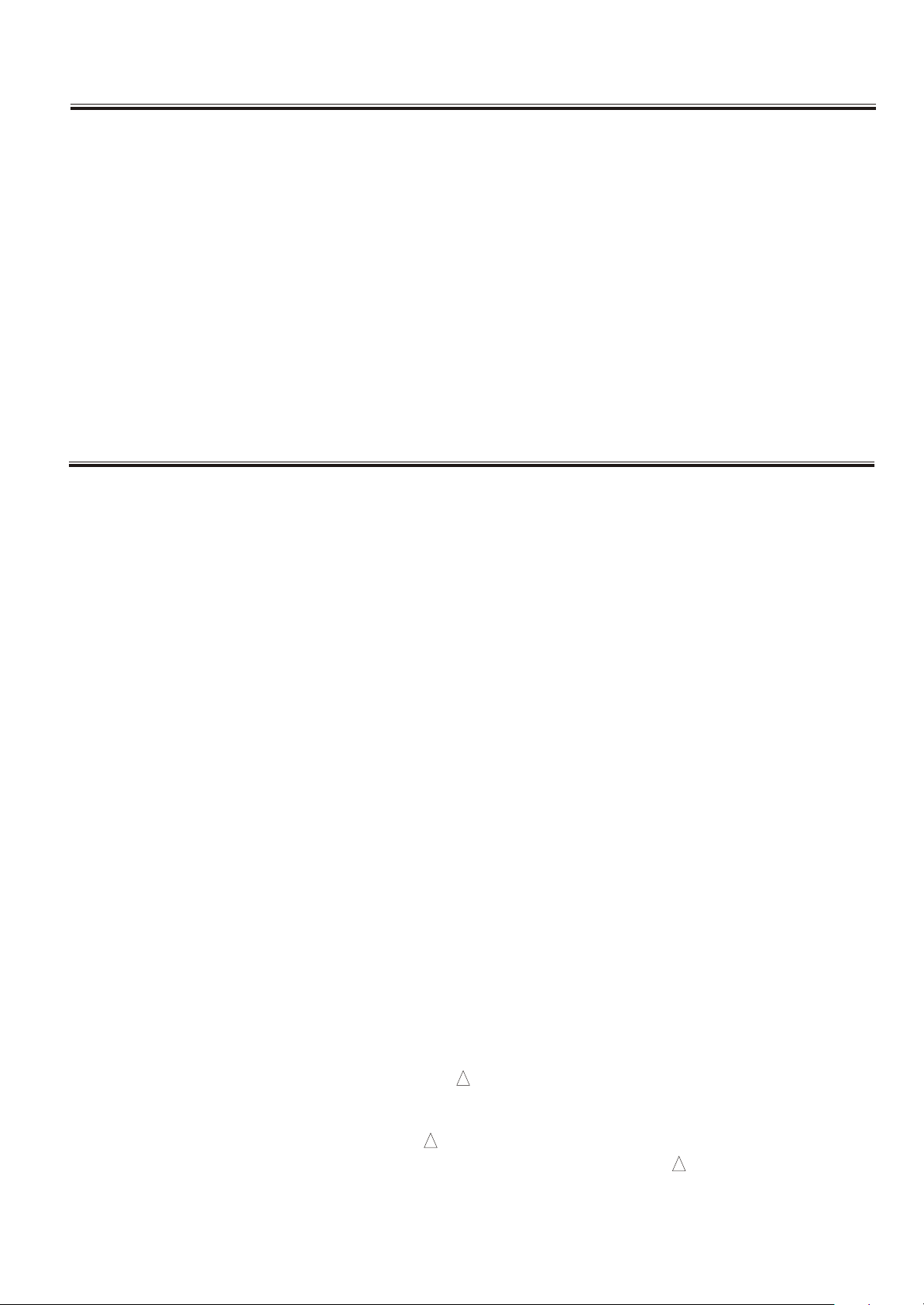

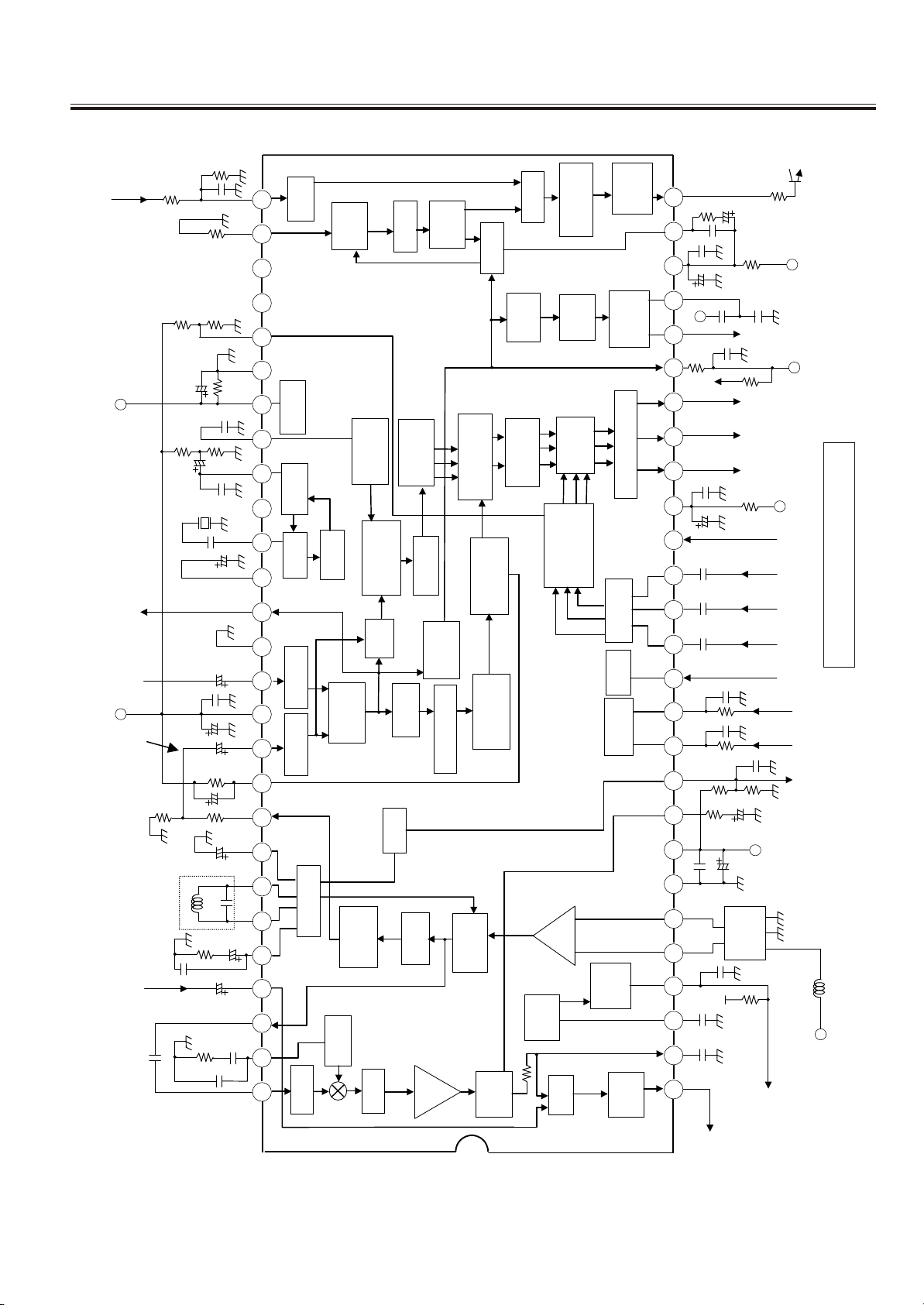

Chassis Block Diagram

SPEAKER-L

SPEAKER-R

AV1/AV2

VIDEO-OUT

CRT

FOUCS

SCREEN

Ic400

IC403

La4285

AV1/AV2 AUDIOIN

HEF4O53BP

La7840

VERTICAL

I c301

RGB AMP

DEFLECTION

HORIZONTAL

FBP

DEFECTION

I c401

HEF4O52BP

V-OUT

40

VIDEO-IN

TV-AUDIO

41

19-21

23

H-OUT

24V

9V/12V

H-FBP

28 27

I c201

SAW.FIL

PRE.AMP

SDA/SCL

RF-AGC

SCL

TUNER

Ic002

SDA

EEPROM

4 5 6 2

11 1 2

40

AFC

VIDEO

29

19

30

LA76814/76810

14-17

110V (B+)

10

R G B Y

V.SYN

H.SYN

22-25

14

21

20

21V5V9V

LC863224A-5V23

27 28

Ic001

POWER

VIDEOIN

-3-

Page 4

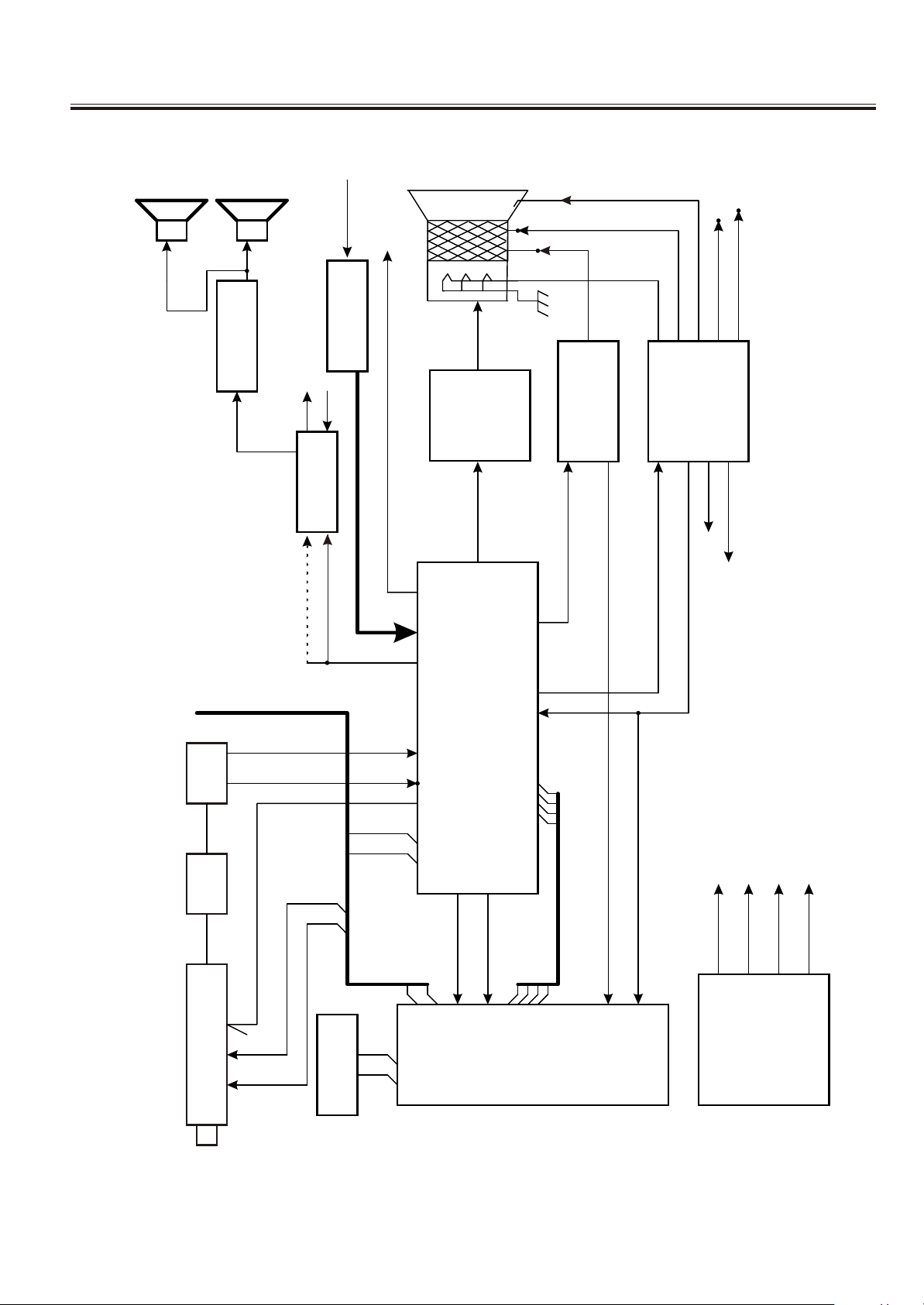

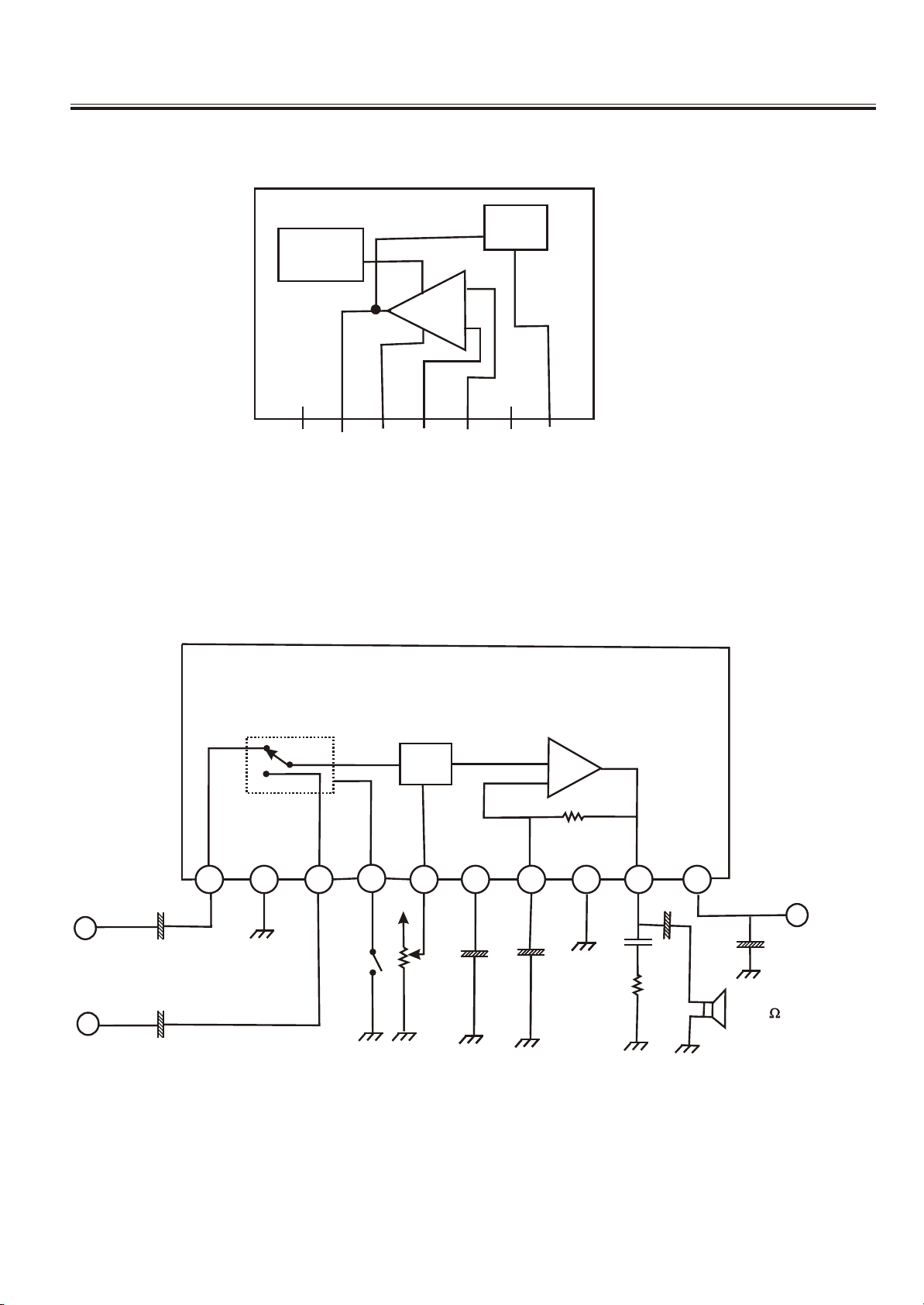

IC Block Diagram

IC 001 (MULTI SYSTEM COLOR TV CPU) LC863224A

-4-

Page 5

IC Block Diagram

IC 201 (IIC BUS SINGLE CHIP VIF,SIF,VIDEO CHROMA) LA76814K

7.5K

IN

FBP

V/C

VCC

10K

330p

REF

4.7K

MetalFilm(1%)

1K

1K

HOR

GND

10K

1u

1000p

24K

24K

0.47u

0.01u

16p

10u

SVO

V/C

GND

1u

[Y-IN ]

EXT-V IN

EXT-AUDIO

0.01u

47u

[S-C IN]

INT-V IN

15uH

1K

VCO

1000p

IN

10p

1u

680K

330

2.2u

1K

0.47u

COIL

0.47u

330

10u

3K

0.01

1000p

FBP

C/D

VCO

29 28

32 31 30

XRAY

36 35 34 33

APC1

VCO

39 38

40 37

43 42 41

44

CLAMP CLAMP

46 45

48 47

50

52 51 49

53

54

HOR

ACC

KILLER

TINT

BPF

(ON/OFF)

SW

SW

VIDEO

AFT

A2C PLL

AMP

VIDEO

SPLL

BPF

BPF

HOR

1/256

COLOR

CLAMP

DEMO

SYNC

TRAP

TRAP

LIM

AMP

BRIGHT

CONTRAST

BLACK

SEP

PEAKING

DELAYLINE

DET

VIDEO

AFC2

PHASE

AFC1

VER

RGB

STRETCH

CORING

FM

DET

VER

SEP

OSD

MATRIX

OSD

CONTRAST

VIF

IF

AGC

SW

HOR

OUT

SHIFTER

Vcc

HOR

C/D

VER

RAMP

SW

DRIVE/CUTOFF

BRIGHT

CLAMP

ABL

BUS

5V

IF Vcc

RF

AGC

DC

VOL

OUT

HOR

1u

3K

0.01u

10u

56p

100

Vcc

0.01u

10u

0.1u( )

0.1u( )

0.1u( )

1K

1K

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

100K

0.01u

5 6 7 8 9

0.01u

0.022u( )

0.01u( )

1 2 3 4

VC

AUDIO

0.015u

150

0.33u( ) 0.33u( )

VER

5.6k

B

G

R

100

100

0.1u

100K

1u

100

SAW

FILTER

30K

OUTP

150

OUT

OUT

OUT

OUT

IF

HOR

VCC(9V)

Out

Sync

VCC

(9 12V)

IN

FB

B

IN

G

IN

R

IN

LA76814K BLOCK DIAGRAM

ABL

BUS

CLOCK

BUS

DATA

AF

VCC

IF IN

RF

-5-

Page 6

IC Block Diagram

IC301<Vertical Output> LA7840

THERMAL

PROTECTION

PUMP

UP

-

AMP

+

1

2

GND

Ver.OUTPUT

IC 403(3W AUDIO OUTPUT)LA 4285

3

OUTPUT STAGE Vcc

EVR

4

5

NON INV.INPUT

INVERTINO INPUT

7

6

c

c

V

PUMP UP OUT

+

-

INT

EXT

1 2 6543 1097 8

5V

++6++

++++

PRE

GND

INT/EXT

SM

EVR

CONT

-6-

D.C.

PWR

NF

PWR

GND

VCC

++

+

+

RL 8

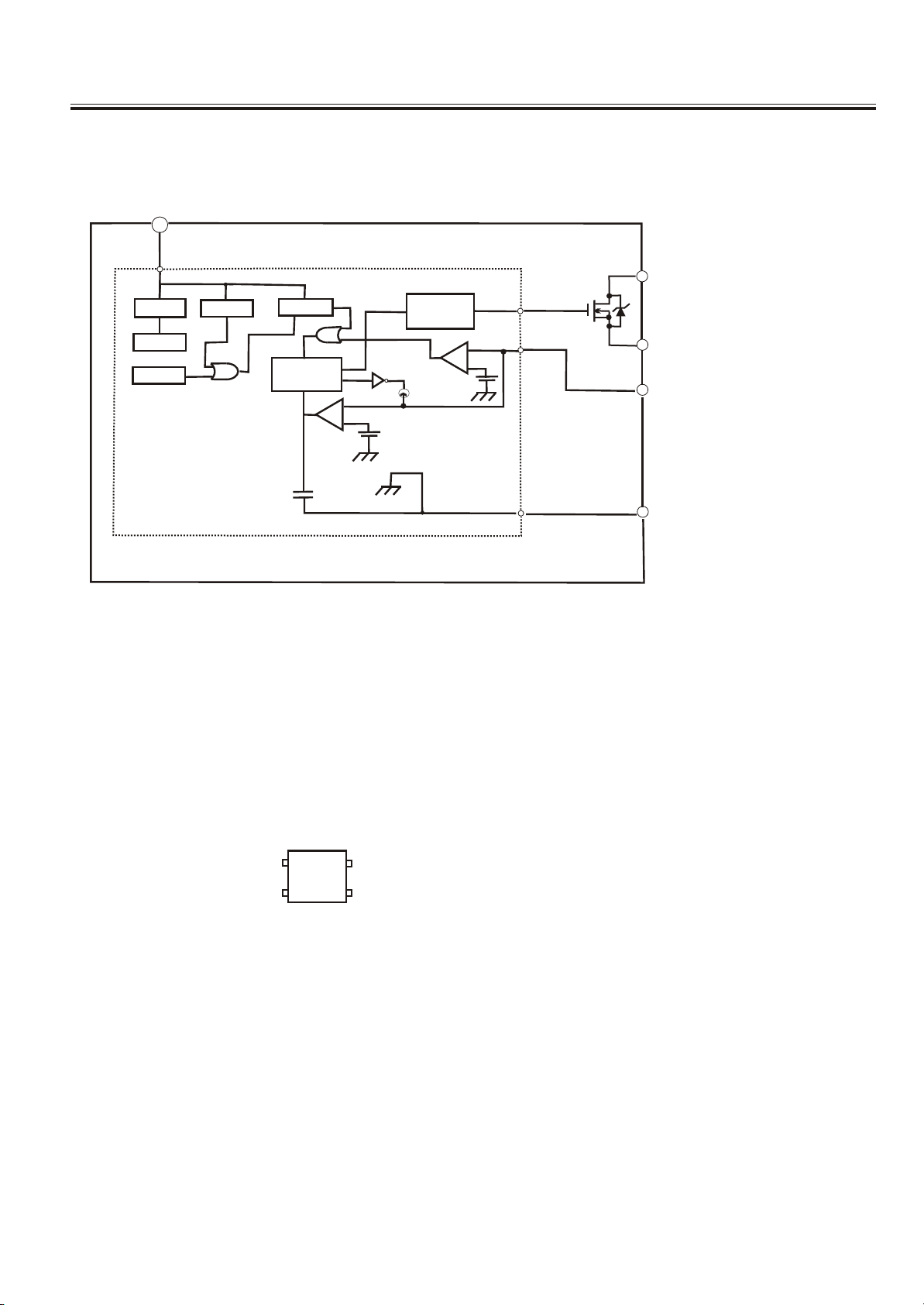

Page 7

IC Block Diagram

IC602<POWER > STR-G6653

VIN

4

1

D

START

REG.

T.S.D

O.V.P

LATCH

O.S.C

+

Comp2

Comp2

DRIVE

2

-

Vth(1)

+

Comp1

-

Vth(2)

S

5

O.C.P/F.B

3

GND

IC603<PHOTO TRANSISTOR> TLP621

TLP621

1

2

1:ANODE

2:CATHODE

3:EMITTER

4:COLLECTOT

4

3

-7-

Page 8

MAIN PCB Top Layer

-8-

Page 9

CRT, FRONT AV&CONTROL PCB Top Layer

FRONT AV & CONTROL PCB TOP LAYER

-9-

Page 10

Service Adjustments

Please notice the following before alignment and equipment

1. Don’t short any two soldering points, which should not be shorted and don’t touch any components,

which should not be touched.

2. Please pull out plug before equipment.

3. For safety reasons, all components equipped or replaced should be identical with BOM.

4. Must be warm up for 30 minutes or more and degauss CRT thoroughly with demagnetizer before

alignment.

The data of EEPROM must be stored before the adjustment for main chassis. And EEPROM must be

corrected by the correct file “3Y03_ROM_CORRECT.hex” to avoid signal of CH6 weaken. R.bias,

G.bias, B.bias, R.drv, G.drv, B.drv should be set to proper values. Sub_bright is set to 63 usually.

Tools and equipments for adjustment

1. small “-“ screwdriver

2. screwdriver without inductance

3. Pattern Generator

4. DC Regulated power supply

5. Digital Voltmeter

6. Sweep Signal Generator

7. 20MHz 2-channel Oscilloscope

Signal condition

ITEMS LOGO

PICTURE

CARRIER

PATTER N SYSTEM

SOUND

MODE

REMARK

1 CH14 471.25 MHZ COLOR BAR NTSC/M

MONO

1KHz

2 CH3 61.25 MHz GRAY SCALE NTSC/M

BTSC

0.3k,3kHz

3 CH8 181.25 MHz MONOSCOPE NTSC/M

MONO

MUSIC

4 CH12 205.25 MHz

CROSS HATCH

NTSC/M

MONO

1KHz

Adjust for main chassis

PIF Adjustment (45.75MHz)

a. Tuner AGC connects to GND. Pattern Generator outputs 45.75MHz I.F. signal (70dbµV)and connects to SAW filter

output terminal through a capacitor .

b. Connect Digital voltmeter across C227. DC Regulated power supply positive terminal output +14V to C617.

c. Adjust L203 coil to obtain 3.6V Digital voltage meter reading.

NOTE: To cancel this adjustment , L203 can be adjusted before inserted to the chassis with a special equipment.

-10-

Page 11

Service Adjustments

B+ adjustment

a. Disconnect horizontal load. Connect a bulb (100 W) AC 250V across C321.

b. Add 220V AC 50HZ to CN601 and switch on power switch.

c. Test the voltage with digital voltage meter between C321 two terminals.

d. Adjust VR601 to obtain +110V¡À0.5V.

AGC alignment

a. Receive 60dB RF signal. Connect Digital voltmeter positive terminal to tuner AGC terminal and negative terminal

to GND.

b. Press “MENU” key, then press “Q.VIEW” key, “MUTE” key in turn on telecontroller. TV SET will go to factory mode.

Press “TIMER” key to go to the next factory menu. Go to MENU5 status by this means. Press “MENU” key to exit

factory mode.

c. Select RF.AGC by pressing “CH+” and “CH-“keys. Adjust “VOL+” and “VOL-“ keys to obtain 4V Digital voltage

meter reading.

COMPLETE MACHINE GENERAL ADJUSTMENT

Go to factory mode according to 4-2-2 before warm up line

Focus Adjustment

a. Receive monoscope pattern.

b. Set TV to work in dynamic status.

c. Adjust the focus knob of FBT to get the clearest picture.

Screen Voltage Adjustment

a. Check the R.bias, G.bias, B.bias, R.drv, G.drv, B.drv and sub_bright. Go to factory mode “MENU2” status

according to 4-2-2. Usually G.bias should be same as the value of auto white balance equipment. And

SUB_BRIGHT is 63.

b. Set Cross_BW ‘3”. Then the picture will be a white “+”. Cross_BW is in factory menu 3.

c. In menu 5, select SUBB.ADJ and set it to “1”. Adjust the screen knob of FBT to get a faintness “+”.

d. Restore the SUBB.ADJ to “0” and CROSS.BW to “0”.

White Balance Adjustment (Applied in factory)

a. Set TV AV status in custom mode(Or other mode need for the adjustment) . Receive black white pattern.

b. Insert six-row-wire into CN002.Press adjustment keys, and then go to automatic white balance adjustment.

c. PIN DISCRIPTIONN OF CN002:

1£ºSDA£¬ 2£ºSCL£¬ 3£ºGND£¬ 4£ºGND£¬ 5£ºSCL£¬ 6£ºSDA¡£

d. After adjusting well, pull out six-row-wire.

-11-

Page 12

Ver tical size and pincushion adjustment

White balance adjustment (Applied when servicing)

a. Set TV AV status and receive GREY SCAL.

b. The one sampling tube of CRT color analyzer (CA-100) covers on GREY signal and

the another covers on white signal.

c. Go to factory mode “MENU2”. Obtain GREY signal X=281 and y=311 by adjusting R-CUT and B-cut. Obtain white

signal X=281 and y=311 by adjusting R-DRV and B-DRV. Obtain both X=281 and Y=311 by adjusting the two

status repeatedly.

Sub_bright adjustment

Receive the gray scale . Get into the menu5 of factory mode. Set SUBB.ADJ to “1”. Then adjust the SUB..BRI

option to get a scale to be seen a little brightness(Only two rows can be seen).

Vertical Size and PinCushion Adjustment

a. Receive monoscope pattern. Set TV standard status. Adjust V.size to obtain picture’s vertical redisplay ratio more

than 90% in factory mode “MENU1”.

b. Receive cross hatch pattern. Set TV standard status. Adjust V.LINE and V.SC to obtain picture’s vertical pin

cushion a good status in factory mode “MENU1”.

c. Receive cross hatch pattern. Set TV standard status. In factory mode “MENU1” adjust V.POS to obtain picture’s

vertical center at the center of CRT screen.

Horizontal Center Adjustment and horizontal position of OSD adjustment

a. Receive monoscope PATTERN. Set TV standard status. Adjust H.PHASE in menu 1 to obtain horizontal center

at the center of CRT screen.

b. Adjust the “OSD.HPOS” to get right display position.

SUB.TINT ADJUSTMENT

Receive the color bar signal of NTSC system. Set the picture mode at normal mode. Adjust the ‘SUB.TINT’ option

in menu5 at sevice mode to get the right hue .

MTS ADJUSTMENT

Receive the RF CROSS-TALK signals , but FM with BTSC .Enter into the factory mode. Set ADJ.FREQ to 1 in

“9852 AUTO.ADJ”. Wait 1 second . Quit factory menu after “ADJUSTING ” change to “0” .

Service Adjustments

-12-

Page 13

COLOR PURITY ADJUSTMENT

a. Before color purity adjustment, Warm up the TV set over 15 minutes and fully degauss.

b. Receive pure white signal in AV status and set the TV receiver dynamic.

c. Go to factory mode “MENU2”. After write down the values of R-BIAS and B-BIAS, set the values of R-BIAS and

B-BIAS zero.

d. Loosen the clamp screw of the deflection yoke and pull the deflection yoke towards color purity magnetic loop.

e. Adjust color purity magnetic loop to make the green area at the center of CRT screen.

f. Slowly push the deflection yoke toward the front of CRT and set it where a uniform green field is obtained.

Tighten the clamp screw of the deflection yoke.

g. Restore the values of R-BIAS, G-BIAS and B-BIAS.

CONVERGENCE ADJUSTMENT

a. Receive a dotted pattern. Set the TV receiver dynamic.

b. Loose the convergence magnet clamper and align red with blue dots at the center of the screen by rotating (R, B)

static convergence magnets.

c. Align Red/Blue with green dots at the center of the screen by rotating (RB-G) static convergence magnet.

d. Remove the DY wedges and slightly tilt the deflection yoke horizontally and vertically to obtain the good overall

convergence. Fix them after the good overall convergence got.

e. Fix the convergence magnets by turning the clamper.

f. If purity error is found, follow “PURITY ADJUSTMENT” instructions.

Purity Magnet

RB-G RB

Magnet Clamper

Static Magnet

Ver tical size and pincushion adjustment

Service Adjustments

-13-

Page 14

Ver tical size and pincushion adjustment

APPENDIX

FACTORY MENU DISCRIPTION

MENU1 VAL UE DISCRIPTION

1 V.SIZE 101 Align vertical amplitude

2 V.POS 32 Align vertical DC bias

3 V.LINE 16 Align vertical linearity

4 V.S C 0 Align vertical S-correction

5 H.PHASE 8 Align sync to flyback phase

6 H.BLK.RL 4 H-blanking Control(Width /Phase)

7 H.FREQ 22 Align ES Sample horizontal frequency

MENU2

1 V.KILL 0 Disable vertical output

2 R.B 138 Align Red out DC level

3 G.B 182 Align Green out DC level

4 B.B 148 Align Blue out DC level

5 R.D 67 Align Red out AC level

6 G.D 8 Align Green out AC level

7 B.D 45 Align Blue out AC level

MENU3

1 RG.GAM 1 Disable R/G gamma correction (0/ON; 1/OFF)

2 B.GAM 3 Select and Disable B gamma correction(0~2/ON;3/OFF)

3 R.B.ANG 1 Adjust the demodulation angle of R-Y and B-Y

4 AT.FLESH 0

5 GRAY.MODE 0 Select Test mode (0/White; 1/Gray)

6 CROSS.BW 0 Service Test mode (0/TV; 1/Black; 2/White; 3/Crosshatch)

7 AFC.GAIN 0 Select Horiz. 1st loop gain & H-sync gate on/off(0/auto;1/enforce)

8 H.BLK.SW 0 H BLK R&L selection(0/right side blanking can be adjusted;1/left)

MENU4

1 FILT.SYS 1 Select Y/C filter mode(0,2/3.58 unsymm.; 1,3/3.58 sym.; 4~7/no filt)

2 CORING 1 Enable Luminance coring( 0/Off; 1/ON)

3 OSD.CONT 1

4 OSD.HPOS 30 Align the horizontal position of OSD

5 BLK.STR.D 0 Disable black stretch

6 BRIABL.T 0 Align brightness ABL threshold

MENU5

1 RF.AGC 31 Align RF AGC threshold

Service Adjustments

-14-

Page 15

Service Adjustments

OPTION

1 2 AV.CH 3 Select AV numbers(0/ No AV;1/1 AV; 2,3/2AV)

2 SRH.SPEED 0 Select auto search speed(0/fastest, 7/lowest)

3 TDA9852 1 Disable 9852(0/disable; 1/able)

4 TUN.AS.V 1 Select the Tuner address(0/Tuner pin3 to ground;1/pin3 not used)

9852 AUTO.ADJ

1 ADJ.FREQ 0 Disable auto adjusting(0/disable; 1/get into autoadjust mode)

2 ADJUSTING 0

3 FM.LVL 16

4 76075.VOL 0

5 L3-L0 0 input level adjust

6 TC2-TC0 0 timing current alignment data

7 A14-A10 0 stereo alignment data for wideband expander

8 A24-A20 0 stereo alignment data for spectral expander

TDA1

1 VOL.RIGHT 125 volume control right

2 VOL.LEFT 125 volume control left

3 GMU 0 mute control for all outputs (general mute )

4 AVLON 0

auto volume control (with 0.1Vrms-1.1Vrms input to get constant output

0.2Vrms)

5 LOFF 0 switch loudness on/off

6 CCD 0

7 SC2-SC0 2 selection between line in and line out

8 SAP.ID 0

TDA2

1 STERO.ID 1

2 TZCM 0 zero cross mode in volume operation

3 LMU 0 mute control for line out

4 EF2-EF0 0 selection between mono, stereo linear, spatial stereo and pseudo mode

5 L3-L0 0 input level adjust

6 A14-A10 0 stereo alignment data for wideband expander

7 A24-A20 0 stereo alignment data for spectral expander

8 STS 0 stereo level switch

Ver tical size and pincushion adjustment

-15-

Page 16

White Balance address

White Balance address

Data Name E2PROM Address

LA76814 ADDRESS

#1011 1010B

bright 12H #0001 0100B

contrast 11H #0001 0101B

color 10H #1011 1010B

Sub-bright 24H #0001 0011B

R.B 1EH #0000 1101B

G.B 1FH #0000 1110B

B.B 20H #0000 1111B

R.D 21H #0001 0000B

G.D 22H #0001 0000B

B.D 23H #0001 0010B

TDA3

1 ADJ 0 stereo adjust on/off

2 AT1 -AT2 0 attack time at AVL

3 TC2-TC0 0 timing current alignment data

4 WR.ERR 0

5 RD ERR 0

6 MANU ADJ 0

7 STEREO 0 mode selection for line out

8 SAP 0 mode selection for line out

Service Adjustments

Ver tical size and pincushion adjustment

-16-

Page 17

Purity Magnet

RB-G RB

Magnet Clamper

Static Magnet

Purity and Convergence Adjustment

COLOR PURITY ADJUSTMENT

(1) Before color purity adjustment,warm up the TV set over 15 minutes and fully degauss.

(2) Receive pure white signal in AV status and set the TV receiver dynamic.

(3) Go to factory mod MENU2. After write down the values of R-BIAS and B-BIAS, set the values of R BIAS and B-BIAS zero.

(4) Loosen the clamp screw of the deflection yoke and pull the deflection yoke towards color purity

Magnetic loop.

(5) Adjust color purity magnetic loop to make the green area at the center of CRT screen.

(6) Slowly push the deflection yoke toward the front of CRT and set it where a uniform green field is

Obtained. Tighten the clamp screw of the deflection yoke.

(7) Restore the values of R-BIAS,G-BIAS AND B-BIAS.

CONVERGENCE ADJUSTMENT

(1) Receive a dotted pattern. Set the TV receiver dynamic.

(2) Loose the convergence magnet clamperrrrr and align red with blu dots at the center of the screen by

rotating(R,B) static convergence magnets.

(3) Align Red/Blue with green dots at the center of the screen by rotating(RB-G) static convergence

magnet.

(4) Remove the DY wedges and slightly tilt the deflection yoke horizontally and vertically to obtain the

good

-17-

Page 18

Control Location

1. Remote Sensor

2. Power Indicator

3. Main Switch

4. Speakers

5. Program Down & Up Button

6. Volume Down & Up Button

7. Menu Button

8. AV/TV Button

9. Front AV In (Option)

10. Audio/Video - In/Out Jack

11. AC Power Cord

12. Terminal Antenna (75 Ohm)

(STEREO)

5 86 74 9 4

2

3

1

(MONO)

11

10

12

-18-

Page 19

Input and Output Terminals

VIDEO AND AUDIO INPUT/OUTPUT TERMINALS

1. Video / Audio input for playback for VCR.

2. Video / Audio output for TV monitor output.

*Please keep AC cord unplugged when connecting TV system.

(STEREO)

AV-OUT

VIDEOVIDEO AUDIOAUDIO

R

(MONO)

OUT IN

VIDEO VIDEOAUDIO AUDIO

AV-IN

LL

R

NOTE:

This is a mono CTV even though there are R & L audio input & output jack. These

audio R/L input terminals are parallel connected inside and make mixed monaural

sound output .There are same monaural audio output come from R/L output terminals.

-19-

Page 20

Operation Instructions

Turn the TV set on, then power indicator will light up. After a few seconds , the currently program number is

displayed on the top right -hand corner of the screen.

MENU BUTTON

1.Press this button to select menu. VIDEO, TIME, and SETUP menu can be selected cyclically.

Video Menu Time Menu Setup Menu

Audio Menu

(Option)

Exit Menu

2.After enters each menu, you can select the desired adjusting item by the PROG.+/- buttons, and adjust the

item by the VOL. +/- buttons.

*When you select a item, symbols¡° / ¡± will display both sides of the item.

Video menu

1.Enter the video menu , you can select the picture quality instantly among four

Video

Audio

Time

Setup

Custom

Contrast

Bright

Sharpness

Color

Tint

-15

16

16

16

16

preset modes and one user-set mode.

(User-set mode)

Custom Standard Sports Movies Mild

*You can adjust CONTRAST ,BRIGHT , SHARPNESS , COLOR and TINT items

by pressing the VOL. +/- buttons . The adjusted level is stored in Custom mode.

Audio menu(option)

Video

Audio

Time

ST

SAP

Balance

Mono

On

00

1.ST:

Press the VOL.+/-buttons can select the stereo mode , the order shown below:

Mono Spatial Linear Psuedo

Setup

Time menu

Video

Audio

Time

Setup

Clock

Timer

TV On

TV Off

--:-Off

--:--

--:--

2.SAP:

You can adjust the SAP ON to SAP OFF by the VOL+/-buttons ,.

You can use the Second Audio Program when you select the SAP ON .

3.BALANCE:

Press the VOL+/-buttons can adjust the left or right volume balance .

* The MTS/SAP function is only an option for some models.

1.CLOCK:

Press the VOL.- button to set hour, and the VOL.+ button set minute .

2.TIMER£º

When you select the "Timer ON" mode, you can set the time of TV ON or TV

OFF.

*TV On: The TV will automatically turn on at the preset time.

TV Off: The TV will automatically turn off at the preset time.

-20-

Page 21

Operation Instructions

Setup menu

1.After enters the setup menu, you press the PROG+/-buttons to select

Video

Audio

Preset

Captain

Time

V-Chip

Setup

Language

PRESET MENU , CCD MENU AND V-CHIP MENU

PRESET MENU

Preset

System

Channel

Skip

Auto Search

Fine Tune

Antenna

03

Off

PRESET MENU, CCD MENU and V-CHIP MENU.

2.Select the Language item by the PROG+/-buttons, and press the VOL.+/buttons to select the desired language . The screen menu is automatically

displayed in that language.

The order shown below:

English Espanol Portugues

1.SYSTEM

you can switch two signals :CABLE and ANTENNA .

2. CHANNEL

Select the cable signal ,there are 01~125 channels

Select the antenna signal , there are 02~69 channels .

3.SKIP

Select "Skip ON" by VOL.+/- Buttons to skip unnecessary program

number.

4.AUTO SEARCH

Press VOL.+/-buttons to start auto searching.

5.FINE TUNE

In areas of inferior broadcast conditions where adjustment is necessary for

CCD MENU

Closed

Caption

Caption

Mode

Channel

Field

V-CHIP MENU

V-Chip

Input Pwd

V-Chip

V-Chip On

MPAA

TVPG

Content-V

Content-S

Content-L

Content-D

Off

Capt.

PG

TV-14

1.CAPTION

Set the caption OFF or ON .

2.MODE

1

1

Select the caption mode or teletext mode .

3.CHANNEL

Select channel 1 or channel 2 .

4.FIELD

Select field 1 or field 2 .

Input the password¡° 9999 ¡±to call up V-Chip, MPAA and TVPG item.

1.V-CHIP

Set the V-Chip OFF or ON .

2.MPAA movie rating

B

B

B

B

Select the type of program

3.TVPG(TV Parental Guidelines)

Parents can guide their children watching some programmes by the item.

-21-

Page 22

Mechanical Disassemblies

CABINET BACK REMOVAL

1. Refer to Figure 1,remove 9 screws.

2. Pull off cabinet back and remove.

CHASSIS REMOVAL

1. Remove cabinet back.

2. Discharge the picture tube anode(2nd anode lead) to the

dag coating (picture tube grounding lead).

3. Disconnect Degaussing coil socket(KE),Picture tube socket,

Deflection yoke connector (KDY), Speaker connectors(KL

and KR), and 2nd anode lead.

4. Remove chassis completely by sliding it straight back.

PICTURE TUBE REMOVAL

CAUTION: Do not disturb the deflection yoke

or magnet assembly on the picture tube

Neck. Care must be taken to keep these

assemblies intact, unless picture tube is

being replaced. Discharge the picture tube

to the coating before handing the Tube.

1. Remove chassis, referring to Chassis Removal instructions.

2. Place cabinet front face down on the soft surface.

3. Remove the screw on each corner of the picture tube and

GENTLY lift the picture tube out of the cabinet.

4. Install a replacement picture tube in reverse order.

Properly install the degaussing coil and picture tube

grounding lead on the picture tube. See Figure 2.

DEGAUSSING

COIL

Note: If the Picture Tube is being replaced, mount the

Degaussing Coil on the picture tube. See following..

DEGAUSSING

COIL HOLDER

PICTURE TUBE

GROUNDING LEAD

DEGAUSSING

COIL SOCKET

To CRT Unit

ground

-22-

Page 23

Cabinet Parts List

1

5

6

3

4

2

1

7

10

8

9

Key No. Part Number Description

1 SKCM 0021NZM110 CABINET COLOUR MATCH-METAL SILVER GREY #MSG001(3Y07)(3Y03) FOR SANYO

2 SK100721NZM 002 FRONT LENS (REMOTE CONTROL WINDOW)

3 SK100721NZM 002 FRONT LENS (LED WINDOW)

4 Sk190100821210 POWER KNOB SPRING - DIA.0.6SPRING WIRE

5 SK100425TM 0002 SIDE AV JACK BRACKET-DARK GREY #DG001(ABS)

6 SK100821NZM 001 CONTROL KEY KNOB-ELECTROPLATING SILVER(ABS)

7 SK060121NZM 001 BACK LABEL "SKYWORTH" OVERSEAS ENG

8 SK100221NX0001 BACK CABINET-DARK GREY #DG001

9 SK1016HS080003 BATTERY DOOR-NORMAL GREY #NG001(ABS)

10 SKHS08S0300000 HANDSET-30 KEYS FOR OVERSEAS NORMAL GREY ENG(3Y03)

-23-

,, ,,

,, ,,

Page 24

5V(1)

(OPTION)

FRONT AV

AC110V

VOL

POWER

PROG-

SW008

RD2

56K

5V(1)

AFT

R032

1.5K

ZD003

3.6V

AV V OUT

IC201 PIN40

V OUT

AR OUT

AL OUT

V IN 1

AR IN 1

AL IN 1

!

F601

T3.15A/AC250

!

LN

PROG+

SW007

RD3

22K

CN601

!

M001

PMA64xxM

VOL-

SW006

R033

8.2K

10U/50V

T601

AR IN

9V(2)

C205

100U/16V

C620

Q609

9V(2)

9V(1)

AR-OUT

R409

2.2K

C426

R410

0.0082UF

20K

C427

0.015UF

AUDIO R

AUDIO L

FM

0.022U

C207

5V(2)

C016

0.1U

R200 470

R209 470

C237 100P

C240 10U/25V

C222 0.01U

C212

470U/16V

SAW101

45B

R008

100K

2.2U/50V

C236 100P

C239 0.22U

R255 100

R254 100

R256 100

C217 0.1U

C219

0.33U

R210

3K3

C216

1U/50V

C206

0.01U

R007

100K

R208 47

47U/16V

R211

120

C214

0.01U

POWER

B+

IC004

33V

33V

C424 0.015UF

C423 0.015UF

C425 2.2U/50V

42

40

39

41

38

VIR

EOR

LDR

Cps237Cps1

OUTR

OUTL1LDL2VIL3EOL4CAV5Vref6LIL7AVL8SOL9LOL10CTW11CTS12CW13CS14VEO15VEI16CNR17Cm18Cdec19GND20SDA

2.2U/50V

C402

C404

C401

C406 100U/16V

C403 4.7U/50V

0.1U/M

0.0082UF

R402

20K

R401

2.2K

C243

0.047U/M

C203

C221

0.022U

R201

20K

C215

LA76814

1

A OUT

2

FM OUT

3

PIF AGC

4

RF AGC

5

IF IN

6

IF IN

7

IF GND

8

IF VCC

9

FM FIL

10

AFT OUT

11

BUS DATA

12

BUS CLOCK

13

ABL

14

R IN

15

G IN

16

B IN

17

FB IN

18

VCC

19

R OUT

20

G OUT

21

B OUT

22

SYNC

23

V OUT

24

RAMP ALC

25

H VCC

26

H AFC FIL

H OUT27FBP IN

V-SYNC

C315

1U/50V

C316

0.033U/M

IC201

R340

5.1K

V-IN

C422 2.2U/50V

36

LIR

47U/16V

C405

BLACK S.F

VCC V/C/D

KILLER FIL

C450

0.022U

35

AVR

C450

0.022U

AL-OUT

SIF IN

SIF FIL

SIF OUT

EXT.A IN

APC FIL

FLL FIL

TV OUT

INT.V IN

EXT.V IN

G V/C/B

V OUT

ACC FIL

XRAL

FSC OUT

APC1 FIL

XRAY

H GND

OSD CON

VCO IREF

R301

47K

C325

100/16V

D301

BA158

C304

220U/50V

R407

2.2K

C419

X401

2.2U/50V

503F58

C421 4.7U/50V

C420 4.7U/50V

31

34

32

Css

LOR33SOR

10U/16V

10U/16V

1U/50V

C408

C407

C409

AL IN

C245

39PF

54

53

52

51

C241

39PF

50

49

VCO

48

VCO

C209

47

0.47U

46

R225 1K R229 1K

45

C230

44

1U/50V

43

42

41

1U/50V

40

39

C235

38

15P

37

C238

5n6

0.01U

36

35

C228

34

1000P

33

32

31

NC

R213

1K5

30

NC

29

28

R212

R241

4.7K

10K

IC301

LA7840

7

R319

15K

R329

10K

R320

1.2 2W

20V

5V(1)

C630

0.01U

IC203

L7805

5V(2)

B+

9V(1)

R630

R644

100K/2W

10K

Q301

2SC2482

R307

100

R114

R110

47

BLK

IC201 PIN42

100U/160V

C640

1000U/25V

C621

0.01U/50V

R653

ZD601

3V9

R109

270

2SC2717

C321

C618

470U/25V

Q101

AFT

OSD-R

OSD-G

OSD-B

BLK

V-IN

R629

10K

R646

3K9

C642

0.01U

R621

L102

0.82UH

CN201

R625

15K 2W

0

Q611

2SA966

2KB(H)

220

C109

0.01U

5V(2)

5V(1)

9V(2)

ABL

IC601

L7805

10U/50V

R626

0

R628

22

R632

10K

78L09

Q610

2SC1815

VR601

NC

SCL

ADD

RFAGC

R103

123456789

120K

C104

4.7U/50V

R107

33K

R101 100

L101

100UH

5V(2)

R002

5V(1)

C001 0.01U

1K

13

Q003

2SA1015

C009

330U/16V

C012

2.2U/50V

R719

AR OUT

12

ACOM

R435

100

!

C607

1

2

5

3

4.7K

R065

OCP/FB

R043

10K

R437

R438

R436

R439

1000P

C010 0.01U

AI311AI0

R431

10K

R434

10K

220U/200V

C614

R022

22K

R021

C007

R037 10K

R036 10K

Q008

2SC1815

9V(2)

10K

10K

10K

10K

10

8

R605

2M2

R608

2M2

15P

C008

15P

CONA9CONB

4K7

R001 10K

33K

C004

220P

C005

100P

32.768K

C014

4.7U/50V

R465

10K

R464

10K

IC401

HEF4052

L602

R610

680

R603

0.22/1W

D605

4148

R013

4.7K

X001

Q007

2SC1815

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Q462

2SC1815

C608

0.001U/2KV

R604

0.22/1W

WRITE

IDsecam

IDscart

VOL

COB.F

POWER

TUNE

GND

XTF1

XTF2

VDD

KEY

AFT

PGCin

OPT

RESET

FIL

OPTselect

Vsyn

Hsyn

D201

1N4148

AV/TV SW

Q601

2SC2482

LA8633XX

V-SYNC

Q461

2SC1815

L601

D609

IN4148

IC001

AV1/2 SW

R612 10K

ZD602

15V

D604

IN4148

R643

1K

R613

47/0.5W

BA158

C610

100UF/35V

BALANCE

H-SYNC

AL-OUT

4.7UF/160V

D611

3

CR1

0.022U

2

RD11

1

LED

RR1

1K

1

5V(1)

SLEEP

VOL+

MENU

SEARCH

AV/TV

R067

24K

SW002

SW004

SW005

SW003

10U/50V

R602

SCK473

!

SW

C436

R445

10K

C601A

.0047

C601D

.0047

R601

PTC

RD7

4.3K

5V(2)

AR-OUT

10

9V(2)

Q401

2SC1815

9V(2)

C011

0.01U

R038

47U/16V

D601D

39K/3W

SW001

RD8

RD9

3K

2K

RD21 15K

RD21

16K

CN001 PIN3

5V(1)

R039

100

C013

0.022U

1M

5V(1)

Q221

J147

2SC1815

1K

R226

2.2K

AL-OUT

R440

100

C432

47U/16V

C431

47U/16V

15

16

VDD

BI01BCOM3BI34BI15INHBIT6VEE7GND

BI2

2

C434

47U/16V

C433

R433

R432

10K

10K

9V(2)

1N5397 X4

D601A

D601C

!

D601B

R607

STR-G6653

4

!

BLOCK

CONTROL

IC602

AR-IN

AI114AI2

RD5

RD4

RD6

6.8K

11K

4.7K

Q006

2SA1015

R034

4.7K

9V(2)

VOUT

Q402

2SC1815

C435

R446

10K

!

C602

.22/250V

!

R622

!

2M7

!

CN602

L601

DEG.COIL

!

R102 100

S_VHS

M_TRAP

REMOTE

SAFTY

IICCLK

IICDATA

0.1U/63V

SDA

MUTE

DATA

V_L

V_H

UHF

AV2

AV1

SD

CLK

BLK

AL-IN

9V(2)

C623

R609

47

R611

C611

B

G

R

2K2

VCC

C111

0.01U

C110

330U/16V

R463

10K

VCC

R462

10K

BA158

NC

33V

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

D610

680P/500V

0.0033/100V

IC603

5V(1)

T601

D602

IN4148

C609

33V

10

5V(1)

R051 100

R052 100

C605

0.0022U/250V

IF1

IF2

11

C108

1U/50V

R050 9K1

R049 4.7K

D010 1N4148

D009 1N4148

D008 1N4148

D007 1N4148

R240

100K

1

!

3 7

4

5

6

!

C613

TUNER

C107

0.01U

R048 4.7K

R7125K1

R4F1

75

0.68/2W

!

C114

R108

0.01U

5.6K

R105

0

R111

1K

AV1/2 SW

AV/TV SW

R047 4.7K

R046 4.7K

IC002

24C04

R031

330

OSD-B

R030

330

OSD-G

R029

330

R7115K1

R710

5K1

OSD-R

R7091K

AV VOUT

C615

680P/500V

C616

100U/160V

R618

D607

BYW36

C641

680P/500V

9

D640

BA158

R619

2.2 /2W

10

11

D608

C617

BA158

2200U/25V

12

C619

680P/500V

BA158

R642

C612

1.2K

0.1U

R645

1K

Q602

2SC1815

10U/16V

C439

Cadj29CER30Cmo

R403

1U/50V

R404

C410

150

C411

0.047UF

L203

45.75M

C232

3.579545M

C227

R214

1K

C328

100U/16V

R308

2.7K 1/2W

0.0022U/1KV

28

X201

!

9V(2)

C309

C417 0.47U/M

8.2K

10U/16V

R327

2.2 2W

C324

0.47U

R318

C323

1U/50V

R324

3.9K

C414 10U/16V

C233

1122334455667

100K

25V

C322

560P/500V

C418

0.22U/M

C416

25

Cp126Cp227Cph

C413 0.1U/C

R243

1K

L241

15UH

R303

5.1K

C326

2200U/25V

220U/16V

100U/16V

24

Vcap

C412 4.7U/50V

C242

0.001U

C231

0.1U

R221

10K

9V(2)

C320

0.056U/250V

9V(2)

COMP

C246

0.01U

R222

22K

5V(2)

R330

1.5K

R306

5.1K 5W

C310

C441

100P

23

Vcc

C224

0.001U

T301

R408

12/1W

220U/16V

22

21

R233

390

5V(2)

R309

1K 1W

C415

SCL

C440

100P

123

!

C442

0.01U

IC404TDA9852

R405

100

D221 IN4148

180 1W

IC302

LA7809

C301

47U/50V

150K 1/2W

R310

22 1/2W

R406

100

C247

0.47U/50V

AV V IN

AV V OUT

R311

R620

ZD401

8V2

SCL

SDA

.0047/2KV

3.9/2W

R316

C313

Q302

2SD2499

!

AUDIO L

VOL

CPU PIN5

AUDIO R

CN301B

FROM CN301

CN201B

FROM CN201

C327

0.1U

C317

680P/500V

D304

BA158

C318

680P/500V

D310

BA158

C314

.0076/2KV

IC402

LA4285

INT1GND2EXT3SW4VOL566NF7GND8OUT9VCC

Q503

D505

1N4148

C506

470u/16V

D504

2SC2482

C448

100U/25V

C445

100U/25V

IC403

LA4285

R508

2K2

R441

R442

R237

560K

R412

4.7K

C437

10UF/50V

9V(2)

R468

15K

Q464

2SC1815

R466

4.7K

D401

R467

W1 W2 W3

1 BO

2 GO

3 RO

4 GND

5 +9V(2)

1.8K

3 HEATER

2 GND

1 +180V

10u/25V

4

1

10U/50V

C438

10UF/50V

C507

C505

0.01U

R326

270 2W

T603 FBT

4148

C453

R523

R530

150K/1W

R503

150

10K

R413

4.7K

15K/2W

R502

150

Q508

2SC1815

INT1GND2EXT3SW4VOL566NF7GND8OUT9VCC

R514

R506

390

C503

150P

R524

270

BA158

!

!

1K

1U/50V

100

1U/50V

C446

C451

R235

5K1

C452

1000UF/25V

R513

15K/2W

R505

390

R501

150

10

10

20V

C502

150P

D306

BA157

R315

22K 1W

R317

0.68 2W

C444

220/25V

C447

220/25V

R511

2K7 1/2W

R510

2K7 1/2W

Q502

2SC2482

D506

R507

1N4148

2K2

CRT PCB

C312

1U/250V

C311

0.47U 250V

15K/2W

R515

390

SPEAKER

8R 3W

SPEAKER

8R 3W

CRT

V501

EHT

R512

R509

2K7 1/2W

Q501

2SC2482

C504

1000P/2KV

C501

150P

D507

R504

1N4148

2K2

CN302

!

R331

44UH

1K5/1W

L301

CN301

3

2

1

!

!

2

TITLE:

SYSTEM:

P/N:

DATE:

FOCUS

SCREEN

3Y03 DIAGRAM

NTSC M

2001-09-27

R322

0.68 2W

7

3

8

R207

10

6

D305

BA158

C302

C303

10U/250V

680P/500V

C308

0.056U/M

R236

1K

680

5V(2)

Page 25

Chassis Electrical Parts List

location quantity description

SK013YA3Y03203M MAIN¡¡ASSEMBLY

&C308 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

&D221 SK4300BE476ET0 ELECTROLYTIC CAPACITOR 47uF 35V +/-20%

&D602 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

&J123 SK4500400056T0 ZENER DIODE 5V6 1/2W

C001 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C004 SK4300AF221CT0 CERAMIC CAPACITOR 220PF 50V +/-5%

C005 SK4300AF101CT0 CERAMIC CAPACITOR 100PF 50V +/-5%

C007 SK4300NF150CT0 NPO CERAMIC CAPACITOR 15PF 50V +/-5%

C008 SK4300NF150CT0 NPO CERAMIC CAPACITOR 15PF 50V +/-5%

C009 SK4300BC337ET0 ELECTROLYTIC CAPACITOR 330uF 16V +/-20%

C010 SK4300AF104HT0 CERAMIC CAPACITOR 0.1uF 50V +80-20%

C011 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C012 SK4300AF223HT0 CERAMIC CAPACITOR 0.022uF 50V +80-20%

C013 SK4300BF225ET0 ELECTROLYTIC CAPACITOR 2.2uF 50V +/-20%

C014 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C016 SK4300EF104DT0 METALLIZED POLYESTER FILM CAPACITOR 0.1UF 63-100V +/-10%

C101 SK4300BC476ET0 ELECTROLYTIC CAPACITOR 47uF 16V +/-20%

C104 SK4300BF475ET0 ELECTROLYTIC CAPACITOR 4.7uF 50V-100V +/-20%

C107 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C108 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C109 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C110 SK4300BC337ET0 ELECTROLYTIC CAPACITOR 330uF 16V +/-20%

C111 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C114 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C203 SK4300MG223DT0 MYLAR CAPACITOR 0.022uF 100V +/-10%

C205 SK4300BC107ET0 ELECTROLYTIC CAPACITOR 100uF 16V +/-20%

C206 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C207 SK4300BC476ET0 ELECTROLYTIC CAPACITOR 47uF 16V +/-20%

C209 SK4300EF474DT0 METALLIZED POLYESTER FILM CAPACITOR 0.47UF 63-100V +/-10%

C212 SK4300BC477ET0 ELECTROLYTIC CAPACITOR 470uF 16V +/-20%

C214 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C215 SK4300MG223DT0 MYLAR CAPACITOR 0.022uF 100V +/-10%

C216 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C217 SK4300EF104DT0 METALLIZED POLYESTER FILM CAPACITOR 0.1UF 63-100V +/-10%

C219 SK4300EF334DT0 METALLIZED POLYESTER FILM CAPACITOR 0.33uF 63-100V +/-10%

C221 SK4300BF225ET0 ELECTROLYTIC CAPACITOR 2.2uF 50V +/-20%

C222 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C224 SK4300MG102DT0 MYLAR CAPACITOR 0.001uF 100V +/-10%

C225 SK4300BF474ET0 ELECTROLYTIC CAPACITOR 0.47uF 50V-100V +/-20%

C227 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C228 SK4300MG102DT0 MYLAR CAPACITOR 0.001uF 100V +/-10%

C230 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C231 SK4300AF104HT0 CERAMIC CAPACITOR 0.1uF 50V +80-20%

C232 SK4300LF105ET0 NONPOLAR ELECTROLYTIC CAPACITO R 1UF 50V+/-20%

C233 SK4300BC106ET0 ELECTROLYTIC CAPACITOR 10UF 16V +/-20%

C234 SK4300BC476ET0 ELECTROLYTIC CAPACITOR 47uF 16V +/-20%

C235 SK4300NF150CT0 NPO CERAMIC CAPACITOR 15PF 50V +/-5%

C236 SK4300AF101CT0 CERAMIC CAPACITOR 100PF 50V +/-5%

C237 SK4300AF101CT0 CERAMIC CAPACITOR 100PF 50V +/-5%

-25-

Page 26

location quantity description

C238 SK4300MG562DT0 MYLAR CAPACITOR 0.0056uF 100V +/-10%

C239 SK4300EF224DT0 METALLIZED POLYESTER FILM CAPACITOR 0.22UF 63-100V +/-10%

C240 SK4300BD106ET0 ELECTROLYTIC CAPACITOR 10uF 25V +/-20%

C241 SK4300NF390CT0 NPO CERAMIC CAPACITOR 39PF 50V +/-5%

C242 SK4300MG102DT0 MYLAR CAPACITOR 0.001uF 100V +/-10%

C245 SK4300NF390CT0 NPO CERAMIC CAPACITOR 39PF 50V +/-5%

C246 SK4300MG103DT0 MYLAR CAPACITOR 0.01UF 100V +/-10%

C247 SK4300BF474ET0 ELECTROLYTIC CAPACITOR 0.47uF 50V-100V +/-20%

C250 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C301 SK4300BF476ET0 ELECTROLYTIC CAPACITOR 47uF 50V +/-20%

C302 SK4300AM681DT0 CERAMIC CAPACITOR 680PF 500V +/-10%

C303 SK4300BJ106EC0 ELECTROLYTIC CAPACITOR 10uF 250V +/-20%(FORMED, PITCH=5mm)

C304 SK4300BF227ET0 ELECTROLYTIC CAPACITOR 220uF 50V +/-20%

C306 SK4300BE477E00 ELECTROLYTIC CAPACITOR 470UF 35V +/-20%

C308 SK4300EJ563C01 METALLIZED POLYESTER FILM CAPACITOR 0.056uF 250V +/-5%

C309 SK4300AR222DT0 CERAMIC CAPACITOR 0.0022uF 1KV +/-10%

C310 SK4300EJ563C01 METALLIZED POLYESTER FILM CAPACITOR 0.056uF 250V +/-5%

C312 SK4300BJ475EC0 ELECTROLYTIC CAPACITOR 4.7UF 2 50V +/-20%(FORMED,PITCH=5mm)

C315 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C316 SK4300MG333DT0 MYLAR CAPACITOR 0.033uF 100V +/-10%

C317 SK4300AM681DT0 CERAMIC CAPACITOR 680PF 500V +/-10%

C318 SK4300AM681DT0 CERAMIC CAPACITOR 680PF 500V +/-10%

C320 SK4300BC227ET0 ELECTROLYTIC CAPACITOR 220uF 16V +/-20%

C321 SK4300BH107EC1 ELECTROLYTIC CAPACITOR 100uF 160V +/-20%(FORMED, PITCH=7.5mm)

C322 SK4300AM561DT0 CERAMIC CAPACITOR 560PF 500V +/-10%

C323 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C324 SK4300EF474DT0 METALLIZED POLYESTER FILM CAPACITOR 0.47UF 63-100V +/-10%

C325 SK4300BE107ET0 ELECTROLYTIC CAPACITOR 100uF 35V +/-20%

C326 SK4300BD228E00 ELECTROLYTIC CAPACITOR 2200uF 25V +/-20%(16 X 25mm)

C328 SK4300BC107ET0 ELECTROLYTIC CAPACITOR 100uF 16V +/-20%

C430 SK4300BC476ET0 ELECTROLYTIC CAPACITOR 47uF 16V +/-20%

C431 SK4300BC476ET0 ELECTROLYTIC CAPACITOR 47uF 16V +/-20%

C435 SK4300BF106ET0 ELECTROLYTIC CAPACITOR 10uF 50V-63V +/-20%

C438 SK4300BF106ET0 ELECTROLYTIC CAPACITOR 10uF 50V-63V +/-20%

C447 SK4300BD227E00 ELECTROLYTIC CAPACITOR 220uF 25V +/-20%

C448 SK4300BD107ET0 ELECTROLYTIC CAPACITOR 100uF 25V +/-20%

C451 SK4300BF105ET0 ELECTROLYTIC CAPACITOR 1uF 50V +/-20%

C452 SK4300BD108E00 ELECTROLYTIC CAPACITOR 1000uF 25V +/-20%

C453 SK4300BF106ET0 ELECTROLYTIC CAPACITOR 10uF 50V-63V +/-20%

C455 SK4300MG103DT0 MYLAR CAPACITOR 0.01UF 100V +/-10%

C465 SK4300EF104DT0 METALLIZED POLYESTER FILM CAPACITOR 0.1UF 63-100V +/-10%

C601A SK4300AM472DT0 CERAMIC CAPACITOR 0.0047uF 500V +/-10%

C601D SK4300AM472DT0 CERAMIC CAPACITOR 0.0047uF 500V +/-10%

C602 SK4300FW224D00 AC CAPACITOR 0.22uF AC250V-500V +/-10%

C605 SK4300AM681DT0 CERAMIC CAPACITOR 680PF 500V +/-10%

C607 SK4300BI227EC1 ELECTROLYTIC CAPACITOR 220uF 200V +/-20%(FORMED, PITCH=7.5mm)

C608 SK4300ET102C00 METALLIZED POLYPROPYLENE FILM CAPACITOR0.001uF 2KV +/-5%

C609 SK4300MG152DT0 MYLAR CAPACITOR 0.0015UF 100V +/-10%

C610 SK4300BE107ET0 ELECTROLYTIC CAPACITOR 100uF 35V +/-20%

C611 SK4300EF104DT0 METALLIZED POLYESTER FILM CAPACITOR 0.1UF 63-100V +/-10%

C612 SK4300AF104HT0 CERAMIC CAPACITOR 0.1uF 50V +80-20%

C613 SK4300SX222E00 SAFETY CERAMIC CAPACITOR 0.0022uF AC250V-400V +/-20%

C614 SK4300AF471CT0 CERAMIC CAPACITOR 470PF 50V +/-5%

C615 SK4300AM681DC1 CERAMIC CAPACITOR 680PF 500V +/-10% (FORMED,PITCH=7.5mm)

-26-

Page 27

location quantity description

C616 SK4300BH107EC1 ELECTROLYTIC CAPACITOR 100uF 160V +/-20%(FORMED, PITCH=7.5mm)

C617 SK4300BD108E00 ELECTROLYTIC CAPACITOR 1000uF 25V +/-20%

C618 SK4300BD477E00 ELECTROLYTIC CAPACITOR 470uF 25V +/-20%

C619 SK4300AM681DT0 CERAMIC CAPACITOR 680PF 500V +/-10%

C620 SK4300BF106ET0 ELECTROLYTIC CAPACITOR 10uF 50V-63V +/-20%

C621 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C623 SK4300BH475ET0 ELECTROLYTIC CAPACITOR 4.7uF 160V +/-20%

C630 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C640 SK4300BD108E00 ELECTROLYTIC CAPACITOR 1000uF 25V +/-20%

C641 SK4300AM681DT0 CERAMIC CAPACITOR 680PF 500V +/-10%

C642 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

CN002 SK540092500006 WAFER 2.5mm H X 6 PIN

CN302 SK540095000005 WAFER 5MM TV-50P-05-V1 5 PIN

CN402 SK540092500002 WAFER 2.5mm H X 2 PIN

CN405 SK540092500003 WAFER 2.5mm H X 3 PIN

CN601 SK540091000002 WAFER 10mm 2.35mm TJC1-2A 2 PIN

CN602 SK540091000002 WAFER 10mm 2.35mm TJC1-2A 2 PIN

D007 SK4100AD5110T0 CARBON FILM RESISTOR 510 OHM 1/4W +/-5%

D008 SK4100AD5110T0 CARBON FILM RESISTOR 510 OHM 1/4W +/-5%

D009 SK4100AD5110T0 CARBON FILM RESISTOR 510 OHM 1/4W +/-5%

D010 SK4100AD5110T0 CARBON FILM RESISTOR 510 OHM 1/4W +/-5%

D221 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D301 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D304 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D305 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D306 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D310 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D401 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D601A SK450015397000 NORMAL RECTIFIER DIODE 1N5397 1.5A/600V(DO-15)

D601B SK450015397000 NORMAL RECTIFIER DIODE 1N5397 1.5A/600V(DO-15)

D601C SK450015397000 NORMAL RECTIFIER DIODE 1N5397 1.5A/600V(DO-15)

D601D SK450015397000 NORMAL RECTIFIER DIODE 1N5397 1.5A/600V(DO-15)

D602 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D604 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D605 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D607 SK45052BYW3600 HIGH SPEED RECTIFIER DIODE BYW36 2A/600V TELEFUNKEN

D608 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D609 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D610 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D611 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D640 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

F601 SK600135000100 FUSE T3.15A 250V W/APPROVAL MARKING HOLLYLAND

IC001 SK4703L8624142 I.C. LC863224A-5V23 SANYO (8-BIT SINGLECHIP MICROCOMPUTER) DIP PACKAGE

IC002 SK4707C24C0408 I.C. ST24C04 OR M24C04 SGS (EEPROM)

IC004 SK4709KA33VT02 I.C. KA33V SAM SUNG (VT)

IC201 SK4703L7681454 I.C. LA76814B SANYO (ONE CHIP IC FOR NTSC ONLY)

IC203 SK4707L7805E03 I.C. L7805CV SGS (STABILIZING)

IC301 SK4703L7840007 I.C. LA7840 SANYO (VERTICAL DEFLECTION)

IC302 SK4707L7809003 I.C. L7809CV SGS (STABILIZING) OR 4717-L78090-03

IC400 SK4707H4052016 I.C. HCF4052BF SGS (4CH SWITCH) OR 4701-A40520-16

IC401 SK4707H4052016 I.C. HCF4052BF SGS (4CH SWITCH) OR 4701-A40520-16

IC403 SK4703L4285010 I.C. LA4285 SANYO (3W AUDIO OUTPUT)

IC601 SK4707L7805E03 I.C. L7805CV SGS (STABILIZING)

IC602 SK4704R6653005 I.C. STR-G6653 SANKEN (FLYBACK SWITCHINGREGULATOR 650V 120W)

-27-

Page 28

location quantity description

IC603 SK4701T6210J04 I.C. TLP621 TOSHIBA (PHOTO TRANSISTOR)

J058 SK4100AD6800T0 CARBON FILM RESISTOR 68 OHM 1/4W +/-5%

J147 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

L101 SK4800011010T0 PEAKING COIL 100uH +/-10%

L102 SK480001008200 PEAKING COIL 0.82uH

L203 SK480020457500 PIF AND AFC COIL FOR NTSC 45.75MHz TDA8222 I.C. USE

L241 SK4800011500T0 PEAKING COIL 15uH +/-10%

L601 SK640003004100 FERRITE BEAD 3.5 X 1 X 9 W/JUMPER FOR 5T01

L602 SK640003004100 FERRITE BEAD 3.5 X 1 X 9 W/JUMPER FOR 5T01

P404 SK610016032040 RCA JACK H=8mm YELLOW H-TYPE

P405 SK610016215092 RCA JACK X 2 H-TYPE W/MOUNTING BOSS(PCB-MTG PITCH=15mm) WHITE,RED

P406 SK610016032040 RCA JACK H=8mm YELLOW H-TYPE

P407 SK610016215092 RCA JACK X 2 H-TYPE W/MOUNTING BOSS(PCB-MTG PITCH=15mm) WHITE,RED

PCB SK5800A3Y03104 MAIN P.C.BOARD 304 X 246 X 1.6mm FOR 3Y03 CHASSIS W/CRT BOARD

PE-PF SK5900E2022260 MULTI TWIST WIRE AWG22 UL1015 BLUE 200mm

Q003 SK4600A10150T0 TRANSISTOR 2SA1015Y\2PA1015

Q006 SK4600A10150T0 TRANSISTOR 2SA1015Y\2PA1015

Q007 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q008 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q101 SK4600C27170T0 TRANSISTOR 2SC2717

Q221 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q301 SK4600C24822T0 TRANSISTOR 2SC2482/3DG2482Y

Q302 SK4601D2499000 TRANSISTOR 2SD2499 TOSHIBA (F OR HOR. DEFLECTION)

Q402 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q461 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q462 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q464 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q601 SK4600C24822T0 TRANSISTOR 2SC2482/3DG2482Y

Q602 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q609 SK4707L78L0903 I.C. L78L09CZ SGS TO-92 (POSITIVE VOLTAGE REGULATOR)

Q610 SK4600C18150T0 TRANSISTOR 2SC1815Y/2PC1815

Q611 SK4600A0966000 TRANSISTOR 2SA966Y

R001 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R002 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R007 SK4100AD1040T0 CARBON FILM RESISTOR 100K OHM 1/4W +/-5%

R008 SK4100AD1040T0 CARBON FILM RESISTOR 100K OHM 1/4W +/-5%

R013 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R021 SK4100AD3330T0 CARBON FILM RESISTOR 33K OHM 1/4W +/-5%

R022 SK4100AD2230T0 CARBON FILM RESISTOR 22K OHM 1/4W +/-5%

R029 SK4100AD3310T0 CARBON FILM RESISTOR 330 OHM 1/4W +/-5%

R030 SK4100AD3310T0 CARBON FILM RESISTOR 330 OHM 1/4W +/-5%

R031 SK4100AD3310T0 CARBON FILM RESISTOR 330 OHM 1/4W +/-5%

R032 SK4100AD1520T0 CARBON FILM RESISTOR 1.5K OHM 1/4W +/-5%

R033 SK4100AD8220T0 CARBON FILM RESISTOR 8.2K OHM 1/4W +/-5%

R034 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R036 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R037 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R038 SK4100AD1050T0 CARBON FILM RESISTOR 1M OHM 1/4W +/ -5%

R039 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R043 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R044 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R046 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R047 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R048 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

-28-

Page 29

location quantity description

R049 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R050 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R051 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R052 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R065 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R067 SK4100AD2430T0 CARBON FILM RESISTOR 24K OHM 1/4W +/-5%

R101 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R102 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R103 SK4100AD1240T0 CARBON FILM RESISTOR 120K OHM 1/4W +/-5%

R107 SK4100AD3330T0 CARBON FILM RESISTOR 33K OHM 1/4W +/-5%

R108 SK4100AD5620T0 CARBON FILM RESISTOR 5.6K OHM 1/4W +/-5%

R109 SK4100AD2710T0 CARBON FILM RESISTOR 270 OHM 1/4W +/-5%

R110 SK4100AD4700T0 CARBON FILM RESISTOR 47 OHM 1/4W +/ -5%

R111 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R114 SK4100AD2210T0 CARBON FILM RESISTOR 220 OHM 1/4W +/-5%

R200 SK4100AD4710T0 CARBON FILM RESISTOR 470 OHM 1/4W +/-5%

R201 SK4100AD2030T0 CARBON FILM RESISTOR 20K OHM 1/4W +/-5%

R207 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R208 SK4100AD4700T0 CARBON FILM RESISTOR 47 OHM 1/4W +/ -5%

R209 SK4100AD4710T0 CARBON FILM RESISTOR 470 OHM 1/4W +/-5%

R210 SK4100AD3320T0 CARBON FILM RESISTOR 3.3K OHM 1/4W +/-5%

R211 SK4100AD1210T0 CARBON FILM RESISTOR 120 OHM 1/4W +/-5%

R212 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R213 SK4100AD1520T0 CARBON FILM RESISTOR 1.5K OHM 1/4W +/-5%

R214 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R219 SK4100AD2430T0 CARBON FILM RESISTOR 24K OHM 1/4W +/-5%

R220 SK4100AD2430T0 CARBON FILM RESISTOR 24K OHM 1/4W +/-5%

R221 SK4100D1272000 METAL OXIDE FILM RESISTOR 2.7K OHM 1/4W+/-1%

R222 SK4100D11040T0 METAL OXIDE FILM RESISTOR 100K OHM 1/4W+/-1%

R225 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R226 SK4100AD2220T0 CARBON FILM RESISTOR 2.2K OHM 1/4W +/-5%

R229 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R233 SK4100AD3910T0 CARBON FILM RESISTOR 390 OHM 1/4W +/-5%

R235 SK4100AD5120T0 CARBON FILM RESISTOR 5.1K OHM 1/4W +/-5%

R240 SK4100AD1040T0 CARBON FILM RESISTOR 100K OHM 1/4W +/-5%

R241 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R243 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R254 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R255 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R256 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R301 SK4100AD4730T0 CARBON FILM RESISTOR 47K OHM 1/4W +/-5%

R303 SK4100AD5120T0 CARBON FILM RESISTOR 5.1K OHM 1/4W +/-5%

R306 SK4100DK512001 METAL OXIDE FILM RESISTOR 5.1K OHM 5W+/-5%

R307 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R308 SK4100AF2720T0 CARBON FILM RESISTOR 2.7K OHM 1/2W +/-5%

R310 SK4100AF2200T0 CARBON FILM RESISTOR 22 OHM 1/2W +/ -5%

R311 SK4100DG181001 METAL OXIDE FILM RESISTOR 180 OHM 1W+/-5%

R315 SK4100DG223001 METAL OXIDE FILM RESISTOR 22K OHM 1W+/-5%

R319 SK4100AD1530T0 CARBON FILM RESISTOR 15K OHM 1/4W +/5%

R322 SK4100DH006801 METAL OXIDE FILM RESISTOR 0.68 OHM 2W+/-5%

R324 SK4100AD3920T0 CARBON FILM RESISTOR 3.9K OHM 1/4W +/-5%

R327 SK4100DH022001 METAL OXIDE FILM RESISTOR 2.2 OHM 2W+/-5%

R330 SK4100AD1520T0 CARBON FILM RESISTOR 1.5K OHM 1/4W +/-5%

R340 SK4100AD5120T0 CARBON FILM RESISTOR 5.1K OHM 1/4W +/-5%

-29-

Page 30

location quantity description

R413 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R427 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R428 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R429 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R430 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R436 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R437 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R438 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R439 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R440 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R442 SK4100AD1010T0 CARBON FILM RESISTOR 100 OHM 1/4W +/-5%

R446 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R450 SK4100AD7500T0 CARBON FILM RESISTOR 75 OHM 1/4W +/ -5%

R462 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R463 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R464 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R465 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R466 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

R467 SK4100AD1820T0 CARBON FILM RESISTOR 1.8K OHM 1/4W +/-5%

R468 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R470 SK4100AF0220T0 CARBON FILM RESISTOR 2.2 OHM 1/2W + /-5%

R601 SK4100KZ120002 P.T.C. THERMISTOR RESISTOR 12 OHM +0-20%MAX INPUT 270V

R602 SK4100FK040001 WIRE WOUND RESISTOR 4 OHM 5W +/-5%

R603 SK4100DG002201 METAL OXIDE FILM RESISTOR 0.22 OHM 1W+/-5%

R604 SK4100DG002201 METAL OXIDE FILM RESISTOR 0.22 OHM 1W+/-5%

R605 SK4100HF2250T0 HIGH-VOLT RESISTOR 2.2M OHM 1/2W +/-5%

R607 SK4100DI393001 METAL OXIDE FILM RESISTOR 39K OHM 3W +/-5%

R608 SK4100HF2250T0 HIGH-VOLT RESISTOR 2.2M OHM 1/2W +/-5%

R609 SK4100AD4700T0 CARBON FILM RESISTOR 47 OHM 1/4W +/ -5%

R610 SK4100AD6810T0 CARBON FILM RESISTOR 680 OHM 1/4W +/-5%

R611 SK4100AD2220T0 CARBON FILM RESISTOR 2.2K OHM 1/4W +/-5%

R612 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R613 SK4100DF470001 METAL OXIDE FILM RESISTOR 47 OHM 1/2W+/-5%

R618 SK640003004101 FERRITE BEAD 3.5 X 1 X 9.5mm W/JUMPER PITCH=15mm

R619 SK640003004101 FERRITE BEAD 3.5 X 1 X 9.5mm W/JUMPER PITCH=15mm

R620 SK4100DF154001 METAL OXIDE FILM RESISTOR 150K OHM 1/2W +/-5%

R622 SK4100HG8250T0 HIGH-VOLT RESISTOR 8.2M OHM 1W +/-5 %

R625 SK4100DH153001 METAL OXIDE FILM RESISTOR 15K OHM 2W+/-5%

R629 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R630 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R632 SK4100AD1220T0 CARBON FILM RESISTOR 1.2K OHM 1/4W +/-5%

R642 SK4100AD2020T0 CARBON FILM RESISTOR 2K OHM 1/4W +/-5%

R643 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R644 SK4100DH104001 METAL OXIDE FILM RESISTOR 100K OHM 2W+/-5%

R645 SK4100AD3910T0 CARBON FILM RESISTOR 390 OHM 1/4W +/-5%

R646 SK4100AD3920T0 CARBON FILM RESISTOR 3.9K OHM 1/4W +/-5%

R653 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

R709 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R710 SK4100AD5120T0 CARBON FILM RESISTOR 5.1K OHM 1/4W +/-5%

R711 SK4100AD5120T0 CARBON FILM RESISTOR 5.1K OHM 1/4W +/-5%

R712 SK4100AD5120T0 CARBON FILM RESISTOR 5.1K OHM 1/4W +/-5%

R719 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

RD21 SK4100AD1530T0 CARBON FILM RESISTOR 15K OHM 1/4W +/5%

SAW101 SK490030062500 NTSC-M SAW FILTER Q062QSM 45.75MHz FOR VIDEO

-30-

Page 31

location quantity description

T301 SK510004100000 HORIZONTAL DRIVE TRANSFORMER F OR LOW VOLTAGE

T601 SK480006300500 LINE FILTER 30mH X 2

TUNER SK5200457W0200 M/N 181CH WORLD STANDARD FS TUNER IF45.75MHz FOR 5V W/O AFT AGC 4V F-TYPE

VR601 SK420022020000 SEMI-FIXED RESISTOR 2KB (H)

X001 SK490013275200 CRYSTAL 32.768000KHz JU38 CL:12.5PF +/-20PPM

X201 SK490013584200 CRYSTAL 3.579545MHz HC-49/U CL:16PF

ZD003 SK4500400036T5 ZENER DIODE 3V6 1/2W +/-5%

ZD210 SK4500400082T0 ZENER DIODE 8V2 1/2W

ZD211 SK4500400082T0 ZENER DIODE 8V2 1/2W

ZD212 SK4500400082T0 ZENER DIODE 8V2 1/2W

ZD601 SK4500400039T0 ZENER DIODE 3V9 1/2W

ZD602 SK4500400150T0 ZENER DIODE 15V 1/2W

SK033YC3Y04200M CRT BOARD ASSEMBLY

C501 SK4300BC477E00 ELECTROLYTIC CAPACITOR 470uF 16V +/-20%

C502 SK4300AF103HT0 CERAMIC CAPACITOR 0.01uF 50V +80-20%

C503 SK4300BD106E00 ELECTROLYTIC CAPACITOR 10UF 25V +/-20%

C506C SK4300AT222DT0 CERAMIC CAPACITOR 0.0022UF 2KV +/-10%

C511 SK4300AF471CT0 CERAMIC CAPACITOR 470PF 50V +/-5%

C521 SK4300AF471CT0 CERAMIC CAPACITOR 470PF 50V +/-5%

C531 SK4300AF471CT0 CERAMIC CAPACITOR 470PF 50V +/-5%

CN201 SK540092500005 WAFER 2.5mm H X 5 PIN

CN201B SK540102046205 PIN 05 + HOUSING 05 (TJC3) + 460mm FLATCABLE UL2468 AWG24

CN301 SK540092500004 WAFER 2.5mm H X 4 PIN

CN301B SK540102040204 PIN 04 + HOUSING 04 (TJC3) + 400mm FLATCABLE (3C) UL2468 AWG22

CN504C SK610006010829 CRT SOCKET GZS10-2-108 E/E 15-18KV FOR 21"-29"

D501 SK4500215800T0 HIGH SPEED RECTIFIER DIODE BA158 600V/1A

D511 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D521 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

D531 SK4500141481T0 NORMAL RECTIFIER DIODE 1N4148 150mA/100V

J501 SK5900G4010600 COPPER JUMPER 0.6MM DIA. L=40mm

PGNDC SK540090000001 WAFER 2.35mm 1 PIN

Q501 SK4600C24822T0 TRANSISTOR 2SC2482/3DG2482Y

Q511 SK4600C2482201 TRANSISTOR 2SC2482

Q521 SK4600C2482201 TRANSISTOR 2SC2482

Q531 SK4600C2482201 TRANSISTOR 2SC2482

R501 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R502 SK4100AD2710T0 CARBON FILM RESISTOR 270 OHM 1/4W +/-5%

R511 SK4100AD1510T0 CARBON FILM RESISTOR 150 OHM 1/4W +/-5%

R512 SK4100AD2720T0 CARBON FILM RESISTOR 2.7K OHM 1/4W +/-5%

R513 SK4100AD3310T0 CARBON FILM RESISTOR 330 OHM 1/4W +/-5%

R514 SK4100BF2720T0 CARBON COMPOSITION RESISTOR 2.7K OHM 1/2W +/-5%

R515 SK4100DH123001 METAL OXIDE FILM RESISTOR 12K OHM 2W+/-5%

R521 SK4100AD1510T0 CARBON FILM RESISTOR 150 OHM 1/4W +/-5%

R522 SK4100AD2720T0 CARBON FILM RESISTOR 2.7K OHM 1/4W +/-5%

R523 SK4100AD3310T0 CARBON FILM RESISTOR 330 OHM 1/4W +/-5%

R524 SK4100BF2720T0 CARBON COMPOSITION RESISTOR 2.7K OHM 1/2W +/-5%

R525 SK4100DH123001 METAL OXIDE FILM RESISTOR 12K OHM 2W+/-5%

R531 SK4100AD1510T0 CARBON FILM RESISTOR 150 OHM 1/4W +/-5%

R532 SK4100AD2720T0 CARBON FILM RESISTOR 2.7K OHM 1/4W +/-5%

R533 SK4100AD3310T0 CARBON FILM RESISTOR 330 OHM 1/4W +/-5%

R534 SK4100BF2720T0 CARBON COMPOSITION RESISTOR 2.7K OHM 1/2W +/-5%

R535 SK4100DH123001 METAL OXIDE FILM RESISTOR 12K OHM 2W+/-5%

R540 SK4100DG154001 METAL OXIDE FILM RESISTOR 150K OHM 1W+/-5%

-31-

Page 32

location quantity description

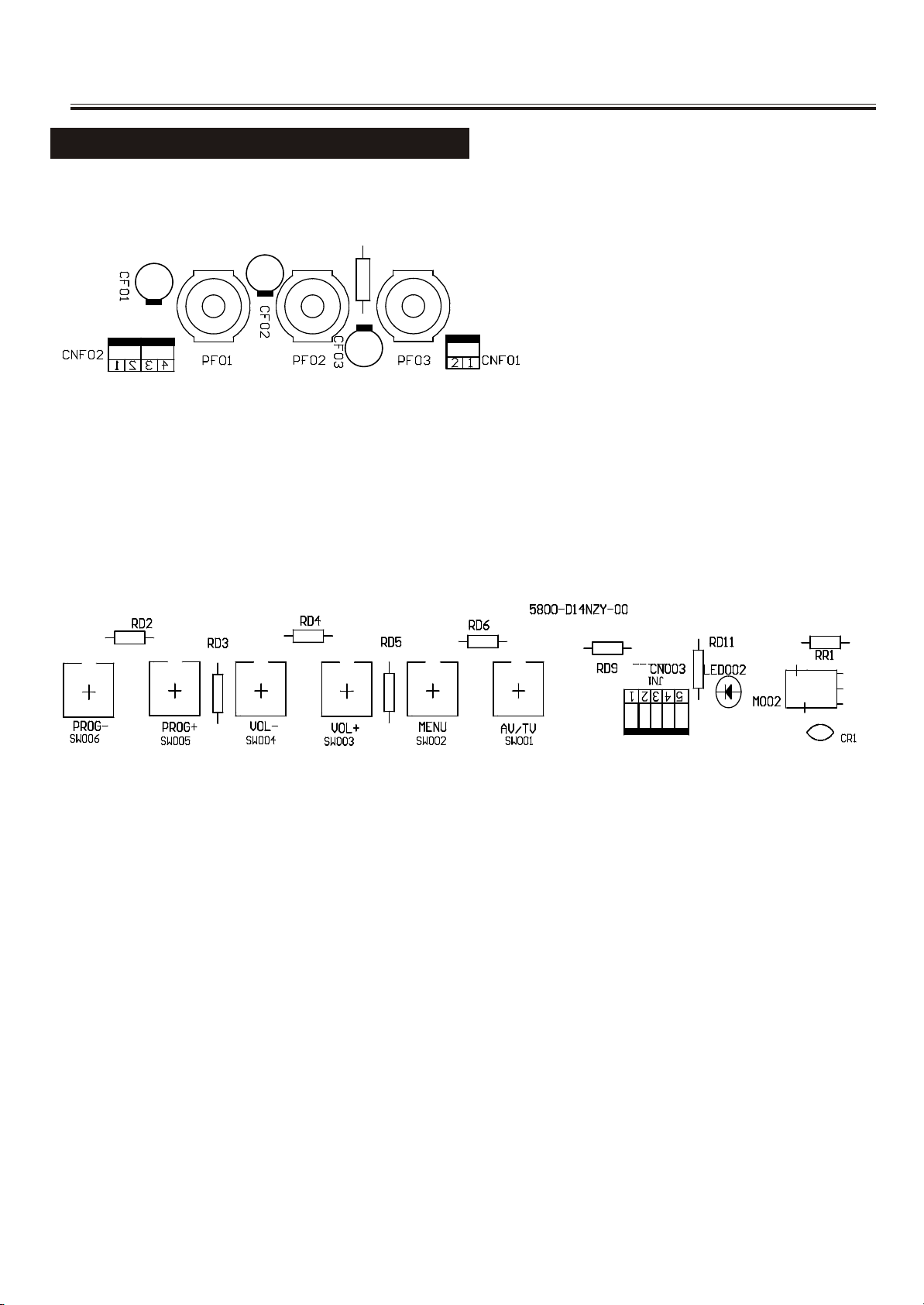

SK043YD21NZY01M CONTROL ASSEMBLY

CN001 SK540092500005 WAFER 2.5mm H X 5 PIN

CN0011 SK540142036205 90 DEGREE PIN 05+HOUSING 05(TJC3)+360mmFLAT CABLE UL2468 AWG26

CR1 SK4300AF223HT0 CERAMIC CAPACITOR 0.022uF 50V +80-20%

LED002 SK570015012000 LED LIGHT EMISSION 3.1mm RED LONG LEAD

M002 SK530014261100 INFRARED RECEIVER MODULE 38KHz GP1U261R/GP1UA261RK 90 DEGREE PIN

PCB SK5800D21NZY00 CONTROL P.C.BOARD 215 X 34 X 1.6mm 8 KEYS FOR 21NZ 3Y07

RD11 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

RD2 SK4100AD5630T0 CARBON FILM RESISTOR 56K OHM 1/4W +/-5%

RD3 SK4100AD2230T0 CARBON FILM RESISTOR 22K OHM 1/4W +/-5%

RD4 SK4100AD1130T0 CARBON FILM RESISTOR 11K OHM 1/4W +/-5%

RD5 SK4100AD6820T0 CARBON FILM RESISTOR 6.8K OHM 1/4W +/-5%

RD6 SK4100AD4720T0 CARBON FILM RESISTOR 4.7K OHM 1/4W +/-5%

RD7 SK4100AD4320T0 CARBON FILM RESISTOR 4.3K OHM 1/4W +/-5%

RD8 SK4100AD3020T0 CARBON FILM RESISTOR 3K OHM 1/4W +/-5%

RD9 SK4100AD2020T0 CARBON FILM RESISTOR 2K OHM 1/4W +/-5%

RR1 SK4100AD1000T0 CARBON FILM RESISTOR 10 OHM 1/4W +/ -5%

SW1 SK550011015000 TACT SWITCH VERTICAL TYPE H = 5mm KPT-1105A 4 PINS

SW2 SK550011015000 TACT SWITCH VERTICAL TYPE H = 5mm KPT-1105A 4 PINS

SW3 SK550011015000 TACT SWITCH VERTICAL TYPE H = 5mm KPT-1105A 4 PINS

SW4 SK550011015000 TACT SWITCH VERTICAL TYPE H = 5mm KPT-1105A 4 PINS

SW5 SK550011015000 TACT SWITCH VERTICAL TYPE H = 5mm KPT-1105A 4 PINS

SW6 SK550011015000 TACT SWITCH VERTICAL TYPE H = 5mm KPT-1105A 4 PINS

SK073YG21NZY03M FRONT AV IN ASSEMBLY

CF01 SK4300BB106E00 ELECTROL YTIC CAPACITOR 10uF 10V +/-20% (4 X 5mm)

CF02 SK4300BB106E00 ELECTROLYTIC CAPACITOR 10uF 10V +/-20% (4 X 5mm)

CF03 SK4300BB476E00 ELECTROLYTIC CAPACITOR 47UF 10V +/-20%

CNF01 SK540142360203 90 DEGREE PIN 03 + HOUSING 03 (TJC3) + 600mm SHIELD UL2547 AWG24

PCB SK5800G21NZY00 FRONT AV IN P.C.BOARD 83 X 30 X 1.6mm FOR 21NZ 3Y07

PF01 SK610016195121 RCA JACK H=19.5mm RED VERTICAL TYPE 3 PINS W/SW

PF02 SK610016195191 RCA JACK H=19.5mm WHITE VERTICAL TYPE 3PINS W/SW

PF03 SK610016195141 RCA JACK H=19.5mm YELLOW VERTICAL TYPE 3PINS W/SW

SK2021T3Y03102M TABLE ASSEMBLY

C311 SK4300EJ474C00 METALLIZED POLYPROPYLENE FILM CAPACITOR0.47uF 250V +/-5%

C313 SK4300ET192C00 METALLIZED POLYPROPYLENE FILM CAPACITOR0.0019uF 2KV +/-5%

C314 SK4300ET762C00 METALLIZED POLYPROPYLENE FILM CAPACITOR0.0076uF 2KV +/-5%

C327 SK4300EF334C00 METALLIZED POLYESTER FILM CAPACITOR 0.33UF 63-100V +/-5%

CRT SK500351000B02 21" SEG-HITACHI COLOR PICTURE TUBE A51JFC82 X 13(C) NTSC TYPE NORTH 29.1mm

H301 SK540025040205 HOUSING 05 + 400mm WIRE X 4 1=RED 3=BLUE4=YELLOW 5=GREEN UL1015 AWG22

H501 SK540021511301 HOUSING 01 + 380mm 1015#20 WIRE + 1060mmKNITTING COPPER WIRE (FOR 21" TV)

H602 SK480008230002 DEGAUSSING COIL FOR 21" TV L=2300mm T=70110V-260V

J143 SK4100DH220001 METAL OXIDE FILM RESISTOR 22 OHM 2W +/-5%

L301 SK480004440213 LINEAR COIL 44uH 13mm W/BRACKET FOR 14"-21" TV (SHORT LEAD PITCH=5mm)

R236 SK4100AD1020T0 CARBON FILM RESISTOR 1K OHM 1/4W +/-5%

R237 SK4100AD5640T0 CARBON FILM RESISTOR 560K OHM 1/4W +/-5%

R309 SK4100DG102001 METAL OXIDE FILM RESISTOR 1K OHM 1W+/-5%

R316 SK4100DH039001 METAL OXIDE FILM RESISTOR 3.9 OHM 2W+/-5%

R317 SK4100DH012001 METAL OXIDE FILM RESISTOR 1.2 OHM 2W+/-5%

R318 SK4100AD1040T0 CARBON FILM RESISTOR 100K OHM 1/4W +/-5%

R320 SK4100DH012001 METAL OXIDE FILM RESISTOR 1.2 OHM 2W+/-5%

R326 SK4100DH181001 METAL OXIDE FILM RESISTOR 180 OHM 2W +/-5%

R329 SK4100AD1030T0 CARBON FILM RESISTOR 10K OHM 1/4W +/-5%

R331 SK4100DG152001 METAL OXIDE FILM RESISTOR 1.5K OHM 1W +/-5%

-32-

Page 33

location quantity description

R628 SK4100AD2200T0 CARBON FILM RESISTOR 22 OHM 1/4W +/-5%

T302 SK510105110000 20" FLYBACK TRANSFORMER MULTI-LAYER JF0501-0500B FOCUS 23-31%

T603 SK510006350000 SWITCHING TRANSFORMER BCK-35-087A F OR 3Y03

SK273Y21NZNM00M NON COMMON PARTS FOR MODEL 21NANM

H601 SK5900A2231820 AC LINE CORD 2200mm (105C) W/HOLDER + 2PIN HOUSING X 1 + UL PLUG (GMU01)

SP- SK5900B7832200 MULTI TWIST WIRE #AWG22 1007 BLACK 780mm

SP+ SK5900B7832290 MULTI TWIST WIRE #AWG22 1007 WHITE 780mm

SPL SK560011605401 SPEAKER 16 OHM 5W 2 1/4 X 5 INCH FOR TV-2188

SPLINE SK540122050202 HOUSING 02 (TJC3) + 500mm WIRE X 2 1=BLACK 2=WHITE UL1007 AWG24

SPR SK560011605401 SPEAKER 16 OHM 5W 2 1/4 X 5 INCH FOR TV-2188

SW SK550021010400 TACT SWITCH FOR NTSC POWER ON/OFF

location quantity description

SK100521990001 1 JACK PLATE BRACKET - BLACK (HIPS)

SK190200821810 2 GROUNDING WIRE SPRING - FOR KNITTI NG WIRE

SK190300821810 2 GROUNDING WIRE - DIA. 0.6 SPRING WIRE

Miscellaneons

-33-

Page 34

SANYO Electric Co.,Ltd

Osaka,Japan

Loading...

Loading...