Page 1

GE Fanuc Automation

Computer Numerical Control Products

Super CAP T and Super CAP II T

for Series 16/18-TB, 16/18-TC, and 16i/18i-TA

Operator's Manual

GFZ-62444E-1/04 October 1997

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

PowerMotion is a trademark of GE Fanuc Automation North America, Inc.

©Copyright 1997 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

SAFETY PRECAUTIONS

When using a machine equipped with the F ANUC Super CAP T and F ANUC Super CAP II T, be sure to observe

the following safety precautions.

s–1

Page 4

1

SAFETY PRECAUTIONS

B–62444E–1/04

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

s–2

Page 5

B–62444E–1/04

2

SAFETY PRECAUTIONS

GENERAL WARNINGS AND CAUTIONS

WARNING

1.

Before starting to use the conversational functions (such as creation/run of machining programs,

measurement of tool compensation, and specification of a chuck barrier), close the doors of the

machine, and take any other necessary safety measures.

Failure to take a necessary safety measure may bring about the death of, or a serious injury to,

the user.

2.

Before going to the next step of handling or operation, check the display on the screen carefully

to assure that the intended data has been entered correctly.

If the machine is used with incorrect data, the tool may bump against the machine and/or

workpiece, possibly causing damage to the tool and/or machine, and even injuries.

3.

When you are using a tool compensation function, before starting the machine, check the

direction and amount of compensation so that the tool will not bump against the workpiece or

machine.

If the tool bumps against the machine and/or workpiece, the tool and/or machine may be

damaged, and even injuries may occur.

4.

After you create a machining program using a conversational function, do not run the machine

on that program immediately . Instead, carry out machining simulation to make sure that the tool

path and machining operation are correct and that the tool will not bump against the workpiece

or machine (including the chuck and tailstock).

If the tool bumps against the machine and/or workpiece, the tool and/or machine may be

damaged, and even injuries may occur.

5.

After you convert a machining program created using a conversational function to NC program

format, do not run the machine on that program immediately . Instead, confirm every step of the

resultant NC program, and make sure that the tool path and machining operation are correct and

that the tool will not bump against the workpiece or machine (including the chuck and tailstock).

Before starting production machining, run the machine with no workpiece attached to the

machine to make sure that the tool will not bump against a workpiece (when attached) or the

machine (including the chuck and tailstock).

If the tool bumps against the machine and/or workpiece, the tool and/or machine may be

damaged, and even injuries may occur.

6.

Before starting to create a machining program using a conversational function, make sure that

all necessary data among the tool data, cutting condition data, surface roughness data, pre–tool

list, and chuck and tailstock data, and all parameters necessary for the conversational function

are set correctly.

If the necessary data is not set correctly , any required cutting conditions will not be set correctly ,

possibly causing damage to the tool, and even injuries.

s–3

Page 6

SAFETY PRECAUTIONS

B–62444E–1/04

W ARNING

7.

When you run the machine using a machining program created using a conversational function

or a machining program generated by converting another machining program to NC program

format, be sure to use the correct tool geometry compensation data measured on the relevant

measurement guidance screen provided by the conversational function.

If the machine is used with incorrect data, the tool may bump against the machine and/or

workpiece, possibly causing damage to the tool and/or machine, and even injuries.

The method to measure the tool compensation amount may be provided by the machine tool

builder. If this is the case, before starting measurement, read carefully and understand

sufficiently the applicable user’s guide from the machine tool builder.

8.

Before using a chuck barrier or chuck/tailstock barrier, perform a manual operation (such as jog

feed or manual pulse generator feed) to make sure that the barrier area data is set correctly , that

the barrier function occurs at the correct position, and that the tool will not bump against the

chuck or tailstock.

If the tool bumps against the chuck and/or tailstock, the tool and/or machine may be damaged,

and even injuries may occur.

9.

When pressing the power ON button, do not touch any key on the keyboard before a display

appears on the screen. Some keys on the keyboard are allocated to maintenance or other special

operations. Pressing any of these keys may cause the machine to behave unexpectedly.

s–4

Page 7

B–62444E–1/04

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. GENERAL

1. OVERVIEW 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SYMBOLS USED 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. FLOWCHART FROM CREATING A PROGRAM TO EXECUTING IT 6. . . . . . . . . . . . . .

3.1 CREATING A MACHINING PROGRAM 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 CHECKING A MACHINING PROGRAM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 SELECTING A MACHINING PROGRAM TO BE EXECUTED 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. SELECTING THE MENU AND INPUTTING DATA 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 SOFT KEYS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 CALCULATION FUNCTIONS SIMILAR TO THOSE OF A HAND–HELD CALCULATOR 12. . . .

4.2.1 Operation for Calculation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Keys for Calculation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. HIERARCHY OF THE CONVERSATIONAL SCREENS 15. . . . . . . . . . . . . . . . . . . . . . . . .

II. OPERATION

1. OVERVIEW OF THE PROCEDURE 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. DESCRIPTION OF THE KEYBOARD 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 KEYBOARD TYPES 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 DETAILS OF THE KEYBOARD 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. OPERATION MODES 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TYPES OF SCREENS 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 ONE–PATH LATHES 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 TWO–PATH LATHES 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. DESCRIPTION OF COORDINATE SYSTEMS 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 ONE–PATH LATHER 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Machine Coordinate System 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Workpiece Coordinate System 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Program Coordinate System 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 8

T ABLE OF CONTENTS

5.2 TWO–PATH LATHES WITH TWO OPPOSING SPINDLES 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Machine Coordinate System 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Workpiece Coordinate System 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Program Coordinate System 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 FOR TWO–PATH LATHES WITH ONE SPINDLE 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Machine Coordinate System 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Workpiece Coordinate System 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Program Coordinate System 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62444E–1/04

6. CREATING MACHINING PROGRAMS 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 FORMAT OF MACHINING PROGRAM USED FOR THE ONE–PATH LATHES 54. . . . . . . . . . . . .

6.2 FORMAT OF MACHINING PROGRAM USED FOR THE TWO–PATH LATHES 55. . . . . . . . . . . . .

6.3 SELECTING THE CONVERSATIONAL MODE 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 CREATING A MACHINING PROGRAM 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Entering the Number and Name of a Program 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 INITIAL SETTINGS 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Details of Settings 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Operation for Initial Settings 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 PROCESS DATA SCREEN 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Operation for the Process Data Screen 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 FIGURE DATA SCREEN 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Operation on the Contour Data Screen 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 Operation for Data other than Contour Data on the Figure Data Screen 70. . . . . . . . . . . . . . . . . . .

6.8 CREATING A NEW PROGRAM USING OTHER PROGRAMS 72. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.1 Registered–program Directory Screen for Editing 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.2 Copying a Program 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. CHECKING MACHINING PROGRAMS 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 CHECKING INPUT FIGURES 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Registered–program Directory Screen for Editing 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Specifying the Program to be Edited 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Displaying the Contents of the Machining Program 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Enlarging the Part of the Contour 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 End of Checking Machining Programs 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 CHECKING MACHINING PROGRAMS USING THE SIMULATION 77. . . . . . . . . . . . . . . . . . . . . .

7.2.1 Selecting a Machining Program 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Simulating Machining 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Enlarging a Figure and Displaying Other Screens 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 SIMULATION OF Y–AXIS MACHINING 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Simulation of Y–axis Machining by a One–path Lathe 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Simulation of Y–axis Machining by a Two–path Lathe 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 OFFSET DATA SAVE AND RESTORE FUNCTION 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Generals 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 Parameter 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.3 Details 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.4 Execution Selection State Display 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.5 Tool Changing Position Temporary Setting 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.6 Alternation of G30 Command in Macro Program 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 9

B–62444E–1/04

7.5 MACHINING SIMULATION BASED ON A SOLID MODEL (SUPER CAP II T) 91. . . . . . . . . . . . .

7.5.1 Simulating a Cutting Operation Based on a Solid Model 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Simulation of C–/Y–axis Machining 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

8. EDITING MACHINING PROGRAMS 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 SELECTING THE MACHINING PROGRAM TO BE EDITED 95. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Registered–program Directory Screen for Editing 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Selecting a Machining Program 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 EDITING A MACHINING PROGRAM IN UNITS OF PROCESSES (PROGRAM SCREEN) 97. . . .

8.2.1 Deleting a Process 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Adding a New Process 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 CHANGING THE PROCESS DATA 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 CHANGING PART OF THE CONTOUR DATA 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Changing Entered Figure Data 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Changing the Figure 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Adding a Figure 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.4 Deleting a Figure 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 CHANGING FIGURE DATA OTHER THAN CONTOUR DATA 105. . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 EDITING MACHINING PROGRAMS IN UNITS OF PROCESSES

(PROCESS EDITING SCREEN) 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 Displaying the Process Directory Screen 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Moving a Process for a Tool Post 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.3 Moving a Process between the Two Tool Posts 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.4 Copying a Process 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.5 Deleting a Process 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.6 Searching for a Process (Editing) 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 AUTOMATIC SCHEDULING 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.1 Operation of Automatic Scheduling 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.2 Details of Automatic Scheduling 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 DELETING MACHINING PROGRAMS 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 EDITING NC PROGRAMS (CROSS EDITING) 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. OUTPUTTING MACHINING PROGRAMS 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. READING MACHINING PROGRAMS 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. CONVERTING MACHINING PROGRAMS INTO NC PROGRAMS 120. . . . . . . . . . . . . .

11.1 CONVER TING A MACHINING PROGRAM TO AN NC PROGRAM 121. . . . . . . . . . . . . . . . . . . . . .

11.1.1 Registered–program Directory Screen for Conversion to NC Program 121. . . . . . . . . . . . . . . . . . .

11.1.2 Converting a Machining Program to an NC Program 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.3 Entering Setting Data Before Execution 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 ALARMS DURING CONVERSION OF THE MACHINING PROGRAM

INTO THE NC PROGRAM 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 SETTING THE READER/PUNCH INTERFACE 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 10

T ABLE OF CONTENTS

B–62444E–1/04

12. DIRECT OPERATION FOR MACHINING PROGRAMS CREATED

CONVERSATIONALLY 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 OPERATION BEFORE EXECUTION

(SUCH AS SELECTING A PROGRAM, MOUNTING A TOOL, ETC.) 127. . . . . . . . . . . . . . . . . . . . .

12.1.1 Displaying the Registered–program Directory Screen for Direct Operation 127. . . . . . . . . . . . . . .

12.1.2 Specifying a Machining Program 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.3 Setting Data on the Setting Screen Before Execution 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.4 Mounting Tools 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.5 Measuring Tool Geometry Compensation when no Tool Setter is Used 137. . . . . . . . . . . . . . . . . .

12.1.6 Measuring Tool Geometry Compensation when a Tool Setter is Used 143. . . . . . . . . . . . . . . . . . .

12.1.7 Chuck Barrier 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.8 Chuck/Tailstock Barrier 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 EXECUTING MACHINING PROGRAMS 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.1 Starting Execution of Machining Programs 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.2 Override Playback Function 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.3 Execution of a Conversational Machining Program After Conversion to an NC Program 159. . . .

13. SETTING DATA 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 TOOL DATA FILE 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.1 Displaying the Tool Data Directory Screen 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.2 Operations on the Tool Data Directory Screen 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.3 Tool Data for Machining Outer Surfaces, Inner Surfaces, End Faces,

and Inner Bottom Faces 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.4 Tool Data for External Threads and Internal Threads 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.5 Tool Data for Grooving on Outer Surfaces, Inner Surfaces, and End Faces 172. . . . . . . . . . . . . . .

13.1.6 Tool Data for Drilling 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.7 Tool Data for Tapping 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.8 Tool Data for Center Drills 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.9 Tool Data for Throw–away Drills 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.10 Tool Data for End Mills 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.11 Tool Data for Side Cutters 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.12 Tool Data for Chamfering 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.13 Tool Data for Reamers 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.14 Tool Data for Boring 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.15 Automatic Tool Specification Function 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.16 Tool Geometry Data for Drawing 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.17 Details of the Automatic Setting of Tool Geometry Data for Drawing 198. . . . . . . . . . . . . . . . . . .

13.2 MACHINING CONDITION DATA AND SURFACE ROUGHNESS DATA 203. . . . . . . . . . . . . . . . . .

13.2.1 Machining Condition Data for General–purpose Tools 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.2 Cutting Condition Data for Threading Tools 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.3 Cutting Condition Data for Grooving Tools 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.4 Cutting Condition Data for Drilling Tools 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.5 Cutting Condition Data for Tapping Tools 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.6 Cutting Condition Data for C–axis/Y–axis Machining Tools 209. . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.7 Coefficients 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.8 Surface Roughness Data 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 PRE–TOOL LIST 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 11

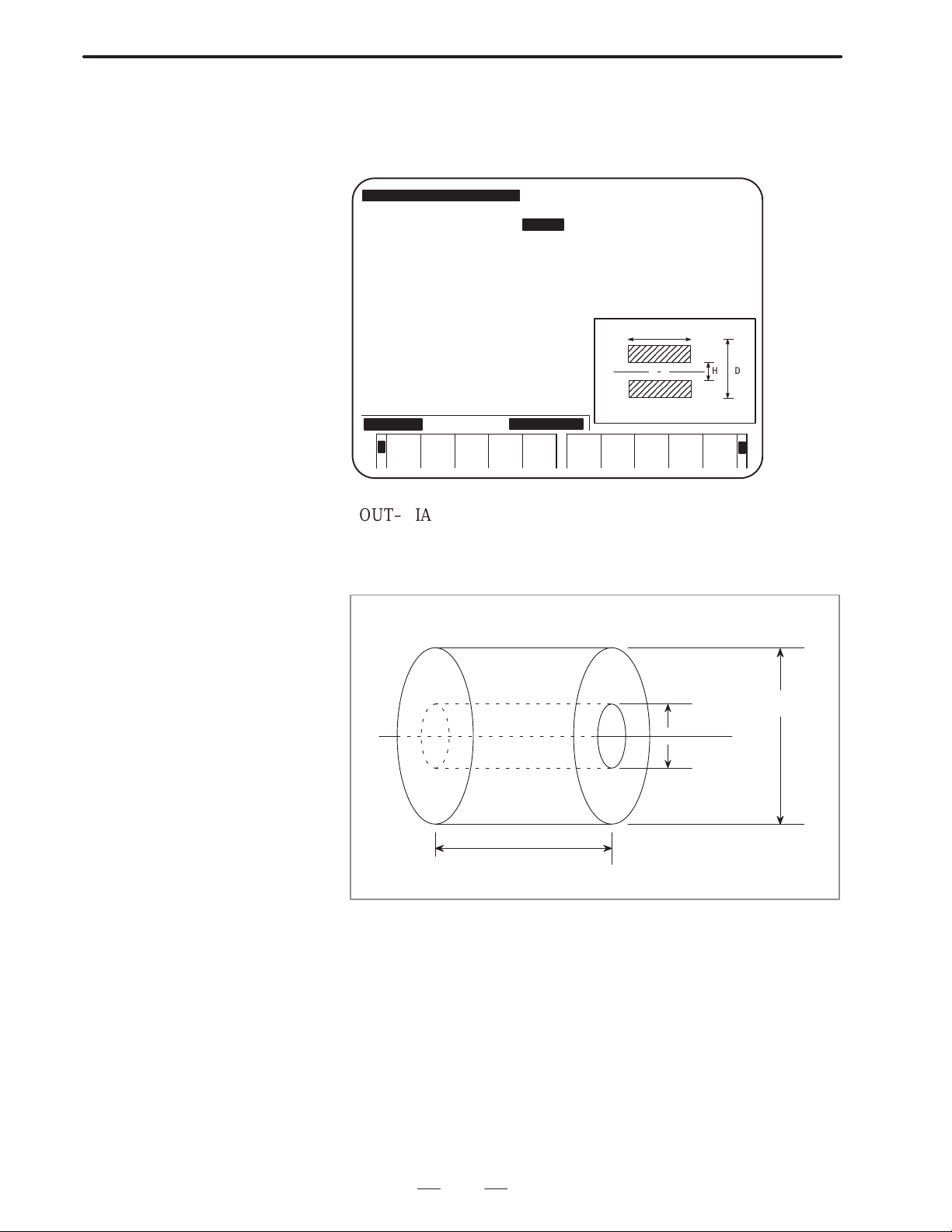

B–62444E–1/04

13.4 CHUCK/TAIL STOCK FIGURE DA TA 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.1 Chuck Figure Data 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.2 Chuck Data Extension Function (Optional) 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.3 Tail Stock Figure Data 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 PUNCHING OUT SETTING DATA 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6 READING SETTING DATA 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 CLEARING SETTING DATA 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

14. BATCH DATA INPUT/OUTPUT FUNCTION 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 DATA THAT CAN BE ENTERED AND OUTPUT 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 DATA OUTPUT 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 DATA INPUT 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 I/O PARAMETER DISPLAY 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15. CHANGING SCREEN DISPLAY COLORS (Super CAP II T) 237. . . . . . . . . . . . . . . . . . .

15.1 HOW TO CHANGE DISPLAY COLORS 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 STORING AND CALLING DISPLAY COLOR DATA 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2.1 Storing Display Color Data 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2.2 Calling Display Color Data 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III. TYPES OF MACHINING PROGRAMS

1. MACHINING PROGRAMS FOR 2–AXES (X AND Z AXIS) LATHES 246. . . . . . . . . . . .

1.1 BAR MACHINING 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Machining Type Selection 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Details of Setting Data 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Details of Figure Data 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Details of Contour Calculation 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 Partially Enlarged Drawing of a Contour 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.6 Automatic Residual Machining Function 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.7 Details of Bar Machining 276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.8 Entering Contour Data for Machining on the 2–Path Lathe with Two Spindles Facing

Each Other 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.9 Entering Contour Data for Machining on the Single–spindle 2–path Lathe (16–TB) 281. . . . . . . .

1.1.10 Null Cutting Cancel Function 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.11 Compensation by Tool Cutting Edge 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.12 Bar and Pattern Repeating Finishing Processing without Using G41/G42 Command 290. . . . . . . .

1.1.13 Improving the Machining of Figures that Differ Slightly in Level 291. . . . . . . . . . . . . . . . . . . . . .

1.2 PA TTERN REPEATING 292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Machining Type Selection 292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Details of Setting Data 293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Figure Data Input 293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Details of Pattern Repeating 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Automatic Reverse Machining 296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Compensation by Tool Cutting Edge 296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 12

T ABLE OF CONTENTS

1.2.7 Improvement of Pattern Repeating Cutting Retract Movement 297. . . . . . . . . . . . . . . . . . . . . . . . .

1.2.8 Pattern Repeating Approach to Shape Start Point 300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.9 Bar and Pattern Repeating Finishing Processing without Using G41/G42 Command 304. . . . . . . .

1.3 RESIDUAL MACHINING 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Machining Type Selection 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Details of Process Data 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Details of Figure Data 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Details of Residual Machining 312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 END FACING 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Machining Type Selection 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Details of Process Data 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 Details of End Facing 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 THREADING 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Machining Type Selection 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Details of Process Data 316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 Details of Figure Data 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.4 Details of Threading 326. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 GROOVING 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Machining Type Selection 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Details of Process Data 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3 Details of Figure Data 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.4 Details of Grooving 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 NECKING 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 Machining Type Selection 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Details of Process Data 346. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.3 Automatic Tool Selection 351. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.4 Details of Figure Data 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.5 Details of Necking 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 CENTER DRILLING, DRILLING, REAMING, BORING, AND TAPPING 354. . . . . . . . . . . . . . . . . .

1.8.1 Machining Type Selection 355. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 Process Data 356. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.3 Automatic Pre–tool Determination Function 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 SINGLE ACTION 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.1 Machining Type Selection 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.2 Details of Process Data 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.3 Details of Figure Data 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.4 Figure Data Input Operation 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.5 Selecting the Type of Machining (Single Action II) 368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.6 Process Data (For Single Action II) 368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.7 Figure Data (For Single Action II) 369. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 CALLING SUBPROGRAMS 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Machining Type Selection 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 Details of Process Data 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.3 Notes on Subprograms 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.4 Selecting the Type of Machining (For Sub–call II) 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.5 Process Data (For Sub–call II) 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.6 Subprograms to be Called (Sub–call II) 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.7 NC Program Conversion For Sub–call II 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62444E–1/04

c–6

Page 13

B–62444E–1/04

1.11 AUXILIARY AND TRANSFER PROCESSES 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12 M–CODE AND PROGRAM END PROCESSES 375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.1 M–code Process 375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.2 Program End Process 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

2. MACHINING PROGRAMS FOR LATHES WITH C–AXIS 377. . . . . . . . . . . . . . . . . . . . . .

2.1 CENTER DRILLING, DRILLING, REAMING, AND TAPPING FOR END FACES 378. . . . . . . . . . .

2.1.1 Machining Type Selection 378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Details of Process Data 379. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Details of Figure Data 382. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Automatic Pre–tool Selection Function 384. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 CENTER DRILLING, DRILLING, REAMING, AND TAPPING FOR SIDE FACES 385. . . . . . . . . .

2.2.1 Machining Type Selection 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Details of Process Data 386. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Details of Figure Data 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Automatic Pre–tool Selection Function 390. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 GROOVING FOR END F ACES 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Machining Type Selection 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Details of Process Data 392. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Details of Figure Data 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 C–AXIS GROOVING FOR SIDE FACES 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Machining Type Selection 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Details of Process Data 399. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Details of Figure Data 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 C–AXIS NOTCHING FOR END FACES 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Machining Type Selection 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Details of Process Data 407. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Details of Figure Data 408. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Details of C–axis Notching 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 NC Program Conversion for C–axis Notching 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 C–AXIS NOTCHING FOR SIDE FACES 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Machining Type Selection 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Details of Process Data 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Details of Figure Data 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Details of C–axis Notching for Side Faces 417. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 C–AXIS CYLINDRICAL MACHINING 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Machining Type Selection 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Details of Set Data 419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Details of Figure Data 421. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 Details of Cylindrical Machining 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CREATING MACHINING PROGRAMS FOR A LATHE HAVING

THE Y–AXIS MACHINING FUNCTION 424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Y–AXIS CENTER DRILLING, DRILLING, AND TAPPING (ON THE END FACE) 425. . . . . . . . . .

3.1.1 Selecting a Machining Type 426. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Setting 427. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Figure Data 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Automatic Pre–tool Selection Function 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 14

T ABLE OF CONTENTS

3.2 CENTER DRILLING, DRILLING, REAMING, AND TAPPING (ON THE SIDE FACE) 434. . . . . . .

3.2.1 Machining Type Selecting 436. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Process Data 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Figure Data 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Automatic Pre–tool Selection Function 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Y–AXIS MILLING (ON THE END FACE) 443. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Machining Type Selection 443. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Process Data 444. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Figure Data 446. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Y–AXIS MILLING (ON THE SIDE FACE) 448. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Machining Type Selection 449. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Setting 450. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Figure Data 452. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62444E–1/04

4. CONVERTING A MACHINE PROGRAM IN THE RIGHT–HAND COORDINATE

SYSTEM TO THAT IN THE LEFT–HAND COORDINATE SYSTEM 454. . . . . . . . . . . . .

4.1 OVER VIEW 455. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 DETAILS OF CONVERSION TO MACHINING PROGRAM IN THE LEFT–HAND

COORDINATE SYSTEM 457. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Conversion of Machining Programs 457. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Restrictions on Conversion to Machining Programs in the Left–hand Coordinate System 458. . . .

5. BACK MACHINING FUNCTIONS FOR A LATHE WITH A SUB–SPINDLE 459. . . . . .

5.1 SELECTING THE SUB–SPINDLE 460. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 BACK MACHINING WITH THE SUB–SPINDLE 461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 COORDINATE SYSTEM FOR C–AXIS MACHINING WITH THE SUB–SPINDLE 462. . . . . . . . . .

5.4 ANIMATED SIMULATION FUNCTION FOR MACHINING WITH THE SUB–SPINDLE 463. . . . .

5.5 FUNCTION FOR CONTROLLING THE C–AXIS BRAKE 463. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 C–AXIS MACHINING FUNCTION UNDER CONTROL OF SPINDLE POSITIONING 464. . . . . . .

5.7 AUTOMATIC OUTPUT OF THE M CODE FOR CONTROLLING THE SUB–SPINDLE

(AND THE M CODES FOR CALLING SUBPROGRAMS) 465. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV. EXAMPLES OF CREATING PROGRAMS

1. CREATING MACHINING PROGRAMS FOR TWO–PATH

4–AXIS (X1, Z, X2, AND Z2) LATHES 469. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 SETTING PARAMETERS 470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SETTING TOOL DATA AND CUTTING CONDITION DATA 474. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Setting Tool Data 474. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Setting Cutting Condition Data 475. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 EXAMPLES OF PROGRAMS FOR MACHINING THE CYLINDRICAL SURF ACE

OF BARS 476. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Creating a Machining Program 476. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Entering Initial Data 477. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Specifying the Primary Machining Process (For the Left–side Tool Post) 478. . . . . . . . . . . . . . . .

1.3.4 Specifying a Transfer Process 480. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–8

Page 15

B–62444E–1/04

1.3.5 Specifying the Secondary Machining Process (For the Right–side Tool Post) 481. . . . . . . . . . . . .

1.3.6 Displaying the Figure of a Product 483. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.7 Animated Simulation 484. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.8 Returning to the Main Menu 484. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 SETTING UP MACHINING 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Setting the Workpiece Shift Amount 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Another Setup Operation for Machining 486. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

2. EXAMPLE OF INPUTTING CONTOURS FOR BAR MACHINING AND

PATTERN REPEATING 487. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CREATING MACHINING PROGRAMS FOR LATHES WITH THE C–AXIS 505. . . . . . .

3.1 SETTING PARAMETERS 506. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 SETTING TOOL AND CUTTING CONDITION DATA 507. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Setting Tool Data for Machining Around the C–axis 507. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 EXAMPLE OF CREATING A PROGRAM FOR NOTCHING AND

CYLINDRICAL MACHINING AROUND THE C–AXIS 509. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Creating a Machining Program 510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Entering the Initial Data 511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Specifying Process 1 (End Face and Cylindrical Surface Machining) 512. . . . . . . . . . . . . . . . . . . .

3.3.4 Specifying Process 2 (Notching the End Face Around the C–axis) 513. . . . . . . . . . . . . . . . . . . . . .

3.3.5 Specifying Process 3 (Cylindrical Surface Machining Around the C–axis) 516. . . . . . . . . . . . . . . .

3.3.6 Input for the End Process 518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.7 Animated Simulation 519. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.8 Returning to the Main Menu 521. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. PARAMETERS 525. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 DRILLING PARAMETERS (1) 526. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 PARAMETERS FOR CONVERSA TIONAL PERIPHERAL FUNCTIONS 527. . . . . . . . . . . . . . . . . . .

A.3 ENTERING WORKPIECE MATERIAL 528. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 PARAMETERS FOR THE M–FUNCTION–LIST SCREEN 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5 REGISTERING THE TOOL MATERIAL 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.6 USER PARAMETERS 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.7 ENTERING SUB–PROGRAM NAMES ON THE SUB–PROGRAM CALLING SCREEN 538. . . . . .

A.8 TOOL POST NAME PARAMETERS 539. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.9 PARAMETERS NECESSARY FOR USING THE CONVERSATIONAL AUTOMATIC

PROGRAMMING FUNCTION (BIT–TYPE) 540. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.10 PARAMETERS NECESSARY FOR USING THE CONVERSATIONAL AUTOMATIC

PROGRAMMING FUNCTION (COMMON DATA) 554. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.11 PARAMETERS FOR BAR MACHINING, PATTERN REPEATING, END FACING,

AND RESIDUAL MACHINING 562. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.12 PARAMETERS FOR NECKING 567. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.13 PARAMETERS FOR GROOVING 568. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.14 PARAMETERS FOR THREADING 570. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–9

Page 16

T ABLE OF CONTENTS

A.15 PARAMETERS FOR Y–AXIS MACHINING 572. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.16 PARAMETERS FOR DRILLING 573. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.17 PARAMETERS FOR NOTCHING 577. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.18 PARAMETERS FOR OTHER CONVERSA TIONAL FUNCTIONS 578. . . . . . . . . . . . . . . . . . . . . . . .

A.19 SETTING PARAMETERS IN THE NC 584. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62444E–1/04

B. ALARMS 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–10

Page 17

I. GENERAL

Page 18

B–62444E–1/04

1

OVERVIEW

GENERAL

1. OVERVIEW

Overview of the manual

This manual describes the functions related to the one–/two–path lathe

Super CAP T and Super CAP II T of the FANUC Series 16/18–TB and

FANUC Series 16/18–TC Series 16i/18i–TA. (The Super CAP II T is

usable only with the FANUC Series 16/18–TC, Series 16i/18i–TA.)

The one–/two–path Super CAP T and Super CAP II T differ from each

other only in conversational programming screens and machining

simulation. All other aspects such as screen displays, key operations, and

machining operations are identical. Therefore, this manual mainly

describes the former Super CAP, and explains the conversational

automatic programming function of the latter Super CAP as required.

For other functions, refer to the operator’s manual for the F ANUC Series

16/18–TB or FANUC Series 16/18–TC Series 16i/18i–TA.

The specifications and usage of the conversational automatic

programming function may vary according to the specifications of the

operator’s panel of a machine tool. Be sure to read the manual provided

by the machine tool builder.

The functions of the CNC machine tool system are determined not only

by the CNC, but by the combination of the machine tool, the power

magnetic circuit in the machine tool, the servo system, the CNC, and the

operator’s panel.

It is impossible to cover all possible combinations of all functions,

programming methods, and operations in a single manual.

This manual explains only the conversational automatic programming

function provided for the CNC. For individual CNC machine tools, refer

to applicable manuals from the machine tool builders.

The manuals from machine tool builders take precedence over this

manual.

This manual explains as many detailed functions as possible. However,

it is not possible to describe all of the items which cannot be done or which

the operator must not do. Therefore, please assume that functions other

than those described in this manual cannot be performed.

Detailed information and special conditions are explained in notes. The

readers may encounter new technical terms in the notes not previously

defined or described. In this case, read this manual through first, then

review the details.

3

Page 19

1. OVERVIEW

GENERAL

B–62444E–1/04

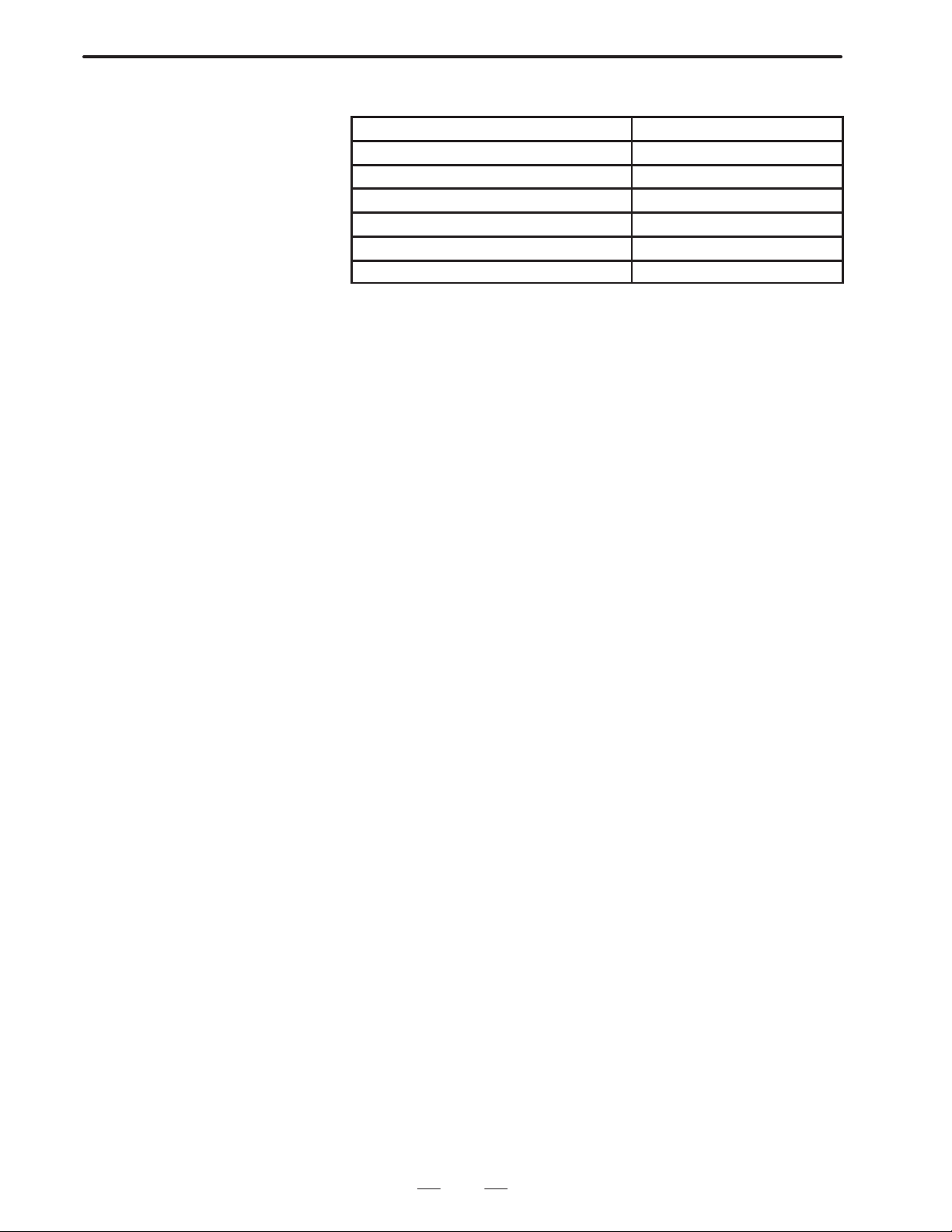

The models covered by this manual, and their abbreviations, are:

MODEL ABBREVIATION

FANUC Series 16–TB 16–TB

FANUC Series 18–TB 18–TB

FANUC Series 16–TC 16–TC

FANUC Series 18–TC 18–TC

FANUC Series 16i–TA 16i–TA

FANUC Series 18i–TA 18i–TA

About the Super CAP II T

The Super CAP II T is added with the following functions, as compared

with the Super CAP T.

1 Background color of the display screen, and stereoscopic frames of the

window/soft keys

2 Stereoscopic display of a soft key when it is in a depressed state

3 Machining simulation based on a solid model

4 Tool trajectory drawing based on isometric projection in C–/Y–axis

machining simulation

5 Changes to screen display colors, and storage of additional four groups

of screen display colors

All other functions such as screen displays, key operations, and

machining functions are the same as conventional ones.

Moreover, machining programs, tool data, and conversational function

parameters created on the Super CAP T can be used also on the Super CAP

II T.

4

Page 20

B–62444E–1/04

2

SYMBOLS USED

The following explains how keys and buttons are indicated in this manual.

(1) Function buttons are indicated in bold type:

(2) Numeric keys to be entered from the key board are underlined:

(3) The input key is indicated in bold type in the same way as the

GENERAL

Example) PRGRM, OFSET

Example) 12.345

function buttons. Generally, the input key follows numeric key

input.

Example) 12.345

INPUT

2. SYMBOLS USED

(4) The edit keys are also indicated in bold type:

Example) ALTER key: ALTER

INSRT key: INSRT

DELET key: DELET

(5) Soft keys are enclosed in brackets [ ]:

Example) [NEW], [NEW-PR]

(6) The cursor keys are indicated by the following symbols:

↑, ↓, ←, and →.

(7) The page keys are indicated by the following symbols:

and

.

5

Page 21

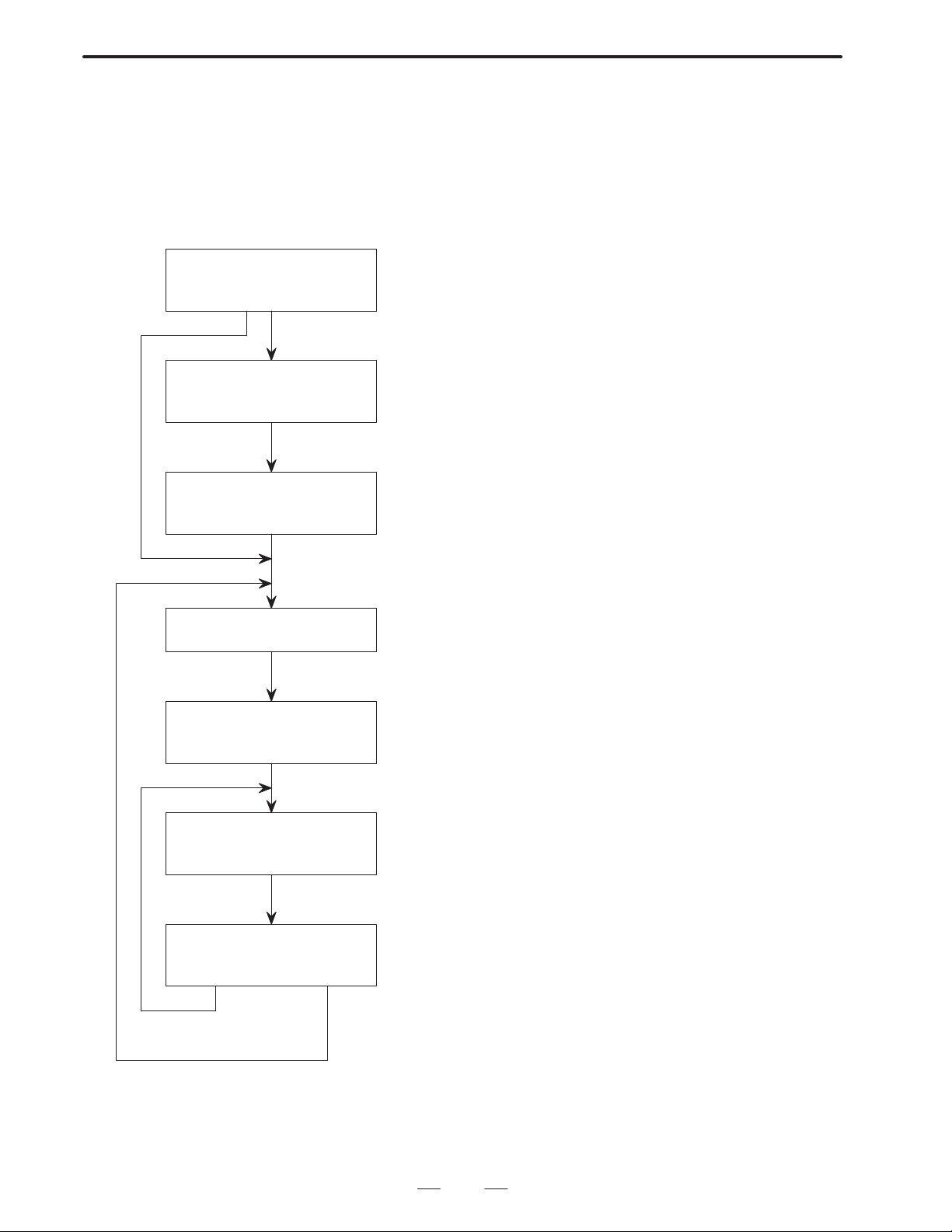

3. FLOWCHART FROM CREATING

A PROGRAM TO EXECUTING IT

FLOWCHART FROM CREATING A PROGRAM TO

EXECUTING IT

3

GENERAL

This chapter shows a flow indicating how a machining program is created

and executed using the conversational automatic programming function.

B–62444E–1/04

6

Page 22

B–62444E–1/04

3.1

CREATING A MACHINING PROGRAM

Press the PRGRM function

button.

NC-format programming input

menu

GENERAL

3. FLOWCHART FROM CREATING

A PROGRAM TO EXECUTING IT

Select the conversational mode.

Main menu

Program input menu

(initial settings)

Program input menu (process data)

Program input menu

(figure data)

[FIGURE END]

To select the conversational mode, press the conversational key on the

machine operator’s panel or press the [CAP-I] soft key after entering the

EDIT mode.

Press the [1] soft key to create a new machining program on the main menu.

Enter necessary data, such as the number and name of a machining program, the material of tools used in common in machining programs, and

blank figures.

Moving the cursor forward automatically creates processes.

Select entries for necessary items, such as the type of machining and the

area to be machined. The tools and cutting conditions used for the machining are then automatically determined.

Following the operation guidance on the screen, specify a contour figure.

Press the [PLOT] soft key, if necessary, to display and check the contour

figures previously entered for other processes.

After specifying all necessary figures, press the [FIGURE END] soft key.

After specifying all necessary processes, press the [PRGRM END] soft key.

[PRGRM END]

7

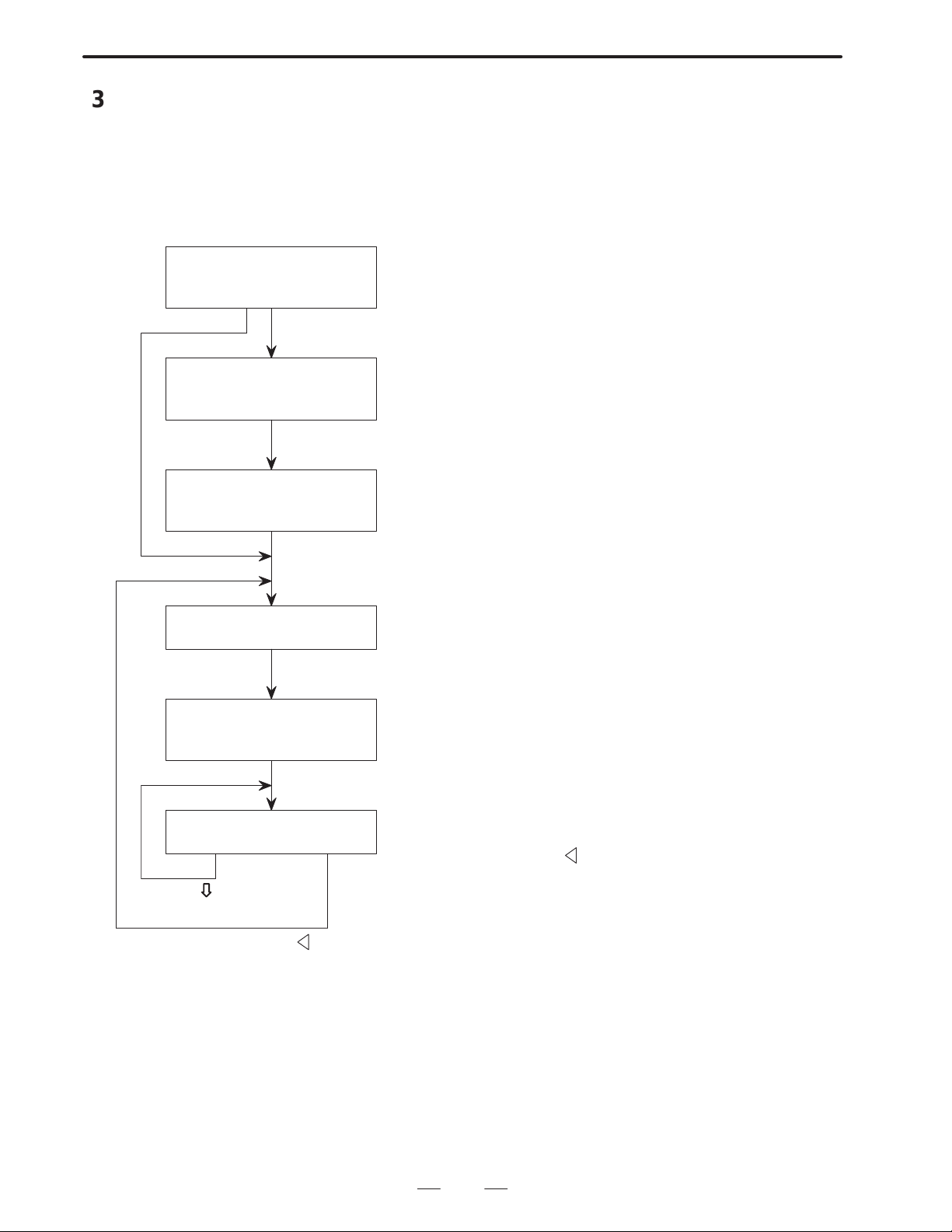

Page 23

3. FLOWCHART FROM CREATING

A PROGRAM TO EXECUTING IT

3.2

CHECKING A MACHINING PROGRAM

Press the PRGRM function button.

NC-format programming input

menu

GENERAL

B–62444E–1/04

Select the conversational mode.

Main menu

Registered-program directory

screen

Program screen

Page key

To select the conversational mode, either press the conversational key on

the machine operator’s panel or enter the EDIT mode and press the [CAP-I]

soft key.

Press the [2] soft key for creating a new machining program on the main

menu.

Move the cursor to the program to be edited. Press the [EDIT] soft key.

If the program does not fit on one page, press the page key to scroll the

screen.

Pressing the leftmost soft key [ ] returns to the main menu.

[ ]

8

Page 24

B–62444E–1/04

3.3

SELECTING A MACHINING PROGRAM TO BE EXECUTED

Press the PRGRM function button.

NC-format programming input menu

GENERAL

3. FLOWCHART FROM CREATING

A PROGRAM TO EXECUTING IT

Select the conversational mode.

Main menu

Registered-program directory

screen

Setting screen before execution

To select the conversational mode, press the conversational key on the

machine operator’s panel or enter the EDIT mode and press the [CAP-I] soft

key.

Select the automatic operation mode on the machine operator’s mode.

Press the [4] soft key to operate a conversational machining program direct-

ly after entering the MEM mode on the main menu.

[PRE-EX]: Press this key to specify a chuck barrier, workpiece shift, and

position where the tool is changed (tool change position).

[EXEC]: Press this key to select a machining program to be executed

only when the power is turned on or when a new program is

selected.

On the setting screen before execution, specify the chuck barrier, workpiece

shift, and tool change position. This operation is required only once for each

machining program.

Program screen

Program execution screen

End of execution

When another machining program is selected

Check that the selected machining program is correct, then start automatic

operation.

While the machining program created conversationally is being executed,

the program execution screen is displayed.

9

Page 25

4. SELECTING THE MENU AND

INPUTTING DA TA

SELECTING THE MENU AND INPUTTING DATA

4

GENERAL

Whenever you are uncertain of the operation to be performed next, check

relevant part of this manual. Alternatively, press the [GUIDE] soft key

to display the operation guidance screen for the current operation.

When the screen selected on the conversational main menu is displayed

and you are at a loss what to do next, press the leftmost soft key [

main menu then appears on the screen and you can start from the

beginning.

B–62444E–1/04

]. The

10

Page 26

B–62444E–1/04

GENERAL

4. SELECTING THE MENU

AND INPUTTING DATA

4.1

SOFT KEYS

Example

Example

Soft keys displayed on the conversational screens have different colors

depending on their functions as follows:

(1) Green soft keys

Used mainly for displaying other screens.

[MCHN–C] : Displaying the cutting condition data screen

[TOOL–D] : Displaying the registered tool directory screen

[DETAIL DATA] : Displaying process data not shown on the

machining program screen

[GUIDE] : Displaying operation guidance

(2) Yellow soft keys

Used for selecting the menus.

[1 BAR] : Selecting the type of machining

[1 O–END] : Selecting the area to be machined

[↑↓] : Selecting a figure pattern

(3) Purple soft keys

Used for editing.

Example

[DELETE] : Deleting a process or figure

[INSERT] : Inserting a process or figure

[COPY] : Copying a program or process

When the [+] soft key appears at the right end of the screen, there are soft

keys other than those displayed on the current screen. Press the [+] soft

key to display the other soft keys, if necessary.

The leftmost soft key [<], which is called the super return key , is used to

return from a conversational screen to the main menu.

11

Page 27

4. SELECTING THE MENU AND

INPUTTING DA TA

GENERAL

B–62444E–1/04

4.2

CALCULATION

FUNCTIONS SIMILAR

TO THOSE OF A

HAND–HELD

CALCULATOR

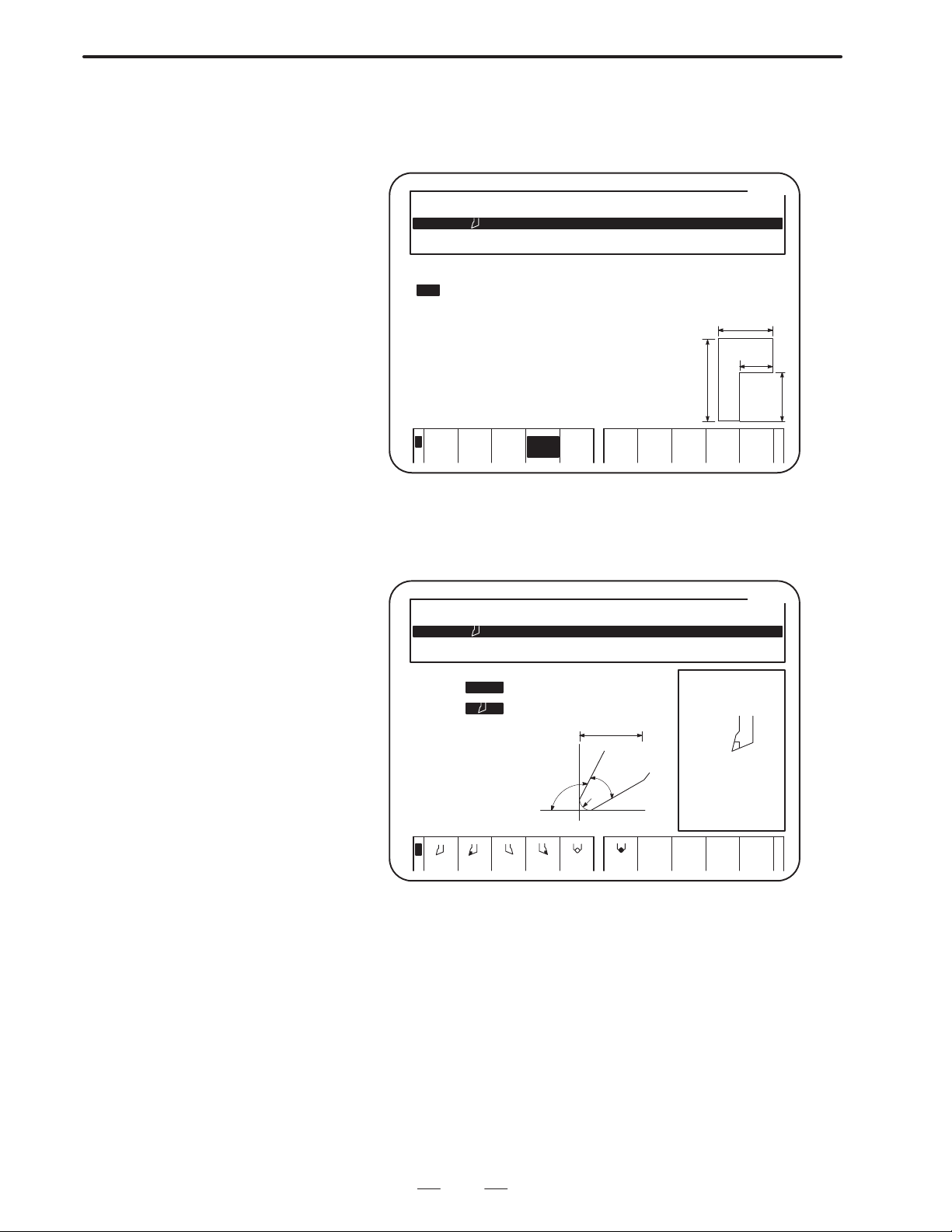

4.2.1

Operation for Calculation

· Addition 100. +200. INPUT

· Subtraction 200. –100. INPUT

· Multiplication 100.

· Division 200. /10. INPUT

20. INPUT

*

Data can be entered for items on the conversational programming menus

(except for the detailed data screen) while calculation is performed on the

same menu.

The four arithmetic functions, addition, subtraction, multiplication, and

division, operate on two numbers. By substituting the result as one term

at the next calculation, calculation can be iterated indefinitely.

Data to be entered for an item must conform to the type of data in the item.

If data contains a component less than the minimum input limit, the

component is ignored.

The following shows key operations for each function.

The result reads at the location where input

keys are displayed.

Example of operation)

12

0 6

.

210.0–65.3

DELETE WINDOW

(INPUT key) ↓

INSERT FIGURE PROCES

To enter the calculated result for the desired item, press the INPUT key

again after checking the result.

Pressing the CAN key deletes characters successively in the input field

from the last character entered.

Key input operation and input key display when the following expression

is calculated:

210. – 65.3 + 1.25

.

–

5 3 INPUT 1

START POINT X

ON/OFF

EDIT

+ 2.5

MCHN–C TOOL–D DETAIL

DATA

INPUT INPUT

PLOT GUIDE

144.7

DELETE WINDOW

INSERT FIGURE PROCES

ON/OFF

START POINT X

MCHN–C TOOL–D DETAIL

EDIT

12

PLOT GUIDE

DATA

Page 28

B–62444E–1/04

GENERAL

Second key operation for the calculation ↓

4. SELECTING THE MENU

AND INPUTTING DATA

144.7+1.25

DELETE WINDOW

INSERT FIGURE PROCES

ON/OFF

(INPUT key) ↓

145.95

DELETE WINDOW

INSERT FIGURE PROCES

ON/OFF

(INPUT key) ↓

The result, 145.95, is entered for the item START POINT X. The cursor

automatically proceeds to the next data item.

START POINT X

MCHN–C TOOL–D DETAIL

EDIT

START POINT X

MCHN–C TOOL–D DETAIL

EDIT

PLOT GUIDE

DATA

PLOT GUIDE

DATA

13

Page 29

4. SELECTING THE MENU AND

INPUTTING DA TA

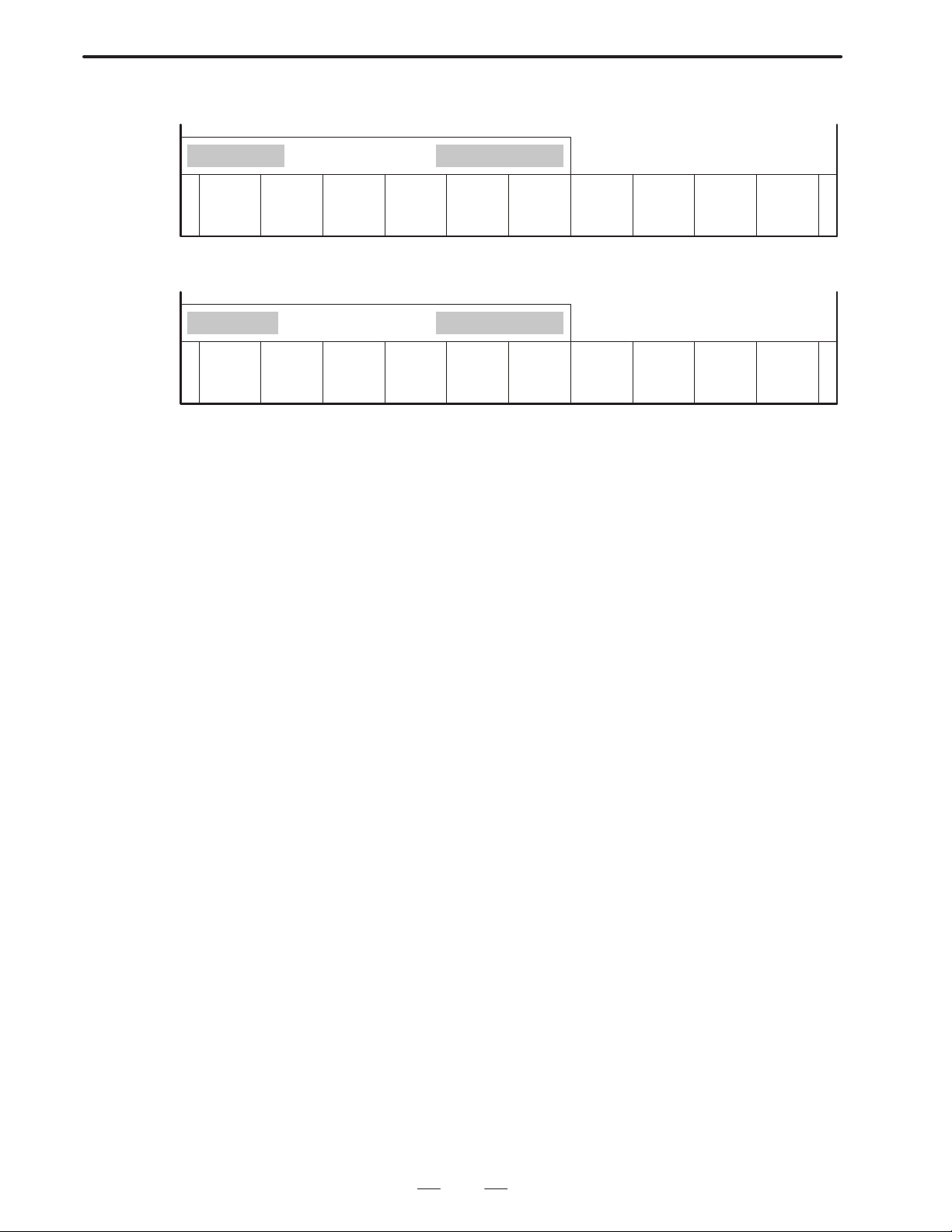

4.2.2

Keys for Calculation

GENERAL

B–62444E–1/04

Example of a keyboard)

T

For the 10″ LCD

L

*

7 8 9

4 5 6

1 2 3

+

/

SHIFT INPUT

0 .

CAN

(1) Addition (+)

SHIFT

(2) Subtraction ()

(3) Multiplication ()

SHIFT

(4) Division (/)

/

→

→

L

+

T

*

14

Page 30

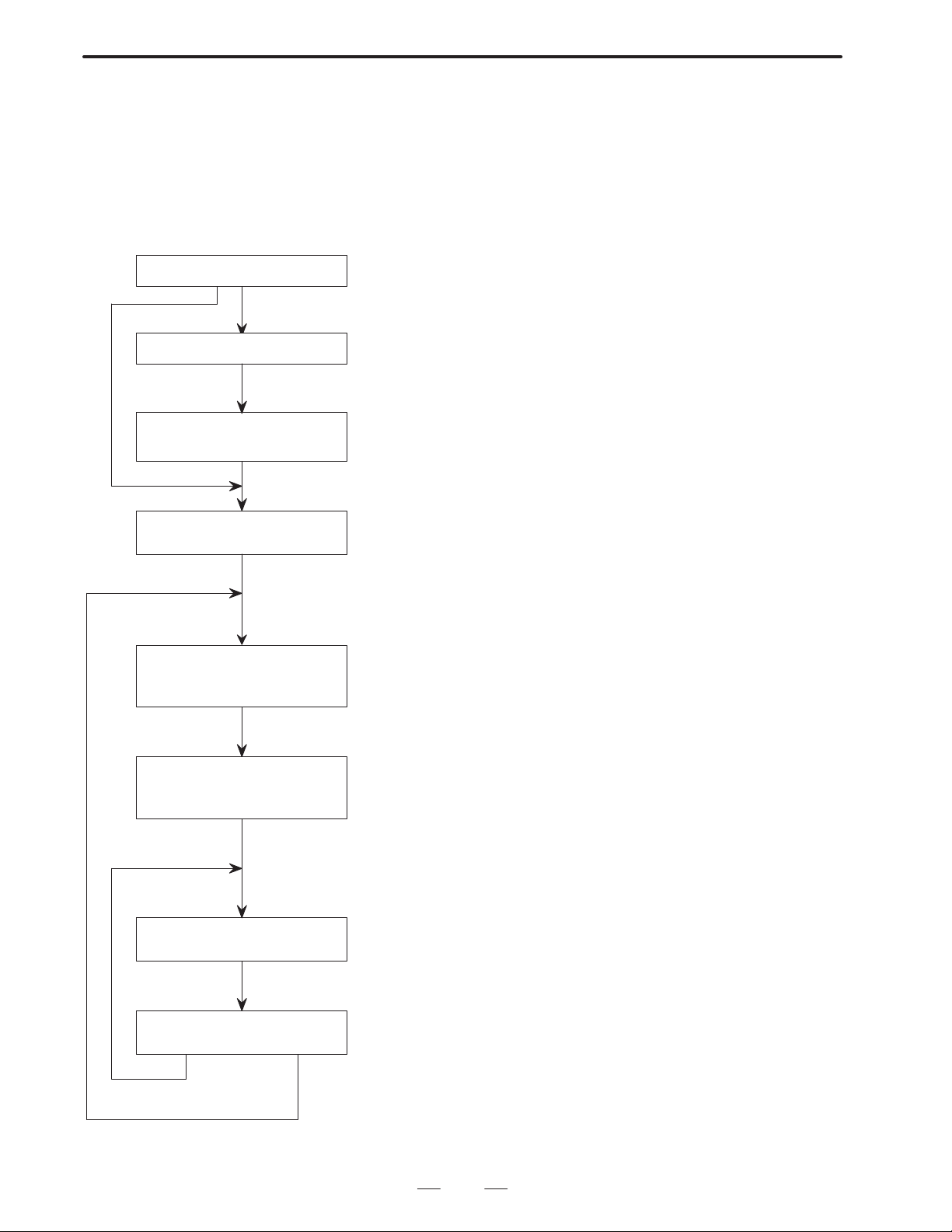

B–62444E–1/04

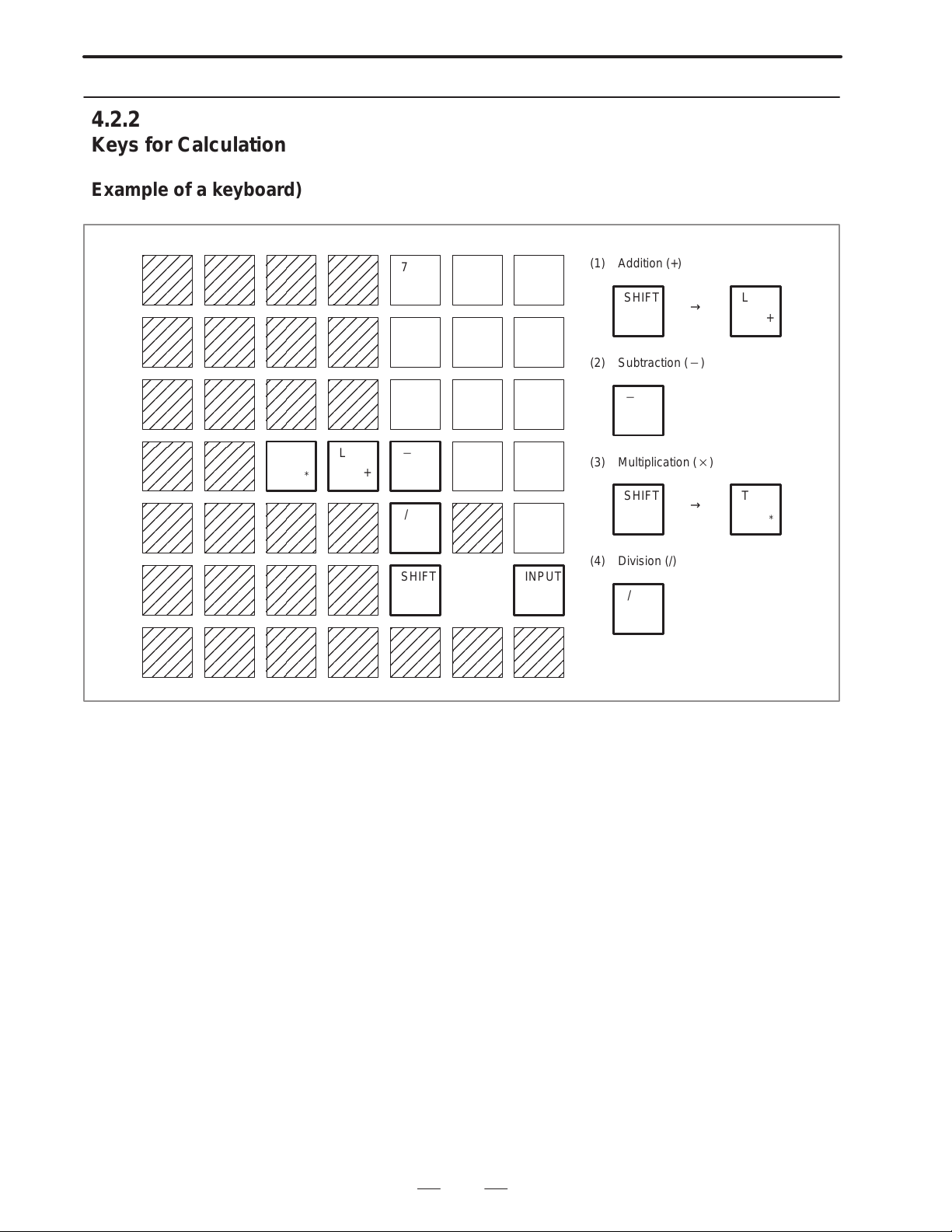

5

5. HIERARCHY OF THE

GENERAL

CONVERSA TIONAL SCREENS

HIERARCHY OF THE CONVERSATIONAL SCREENS

Main menu

Creating programs

PROGRAM

NO

Selecting processes Program screen

TYPE OF

MACHINING

=

Inputting figures Animated simulation

Editing programs

PROGRAM LIST

FOR EDITING

Editing processes

Machining simulation

PROGRAM LIST

FOR

SIMULATION

Setting

before execution

Chuck

barrier

Animated simulation

plus path drawing

Direct operation

PROGRAM LIST

FOR DIRECT

OPERATION

Setting

before execution

Chuck

barrier

T ooling data

Measuring tool offset Cutting condition data

Converting NC programs

PROGRAM LIST

FOR CONVERTING

NC PROGRAMS

Setting

before execution

Chuck

barrier

Animated simulation

plus path drawing

Tool/cutting condition data

TOOL DA TA

MENU

T ool list

Tool data file

T ool of fset

Editting NC programs

Path drawing Position screen

15

Pre-tool list

FINAL TOOL

PRE-TOOL

Chuck/tail stock data

Page 31

II. OPERATION

Page 32

B–62444E–1/04

1

OPERATION

OVERVIEW OF THE PROCEDURE

The following shows the general procedure from creating a machining

program to executing it using Super CAP for the F ANUC Series 16–TB.

1. OVERVIEW OF THE PROCEDURE

Reference

Setting parameters

Setting cutting condition data

Setting a pre-tool list when drilling is included

Setting the figures of a chuck and tail stock

Setting a tool data file

Creating a machining program

Selecting a machining program

APPENDIX

II.13 SETTING DATA

II.13 SETTING DATA

II.13 SETTING DATA

II.13 SETTING DATA

II.6 CREATING MACHINING PROGRAMS

II.12 EXECUTING MACHINING PROGRAMS

Mounting tools (and referring to the tooling data)

II.12 EXECUTING MACHINING PROGRAMS

19

Page 33

1. OVERVIEW OF THE PROCEDURE

OPERATION

B–62444E–1/04

Measuring the tool offset

Specifying a tool change position

Setting data before execution

Checking the machining program with the check drawing

Trial machining

Specifying tool wear compensation

II.12 EXECUTING MACHINING PROGRAMS

II.12 EXECUTING MACHINING PROGRAMS

II.12 EXECUTING MACHINING PROGRAMS

II.8 CHECKING MACHINING PROGRAMS

Actual machining

20

Page 34

B–62444E–1/04

2

OPERATION

DESCRIPTION OF THE KEYBOARD

2. DESCRIPTION OF THE KEYBOARD

21

Page 35

2. DESCRIPTION OF THE KEYBOARD

OPERATION

B–62444E–1/04

2.1

KEYBOARD TYPES

FANUC Serlee 16–T

POWER

The CRT/MDI panel consists of a display unit, such as a color 14″ CRT

or color 9.5″ LCD, and a keyboard.

(1) CRT/MDI panel with the 14″ color CRT

Address/numerical key

RESET key

RESET

O

N

(

X

Z

A

U

W

.

M

S

#

I

K

[

8

7

²

5

4

¼

2

1

0

–

EOB

/

POS

PROG

SYSTEM

MESSAGE

↑

PAGE

←

PAGE

↓

)

B

J

=

]

°9½

m

±

G

C

R

OFFSET

SETTING

GRAPH

H

T

³

6

3

.

CAN

↑

↓

HELP key

HELP

P

E

Q

Y

D

?

V

,

L

*

+

F

SP

&

SHIFT

ALTER

INSERT

DELETE

INPUT

CUSTOM

→

SHIFT key

Program edit key

INPUT key

Cancel (CAN) key

Function key

Cursor move key

POWER

FANUC Serles 16–T

Page change keySoft keyPower ON/OFF button

(2) CRT/MDI panel with the 9.5″ color LCD

Function key

Address/numerical key

O

N

G

W

S

PROG

MESSAGE

P

)

E

Q

Z

C

Y

B

D

?

H

V

J

,

L

T

=

*

+

K

R

F

SP

]

&

OFFSET

CUSTOM

SETTING

GRAPH

↑

←

→

↓

X

M

SYSTEM

PAGE

PAGE

(

A

U

.

#

I

[

POS

↑

↓

°9½

7

8

²

³

m

5

4

6

±

¼

2

1

3

0

–

EOB.CAN

/

INPUT

SHIFT

DELETE

INSERT

ALTER

HELP

RESET

Cancel (CAN) key

SHIFT key

INPUT key

HELP key

RESET key

Power ON/OFF button

Soft key

Page change key

22

Program edit key

Cursor move key

Page 36

B–62444E–1/04

OPERATION

2. DESCRIPTION OF THE KEYBOARD

2.2

DETAILS OF THE

KEYBOARD

The keys mainly used for the conversational automatic programming

function are explained here. For other keys that are not dealt with in this

manual, refer to the relevant operator’s manuals.

When the conversational automatic programming function is used, the

operator sometimes has to perform certain operations manually from the

machine operator’s panel. There may include reference position return

operation and turret turning operation (tool replacement). The operator’s

panel varies depending on the machine tool builders and the individual