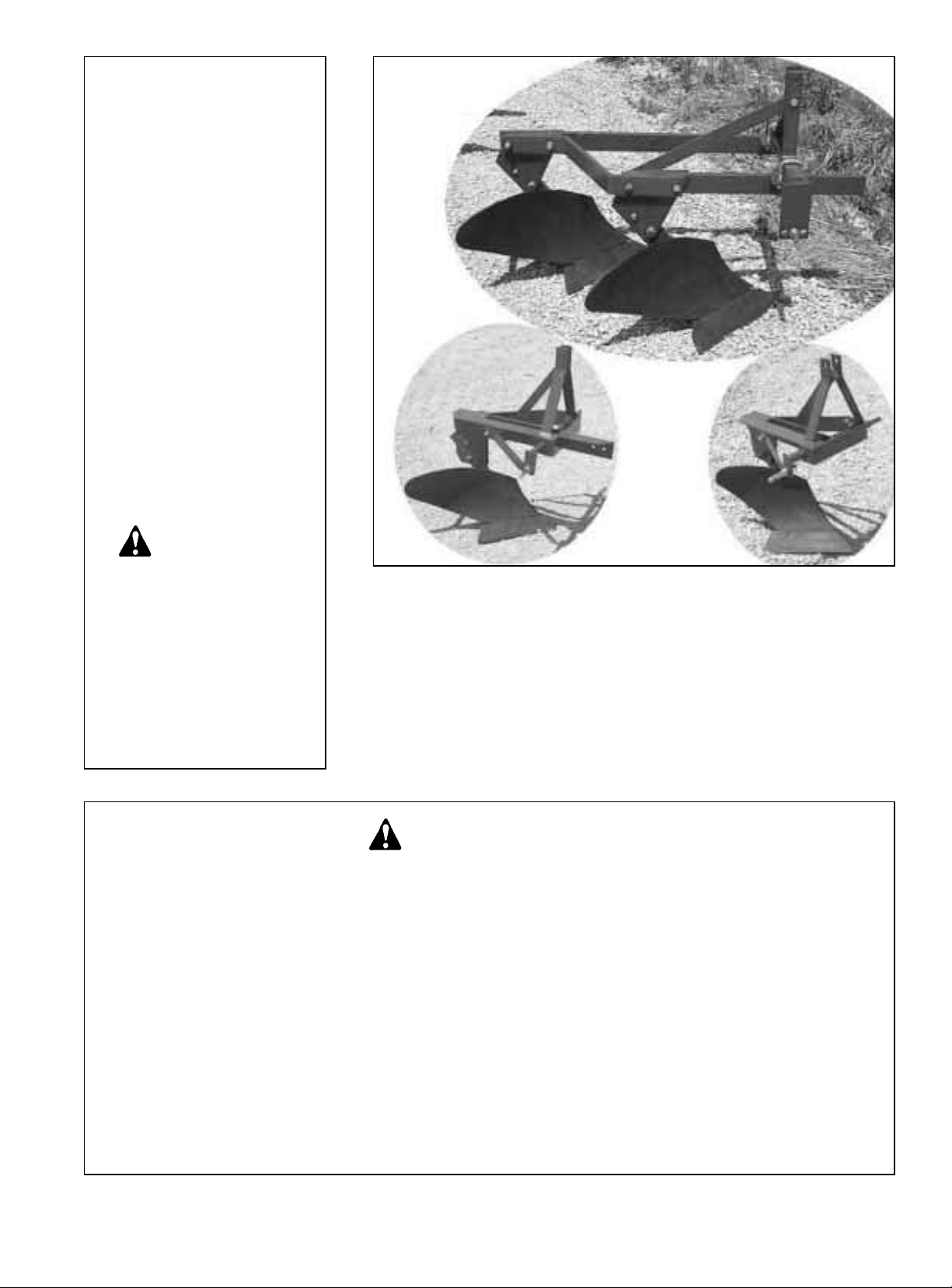

Farm Star MP-214 User Manual

OWNER’S/

OPERATOR’S

MANUAL

MODEL NO.’s

MPLP-112

MP-114

MP-214

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SINO LEEINGLES, PIDAAYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

3 PT. MOLDBOARD PLOWS

Safety Instructions Assembly & Mounting

Tractor Preparation Maintenance

Operating Instructions Repair Parts

2 Bottom

Standard

1 Bottom

Standard

Low

Profile

CAUTION

THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD

BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE

1. Select an area for assembly that is clean and free of any

debris which might cause persons working on the

assembly to trip.

2. Do not lift heavy parts or assemblies. Use crane, jack,

tackle, fork trucks or other mechanical devices.

3. Preview the assembly instructions in your operator’s

manual before proceeding further.

4. If the assembly instructions call for parts or assemblies to

be blocked up, use only blocking material that is in good

condition and is capable of handling the weight of the

assembly to be blocked. Also insure that the blocking

material is on a clean, dry surface.

5. Never put hands, or any part of body, under blocked up

assemblies if at all possible.

6. After completing assembly, thoroughly inspect the

machine to be sure that all nuts, bolts, hydraulic fittings

or any other fastened assemblies have been thoroughly

tightened.

7. Before operating the machine, thoroughly read the

operation section of your operator’s manual.

8. Before operating, read the maintenance section of your

operator’s manual to be sure that any parts requiring

lubrication, such as gearboxes, are full, to avoid any

possible damage.

9. Before operating equipment – If you have any

questions regarding the proper assembly or

operation, contact your dealer or representative.

1 22

TABLE

OF

CONTENTS

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . 8

OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . 13

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TO THE OWNER:

Read this manual before using your Moldboard Plow. This manual is provided to give you the necessary

operating and maintenance instructions for keeping your plow in top operating condition. Please read this manual thoroughly. Understand what each control is for and how to use it. Observe all safety signs on the machine

and noted throughout the manual for safe operation of implement. Keep this manual handy for ready reference.

Like all mechanical products, it will require cleaning and upkeep. Lubricate the plow as specified.

Use only genuine Farm Star service parts. Substitute parts will void the warranty and may not meet standards

required for safe and satisfactory operation. Record the model and serial number of your plow here:

Model:________________________________________ Serial Number:_______________________________

RETAIL CUSTOMER’S RESPONSIBILITY

It is the Retail Customer and/or Operator’s responsibility to read the Operator’s Manual, to operate,

lubricate, maintain, and store the product in accordance with all instructions and safety procedures.

Failure of the operator to read the Operator’s Manual is a misuse of this equipment.

It is the Retail Customer and/or Operator’s responsibility to inspect the product and to have any part(s)

repaired or replaced when continued operation would cause damage or excessive wear to other parts or

cause a safety hazard.

It is the Retail Customer’s responsibility to deliver the product to the authorized Farm Star Dealer, from

whom he purchased it, for service or replacement of defective parts which are covered by warranty.

Repairs to be submitted for warranty consideration must be made within forty-five (45) days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or hauling

of the product for the purpose of performing a warranty obligation or inspection.

SINO LEEINGLES, PIDA AYUDA A

AIGUIEN QUE SI LO LEA PARA QUE

LE TRADUZCA LAS MEDIDAS DE

SEGURIDAD.

STATEMENT

OF POLICY

It is the policy of Farm Star

to improve its products

where it is possible and practical

to do so. Farm Star

reserves the right to make

changes or improvements in

design and construction at any

time, without incurring the obligation to make these changes on

previously manufactured units.

T o the Owner/Operator/Dealer

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this

implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!!

Read the safety messages on the implement and shown in your manual.

Observe the rules of safety and common sense!

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT

SAFETY WARNING MESSAGES. CAREFULL YREAD EACH

WARNING MESSAGE THAT FOLLOWS. FAILURE TO

UNDERSTAND AND OBEY A SAFETY WARNING, OR

RECOGNIZE A SAFETY HAZARD, COULD RESULT IN AN

INJURY OR DEATH TO YOU OR OTHERS AROUND YOU.

THE OPERATOR IS ULTIMATELY RESPONSIBLE FOR THE

SAFETY OF HIMSELF, AS WELL AS OTHERS, IN THE

OPERATING AREA OF THE TRACTOR AND ATTACHED

EQUIPMENT.

IMPORTANT SAFETY INFORMATION!

Working with unfamiliar equipment can lead to careless injuries. Read this manual, and the manual for your tractor,

before assembly or operating, to acquaint yourself with the machines. It is the implement owner’s responsibility, if this

machine is used by any person other than yourself, is loaned or rented, to make certain that the operator, prior to

operating:

1. Reads and understands the operator’s manuals.

2. Is instructed in safe and proper use.

The use of this equipment is subject to certain hazards which cannot be protected against by mechanical

means or product design. All operators of this equipment must read and understand this entire manual, paying

particular attention to safety and operating instructions, prior to using. If there is something in this manual you

do not understand, ask your supervisor, or your dealer, to explain it to you.

THIS SYMBOL MEANS

– A TTENTION!

– BECOME ALERT!

– YOUR SAFETY IS INVOLVED!

UNDERSTAND SIGNAL WORDS

Note the use of the signal words DANGER, WARNING

and CAUTION with the safety messages. The

appropriate signal word for each has been selected

using the following guidelines:

DANGER: Indicates an imminently hazardous situation

that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme

situations typically for machine components which, for

functional purposes, cannot be guarded.

If you have questions not answered in this manual or require additional copies or the manual is damaged, please

contact your dealer or the manufacturer directly.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury, and includes hazards that are

exposed when guards are removed. It may also

be used to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

3 20

SAFETY INFORMATION (continued)

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every year many

accidents occur which could have been avoided by a few seconds of thought and a more careful approach to

handling equipment. You, the operator, can avoid many accidents by observing the following precautions in

this section. To avoid personal injury, study the following precautions and insist those working with you, or for

you, follow them.

To prevent injury or death, use a tractor equipped with a Roll-Over Protective System (ROPS). Do not paint

over, remove or deface any safety signs or warning signs on your equipment. Observe all safety signs and

practice the instruction on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in question –

DON’T TRY IT.

Do not modify the equipment in any way. Unauthorized modification may impair the function and/or safety and

could affect the life of the equipment.

In addition to the design and configuration of this implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also

to Safety Messages and Operation Instructions in each of the appropriate sections of the Tractor and

Implement Manuals. Pay close attention to the Safety Signs affixed to the Tractor and the Implement.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations. Do not allow

persons to operate or assemble this unit until they have read this manual and have developed a

thorough understanding of the safety precautions and of how it works.

EQUIPMENT SAFETY GUIDELINES

Keep safety signs clean and legible at all times.

Replace safety signs that are missing or have become illegible.

Replaced parts that displayed a safety sign should also display the current sign.

Safety signs are available from your Distributor or Dealer Parts Department or the factory.

SAFETY SIGNS

SAFETY INFORMATION

(continued)

All equipment is potentially hazardous. There is no substitute for a cautious, safe-minded operator who

recognizes potential hazards and follows reasonable safety practices.

When the use of hand tools is required to perform any part of assembly, installation, adjustment, maintaining,

repairing of the implement, be sure the tools used are designed and recommended by the tool manufacturer

for that specific task.

Personal protection equipment including safety glasses, safety shoes, and gloves are recommended during

assembly, installation, operation, adjustment, maintaining, repairing of the implement.

Always use two people to handle heavy, unwieldy components during assembly, installation of the implement.

Never place any part of your body where it would be in danger if movement should occur during assembly,

installation, operation, maintaining, repairing of the implement.

Never place yourself between the tractor and implement while implement is in operation.

Do not work under a raised implement unless it is securely blocked or held in position. Do not depend on the

tractor hydraulic system to hold the implement in place.

Aheavy load can cause instability of the tractor . Use extreme care during travel. Slow down on turns and watch

out for bumps. The tractor may need front counter-weights to counter-balance the weight of the implement.

Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating this

equipment. Consult your doctor about operating this machine while taking prescription medications.

Do not allow others to ride on the tractor with an operator. Riders are subject to injury such as being struck by

foreign objects or being thrown off. Riders obstruct the operator’s view resulting in unsafe operation. Never

allow anyone to ride on the implement!

Before you operate the equipment, check over all pins, bolts and connections to be sure all are securely in

place. Replace any damaged or worn parts immediately.

Do not allow anyone who is not familiar with the safety rules and operation instructions to use this equipment.

Never allow children to operate or be around equipment.

Know your controls and how to stop tractor, engine, and implement quickly in an emergency. Read this

manual and the one provided with your tractor.

Keep alert and watch the front as well as the rear when working with equipment.

5 18

SAFETY INFORMATION (continued)

When maneuvering close to buildings or passing through narrow areas, be sure to allow sufficient clearance

for the implement and tractor.

Do not operate close to ditches or creeks. Slow down when operating over rough ground.

When removing, or adjusting equipment, be sure that your feet are never under the implement.

Be careful to avoid catching the implements on stumps, rocks, or other immovable objects.

Use extra care when working on slopes.

Avoid excessive speed during operation.

Make implement adjustments only when the implement is attached to the tractor.

Do not replace shear bolt with a hard bolt. Damage could result to implement and sudden stop to tractor could

dislodge operator from tractor seat causing injury.

Always ease the tractor into the load.

Never operate tractor and implement under trees with low hanging limbs. Operators can be knocked off the

tractor and then run over by the implement.

When driving the tractor and equipment on the road or highway under 20 mph (32 kph) at night or during the

day, use flashing amber warning lights and a slow moving vehicle (SMV) identification emblem.

Always be sure the implement is in the proper raised position for transport.

Reduce speed when transporting mounted implements to avoid bouncing and momentary loss of steering

control. Reduce speed on rough roads.

Coulter blades are sharp. Do not allow blades to roll over or fall onto any part of body. Do not allow wrenches

to slip when working near coulter blades. Do not climb over machine above coulter blades when there is a

possibility of slipping and falling on them. Serious injury can result from carelessness while working near

coulter blades.

Be certain the tractor is in neutral or park position before starting engine.

Take all possible precautions when leaving unit unattended: Disengage PTO, set parking brake, stop engine

and remove key from ignition. Park in level area.

SAFETY INFORMATION

(continued)

Following operation or when unhooking, stop the tractor, set the brakes, shut off the engine, relieve all

hydraulic pressure and remove the ignition keys.

Store the unit in an area away from human activity. Do not park equipment where it will be exposed to livestock for long periods of time. Damage and livestock injury could result.

Do not permit children to play on or around the stored unit.

Make sure all parked machines are on a hard, level surface and engage all safety devices.

If blocking is used, make sure it is solid and secure before leaving area.

Never replace hex bolts with less than grade five bolts unless otherwise specified, i.e. shear bolts. Refer to

bolt torque chart for head identification marking.

Where replacement parts are necessary for periodic maintenance and servicing, genuine factory replacement

parts must be used to restore your equipment to original specifications. The manufacturer will not claim

responsibility for use of unapproved parts and/or accessories and other damages as a result of their use.

If equipment has been altered in any way from original design, the manufacturer does not accept any liability

for injury or warranty.

Never work under equipment unless it is blocked securely. Never depend on hydraulic system to keep implement in raised position.

Keep all persons away from operator control area while performing adjustments, service, or maintenance.

Turn curves or go up or down hills only at a low speed and at a gradual steering angle. Make certain that at

least 20% of the tractor’s weight is on the front wheels to maintain safe steerage. Slow down on rough or

uneven surfaces, and loose gravel.

Pick up all rocks and other debris before operation. Enter new areas carefully. Never assume an area is clear.

Always Check!

7 16

TRACTOR REQUIREMENTS

AND PREPA R ATION

The One and Two Bottom Moldboard Plows provide

excellent soil tillage for small and hobby farms. Each

plow has shear-bolt protection to protect the unit from

underground objects.

The “low profile” one bottom 12” plow is designed for

small tractors having low profile configuration and a Cat.

O (20” spacing) or a Cat. I (26” spacing) with 7/8” pull

pins.

Coulters and trashboards are NOT available for this

model.

The one and two bottom 14” plows are for standard

size tractors equipped with a Cat. I (26” spacing) 3 pt.

hitch.

Generally, it requires 1 hp for each 1 inch of moldboard

plow width, ie, 12” plow requires 12 hp, 14” plow requires

14 hp, and a two bottom 14” plow requires 28 hp. Small

compact tractors may need to be larger than this general

rule.

Check the tractor’s 3-point hydraulic lift system. It

should operate up and down smoothly and hold its

position when set. Refer to your tractor owner’s manual

or dealer for any adjustments necessary to put the 3point hydraulic lift system in good working order. (I&T

shop manuals will list most specifications and adjustment

instructions – available from most farm equipment

dealers.)

Check the hydraulic system. Be sure the tractor

hydraulic oil and filter have been serviced according to

the tractor manufacturer’s recommendations.

Smaller size tractors may need front counter weights to

counter-balance the weight of the implement.

It is recommended that the tractor be equipped with a

Rollover Protection System (ROPS) and a seat belt that

is used.

It is important that your tractor be properly prepared to

obtain the best and safest operation from your plow. The

following procedures are recommended. In addition,

review your tractor manual for instructions on adjustments and use of three point hitch control features,

ballast weighting, and tire pressures.

BALLAST WEIGHTING

Mounted plows normally require added weight to the

tractor to maintain proper stability and traction during

operation and transport.

1) An 80% tire fill of ballast fluid is usually enough for the

rear tires. It may be necessary in some cases to add

metal weights to prevent tire slippage.

2) Add front end weights if there is floating action on the

front of the tractor when plowing. Approximately 100 lbs.

of additional front end weight is usually needed for each

plow bottom when working in average soil.

3) To determine proper weighting, check the soil

between the rear tire lug prints. When pulling a full plow

load, the soil should be broken or shifted slightly. Too

much weight will cause sharp, firm tread marks. Slippage

results from insufficient weight, will show up in poorly

defined tread marks.

WHEEL TREAD SETTINGS

Fig. 1 & Table 1 (page 9)

The rear tractor wheel measurements should be made

from center line of tractor to inside wall of tires. The right

tractor wheel should be set to correspond exactly with

the right rear wheel as measured to inside walls of the

tires. See table 1 for correct wheel spacings for number

and size of plow bottoms being used.

TIRE INFLATION

Proper tire inflation can be determined by checking the

tire lugs on a cement surface. The tire is correctly inflated if approximately 90% of the lug makes contact with

the surface when the tractor is fully weighted.

COULTER ATTACHMENT

Rolling coulters are recommended to make plowing

smoother and neater. Coulters also make plowing easier

by reducing drag. (Not available on 12” low profile

model.)

NOTE: Quick hitches cannot be used with these 3 pt.

moldboard plows. They must connect directly to the

tractor lift arms.

INSTRUCTIONS

Be sure your tractor is in good condition and

properly equipped with counter weights. Read all the

safety precautions and make sure all tractor

operators are familiar with the safety rules of tractor

operation.

CAUTION!

Loading...

Loading...